ad blue JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 436 of 1803

sends the proper vehicle speed messages to the

instrument cluster. For further diagnosis of the

speedometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the BCM, the PCM, the

PCI data bus, or the electronic message inputs to the

instrument cluster that control the speedometer, a

DRBIIItscan tool is required. Refer to the appropri-

ate diagnostic information.

TACHOMETER

DESCRIPTION

A tachometer is standard equipment on all instru-

ment clusters. The tachometer is located to the left of

the speedometer in the instrument cluster. The

tachometer consists of a movable gauge needle or

pointer controlled by the instrument cluster circuitry,

and a fixed 255 degree scale on the gauge dial face

that reads left-to-right from 0 to 7 for gasoline

engines, or from 0 to 5 for diesel engines. The text

ªRPM X 1000º imprinted on the cluster overlay

directly below the hub of the tachometer needle iden-

tifies that each number on the tachometer scale is to

be multiplied by 1000 rpm. The gasoline engine

tachometer has a red zone beginning at 5800 RPM,

while the red zone for the diesel engine tachometer

begins at 4300 RPM. The tachometer graphics are

dark blue and red against a beige field, making them

clearly visible within the instrument cluster in day-

light. When illuminated from behind by the panel

lamps dimmer controlled cluster illumination lighting

with the exterior lamps turned On, the dark blue

graphics appear blue and the red graphics appear

red. The orange gauge needle is internally illumi-

nated. Gauge illumination is provided by replaceable

incandescent bulb and bulb holder units located on

the instrument cluster electronic circuit board. The

tachometer is serviced as a unit with the instrument

cluster.

OPERATION

The tachometer gives an indication to the vehicle

operator of the engine speed. This gauge is controlled

by the instrument cluster electronic circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Powertrain

Control Module (PCM) over the Programmable Com-

munications Interface (PCI) data bus. The tachome-

ter is an air core magnetic unit that receives battery

current on the instrument cluster electronic circuit

board through the fused ignition switch output (run-

start) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed tomove the gauge needle back to the low end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²Engine Speed Message- Each time the cluster

receives an engine speed message from the PCM it

will calculate the correct engine speed reading and

position the gauge needle at that speed position on

the gauge scale. The cluster will receive a new

engine speed message and reposition the gauge

pointer accordingly about every 86 milliseconds. The

gauge needle will continue to be positioned at the

actual engine speed position on the gauge scale until

the ignition switch is turned to the Off position.

²Communication Error- If the cluster fails to

receive an engine speed message, it will hold the

gauge needle at the last indication for about six sec-

onds, or until the ignition switch is turned to the Off

position, whichever occurs first. If a new engine

speed message is not received after about six sec-

onds, the gauge needle will return to the far left

(low) end of the scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept to several calibration points on the gauge scale

in sequence in order to confirm the functionality of

the gauge and the cluster control circuitry.

The PCM continually monitors the crankshaft posi-

tion sensor to determine the engine speed, then

sends the proper engine speed messages to the

instrument cluster. For further diagnosis of the

tachometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the crankshaft position

sensor, the PCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the tachometer, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

TRANS TEMP INDICATOR

DESCRIPTION

A transmission over-temperature indicator is stan-

dard equipment on all instrument clusters, but is

only functional on vehicles equipped with an optional

automatic transmission. The transmission over-tem-

perature indicator is located near the lower edge of

the instrument cluster, between the tachometer and

the speedometer. The transmission over-temperature

indicator consists of a stencil-like cutout of the words

ªTRANS TEMPº in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents the indicator from being clearly vis-

KJINSTRUMENT CLUSTER 8J - 33

SPEEDOMETER (Continued)

Page 438 of 1803

The turn signal indicators are connected in parallel

with the other turn signal circuits. This arrangement

allows the turn signal indicators to remain func-

tional, regardless of the condition of the other cir-

cuits in the turn signal and hazard warning systems.

The combination flasher outputs of the hazard switch

to the instrument cluster turn signal indicator inputs

can be diagnosed using conventional diagnostic tools

and methods. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/HAZARD SWITCH -

DESCRIPTION) for more information on the combi-

nation flasher and hazard switch operation.

