Bus JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 597 of 1803

REMOVAL

OVERHEAD CONSOLE - REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the overhead console retaining screw,

located in the front of console near the windshield.

(3) Using your fingertips, grasp the sides of the

overhead console and pull straight down evenly to

disengage the two snap clips at the rear of the unit.

(4) Lower the overhead console far enough to

access the wire harness connectors.

(5) Disconnect the control module, courtesy lamps

and power sunroof switch electrical connectors, if

equipped.

(6) Remove the overhead console assembly from

the vehicle.

INSTALLATION

(1) Position the overhead console in the vehicle

and connect the wire harness connectors.

(2) Connect the control module, courtesy lamps

and power sunroof switch electrical connectors, if

equipped.

(3) Grasp the sides of the overhead console and

push straight up evenly to engage the two snap clips

at the rear of the unit.

(4) Install the overhead console retaining screw,

located in the front of console near the windshield.

Torque the screw to 1.2 N´m (10 in. lbs.).

(5) Connect the negative battery cable.

COMPASS/MINI-TRIP

COMPUTER

DESCRIPTION

The Compass Mini-Trip Computer (CMTC) is

located in the overhead console on models equipped

with this option. The Compass Mini-Trip Computer

module features a large Vacuum Fluorescent Display

(VFD) screen for displaying information, and four

back-lit push button function switches labeled C/T

(compass/thermometer), RESET, STEP, and US/M

(United States/Metric Scale).

The Compass Mini-Trip Computer module contains

a central processing unit and interfaces with other

electronic modules in the vehicle over the Program-

mable Communications Interface (PCI) data bus net-

work. The PCI data bus network allows the sharing

of sensor information. This helps to reduce wire har-

ness complexity, reduce internal controller hardware,

and reduce component sensor current loads. At the

same time, this system provides increased reliability,

enhanced diagnostics, and allows the addition of

many new feature capabilities.

The Compass Mini-Trip Computer module contains

six informational displays which can be displayed

using the four outer buttons on the overhead console.

When the vehicle is first turned ON:

²CMTC blanks the display for a half second

²Displays whatever was being viewed when the

ignition was last turned OFF

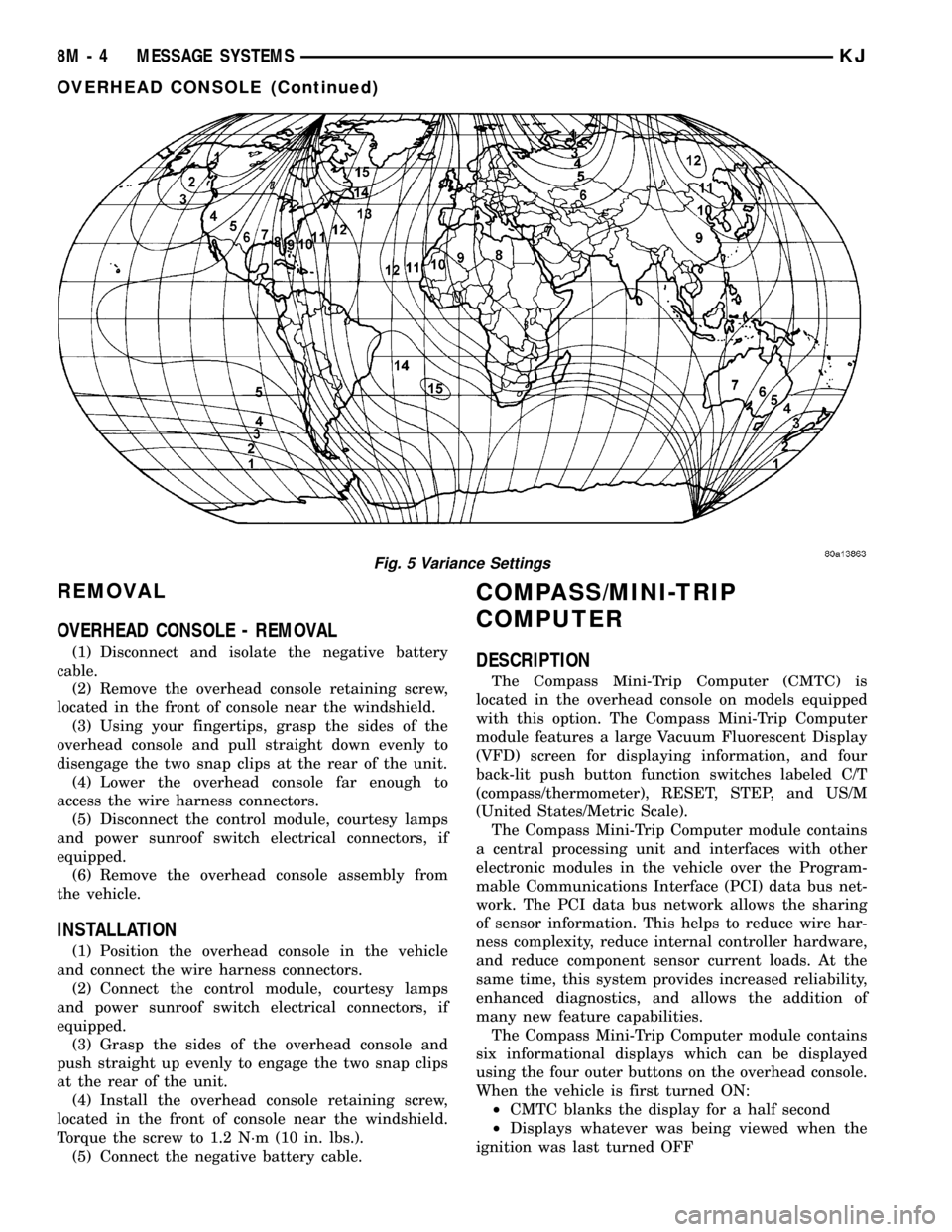

Fig. 5 Variance Settings

8M - 4 MESSAGE SYSTEMSKJ

OVERHEAD CONSOLE (Continued)

Page 598 of 1803

The CMTC may also be integrated with the Uni-

versal Transmitter. If so, your CMTC module will

have three buttons centered together between the

outer four buttons. Below the three buttons are cor-

responding dots to indicate which button you are

using.

The Compass Mini-Trip Computer includes the fol-

lowing display options:

²Compass and thermometer- provides the out-

side temperature and one of eight compass readings

to indicate the direction the vehicle is facing.

²Average fuel economy- shows the average

fuel economy since the last trip computer reset.

²Distance to empty- shows the estimated dis-

tance that can be travelled with the fuel remaining

in the fuel tank. This estimated distance is computed

using the average miles-per-gallon from the last 30

gallons of fuel used.

²Instant fuel economy- shows the present fuel

economy based upon the current vehicle distance and

fuel used information.

²Trip odometer- shows the distance travelled

since the last trip computer reset.

²Elapsed time- shows the accumulated igni-

tion-on time since the last trip computer reset.

²Blank screen- the CMTC compass/thermome-

ter/trip computer VFD is turned off.

If the vehicle is equipped with the optional Univer-

sal Transmitter transceiver, the CMTC will also dis-

play messages and an icon indicating when the

Universal Transmitter is being trained, which of the

three transmitter buttons is transmitting, and when

the transceiver is cleared.

