fuel cap JEEP GRAND CHEROKEE 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2020, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2020Pages: 378, PDF Size: 6.88 MB

Page 11 of 378

EVENT DATA RECORDER (EDR)............ 235

SERVICING AND MAINTENANCE

SCHEDULED SERVICING................ 236Scheduled Servicing — Non SRT....... 236

Scheduled Servicing — SRT.......... 240

Scheduled Servicing — Diesel Engine.... 244

ENGINE COMPARTMENT............... 2483.6L Engine.................... 248

5.7L Engine.................... 249

6.2L Supercharged Engine........... 250

6.4L Engine.................... 251

3.0L Diesel Engine............... 252

Checking Oil Level — Gasoline Engine.... 253

Checking Oil Level — 3.0 Diesel Engine . . . 253

Adding Washer Fluid............... 254

Brake System.................. 255

Automatic Transmission............. 256

Maintenance-Free Battery........... 256

DEALER SERVICE................... 257Air Conditioner Maintenance......... 257

Windshield Wiper Blades............ 258

Cooling System.................. 262

RAISING THE VEHICLE................. 262

TIRES.......................... 262

Tires — General Information......... 262

Tire Types..................... 267

Spare Tires — If Equipped........... 268

Wheel And Wheel Trim Care.......... 270

Tire Chains (Traction Devices) — Non-SRT . 271

Tire Chains (Traction Devices) — SRT.... 272

Tire Rotation Recommendations........ 272

STORING THE VEHICLE................ 273

BODYWORK....................... 274

Preserving The Bodywork............ 274

INTERIORS....................... 275Seats And Fabric Parts............. 275

Plastic And Coated Parts............ 276

Leather Parts................... 276

Glass Surfaces.................. 276

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA................. 277Vehicle Identification Number......... 277

WHEEL AND TIRE TORQUE SPECIFICATIONS.... 278Torque Specifications.............. 278

DIMENSIONS...................... 279

WHEELS........................ 280

WEIGHTS........................ 281

FUEL REQUIREMENTS — GASOLINE ENGINES.... 282

3.6L Engine.................... 282

5.7L Engine.................... 282

6.2L/6.4L Engine................ 283

Methanol..................... 283

Ethanol....................... 283

Reformulated Gasoline............. 284

Do Not Use E-85 In Non-Flex Fuel Vehicles . 284

CNG And LP Fuel System Modifications . . . 284

Materials Added To Fuel............ 284

Fuel Icon Identification Compliant To

EN16942..................... 284

Carbon Monoxide Warnings.......... 286

FUEL REQUIREMENTS – DIESEL ENGINE....... 287Fuel Icon Identification Compliant To

EN16942..................... 287

NON-SRT FLUID CAPACITIES............. 290

SRT FLUID CAPACITIES................ 291FLUIDS AND LUBRICANTS NON-SRT......... 291

Engine....................... 291

Chassis....................... 294

FLUIDS AND LUBRICANTS — SRT.......... 295Engine....................... 295

Chassis....................... 297

FUEL CONSUMPTION AND CO2EMISSIONS..... 298

MOPAR ACCESSORIES................. 298

Authentic Accessories By Mopar........ 298

MULTIMEDIA

CYBERSECURITY................... 300

UCONNECT 4 WITH 7-INCH DISPLAY......... 301

Uconnect 4 At A Glance............ 301

Drag & Drop Menu Bar............. 302

Radio....................... 303

Android Auto — If Equipped.......... 304

Apple CarPlay Integration — If Equipped . . 305

Apps — If Equipped............... 306

UCONNECT 4C/4C NAV WITH 8.4-INCH DISPLAY . . 307Uconnect 4C/4C NAV At A Glance...... 307

Drag & Drop Menu Bar............. 308

Radio....................... 309

Android Auto — If Equipped.......... 310

Apple CarPlay Integration — If Equipped . . 314

Apps — If Equipped............... 316

UCONNECT SETTINGS................. 316

OFF ROAD PAGES — IF EQUIPPED.......... 317

Off Road Pages Status Bar........... 317

Vehicle Dynamics................ 318

Suspension.................... 318

Pitch And Roll.................. 319

Accessory Gauges................ 319

Selec-Terrain — If Equipped.......... 320

9

Page 79 of 378

If the ABS light does not turn on when the

ignition is placed in the ON/RUN or ACC/ON/

RUN position, have the brake system in-

spected by an authorized dealer.

