fuse panel JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1668 of 1803

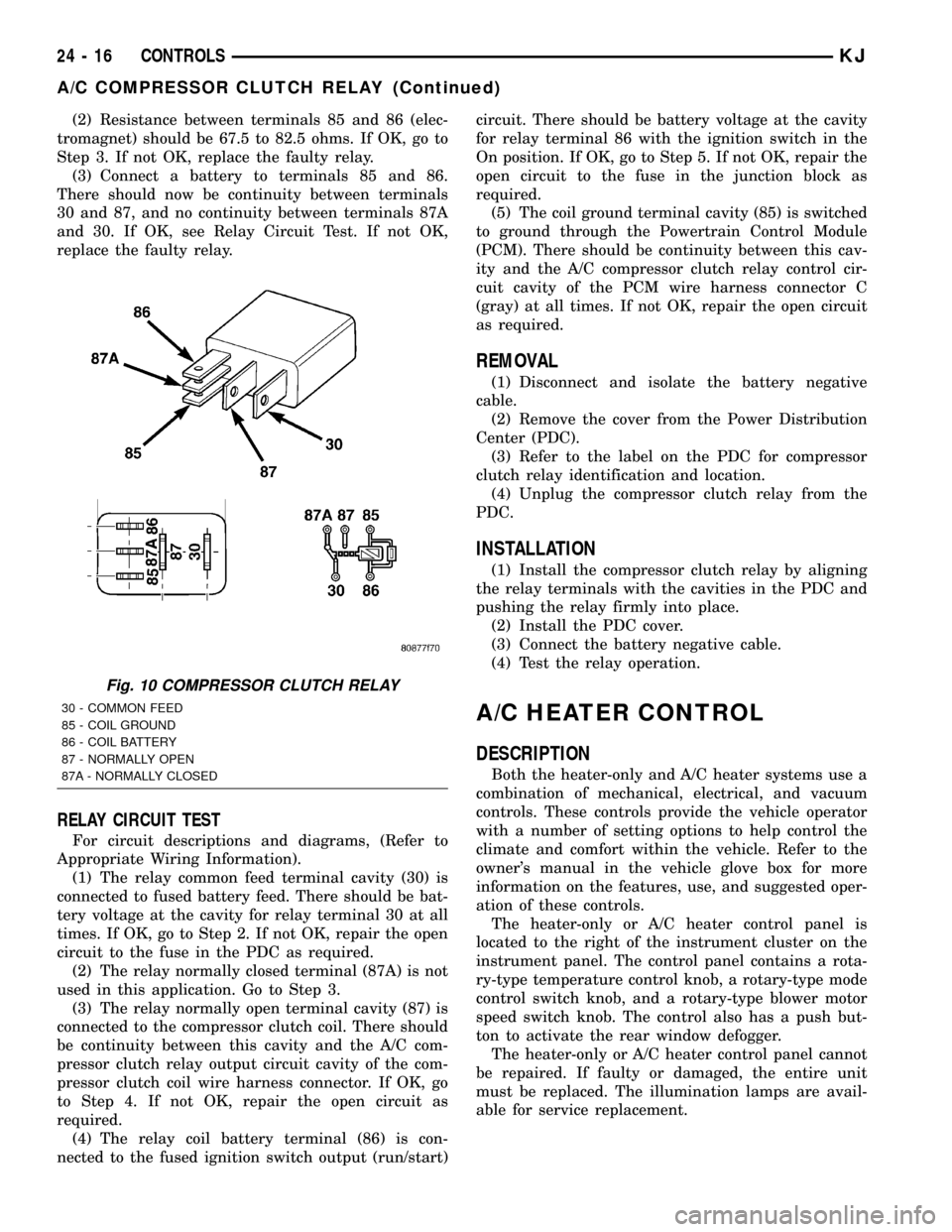

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 67.5 to 82.5 ohms. If OK, go to

Step 3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see Relay Circuit Test. If not OK,

replace the faulty relay.

RELAY CIRCUIT TEST

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed. There should be bat-

tery voltage at the cavity for relay terminal 30 at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is not

used in this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the compressor clutch coil. There should

be continuity between this cavity and the A/C com-

pressor clutch relay output circuit cavity of the com-

pressor clutch coil wire harness connector. If OK, go

to Step 4. If not OK, repair the open circuit as

required.

(4) The relay coil battery terminal (86) is con-

nected to the fused ignition switch output (run/start)circuit. There should be battery voltage at the cavity

for relay terminal 86 with the ignition switch in the

On position. If OK, go to Step 5. If not OK, repair the

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

Both the heater-only and A/C heater systems use a

combination of mechanical, electrical, and vacuum

controls. These controls provide the vehicle operator

with a number of setting options to help control the

climate and comfort within the vehicle. Refer to the

owner's manual in the vehicle glove box for more

information on the features, use, and suggested oper-

ation of these controls.

The heater-only or A/C heater control panel is

located to the right of the instrument cluster on the

instrument panel. The control panel contains a rota-

ry-type temperature control knob, a rotary-type mode

control switch knob, and a rotary-type blower motor

speed switch knob. The control also has a push but-

ton to activate the rear window defogger.

The heater-only or A/C heater control panel cannot

be repaired. If faulty or damaged, the entire unit

must be replaced. The illumination lamps are avail-

able for service replacement.

Fig. 10 COMPRESSOR CLUTCH RELAY

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

24 - 16 CONTROLSKJ

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 1672 of 1803

(2) Install and tighten the a/c low pressure switch

on the accumulator fitting. The switch should be

hand-tightened onto the accumulator fitting.

(3) Plug the wire harness connector into the a/c

low pressure switch.

(4) Connect the battery negative cable.

BLEND DOOR ACTUATOR

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove A/C housing from vehicle(Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL).

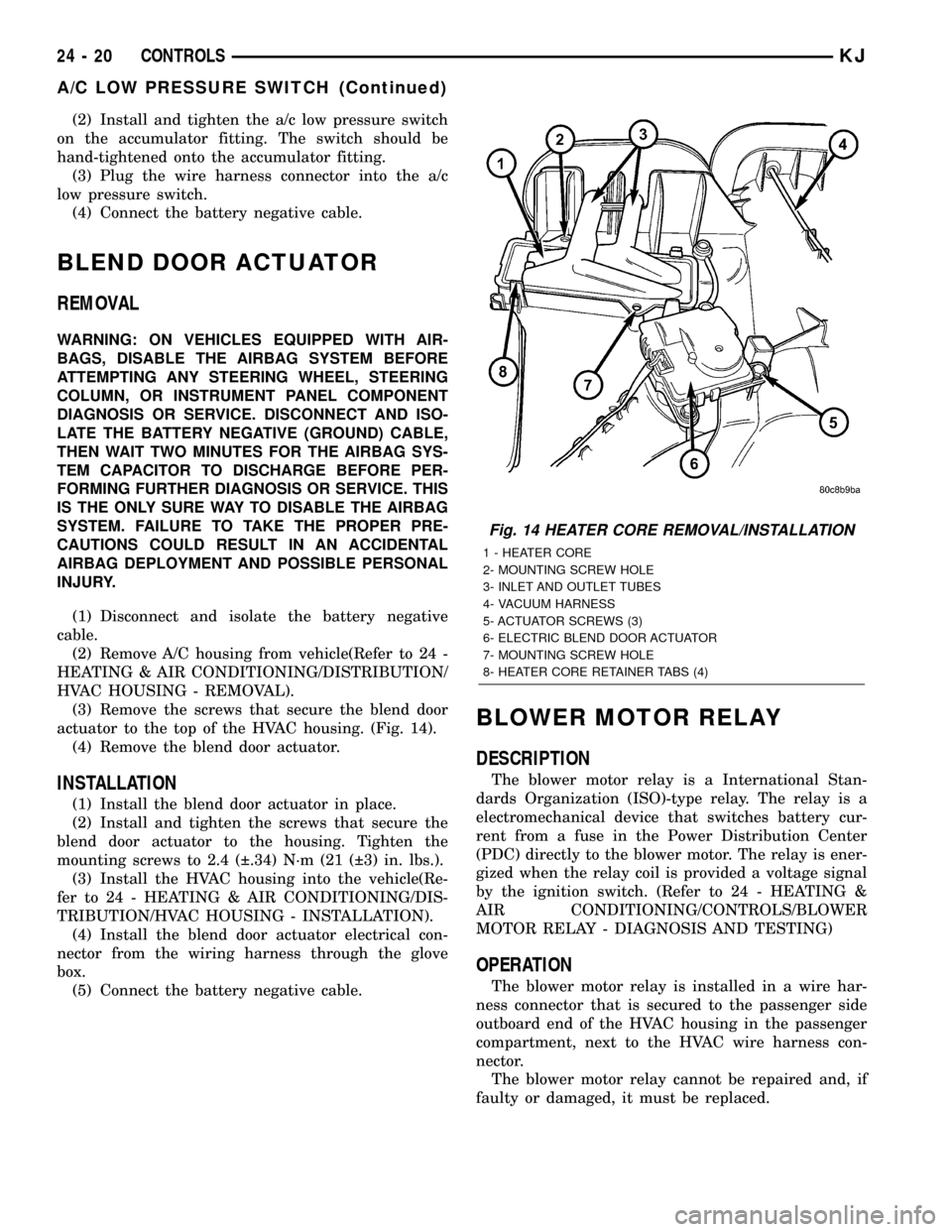

(3) Remove the screws that secure the blend door

actuator to the top of the HVAC housing. (Fig. 14).

(4) Remove the blend door actuator.

INSTALLATION

(1) Install the blend door actuator in place.

(2) Install and tighten the screws that secure the

blend door actuator to the housing. Tighten the

mounting screws to 2.4 ( .34) N´m (21 ( 3) in. lbs.).

(3) Install the HVAC housing into the vehicle(Re-

fer to 24 - HEATING & AIR CONDITIONING/DIS-

TRIBUTION/HVAC HOUSING - INSTALLATION).

(4) Install the blend door actuator electrical con-

nector from the wiring harness through the glove

box.

(5) Connect the battery negative cable.

BLOWER MOTOR RELAY

DESCRIPTION

The blower motor relay is a International Stan-

dards Organization (ISO)-type relay. The relay is a

electromechanical device that switches battery cur-

rent from a fuse in the Power Distribution Center

(PDC) directly to the blower motor. The relay is ener-

gized when the relay coil is provided a voltage signal

by the ignition switch. (Refer to 24 - HEATING &

AIR CONDITIONING/CONTROLS/BLOWER

MOTOR RELAY - DIAGNOSIS AND TESTING)

OPERATION

The blower motor relay is installed in a wire har-

ness connector that is secured to the passenger side

outboard end of the HVAC housing in the passenger

compartment, next to the HVAC wire harness con-

nector.

