3.7 v6 JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1297 of 1803

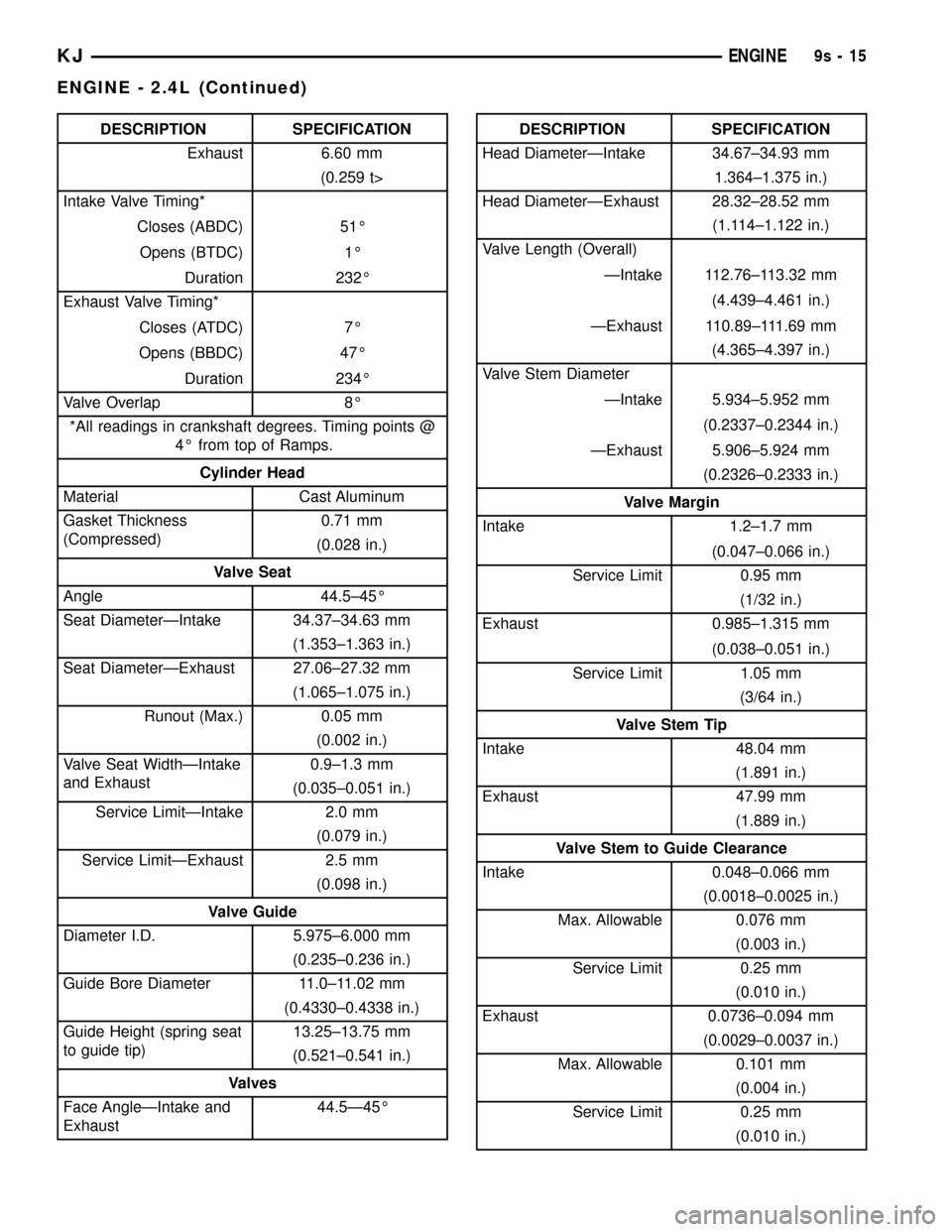

(20) After installing all chains, it is recommended

that the idler gear end play be checked (Fig. 112).

The end play must be within 0.10±0.25 mm (0.004±

0.010 in.). If not within specification, the idler gear

must be replaced.

(21) Install timing chain cover and crankshaft

damper. Refer to procedures.

(22) Install cylinder head covers. Refer to proce-

dures.

NOTE: Before installing threaded plug in right cylin-

der head, the plug must be coated with sealant to

prevent leaks.(23) Coat the large threaded access plug with

MopartThread Sealant with Teflon, then install

into the right cylinder head and tighten to 81 N´m

(60 ft. lbs.).

(24) Install the oil fill housing.

(25) Install access plug in left cylinder head.

(26) Install power steering pump.

(27) Fill cooling system.

(28) Connect negative cable to battery.