— Electronic Stability Control (ESC) Off

Warning Light — If Equipped

This warning light indicates the Electronic

Stability Control (ESC) is off.

Each time the ignition is turned to ON/RUN

or ACC/ON/RUN, the ESC system will be on,

even if it was turned off previously.

The ESC OFF indicator will be lit any time the

Traction Mode is set to Sport, Track or Full

OFF in Drive Modes.

— Electronic Stability Control (ESC)

Active Warning Light — If Equipped

This warning light will indicate when the

Electronic Stability Control system is Active.

The “ESC Indicator Light” in the instrument

cluster will come on when the ignition is

placed in the ON/RUN or ACC/ON/RUN posi-

tion, and when ESC is activated. It should go

out with the engine running. If the “ESC

Indicator Light” comes on continuously withthe engine running, a malfunction has been

detected in the ESC system. If this warning

light remains on after several ignition cycles,

and the vehicle has been driven several miles

(kilometers) at speeds greater than 30 mph

(48 km/h), see an authorized dealer as soon

as possible to have the problem diagnosed

and corrected.

• The “ESC Off Indicator Light” and the

“ESC Indicator Light” come on momen-

tarily each time the ignition is placed in the

ON/RUN or ACC/ON/RUN position.

• The ESC system will make buzzing or click-

ing sounds when it is active. This is normal;

the sounds will stop when ESC becomes

inactive.

• This light will come on when the vehicle is

in an ESC event.— Service LaneSense Warning Light

— If Equipped

This warning light will illuminate when the

LaneSense system is not operating and re-

quires service. Please see an authorized

dealer.

— LaneSense Warning Light — If

Equipped

The LaneSense Warning Light will be solid

yellow when the vehicle is approaching a lane

marker. The warning light will flash when the

vehicle is crossing the lane marker.

Refer to “LaneSense — If Equipped" in

“Starting And Operating” for further informa-

tion.

— Loose Fuel Filler Cap Warning Light

— If Equipped

This warning light will illuminate when the

fuel filler cap is loose. Properly close the filler

cap to disengage the light. If the light does

not turn off, please see an authorized dealer.

— Low Fuel Warning Light

When the fuel level reaches approximately

2.4 gal (9.1 L) this light will turn on, and

remain on until fuel is added.

A single warning chime will sound with Low

Fuel Warning.

77

Page 80 of 378

— Low Washer Fluid Warning Light —

If Equipped

This warning light will illuminate when the

windshield washer fluid is low.

— Engine Check/Malfunction Indica-

tor Warning Light (MIL)

The Engine Check/Malfunction Indicator

Light (MIL) is a part of an Onboard Diagnostic

System called OBD II that monitors engine

and automatic transmission control systems.

This warning light will illuminate when the

ignition is in the ON/RUN position before

engine start. If the bulb does not come on

when turning the ignition switch from OFF to

ON/RUN, have the condition checked

promptly.

Certain conditions, such as a loose or missing

gas cap, poor quality fuel, etc., may illumi-

nate the light after engine start. The vehicle

should be serviced if the light stays on

through several typical driving styles. In most

situations, the vehicle will drive normally and

will not require towing.When the engine is running, the MIL may

flash to alert serious conditions that could

lead to immediate loss of power or severe

catalytic converter damage. The vehicle

should be serviced by an authorized dealer as

soon as possible if this occurs.WARNING!