The blower motor relay cannot be repaired and, if

faulty or damaged, it must be replaced.

Fig. 14 HEATER CORE REMOVAL/INSTALLATION

1 - HEATER CORE

2- MOUNTING SCREW HOLE

3- INLET AND OUTLET TUBES

4- VACUUM HARNESS

5- ACTUATOR SCREWS (3)

6- ELECTRIC BLEND DOOR ACTUATOR

7- MOUNTING SCREW HOLE

8- HEATER CORE RETAINER TABS (4)

24 - 20 CONTROLSKJ

A/C LOW PRESSURE SWITCH (Continued)

Page 1673 of 1803

DIAGNOSIS AND TESTING - BLOWER MOTOR

RELAY

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

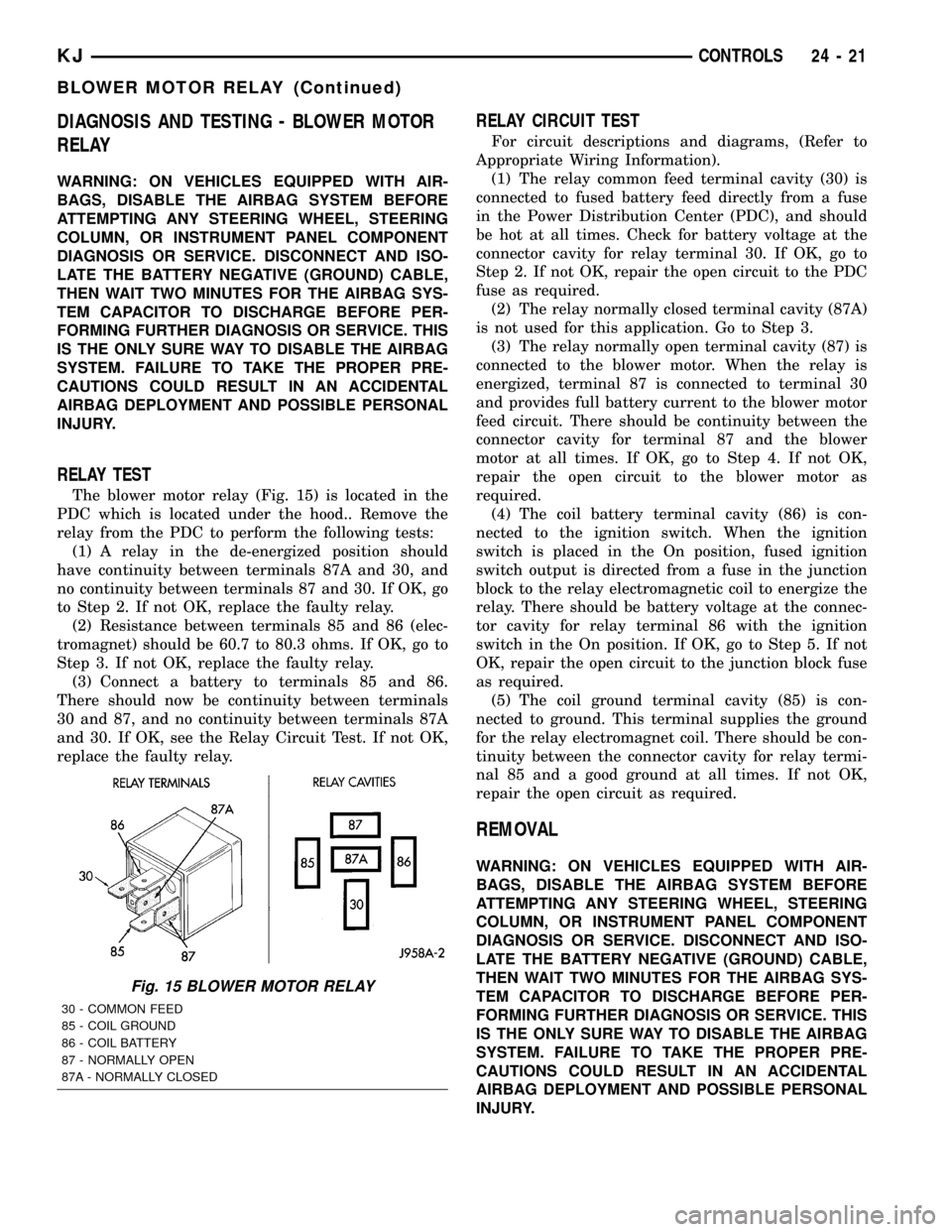

RELAY TEST

The blower motor relay (Fig. 15) is located in the

PDC which is located under the hood.. Remove the

relay from the PDC to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 60.7 to 80.3 ohms. If OK, go to

Step 3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see the Relay Circuit Test. If not OK,

replace the faulty relay.

RELAY CIRCUIT TEST

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed directly from a fuse

in the Power Distribution Center (PDC), and should

be hot at all times. Check for battery voltage at the

connector cavity for relay terminal 30. If OK, go to

Step 2. If not OK, repair the open circuit to the PDC

fuse as required.

(2) The relay normally closed terminal cavity (87A)

is not used for this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the blower motor. When the relay is

energized, terminal 87 is connected to terminal 30

and provides full battery current to the blower motor

feed circuit. There should be continuity between the

connector cavity for terminal 87 and the blower

motor at all times. If OK, go to Step 4. If not OK,

repair the open circuit to the blower motor as

required.

(4) The coil battery terminal cavity (86) is con-

nected to the ignition switch. When the ignition

switch is placed in the On position, fused ignition

switch output is directed from a fuse in the junction

block to the relay electromagnetic coil to energize the

relay. There should be battery voltage at the connec-

tor cavity for relay terminal 86 with the ignition

switch in the On position. If OK, go to Step 5. If not

OK, repair the open circuit to the junction block fuse

as required.

(5) The coil ground terminal cavity (85) is con-

nected to ground. This terminal supplies the ground

for the relay electromagnet coil. There should be con-

tinuity between the connector cavity for relay termi-

nal 85 and a good ground at all times. If not OK,

repair the open circuit as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Fig. 15 BLOWER MOTOR RELAY

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJCONTROLS 24 - 21

BLOWER MOTOR RELAY (Continued)

Page 1675 of 1803

BLOWER MOTOR SWITCH

DESCRIPTION

The heater-only or A/C Heater blower motor is con-

trolled by a four position rotary-type blower motor

switch, mounted in the A/C Heater control panel. The

switch allows the selection of one of four blower

motor speeds, but can only be turned off by selecting

the Off position with the heater-only or A/C Heater

mode control switch knob.

OPERATION

The blower motor switch directs the blower motor

ground path through the mode control switch to the

blower motor resistor, or directly to ground, as

required to achieve the selected blower motor speed.

The blower motor switch cannot be repaired and, if

faulty or damaged, the entire heater-only or A/C

Heater control unit must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

SWITCH

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check for battery voltage at the fuse in the

Power Distribution Center (PDC). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the A/C Heater control from the instrument

panel. Check for continuity between the ground cir-

cuit cavity of the A/C Heater control wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 3. If not OK, repair the open

circuit to ground as required.

(3) With the A/C Heater control wire harness con-

nector unplugged, place the A/C Heater mode control

switch knob in any position except the Off position.

Check for continuity between the ground circuit ter-minal and each of the blower motor driver circuit ter-

minals of the A/C Heater control as you move the

blower motor switch knob to each of the four speed

positions. There should be continuity at each driver

circuit terminal in only one blower motor switch

speed position. If OK, test and repair the blower

driver circuits between the A/C Heater control con-

nector and the blower motor resistor as required. If

not OK, replace the faulty A/C Heater control unit.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The blower motor switch cannot be repaired and, if

faulty or damaged, the entire heater-only or A/C

Heater control unit must be replaced. (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - REMOVAL)

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) The blower motor switch cannot be repaired

and, if faulty or damaged the entire heater-only or

A/C heater control unit must be replaced(Refer to 24

- HEATING & AIR CONDITIONING/CONTROLS/

A/C HEATER CONTROL - INSTALLATION).

KJCONTROLS 24 - 23

Page 1682 of 1803

BLOWER MOTOR

DESCRIPTION

The blower motor and blower wheel are located in

the passenger side end of the HVAC housing, below

the glove box. The blower motor controls the velocity

of air flowing through the HVAC housing by spinning

a squirrel cage-type blower wheel within the housing

at the selected speed. The blower motor and wheel

can be removed from the housing inside the vehicle

without removing the dash or HVAC housing assem-

bly.

OPERATION

The blower motor will only operate when the igni-

tion switch is in the On position, and the A/C Heater

mode control switch knob is in any position, except

Off. The blower motor receives a fused battery feed

through the blower motor relay whenever the igni-

tion switch is in the On position. The blower motor

battery feed circuit is protected by a fuse in the

Power Distribution Center (PDC). Blower motor

speed is controlled by regulating the ground path

through the A/C Heater control blower motor switch

and the blower motor resistor.

The blower motor and blower motor wheel cannot

be repaired and, if faulty or damaged, they must be

replaced. The blower motor and blower wheel are ser-

viced only as a unit.

DIAGNOSIS AND TESTING - BLOWER MOTOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information). Possible causes of

an inoperative blower motor include:²Faulty fuse

²Faulty blower motor circuit wiring or wire har-

ness connectors

²Faulty blower motor resistor

²Faulty blower motor relay

²Faulty blower motor switch

²Faulty A/C Heater mode control switch

²Faulty blower motor.

Possible causes of the blower motor not operating

in all speeds include:

²Faulty blower motor switch

²Faulty blower motor resistor

²Faulty blower motor circuit wiring or wire har-

ness connectors.

VIBRATION

Possible causes of blower motor vibration include:

²Improper blower motor mounting

²Improper blower wheel mounting

²Blower wheel out of balance or bent

²Blower motor faulty.