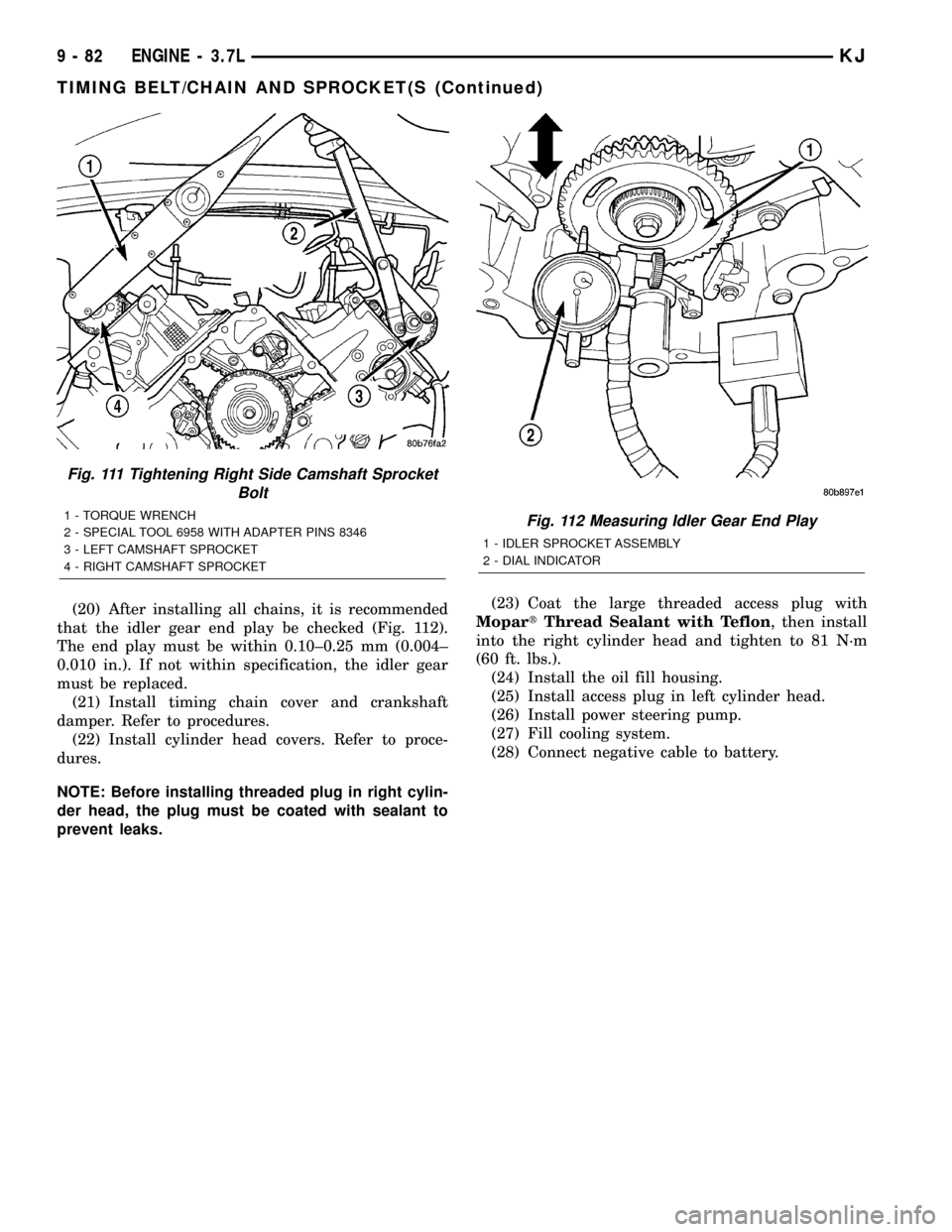

Fig. 111 Tightening Right Side Camshaft Sprocket

Bolt

1 - TORQUE WRENCH

2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 - LEFT CAMSHAFT SPROCKET

4 - RIGHT CAMSHAFT SPROCKETFig. 112 Measuring Idler Gear End Play

1 - IDLER SPROCKET ASSEMBLY

2 - DIAL INDICATOR

9 - 82 ENGINE - 3.7LKJ

TIMING BELT/CHAIN AND SPROCKET(S (Continued)

Page 1312 of 1803

DESCRIPTION SPECIFICATION

Exhaust 6.60 mm

(0.259 t>

Intake Valve Timing*

Closes (ABDC) 51É

Opens (BTDC) 1É

Duration 232É

Exhaust Valve Timing*

Closes (ATDC) 7É

Opens (BBDC) 47É

Duration 234É

Valve Overlap 8É

*All readings in crankshaft degrees. Timing points @

4É from top of Ramps.

Cylinder Head

Material Cast Aluminum

Gasket Thickness

(Compressed)0.71 mm

(0.028 in.)

Valve Seat

Angle 44.5±45É

Seat DiameterÐIntake 34.37±34.63 mm

(1.353±1.363 in.)

Seat DiameterÐExhaust 27.06±27.32 mm

(1.065±1.075 in.)

Runout (Max.) 0.05 mm

(0.002 in.)

Valve Seat WidthÐIntake

and Exhaust0.9±1.3 mm

(0.035±0.051 in.)

Service LimitÐIntake 2.0 mm

(0.079 in.)

Service LimitÐExhaust 2.5 mm

(0.098 in.)

Valve Guide

Diameter I.D. 5.975±6.000 mm

(0.235±0.236 in.)

Guide Bore Diameter 11.0±11.02 mm

(0.4330±0.4338 in.)

Guide Height (spring seat

to guide tip)13.25±13.75 mm

(0.521±0.541 in.)

Valves

Face AngleÐIntake and

Exhaust44.5Ð45ÉDESCRIPTION SPECIFICATION

Head DiameterÐIntake 34.67±34.93 mm

1.364±1.375 in.)

Head DiameterÐExhaust 28.32±28.52 mm

(1.114±1.122 in.)

Valve Length (Overall)

ÐIntake 112.76±113.32 mm

(4.439±4.461 in.)

ÐExhaust 110.89±111.69 mm

(4.365±4.397 in.)

Valve Stem Diameter

ÐIntake 5.934±5.952 mm

(0.2337±0.2344 in.)

ÐExhaust 5.906±5.924 mm

(0.2326±0.2333 in.)

Valve Margin

Intake 1.2±1.7 mm

(0.047±0.066 in.)

Service Limit 0.95 mm

(1/32 in.)

Exhaust 0.985±1.315 mm

(0.038±0.051 in.)

Service Limit 1.05 mm

(3/64 in.)

Valve Stem Tip

Intake 48.04 mm

(1.891 in.)

Exhaust 47.99 mm

(1.889 in.)

Valve Stem to Guide Clearance

Intake 0.048±0.066 mm

(0.0018±0.0025 in.)

Max. Allowable 0.076 mm

(0.003 in.)

Service Limit 0.25 mm

(0.010 in.)

Exhaust 0.0736±0.094 mm

(0.0029±0.0037 in.)

Max. Allowable 0.101 mm

(0.004 in.)

Service Limit 0.25 mm

(0.010 in.)

KJENGINE9s-15

ENGINE - 2.4L (Continued)

Page 1318 of 1803

Remove all gasket material from cylinder head and

block (Refer to 9 - ENGINE - STANDARD PROCE-

DURE). Be careful not to gouge or scratch the alumi-

num head sealing surface.

Clean all engine oil passages.

