Coolant flush JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 266 of 1803

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Mixing of

coolants other than specified (non-HOAT or other

HOAT), may result in engine damage that may not

be covered under the new vehicle warranty, and

decreased corrosion protection.

COOLANT PERFORMANCE

The required ethylene-glycol (antifreeze) and water

mixture depends upon climate and vehicle operating

conditions. The coolant performance of various mix-

tures follows:

Pure Water-Water can absorb more heat than a

mixture of water and ethylene-glycol. This is for pur-

pose of heat transfer only. Water also freezes at a

higher temperature and allows corrosion.

100 percent Ethylene-Glycol-The corrosion

inhibiting additives in ethylene-glycol need the pres-

ence of water to dissolve. Without water, additives

form deposits in system. These act as insulation

causing temperature to rise to as high as 149ÉC

(300ÉF). This temperature is hot enough to melt plas-

tic and soften solder. The increased temperature can

result in engine detonation. In addition, 100 percent

ethylene-glycol freezes at -22ÉC (-8ÉF).

50/50 Ethylene-Glycol and Water-Is the recom-

mended mixture, it provides protection against freez-

ing to -37ÉC (-34ÉF). The antifreeze concentration

must alwaysbe a minimum of 44 percent, year-

round in all climates. If percentage is lower, engine

parts may be eroded by cavitation. Maximum protec-

tion against freezing is provided with a 68 percent

antifreeze concentration, which prevents freezing

down to -67.7ÉC (-90ÉF). A higher percentage will

freeze at a warmer temperature. Also, a higher per-

centage of antifreeze can cause the engine to over-

heat because specific heat of antifreeze is lower than

that of water.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

COOLANT SELECTION AND ADDITIVES

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

corrosion inhibitors called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain to obtain a

freeze point of -37ÉC (-35ÉF). If it loses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed coolant solution.CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

DESCRIPTION - ENGINE COOLANT

ETHYLENE-GLYCOL MIXTURES

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

The required ethylene-glycol (antifreeze) and water

mixture depends upon the climate and vehicle oper-

ating conditions. The recommended mixture of 50/50

ethylene-glycol and water will provide protection

against freezing to -37 deg. C (-35 deg. F). The anti-

freeze concentrationmust alwaysbe a minimum of

44 percent, year-round in all climates.If percentage

is lower than 44 percent, engine parts may be

eroded by cavitation, and cooling system com-

ponents may be severely damaged by corrosion.

Maximum protection against freezing is provided

with a 68 percent antifreeze concentration, which

prevents freezing down to -67.7 deg. C (-90 deg. F). A

higher percentage will freeze at a warmer tempera-

ture. Also, a higher percentage of antifreeze can

cause the engine to overheat because the specific

heat of antifreeze is lower than that of water.

Use of 100 percent ethylene-glycol will cause for-

mation of additive deposits in the system, as the cor-

rosion inhibitive additives in ethylene-glycol require

the presence of water to dissolve. The deposits act as

insulation, causing temperatures to rise to as high as

149 deg. C (300) deg. F). This temperature is hot

enough to melt plastic and soften solder. The

increased temperature can result in engine detona-

tion. In addition, 100 percent ethylene-glycol freezes

at 22 deg. C (-8 deg. F ).

PROPYLENE-GLYCOL MIXTURES

It's overall effective temperature range is smaller

than that of ethylene-glycol. The freeze point of 50/50

propylene-glycol and water is -32 deg. C (-26 deg. F).

5 deg. C higher than ethylene-glycol's freeze point.

The boiling point (protection against summer boil-

over) of propylene-glycol is 125 deg. C (257 deg. F )

at 96.5 kPa (14 psi), compared to 128 deg. C (263

deg. F) for ethylene-glycol. Use of propylene-glycol

can result in boil-over or freeze-up on a cooling sys-

tem designed for ethylene-glycol. Propylene glycol

also has poorer heat transfer characteristics than

ethylene glycol. This can increase cylinder head tem-

peratures under certain conditions.

KJENGINE7s-19

COOLANT (Continued)

Page 271 of 1803

(8) Disconnect the power steering cooler line from

cooler.

(9) Disconnect the radiator upper and lower hoses.

(10) Disconnect the overflow hose from radiator.

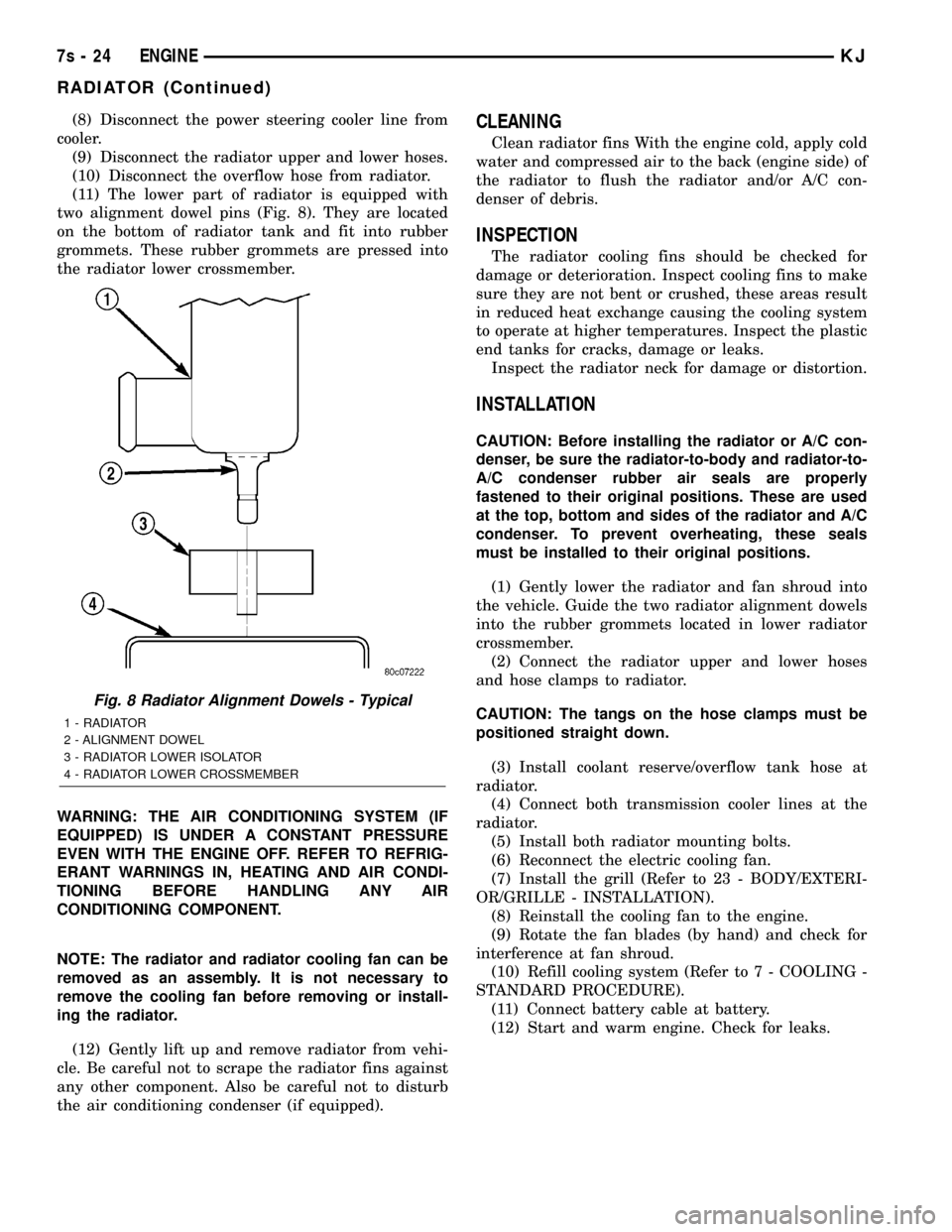

(11) The lower part of radiator is equipped with

two alignment dowel pins (Fig. 8). They are located

on the bottom of radiator tank and fit into rubber

grommets. These rubber grommets are pressed into

the radiator lower crossmember.

WARNING: THE AIR CONDITIONING SYSTEM (IF

EQUIPPED) IS UNDER A CONSTANT PRESSURE

EVEN WITH THE ENGINE OFF. REFER TO REFRIG-

ERANT WARNINGS IN, HEATING AND AIR CONDI-

TIONING BEFORE HANDLING ANY AIR

CONDITIONING COMPONENT.

NOTE: The radiator and radiator cooling fan can be

removed as an assembly. It is not necessary to

remove the cooling fan before removing or install-

ing the radiator.

(12) Gently lift up and remove radiator from vehi-

cle. Be careful not to scrape the radiator fins against

any other component. Also be careful not to disturb

the air conditioning condenser (if equipped).CLEANING

Clean radiator fins With the engine cold, apply cold

water and compressed air to the back (engine side) of

the radiator to flush the radiator and/or A/C con-

denser of debris.

INSPECTION

The radiator cooling fins should be checked for

damage or deterioration. Inspect cooling fins to make

sure they are not bent or crushed, these areas result

in reduced heat exchange causing the cooling system

to operate at higher temperatures. Inspect the plastic

end tanks for cracks, damage or leaks.

Inspect the radiator neck for damage or distortion.