NOISE

To verify that the blower is the source of the noise,

unplug the blower motor wire harness connector and

operate the HVAC system. If the noise goes away,

possible causes include:

²Foreign material in the HVAC housing

²Improper blower motor mounting

²Improper blower wheel mounting

²Blower motor faulty.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

24 - 30 DISTRIBUTIONKJ

Page 1750 of 1803

FUEL PRESSURE REGULATOR -

DESCRIPTION.......................14-13

FUEL PRESSURE REGULATOR -

INSTALLATION.......................14-14

FUEL PRESSURE REGULATOR -

OPERATION.........................14-14

FUEL PRESSURE REGULATOR -

REMOVAL..........................14-14

FUEL PUMP - DESCRIPTION............14-15

FUEL PUMP - OPERATION.............14-15

FUEL PUMP AMPERAGE TEST -

DIAGNOSIS AND TESTING.............14-16

FUEL PUMP CAPACITY TEST -

DIAGNOSIS AND TESTING.............14-15

FUEL PUMP MODULE - DESCRIPTION....14-18

FUEL PUMP MODULE - INSTALLATION . . . 14-19

FUEL PUMP MODULE - OPERATION......14-18

FUEL PUMP MODULE - REMOVAL.......14-18

FUEL PUMP PRESSURE TEST -

DIAGNOSIS AND TESTING.............14-15

FUEL PUMP RELAY - DESCRIPTION......14-34

FUEL PUMP RELAY - DIAGNOSIS AND

TESTING...........................14-34

FUEL PUMP RELAY - INSTALLATION.....14-34

FUEL PUMP RELAY - OPERATION........14-34

FUEL PUMP RELAY - REMOVAL.........14-34

FUEL PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD........................8I-4

FUEL RAIL - DESCRIPTION.............14-21

FUEL RAIL - INSTALLATION..............14-24

FUEL RAIL - OPERATION...............14-21

FUEL RAIL - REMOVAL................14-22

FUEL SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE................14-4

FUEL SYSTEM PRESSURE,

SPECIFICATIONS......................14-5

FUEL SYSTEM, SPECIAL TOOLS..........14-6

FUEL TANK - DESCRIPTION............14-24

FUEL TANK - INSTALLATION............14-27

FUEL TANK - OPERATION..............14-24

FUEL TANK - REMOVAL...............14-25

FUEL TANK CHECK VALVE -

DESCRIPTION.......................14-28

FUEL TANK CHECK VALVE -

INSTALLATION.......................14-28

FUEL TANK CHECK VALVE - OPERATION . . 14-28

FUEL TANK CHECK VALVE - REMOVAL....14-28

FUEL TANK SKID PLATE - INSTALLATION . . . 13-9

FUEL TANK SKID PLATE - REMOVAL......13-9

FULL TIME INDICATOR - DESCRIPTION . . . 8J-29

FULL TIME INDICATOR - OPERATION.....8J-30

FUNCTION - DIAGNOSIS AND TESTING,

REAR HVAC CONTROL ASSEMBLY

WINDOW DEFOGGER..................8G-9

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD...........8W-97-3

FUSE - INSTALLATION, IOD..........8W-97-3

FUSE - OPERATION, IOD.............8W-97-3

FUSE - REMOVAL, IOD..............8W-97-3

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON.......8W-01-9

GALLERY PLUGS - STANDARD

PROCEDURE, ENGINE CORE AND OIL.....9-10

GAP AND FLUSH - SPECIFICATIONS.....23-116

GAS ENGINES - GENERATOR RATINGS....8F-23

GAS POWERED - STARTER MOTOR......8F-39

GAS POWERED - TORQUE

.............8F-38

GASKET - DIAGNOSIS AND TESTING,

CYLINDER HEAD

..................9-19,9-30

GASKET SURFACE PREPARATION -

STANDARD PROCEDURE, ENGINE

.........9-9

GATE - INSTALLATION, SWING

.........23-138

GATE - REMOVAL, SWING

............23-138

GATE AJAR INDICATOR - DESCRIPTION

. . . 8J-20

GATE AJAR INDICATOR - OPERATION

.....8J-20

GATE BELTLINE WEATHERSTRIP -

INSTALLATION, SWING

...............23-186

GATE BELTLINE WEATHERSTRIP -

REMOVAL, SWING

...................23-186

GATE OPENING WEATHERSTRIP -

INSTALLATION, SWING

...............23-186

GATE OPENING WEATHERSTRIP -

REMOVAL, SWING

...................23-186

GAUGE - DESCRIPTION, ENGINE

TEMPERATURE

......................8J-18

GAUGE - DESCRIPTION, FUEL

...........8J-19GAUGE - OPERATION, ENGINE

TEMPERATURE......................8J-18

GAUGE - OPERATION, FUEL............8J-20

GEAR - DESCRIPTION.................19-13

GEAR - INSTALLATION, PINION

GEAR/RING..........................3-46

GEAR - OPERATION...................19-13

GEAR - REMOVAL, PINION GEAR/RING....3-44

GEAR/RING GEAR - INSTALLATION,

PINION.............................3-46

GEAR/RING GEAR - REMOVAL, PINION....3-44

GEAR/RING GEAR/TONE RING -

INSTALLATION, PINION............3-112,3-82

GEAR/RING GEAR/TONE RING -

REMOVAL, PINION...............3-110,3-79

GEARSHIFT CABLE - ADJUSTMENTS....21-130

GEARSHIFT CABLE - DIAGNOSIS AND

TESTING..........................21-128

GEARSHIFT CABLE - INSTALLATION.....21-129

GEARSHIFT CABLE - REMOVAL........21-128

GEAR/TONE RING - INSTALLATION,

PINION GEAR/RING...............3-112,3-82

GEAR/TONE RING - REMOVAL, PINION

GEAR/RING.....................3-110,3-79

GEARTRAIN - ASSEMBLY, PLANETARY . . . 21-160

GEARTRAIN - CLEANING, PLANETARY . . . 21-159

GEARTRAIN - DESCRIPTION,

PLANETARY........................21-157

GEARTRAIN - DISASSEMBLY,

PLANETARY........................21-159

GEARTRAIN - INSPECTION, PLANETARY . 21-159

GEARTRAIN - OPERATION, PLANETARY . . 21-157

GENERAL - WARNINGS.............8W-01-7

GENERATOR - DESCRIPTION...........8F-25

GENERATOR - INSTALLATION...........8F-26

GENERATOR - OPERATION.............8F-25

GENERATOR - REMOVAL...............8F-25

GENERATOR DECOUPLER - DIAGNOSIS

AND TESTING.......................8F-27

GENERATOR DECOUPLER PULLEY -

DESCRIPTION.......................8F-26

GENERATOR DECOUPLER PULLEY -

INSTALLATION.......................8F-30

GENERATOR DECOUPLER PULLEY -

OPERATION.........................8F-27

GENERATOR DECOUPLER PULLEY -

REMOVAL..........................8F-27

GENERATOR RATINGS, GAS ENGINES....8F-23

GLASS - INSTALLATION, DOOR . . 23-122,23-129,

23-172

GLASS - INSTALLATION, FLIP-UP.......23-136

GLASS - REMOVAL, DOOR......23-122,23-129,

23-172

GLASS - REMOVAL, FLIP-UP..........23-136

GLASS AJAR INDICATOR - DESCRIPTION . . 8J-21

GLASS AJAR INDICATOR - OPERATION . . . 8J-21

GLASS AJAR SWITCH - DESCRIPTION,

FLIP-UP............................8L-77

GLASS AJAR SWITCH - OPERATION,

FLIP-UP............................8L-77

GLASS HEATING GRID REPAIR -

STANDARD PROCEDURE, REAR..........8G-4

GLASS LATCH - INSTALLATION, FLIP-UP . 23-136

GLASS LATCH - REMOVAL, FLIP-UP.....23-136

GLASS PANEL - INSTALLATION........23-178

GLASS PANEL - REMOVAL............23-178

GLASS PANEL ADJUSTMENT,

ADJUSTMENTS - SUNROOF...........23-178

GLASS PANEL SEAL - INSTALLATION

....23-178

GLASS PANEL SEAL - REMOVAL

.......23-178

GLASS RELEASE SWITCH - DIAGNOSIS

AND TESTING, FLIP-UP

................8N-5

GLASS RUN CHANNEL - INSTALLATION

. 23-123,

23-130

GLASS RUN CHANNEL - REMOVAL

.....23-123,

23-130

GLASS SUPPORT CYLINDER -

INSTALLATION, FLIP-UP

..............23-139

GLASS SUPPORT CYLINDER -

REMOVAL, FLIP-UP

..................23-139

GLOVE BOX - INSTALLATION

..........23-148

GLOVE BOX - REMOVAL

..............23-148

GLOVE BOX LATCH - INSTALLATION

....23-148

GLOVE BOX LATCH - REMOVAL

........23-148

GLOVE BOX LATCH STRIKER -

INSTALLATION

......................23-149

GLOVE BOX LATCH STRIKER - REMOVAL

. 23-148GRAB HANDLE - INSTALLATION,

A-PILLAR TRIM.....................23-156

GRAB HANDLE - REMOVAL, A-PILLAR

TRIM.............................23-156

GRID - DESCRIPTION, REAR WINDOW

DEFOGGER..........................8G-5

GRID - DIAGNOSIS AND TESTING, REAR

WINDOW DEFOGGER..................8G-5

GRID - OPERATION, REAR WINDOW

DEFOGGER..........................8G-5

GRID REPAIR - STANDARD PROCEDURE,

REAR GLASS HEATING.................8G-4

GRILLE - INSTALLATION..............23-142

GRILLE - INSTALLATION, COWL........23-140

GRILLE - REMOVAL..................23-142

GRILLE - REMOVAL, COWL...........23-140

GRILLE OPENING REINFORCEMENT -

INSTALLATION......................23-142

GRILLE OPENING REINFORCEMENT -

REMOVAL.........................23-142

GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT TO..........8W-01-9

GROUND AND SPLICE INFORMATION -

DESCRIPTION, CONNECTOR..........8W-01-7

GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO..............................8W-01-9