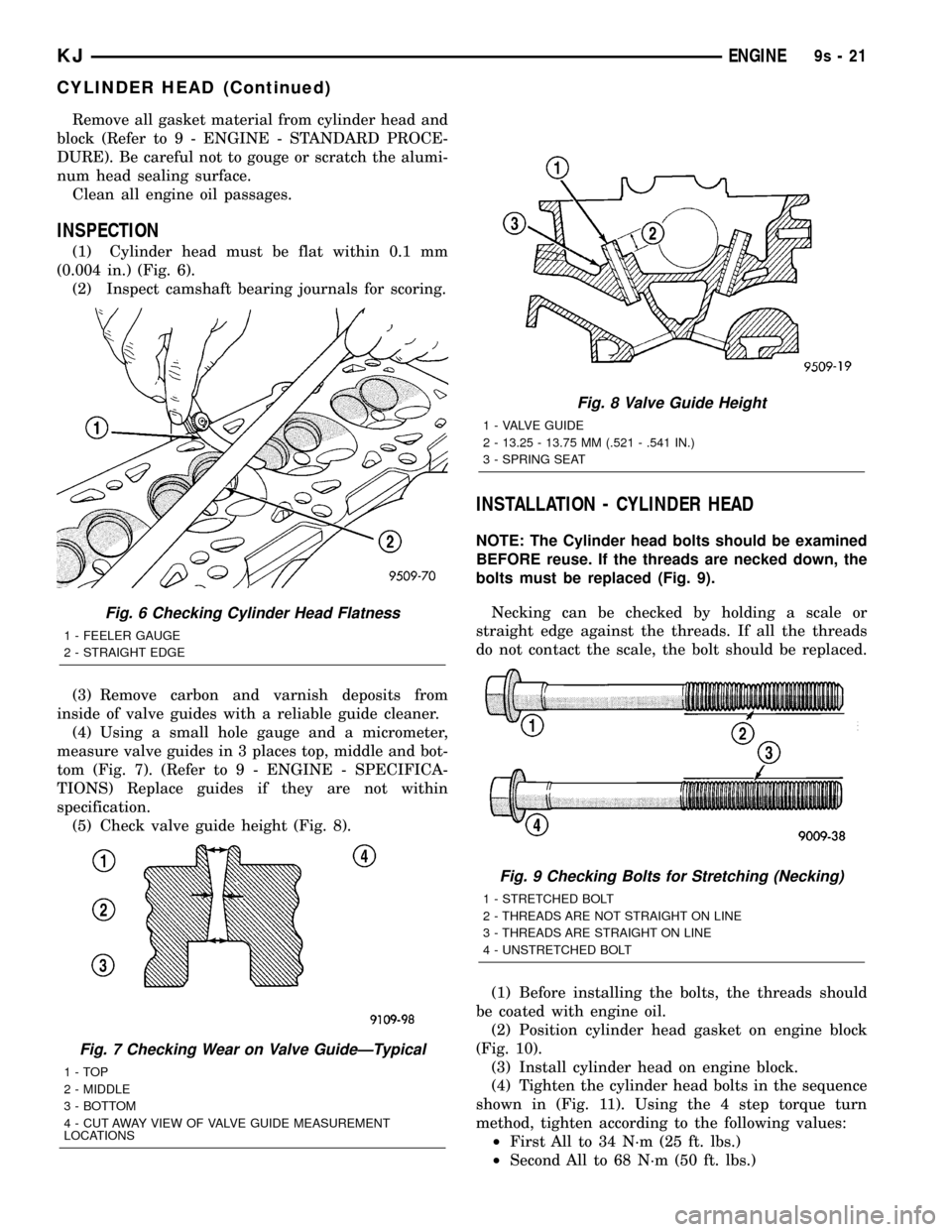

INSPECTION

(1) Cylinder head must be flat within 0.1 mm

(0.004 in.) (Fig. 6).

(2) Inspect camshaft bearing journals for scoring.

(3) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(4) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 7). (Refer to 9 - ENGINE - SPECIFICA-

TIONS) Replace guides if they are not within

specification.

(5) Check valve guide height (Fig. 8).

INSTALLATION - CYLINDER HEAD

NOTE: The Cylinder head bolts should be examined

BEFORE reuse. If the threads are necked down, the

bolts must be replaced (Fig. 9).

Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale, the bolt should be replaced.

(1) Before installing the bolts, the threads should

be coated with engine oil.

(2) Position cylinder head gasket on engine block

(Fig. 10).

(3) Install cylinder head on engine block.

(4) Tighten the cylinder head bolts in the sequence

shown in (Fig. 11). Using the 4 step torque turn

method, tighten according to the following values:

²First All to 34 N´m (25 ft. lbs.)

²Second All to 68 N´m (50 ft. lbs.)

Fig. 6 Checking Cylinder Head Flatness

1 - FEELER GAUGE

2 - STRAIGHT EDGE

Fig. 7 Checking Wear on Valve GuideÐTypical

1-TOP

2 - MIDDLE

3 - BOTTOM

4 - CUT AWAY VIEW OF VALVE GUIDE MEASUREMENT

LOCATIONS

Fig. 8 Valve Guide Height

1 - VALVE GUIDE

2 - 13.25 - 13.75 MM (.521 - .541 IN.)

3 - SPRING SEAT

Fig. 9 Checking Bolts for Stretching (Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

KJENGINE9s-21

CYLINDER HEAD (Continued)

Page 1342 of 1803

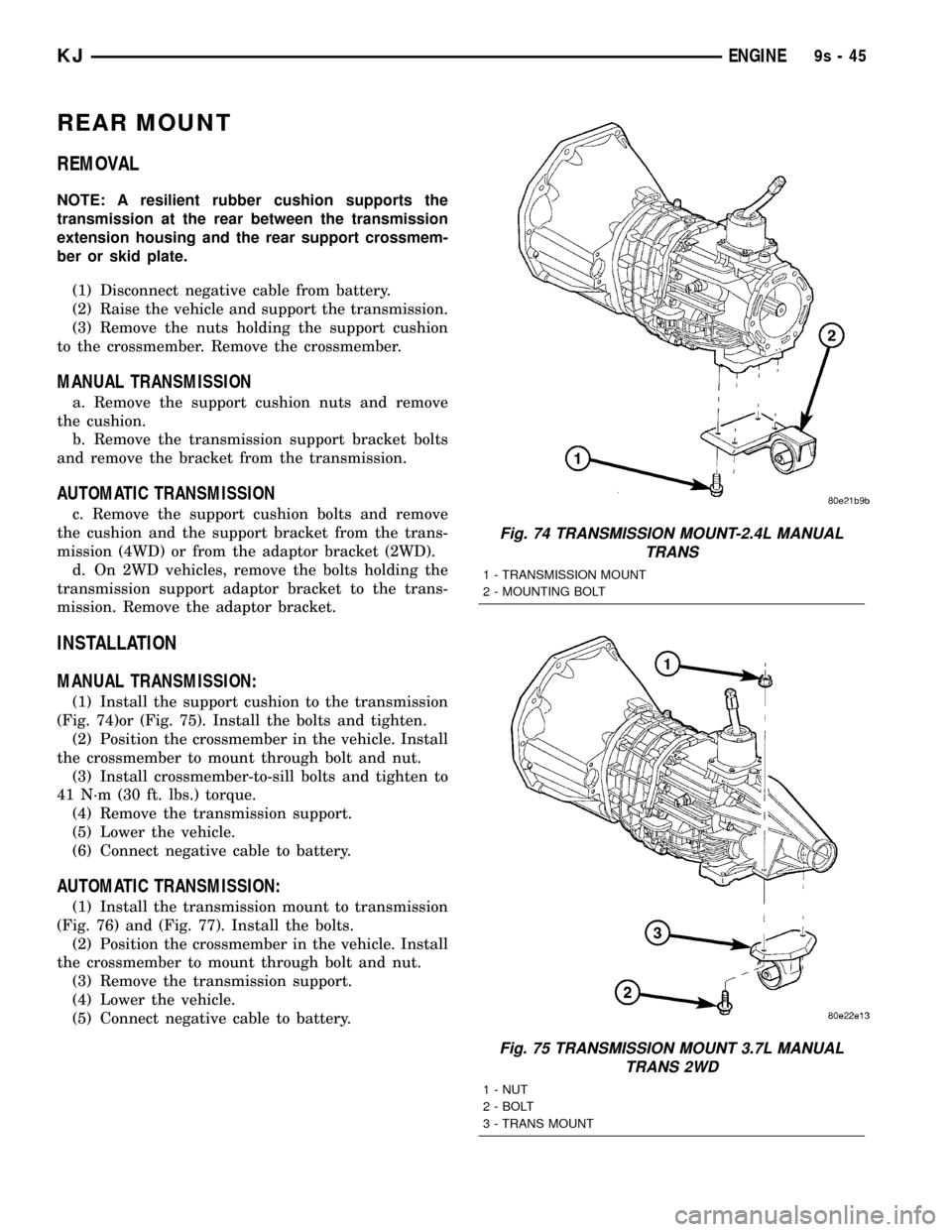

REAR MOUNT

REMOVAL

NOTE: A resilient rubber cushion supports the

transmission at the rear between the transmission

extension housing and the rear support crossmem-

ber or skid plate.