A malfunctioning catalytic converter, as

referenced above, can reach higher tem-

peratures than in normal operating condi-

tions. This can cause a fire if you drive

slowly or park over flammable substances

such as dry plants, wood, cardboard, etc.

This could result in death or serious injury

to the driver, occupants or others.

CAUTION!

Prolonged driving with the Malfunction

Indicator Light (MIL) on could cause dam-

age to the vehicle control system. It also

could affect fuel economy and driveability.

If the MIL is flashing, severe catalytic

converter damage and power loss will soon

occur. Immediate service is required.

— AdBlue® (UREA) Injection System

Failure Warning Light — If Equipped

This warning light will illuminate along with a

dedicated message on the display (If

Equipped) if an unknown fluid not conform-

ing with acceptable characteristics is in-

serted, or if an average consumption of

AdBlue

®(UREA) over 50% is detected. Con-

tact an authorized dealer as soon as possible.

If the problem is not solved, a specific mes-

sage will appear on the Instrument Cluster

Display whenever a certain threshold is

reached until it will no longer be possible to

start the engine.

When about 125 mi (200 km) are remaining

before the AdBlue

®tank is empty, a continu-

ous dedicated message will appear on the

instrument panel, accompanied by a buzzer

sound (If Equipped).

SERV4WD— Service 4WD Warning Light — If

Equipped

This warning light will illuminate to signal a

fault with the 4WD system. If the light stays

on or comes on during driving, it means that

the 4WD system is not functioning properlyGETTING TO KNOW YOUR INSTRUMENT PANEL

78

Page 106 of 378

(193 kPa), a temperature drop to 20°F (-7°C)

will decrease the tire pressure to approxi-

mately 24 psi (165 kPa). This tire pressure is

sufficiently low enough to turn on the TPMS

Warning Light. Driving the vehicle may cause

the tire pressure to rise to approximately

28 psi (193 kPa), but the TPMS Warning

Light will still be on. In this situation, the

TPMS Warning Light will turn off only after

the tires have been inflated to the vehicle’s

recommended cold tire pressure value.

CAUTION!

• The TPMS has been optimized for the

original equipment tires and wheels.

TPMS pressures and warnings have

been established for the tire size

equipped on your vehicle. Undesirable

system operation or sensor damage may

result when using replacement equip-

ment that is not of the same size, type,

and/or style. The TPM sensor is not de-

signed for use on aftermarket wheels

and may contribute to a poor overall

system performance or sensor damage.

Customers are encouraged to use OEM

CAUTION!

wheels to assure proper TPM feature

operation.

• Using aftermarket tire sealants may

cause the Tire Pressure Monitoring Sys-

tem (TPMS) sensor to become inoper-

able. After using an aftermarket tire

sealant it is recommended that you take

your vehicle to an authorized dealership

to have your sensor function checked.

• After inspecting or adjusting the tire

pressure, always reinstall the valve stem

cap. This will prevent moisture and dirt

from entering the valve stem, which

could damage the Tire Pressure Monitor-

ing Sensor.

NOTE:

• The TPMS is not intended to replace nor-

mal tire care and maintenance, or to pro-

vide warning of a tire failure or condition.

• The TPMS should not be used as a tire

pressure gauge while adjusting your tire

pressure.• Driving on a significantly under-inflated tire

causes the tire to overheat and can lead to

tire failure. Under-inflation also reduces

fuel efficiency and tire tread life, and may

affect the vehicle’s handling and stopping

ability.

• The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s respon-

sibility to maintain correct tire pressure

using an accurate tire gauge, even if under-

inflation has not reached the level to trigger

illumination of the TPMS Warning Light.

• Seasonal temperature changes will affect

tire pressure, and the TPMS will monitor

the actual tire pressure in the tire.

• The system only warns the tire pressure is

low: it is not able to inflate them.

The Tire Pressure Monitor System (TPMS)

uses wireless technology with wheel rim-

mounted electronic sensors to monitor tire

pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire

pressure readings to the Receiver Module.