INSTALLATION

CAUTION: Before installing the radiator or A/C con-

denser, be sure the radiator-to-body and radiator-to-

A/C condenser rubber air seals are properly

fastened to their original positions. These are used

at the top, bottom and sides of the radiator and A/C

condenser. To prevent overheating, these seals

must be installed to their original positions.

(1) Gently lower the radiator and fan shroud into

the vehicle. Guide the two radiator alignment dowels

into the rubber grommets located in lower radiator

crossmember.

(2) Connect the radiator upper and lower hoses

and hose clamps to radiator.

CAUTION: The tangs on the hose clamps must be

positioned straight down.

(3) Install coolant reserve/overflow tank hose at

radiator.

(4) Connect both transmission cooler lines at the

radiator.

(5) Install both radiator mounting bolts.

(6) Reconnect the electric cooling fan.

(7) Install the grill (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION).

(8) Reinstall the cooling fan to the engine.

(9) Rotate the fan blades (by hand) and check for

interference at fan shroud.

(10) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Connect battery cable at battery.

(12) Start and warm engine. Check for leaks.

Fig. 8 Radiator Alignment Dowels - Typical

1 - RADIATOR

2 - ALIGNMENT DOWEL

3 - RADIATOR LOWER ISOLATOR

4 - RADIATOR LOWER CROSSMEMBER

7s - 24 ENGINEKJ

RADIATOR (Continued)

Page 1745 of 1803

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-2

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-2

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING..............8M-6

COMPASS MINI-TRIP ILLUMINATION

BULB - INSTALLATION................8L-75

COMPASS MINI-TRIP ILLUMINATION

BULB - REMOVAL....................8L-74

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-3

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-4

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION.......................8M-8

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-5

COMPASS/MINI-TRIP COMPUTER -

REMOVAL...........................8M-7

COMPRESSION PRESSURE - DIAGNOSIS

AND TESTING, CYLINDER................9-8

COMPRESSOR CLUTCH - INSPECTION,

A/C................................24-14

COMPRESSOR CLUTCH - INSTALLATION,

A/C................................24-14

COMPRESSOR CLUTCH - REMOVAL, A/C . . 24-13

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE, A/C...........24-12

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C..........24-12

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C...................24-15

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING.............24-15

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C...................24-16

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C.....................24-15

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C......................24-16

COMPRESSOR NOISE - DIAGNOSIS AND

TESTING, A/C.......................24-42

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP..........................8M-4

COMPUTER - DIAGNOSIS AND TESTING,

COMPASS MINI-TRIP..................8M-6

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP..........................8M-8

COMPUTER - OPERATION, COMPASS/

MINI-TRIP..........................8M-5

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP..........................8M-7