Data input for all CMTC functions, including VFD

dimming level, is received through PCI data bus

messages. The CMTC module uses its internal pro-

gramming and all of its data inputs to calculate and

display the requested data. If the data displayed is

incorrect, perform the self-diagnostic tests as

described in this group. If these tests prove inconclu-

sive, the use of a DRBIIItscan tool and the proper

Diagnostic Procedures manual are recommended for

further testing of the CMTC module and the PCI

data bus.

The CMTC module cannot be repaired, and is

available for service only as a unit. This unit

includes the push button switches and the plastic

module and display lens. If any of these components

is faulty or damaged, the complete CMTC module

must be replaced. The incandescent bulbs used for

CMTC push button back-lighting are available for

service replacement.

DESCRIPTION - COMPASS

While in the compass/thermometer mode, the com-

pass will display the direction in which the vehicle ispointed using the eight major compass headings

(Examples: north is N, northeast is NE). The self-cal-

ibrating compass unit requires no adjusting in nor-

mal use. The only calibration that may prove

necessary is to drive the vehicle in three complete

circles at 5 to 8 kilometers-per-hour (3 to 5 miles-per-

hour), on level ground, in not less than forty-eight

seconds. This will reorient the compass unit to its

vehicle.

The compass unit also will compensate for magne-

tism the body of the vehicle may acquire during nor-

mal use. However, avoid placing anything magnetic

directly on the roof of the vehicle. Magnetic mounts

for an antenna, a repair order hat, or a funeral pro-

cession flag can exceed the compensating ability of

the compass unit if placed on the roof panel. Mag-

netic bit drivers used on the fasteners that hold the

overhead console assembly to the roof header can

also affect compass operation. If the vehicle roof

should become magnetized, the demagnetizing and

calibration procedures found in this group may be

required to restore proper compass operation.

DESCRIPTION - THERMOMETER

The thermometer displays the outside ambient

temperature in whole degrees. The temperature dis-

play can be toggled from Fahrenheit to Celsius by

using the U.S./Metric button. The displayed temper-

ature is not an instant reading of conditions, but an

average temperature. It may take the thermometer

display several minutes to respond to a major tem-

perature change, such as driving out of a heated

garage into winter temperatures.

When the ignition switch is turned to the Off posi-

tion, the last displayed temperature reading stays in

the Body Control Module (BCM) unit memory. When

the ignition switch is turned to the On position

again, the CMTC will display the memory tempera-

ture for one minute; then update the display to the

current average temperature reading within five

minutes.

The thermometer function is supported by an

ambient temperature sensor. The sensor is mounted

outside the passenger compartment near the front

and center of the vehicle, and is hard wired to the

Body Control Module (BCM). The BCM sends tem-

perature status messages to the CMTC module over

the PCI data bus network. The ambient temperature

sensor is available as a separate service item, refer to

additional information later in this section.

OPERATION

The compass mini-trip computer operates when the

ignition is in the ON position. The VFD will display

the last display before ignition was turned OFF. The

four outer buttons operate:

KJMESSAGE SYSTEMS 8M - 5

COMPASS/MINI-TRIP COMPUTER (Continued)

Page 599 of 1803

²STEP

²C/T - Compass/Temperature

²US/M - English/Metric

²RESET

1. STEP BUTTON

Pressing the STEP button selects one of the follow-

ing 6 displays:

²Average fuel economy

²Distance to empty

²Instantaneous fuel economy

²Trip odometer

²Elapsed time

²Blank Screen

2. C/T (COMPASS/TEMPERATURE)

BUTTON

Pressing the C/T button selects the Compass/Tem-

perature display.

3. US/M (ENGLISH/METRIC

MEASUREMENT) BUTTON

Pressing the US/M button switches the display

units between English and Metric readings.

4. RESET BUTTON

Pressing the RESET button resets the function on

the display, provided that function can be reset. The

functions which can be reset are Average fuel econ-

omy, Trip odometer and Elapsed time.

Global ResetThis feature allows all three dis-

plays (Average fuel economy, Trip odometer and

Elapsed time) to be reset easily, by pressing the

RESET button twice within three seconds with any

of the screens in display. This eliminates the need to

reset each display individually.

The RESET button is also used to set the variance

and/or calibrate the compass. Refer to the Variance

Procedure and Calibration Procedure in this section.

For more information on the features, control func-

tions and setting procedures for the CMTC module,

see the owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER

The following diagnostic procedure can be used if

the compass mini-trip computer is not operational in

any way. If the problem is specific to a individual

CMTC display, go to the appropriate display title

noted below and diagnose using the information pro-

vided on how these displays are generated.

(1) Remove the overhead console from the head-

liner (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

(2) Using a ohmmeter, check the ground circuit

cavity of the compass mini-trip computer electricalconnector for proper continuity to ground. Continuity

should be present, If OK go to Step 3, If not OK

repair the open or shorted ground circuit as required.

NOTE: Connect the negative battery cable before

proceeding.

(3) Using a voltmeter, check the fused (B+) circuit

cavity of the compass mini-trip computer electrical

connector for 12v. Voltage should be present, If OK go

to Step 4, If not OK repair the open or shorted fused

(B+) circuit as required.

(4) Using a voltmeter, check the fused ignition

switch output circuit cavity of the compass mini-trip

computer electrical connector for 12v with Key ON.

Voltage should be present, If OK, replace the inoper-

ative CMTC module, If not OK repair the open or

shorted fused ignition switch output circuit as

required.

TEMPERATURE

The compass mini-trip computer receives Program-

mable Communications Interface bus (PCI bus) mes-

sages from the Body Control Module (BCM) for all

displayed information except the compass display. If

a dash (-) is displayed, the compass mini-trip com-

puter is not receiving a PCI bus message from the

BCM. To check out the PCI bus line and the BCM,

use the DRB llltscan tool and proper Body Diagnos-

tic Procedure Manual.

If the compass mini-trip computer displays a tem-

perature more than 54É C (130É F), check for a short

circuit between the temperature sensor and the

BCM.

If the compass mini-trip computer displays a tem-

perature less than -40É C (-67É F), check for an open

circuit between the temperature sensor and the

BCM.

AVERAGE FUEL ECONOMY

The compass mini-trip computer receives average

fuel economy information from the BCM over the PCI

bus line. If the compass mini-trip computer displays

-.- instead of an average fuel economy value, it is not

receiving a PCI bus message for the average fuel

economy from the BCM. To check out the PCI bus

line and the BCM use the DRB llltscan tool and

proper Body Diagnostic Procedure Manual.

DISTANCE TO EMPTY

The compass mini-trip computer receives distance

to empty information from the BCM over the PCI bus

line. If compass mini-trip computer displays a dash

(-) instead of a distance to empty value, it is not

receiving a PCI bus message for the distance to

empty from the BCM. To check out the PCI bus line

8M - 6 MESSAGE SYSTEMSKJ

COMPASS/MINI-TRIP COMPUTER (Continued)

Page 600 of 1803

and the BCM use the DRB llltscan tool and proper

Body Diagnostic Procedure Manual.

INSTANTANEOUS FUEL ECONOMY

The compass mini-trip computer receives instanta-

neous fuel economy information from the BCM over

the PCI bus line. If compass mini-trip computer dis-

plays a dash (-) instead of an instantaneous fuel

economy value, it is not receiving a PCI bus message

for the instantaneous fuel economy from the BCM. To

check out the PCI bus line and the BCM use the

DRB llltscan tool and proper Body Diagnostic Pro-

cedure Manual.