SAFETY

104

Page 188 of 378

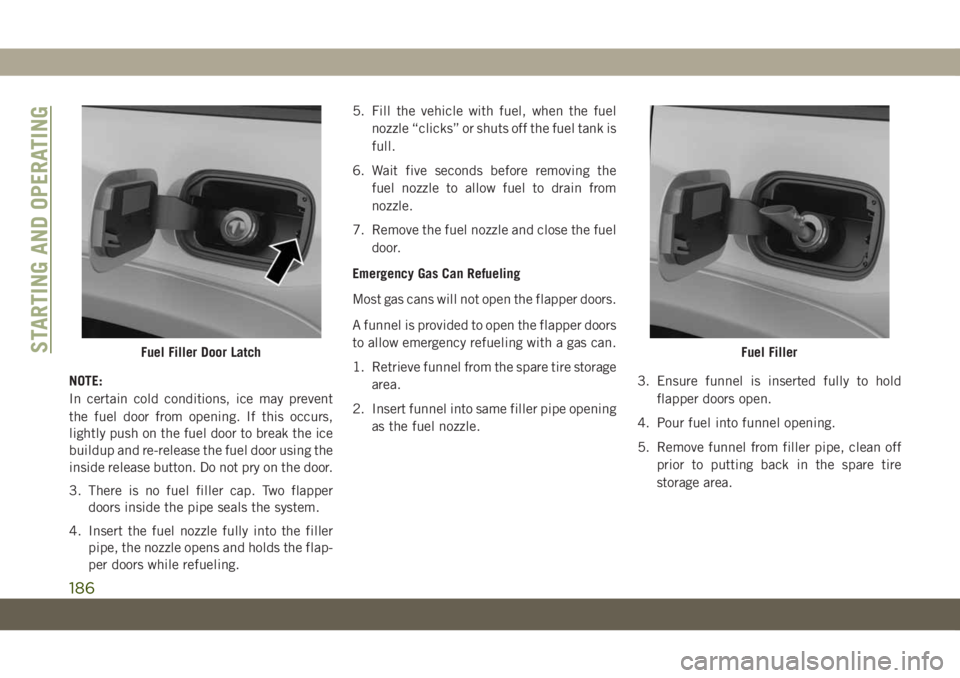

NOTE:

In certain cold conditions, ice may prevent

the fuel door from opening. If this occurs,

lightly push on the fuel door to break the ice

buildup and re-release the fuel door using the

inside release button. Do not pry on the door.

3. There is no fuel filler cap. Two flapper

doors inside the pipe seals the system.

4. Insert the fuel nozzle fully into the filler

pipe, the nozzle opens and holds the flap-

per doors while refueling.5. Fill the vehicle with fuel, when the fuel

nozzle “clicks” or shuts off the fuel tank is

full.

6. Wait five seconds before removing the

fuel nozzle to allow fuel to drain from

nozzle.

7. Remove the fuel nozzle and close the fuel

door.

Emergency Gas Can Refueling

Most gas cans will not open the flapper doors.

A funnel is provided to open the flapper doors

to allow emergency refueling with a gas can.

1. Retrieve funnel from the spare tire storage

area.

2. Insert funnel into same filler pipe opening

as the fuel nozzle.3. Ensure funnel is inserted fully to hold

flapper doors open.

4. Pour fuel into funnel opening.

5. Remove funnel from filler pipe, clean off

prior to putting back in the spare tire

storage area.

Fuel Filler Door LatchFuel FillerSTARTING AND OPERATING

186

Page 189 of 378

WARNING!

• Never have any smoking materials lit in

or near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most coun-

tries regulations and may cause the

“Malfunction Indicator Light” to turn

on.

• Do not apply any object/cap to the end of

the filler which is not provided for the

car. The use of non-compliant objects/

plugs could cause a pressure increase

inside the tank, resulting in dangerous

situations.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

CAUTION!