CONDENSER - DESCRIPTION, A/C.......24-45

CONDENSER - INSTALLATION, A/C.......24-46

CONDENSER - OPERATION, A/C.........24-45

CONDENSER - REMOVAL, A/C..........24-45

CONDITIONER - DESCRIPTION, HEATER

AND AIR ............................24-1

CONDITIONER - OPERATION, HEATER

AND AIR ............................24-2

CONDITIONS - DIAGNOSIS AND

TESTING, SPARK PLUG................8I-13

CONNECT FITTING - DESCRIPTION,

QUICK.............................14-10

CONNECTING ROD - DESCRIPTION,

PISTON.............................9-49

CONNECTING ROD BEARING - FITTING -

STANDARD PROCEDURE................9-40

CONNECTING ROD BEARING, FITTING.....9-49

CONNECTOR - DESCRIPTION, DATA LINK . 8E-10

CONNECTOR - INSTALLATION

.......8W-01-11

CONNECTOR - INSTALLATION, TRAILER

TOW

..............................8L-61

CONNECTOR - OPERATION, DATA LINK

. . . 8E-10

CONNECTOR - REMOVAL

...........8W-01-11

CONNECTOR - REMOVAL, TRAILER TOW

. . 8L-61

CONNECTOR, GROUND AND SPLICE

INFORMATION - DESCRIPTION

........8W-01-7

CONNECTOR/GROUND/SPLICE LOCATION

- DESCRIPTION

....................8W-91-1

CONSOLE - DESCRIPTION, OVERHEAD

....8M-1

CONSOLE - INSTALLATION, FLOOR

.....23-158

CONSOLE - OPERATION, OVERHEAD

......8M-2

CONSOLE - REMOVAL, FLOOR

.........23-158

CONSOLE DUCT - INSTALLATION, FLOOR

. 24-31

CONSOLE DUCT - REMOVAL, FLOOR

.....24-31CONSOLE LID LATCH - INSTALLATION,

FLOOR............................23-158

CONSOLE LID LATCH - REMOVAL,

FLOOR............................23-158

CONSOLE, REMOVAL - OVERHEAD.......8M-4

CONTAINER - DESCRIPTION, COOLANT

RECOVERY PRESS....................7-19

CONTAINER - OPERATION, COOLANT

RECOVERY PRESS....................7-19

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID................5-26

CONTAMINATION - DIAGNOSIS AND

TESTING, FLUID....................21-125

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-9

CONTROL - DESCRIPTION, A/C HEATER . . . 24-16

CONTROL - DESCRIPTION, IGNITION......8I-1

CONTROL - DESCRIPTION, SPEED........8P-1

CONTROL - INSTALLATION, A/C HEATER . . 24-17

CONTROL - OPERATION, IGNITION........8I-1

CONTROL - OPERATION, SPEED..........8P-1

CONTROL - REMOVAL, A/C HEATER......24-17

CONTROL - TORQUE, SPEED............8P-2

CONTROL ARM - DESCRIPTION, LOWER . . . 2-21

CONTROL ARM - INSTALLATION, LOWER . . 2-10,

2-21

CONTROL ARM - INSTALLATION, UPPER . . . 2-21

CONTROL ARM - OPERATION, LOWER.....2-21

CONTROL ARM - REMOVAL, LOWER . . 2-10,2-21

CONTROL ARM - REMOVAL, UPPER......2-20

CONTROL ASSEMBLY WINDOW

DEFOGGER FUNCTION - DIAGNOSIS

AND TESTING, REAR HVAC.............8G-9

CONTROL CABLE - INSTALLATION,

THROTTLE..........................14-46

CONTROL CABLE - REMOVAL,

THROTTLE..........................14-45

CONTROL ILLUMINATION BULB -

INSTALLATION, HEATER-A/C............8L-78

CONTROL ILLUMINATION BULB -

REMOVAL, HEATER-A/C...............8L-78

CONTROL INFORMATION (VECI) LABEL -

DESCRIPTION, VEHICLE EMISSION.....Intro.-8

CONTROL MODULE - DESCRIPTION,

AIRBAG.............................8O-9

CONTROL MODULE - DESCRIPTION,

BODY...............................8E-2

CONTROL MODULE - DESCRIPTION,

SIDE IMPACT AIRBAG.................8O-43

CONTROL MODULE - DESCRIPTION,

TRANSMISSION......................8E-18

CONTROL MODULE - DIAGNOSIS AND

TESTING, BODY.......................8E-7

CONTROL MODULE - INSTALLATION....23-183

CONTROL MODULE - INSTALLATION,

AIRBAG............................8O-12

CONTROL MODULE - INSTALLATION,

BODY...............................8E-7

CONTROL MODULE - INSTALLATION,

SIDE IMPACT AIRBAG.................8O-45

CONTROL MODULE - OPERATION,

AIRBAG............................8O-10

CONTROL MODULE - OPERATION, BODY . . . 8E-5

CONTROL MODULE - OPERATION, SIDE

IMPACT AIRBAG.....................8O-43

CONTROL MODULE - OPERATION,

TRANSMISSION......................8E-18

CONTROL MODULE - REMOVAL........23-183

CONTROL MODULE - REMOVAL, AIRBAG . 8O-11

CONTROL MODULE - REMOVAL, BODY....8E-7

CONTROL MODULE - REMOVAL, SIDE

IMPACT AIRBAG.....................8O-44

CONTROL MOTOR - DESCRIPTION, IDLE

AIR ...............................14-35

CONTROL MOTOR - INSTALLATION, IDLE

AIR ...............................14-36

CONTROL MOTOR - OPERATION, IDLE

AIR ...............................14-35

CONTROL MOTOR - REMOVAL, IDLE AIR . . 14-36

CONTROL RELAY - DESCRIPTION,

TRANSMISSION.....................21-168

CONTROL RELAY - OPERATION,

TRANSMISSION

.....................21-168

CONTROL SWITCH - DESCRIPTION

.....23-184

CONTROL SWITCH - DIAGNOSIS AND

TESTING

..........................23-184

CONTROL SWITCH - INSTALLATION

.....23-184

CONTROL SWITCH - OPERATION

.......23-184CONTROL SWITCH - REMOVAL........23-184

CONTROL SYSTEM - DESCRIPTION,

EMISSION...........................25-1

CONTROL SYSTEM - DESCRIPTION,

EVAPORATION.......................25-24

CONTROLLER ANTILOCK BRAKE -

INSTALLATION.......................8E-10

CONTROLLER ANTILOCK BRAKE -

REMOVAL..........................8E-10

CONVERTER - DESCRIPTION, CATALYTIC . . . 11-2

CONVERTER - DESCRIPTION, TORQUE . . . 21-162

CONVERTER - INSPECTION, CATALYTIC....11-3

CONVERTER - INSTALLATION, CATALYTIC . . 11-3

CONVERTER - INSTALLATION, TORQUE . . 21-167

CONVERTER - OPERATION, TORQUE....21-166

CONVERTER - REMOVAL, CATALYTIC......11-2

CONVERTER - REMOVAL, TORQUE......21-167

CONVERTER HOUSING FLUID LEAK -

DIAGNOSIS AND TESTING.............21-80

COOLANT - DESCRIPTION, ENGINE........0-3

COOLANT LOW INDICATOR -

DESCRIPTION.......................8J-15

COOLANT LOW INDICATOR - OPERATION . 8J-16

COOLANT RECOVERY PRESS

CONTAINER - DESCRIPTION.............7-19

COOLANT RECOVERY PRESS

CONTAINER - OPERATION...............7-19

COOLANT TEMPERATURE SENSOR -

DESCRIPTION, ENGINE.................7-19

COOLANT TEMPERATURE SENSOR -

INSTALLATION, ENGINE................7-21

COOLANT TEMPERATURE SENSOR -

OPERATION, ENGINE...................7-20

COOLANT TEMPERATURE SENSOR -

REMOVAL, ENGINE....................7-20

COOLANT THERMOSTAT - OPERATION,

ENGINE.............................7-21

COOLER - DESCRIPTION, FLUID.........19-20

COOLER - DESCRIPTION, TRANS.........7-32

COOLER - INSTALLATION, FLUID........19-20

COOLER - OPERATION, FLUID..........19-20

COOLER - REMOVAL, FLUID............19-20

COOLING, SPECIAL TOOLS..............7-14

COOLING SYSTEM - OPERATION..........7-2

COOLING SYSTEM - REVERSE

FLUSHING - STANDARD PROCEDURE.....7-12

COOLING SYSTEM 3.7L ENGINE -

DESCRIPTION.........................7-1

COOLING SYSTEM 3.7L ENGINE -

STANDARD PROCEDURE, DRAINING......7-12

COOLING SYSTEM 3.7L ENGINE -

STANDARD PROCEDURE, REFILLING......7-12

COOLING SYSTEM DIAGNOSIS CHART -

DIAGNOSIS AND TESTING...............7-6

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING.........................7-4

COOLING SYSTEM REQUIREMENTS -

DESCRIPTION........................24-1

COOLING SYSTEM ROUTING 3.7L

ENGINE - DESCRIPTION.................7-2

CORE - DESCRIPTION, HEATER.........24-52

CORE - INSTALLATION, HEATER.........24-53

CORE - OPERATION, HEATER...........24-52

CORE - REMOVAL, HEATER............24-52

CORE AND OIL GALLERY PLUGS -

STANDARD PROCEDURE, ENGINE........9-10

COURTESY LAMP BULB - INSTALLATION . . 8L-76

COURTESY LAMP BULB - REMOVAL.....8L-75

COURTESY LAMP REPLACEMENT -

STANDARD PROCEDURE...............8M-2

COURTESY LAMP UNIT - INSTALLATION . . 8L-77

COURTESY LAMP UNIT - REMOVAL......8L-76

COVER - DESCRIPTION, STRUCTURAL.....9-55

COVER - FRONT - INSTALLATION, SEAT

BACK.............................23-167

COVER - FRONT - INSTALLATION, SEAT

CUSHION..........................23-167

COVER - FRONT - REMOVAL, SEAT BACK . 23-166

COVER - FRONT - REMOVAL, SEAT

CUSHION..........................23-167

COVER - INSTALLATION, COWL TRIM . . . 23-157

COVER - INSTALLATION, INSTRUMENT

PANEL TOP

........................23-153

COVER - INSTALLATION, STRUCTURAL

....9-55

COVER - OPERATION, STRUCTURAL

......9-55

COVER - REAR - INSTALLATION, SEAT

BACK

.............................23-169

COVER - REAR - REMOVAL, SEAT BACK

. 23-169

6 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1771 of 1803

COOLANT TEMPERATURE SENSOR -

OPERATION, ENGINE...................7-21

COOLANT TEMPERATURE SENSOR -

REMOVAL, ENGINE....................7-21

COOLER - DESCRIPTION, TRANS.........7-30

COOLERS AND TUBES - STANDARD

PROCEDURE, FLUSHING................7-30

COOLING, SPECIAL TOOLS..............7-13

COOLING SYSTEM - OPERATION..........7-2

COOLING SYSTEM - REVERSE

FLUSHING - STANDARD PROCEDURE.....7-12

COOLING SYSTEM - STANDARD

PROCEDURE, DRAINING................7-11

COOLING SYSTEM - STANDARD

PROCEDURE, REFILLING................7-11

COOLING SYSTEM 2.4L ENGINE -

DESCRIPTION.........................7-1

COOLING SYSTEM DIAGNOSIS CHART -

DIAGNOSIS AND TESTING...............7-5

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING.........................7-2

CORE AND OIL GALLERY PLUGS -

STANDARD PROCEDURE, ENGINE.........9-9

COVER - CLEANING, CYLINDER HEAD.....9-26

COVER - INSPECTION, CYLINDER HEAD . . . 9-26

COVER - INSTALLATION, CYLINDER

HEAD...............................9-26

COVER - REMOVAL, CYLINDER HEAD.....9-26

COVER(S) - INSTALLATION, TIMING

BELT ...............................9-53

COVER(S) - REMOVAL, TIMING BELT......9-53

CRANKSHAFT - DESCRIPTION...........9-32

CRANKSHAFT - INSPECTION.............9-34

CRANKSHAFT - INSTALLATION...........9-34

CRANKSHAFT - OPERATION.............9-33

CRANKSHAFT - REMOVAL..............9-33

CRANKSHAFT END PLAY - STANDARD

PROCEDURE.........................9-33

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION........................9-37

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL...........................9-37

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION........................9-39