TRIP ODOMETER

The compass mini-trip computer receives trip

odometer information from the Cluster over the PCI

bus line. If compass mini-trip computer displays

dashes - - instead of the trip odometer value, it is not

receiving a PCI bus message for the trip odometer

from the cluster. To check out the PCI bus line and

the Cluster, use the DRB llltscan tool and proper

Body Diagnostic Procedure Manual.

ELAPSED TIME

The compass mini-trip computer receives a PCI

bus message containing elapsed time information. If

compass mini-trip computer displays dashes --

instead of the elapsed time, it is not receiving a PCI

bus message for the elapsed time from the BCM. To

check out the PCI bus line and the BCM, use the

DRB llltscan tool and proper Body Diagnostic Pro-

cedure Manual.

COMPASS DISPLAY

To display the vehicle direction, the compass mini-

trip computer processes information from a sensor

internal to the module. The compass mini-trip com-

puter is self- calibrating and requires only variance

adjustments dependent upon location. The compass

mini-trip computer displays the label CAL whenever

the compass is in the fast calibration mode.

If all three of the following conditions listed below

occur, the vehicle must be demagnetized.

²Compass portion of the display is blank

²Temperature portion of the display is OK

²The label CAL is illuminated

If demagnetizing the vehicle is needed, refer to the

demagnetizing procedure in this section. After

demagnetizing, to calibrate the compass refer to Cal-

ibration Procedure and to set the variance refer to

Variance Procedure, both within this section. If the

compass portion of the display is still blank, replace

the compass mini-trip computer.

COMPASS MINI-TRIP COMPUTER - SELF

DIAGNOSTIC TEST

(1) With the ignition switch in the OFF position

simultaneously press the C/T and STEP buttons and

hold.

(2) Turn the ignition switch ON, then release C/T

and STEP buttons.

(3) The Compass mini-trip computer should light

all segments on the VF Display Screen for 2-4 sec-

onds. Check for segments that are not illuminated.

(4) If the compass mini-trip computer displays

PASS, the module is OK.

(5) If the compass mini-trip computer displays

FAIL, replace the module.

(6) If the compass mini-trip computer displays

bUS, check for an open or a short on the PCI bus

communication circuit.

(7) Press the C/T or the STEP button to exit the

self-diagnostic test.

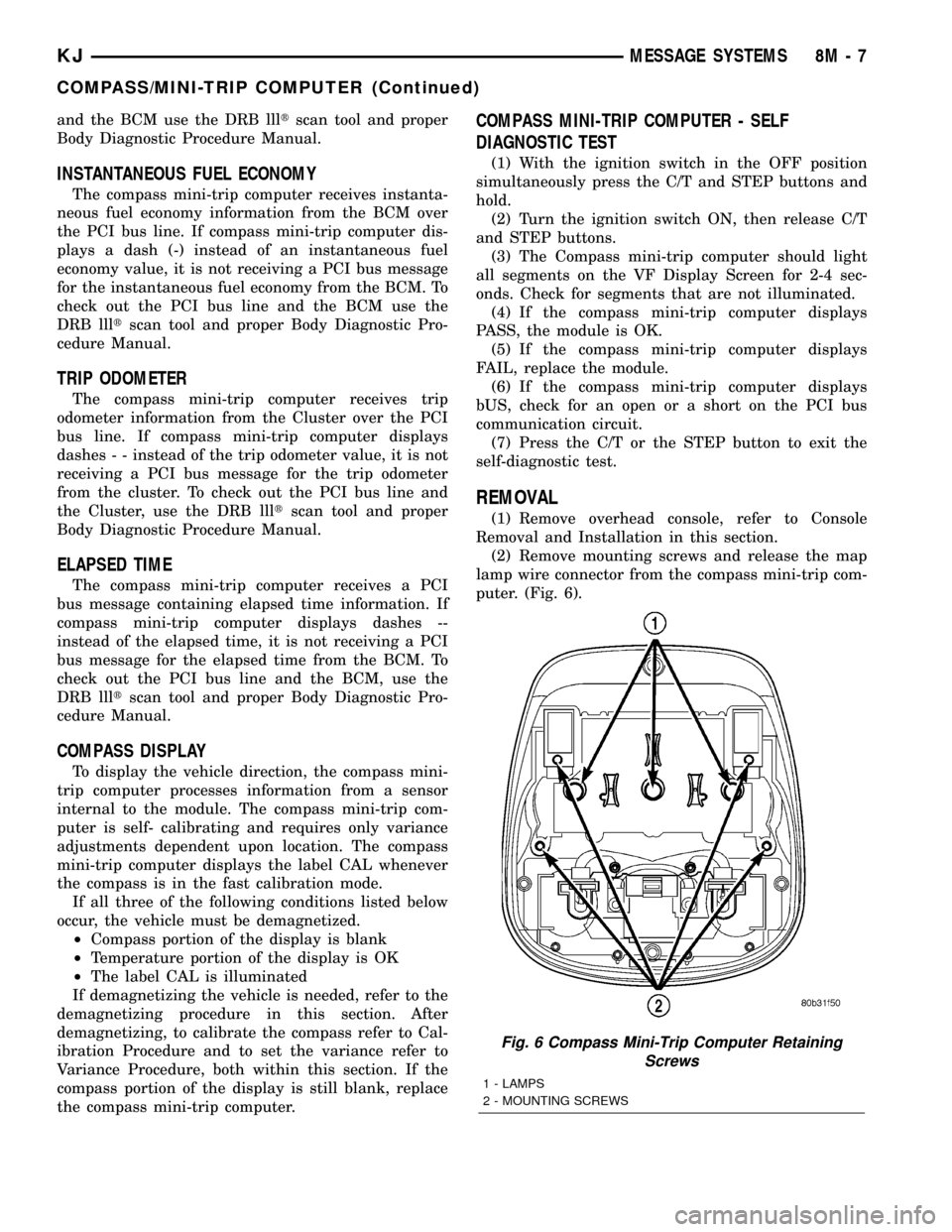

REMOVAL

(1) Remove overhead console, refer to Console

Removal and Installation in this section.

(2) Remove mounting screws and release the map

lamp wire connector from the compass mini-trip com-

puter. (Fig. 6).

Fig. 6 Compass Mini-Trip Computer Retaining

Screws

1 - LAMPS

2 - MOUNTING SCREWS

KJMESSAGE SYSTEMS 8M - 7

COMPASS/MINI-TRIP COMPUTER (Continued)

Page 602 of 1803

NOTE: Individual channels cannot be erased. Eras-

ing the transmitter codes will erase ALL pro-

grammed codes.

STANDARD PROCEDURE - SETTING

TRANSMITTER CODES

(1) Turn off the engine.

(2) Erase the factory test codes by pressing but-

tons 1 and 3. Release the buttons when the two

green lights begin to flash (about 20 seconds).

(3) Choose one of the three buttons to train. Place

the hand-held transmitter within one inch of the uni-

versal transmitter and push the buttons on both

transmitters. The green dot below the house symbol

will begin to flash slowly.

(4) When the red light on the universal transmit-

ter begins to flash rapidly (this may take as long as

60 seconds), release both buttons. Your universal

transmitter is now ªtrainedº. To train the other but-

tons, repeat Step 3 and Step 4. Be sure to keep your

hand-held transmitter in case you need to retrain the

universal transmitter.