To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

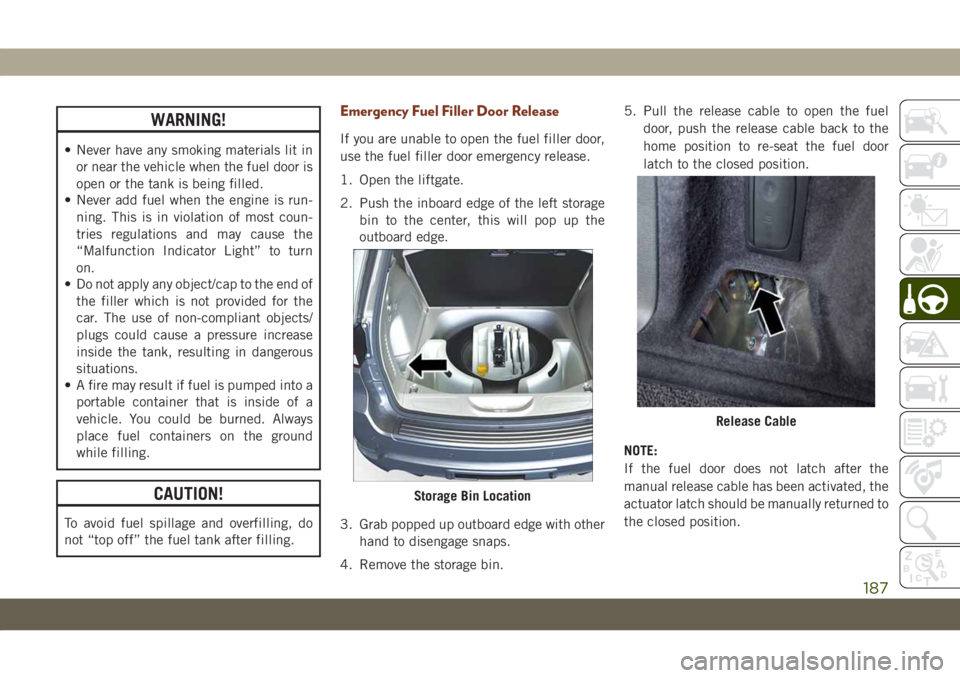

Emergency Fuel Filler Door Release

If you are unable to open the fuel filler door,

use the fuel filler door emergency release.

1. Open the liftgate.

2. Push the inboard edge of the left storage

bin to the center, this will pop up the

outboard edge.

3. Grab popped up outboard edge with other

hand to disengage snaps.

4. Remove the storage bin.5. Pull the release cable to open the fuel

door, push the release cable back to the

home position to re-seat the fuel door

latch to the closed position.

NOTE:

If the fuel door does not latch after the

manual release cable has been activated, the

actuator latch should be manually returned to

the closed position.