CRANKSHAFT OIL SEAL - REAR -

REMOVAL...........................9-38

CRANKSHAFT SPROCKET -

INSTALLATION........................9-56

CRANKSHAFT SPROCKET - REMOVAL.....9-55

CROSS-OVER PIPE - INSTALLATION.......11-4

CROSS-OVER PIPE - REMOVAL..........11-4

CYLINDER BORE FITTING - STANDARD

PROCEDURE, PISTON TO...............9-30

CYLINDER BORE HONING - STANDARD

PROCEDURE.........................9-31

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST - DIAGNOSIS AND

TESTING.............................9-3

CYLINDER COMPRESSION PRESSURE

TEST - DIAGNOSIS AND TESTING.........9-3

CYLINDER HEAD - CLEANING............9-20

CYLINDER HEAD - DESCRIPTION.........9-19

CYLINDER HEAD - INSPECTION..........9-21

CYLINDER HEAD - INSTALLATION........9-21

CYLINDER HEAD - OPERATION...........9-19

CYLINDER HEAD - REMOVAL............9-20

CYLINDER HEAD COVER - CLEANING......9-26

CYLINDER HEAD COVER - INSPECTION....9-26

CYLINDER HEAD COVER -

INSTALLATION

........................9-26

CYLINDER HEAD COVER - REMOVAL

......9-26

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING

........................9-19

CYLINDER HEAD OFF - INSTALLATION

.....9-28

CYLINDER HEAD OFF - REMOVAL

........9-27

CYLINDER HEAD ON - INSTALLATION

.....9-28

CYLINDER HEAD ON - REMOVAL

.........9-27

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR OF

.......9-9

DAMPER - INSTALLATION, VIBRATION

.....9-43

DAMPER - REMOVAL, VIBRATION

........9-43

DAYTIME RUNNING LAMP RELAY -

DESCRIPTION

.......................8L-20

DAYTIME RUNNING LAMP RELAY -

INSTALLATION

.......................8L-21

DAYTIME RUNNING LAMP RELAY -

OPERATION

.........................8L-20DAYTIME RUNNING LAMP RELAY -

REMOVAL..........................8L-21

DESCRIPTION - OPERATION.............7-20

DESCRIPTION, BACKUP LAMP SWITCH . . . 8L-15

DESCRIPTION, BALANCE SHAFT..........9-59

DESCRIPTION, BRAKE LAMP SWITCH....8L-16

DESCRIPTION, CAMSHAFT(S)............9-23

DESCRIPTION, CATALYTIC CONVERTER....11-2

DESCRIPTION, COMBINATION FLASHER . . . 8L-19

DESCRIPTION, COOLANT RECOVERY

PRESS CONTAINER....................7-20

DESCRIPTION, COOLING SYSTEM 2.4L

ENGINE..............................7-1

DESCRIPTION, CRANKSHAFT............9-32

DESCRIPTION, CYLINDER HEAD..........9-19

DESCRIPTION, DAYTIME RUNNING

LAMP RELAY........................8L-20

DESCRIPTION, ENGINE - 2.4L.............9-3

DESCRIPTION, ENGINE BLOCK...........9-30

DESCRIPTION, ENGINE BLOCK HEATER -

2.4L................................7-20

DESCRIPTION, ENGINE COOLANT.........7-19

DESCRIPTION, ENGINE COOLANT

TEMPERATURE SENSOR................7-21

DESCRIPTION, ENGINE MOUNTING.......9-44

DESCRIPTION, EXHAUST MANIFOLD......9-53

DESCRIPTION, EXHAUST SYSTEM........11-1

DESCRIPTION, FRONT FOG LAMP RELAY . . 8L-22

DESCRIPTION, HAZARD SWITCH........8L-28

DESCRIPTION, HEADLAMP HIGH BEAM

RELAY.............................8L-33

DESCRIPTION, HEADLAMP LEVELING

MOTOR............................8L-35

DESCRIPTION, HEADLAMP LEVELING

SWITCH............................8L-37

DESCRIPTION, HEADLAMP LOW BEAM

RELAY.............................8L-39

DESCRIPTION, HEAT SHIELDS...........11-4

DESCRIPTION, HOAT COOLANT..........7-18

DESCRIPTION, HOSE CLAMPS............7-1

DESCRIPTION, INTAKE MANIFOLD........9-51

DESCRIPTION, INTAKE/EXHAUST VALVES

& SEATS ............................9-27

DESCRIPTION, LAMP BAR.............8L-65

DESCRIPTION, LAMP BAR SWITCH......8L-67

DESCRIPTION, LAMPS/LIGHTING -

EXTERIOR...........................8L-2

DESCRIPTION, LUBRICATION............9-46

DESCRIPTION, MUFFLER...............11-4

DESCRIPTION, MULTI-FUNCTION

SWITCH............................8L-46

DESCRIPTION, OIL FILTER..............9-47

DESCRIPTION, OIL PRESSURE

SENSOR/SWITCH.....................9-48

DESCRIPTION, PARK LAMP RELAY.......8L-54

DESCRIPTION, PISTON & CONNECTING

ROD................................9-40

DESCRIPTION, RADIATOR...............7-22

DESCRIPTION, RADIATOR FAN -

ELECTRIC...........................7-26

DESCRIPTION, RADIATOR PRESSURE

CAP ................................7-25

DESCRIPTION, REAR FOG LAMP RELAY . . . 8L-56

DESCRIPTION, TRAILER TOW RELAY.....8L-62

DESCRIPTION, TRAILER TOW WIRING....8L-64

DESCRIPTION, TRANS COOLER..........7-30

DESCRIPTION, WATER PUMP - 2.4L......7-27

DIAGNOSIS - DIAGNOSIS AND TESTING,

LASH ADJUSTER (TAPPET) NOISE........9-28

DIAGNOSIS - DIAGNOSIS AND TESTING,

SERPENTINE DRIVE BELT...............7-15

DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING, ENGINE........9-5

DIAGNOSIS AND TESTING, BACKUP

LAMP SWITCH......................8L-15

DIAGNOSIS AND TESTING, BRAKE LAMP

SWITCH............................8L-17

DIAGNOSIS AND TESTING, COOLING

SYSTEM DIAGNOSIS CHART

..............7-5

DIAGNOSIS AND TESTING, COOLING

SYSTEM LEAKS

........................7-2

DIAGNOSIS AND TESTING, CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST

................................9-3

DIAGNOSIS AND TESTING, CYLINDER

COMPRESSION PRESSURE TEST

..........9-3

DIAGNOSIS AND TESTING, CYLINDER

HEAD GASKET

........................9-19DIAGNOSIS AND TESTING, ENGINE........9-5

DIAGNOSIS AND TESTING, ENGINE

DIAGNOSIS - PERFORMANCE.............9-5

DIAGNOSIS AND TESTING, ENGINE

MECHANICAL.........................9-7

DIAGNOSIS AND TESTING, ENGINE OIL

LEAK INSPECTION......................9-4

DIAGNOSIS AND TESTING, ENGINE OIL

PRESSURE CHECKING.................9-46

DIAGNOSIS AND TESTING, EXHAUST

SYSTEM............................11-2

DIAGNOSIS AND TESTING, FRONT FOG

LAMP RELAY........................8L-23

DIAGNOSIS AND TESTING, HEADLAMP

HIGH BEAM RELAY...................8L-34

DIAGNOSIS AND TESTING, HEADLAMP

LEVELING SWITCH...................8L-37

DIAGNOSIS AND TESTING, HEADLAMP

LOW BEAM RELAY...................8L-40

DIAGNOSIS AND TESTING, INTAKE

MANIFOLD LEAKS.....................9-51

DIAGNOSIS AND TESTING, LAMP BAR....8L-65

DIAGNOSIS AND TESTING, LAMPS/

LIGHTING - EXTERIOR.................8L-7

DIAGNOSIS AND TESTING, LASH

ADJUSTER (TAPPET) NOISE

DIAGNOSIS..........................9-28

DIAGNOSIS AND TESTING, MULTI-

FUNCTION SWITCH...................8L-50

DIAGNOSIS AND TESTING, ON-BOARD

DIAGNOSTICS (OBD)....................7-2

DIAGNOSIS AND TESTING, PARK LAMP

RELAY.............................8L-55

DIAGNOSIS AND TESTING,

PRELIMINARY CHECKS..................7-2

DIAGNOSIS AND TESTING, RADIATOR

PRESSURE CAP.......................7-25

DIAGNOSIS AND TESTING, REAR FOG

LAMP RELAY........................8L-57

DIAGNOSIS AND TESTING, SERPENTINE

DRIVE BELT DIAGNOSIS................7-15

DIAGNOSIS AND TESTING, TRAILER

TOW RELAY.........................8L-62

DIAGNOSIS CHART - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-5

DIAGNOSTICS (OBD) - DIAGNOSIS AND

TESTING, ON-BOARD...................7-2

DISASSEMBLY, OIL PUMP...............9-49

DRAINING COOLING SYSTEM -

STANDARD PROCEDURE................7-11

DRIVE BELT DIAGNOSIS - DIAGNOSIS

AND TESTING, SERPENTINE.............7-15

ELECTRIC - DESCRIPTION, RADIATOR

FAN ................................7-26

ELECTRIC - INSTALLATION, RADIATOR

FAN ................................7-27

ELECTRIC - OPERATION, RADIATOR FAN . . . 7-26

ELECTRIC - REMOVAL, RADIATOR FAN....7-26

END PLAY - STANDARD PROCEDURE,

CRANKSHAFT........................9-33

END-PLAY - STANDARD PROCEDURE,

CAMSHAFT..........................9-23

ENGINE - 2.4L - DESCRIPTION............9-3

ENGINE - DESCRIPTION, COOLING

SYSTEM 2.4L.........................7-1

ENGINE - DIAGNOSIS AND TESTING.......9-5

ENGINE - INSTALLATION, 2.4L . . 7-14,7-17,7-22,

7-28

ENGINE - REMOVAL, 2.4L . . . 7-14,7-16,7-22,7-27

ENGINE - SPECIFICATIONS, 2.4L.........9-13

ENGINE - STANDARD PROCEDURE,

HYDROSTATIC LOCKED..................9-9

ENGINE ASSEMBLY - INSTALLATION......9-12

ENGINE ASSEMBLY - REMOVAL..........9-12

ENGINE BLOCK - DESCRIPTION..........9-30

ENGINE BLOCK HEATER - 2.4L -

DESCRIPTION........................7-20

ENGINE BLOCK HEATER - 2.4L -

OPERATION..........................7-20

ENGINE COOLANT - DESCRIPTION

........7-19

ENGINE COOLANT TEMPERATURE

SENSOR - DESCRIPTION

...............7-21

ENGINE COOLANT TEMPERATURE

SENSOR - INSTALLATION

...............7-22

ENGINE COOLANT TEMPERATURE

SENSOR - OPERATION

.................7-21

ENGINE COOLANT TEMPERATURE

SENSOR - REMOVAL

...................7-21

2 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1772 of 1803

ENGINE CORE AND OIL GALLERY PLUGS

- STANDARD PROCEDURE...............9-9

ENGINE DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING...............9-5