(1) Disconnect negative cable from battery.

(2) Raise the vehicle and support the transmission.

(3) Remove the nuts holding the support cushion

to the crossmember. Remove the crossmember.

MANUAL TRANSMISSION

a. Remove the support cushion nuts and remove

the cushion.

b. Remove the transmission support bracket bolts

and remove the bracket from the transmission.

AUTOMATIC TRANSMISSION

c. Remove the support cushion bolts and remove

the cushion and the support bracket from the trans-

mission (4WD) or from the adaptor bracket (2WD).

d. On 2WD vehicles, remove the bolts holding the

transmission support adaptor bracket to the trans-

mission. Remove the adaptor bracket.

INSTALLATION

MANUAL TRANSMISSION:

(1) Install the support cushion to the transmission

(Fig. 74)or (Fig. 75). Install the bolts and tighten.

(2) Position the crossmember in the vehicle. Install

the crossmember to mount through bolt and nut.

(3) Install crossmember-to-sill bolts and tighten to

41 N´m (30 ft. lbs.) torque.

(4) Remove the transmission support.

(5) Lower the vehicle.

(6) Connect negative cable to battery.

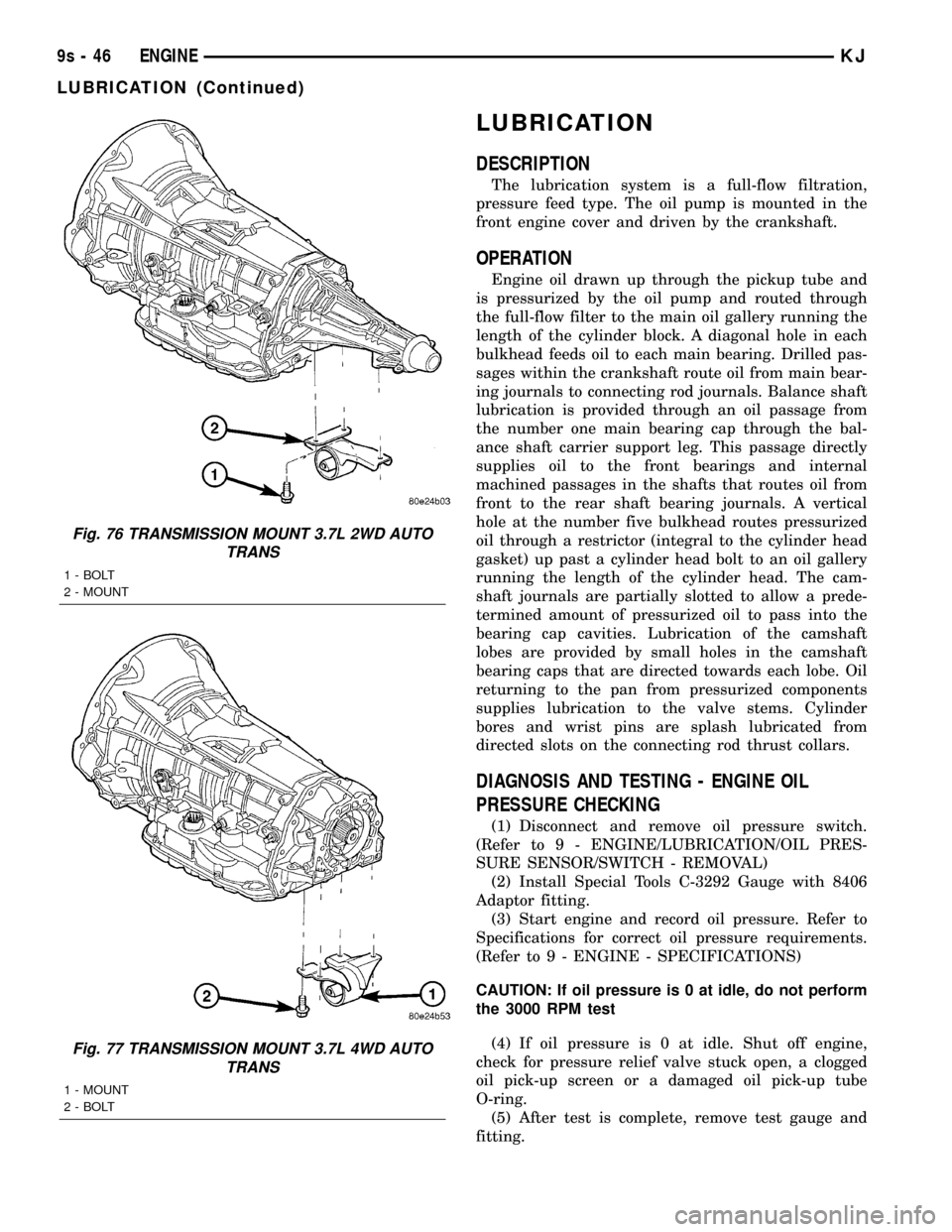

AUTOMATIC TRANSMISSION:

(1) Install the transmission mount to transmission

(Fig. 76) and (Fig. 77). Install the bolts.

(2) Position the crossmember in the vehicle. Install

the crossmember to mount through bolt and nut.

(3) Remove the transmission support.

(4) Lower the vehicle.

(5) Connect negative cable to battery.

Fig. 74 TRANSMISSION MOUNT-2.4L MANUAL

TRANS

1 - TRANSMISSION MOUNT

2 - MOUNTING BOLT

Fig. 75 TRANSMISSION MOUNT 3.7L MANUAL

TRANS 2WD

1 - NUT

2 - BOLT

3 - TRANS MOUNT

KJENGINE9s-45

Page 1343 of 1803

LUBRICATION

DESCRIPTION

The lubrication system is a full-flow filtration,

pressure feed type. The oil pump is mounted in the

front engine cover and driven by the crankshaft.

OPERATION

Engine oil drawn up through the pickup tube and

is pressurized by the oil pump and routed through

the full-flow filter to the main oil gallery running the

length of the cylinder block. A diagonal hole in each

bulkhead feeds oil to each main bearing. Drilled pas-

sages within the crankshaft route oil from main bear-

ing journals to connecting rod journals. Balance shaft

lubrication is provided through an oil passage from

the number one main bearing cap through the bal-

ance shaft carrier support leg. This passage directly

supplies oil to the front bearings and internal

machined passages in the shafts that routes oil from

front to the rear shaft bearing journals. A vertical

hole at the number five bulkhead routes pressurized

oil through a restrictor (integral to the cylinder head

gasket) up past a cylinder head bolt to an oil gallery

running the length of the cylinder head. The cam-

shaft journals are partially slotted to allow a prede-

termined amount of pressurized oil to pass into the

bearing cap cavities. Lubrication of the camshaft

lobes are provided by small holes in the camshaft

bearing caps that are directed towards each lobe. Oil

returning to the pan from pressurized components

supplies lubrication to the valve stems. Cylinder

bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE CHECKING

(1) Disconnect and remove oil pressure switch.