GROUND STRAP - DESCRIPTION, RADIO

NOISE SUPPRESSION..................8A-9

GROUND STRAP - INSTALLATION,

RADIO NOISE SUPPRESSION...........8A-11

GROUND STRAP - OPERATION, RADIO

NOISE SUPPRESSION.................8A-10

GROUND STRAP - REMOVAL, RADIO

NOISE SUPPRESSION.................8A-10

GROUNDS - DESCRIPTION, POWER......8E-13

GUARD - DESCRIPTION, THERMAL......8F-20

GUARD - INSTALLATION, THERMAL......8F-20

GUARD - OPERATION, THERMAL........8F-20

GUARD - REMOVAL, THERMAL..........8F-20

GUIDE ASSEMBLY - INSTALLATION.....23-179

GUIDE ASSEMBLY - REMOVAL.........23-179

GUIDE SEALS - DESCRIPTION, VALVE . 9-29,9-38

GUIDES - DESCRIPTION, VALVE......9-19,9-30

HALF SHAFT - CAUTION................3-10

HALF SHAFT - DIAGNOSIS AND TESTING . . 3-10

HALF SHAFT - INSTALLATION............3-11

HALF SHAFT - REMOVAL...............3-10

HALF SHAFT, SPECIFICATIONS...........3-11

HANDLE - INSTALLATION, A-PILLAR

TRIM AND GRAB....................23-156

HANDLE - INSTALLATION, ASSIST......23-157

HANDLE - INSTALLATION, EXTERIOR . . . 23-123,

23-130,23-136

HANDLE - INSTALLATION, LATCH

RELEASE..........................23-120

HANDLE - REMOVAL, A-PILLAR TRIM

AND GRAB.........................23-156

HANDLE - REMOVAL, ASSIST..........23-157

HANDLE - REMOVAL, EXTERIOR . 23-123,23-130,

23-136

HANDLE - REMOVAL, LATCH RELEASE . . 23-120

HANDLING NON-DEPLOYED

SUPPLEMENTAL RESTRAINTS -

STANDARD PROCEDURE...............8O-6

HARNESS - DIAGNOSIS AND TESTING,

WIRING

..........................8W-01-7

HAZARD SWITCH - DESCRIPTION

.......8L-29

HAZARD SWITCH - INSTALLATION

.......8L-30

HAZARD SWITCH - OPERATION

.........8L-29

HAZARD SWITCH - REMOVAL

..........8L-30

HCU (HYDRAULIC CONTROL UNIT) -

DESCRIPTION

........................5-35

HCU (HYDRAULIC CONTROL UNIT) -

INSTALLATION

........................5-36

HCU (HYDRAULIC CONTROL UNIT) -

OPERATION

..........................5-35

HCU (HYDRAULIC CONTROL UNIT) -

REMOVAL

...........................5-36

HEAD - DESCRIPTION, CYLINDER

........9-30

HEAD COVER(S) - DESCRIPTION,

CYLINDER

...........................9-25

HEAD COVER(S) - INSTALLATION,

CYLINDER

.......................9-26,9-34

HEAD COVER(S) - REMOVAL, CYLINDER

. . 9-25,

9-34

KJINDEX 11

Description Group-Page Description Group-Page Description Group-Page

Page 1753 of 1803

INTAKE MANIFOLD LEAKS - DIAGNOSIS

AND TESTING........................9-68

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION........................9-26

INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION....................9-28,9-36

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL.......................9-27,9-35

INTERIOR - DESCRIPTION, LAMPS/

LIGHTING..........................8L-65

INTERIOR - DIAGNOSIS AND TESTING,

LAMPS/LIGHTING....................8L-68

INTERIOR - OPERATION, LAMPS/

LIGHTING..........................8L-67

INTERIOR - SPECIFICATIONS,

LAMPS/LIGHTING....................8L-71

INTERLOCK CABLE - INSTALLATION,

PARK .............................21-153

INTERLOCK CABLE - REMOVAL, PARK . . . 21-153

INTERLOCK SYSTEM - DESCRIPTION,

BRAKE TRANSMISSION SHIFT.........21-124

INTERLOCK SYSTEM - DIAGNOSIS AND

TESTING, BRAKE TRANSMISSION

SHIFT.............................21-125

INTERLOCK SYSTEM - OPERATION,

BRAKE TRANSMISSION SHIFT.........21-125

INTERMEDIATE SHAFT - INSTALLATION . . . 19-11

INTERMEDIATE SHAFT - REMOVAL......19-11

INTERNATIONAL SYMBOLS -

DESCRIPTION......................Intro.-4

INTERNATIONAL SYMBOLS -

DESCRIPTION.........................0-1

INTRODUCTION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS............9-4

INTRUSION TRANSCEIVER MODULE -

DESCRIPTION.......................8Q-14

INTRUSION TRANSCEIVER MODULE -

INSTALLATION......................8Q-16

INTRUSION TRANSCEIVER MODULE -

OPERATION.........................8Q-15

INTRUSION TRANSCEIVER MODULE -

REMOVAL..........................8Q-15

INVERTED FLARING - STANDARD

PROCEDURE, DOUBLE..................5-8

IOD FUSE - DESCRIPTION...........8W-97-3

IOD FUSE - INSTALLATION...........8W-97-3

IOD FUSE - OPERATION.............8W-97-3

IOD FUSE - REMOVAL..............8W-97-3

ISO FLARING - STANDARD PROCEDURE....5-8

JOINT - DESCRIPTION, UPPER

SUSPENSION ARM, BUSHINGS, AND

BALL...............................2-20

JOINT - DIAGNOSIS AND TESTING,

LOWER BALL........................2-10

JOINT - INSTALLATION, UPPER BALL.....2-20

JOINT - OPERATION, UPPER

SUSPENSION ARM, BUSHINGS, AND

BALL...............................2-20

JOINT - REMOVAL, UPPER BALL.........2-20

JOINT/BOOT-INNER - INSTALLATION, CV . . . 3-17

JOINT/BOOT-INNER - REMOVAL, CV.......3-15

JOINT/BOOT-OUTER - INSTALLATION, CV . . . 3-13

JOINT/BOOT-OUTER - REMOVAL, CV......3-12

JOINTS - ASSEMBLY, SINGLE CARDAN

UNIVERSAL...........................3-9

JOINTS - DISASSEMBLY, SINGLE

CARDAN UNIVERSAL...................3-8

JOUNCE BUMPER - INSTALLATION.......2-19

JOUNCE BUMPER - REMOVAL...........2-19

JUMP STARTING PROCEDURE -

STANDARD PROCEDURE

.................0-5

JUNCTION BLOCK - DESCRIPTION

.....8W-97-4

JUNCTION BLOCK - DESCRIPTION

........5-20

JUNCTION BLOCK - DIAGNOSIS AND

TESTING

.........................8W-97-4

JUNCTION BLOCK - INSTALLATION

.......5-20

JUNCTION BLOCK - OPERATION

......8W-97-4

JUNCTION BLOCK - OPERATION

..........5-20

JUNCTION BLOCK - REMOVAL

...........5-20

KEY - DESCRIPTION, TRANSPONDER

....8Q-18

KEY - OPERATION, TRANSPONDER

......8Q-18

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY

................8E-15

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY

...............8E-18

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY

.................8E-16KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY............................8E-17

KEY TRANSPONDER PROGRAMMING -

STANDARD PROCEDURE, SENTRY........8Q-8

KEY-IN IGNITION SWITCH -

DESCRIPTION.......................19-10

KEY-IN IGNITION SWITCH - DIAGNOSIS

AND TESTING.......................19-10

KEYLESS ENTRY MODULE -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY MODULE - DIAGNOSIS