WAIT-TO-START INDICATOR

DESCRIPTION

A wait-to-start indicator is only found in the

instrument clusters of vehicles equipped with an

optional diesel engine. The wait-to-start indicator is

located above the fuel gauge and to the left of the

tachometer in the instrument cluster. The wait-to-

start indicator consists of a stencil-like cutout of the

International Control and Display Symbol icon for

ªDiesel Preheatº in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents the indicator from being clearly vis-

ible when it is not illuminated. An amber Light

Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

in amber through the translucent outer layer of the

overlay when it is illuminated from behind by the

LED, which is soldered onto the instrument cluster

electronic circuit board. The wait-to-start indicator is

serviced as a unit with the instrument cluster.

OPERATION

The wait-to-start indicator gives an indication to

the vehicle operator when the diesel engine glow

plugs are energized in their pre-heat operating mode.

This indicator is controlled by a transistor on the

instrument cluster electronic circuit board based

upon the cluster programming and electronic mes-

sages received by the cluster from the Powertrain

Control Module (PCM) over the Programmable Com-

munications Interface (PCI) data bus. The wait-to-

start indicator Light Emitting Diode (LED) is

completely controlled by the instrument cluster logic

circuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the LED will

always be off when the ignition switch is in any posi-

tion except On or Start. The LED only illuminates

when it is provided a path to ground by the instru-

ment cluster transistor. The instrument cluster willturn on the wait-to-start indicator for the following

reasons:

²Wait-To-Start Lamp-On Message- Each time

the cluster receives a wait-to-start lamp-on message

from the PCM indicating the glow plugs are heating

and the driver must wait to start the engine, the

wait-to-start indicator will be illuminated. The indi-

cator remains illuminated until the cluster receives a

wait-to-start lamp-off message, or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Actuator Test- Each time the cluster is put

through the actuator test, the wait-to-start indicator

will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

The PCM continually monitors the ambient tem-

perature and the glow plug pre-heater circuits to

determine how long the glow plugs must be heated in

the pre-heat operating mode. The PCM then sends

the proper wait-to-start lamp-on and lamp-off mes-

sages to the instrument cluster. For further diagnosis

of the wait-to-start indicator or the instrument clus-

ter circuitry that controls the indicator, (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - DIAGNO-

SIS AND TESTING). For proper diagnosis of the

glow plug pre-heater control circuits, the PCM, the

PCI data bus, or the electronic message inputs to the

instrument cluster that control the wait-to-start indi-

cator, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

WASHER FLUID INDICATOR

DESCRIPTION

A washer fluid indicator is standard equipment on

all instrument clusters. The washer fluid indicator

consists of the text ªlowashº, which appears in place

of the odometer/trip odometer information in the Vac-

uum-Fluorescent Display (VFD) of the instrument

cluster. The VFD is part of the cluster electronic cir-

cuit board, and is visible through a cutout located

near the lower edge of the speedometer dial face in

the instrument cluster. The dark outer layer of the

overlay prevents the VFD from being clearly visible

when it is not illuminated. The text message

ªlowashº appears in the same blue-green color and at

the same lighting level as the odometer/trip odometer

information through the translucent outer layer of

the overlay when it is illuminated by the instrument

cluster electronic circuit board. The washer fluid

indicator is serviced as a unit with the instrument

cluster.

KJINSTRUMENT CLUSTER 8J - 35

TURN SIGNAL INDICATOR (Continued)