(Refer to 9 - ENGINE/LUBRICATION/OIL PRES-

SURE SENSOR/SWITCH - REMOVAL)

(2) Install Special Tools C-3292 Gauge with 8406

Adaptor fitting.

(3) Start engine and record oil pressure. Refer to

Specifications for correct oil pressure requirements.

(Refer to 9 - ENGINE - SPECIFICATIONS)

CAUTION: If oil pressure is 0 at idle, do not perform

the 3000 RPM test

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

(5) After test is complete, remove test gauge and

fitting.

Fig. 76 TRANSMISSION MOUNT 3.7L 2WD AUTO

TRANS

1 - BOLT

2 - MOUNT

Fig. 77 TRANSMISSION MOUNT 3.7L 4WD AUTO

TRANS

1 - MOUNT

2 - BOLT

9s - 46 ENGINEKJ

LUBRICATION (Continued)

Page 1365 of 1803

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

(1) Install the crossove pipe into the hanger insu-

lator.

(2) Install and torque the fasteners in the cross-

over pipe to the left and right catalytic converter con-

nection.

(3) Install and torque the retaining fasteners hold-

ing the crossover pipe to exhaust pipe.

(4) Lower vehicle..

(5) Start engine and check for leaks.

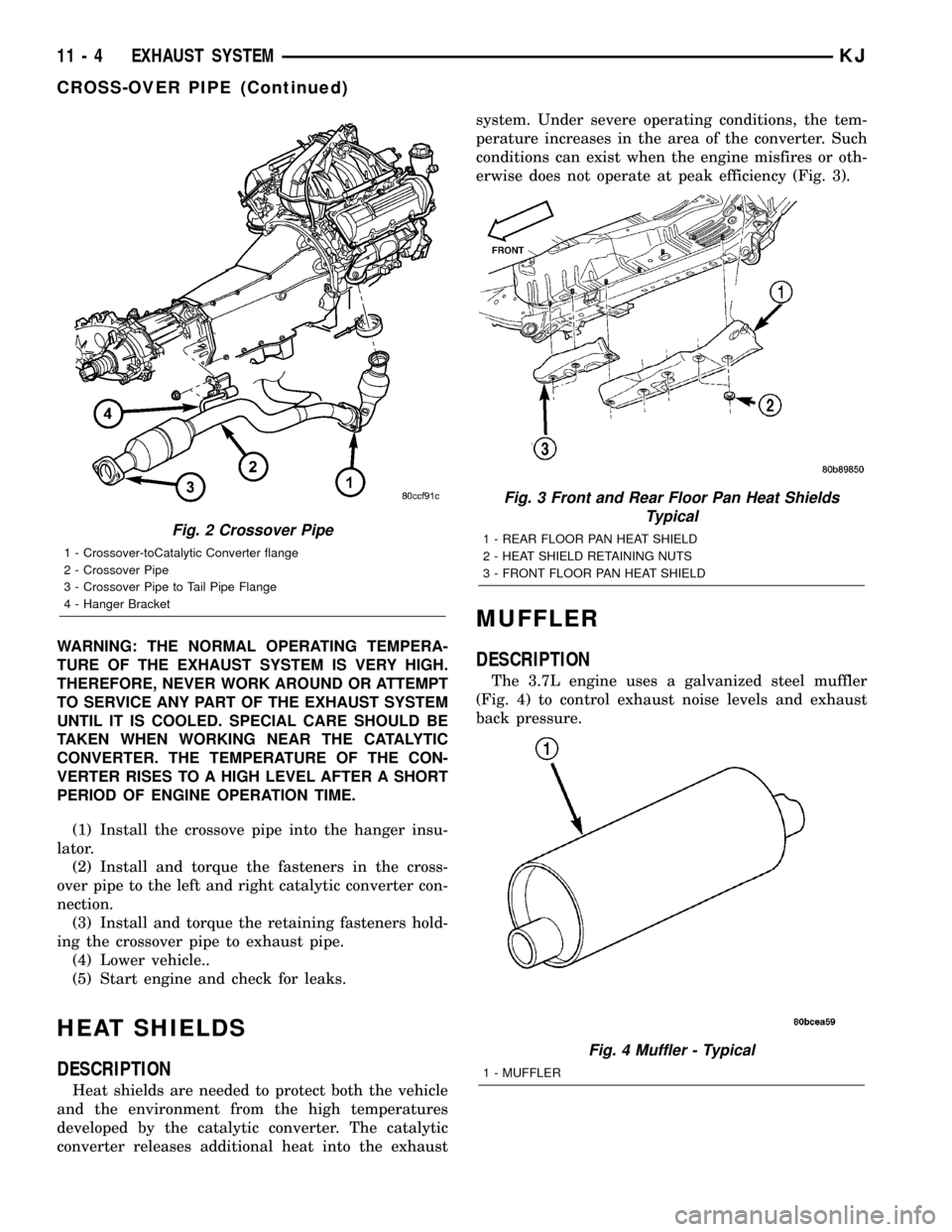

HEAT SHIELDS

DESCRIPTION

Heat shields are needed to protect both the vehicle

and the environment from the high temperatures

developed by the catalytic converter. The catalytic

converter releases additional heat into the exhaustsystem. Under severe operating conditions, the tem-

perature increases in the area of the converter. Such

conditions can exist when the engine misfires or oth-

erwise does not operate at peak efficiency (Fig. 3).

MUFFLER

DESCRIPTION

The 3.7L engine uses a galvanized steel muffler

(Fig. 4) to control exhaust noise levels and exhaust

back pressure.

Fig. 2 Crossover Pipe

1 - Crossover-toCatalytic Converter flange

2 - Crossover Pipe

3 - Crossover Pipe to Tail Pipe Flange

4 - Hanger Bracket

Fig. 3 Front and Rear Floor Pan Heat Shields

Typical

1 - REAR FLOOR PAN HEAT SHIELD

2 - HEAT SHIELD RETAINING NUTS

3 - FRONT FLOOR PAN HEAT SHIELD

Fig. 4 Muffler - Typical

1 - MUFFLER

11 - 4 EXHAUST SYSTEMKJ

CROSS-OVER PIPE (Continued)