AND TESTING, REMOTE................8N-7

KEYLESS ENTRY MODULE -

INSTALLATION, REMOTE...............8N-7

KEYLESS ENTRY MODULE - OPERATION,

REMOTE............................8N-7

KEYLESS ENTRY MODULE - REMOVAL,

REMOTE............................8N-7

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-8

KEYLESS ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE..............8N-9

KNEE BLOCKER - INSTALLATION.......23-155

KNEE BLOCKER - REMOVAL...........23-155

KNOCK SENSOR - DESCRIPTION.........8I-11

KNOCK SENSOR - INSTALLATION........8I-12

KNOCK SENSOR - OPERATION..........8I-11

KNOCK SENSOR - REMOVAL............8I-12

KNUCKLE - INSTALLATION...............2-9

KNUCKLE - REMOVAL...................2-9

LABEL - DESCRIPTION, VEHICLE

EMISSION CONTROL INFORMATION

(VECI)............................Intro.-8

LABEL - DESCRIPTION, VEHICLE SAFETY

CERTIFICATION.....................Intro.-9

LACE - INSTALLATION, OPENING TRIM . . 23-180

LACE - REMOVAL, OPENING TRIM......23-180

LAMP BULB - INSTALLATION, ASH

RECEIVER..........................8L-71

LAMP BULB - INSTALLATION, CARGO....8L-73

LAMP BULB - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-19

LAMP BULB - INSTALLATION,

COURTESY.........................8L-76

LAMP BULB - INSTALLATION, FRONT....8L-27

LAMP BULB - INSTALLATION, FRONT

FOG ...............................8L-22

LAMP BULB - INSTALLATION, FRONT

POSITION..........................8L-28

LAMP BULB - INSTALLATION, LICENSE

PLATE .............................8L-45

LAMP BULB - INSTALLATION, READING . . . 8L-79

LAMP BULB - INSTALLATION, REAR.....8L-59

LAMP BULB - INSTALLATION, REPEATER . . 8L-60

LAMP BULB - INSTALLATION, VANITY....8L-84

LAMP BULB - REMOVAL, ASH RECEIVER . . 8L-71

LAMP BULB - REMOVAL, CARGO........8L-72

LAMP BULB - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-18

LAMP BULB - REMOVAL, COURTESY.....8L-75

LAMP BULB - REMOVAL, FRONT........8L-26

LAMP BULB - REMOVAL, FRONT FOG....8L-21

LAMP BULB - REMOVAL, FRONT

POSITION..........................8L-28

LAMP BULB - REMOVAL, LICENSE

PLATE .............................8L-44

LAMP BULB - REMOVAL, READING......8L-79

LAMP BULB - REMOVAL, REAR.........8L-58

LAMP BULB - REMOVAL, REPEATER.....8L-60

LAMP BULB - REMOVAL, VANITY........8L-83

LAMP INDICATOR - DESCRIPTION,

FRONT FOG.........................8J-19

LAMP INDICATOR - DESCRIPTION, REAR

FOG ...............................8J-27

LAMP INDICATOR - OPERATION, FRONT

FOG ...............................8J-19

LAMP INDICATOR - OPERATION, REAR

FOG ...............................8J-27

LAMP (MIL) - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-24

LAMP (MIL) - OPERATION,

MALFUNCTION INDICATOR

.............8J-24

LAMP RELAY - DESCRIPTION, DAYTIME

RUNNING

...........................8L-20

LAMP RELAY - DESCRIPTION, FRONT

FOG

...............................8L-22

LAMP RELAY - DESCRIPTION, PARK

.....8L-54

LAMP RELAY - DESCRIPTION, REAR FOG

. 8L-56LAMP RELAY - DIAGNOSIS AND

TESTING, FRONT FOG.................8L-23

LAMP RELAY - DIAGNOSIS AND

TESTING, PARK......................8L-55

LAMP RELAY - DIAGNOSIS AND

TESTING, REAR FOG..................8L-57

LAMP RELAY - INSTALLATION, DAYTIME

RUNNING...........................8L-21

LAMP RELAY - INSTALLATION, FRONT

FOG ...............................8L-24

LAMP RELAY - INSTALLATION, PARK.....8L-56

LAMP RELAY - INSTALLATION, REAR

FOG ...............................8L-58

LAMP RELAY - OPERATION, DAYTIME

RUNNING...........................8L-20

LAMP RELAY - OPERATION, FRONT FOG . . 8L-22

LAMP RELAY - OPERATION, PARK.......8L-54

LAMP RELAY - OPERATION, REAR FOG . . . 8L-57

LAMP RELAY - REMOVAL, DAYTIME

RUNNING...........................8L-21

LAMP RELAY - REMOVAL, FRONT FOG . . . 8L-24

LAMP RELAY - REMOVAL, PARK........8L-55

LAMP RELAY - REMOVAL, REAR FOG....8L-58

LAMP REPLACEMENT - STANDARD

PROCEDURE, CMTC...................8M-2

LAMP REPLACEMENT - STANDARD

PROCEDURE, COURTESY...............8M-2

LAMP SWITCH - DESCRIPTION, BACKUP . . 8L-15

LAMP SWITCH - DESCRIPTION, BRAKE . . . 8L-16

LAMP SWITCH - DIAGNOSIS AND

TESTING, BACKUP.....................8L-15

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE.....................8L-17

LAMP SWITCH - INSTALLATION, BRAKE . . 8L-18

LAMP SWITCH - INSTALLATION, CARGO . . 8L-74

LAMP SWITCH - INSTALLATION,

READING...........................8L-80

LAMP SWITCH - OPERATION, BACKUP . . . 8L-15

LAMP SWITCH - OPERATION, BRAKE.....8L-16

LAMP SWITCH - REMOVAL, BRAKE......8L-17

LAMP SWITCH - REMOVAL, CARGO......8L-73

LAMP SWITCH - REMOVAL, READING....8L-80

LAMP UNIT - ADJUSTMENT, FRONT FOG . . 8L-25

LAMP UNIT - INSTALLATION, ASH

RECEIVER..........................8L-72

LAMP UNIT - INSTALLATION, CARGO.....8L-74

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-19

LAMP UNIT - INSTALLATION, COURTESY . . 8L-77

LAMP UNIT - INSTALLATION, FRONT.....8L-28

LAMP UNIT - INSTALLATION, FRONT

FOG ...............................8L-25

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-46

LAMP UNIT - INSTALLATION, READING . . . 8L-81

LAMP UNIT - INSTALLATION, REAR......8L-60

LAMP UNIT - INSTALLATION, REPEATER . . 8L-61

LAMP UNIT - REMOVAL, ASH RECEIVER . . 8L-72

LAMP UNIT - REMOVAL, CARGO........8L-74

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-19

LAMP UNIT - REMOVAL, COURTESY.....8L-76

LAMP UNIT - REMOVAL, FRONT.........8L-27

LAMP UNIT - REMOVAL, FRONT FOG.....8L-25

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-45

LAMP UNIT - REMOVAL, READING.......8L-81

LAMP UNIT - REMOVAL, REAR..........8L-59

LAMP UNIT - REMOVAL, REPEATER......8L-60

LAMPS/LIGHTING - EXTERIOR -

DESCRIPTION........................8L-2

LAMPS/LIGHTING - EXTERIOR -

DIAGNOSIS AND TESTING..............8L-7

LAMPS/LIGHTING - EXTERIOR -

OPERATION..........................8L-5

LAMPS/LIGHTING - EXTERIOR -

SPECIFICATIONS.....................8L-15

LAMPS/LIGHTING - INTERIOR -

DESCRIPTION.......................8L-65

LAMPS/LIGHTING - INTERIOR -

DIAGNOSIS AND TESTING.............8L-68

LAMPS/LIGHTING - INTERIOR -

OPERATION

.........................8L-67

LAMPS/LIGHTING - INTERIOR -

SPECIFICATIONS

.....................8L-71

LASH ADJUSTER - DIAGNOSIS AND

TESTING, HYDRAULIC

..............9-19,9-30

LATCH - ACCESS PANEL - DESCRIPTION

. 23-139

LATCH - ACCESS PANEL - INSTALLATION

. 23-139

14 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1754 of 1803

LATCH - ACCESS PANEL - REMOVAL....23-139

LATCH - INSTALLATION . . 23-120,23-124,23-131,

23-137

LATCH - INSTALLATION, FLIP-UP GLASS . 23-136

LATCH - INSTALLATION, FLOOR

CONSOLE LID......................23-158

LATCH - INSTALLATION, GLOVE BOX....23-148

LATCH / LOCK - INSTALLATION,

FOLDING REAR SEAT BACK...........23-170

LATCH / LOCK - REMOVAL, FOLDING

REAR SEAT BACK...................23-170

LATCH - REMOVAL......23-120,23-124,23-131,

23-137

LATCH - REMOVAL, FLIP-UP GLASS.....23-136

LATCH - REMOVAL, FLOOR CONSOLE

LID...............................23-158

LATCH - REMOVAL, GLOVE BOX........23-148

LATCH RELEASE CABLE - INSTALLATION . 23-120

LATCH RELEASE CABLE - REMOVAL....23-120

LATCH RELEASE HANDLE -

INSTALLATION......................23-120

LATCH RELEASE HANDLE - REMOVAL . . . 23-120

LATCH STRIKER - INSTALLATION......23-124,

23-132,23-137

LATCH STRIKER - INSTALLATION, GLOVE

BOX ..............................23-149

LATCH STRIKER - INSTALLATION, REAR

SEAT BACK........................23-171

LATCH STRIKER - REMOVAL....23-124,23-132,

23-137

LATCH STRIKER - REMOVAL, GLOVE

BOX ..............................23-148

LATCH STRIKER - REMOVAL, REAR

SEAT BACK........................23-170

LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING FLUID...........21-80

LEAK - DIAGNOSIS AND TESTING,

ENGINE OIL..........................9-60

LEAK DETECTION PUMP - DESCRIPTION . . 25-27

LEAK DETECTION PUMP - INSTALLATION . 25-28

LEAK DETECTION PUMP - OPERATION....25-28

LEAK DETECTION PUMP - REMOVAL.....25-28

LEAK DOWN TEST - DIAGNOSIS AND

TESTING, FUEL PRESSURE..............14-3

LEAKAGE - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE.......9-8

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM.....................7-4

LEAKS - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD....................9-68