ENGINE GASKET SURFACE

PREPARATION - STANDARD

PROCEDURE.........................9-11

ENGINE MECHANICAL - DIAGNOSIS AND

TESTING.............................9-7

ENGINE MOUNTING - DESCRIPTION......9-44

ENGINE OIL AND FILTER CHANGE -

STANDARD PROCEDURE................9-47

ENGINE OIL LEAK INSPECTION -

DIAGNOSIS AND TESTING...............9-4

ENGINE OIL LEVEL CHECK, STANDARD

PROCEDURE.........................9-47

ENGINE OIL PRESSURE CHECKING -

DIAGNOSIS AND TESTING..............9-46

ENGINE, SPECIAL TOOLS - 2.4L..........9-17

EXHAUST MANIFOLD - CLEANING........9-53

EXHAUST MANIFOLD - DESCRIPTION.....9-53

EXHAUST MANIFOLD - INSPECTION.......9-53

EXHAUST MANIFOLD - INSTALLATION.....9-53

EXHAUST MANIFOLD - OPERATION.......9-53

EXHAUST MANIFOLD - REMOVAL.........9-53

EXHAUST SYSTEM - DESCRIPTION.......11-1

EXHAUST SYSTEM - DIAGNOSIS AND

TESTING............................11-2

EXTERIOR - DESCRIPTION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR - DIAGNOSIS AND TESTING,

LAMPS/LIGHTING.....................8L-7

EXTERIOR - OPERATION, LAMPS/

LIGHTING...........................8L-5

EXTERIOR - SPECIFICATIONS,

LAMPS/LIGHTING....................8L-15

FAN - ELECTRIC - DESCRIPTION,

RADIATOR...........................7-26

FAN - ELECTRIC - INSTALLATION,

RADIATOR...........................7-27

FAN - ELECTRIC - OPERATION,

RADIATOR...........................7-26

FAN - ELECTRIC - REMOVAL, RADIATOR . . . 7-26

FILTER - DESCRIPTION, OIL.............9-47

FILTER - INSTALLATION, OIL............9-47

FILTER - REMOVAL, OIL................9-47

FILTER CHANGE - STANDARD

PROCEDURE, ENGINE OIL...............9-47

FITTING - CONNECTING ROD............9-32

FITTING - PISTON RING................9-42

FITTING - STANDARD PROCEDURE,

MAIN BEARING.......................9-35

FITTING - STANDARD PROCEDURE,

PISTON TO CYLINDER BORE............9-30

FLASHER - DESCRIPTION, COMBINATION . 8L-19

FLASHER - OPERATION, COMBINATION . . . 8L-19

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM - REVERSE...........7-12

FLUSHING COOLERS AND TUBES -

STANDARD PROCEDURE................7-30

FOG LAMP BULB - INSTALLATION,

FRONT.............................8L-22

FOG LAMP BULB - REMOVAL, FRONT....8L-21

FOG LAMP RELAY - DESCRIPTION,

FRONT.............................8L-22

FOG LAMP RELAY - DESCRIPTION, REAR . 8L-56

FOG LAMP RELAY - DIAGNOSIS AND

TESTING, FRONT.....................8L-23

FOG LAMP RELAY - DIAGNOSIS AND

TESTING, REAR......................8L-57

FOG LAMP RELAY - INSTALLATION,

FRONT.............................8L-24

FOG LAMP RELAY - INSTALLATION,

REAR..............................8L-58

FOG LAMP RELAY - OPERATION, FRONT . . 8L-22

FOG LAMP RELAY - OPERATION, REAR . . . 8L-57

FOG LAMP RELAY - REMOVAL, FRONT . . . 8L-24

FOG LAMP RELAY - REMOVAL, REAR....8L-58

FOG LAMP UNIT - ADJUSTMENT, FRONT . . 8L-25

FOG LAMP UNIT - INSTALLATION,

FRONT

.............................8L-25

FOG LAMP UNIT - REMOVAL, FRONT

.....8L-24

FORM-IN-PLACE GASKETS AND

SEALERS - STANDARD PROCEDURE

......9-10

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL

............................9-37

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL

...............................9-37FRONT FOG LAMP BULB -

INSTALLATION.......................8L-22

FRONT FOG LAMP BULB - REMOVAL.....8L-21

FRONT FOG LAMP RELAY -

DESCRIPTION.......................8L-22

FRONT FOG LAMP RELAY - DIAGNOSIS

AND TESTING.......................8L-23

FRONT FOG LAMP RELAY -

INSTALLATION.......................8L-24

FRONT FOG LAMP RELAY - OPERATION . . 8L-22

FRONT FOG LAMP RELAY - REMOVAL....8L-24

FRONT FOG LAMP UNIT - ADJUSTMENT . . 8L-25

FRONT FOG LAMP UNIT - INSTALLATION . . 8L-25

FRONT FOG LAMP UNIT - REMOVAL.....8L-24

FRONT LAMP BULB - INSTALLATION.....8L-27

FRONT LAMP BULB - REMOVAL.........8L-27

FRONT LAMP UNIT - INSTALLATION.....8L-28

FRONT LAMP UNIT - REMOVAL.........8L-27

FRONT MOUNT - INSTALLATION..........9-44

FRONT MOUNT - REMOVAL.............9-44

FRONT POSITION LAMP BULB -

INSTALLATION.......................8L-28

FRONT POSITION LAMP BULB -

REMOVAL..........................8L-28

FRONT SUSPENSION, SPECIAL TOOLS.....2-1

GALLERY PLUGS - STANDARD

PROCEDURE, ENGINE CORE AND OIL......9-9

GASKET - DIAGNOSIS AND TESTING,

CYLINDER HEAD......................9-19

GASKET SURFACE PREPARATION -

STANDARD PROCEDURE, ENGINE........9-11

GASKETS AND SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE...........9-10