Page 1370 of 1803

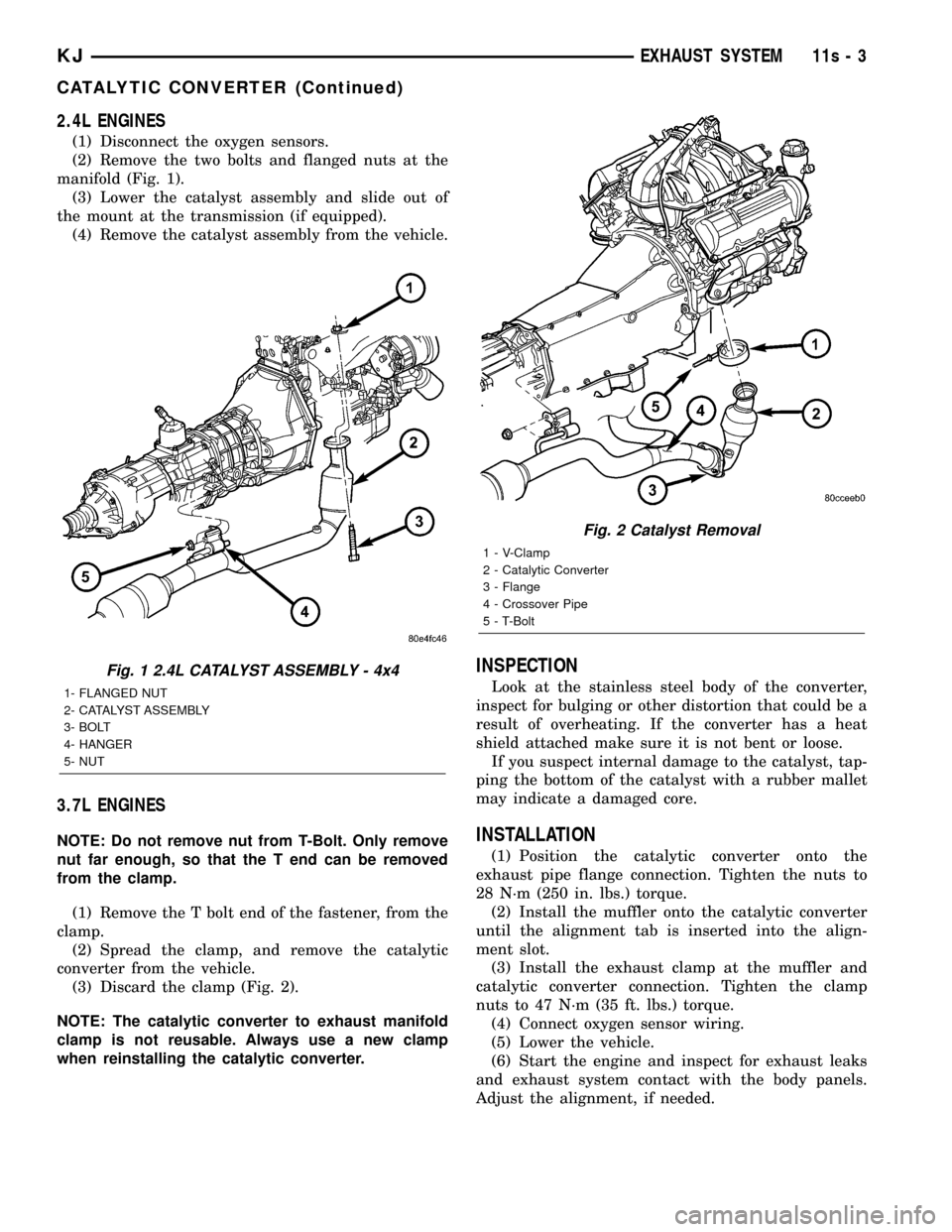

2.4L ENGINES

(1) Disconnect the oxygen sensors.

(2) Remove the two bolts and flanged nuts at the

manifold (Fig. 1).

(3) Lower the catalyst assembly and slide out of

the mount at the transmission (if equipped).

(4) Remove the catalyst assembly from the vehicle.

3.7L ENGINES

NOTE: Do not remove nut from T-Bolt. Only remove

nut far enough, so that the T end can be removed

from the clamp.

(1) Remove the T bolt end of the fastener, from the

clamp.

(2) Spread the clamp, and remove the catalytic

converter from the vehicle.

(3) Discard the clamp (Fig. 2).

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tap-

ping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

INSTALLATION

(1) Position the catalytic converter onto the

exhaust pipe flange connection. Tighten the nuts to

28 N´m (250 in. lbs.) torque.

(2) Install the muffler onto the catalytic converter

until the alignment tab is inserted into the align-

ment slot.

(3) Install the exhaust clamp at the muffler and

catalytic converter connection. Tighten the clamp

nuts to 47 N´m (35 ft. lbs.) torque.

(4) Connect oxygen sensor wiring.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

Fig. 1 2.4L CATALYST ASSEMBLY - 4x4

1- FLANGED NUT

2- CATALYST ASSEMBLY

3- BOLT

4- HANGER

5- NUT

Fig. 2 Catalyst Removal

1 - V-Clamp

2 - Catalytic Converter

3 - Flange

4 - Crossover Pipe

5 - T-Bolt

KJEXHAUST SYSTEM 11s - 3

CATALYTIC CONVERTER (Continued)