LEAKS - DIAGNOSIS AND TESTING,

REAR SEAL AREA.....................9-61

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-2

LEAKS - STANDARD PROCEDURE,

REPAIRING..........................22-8

LEARN - STANDARD PROCEDURE, TCM

QUICK.............................8E-21

LEFT POWER SEAT SWITCH -

DESCRIPTION.......................8N-16

LEFT POWER SEAT SWITCH -

DIAGNOSIS AND TESTING.............8N-17

LEFT POWER SEAT SWITCH -

INSTALLATION......................8N-18

LEFT POWER SEAT SWITCH -

OPERATION

.........................8N-17

LEFT POWER SEAT SWITCH - REMOVAL

. . 8N-18

LEFT SIDE - INSTALLATION

.........2-12,2-15

LEFT SIDE - REMOVAL

.............2-11,2-15

LEVEL - DIAGNOSIS AND TESTING,

EFFECTS OF INCORRECT FLUID

........21-125

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL

...................24-54

LEVEL - STANDARD PROCEDURES,

MASTER CYLINDER FLUID

..............5-26

LEVEL CHECK - STANDARD

PROCEDURE, FLUID

.................21-126

LEVEL SENDING UNIT - DIAGNOSIS AND

TESTING, FUEL

.......................14-9

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL

...................14-9

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL

.................14-10

LEVEL SENDING UNIT / SENSOR -

OPERATION, FUEL

.....................14-9

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL

......................14-9LEVEL SWITCH - DESCRIPTION,

WASHER FLUID.....................8R-17

LEVEL SWITCH - INSTALLATION,

WASHER FLUID.....................8R-18

LEVEL SWITCH - OPERATION, WASHER

FLUID.............................8R-17

LEVEL SWITCH - REMOVAL, WASHER

FLUID.............................8R-17

LEVELING MOTOR - DESCRIPTION,

HEADLAMP.........................8L-35

LEVELING MOTOR - INSTALLATION,

HEADLAMP.........................8L-36

LEVELING MOTOR - OPERATION,

HEADLAMP.........................8L-36

LEVELING MOTOR - REMOVAL,

HEADLAMP.........................8L-36

LEVELING SWITCH - DESCRIPTION,

HEADLAMP.........................8L-37

LEVELING SWITCH - DIAGNOSIS AND

TESTING, HEADLAMP.................8L-37

LEVELING SWITCH - INSTALLATION,

HEADLAMP.........................8L-38

LEVELING SWITCH - OPERATION,

HEADLAMP.........................8L-37

LEVELING SWITCH - REMOVAL,

HEADLAMP.........................8L-38

LEVER - INSTALLATION................5-31

LEVER - INSTALLATION, SHIFT . . . 21-214,21-249

LEVER - REMOVAL....................5-31

LEVER - REMOVAL, SHIFT......21-213,21-248

LHD - INSTALLATION...............8W-97-6

LHD - REMOVAL....................8W-97-5

LICENSE PLATE LAMP BULB -

INSTALLATION.......................8L-45

LICENSE PLATE LAMP BULB - REMOVAL . . 8L-44

LICENSE PLATE LAMP UNIT -

INSTALLATION.......................8L-46

LICENSE PLATE LAMP UNIT - REMOVAL . . 8L-45

LID LATCH - INSTALLATION, FLOOR

CONSOLE..........................23-158

LID LATCH - REMOVAL, FLOOR

CONSOLE..........................23-158

LIGHTER OUTLET - DESCRIPTION,

CIGAR...........................8W-97-2

LIGHTER OUTLET - DIAGNOSIS AND

TESTING, CIGAR...................8W-97-2

LIGHTER OUTLET - OPERATION, CIGAR . 8W-97-2

LIMITS - DESCRIPTION, HIGH AND LOW . . 25-20

LINE - DESCRIPTION, REFRIGERANT.....24-38

LINE - INSTALLATION, A/C DISCHARGE . . . 24-47

LINE - INSTALLATION, A/C LIQUID.......24-47

LINE - INSTALLATION, A/C SUCTION.....24-49

LINE - REMOVAL, A/C DISCHARGE.......24-46

LINE - REMOVAL, A/C LIQUID...........24-47

LINE - REMOVAL, A/C SUCTION.........24-48

LINE AND HOSES - DIAGNOSIS AND

TESTING, BRAKE.......................5-8

LINE PRESSURE (LP) SENSOR -

DESCRIPTION......................21-144

LINE PRESSURE (LP) SENSOR -

INSTALLATION......................21-144

LINE PRESSURE (LP) SENSOR -

OPERATION........................21-144

LINE PRESSURE (LP) SENSOR -

REMOVAL.........................21-144

LINES - DESCRIPTION, BRAKE............5-8

LINES - DESCRIPTION, FUEL...........14-10

LINES - DESCRIPTION, VACUUM........25-33

LINK - INSTALLATION, STABILIZER.......2-14

LINK - REMOVAL, STABILIZER...........2-14

LINK CONNECTOR - DESCRIPTION, DATA . 8E-10

LINK CONNECTOR - OPERATION, DATA . . . 8E-10

LINKAGE - INSTALLATION................6-9

LINKAGE - REMOVAL...................6-8

LINKAGE - STANDARD PROCEDURE,

STEERING..........................19-16

LIQUID LINE - INSTALLATION, A/C.......24-47

LIQUID LINE - REMOVAL, A/C...........24-47

LOAD TEST - STANDARD PROCEDURE....8F-12

LOAD VALUE - DESCRIPTION

...........25-20

LOADS - STANDARD PROCEDURE,

TESTING FOR A SHORT TO GROUND

ON FUSES POWERING SEVERAL

......8W-01-9

LOCATION - DESCRIPTION, CONNECTOR/

GROUND/SPLICE

...................8W-91-1

LOCATIONS - DESCRIPTION, FLUID

FILL/CHECK

...........................0-4

LOCATIONS - SPECIFICATIONS, SEALER

. . 23-87LOCATIONS - SPECIFICATIONS, WELD

AND STRUCTURAL ADHESIVE...........23-9

LOCK - INSTALLATION, FOLDING REAR

SEAT BACK LATCH..................23-170

LOCK - REMOVAL, FOLDING REAR SEAT

BACK LATCH.......................23-170

LOCK / UNLOCK SWITCH -

INSTALLATION, DOOR.................8N-5

LOCK / UNLOCK SWITCH - REMOVAL,

DOOR..............................8N-4

LOCK CYLINDER - INSTALLATION......23-125,

23-138

LOCK CYLINDER - INSTALLATION.......19-11

LOCK CYLINDER - REMOVAL....23-125,23-137

LOCK CYLINDER - REMOVAL...........19-10

LOCK MOTOR - DESCRIPTION, DOOR.....8N-5

LOCK MOTOR - DIAGNOSIS AND

TESTING, DOOR......................8N-5

LOCK MOTOR - OPERATION, DOOR.......8N-5

LOCK OUT - ADJUSTMENT..............5-30

LOCK RELAY - DESCRIPTION, DOOR......8N-6

LOCK RELAY - DIAGNOSIS AND

TESTING, DOOR......................8N-6

LOCK RELAY - INSTALLATION, DOOR.....8N-7

LOCK RELAY - OPERATION, DOOR........8N-6

LOCK RELAY - REMOVAL, DOOR.........8N-6

LOCK SWITCH - DESCRIPTION, DOOR

CYLINDER...........................8Q-9

LOCK SWITCH - DESCRIPTION,

TAILGATE CYLINDER...................8N-9

LOCK SWITCH - DIAGNOSIS AND

TESTING, DOOR CYLINDER............8Q-10

LOCK SWITCH - DIAGNOSIS AND

TESTING, TAILGATE CYLINDER..........8N-9

LOCK SWITCH - INSTALLATION, DOOR

CYLINDER..........................8Q-10

LOCK SWITCH - INSTALLATION,

TAILGATE CYLINDER..................8N-10

LOCK SWITCH - OPERATION, DOOR

CYLINDER..........................8Q-10

LOCK SWITCH - OPERATION, TAILGATE

CYLINDER...........................8N-9

LOCK SWITCH - REMOVAL, DOOR

CYLINDER..........................8Q-10

LOCK SWITCH - REMOVAL, TAILGATE

CYLINDER..........................8N-10

LOCKS - DESCRIPTION, POWER.........8N-1

LOCKS - DIAGNOSIS AND TESTING,

POWER.............................8N-3

LOCKS - OPERATION, POWER...........8N-3

LOCK/UNLOCK SWITCH - DIAGNOSIS

AND TESTING, DOOR..................8N-4

LOOP ADJUSTER - INSTALLATION, SEAT

BELT TURNING......................8O-38

LOOP ADJUSTER - REMOVAL, SEAT

BELT TURNING......................8O-37

LOW BEAM RELAY - DESCRIPTION,

HEADLAMP.........................8L-39

LOW BEAM RELAY - DIAGNOSIS AND

TESTING, HEADLAMP.................8L-40

LOW BEAM RELAY - INSTALLATION,

HEADLAMP.........................8L-41

LOW BEAM RELAY - OPERATION,

HEADLAMP.........................8L-39

LOW BEAM RELAY - REMOVAL,

HEADLAMP

.........................8L-40

LOW FUEL INDICATOR - DESCRIPTION

. . . 8J-22

LOW FUEL INDICATOR - OPERATION

.....8J-22

LOW INDICATOR - DESCRIPTION,

COOLANT

...........................8J-15

LOW INDICATOR - OPERATION,

COOLANT

...........................8J-16

LOW LIMITS - DESCRIPTION, HIGH

......25-20

LOW MODE INDICATOR - DESCRIPTION,

FOUR

..............................8J-29

LOW MODE INDICATOR - OPERATION,

FOUR

..............................8J-30

LOW OIL PRESSURE INDICATOR -

DESCRIPTION

.......................8J-23

LOW OIL PRESSURE INDICATOR -

OPERATION

.........................8J-23

LOW PRESSURE SWITCH -

DESCRIPTION, A/C

...................24-18

LOW PRESSURE SWITCH - DIAGNOSIS

AND TESTING, A/C

...................24-19

LOW PRESSURE SWITCH -

INSTALLATION, A/C

...................24-19

KJINDEX 15

Description Group-Page Description Group-Page Description Group-Page

Page 1763 of 1803

SENSOR - INSTALLATION, OXYGEN......14-43

SENSOR - INSTALLATION, POSITION....21-210,

21-247

SENSOR - INSTALLATION, REAR WHEEL

SPEED..............................5-35

SENSOR - INSTALLATION, THROTTLE

POSITION..........................14-48

SENSOR - OPERATION, AMBIENT TEMP . . . 8M-9

SENSOR - OPERATION, BATTERY

TEMPERATURE......................8F-24

SENSOR - OPERATION, CRANKSHAFT

POSITION..........................14-31

SENSOR - OPERATION, ENGINE

COOLANT TEMPERATURE...............7-20

SENSOR - OPERATION, FRONT IMPACT . . . 8O-21

SENSOR - OPERATION, FUEL LEVEL

SENDING UNIT.......................14-9

SENSOR - OPERATION, INPUT SPEED . . . 21-143

SENSOR - OPERATION, INTAKE AIR

TEMPERATURE......................14-36

SENSOR - OPERATION, KNOCK..........8I-11

SENSOR - OPERATION, LINE PRESSURE

(LP)..............................21-144

SENSOR - OPERATION, MAP...........14-38

SENSOR - OPERATION, OUTPUT SPEED . . 21-152

SENSOR - OPERATION, OXYGEN........14-40

SENSOR - OPERATION, POSITION......21-209,

21-247

SENSOR - OPERATION, THROTTLE

POSITION..........................14-47

SENSOR - OPERATION, TRANSMISSION

RANGE............................21-168

SENSOR - OPERATION, TRANSMISSION

TEMPERATURE.....................21-170

SENSOR - REMOVAL, BATTERY

TEMPERATURE......................8F-24

SENSOR - REMOVAL, CRANKSHAFT

POSITION..........................14-31

SENSOR - REMOVAL, ENGINE COOLANT

TEMPERATURE.......................7-20

SENSOR - REMOVAL, FRONT IMPACT....8O-22

SENSOR - REMOVAL, FRONT WHEEL

SPEED..............................5-34

SENSOR - REMOVAL, FUEL LEVEL

SENDING UNIT.......................14-9

SENSOR - REMOVAL, INPUT SPEED.....21-143

SENSOR - REMOVAL, INTAKE AIR

TEMPERATURE......................14-37

SENSOR - REMOVAL, KNOCK...........8I-12

SENSOR - REMOVAL, LINE PRESSURE

(LP)..............................21-144

SENSOR - REMOVAL, MAP.............14-39

SENSOR - REMOVAL, OUTPUT SPEED . . . 21-152

SENSOR - REMOVAL, OXYGEN..........14-41

SENSOR - REMOVAL, POSITION . . 21-210,21-247

SENSOR - REMOVAL, REAR WHEEL

SPEED..............................5-35

SENSOR - REMOVAL, THROTTLE

POSITION..........................14-47

SENSOR CIRCUIT - DIAGNOSIS AND

TESTING, AMBIENT TEMPERATURE.......8M-9

SENSOR RETURN - DESCRIPTION.......8E-14

SENSOR/SWITCH - DESCRIPTION, OIL

PRESSURE..........................9-65

SENSOR/SWITCH - INSTALLATION, OIL

PRESSURE

..........................9-65

SENSOR/SWITCH - OPERATION, OIL

PRESSURE

..........................9-65

SENSOR/SWITCH - REMOVAL, OIL

PRESSURE

..........................9-65

SENTRY KEY IMMOBILIZER MODULE -

DESCRIPTION

.......................8E-15

SENTRY KEY IMMOBILIZER MODULE -

INSTALLATION

.......................8E-18

SENTRY KEY IMMOBILIZER MODULE -

OPERATION

.........................8E-16

SENTRY KEY IMMOBILIZER MODULE -

REMOVAL

..........................8E-17

SENTRY KEY TRANSPONDER

PROGRAMMING - STANDARD

PROCEDURE

.........................8Q-8

SERPENTINE DRIVE BELT - DIAGNOSIS

AND TESTING

........................7-15

SERVO - DESCRIPTION

.................8P-4

SERVO - INSTALLATION

................8P-5

SERVO - OPERATION

..................8P-4

SERVO - REMOVAL

....................8P-4SETTING TRANSMITTER CODES -

STANDARD PROCEDURE...............8M-9

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO GROUND ON FUSES POWERING . . . 8W-01-9