AMBIENT TEMP SENSOR

DESCRIPTION

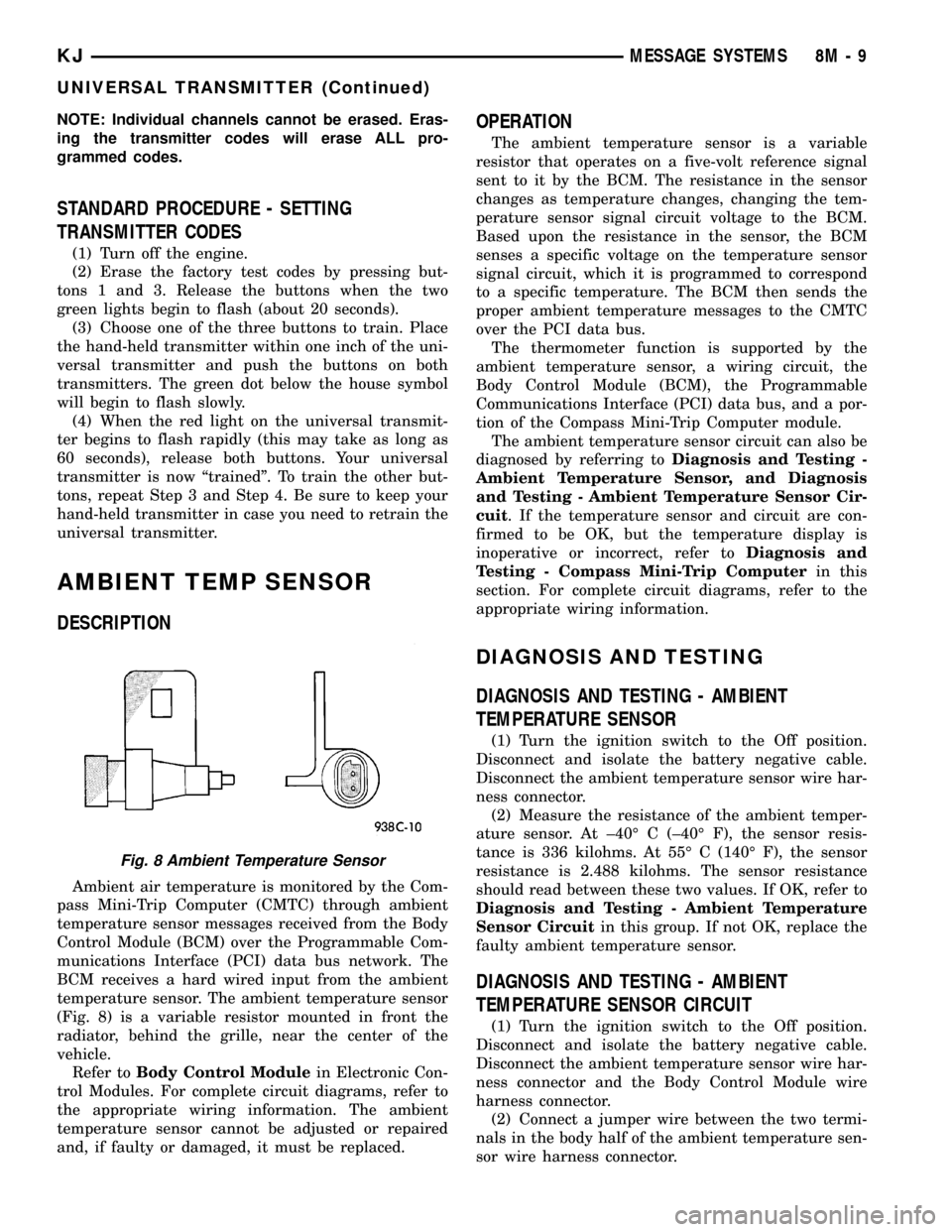

Ambient air temperature is monitored by the Com-

pass Mini-Trip Computer (CMTC) through ambient

temperature sensor messages received from the Body

Control Module (BCM) over the Programmable Com-

munications Interface (PCI) data bus network. The

BCM receives a hard wired input from the ambient

temperature sensor. The ambient temperature sensor

(Fig. 8) is a variable resistor mounted in front the

radiator, behind the grille, near the center of the

vehicle.

Refer toBody Control Modulein Electronic Con-

trol Modules. For complete circuit diagrams, refer to

the appropriate wiring information. The ambient

temperature sensor cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent to it by the BCM. The resistance in the sensor

changes as temperature changes, changing the tem-

perature sensor signal circuit voltage to the BCM.

Based upon the resistance in the sensor, the BCM

senses a specific voltage on the temperature sensor

signal circuit, which it is programmed to correspond

to a specific temperature. The BCM then sends the

proper ambient temperature messages to the CMTC

over the PCI data bus.

The thermometer function is supported by the

ambient temperature sensor, a wiring circuit, the

Body Control Module (BCM), the Programmable

Communications Interface (PCI) data bus, and a por-

tion of the Compass Mini-Trip Computer module.

The ambient temperature sensor circuit can also be

diagnosed by referring toDiagnosis and Testing -

Ambient Temperature Sensor, and Diagnosis

and Testing - Ambient Temperature Sensor Cir-

cuit. If the temperature sensor and circuit are con-

firmed to be OK, but the temperature display is

inoperative or incorrect, refer toDiagnosis and

Testing - Compass Mini-Trip Computerin this

section. For complete circuit diagrams, refer to the

appropriate wiring information.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At ±40É C (±40É F), the sensor resis-

tance is 336 kilohms. At 55É C (140É F), the sensor

resistance is 2.488 kilohms. The sensor resistance

should read between these two values. If OK, refer to

Diagnosis and Testing - Ambient Temperature

Sensor Circuitin this group. If not OK, replace the

faulty ambient temperature sensor.

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector and the Body Control Module wire

harness connector.

(2) Connect a jumper wire between the two termi-

nals in the body half of the ambient temperature sen-

sor wire harness connector.

Fig. 8 Ambient Temperature Sensor

KJMESSAGE SYSTEMS 8M - 9

UNIVERSAL TRANSMITTER (Continued)

Page 605 of 1803

are closed and the accelerator pedal is depressed.

The rolling door lock feature can be disabled if

desired.

This vehicle also offers several customer program-

mable features, which allows the selection of several

optional electronic features to suit individual prefer-

ences.

The power lock system for this vehicle can also be

operated remotely using the available Remote Key-

less Entry (RKE) system radio frequency transmit-

ters, if equipped.

Certain functions and features of the power lock

system rely upon resources shared with other elec-

tronic modules in the vehicle over the Programmable

Communications Interface (PCI) data bus network.

For proper diagnosis of these electronic modules or of

the PCI data bus network, the use of a DRBIIItscan

tool and the appropriate diagnostic information are

required.

REMOTE KEYLESS ENTRY

A Radio Frequency (RF) type Remote Keyless

Entry (RKE) system is an available factory-installed

option on this model. The RKE system allows the use

of a remote battery-powered radio transmitter to sig-

nal the Body Control Module (BCM) to actuate the

power lock system. The RKE receiver operates on

non-switched battery current through a fuse in the

Junction Block (JB), so that the system remains

operational, regardless of the ignition switch position.

The RKE transmitters are also equipped with a

Panic button. If the Panic button on the RKE trans-

mitter is depressed, the horn will sound and the

exterior lights will flash on the vehicle for about

three minutes, or until the Panic button is depressed

a second time. A vehicle speed of about 25.7 kilome-

ters-per-hour (15 miles-per-hour) will also cancel the

panic event.