HAZARD SWITCH - DESCRIPTION.......8L-28

HAZARD SWITCH - INSTALLATION.......8L-30

HAZARD SWITCH - OPERATION.........8L-29

HAZARD SWITCH - REMOVAL..........8L-29

HEAD - CLEANING, CYLINDER...........9-20

HEAD - DESCRIPTION, CYLINDER........9-19

HEAD - INSPECTION, CYLINDER..........9-21

HEAD - INSTALLATION, CYLINDER........9-21

HEAD - OPERATION, CYLINDER..........9-19

HEAD - REMOVAL, CYLINDER...........9-20

HEAD COVER - CLEANING, CYLINDER.....9-26

HEAD COVER - INSPECTION, CYLINDER . . . 9-26

HEAD COVER - INSTALLATION,

CYLINDER...........................9-26

HEAD COVER - REMOVAL, CYLINDER.....9-26

HEAD GASKET - DIAGNOSIS AND

TESTING, CYLINDER...................9-19

HEAD OFF - INSTALLATION, CYLINDER....9-28

HEAD OFF - REMOVAL, CYLINDER........9-27

HEAD ON - INSTALLATION, CYLINDER.....9-28

HEAD ON - REMOVAL, CYLINDER........9-27

HEADLAMP BULB - INSTALLATION.......8L-32

HEADLAMP BULB - REMOVAL..........8L-30

HEADLAMP HIGH BEAM RELAY -

DESCRIPTION.......................8L-33

HEADLAMP HIGH BEAM RELAY -

DIAGNOSIS AND TESTING.............8L-34

HEADLAMP HIGH BEAM RELAY -

INSTALLATION.......................8L-35

HEADLAMP HIGH BEAM RELAY -

OPERATION.........................8L-33

HEADLAMP HIGH BEAM RELAY -

REMOVAL..........................8L-34

HEADLAMP LEVELING MOTOR -

DESCRIPTION.......................8L-35

HEADLAMP LEVELING MOTOR -

INSTALLATION.......................8L-36

HEADLAMP LEVELING MOTOR -

OPERATION.........................8L-36

HEADLAMP LEVELING MOTOR -

REMOVAL..........................8L-36

HEADLAMP LEVELING SWITCH -

DESCRIPTION.......................8L-37

HEADLAMP LEVELING SWITCH -

DIAGNOSIS AND TESTING.............8L-37

HEADLAMP LEVELING SWITCH -

INSTALLATION

.......................8L-38

HEADLAMP LEVELING SWITCH -

OPERATION

.........................8L-37

HEADLAMP LEVELING SWITCH -

REMOVAL

..........................8L-38

HEADLAMP LOW BEAM RELAY -

DESCRIPTION

.......................8L-39

HEADLAMP LOW BEAM RELAY -

DIAGNOSIS AND TESTING

.............8L-40HEADLAMP LOW BEAM RELAY -

INSTALLATION.......................8L-41

HEADLAMP LOW BEAM RELAY -

OPERATION.........................8L-39

HEADLAMP LOW BEAM RELAY -

REMOVAL..........................8L-40

HEADLAMP UNIT - ADJUSTMENT........8L-42

HEADLAMP UNIT - INSTALLATION.......8L-42

HEADLAMP UNIT - REMOVAL...........8L-41

HEAT SHIELDS - DESCRIPTION..........11-4

HEATER - 2.4L - DESCRIPTION, ENGINE

BLOCK..............................7-20

HEATER - 2.4L - OPERATION, ENGINE

BLOCK..............................7-20

HIGH BEAM RELAY - DESCRIPTION,

HEADLAMP.........................8L-33

HIGH BEAM RELAY - DIAGNOSIS AND

TESTING, HEADLAMP.................8L-34

HIGH BEAM RELAY - INSTALLATION,

HEADLAMP.........................8L-35

HIGH BEAM RELAY - OPERATION,

HEADLAMP.........................8L-33

HIGH BEAM RELAY - REMOVAL,

HEADLAMP.........................8L-34

HIGH MOUNTED STOP LAMP BULB -

INSTALLATION, CENTER...............8L-19

HIGH MOUNTED STOP LAMP BULB -

REMOVAL, CENTER...................8L-18

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER...............8L-19

HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER...................8L-19

HOAT COOLANT - DESCRIPTION..........7-18

HONING - STANDARD PROCEDURE,

CYLINDER BORE......................9-31

HOSE CLAMPS - DESCRIPTION...........7-1

HOSE CLAMPS - OPERATION.............7-2

HYDRAULIC LIFTERS - INSTALLATION.....9-29

HYDRAULIC LIFTERS - REMOVAL.........9-29

HYDROSTATIC LOCKED ENGINE -

STANDARD PROCEDURE.................9-9

INSPECTION - DIAGNOSIS AND

TESTING, ENGINE OIL LEAK..............9-4

INSPECTION, CAMSHAFT(S).............9-25

INSPECTION, CATALYTIC CONVERTER.....11-3

INSPECTION, CRANKSHAFT.............9-34

INSPECTION, CYLINDER HEAD...........9-21

INSPECTION, CYLINDER HEAD COVER.....9-26

INSPECTION, EXHAUST MANIFOLD.......9-53

INSPECTION, INTAKE MANIFOLD.........9-52

INSPECTION, OIL PUMP................9-50

INSPECTION, RADIATOR................7-24

INSPECTION, RADIATOR PRESSURE CAP . . . 7-25

INSPECTION, REMOVAL................9-28

INSPECTION, ROCKER ARMS............9-30

INSPECTION, STANDARD PROCEDURE.....9-32

INSPECTION, WATER PUMP - 2.4L........7-28

INSTALLATION - BALANCE SHAFT

TIMING.............................9-61

INSTALLATION, 2.4L...................7-20

INSTALLATION, 2.4L...................9-19

INSTALLATION, 2.4L ENGINE....7-14,7-17,7-22,

7-28

INSTALLATION, BALANCE SHAFT

CARRIER............................9-64

INSTALLATION, BALANCE SHAFT CHAIN . . . 9-64

INSTALLATION, BRAKE LAMP SWITCH....8L-18

INSTALLATION, CAMSHAFT OIL SEAL(S) . . . 9-22

INSTALLATION, CAMSHAFT(S)...........9-25

INSTALLATION, CATALYTIC CONVERTER

....11-3

INSTALLATION, CENTER HIGH MOUNTED

STOP LAMP BULB

....................8L-19

INSTALLATION, CENTER HIGH MOUNTED

STOP LAMP UNIT

....................8L-19

INSTALLATION, CLEVIS BRACKET

BUSHING

.............................2-4

INSTALLATION, CRANKSHAFT

............9-34

INSTALLATION, CRANKSHAFT OIL SEAL -

FRONT

..............................9-37

INSTALLATION, CRANKSHAFT OIL SEAL -

REAR

...............................9-39

INSTALLATION, CRANKSHAFT SPROCKET

. . 9-56

INSTALLATION, CROSS-OVER PIPE

.......11-4

INSTALLATION, CYLINDER HEAD

.........9-21

INSTALLATION, CYLINDER HEAD COVER

. . . 9-26

INSTALLATION, CYLINDER HEAD OFF

......9-28

INSTALLATION, CYLINDER HEAD ON

......9-28

KJINDEX 3

Description Group-Page Description Group-Page Description Group-Page

Page 1775 of 1803

RELAY - DIAGNOSIS AND TESTING,

FRONT FOG LAMP....................8L-23

RELAY - DIAGNOSIS AND TESTING,

HEADLAMP HIGH BEAM...............8L-34

RELAY - DIAGNOSIS AND TESTING,

HEADLAMP LOW BEAM...............8L-40

RELAY - DIAGNOSIS AND TESTING,

PARK LAMP.........................8L-55

RELAY - DIAGNOSIS AND TESTING,

REAR FOG LAMP.....................8L-57

RELAY - DIAGNOSIS AND TESTING,

TRAILER TOW.......................8L-62

RELAY - INSTALLATION, DAYTIME

RUNNING LAMP.....................8L-21

RELAY - INSTALLATION, FRONT FOG

LAMP..............................8L-24

RELAY - INSTALLATION, HEADLAMP

HIGH BEAM.........................8L-35

RELAY - INSTALLATION, HEADLAMP

LOW BEAM.........................8L-41

RELAY - INSTALLATION, PARK LAMP.....8L-56

RELAY - INSTALLATION, REAR FOG

LAMP..............................8L-58

RELAY - INSTALLATION, TRAILER TOW . . . 8L-63

RELAY - OPERATION, DAYTIME

RUNNING LAMP.....................8L-20

RELAY - OPERATION, FRONT FOG LAMP . . 8L-22

RELAY - OPERATION, HEADLAMP HIGH

BEAM..............................8L-33

RELAY - OPERATION, HEADLAMP LOW

BEAM..............................8L-39

RELAY - OPERATION, PARK LAMP.......8L-54

RELAY - OPERATION, REAR FOG LAMP . . . 8L-57

RELAY - OPERATION, TRAILER TOW.....8L-62

RELAY - REMOVAL, DAYTIME RUNNING

LAMP..............................8L-21

RELAY - REMOVAL, FRONT FOG LAMP . . . 8L-24

RELAY - REMOVAL, HEADLAMP HIGH

BEAM..............................8L-34

RELAY - REMOVAL, HEADLAMP LOW

BEAM..............................8L-40

RELAY - REMOVAL, PARK LAMP........8L-55

RELAY - REMOVAL, REAR FOG LAMP....8L-58

RELAY - REMOVAL, TRAILER TOW.......8L-63

REMOVAL - CLEANING.................9-55

REMOVAL - INSPECTION...............9-28

REMOVAL, 2.4L.......................7-20

REMOVAL, 2.4L.......................9-19

REMOVAL, 2.4L ENGINE....7-14,7-16,7-22,7-27

REMOVAL, BALANCE SHAFT.............9-60

REMOVAL, BALANCE SHAFT CARRIER.....9-64

REMOVAL, BALANCE SHAFT CHAIN.......9-64

REMOVAL, BRAKE LAMP SWITCH.......8L-17

REMOVAL, CAMSHAFT OIL SEAL(S).......9-22

REMOVAL, CAMSHAFT(S)...............9-24

REMOVAL, CATALYTIC CONVERTER.......11-2

REMOVAL, CENTER HIGH MOUNTED

STOP LAMP BULB....................8L-18

REMOVAL, CENTER HIGH MOUNTED

STOP LAMP UNIT....................8L-19

REMOVAL, CLEVIS BRACKET BUSHING.....2-2

REMOVAL, CRANKSHAFT...............9-33

REMOVAL, CRANKSHAFT OIL SEAL -

FRONT..............................9-37