SHAFT - CAUTION, HALF................3-10

SHAFT - DIAGNOSIS AND TESTING,

HALF...............................3-10

SHAFT - DIAGNOSIS AND TESTING,

PROPELLER...........................3-1

SHAFT - FRONT - INSTALLATION,

PROPELLER...........................3-6

SHAFT - FRONT - REMOVAL,

PROPELLER...........................3-6

SHAFT - INSTALLATION, BALANCE........9-74

SHAFT - INSTALLATION, HALF...........3-11

SHAFT - INSTALLATION, IDLER..........9-77

SHAFT - INSTALLATION, INTERMEDIATE . . 19-11

SHAFT - REAR - INSTALLATION,

PROPELLER...........................3-7

SHAFT - REAR - REMOVAL, PROPELLER....3-7

SHAFT - REMOVAL, BALANCE...........9-74

SHAFT - REMOVAL, HALF...............3-10

SHAFT - REMOVAL, IDLER..............9-77

SHAFT - REMOVAL, INTERMEDIATE......19-11

SHAFT ANGLE - STANDARD

PROCEDURES, PROPELLER..............3-3

SHAFT SEAL - INSTALLATION, FRONT

OUTPUT.....................21-208,21-246

SHAFT SEAL - INSTALLATION, REAR

OUTPUT............................21-212

SHAFT SEAL - REMOVAL, FRONT

OUTPUT.....................21-208,21-246

SHAFT SEAL - REMOVAL, REAR OUTPUT . 21-210

SHAFT SEALS - INSTALLATION, AXLE....3-102,

3-38

SHAFT SEALS - REMOVAL, AXLE....3-101,3-37

SHAFT, SPECIFICATIONS - HALF..........3-11

SHAFT, SPECIFICATIONS - PROPELLER.....3-6

SHAFTS - INSTALLATION, AXLE . 3-101,3-37,3-65

SHAFTS - REMOVAL, AXLE.....3-101,3-37,3-65

SHIELD - INSTALLATION, FRONT

WHEELHOUSE SPLASH...............23-143

SHIELD - INSTALLATION, REAR

WHEELHOUSE SPLASH...............23-144

SHIELD - REMOVAL, FRONT

WHEELHOUSE SPLASH...............23-143

SHIELD - REMOVAL, REAR

WHEELHOUSE SPLASH...............23-144

SHIELDS - DESCRIPTION, HEAT..........11-4

SHIELDS - INSTALLATION, SEAT

CUSHION SIDE.....................23-167

SHIELDS - REMOVAL, SEAT CUSHION

SIDE.............................23-167

SHIFT BEZEL - INSTALLATION.........23-158

SHIFT BEZEL - REMOVAL.............23-158

SHIFT BOOT - INSTALLATION, 4WD

FLOOR............................23-156

SHIFT BOOT - REMOVAL, 4WD FLOOR . . . 23-156

SHIFT INTERLOCK SYSTEM -

DESCRIPTION, BRAKE TRANSMISSION . . 21-124

SHIFT INTERLOCK SYSTEM - DIAGNOSIS

AND TESTING, BRAKE TRANSMISSION . . 21-125

SHIFT INTERLOCK SYSTEM -

OPERATION, BRAKE TRANSMISSION....21-125

SHIFT LEVER - INSTALLATION . . . 21-214,21-249

SHIFT LEVER - REMOVAL.......21-213,21-248

SHIFT MECHANISM - DESCRIPTION.....21-160

SHIFT MECHANISM - INSTALLATION....21-160

SHIFT MECHANISM - OPERATION

......21-160

SHIFT MECHANISM - REMOVAL

........21-160

SHOCK - INSTALLATION

................2-18

SHOCK - REMOVAL

....................2-18

SHOES - INSTALLATION, DRUM BRAKE

....5-11

SHOES - REMOVAL, DRUM BRAKE

.......5-11

SHORT TO GROUND - STANDARD

PROCEDURE, TESTING FOR A

........8W-01-9

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A

...........................8W-01-9

SIDE - INSTALLATION, LEFT

.........2-12,2-15

SIDE - INSTALLATION, RIGHT

........2-12,2-15

SIDE - REMOVAL, LEFT

.............2-11,2-15

SIDE - REMOVAL, RIGHT

...........2-11,2-14

SIDE BEZEL - INSTALLATION,

INSTRUMENT PANEL PASSENGER

......23-154SIDE BEZEL - REMOVAL, INSTRUMENT

PANEL PASSENGER..................23-154

SIDE BEZELS - INSTALLATION,

INSTRUMENT PANEL DRIVER..........23-154

SIDE BEZELS - REMOVAL, INSTRUMENT

PANEL DRIVER.....................23-153

SIDE CURTAIN AIRBAG - DESCRIPTION . . . 8O-38

SIDE CURTAIN AIRBAG - INSTALLATION . . 8O-41

SIDE CURTAIN AIRBAG - OPERATION....8O-39

SIDE CURTAIN AIRBAG - REMOVAL......8O-40

SIDE IMPACT AIRBAG CONTROL

MODULE - DESCRIPTION..............8O-43

SIDE IMPACT AIRBAG CONTROL

MODULE - INSTALLATION.............8O-45

SIDE IMPACT AIRBAG CONTROL

MODULE - OPERATION................8O-43

SIDE IMPACT AIRBAG CONTROL

MODULE - REMOVAL.................8O-44

SIDE MOLDINGS - INSTALLATION, BODY . 23-140

SIDE MOLDINGS - REMOVAL, BODY....23-140

SIDE RAIL WEATHERSTRIP/RETAINER -

INSTALLATION......................23-186

SIDE RAIL WEATHERSTRIP/RETAINER -

REMOVAL.........................23-186

SIDE SHIELDS - INSTALLATION, SEAT

CUSHION..........................23-167

SIDE SHIELDS - REMOVAL, SEAT

CUSHION..........................23-167

SIDE VIEW MIRROR - INSTALLATION....23-145

SIDE VIEW MIRROR - REMOVAL.......23-145

SIDEVIEW MIRROR - REMOVAL..........8N-13

SIGNAL INDICATOR - DESCRIPTION,

TURN..............................8J-34

SIGNAL INDICATOR - OPERATION, TURN . . 8J-34

SILL SCUFF PLATE - INSTALLATION,

DOOR............................23-157

SILL SCUFF PLATE - REMOVAL, DOOR . . . 23-157

SINGLE CARDAN UNIVERSAL JOINTS -

ASSEMBLY...........................3-9

SINGLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY.........................3-8

SIREN - DESCRIPTION................8Q-16

SIREN - INSTALLATION...............8Q-17

SIREN - OPERATION..................8Q-17

SIREN - REMOVAL...................8Q-17

SKID PLATE - INSTALLATION, FRONT......13-6

SKID PLATE - INSTALLATION, FUEL

TANK ...............................13-9

SKID PLATE - INSTALLATION, TRANSFER

CASE...............................13-7

SKID PLATE - REMOVAL, FRONT.........13-6

SKID PLATE - REMOVAL, FUEL TANK......13-9

SKID PLATE - REMOVAL, TRANSFER

CASE...............................13-7

SKIS INDICATOR - DESCRIPTION........8J-31

SKIS INDICATOR - OPERATION..........8J-31

SKIS INITIALIZATION - STANDARD

PROCEDURE.........................8Q-8

SLEEVE - INSTALLATION, HEADREST....23-164

SLEEVE - REMOVAL, HEADREST.......23-164

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-27

SOLENOID - INSTALLATION, EVAP/

PURGE.............................25-27

SOLENOID - OPERATION, EVAP/PURGE . . . 25-27

SOLENOID - REMOVAL, EVAP/PURGE.....25-27

SOLENOID SWITCH VALVE -

DESCRIPTION......................21-161

SOLENOID SWITCH VALVE - OPERATION . 21-161

SOLENOIDS - DESCRIPTION...........21-161

SOLENOIDS - OPERATION.............21-162

SOLENOID/TRS ASSEMBLY -

DESCRIPTION, TRANSMISSION........21-169

SOLENOID/TRS ASSEMBLY -

INSTALLATION, TRANSMISSION........21-170

SOLENOID/TRS ASSEMBLY -

OPERATION, TRANSMISSION..........21-169

SOLENOID/TRS ASSEMBLY - REMOVAL,

TRANSMISSION.....................21-170

SPACER - INSTALLATION, COLLAPSIBLE . . . 3-70

SPACER - REMOVAL, COLLAPSIBLE.......3-70

SPARE TIRE - INSTALLATION............22-9

SPARE TIRE - REMOVAL

................22-8

SPARE TIRE &TEMPORARY -

DESCRIPTION

........................22-6

SPARK PLUG - CLEANING SPARK

PLUGS

.............................8I-15

SPARK PLUG - DESCRIPTION

...........8I-12

SPARK PLUG - INSTALLATION

...........8I-15

24 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1766 of 1803

TANK - REMOVAL, FUEL...............14-25

TANK CHECK VALVE - DESCRIPTION,

FUEL..............................14-28

TANK CHECK VALVE - INSTALLATION,

FUEL..............................14-28

TANK CHECK VALVE - OPERATION, FUEL . . 14-28

TANK CHECK VALVE - REMOVAL, FUEL . . . 14-28

TANK SKID PLATE - INSTALLATION,

FUEL...............................13-9

TANK SKID PLATE - REMOVAL, FUEL......13-9

TASK MANAGER - DESCRIPTION........25-17

TASK MANAGER - OPERATION..........25-21

TCM QUICK LEARN - STANDARD

PROCEDURE........................8E-21

TEMP INDICATOR - DESCRIPTION,

TRANS.............................8J-33

TEMP INDICATOR - OPERATION, TRANS . . 8J-34

TEMP SENSOR - DESCRIPTION,

AMBIENT...........................8M-9

TEMP SENSOR - OPERATION, AMBIENT . . . 8M-9

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE............................8J-18

TEMPERATURE GAUGE - OPERATION,

ENGINE............................8J-18

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY...........................8F-24

TEMPERATURE SENSOR - DESCRIPTION,

ENGINE COOLANT.....................7-19

TEMPERATURE SENSOR - DESCRIPTION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION.....................21-170

TEMPERATURE SENSOR - DIAGNOSIS

AND TESTING, AMBIENT...............8M-9

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-24

TEMPERATURE SENSOR -

INSTALLATION, ENGINE COOLANT........7-21

TEMPERATURE SENSOR -

INSTALLATION, INTAKE AIR............14-38

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-24

TEMPERATURE SENSOR - OPERATION,

ENGINE COOLANT.....................7-20

TEMPERATURE SENSOR - OPERATION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION.....................21-170