Page 1371 of 1803

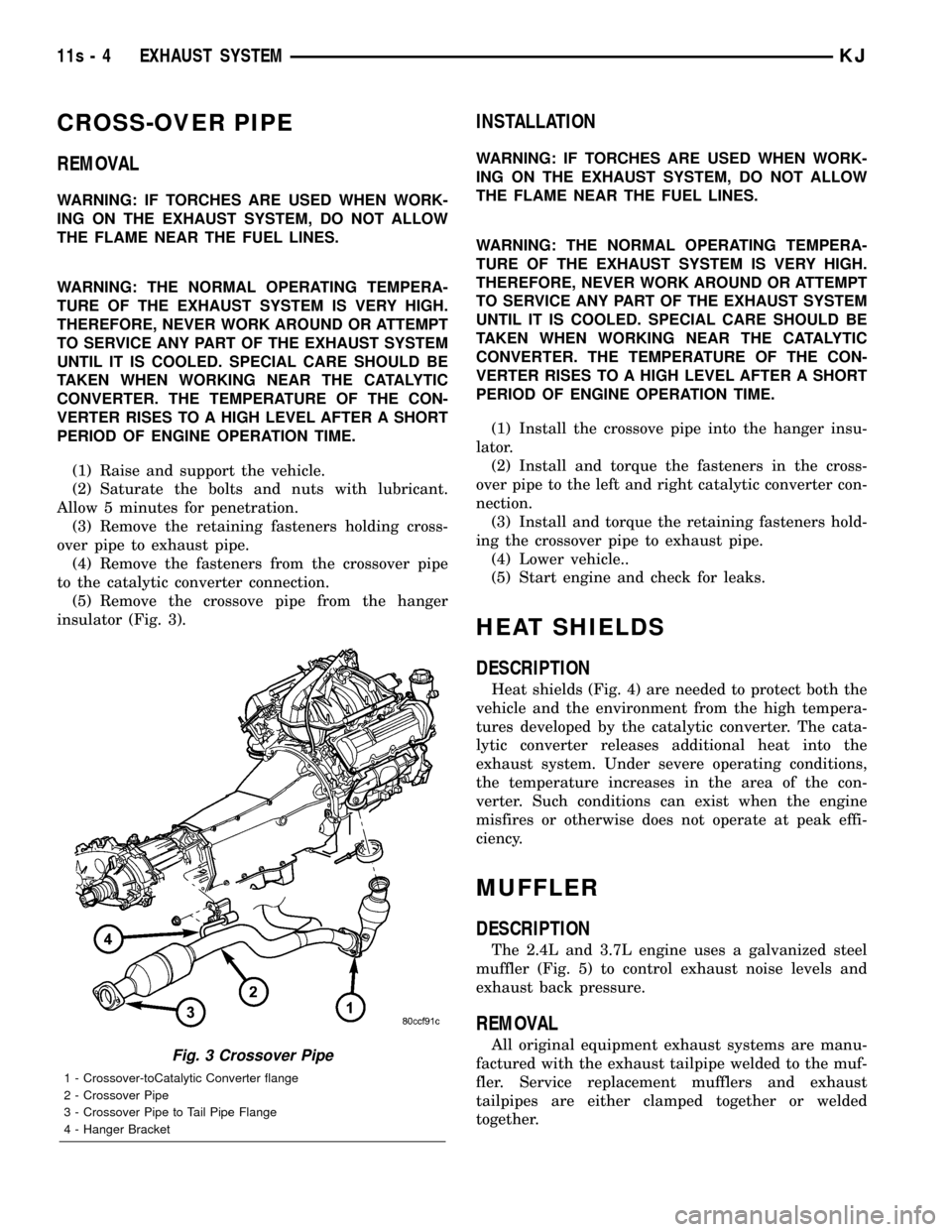

CROSS-OVER PIPE

REMOVAL

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with lubricant.

Allow 5 minutes for penetration.

(3) Remove the retaining fasteners holding cross-

over pipe to exhaust pipe.

(4) Remove the fasteners from the crossover pipe

to the catalytic converter connection.

(5) Remove the crossove pipe from the hanger

insulator (Fig. 3).

INSTALLATION

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

(1) Install the crossove pipe into the hanger insu-

lator.

(2) Install and torque the fasteners in the cross-

over pipe to the left and right catalytic converter con-

nection.

(3) Install and torque the retaining fasteners hold-

ing the crossover pipe to exhaust pipe.

(4) Lower vehicle..

(5) Start engine and check for leaks.

HEAT SHIELDS

DESCRIPTION

Heat shields (Fig. 4) are needed to protect both the

vehicle and the environment from the high tempera-

tures developed by the catalytic converter. The cata-

lytic converter releases additional heat into the

exhaust system. Under severe operating conditions,

the temperature increases in the area of the con-

verter. Such conditions can exist when the engine

misfires or otherwise does not operate at peak effi-

ciency.

MUFFLER

DESCRIPTION

The 2.4L and 3.7L engine uses a galvanized steel

muffler (Fig. 5) to control exhaust noise levels and

exhaust back pressure.

REMOVAL

All original equipment exhaust systems are manu-

factured with the exhaust tailpipe welded to the muf-

fler. Service replacement mufflers and exhaust

tailpipes are either clamped together or welded

together.Fig. 3 Crossover Pipe

1 - Crossover-toCatalytic Converter flange

2 - Crossover Pipe

3 - Crossover Pipe to Tail Pipe Flange

4 - Hanger Bracket

11s - 4 EXHAUST SYSTEMKJ

Page 1387 of 1803

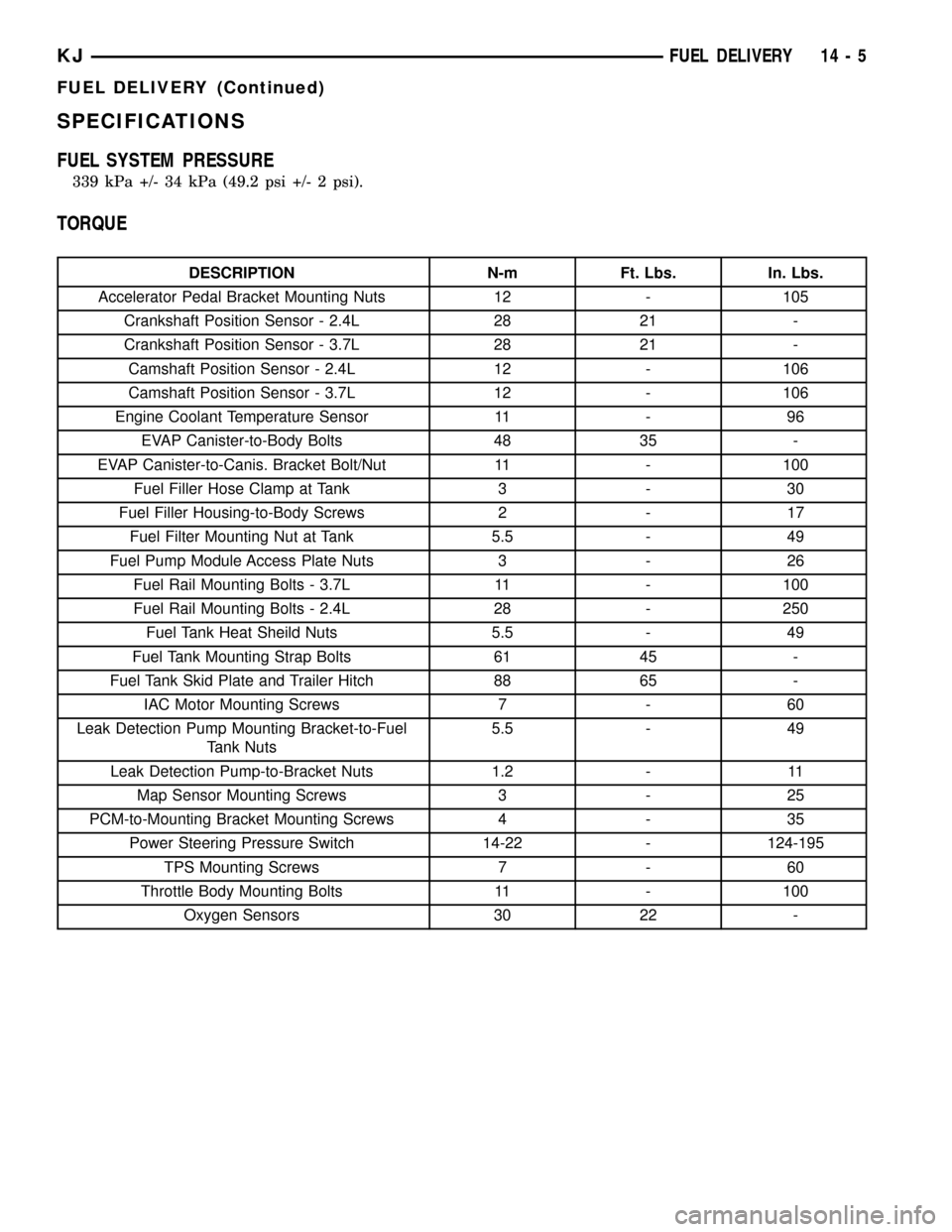

SPECIFICATIONS

FUEL SYSTEM PRESSURE

339 kPa +/- 34 kPa (49.2 psi +/- 2 psi).