Page 642 of 1803

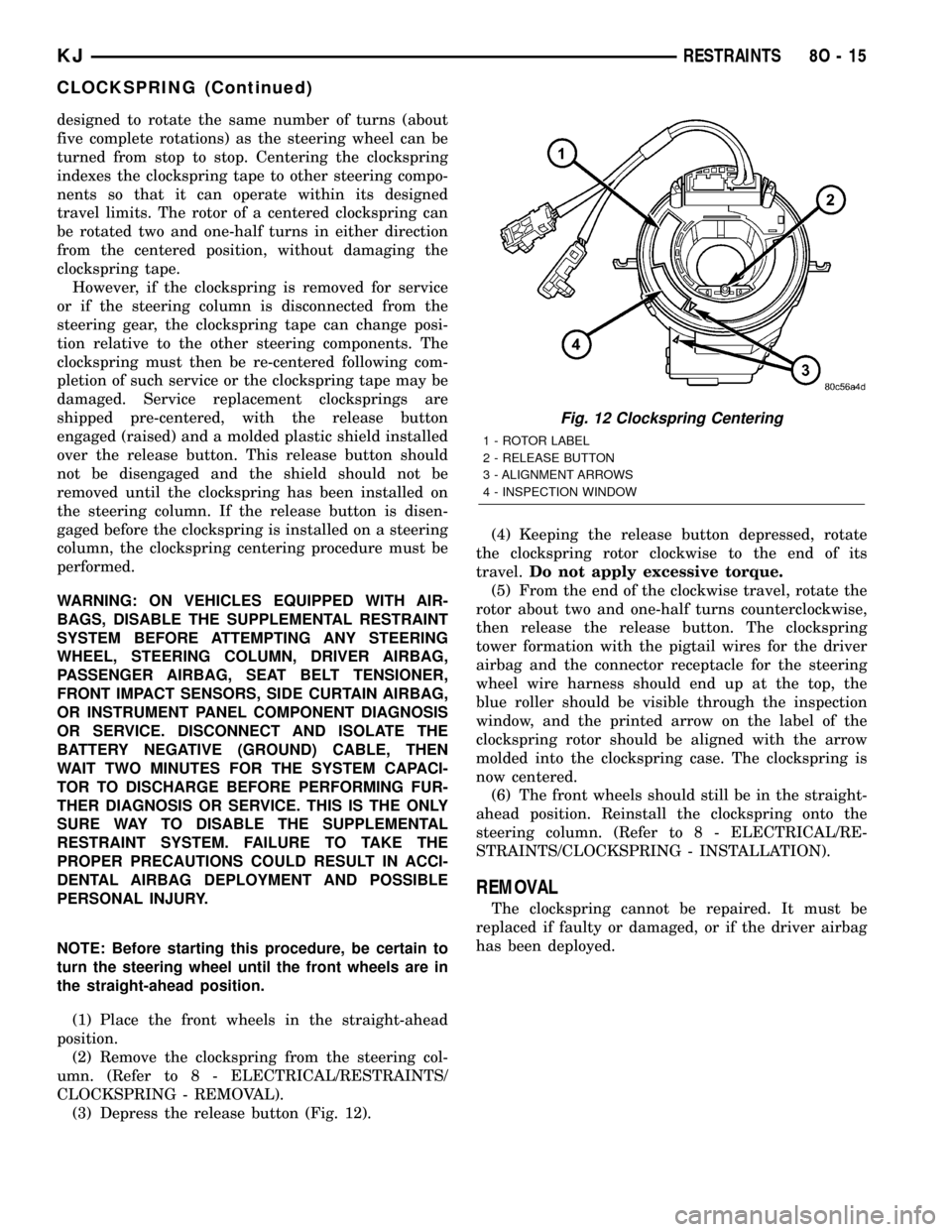

designed to rotate the same number of turns (about

five complete rotations) as the steering wheel can be

turned from stop to stop. Centering the clockspring

indexes the clockspring tape to other steering compo-

nents so that it can operate within its designed

travel limits. The rotor of a centered clockspring can

be rotated two and one-half turns in either direction

from the centered position, without damaging the

clockspring tape.

However, if the clockspring is removed for service

or if the steering column is disconnected from the

steering gear, the clockspring tape can change posi-

tion relative to the other steering components. The

clockspring must then be re-centered following com-

pletion of such service or the clockspring tape may be

damaged. Service replacement clocksprings are

shipped pre-centered, with the release button

engaged (raised) and a molded plastic shield installed

over the release button. This release button should

not be disengaged and the shield should not be

removed until the clockspring has been installed on

the steering column. If the release button is disen-

gaged before the clockspring is installed on a steering

column, the clockspring centering procedure must be

performed.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Place the front wheels in the straight-ahead

position.

(2) Remove the clockspring from the steering col-

umn. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - REMOVAL).

(3) Depress the release button (Fig. 12).(4) Keeping the release button depressed, rotate

the clockspring rotor clockwise to the end of its

travel.Do not apply excessive torque.