Storage Bin Location

Release Cable

187

Page 190 of 378

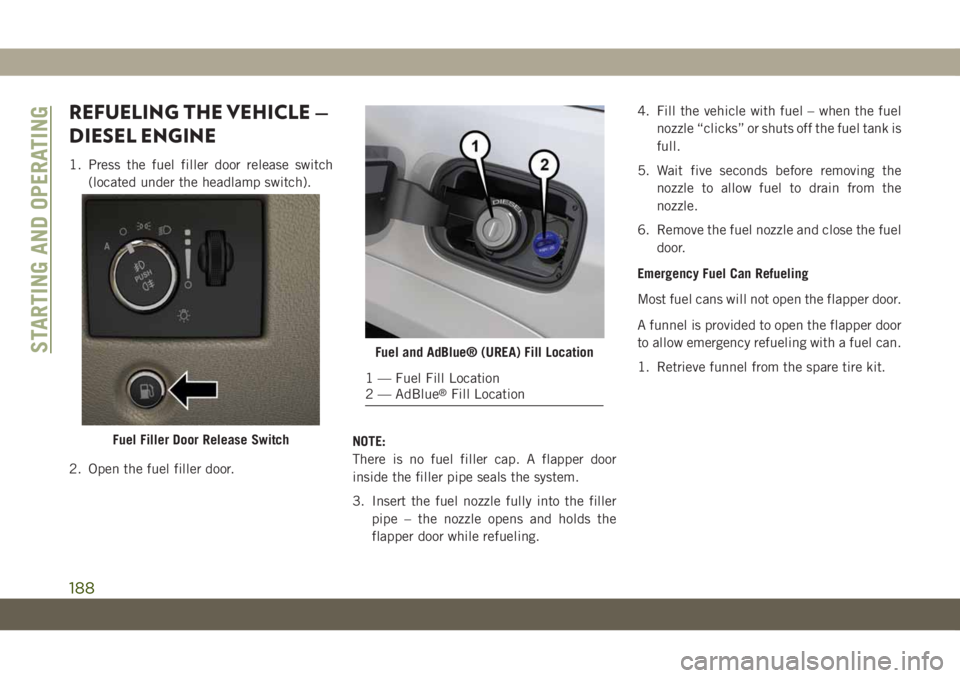

REFUELING THE VEHICLE —

DIESEL ENGINE

1. Press the fuel filler door release switch

(located under the headlamp switch).

2. Open the fuel filler door.NOTE:

There is no fuel filler cap. A flapper door

inside the filler pipe seals the system.

3. Insert the fuel nozzle fully into the filler

pipe – the nozzle opens and holds the

flapper door while refueling.4. Fill the vehicle with fuel – when the fuel

nozzle “clicks” or shuts off the fuel tank is

full.

5. Wait five seconds before removing the

nozzle to allow fuel to drain from the

nozzle.

6. Remove the fuel nozzle and close the fuel

door.

Emergency Fuel Can Refueling

Most fuel cans will not open the flapper door.

A funnel is provided to open the flapper door

to allow emergency refueling with a fuel can.