The RKE system can also perform other functions

on this vehicle. If the vehicle is equipped with the

optional Vehicle Theft Security System (VTSS), the

RKE transmitter will arm the VTSS when the Lock

button is depressed, and disarm the VTSS when the

Unlock button is depressed.

The RKE system includes two transmitters when

the vehicle is shipped from the factory, but the sys-

tem can retain the vehicle access codes of up to four

transmitters. The transmitter codes are retained in

the RKE receiver memory, even if the battery is dis-

connected. If an RKE transmitter is faulty or lost,

new transmitter vehicle access codes can be pro-

grammed into the system using a DRBIIItscan tool.

This vehicle also offers several customer program-

mable features, which allows the selection of several

optional electronic features to suit individual prefer-ences. Customer programmable feature options

affecting the RKE system include:

²Remote Unlock Sequence- Allows the option

of having only the driver side front door unlock when

the RKE transmitter Unlock button is depressed the

first time. The remaining doors and the tailgate

unlock when the button is depressed a second time

within 5 seconds of the first unlock press. Another

option is having all doors and the tailgate unlock

upon the first depression of the RKE transmitter

Unlock button.

²Sound Horn on Lock- Allows the option of

having the horn sound a short chirp as an audible

verification that the RKE system received a valid

Lock request from the RKE transmitter, or having no

audible verification.

²Flash Lights with Lock and Unlock- Allows

the option of having the lights flash as an optical ver-

ification that the RKE system received a valid Lock

request or Unlock request from the RKE transmitter,

or having no optical verification.

²Programming Additional Transmitters-

Allows up to four transmitter vehicle access codes to

be stored in the receiver memory.

Certain functions and features of the RKE system

rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. The

PCI data bus network allows the sharing of sensor

information. This helps to reduce wire harness com-

plexity, internal controller hardware, and component

sensor current loads. For diagnosis of these electronic

modules or of the PCI data bus network, the use of a

DRBIIItscan tool and the appropriate diagnostic

information are required.

TAILGATE / FLIP-UP GLASS POWER RELEASE

SYSTEM

A power operated tailgate / flip-up glass release

system is standard factory installed equipment on

this model. The entire system is controlled by the

Body Control Module (BCM). The tailgate / flip-up

glass power release system allows the flip-up glass

latch to be released electrically by actuating a switch

located integral to the outside tailgate handle. By

pulling the handle to the first detent or turning the

key cylinder to unlock, the flip-up glass will open.

Pulling the handle to the second detent will allow the

tailgate to open.

The tailgate / flip-up glass release system operates

on non-switched battery current supplied through a

fuse in the junction block so that the system remains

functional, regardless of the ignition switch position.

However, the BCM prevents the flip-up glass latch

from being actuated when the tailgate latch is

locked.

8N - 2 POWER LOCKSKJ

POWER LOCKS (Continued)

Page 607 of 1803

proper Diagnostic Procedures manual. The

DRBIIItscan tool can provide confirmation

that the PCI data bus is functional, that all of

the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus,

and that the power lock motors are being sent

the proper hard wired outputs by the relays for

them to perform their power lock system func-

tions.

Following are tests that will help to diagnose the

hard wired components and circuits of the power lock

system. However, these tests may not prove conclu-

sive in the diagnosis of this system. In order to

obtain conclusive testing of the power lock system,

the Programmable Communications Interface (PCI)

data bus network and all of the electronic modules

that provide inputs to, or receive outputs from the

power lock system components must be checked.

The Body Control Module (BCM) will set Diagnos-

tic Trouble Codes (DTC) for the power lock system.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

PRELIMINARY DIAGNOSIS

As a preliminary diagnosis for the power lock sys-

tem, note the system operation while you actuate

both the Lock and Unlock functions with the power

lock switches and with the Remote Keyless Entry

(RKE) transmitter. Then, proceed as follows:

²If the entire power lock system fails to function

with either the power lock switches or the RKE

transmitter, check the fused B(+) fuse in the junction

Block (JB).

²If the power lock system functions with both

power lock switches, but not with the RKE transmit-

ter, proceed to diagnosis of the Remote Keyless Entry

(RKE) system. (Refer to 8 - ELECTRICAL/POWER

LOCKS/KEYLESS ENTRY TRANSMITTER - DIAG-

NOSIS AND TESTING) or (Refer to 8 - ELECTRI-

CAL/POWER LOCKS/REMOTE KEYLESS ENTRY

MODULE - DIAGNOSIS AND TESTING).

²If the power lock system functions with the RKE

transmitter, but not with one or both power lock

switches, proceed to diagnosis of the door lock

switches. (Refer to 8 - ELECTRICAL/POWER

LOCKS/POWER LOCK SWITCH - DIAGNOSIS AND

TESTING).

²If the driver side power lock switch operates

only the driver side front door power lock motor, but

all other power lock motors operate with the passen-

ger side power lock switch or the RKE transmitter,

use a DRBIIItscan tool and the appropriate diagnos-tic information to diagnose the Programmable Com-

munications Interface (PCI) data bus.

²If only one power lock motor fails to operate

with both power lock switches and the RKE trans-

mitter, proceed to diagnosis of the power lock motor.

(Refer to 8 - ELECTRICAL/POWER LOCKS/POWER

LOCK MOTOR - DIAGNOSIS AND TESTING).

DOOR LOCK / UNLOCK

SWITCH

DIAGNOSIS AND TESTING - DOOR LOCK/

UNLOCK SWITCH

(1) Remove the switch to be tested (Refer to 8 -

ELECTRICAL/POWER LOCKS/POWER LOCK

SWITCH - REMOVAL).