(5) From the end of the clockwise travel, rotate the

rotor about two and one-half turns counterclockwise,

then release the release button. The clockspring

tower formation with the pigtail wires for the driver

airbag and the connector receptacle for the steering

wheel wire harness should end up at the top, the

blue roller should be visible through the inspection

window, and the printed arrow on the label of the

clockspring rotor should be aligned with the arrow

molded into the clockspring case. The clockspring is

now centered.

(6) The front wheels should still be in the straight-

ahead position. Reinstall the clockspring onto the

steering column. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/CLOCKSPRING - INSTALLATION).

REMOVAL

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

Fig. 12 Clockspring Centering

1 - ROTOR LABEL

2 - RELEASE BUTTON

3 - ALIGNMENT ARROWS

4 - INSPECTION WINDOW

KJRESTRAINTS 8O - 15

CLOCKSPRING (Continued)

Page 752 of 1803

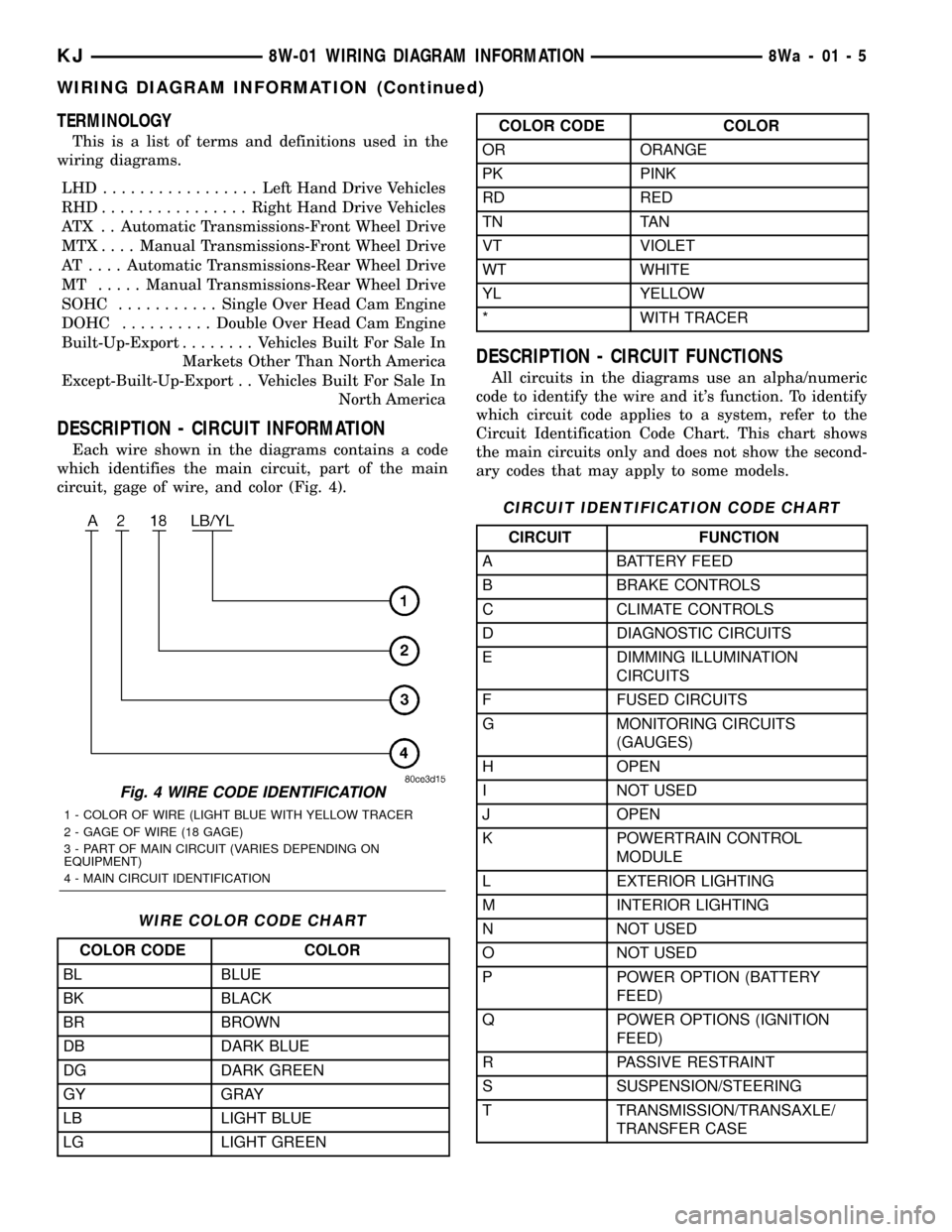

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD .................Left Hand Drive Vehicles