REMOVAL, CRANKSHAFT OIL SEAL -

REAR...............................9-38

REMOVAL, CRANKSHAFT SPROCKET......9-55

REMOVAL, CROSS-OVER PIPE...........11-4

REMOVAL, CYLINDER HEAD.............9-20

REMOVAL, CYLINDER HEAD COVER.......9-26

REMOVAL, CYLINDER HEAD OFF.........9-27

REMOVAL, CYLINDER HEAD ON..........9-27

REMOVAL, DAYTIME RUNNING LAMP

RELAY.............................8L-21

REMOVAL, ENGINE ASSEMBLY...........9-12

REMOVAL, ENGINE COOLANT

TEMPERATURE SENSOR................7-21

REMOVAL, EXHAUST MANIFOLD.........9-53

REMOVAL, FRONT FOG LAMP BULB......8L-21

REMOVAL, FRONT FOG LAMP RELAY.....8L-24

REMOVAL, FRONT FOG LAMP UNIT......8L-24

REMOVAL, FRONT LAMP BULB.........8L-27

REMOVAL, FRONT LAMP UNIT

..........8L-27

REMOVAL, FRONT MOUNT

..............9-44

REMOVAL, FRONT POSITION LAMP

BULB

..............................8L-28

REMOVAL, HAZARD SWITCH

...........8L-29

REMOVAL, HEADLAMP BULB

...........8L-30REMOVAL, HEADLAMP HIGH BEAM

RELAY.............................8L-34

REMOVAL, HEADLAMP LEVELING

MOTOR............................8L-36

REMOVAL, HEADLAMP LEVELING

SWITCH............................8L-38

REMOVAL, HEADLAMP LOW BEAM

RELAY.............................8L-40

REMOVAL, HEADLAMP UNIT...........8L-41

REMOVAL, HYDRAULIC LIFTERS.........9-29

REMOVAL, INTAKE MANIFOLD...........9-52

REMOVAL, LAMP....................8L-66

REMOVAL, LAMP BAR................8L-65

REMOVAL, LAMP BAR SWITCH.........8L-67

REMOVAL, LICENSE PLATE LAMP BULB . . 8L-44

REMOVAL, LICENSE PLATE LAMP UNIT . . . 8L-45

REMOVAL, LOWER BALL JOINT...........2-5

REMOVAL, LOWER CONTROL ARM

BUSHING.............................2-2

REMOVAL, LOWER SUSPENSION ARM

BUSHING.............................2-7

REMOVAL, MUFFLER...................11-4

REMOVAL, MULTI-FUNCTION SWITCH....8L-53

REMOVAL, OIL FILTER.................9-47

REMOVAL, OIL PAN...................9-48

REMOVAL, OIL PUMP..................9-49

REMOVAL, PARK LAMP RELAY..........8L-55

REMOVAL, PISTON & CONNECTING ROD . . . 9-40

REMOVAL, RADIATOR..................7-22

REMOVAL, RADIATOR FAN - ELECTRIC....7-26

REMOVAL, REAR FOG LAMP RELAY......8L-58

REMOVAL, REAR LAMP BULB..........8L-59

REMOVAL, REAR LAMP UNIT...........8L-59

REMOVAL, REAR MOUNT...............9-45

REMOVAL, REPEATER LAMP BULB.......8L-60

REMOVAL, REPEATER LAMP UNIT.......8L-61

REMOVAL, RHD........................5-1

REMOVAL, ROCKER ARMS..............9-29

REMOVAL, STRUCTURAL COLLAR........9-44

REMOVAL, TIMING BELT................9-55

REMOVAL, TIMING BELT COVER(S).......9-53

REMOVAL, TIMING BELT TENSIONER &

PULLEY.............................9-59

REMOVAL, TRAILER TOW CONNECTOR . . . 8L-61

REMOVAL, TRAILER TOW RELAY........8L-63

REMOVAL, UPPER BALL JOINT...........2-6

REMOVAL, UPPER CONTROL ARM

BUSHINGS............................2-3

REMOVAL, UPPER SUSPENSION ARM

BUSHING.............................2-7

REMOVAL, VIBRATION DAMPER..........9-43

REPAIR OF DAMAGED OR WORN

THREADS - STANDARD PROCEDURE.......9-9

REPEATER LAMP BULB - INSTALLATION . . 8L-60

REPEATER LAMP BULB - REMOVAL......8L-60

REPEATER LAMP UNIT - INSTALLATION . . 8L-61

REPEATER LAMP UNIT - REMOVAL......8L-61

REVERSE FLUSHING - STANDARD

PROCEDURE, COOLING SYSTEM.........7-12

RHD - INSTALLATION...................5-1

RHD - REMOVAL.......................5-1

RING, FITTING - PISTON................9-42

ROCKER ARMS - INSPECTION...........9-30

ROCKER ARMS - INSTALLATION.........9-30

ROCKER ARMS - REMOVAL.............9-29

ROD - DESCRIPTION, PISTON &

CONNECTING.........................9-40

ROD - INSTALLATION, PISTON &

CONNECTING.........................9-41

ROD - OPERATION, PISTON &

CONNECTING.........................9-40

ROD - REMOVAL, PISTON &

CONNECTING.........................9-40

ROD, FITTING - CONNECTING............9-32

RUNNING LAMP RELAY - DESCRIPTION,

DAYTIME...........................8L-20

RUNNING LAMP RELAY - INSTALLATION,

DAYTIME...........................8L-21

RUNNING LAMP RELAY - OPERATION,

DAYTIME

...........................8L-20

RUNNING LAMP RELAY - REMOVAL,

DAYTIME

...........................8L-21

SEAL - FRONT - INSTALLATION,

CRANKSHAFT OIL

.....................9-37

SEAL - FRONT - REMOVAL,

CRANKSHAFT OIL

.....................9-37

SEAL - REAR - INSTALLATION,

CRANKSHAFT OIL

.....................9-39SEAL - REAR - REMOVAL, CRANKSHAFT

OIL ................................9-38

SEALERS - STANDARD PROCEDURE,

FORM-IN-PLACE GASKETS..............9-10

SEAL(S) - INSTALLATION, CAMSHAFT

OIL ................................9-22

SEAL(S) - REMOVAL, CAMSHAFT OIL.....9-22

SEATS - CLEANING, INTAKE/EXHAUST

VALVES .............................9-27

SEATS - DESCRIPTION, INTAKE/

EXHAUST VALVES.....................9-27

SENSOR - DESCRIPTION, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - INSTALLATION, ENGINE

COOLANT TEMPERATURE...............7-22

SENSOR - OPERATION, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - REMOVAL, ENGINE COOLANT

TEMPERATURE.......................7-21

SENSOR/SWITCH - DESCRIPTION, OIL

PRESSURE..........................9-48

SENSOR/SWITCH - OPERATION, OIL

PRESSURE..........................9-48

SERPENTINE DRIVE BELT DIAGNOSIS -

DIAGNOSIS AND TESTING..............7-15

SHAFT - DESCRIPTION, BALANCE........9-59

SHAFT - OPERATION, BALANCE..........9-59

SHAFT - REMOVAL, BALANCE...........9-60

SHAFT CARRIER - INSTALLATION,

BALANCE............................9-64

SHAFT CARRIER - REMOVAL, BALANCE....9-64

SHAFT CHAIN - INSTALLATION,

BALANCE............................9-64

SHAFT CHAIN - REMOVAL, BALANCE......9-64

SHAFT TIMING, INSTALLATION -

BALANCE............................9-61

SHIELDS - DESCRIPTION, HEAT..........11-4

SPECIAL TOOLS - 2.4L ENGINE..........9-17

SPECIAL TOOLS - COOLING.............7-13

SPECIAL TOOLS - FRONT SUSPENSION.....2-1

SPECIAL TOOLS - REAR SUSPENSION......2-6

SPECIFICATIONS - TORQUE.............7-13

SPECIFICATIONS, 2.4L ENGINE...........9-13

SPECIFICATIONS, LAMPS/LIGHTING -

EXTERIOR..........................8L-15

SPECIFICATIONS, TORQUE..............9-16

SPROCKET - INSTALLATION,

CRANKSHAFT........................9-56

SPROCKET - REMOVAL, CRANKSHAFT.....9-55

STANDARD PROCEDURE - CLEANING.....9-31

STANDARD PROCEDURE - ENGINE OIL

LEVEL CHECK........................9-47

STANDARD PROCEDURE - INSPECTION....9-32

STANDARD PROCEDURE, CAMSHAFT

END-PLAY...........................9-23

STANDARD PROCEDURE, COOLING

SYSTEM - REVERSE FLUSHING..........7-12

STANDARD PROCEDURE, CRANKSHAFT

END PLAY ...........................9-33

STANDARD PROCEDURE, CYLINDER

BORE HONING........................9-31

STANDARD PROCEDURE, DRAINING

COOLING SYSTEM....................7-11

STANDARD PROCEDURE, ENGINE CORE

AND OIL GALLERY PLUGS...............9-9

STANDARD PROCEDURE, ENGINE

GASKET SURFACE PREPARATION.........9-11

STANDARD PROCEDURE, ENGINE OIL

AND FILTER CHANGE..................9-47

STANDARD PROCEDURE, FLUSHING

COOLERS AND TUBES.................7-30

STANDARD PROCEDURE, FORM-IN-

PLACE GASKETS AND SEALERS..........9-10

STANDARD PROCEDURE, HYDROSTATIC

LOCKED ENGINE.......................9-9

STANDARD PROCEDURE, LAMP BAR

AIMING............................8L-65

STANDARD PROCEDURE, MAIN BEARING

- FITTING

............................9-35

STANDARD PROCEDURE, MEASURING

BEARING CLEARANCE USING

PLASTIGAGE

.........................9-11

STANDARD PROCEDURE, PISTON TO

CYLINDER BORE FITTING

...............9-30

STANDARD PROCEDURE, REFILLING

COOLING SYSTEM

....................7-11

STANDARD PROCEDURE, REPAIR OF

DAMAGED OR WORN THREADS

...........9-9

6 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1776 of 1803

STOP LAMP BULB - INSTALLATION,

CENTER HIGH MOUNTED..............8L-19

STOP LAMP BULB - REMOVAL, CENTER

HIGH MOUNTED.....................8L-18

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED..............8L-19

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED.....................8L-19