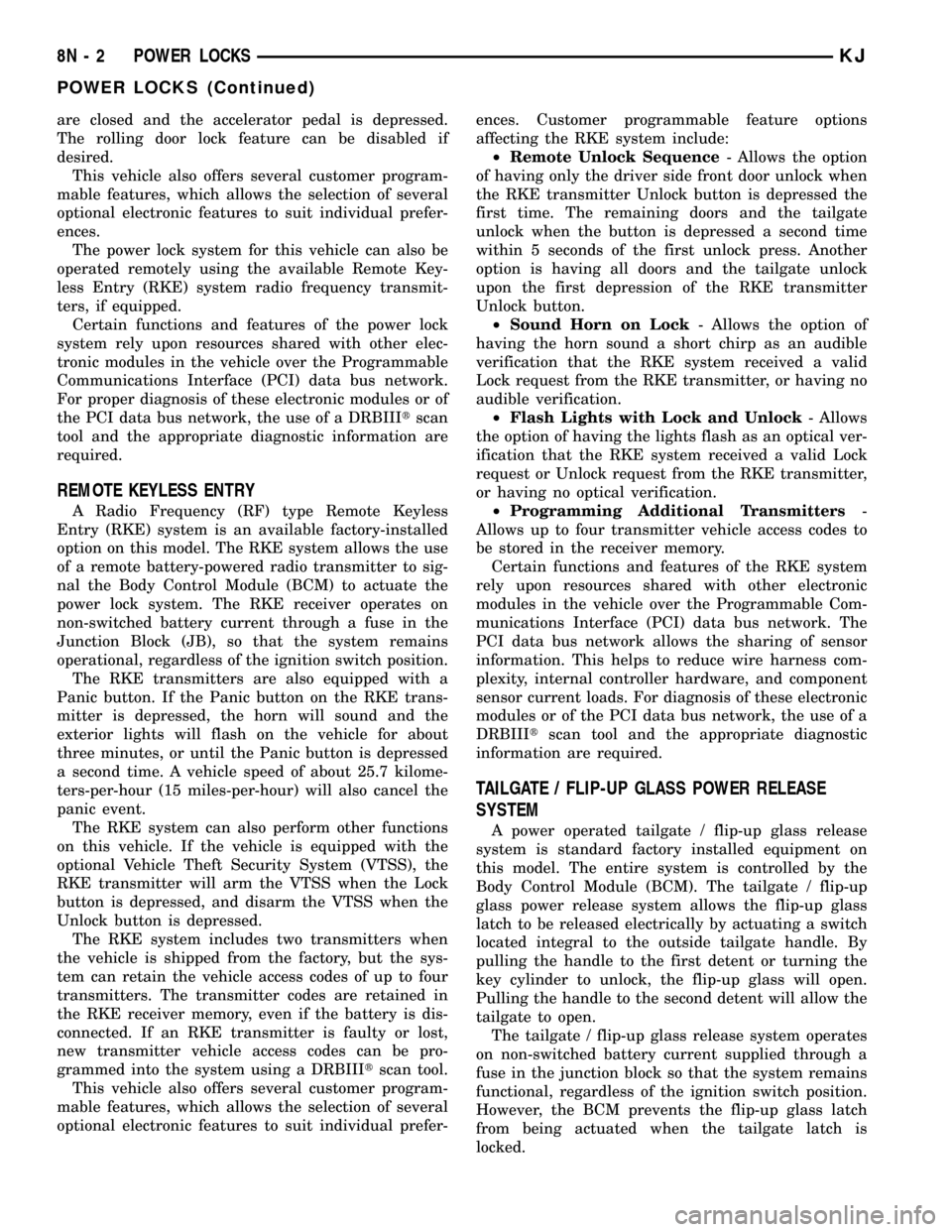

(2) Using an ohmmeter, Test switch for resistance

values (Fig. 1).

DOOR LOCK SWITCH TEST

SWITCH

POSITIONPINS RESISTANCE

VALUE

UNACTUATED 1 AND 4 5.0K OHM 10

%

LOCK 1 AND 4 1.4K OHM 10

%

UNLOCK 1 AND 4 426 OHM 10

%

(3) If test results are not obtained as shown in the

test table, replace the switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

Fig. 1 DOOR LOCK/UNLOCK SWITCH

8N - 4 POWER LOCKSKJ

POWER LOCKS (Continued)

Page 608 of 1803

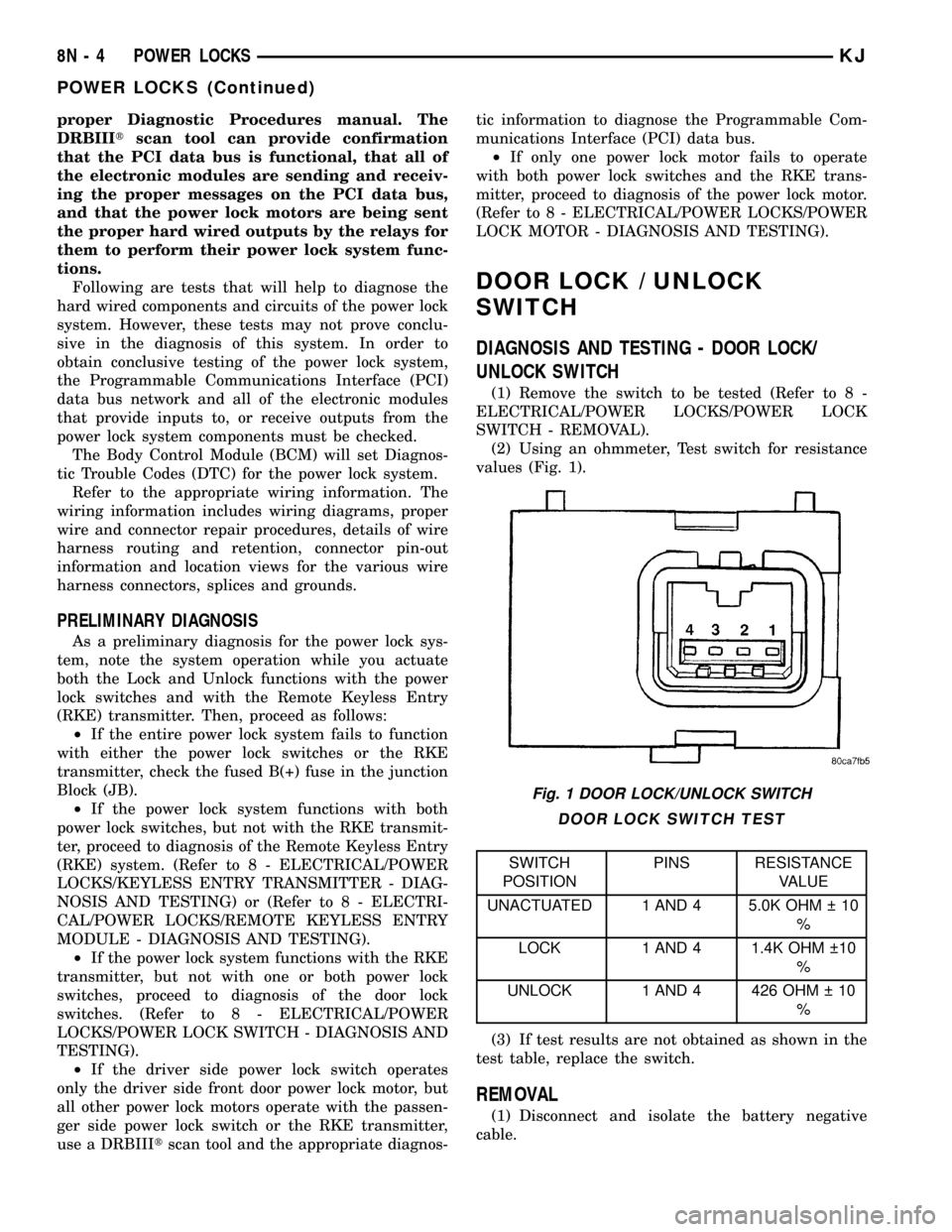

(2) Remove the door trim panel (Fig. 2) (Refer to

23 - BODY/DOOR - FRONT/TRIM PANEL - REMOV-

AL).