RHD................Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX....Manual Transmissions-Front Wheel Drive

AT ....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export........ Vehicles Built For Sale In

Markets Other Than North America

Except-Built-Up-Export . . Vehicles Built For Sale In

North America

DESCRIPTION - CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 4).

WIRE COLOR CODE CHART

COLOR CODE COLOR

BL BLUE

BK BLACK

BR BROWN

DB DARK BLUE

DG DARK GREEN

GY GRAY

LB LIGHT BLUE

LG LIGHT GREEN

COLOR CODE COLOR

OR ORANGE

PK PINK

RD RED

TN TAN

VT VIOLET

WT WHITE

YL YELLOW

* WITH TRACER

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

Fig. 4 WIRE CODE IDENTIFICATION

1 - COLOR OF WIRE (LIGHT BLUE WITH YELLOW TRACER

2 - GAGE OF WIRE (18 GAGE)

3 - PART OF MAIN CIRCUIT (VARIES DEPENDING ON

EQUIPMENT)

4 - MAIN CIRCUIT IDENTIFICATION

KJ8W-01 WIRING DIAGRAM INFORMATION8Wa-01-5

WIRING DIAGRAM INFORMATION (Continued)

Page 1092 of 1803

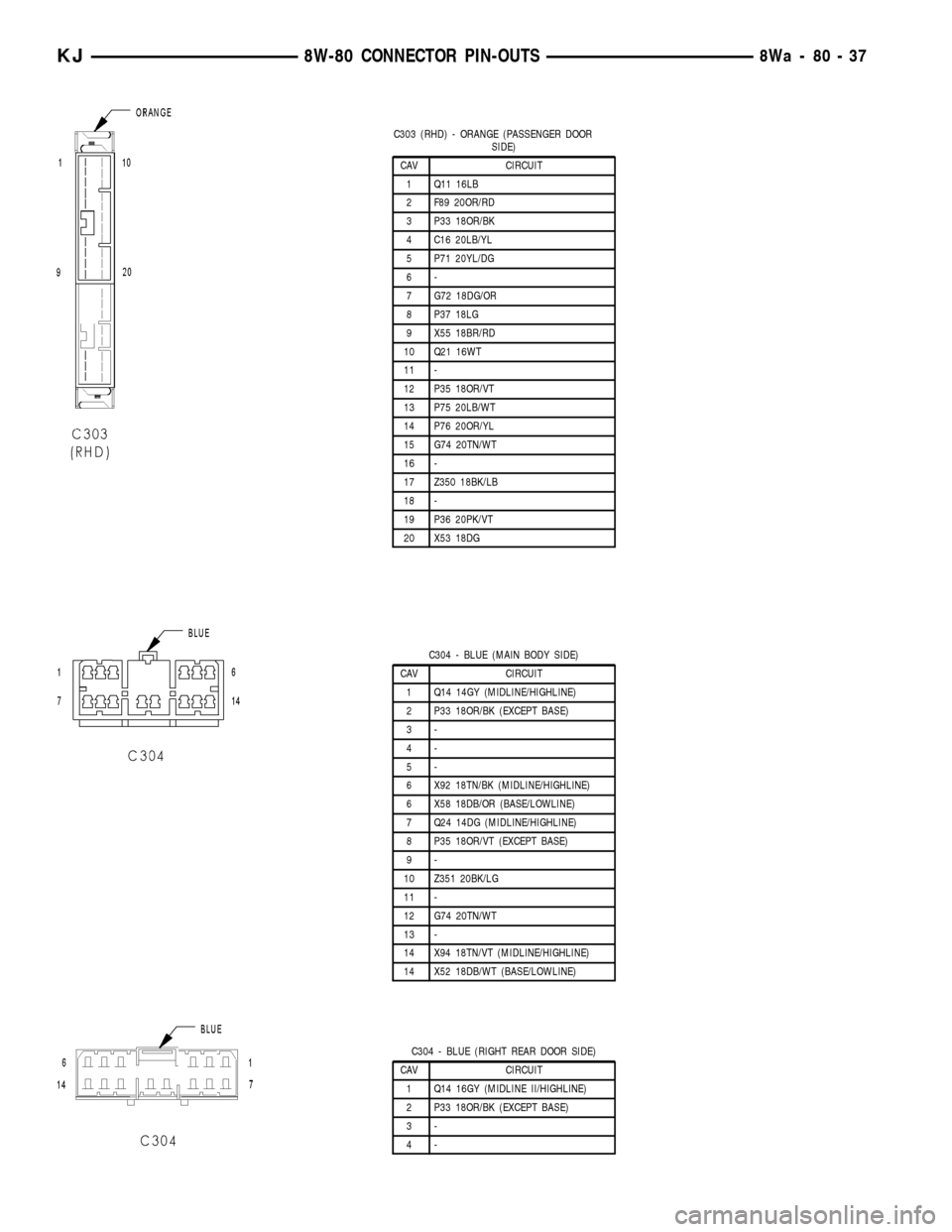

C303 (RHD) - ORANGE (PASSENGER DOOR

SIDE)

CAV CIRCUIT

1 Q11 16LB

2 F89 20OR/RD

3 P33 18OR/BK

4 C16 20LB/YL

5 P71 20YL/DG

6-

7 G72 18DG/OR

8 P37 18LG

9 X55 18BR/RD

10 Q21 16WT

11 -

12 P35 18OR/VT

13 P75 20LB/WT

14 P76 20OR/YL

15 G74 20TN/WT

16 -

17 Z350 18BK/LB

18 -

19 P36 20PK/VT

20 X53 18DG

C304 - BLUE (MAIN BODY SIDE)

CAV CIRCUIT

1 Q14 14GY (MIDLINE/HIGHLINE)

2 P33 18OR/BK (EXCEPT BASE)

3-

4-

5-

6 X92 18TN/BK (MIDLINE/HIGHLINE)

6 X58 18DB/OR (BASE/LOWLINE)

7 Q24 14DG (MIDLINE/HIGHLINE)

8 P35 18OR/VT (EXCEPT BASE)

9-

10 Z351 20BK/LG

11 -

12 G74 20TN/WT

13 -

14 X94 18TN/VT (MIDLINE/HIGHLINE)

14 X52 18DB/WT (BASE/LOWLINE)

C304 - BLUE (RIGHT REAR DOOR SIDE)