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-24

TEMPERATURE SENSOR - REMOVAL,

ENGINE COOLANT.....................7-20

TEMPERATURE SENSOR - REMOVAL,

INTAKE AIR .........................14-37

TEMPERATURE SENSOR CIRCUIT -

DIAGNOSIS AND TESTING, AMBIENT.....8M-9

TENSIONER - DESCRIPTION, SEAT BELT . . 8O-36

TENSIONER - OPERATION, SEAT BELT....8O-36

TERMINAL - INSTALLATION.........8W-01-14

TERMINAL - REMOVAL.............8W-01-14

TEST - DIAGNOSIS AND TESTING, FUEL

PRESSURE LEAK DOWN................14-3

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP AMPERAGE....................14-16

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP CAPACITY.....................14-15

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP PRESSURE....................14-15

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE...............21-79

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-2

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-10

TEST - STANDARD PROCEDURE,

HYDROMETER.......................8F-11

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-14

TEST - STANDARD PROCEDURE, LOAD . . . 8F-12

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE

...............8F-12

TEST - STANDARD PROCEDURE,

VERIFICATION

........................8O-8

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION

..........................25-2

TEST MODE - DESCRIPTION, STATE

DISPLAY

............................25-2

TESTER - STANDARD PROCEDURE,

USING MIDTRONICS ELECTRICAL

.......8F-15TETHER ANCHOR - DESCRIPTION, CHILD . 8O-13

TETHER ANCHOR - OPERATION, CHILD . . . 8O-13

THEFT SECURITY - DESCRIPTION,

VEHICLE............................8Q-1

THEFT SECURITY - OPERATION, VEHICLE . . 8Q-3

THEFT SECURITY SYSTEM - DIAGNOSIS

AND TESTING, VEHICLE................8Q-6

THERMAL GUARD - DESCRIPTION.......8F-20

THERMAL GUARD - INSTALLATION......8F-20

THERMAL GUARD - OPERATION.........8F-20

THERMAL GUARD - REMOVAL..........8F-20

THERMOSTAT - DIAGNOSIS AND

TESTING............................7-21

THERMOSTAT - OPERATION, ENGINE

COOLANT............................7-21

THREAD REPAIR - STANDARD

PROCEDURE, ALUMINUM..............21-81

THREADED HOLE REPAIR -

DESCRIPTION......................Intro.-4

THREADS - STANDARD PROCEDURE,

REPAIR DAMAGED OR WORN............9-9

THROTTLE BODY - DESCRIPTION........14-43

THROTTLE BODY - INSTALLATION.......14-44

THROTTLE BODY - OPERATION.........14-43

THROTTLE BODY - REMOVAL...........14-43

THROTTLE CONTROL CABLE -

INSTALLATION.......................14-46

THROTTLE CONTROL CABLE - REMOVAL . . 14-45

THROTTLE POSITION SENSOR -

DESCRIPTION.........................14-47

THROTTLE POSITION SENSOR -

INSTALLATION.......................14-48

THROTTLE POSITION SENSOR -

OPERATION.........................14-47

THROTTLE POSITION SENSOR -

REMOVAL..........................14-47

TIE ROD END - INSTALLATION..........19-16

TIE ROD END - REMOVAL..............19-16

TIE ROD END REMOVAL TOOL, SPECIAL

TOOLS - OUTER.....................19-15

TIME INDICATOR - DESCRIPTION, FULL . . . 8J-29

TIME INDICATOR - DESCRIPTION, PART . . 8J-29

TIME INDICATOR - OPERATION, FULL....8J-30

TIME INDICATOR - OPERATION, PART....8J-29

TIMING - DESCRIPTION, VALVE..........9-71

TIMING - OPERATION, VALVE............9-71

TIMING - SPECIFICATIONS, IGNITION......8I-2

TIMING BELT / CHAIN COVER(S) -

INSTALLATION........................9-76

TIMING BELT / CHAIN COVER(S) -

REMOVAL...........................9-74

TIMING CHAIN WEAR, STANDARD

PROCEDURE - MEASURING.............9-71

TIRE - INSTALLATION, SPARE...........22-9

TIRE - REMOVAL, SPARE...............22-8

TIRE INFLATION - DIAGNOSIS AND

TESTING............................22-7

TIRE NOISE OR VIBRATION - DIAGNOSIS

AND TESTING........................22-8

TIRE ROTATION - STANDARD

PROCEDURE.........................22-2

TIRE &TEMPORARY - DESCRIPTION,

SPARE..............................22-6

TIRE WEAR PATTERNS - DIAGNOSIS

AND TESTING........................22-8

TIRES - DESCRIPTION.................22-6

TIRES - DESCRIPTION, RADIAL-PLY.......22-6

TIRES - DESCRIPTION, REPLACEMENT....22-7

TIRES AND WHEEL RUNOUT -

DIAGNOSIS AND TESTING..............22-1

TO GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT.............8W-01-9

TO GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT . . 8W-01-9

TO USE WIRING DIAGRAMS -

DESCRIPTION, HOW................8W-01-1

TOE ADJUSTMENT - STANDARD

PROCEDURE..........................2-5

TOE ADJUSTMENT - STANDARD

PROCEDURE, CAMBER, CASTER..........2-5

TOOL, SPECIAL TOOLS - OUTER TIE

ROD END REMOVAL..................19-15

TOOLS - 3.7L ENGINE, SPECIAL

..........9-15

TOOLS - 8 1/4 AXLE, SPECIAL

...........3-98

TOOLS - BASE BRAKES, SPECIAL

.........5-7

TOOLS - BODY, SPECIAL

................23-5

TOOLS - COOLING, SPECIAL

.............7-14TOOLS - FRONT AXLE, SPECIAL..........3-34

TOOLS - FRONT SUSPENSION, SPECIAL....2-8

TOOLS - FUEL SYSTEM, SPECIAL........14-6

TOOLS - OUTER TIE ROD END REMOVAL

TOOL, SPECIAL......................19-15

TOOLS - POWER DISTRIBUTION

SYSTEMS, SPECIAL................8W-97-2

TOOLS - POWER STEERING PUMP,

SPECIAL...........................19-20

TOOLS - REAR AXLE, SPECIAL...........3-63

TOOLS - RFE TRANSMISSION, SPECIAL . . 21-120

TOOLS - STEERING COLUMN, SPECIAL....19-8

TOOLS - WIRING/TERMINAL, SPECIAL . 8W-01-10

TOOLS, BATTERY SYSTEM - SPECIAL.....8F-7

TOOLS, SPECIFICATIONS - SPECIAL....3-12,3-6

TOOLS, SPECIFICATIONS - SPECIAL......8F-24

TOP COVER - INSTALLATION,

INSTRUMENT PANEL.................23-153

TOP COVER - REMOVAL, INSTRUMENT

PANEL............................23-152

TORQUE - SPECIFICATIONS.............13-6

TORQUE CHART, SPECIFICATIONS . . 19-15,19-19,

19-8

TORQUE CHART, SPECIFICATIONS.....2-17,2-8

TORQUE CONVERTER - DESCRIPTION . . . 21-162

TORQUE CONVERTER - INSTALLATION . . . 21-167

TORQUE CONVERTER - OPERATION.....21-166

TORQUE CONVERTER - REMOVAL......21-167

TORQUE, EXCEPT DIESEL..............8F-23

TORQUE, GAS POWERED..............8F-38

TORQUE, IGNITION SYSTEM.............8I-3

TORQUE REFERENCES - DESCRIPTION . . Intro.-7

TORQUE, SPECIFICATIONS...............5-7

TORQUE, SPECIFICATIONS..............7-13

TORQUE, SPECIFICATIONS.............25-26

TORQUE, SPECIFICATIONS..............9-12

TORQUE, SPECIFICATIONS..............14-5

TORQUE, SPEED CONTROL.............8P-2

TOUCH-UP - DESCRIPTION, PAINT......23-163

TOW CONNECTOR - INSTALLATION,

TRAILER...........................8L-61

TOW CONNECTOR - REMOVAL, TRAILER . . 8L-61

TOW HOOK - INSTALLATION, FRONT......13-8

TOW HOOK - INSTALLATION, REAR.......13-8

TOW HOOK - REMOVAL, FRONT..........13-8

TOW HOOK - REMOVAL, REAR...........13-8

TOW RELAY - DESCRIPTION, TRAILER....8L-61

TOW RELAY - DIAGNOSIS AND TESTING,

TRAILER...........................8L-62

TOW RELAY - INSTALLATION, TRAILER . . . 8L-64

TOW RELAY - OPERATION, TRAILER.....8L-62

TOW RELAY - REMOVAL, TRAILER.......8L-63

TOW WIRING - DESCRIPTION, TRAILER . . 8L-64

TOWING - STANDARD PROCEDURE........0-6

TRACK - DESCRIPTION, SEAT..........8N-15

TRACK - DIAGNOSIS AND TESTING,

SEAT ..............................8N-16

TRACK - INSTALLATION, SEAT.........23-168

TRACK - INSTALLATION, SEAT..........8N-16

TRACK - OPERATION, SEAT............8N-15

TRACK - REMOVAL, SEAT.............23-168

TRACK - REMOVAL, SEAT..............8N-16

TRAC-LOK - ASSEMBLY, DIFFERENTIAL . . . 3-109,

3-77

TRAC-LOK - CLEANING, DIFFERENTIAL . . . 3-109,

3-77

TRAC-LOK - DISASSEMBLY,

DIFFERENTIAL...................3-107,3-75

TRAC-LOK - INSPECTION, DIFFERENTIAL . 3-109,

3-77

TRAC-LOKT- DIAGNOSIS AND TESTING . . 3-106,

3-74

TRAILER HITCH - INSTALLATION.........13-9

TRAILER HITCH - REMOVAL.............13-9

TRAILER TOW CONNECTOR -

INSTALLATION.......................8L-61

TRAILER TOW CONNECTOR - REMOVAL . . 8L-61

TRAILER TOW RELAY - DESCRIPTION....8L-61

TRAILER TOW RELAY - DIAGNOSIS AND

TESTING...........................8L-62

TRAILER TOW RELAY - INSTALLATION . . . 8L-64

TRAILER TOW RELAY - OPERATION......8L-62

TRAILER TOW RELAY - REMOVAL

.......8L-63

TRAILER TOW WIRING - DESCRIPTION

. . . 8L-64

TRANS COOLER - DESCRIPTION

.........7-32

TRANS TEMP INDICATOR -

DESCRIPTION

.......................8J-33

TRANS TEMP INDICATOR - OPERATION

. . . 8J-34

KJINDEX 27

Description Group-Page Description Group-Page Description Group-Page