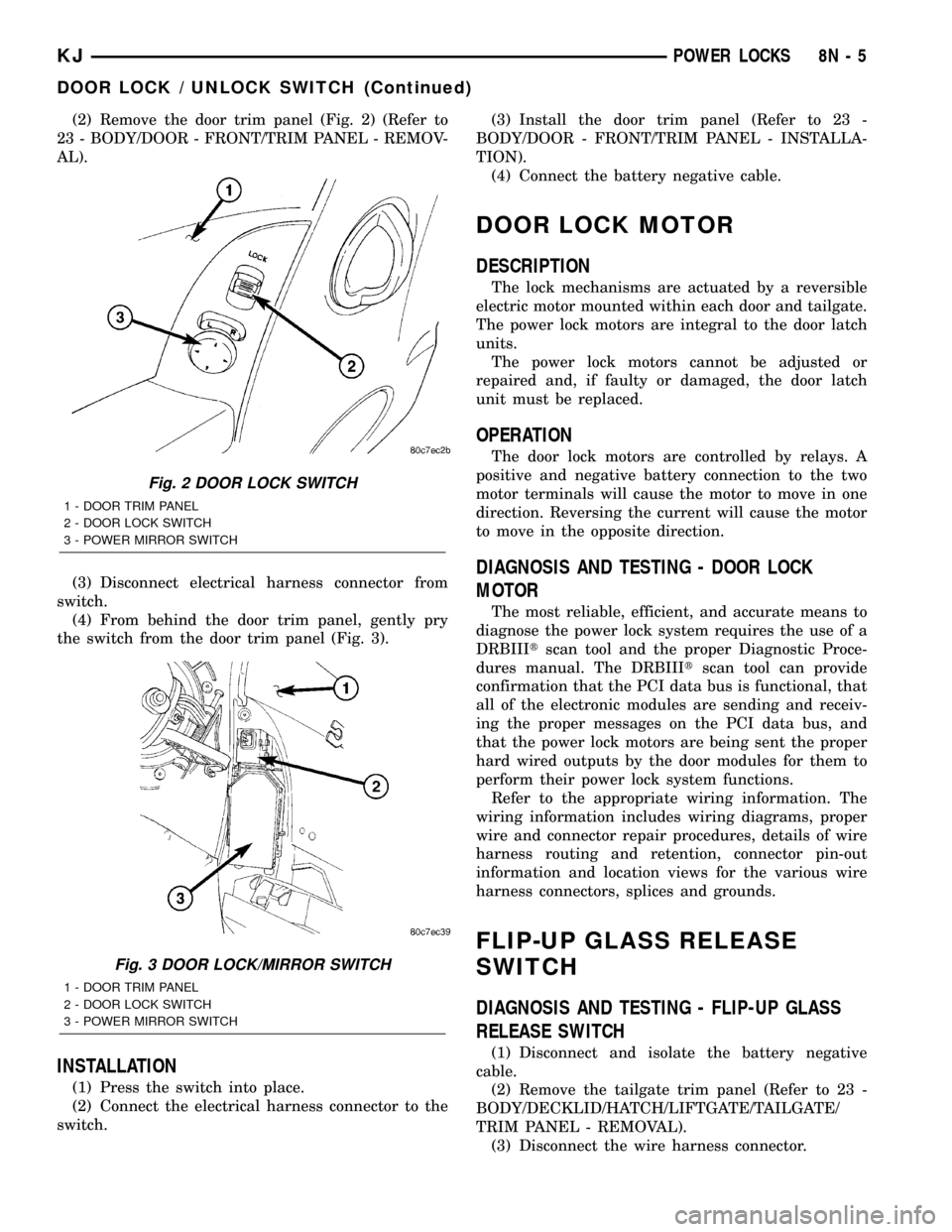

(3) Disconnect electrical harness connector from

switch.

(4) From behind the door trim panel, gently pry

the switch from the door trim panel (Fig. 3).

INSTALLATION

(1) Press the switch into place.

(2) Connect the electrical harness connector to the

switch.(3) Install the door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - INSTALLA-

TION).

(4) Connect the battery negative cable.

DOOR LOCK MOTOR

DESCRIPTION

The lock mechanisms are actuated by a reversible

electric motor mounted within each door and tailgate.

The power lock motors are integral to the door latch

units.

The power lock motors cannot be adjusted or

repaired and, if faulty or damaged, the door latch

unit must be replaced.

OPERATION

The door lock motors are controlled by relays. A

positive and negative battery connection to the two

motor terminals will cause the motor to move in one

direction. Reversing the current will cause the motor

to move in the opposite direction.

DIAGNOSIS AND TESTING - DOOR LOCK

MOTOR

The most reliable, efficient, and accurate means to

diagnose the power lock system requires the use of a

DRBIIItscan tool and the proper Diagnostic Proce-

dures manual. The DRBIIItscan tool can provide

confirmation that the PCI data bus is functional, that

all of the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus, and

that the power lock motors are being sent the proper

hard wired outputs by the door modules for them to

perform their power lock system functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

FLIP-UP GLASS RELEASE

SWITCH

DIAGNOSIS AND TESTING - FLIP-UP GLASS

RELEASE SWITCH

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the tailgate trim panel (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL).

(3) Disconnect the wire harness connector.

Fig. 2 DOOR LOCK SWITCH

1 - DOOR TRIM PANEL

2 - DOOR LOCK SWITCH

3 - POWER MIRROR SWITCH

Fig. 3 DOOR LOCK/MIRROR SWITCH

1 - DOOR TRIM PANEL

2 - DOOR LOCK SWITCH

3 - POWER MIRROR SWITCH

KJPOWER LOCKS 8N - 5

DOOR LOCK / UNLOCK SWITCH (Continued)

Page 611 of 1803

REMOTE KEYLESS ENTRY

TRANSMITTER

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY TRANSMITTER

The most reliable, efficient, and accurate means to

diagnose the remote keyless entry transmitter

requires the use of a DRBIIItscan tool and the

proper Diagnostic Procedures manual. The DRBIIIt

scan tool can provide confirmation that the PCI data

bus is functional, and that all of the electronic mod-

ules are sending and receiving the proper messages

on the PCI data bus.

STANDARD PROCEDURE

STANDARD PROCEDURE - RKE TRANSMITTER

BATTERIES

The Remote Keyless Entry (RKE) transmitter case

snaps open and shut for battery access. To replace

the RKE transmitter batteries:(1) Using a thin coin, gently pry at the notch in

the center seam of the RKE transmitter case halves

near the key ring until the two halves unsnap.

(2) Lift the back half of the transmitter case off of

the RKE transmitter.

(3) Remove the two batteries from the RKE trans-

mitter.

(4) Replace the two batteries with new Panasonic

2016, or equivalent. Be certain that the batteries are

installed with their polarity correctly oriented.

(5) Align the two RKE transmitter case halves

with each other, and squeeze them firmly and evenly

together until they snap back into place.

STANDARD PROCEDURE - RKE TRANSMITTER

CUSTOMER PREFERENCES

AUTOMATIC (ROLLING) LOCKS

The rolling locks feature can be toggled ON/OFF

by using the DRB IIItonly.

HORN CHIRP DISABLING / ENABLING

The horn chirp can be toggled using a DRB IIItor

by using the Remote Keyless Entry (RKE) transmit-

ter.

To DISABLE (cancel) the horn chirp feature, press

and hold the transmitter LOCK button for four to ten

seconds. While pressing the LOCK button in, press

the UNLOCK button. Release both buttons.

To ENABLE the horn chirp feature, repeat the

above procedure.

OPTICAL CHIRP (FLASH) DISABLING / ENABLING

The optical chirp can be toggled using a DRB IIIt

or by using the Remote Keyless Entry (RKE) trans-

mitter.

To DISABLE (cancel) the optical chirp feature,

press and hold the transmitter LOCK button for four

to ten seconds. While pressing the LOCK button in,

press the TAILGATE RELEASE button. Release both

buttons.

To ENABLE the optical chirp feature, repeat the

above procedure.

TAIL GATE RELEASE DELAY

Press the UNLOCK button for four to ten seconds.

While pressing the UNLOCK button, press the TAIL

GATE RELEASE button. Release both buttons.

This will toggle between PRESS AND HOLD and

PRESS (no delay).

UNLOCK SEQUENCE

The unlock sequence can be toggled using a DRB

IIItor by using the Remote Keyless Entry (RKE)

transmitter.