STRUCTURAL COLLAR - INSTALLATION....9-44

STRUCTURAL COLLAR - REMOVAL.......9-44

SURFACE PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET...........9-11

SUSPENSION ARM BUSHING -

INSTALLATION, LOWER.................2-8

SUSPENSION ARM BUSHING -

INSTALLATION, UPPER..................2-8

SUSPENSION ARM BUSHING -

REMOVAL, LOWER.....................2-7

SUSPENSION ARM BUSHING -

REMOVAL, UPPER......................2-7

SUSPENSION, SPECIAL TOOLS - FRONT....2-1

SUSPENSION, SPECIAL TOOLS - REAR.....2-6

SWITCH - DESCRIPTION, BACKUP LAMP . . 8L-15

SWITCH - DESCRIPTION, BRAKE LAMP . . . 8L-16

SWITCH - DESCRIPTION, HAZARD.......8L-28

SWITCH - DESCRIPTION, HEADLAMP

LEVELING..........................8L-37

SWITCH - DESCRIPTION, LAMP BAR.....8L-67

SWITCH - DESCRIPTION, MULTI-

FUNCTION..........................8L-46

SWITCH - DIAGNOSIS AND TESTING,

BACKUP LAMP......................8L-15

SWITCH - DIAGNOSIS AND TESTING,

BRAKE LAMP.......................8L-17

SWITCH - DIAGNOSIS AND TESTING,

HEADLAMP LEVELING.................8L-37

SWITCH - DIAGNOSIS AND TESTING,

MULTI-FUNCTION....................8L-50

SWITCH - INSTALLATION, BRAKE LAMP . . 8L-18

SWITCH - INSTALLATION, HAZARD......8L-30

SWITCH - INSTALLATION, HEADLAMP

LEVELING..........................8L-38

SWITCH - INSTALLATION, LAMP BAR....8L-67

SWITCH - INSTALLATION, MULTI-

FUNCTION..........................8L-53

SWITCH - OPERATION, BACKUP LAMP . . . 8L-15

SWITCH - OPERATION, BRAKE LAMP.....8L-16

SWITCH - OPERATION, HAZARD.........8L-29

SWITCH - OPERATION, HEADLAMP

LEVELING..........................8L-37

SWITCH - OPERATION, MULTI-FUNCTION . 8L-48

SWITCH - REMOVAL, BRAKE LAMP......8L-17

SWITCH - REMOVAL, HAZARD..........8L-29

SWITCH - REMOVAL, HEADLAMP

LEVELING..........................8L-38

SWITCH - REMOVAL, LAMP BAR........8L-67

SWITCH - REMOVAL, MULTI-FUNCTION . . . 8L-53

SYSTEM - DESCRIPTION, EXHAUST.......11-1

SYSTEM - DIAGNOSIS AND TESTING,

EXHAUST............................11-2

SYSTEM - OPERATION, COOLING..........7-2

SYSTEM - REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING.......7-12

SYSTEM - STANDARD PROCEDURE,

DRAINING COOLING...................7-11

SYSTEM - STANDARD PROCEDURE,

REFILLING COOLING...................7-11

SYSTEM 2.4L ENGINE - DESCRIPTION,

COOLING.............................7-1

SYSTEM DIAGNOSIS CHART -

DIAGNOSIS AND TESTING, COOLING.......7-5

SYSTEM LEAKS - DIAGNOSIS AND

TESTING, COOLING.....................7-2

TEMPERATURE SENSOR - DESCRIPTION,

ENGINE COOLANT.....................7-21

TEMPERATURE SENSOR -

INSTALLATION, ENGINE COOLANT........7-22

TEMPERATURE SENSOR - OPERATION,

ENGINE COOLANT.....................7-21

TEMPERATURE SENSOR - REMOVAL,

ENGINE COOLANT.....................7-21TENSIONER & PULLEY - INSTALLATION,

TIMING BELT.........................9-59

TENSIONER & PULLEY - REMOVAL,

TIMING BELT.........................9-59

TEST - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE

LEAKAGE.............................9-3

TEST - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION PRESSURE......9-3

TESTING, BACKUP LAMP SWITCH -

DIAGNOSIS.........................8L-15

TESTING, BRAKE LAMP SWITCH -

DIAGNOSIS.........................8L-17

TESTING, COOLING SYSTEM DIAGNOSIS

CHART - DIAGNOSIS....................7-5

TESTING, COOLING SYSTEM LEAKS -

DIAGNOSIS...........................7-2

TESTING, CYLINDER COMBUSTION

PRESSURE LEAKAGE TEST -

DIAGNOSIS...........................9-3

TESTING, CYLINDER COMPRESSION

PRESSURE TEST - DIAGNOSIS............9-3

TESTING, CYLINDER HEAD GASKET -

DIAGNOSIS..........................9-19

TESTING, ENGINE - DIAGNOSIS...........9-5

TESTING, ENGINE DIAGNOSIS -

PERFORMANCE - DIAGNOSIS.............9-5

TESTING, ENGINE MECHANICAL -

DIAGNOSIS...........................9-7

TESTING, ENGINE OIL LEAK

INSPECTION - DIAGNOSIS...............9-4

TESTING, ENGINE OIL PRESSURE

CHECKING - DIAGNOSIS................9-46

TESTING, EXHAUST SYSTEM -

DIAGNOSIS..........................11-2

TESTING, FRONT FOG LAMP RELAY -

DIAGNOSIS.........................8L-23

TESTING, HEADLAMP HIGH BEAM

RELAY - DIAGNOSIS

..................8L-34

TESTING, HEADLAMP LEVELING SWITCH

- DIAGNOSIS

........................8L-37

TESTING, HEADLAMP LOW BEAM RELAY

- DIAGNOSIS

........................8L-40

TESTING, INTAKE MANIFOLD LEAKS -

DIAGNOSIS

..........................9-51

TESTING, LAMP BAR - DIAGNOSIS

......8L-65

TESTING, LAMPS/LIGHTING - EXTERIOR

- DIAGNOSIS

.........................8L-7

TESTING, LASH ADJUSTER (TAPPET)

NOISE DIAGNOSIS - DIAGNOSIS

.........9-28

TESTING, MULTI-FUNCTION SWITCH -

DIAGNOSIS

.........................8L-50

TESTING, ON-BOARD DIAGNOSTICS

(OBD) - DIAGNOSIS

....................7-2

TESTING, PARK LAMP RELAY -

DIAGNOSIS

.........................8L-55

TESTING, PRELIMINARY CHECKS -

DIAGNOSIS

...........................7-2

TESTING, RADIATOR PRESSURE CAP -

DIAGNOSIS

..........................7-25

TESTING, REAR FOG LAMP RELAY -

DIAGNOSIS

.........................8L-57

TESTING, SERPENTINE DRIVE BELT

DIAGNOSIS - DIAGNOSIS

...............7-15

TESTING, TRAILER TOW RELAY -

DIAGNOSIS

.........................8L-62

THREADS - STANDARD PROCEDURE,

REPAIR OF DAMAGED OR WORN

..........9-9

TIMING BELT - INSTALLATION

...........9-56

TIMING BELT - REMOVAL

...............9-55

TIMING BELT COVER(S) - INSTALLATION

. . . 9-53

TIMING BELT COVER(S) - REMOVAL

......9-53

TIMING BELT TENSIONER & PULLEY -

INSTALLATION

........................9-59

TIMING BELT TENSIONER & PULLEY -

REMOVAL

...........................9-59

TIMING, INSTALLATION - BALANCE

SHAFT

..............................9-61TO CYLINDER BORE FITTING -

STANDARD PROCEDURE, PISTON........9-30

TOOLS - 2.4L ENGINE, SPECIAL..........9-17

TOOLS - COOLING, SPECIAL.............7-13

TOOLS - FRONT SUSPENSION, SPECIAL....2-1

TOOLS - REAR SUSPENSION, SPECIAL.....2-6

TORQUE - SPECIFICATIONS.............9-16

TORQUE, SPECIFICATIONS..............7-13

TOW CONNECTOR - INSTALLATION,

TRAILER...........................8L-61

TOW CONNECTOR - REMOVAL, TRAILER . . 8L-61

TOW RELAY - DESCRIPTION, TRAILER....8L-62

TOW RELAY - DIAGNOSIS AND TESTING,

TRAILER...........................8L-62

TOW RELAY - INSTALLATION, TRAILER . . . 8L-63

TOW RELAY - OPERATION, TRAILER.....8L-62

TOW RELAY - REMOVAL, TRAILER.......8L-63

TOW WIRING - DESCRIPTION, TRAILER . . 8L-64

TRAILER TOW CONNECTOR -

INSTALLATION.......................8L-61

TRAILER TOW CONNECTOR - REMOVAL . . 8L-61

TRAILER TOW RELAY - DESCRIPTION....8L-62

TRAILER TOW RELAY - DIAGNOSIS AND

TESTING...........................8L-62

TRAILER TOW RELAY - INSTALLATION . . . 8L-63

TRAILER TOW RELAY - OPERATION......8L-62

TRAILER TOW RELAY - REMOVAL.......8L-63

TRAILER TOW WIRING - DESCRIPTION . . . 8L-64

TRANS COOLER - DESCRIPTION.........7-30

TUBES - STANDARD PROCEDURE,

FLUSHING COOLERS...................7-30

UNIT - ADJUSTMENT, FRONT FOG LAMP . . 8L-25

UNIT - ADJUSTMENT, HEADLAMP.......8L-42

UNIT - INSTALLATION, CENTER HIGH

MOUNTED STOP LAMP................8L-19

UNIT - INSTALLATION, FRONT FOG

LAMP..............................8L-25

UNIT - INSTALLATION, FRONT LAMP.....8L-28

UNIT - INSTALLATION, HEADLAMP.......8L-42

UNIT - INSTALLATION, LICENSE PLATE

LAMP..............................8L-46

UNIT - INSTALLATION, REAR LAMP......8L-60

UNIT - INSTALLATION, REPEATER LAMP . . 8L-61

UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP LAMP

................8L-19

UNIT - REMOVAL, FRONT FOG LAMP

.....8L-24

UNIT - REMOVAL, FRONT LAMP

.........8L-27

UNIT - REMOVAL, HEADLAMP

..........8L-41

UNIT - REMOVAL, LICENSE PLATE LAMP

. . 8L-45

UNIT - REMOVAL, REAR LAMP

..........8L-59

UNIT - REMOVAL, REPEATER LAMP

......8L-61

UPPER BALL JOINT - INSTALLATION

.......2-6

UPPER BALL JOINT - REMOVAL

...........2-6

UPPER CONTROL ARM BUSHINGS -

INSTALLATION

.........................2-4

UPPER CONTROL ARM BUSHINGS -

REMOVAL

............................2-3

UPPER SUSPENSION ARM BUSHING -

INSTALLATION

.........................2-8

UPPER SUSPENSION ARM BUSHING -

REMOVAL

............................2-7

USING PLASTIGAGE - STANDARD

PROCEDURE, MEASURING BEARING

CLEARANCE

..........................9-11

VALVES & SEATS - CLEANING,

INTAKE/EXHAUST

.....................9-27

VALVES & SEATS - DESCRIPTION,

INTAKE/EXHAUST

.....................9-27

VIBRATION DAMPER - INSTALLATION

.....9-43

VIBRATION DAMPER - REMOVAL

.........9-43

WATER PUMP - 2.4L - DESCRIPTION

......7-27

WATER PUMP - 2.4L - INSPECTION

.......7-28

WATER PUMP - 2.4L - OPERATION

.......7-27

WIRING - DESCRIPTION, TRAILER TOW

. . 8L-64

WORN THREADS - STANDARD

PROCEDURE, REPAIR OF DAMAGED

OR

..................................9-9

KJINDEX 7

Description Group-Page Description Group-Page Description Group-Page