1. Retrieve funnel from the spare tire kit.

Fuel Filler Door Release Switch

Fuel and AdBlue® (UREA) Fill Location

1 — Fuel Fill Location

2 — AdBlue®Fill Location

STARTING AND OPERATING

188

Page 191 of 378

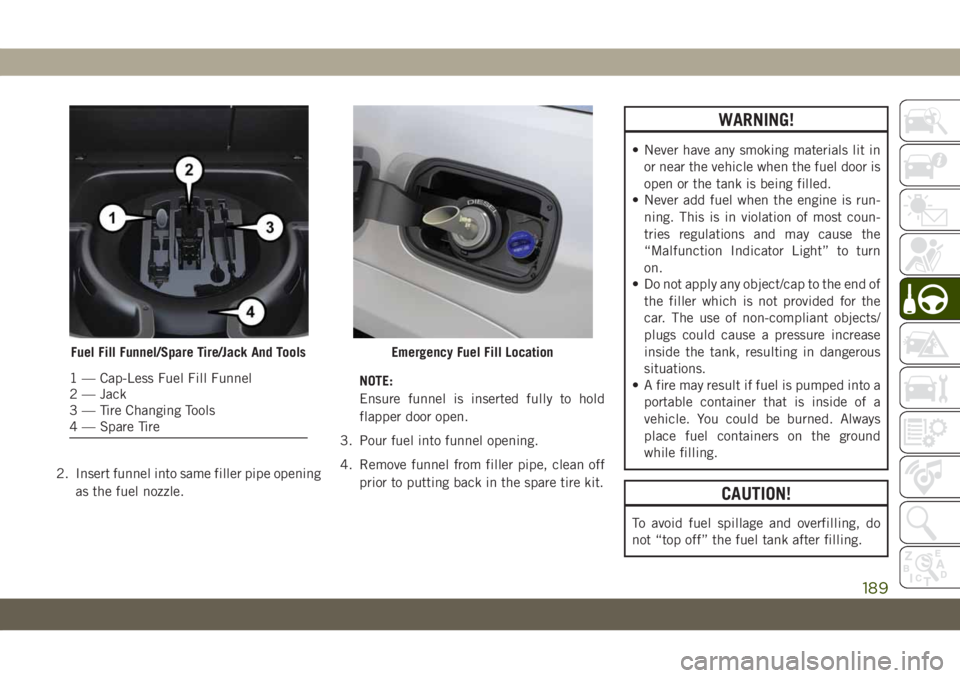

2. Insert funnel into same filler pipe opening

as the fuel nozzle.NOTE:

Ensure funnel is inserted fully to hold

flapper door open.

3. Pour fuel into funnel opening.

4. Remove funnel from filler pipe, clean off

prior to putting back in the spare tire kit.

WARNING!

• Never have any smoking materials lit in

or near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most coun-

tries regulations and may cause the

“Malfunction Indicator Light” to turn

on.

• Do not apply any object/cap to the end of

the filler which is not provided for the

car. The use of non-compliant objects/

plugs could cause a pressure increase

inside the tank, resulting in dangerous

situations.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

CAUTION!

To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

Fuel Fill Funnel/Spare Tire/Jack And Tools

1 — Cap-Less Fuel Fill Funnel

2 — Jack

3 — Tire Changing Tools

4 — Spare Tire

Emergency Fuel Fill Location

189

Page 193 of 378

NOTE:

When working with AdBlue®, it is important

to know that:

• Any containers or parts that come into con-

tact with AdBlue

®must be AdBlue®com-

patible (plastic or stainless steel). Copper,

brass, aluminum, iron or non-stainless

steel should be avoided as they are subject

to corrosion by AdBlue

®.

• If AdBlue

®is spilled, it should be wiped up

completely.

Adding AdBlue®

Preliminary Conditions

AdBlue

®freezes at temperatures lower than

12° F (-11° C). If the car stands for a long

time at this temperature refilling could be

difficult. For this reason, it is advised to park

the vehicle in a garage and/or heated environ-

ment and wait for the urea to return to liquid

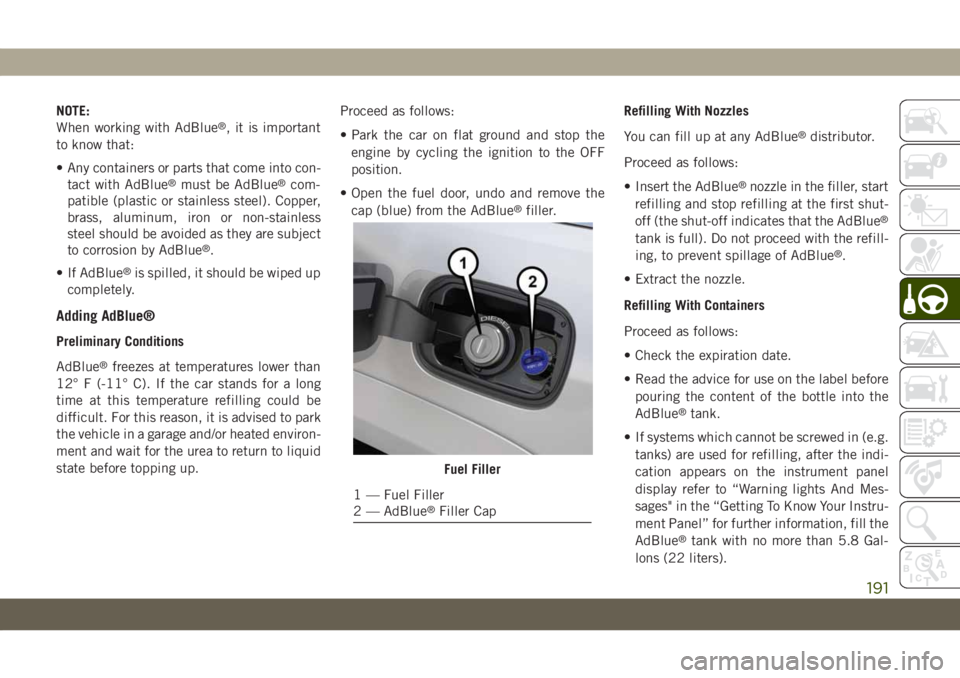

state before topping up.Proceed as follows:

• Park the car on flat ground and stop the

engine by cycling the ignition to the OFF

position.