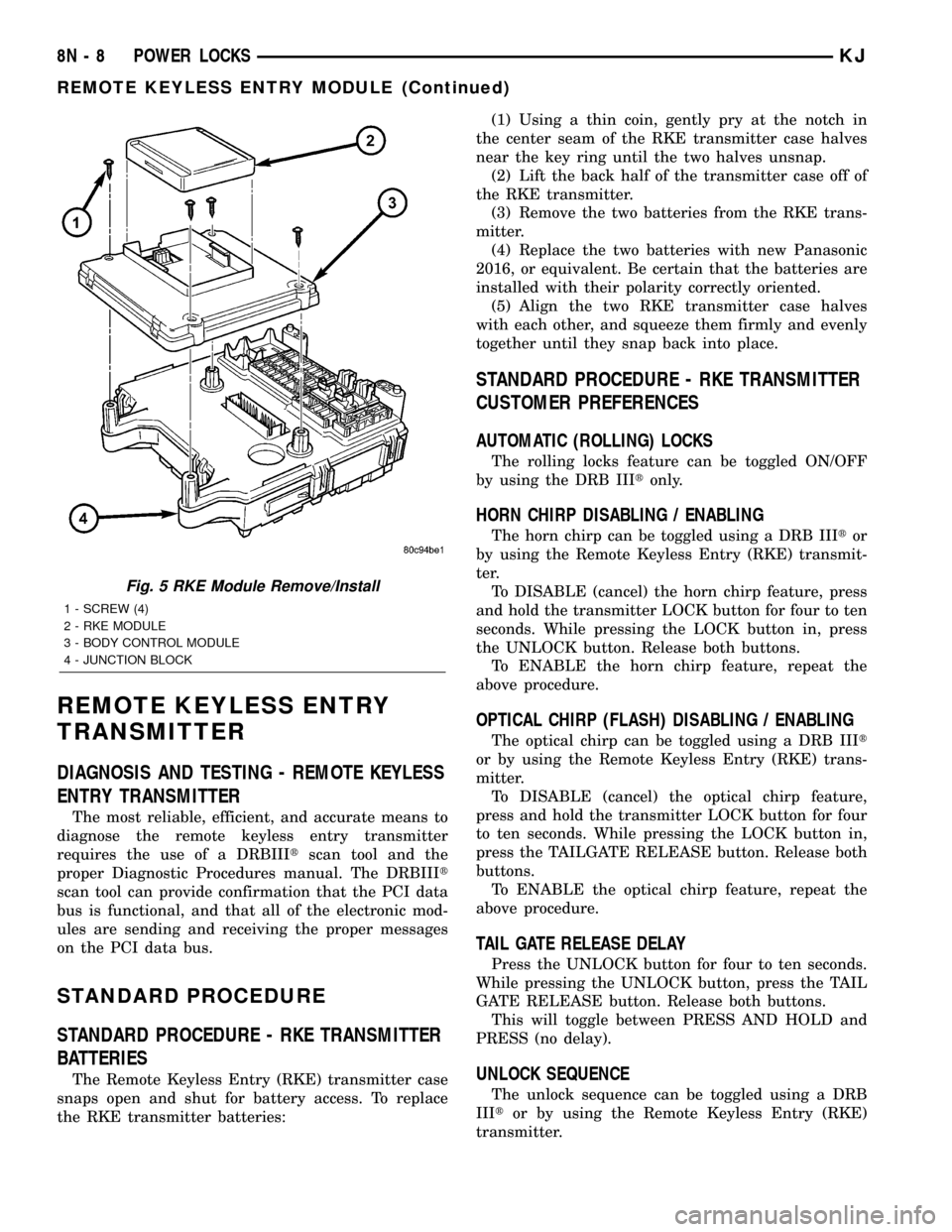

Fig. 5 RKE Module Remove/Install

1 - SCREW (4)

2 - RKE MODULE

3 - BODY CONTROL MODULE

4 - JUNCTION BLOCK

8N - 8 POWER LOCKSKJ

REMOTE KEYLESS ENTRY MODULE (Continued)

Page 612 of 1803

Press and hold the transmitter UNLOCK button

for four to ten seconds. While pressing the UNLOCK

button in, press the LOCK button. Release both but-

tons.

This will toggle between Driver door first and

Unlock all doors function.

STANDARD PROCEDURE - RKE TRANSMITTER

PROGRAMING

New Remote Keyless Entry (RKE) transmitters can

be programed using the DRBIIItscan tool and the

proper Diagnostic Procedures manual. The DRBIIIt

scan tool can provide confirmation that the PCI data

bus is functional, and that all of the electronic mod-

ules are sending and receiving the proper messages

on the PCI data bus.

The following procedure can be used as long as one

functioning transmitter is available:

(1) Using the original transmitter, press the

UNLOCK button for 4 to 10 seconds.

(2) Without releasing the UNLOCK button, press

the PANIC button (within the 4 to 10 second inter-

val).

(3) Release both buttons.

(4) Press LOCK and UNLOCK simultaneously on

the original transmitter.

(5) Release both buttons.

(6) Press any button on the ORIGINAL transmit-

ter. A chime tone from the instrument cluster will

confirm the programming of the ORIGINAL trans-

mitter.

(7) On NEW transmitter, press LOCK and

UNLOCK simultaneously.

(8) Release both buttons.

(9) Press any button on the NEW transmitter. A

chime tone from the instrument cluster will confirm

the programming of the NEW transmitter.

(10) Up to four transmitters can be programed for

one vehicle.

SPECIFICATIONS - REMOTE KEYLESS ENTRY

TRANSMITTER

RANGE

Normal operation range is up to a distance of 3 to

7 meters (10 to 23 ft.) of the vehicle. Range may be

better or worse depending on the environment

around the vehicle.

TAILGATE CYLINDER LOCK

SWITCH

DESCRIPTION

The tailgate cylinder lock switch is integral to the

key lock cylinder inside the tailgate. The tailgate cyl-

inder lock switch is a normally-open momentary

switch that is hard wired directly to the Body Con-

trol Module (BCM), and closes a path to ground

through an internal resistor when the lock cylinder is

rotated to the unlock or lock position.

The tailgate cylinder lock switch cannot be

adjusted or repaired.

OPERATION

The tailgate cylinder lock switch is actuated when

the key is inserted in the lock cylinder and turned to

the unlock or lock position. The tailgate cylinder lock

switch closes a path to ground through an internal

resistor for the Body Control Module (BCM) when

the tailgate key lock cylinder is in the lock or unlock

position, and opens the ground path when the lock

cylinder is in the neutral position. The BCM reads

the switch status, then sends the proper switch sta-

tus messages to other electronic modules over the

Programmable Communications Interface (PCI) data

bus network. The tailgate cylinder lock switch unlock

status message is used by the BCM as an input for

Vehicle Theft Security System (VTSS) operation and

to tell the BCM to lock or unlock the tailgate. There

is no mechanical linkage between the tailgate key

cylinder and the latches.

DIAGNOSIS AND TESTING - TAILGATE

CYLINDER LOCK SWITCH

(1) Disconnect and isolate the battery negative

cable.

(2) Remove tailgate trim panel (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL).

(3) Disconnect tailgate cylinder lock switch har-

ness connector.

(4) Using a ohmmeter, test for resistances as

shown in the Tailgate Cylinder Lock Switch Table.

KJPOWER LOCKS 8N - 9

REMOTE KEYLESS ENTRY TRANSMITTER (Continued)