TORQUE

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket Mounting Nuts 12 - 105

Crankshaft Position Sensor - 2.4L 28 21 -

Crankshaft Position Sensor - 3.7L 28 21 -

Camshaft Position Sensor - 2.4L 12 - 106

Camshaft Position Sensor - 3.7L 12 - 106

Engine Coolant Temperature Sensor 11 - 96

EVAP Canister-to-Body Bolts 48 35 -

EVAP Canister-to-Canis. Bracket Bolt/Nut 11 - 100

Fuel Filler Hose Clamp at Tank 3 - 30

Fuel Filler Housing-to-Body Screws 2 - 17

Fuel Filter Mounting Nut at Tank 5.5 - 49

Fuel Pump Module Access Plate Nuts 3 - 26

Fuel Rail Mounting Bolts - 3.7L 11 - 100

Fuel Rail Mounting Bolts - 2.4L 28 - 250

Fuel Tank Heat Sheild Nuts 5.5 - 49

Fuel Tank Mounting Strap Bolts 61 45 -

Fuel Tank Skid Plate and Trailer Hitch 88 65 -

IAC Motor Mounting Screws 7 - 60

Leak Detection Pump Mounting Bracket-to-Fuel

Tank Nuts5.5 - 49

Leak Detection Pump-to-Bracket Nuts 1.2 - 11

Map Sensor Mounting Screws 3 - 25

PCM-to-Mounting Bracket Mounting Screws 4 - 35

Power Steering Pressure Switch 14-22 - 124-195

TPS Mounting Screws 7 - 60

Throttle Body Mounting Bolts 11 - 100

Oxygen Sensors 30 22 -

KJFUEL DELIVERY 14 - 5

FUEL DELIVERY (Continued)

Page 1403 of 1803

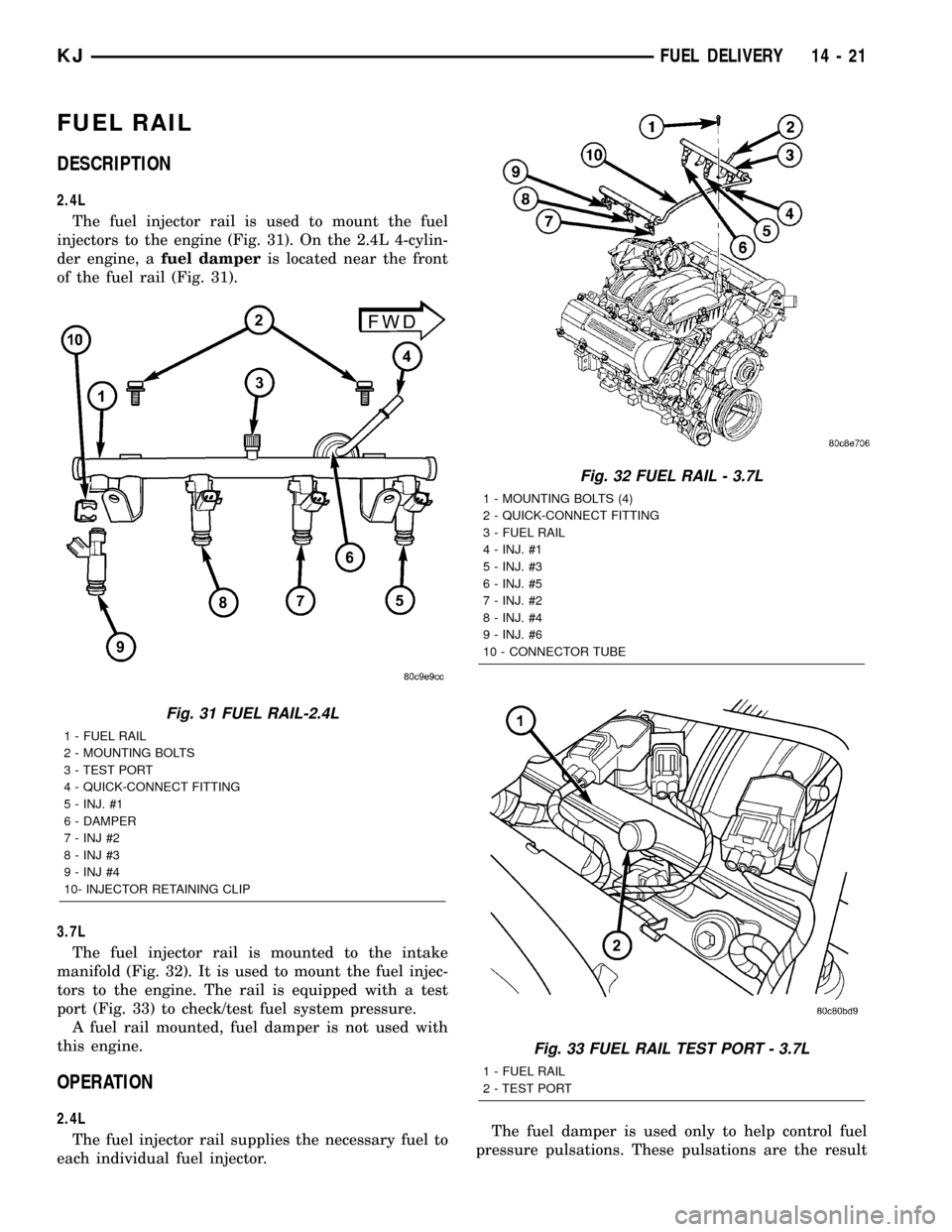

FUEL RAIL

DESCRIPTION

2.4L

The fuel injector rail is used to mount the fuel

injectors to the engine (Fig. 31). On the 2.4L 4-cylin-

der engine, afuel damperis located near the front

of the fuel rail (Fig. 31).

3.7L

The fuel injector rail is mounted to the intake

manifold (Fig. 32). It is used to mount the fuel injec-

tors to the engine. The rail is equipped with a test

port (Fig. 33) to check/test fuel system pressure.

A fuel rail mounted, fuel damper is not used with

this engine.

OPERATION

2.4L

The fuel injector rail supplies the necessary fuel to

each individual fuel injector.The fuel damper is used only to help control fuel

pressure pulsations. These pulsations are the result

Fig. 31 FUEL RAIL-2.4L

1 - FUEL RAIL

2 - MOUNTING BOLTS

3 - TEST PORT

4 - QUICK-CONNECT FITTING

5 - INJ. #1

6 - DAMPER

7 - INJ #2

8 - INJ #3

9 - INJ #4

10- INJECTOR RETAINING CLIP

Fig. 32 FUEL RAIL - 3.7L

1 - MOUNTING BOLTS (4)

2 - QUICK-CONNECT FITTING

3 - FUEL RAIL

4 - INJ. #1

5 - INJ. #3

6 - INJ. #5

7 - INJ. #2

8 - INJ. #4

9 - INJ. #6

10 - CONNECTOR TUBE

Fig. 33 FUEL RAIL TEST PORT - 3.7L

1 - FUEL RAIL

2 - TEST PORT

KJFUEL DELIVERY 14 - 21