• Open the fuel door, undo and remove the

cap (blue) from the AdBlue

®filler.Refilling With Nozzles

You can fill up at any AdBlue

®distributor.

Proceed as follows:

• Insert the AdBlue

®nozzle in the filler, start

refilling and stop refilling at the first shut-

off (the shut-off indicates that the AdBlue

®

tank is full). Do not proceed with the refill-

ing, to prevent spillage of AdBlue®.

• Extract the nozzle.

Refilling With Containers

Proceed as follows:

• Check the expiration date.

• Read the advice for use on the label before

pouring the content of the bottle into the

AdBlue

®tank.

• If systems which cannot be screwed in (e.g.

tanks) are used for refilling, after the indi-

cation appears on the instrument panel

display refer to “Warning lights And Mes-

sages" in the “Getting To Know Your Instru-

ment Panel” for further information, fill the

AdBlue

®tank with no more than 5.8 Gal-

lons (22 liters).

Fuel Filler

1 — Fuel Filler

2 — AdBlue®Filler Cap

191

Page 194 of 378

• If containers which can be screwed to the

filler are used, the reservoir is full when the

AdBlue

®level in the container stops pour-

ing out. Do not proceed further.

CAUTION!

To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

Operations After Refilling

Proceed as follows:

• Fit the cap back on the AdBlue

®filler by

turning it clockwise and screwing it com-

pletely.

• Cycle the ignition to RUN (it is not neces-

sary to start the engine).

• Wait for the indication on the instrument

panel to switch off before moving the car.

The indication may stay on for a few sec-

onds to approximately half a minute. If the

engine is started and the car is moved, the

indication will remain on for longer. This

will not compromise engine operation.• If the AdBlue

®was topped up when the

tank was empty, wait for 2 minutes before

starting the engine.

NOTE:

• If AdBlue

®is spilled out of the filler neck,

clean up well the area and proceed to filling

up again. If the liquid crystallizes, elimi-

nate it with a sponge and warm water.

• DO NOT EXCEED THE MAXIMUM LEVEL:

this could cause damage to the reservoir.

AdBlue

®freezes at under 12° F (-11° C).

Although the system is designed to operate

below the freezing point of the AdBlue

®,it

is advisable not to fill the tank beyond the

maximum level because if the AdBlue

®

freezes the system can be damaged. Follow

the instructions in this section.

• If the AdBlue

®is spilled on painted sur-

faces or aluminium, immediately clean the

area with water and use absorbent material

to collect the fluid that has been spilled on

the ground.

• Do not try to start the engine if AdBlue

®

was accidentally added to the diesel fuel

tank, this can result in serious engine dam-

age, contact an authorized dealer.• Do not add additives or other fluids to

AdBlue

®, doing so could damage the

system.

• The use of non-conforming or degraded

AdBlue

®may lead to indications appearing

on the instrument panel display refer to

“Warning Lights And Messages" in the

“Getting To Know Your Instrument Panel”

for further information.

• Never pour AdBlue

®into another con-

tainer: it could be contaminated.

• If the AdBlue

®runs out, see refer to “Warn-

ing Lights And Messages" in the “Getting To

Know Your Instrument Panel” for further

information to continue using the car

normally.

TRAILER TOWING

Trailer Towing Weights (Maximum Trailer

Weight Ratings) — Non SRT

The following chart provides the maximum

trailer weight ratings towable for your given

drivetrain.

STARTING AND OPERATING

192