CAV CIRCUIT

1 Q14 16GY (MIDLINE II/HIGHLINE)

2 P33 18OR/BK (EXCEPT BASE)

3-

4-

KJ8W-80 CONNECTOR PIN-OUTS8Wa-80-37

Page 1093 of 1803

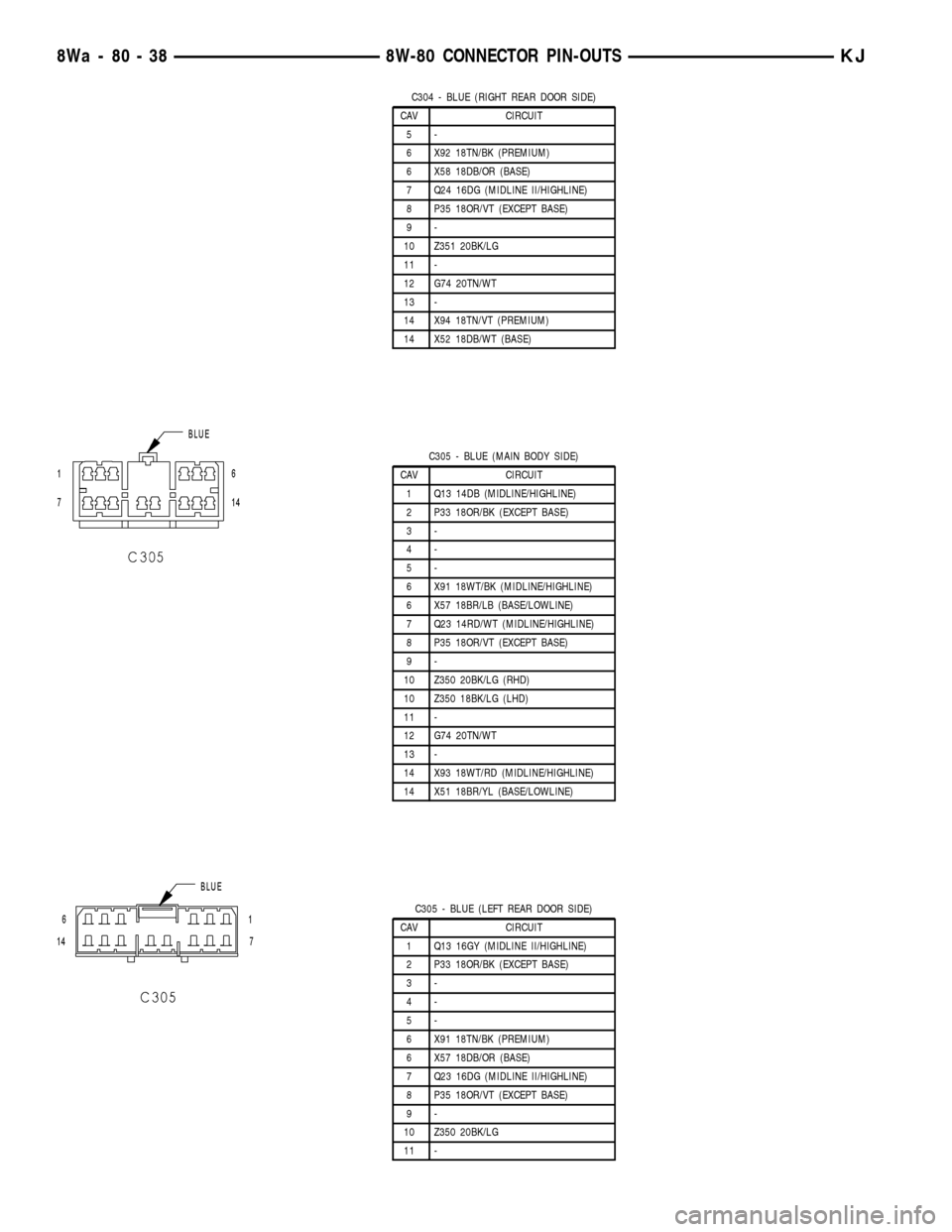

C304 - BLUE (RIGHT REAR DOOR SIDE)

CAV CIRCUIT

5-

6 X92 18TN/BK (PREMIUM)

6 X58 18DB/OR (BASE)

7 Q24 16DG (MIDLINE II/HIGHLINE)

8 P35 18OR/VT (EXCEPT BASE)

9-

10 Z351 20BK/LG

11 -

12 G74 20TN/WT

13 -

14 X94 18TN/VT (PREMIUM)

14 X52 18DB/WT (BASE)

C305 - BLUE (MAIN BODY SIDE)

CAV CIRCUIT

1 Q13 14DB (MIDLINE/HIGHLINE)

2 P33 18OR/BK (EXCEPT BASE)

3-

4-

5-

6 X91 18WT/BK (MIDLINE/HIGHLINE)

6 X57 18BR/LB (BASE/LOWLINE)

7 Q23 14RD/WT (MIDLINE/HIGHLINE)

8 P35 18OR/VT (EXCEPT BASE)

9-

10 Z350 20BK/LG (RHD)

10 Z350 18BK/LG (LHD)

11 -

12 G74 20TN/WT

13 -

14 X93 18WT/RD (MIDLINE/HIGHLINE)

14 X51 18BR/YL (BASE/LOWLINE)

C305 - BLUE (LEFT REAR DOOR SIDE)

CAV CIRCUIT

1 Q13 16GY (MIDLINE II/HIGHLINE)

2 P33 18OR/BK (EXCEPT BASE)

3-

4-

5-

6 X91 18TN/BK (PREMIUM)

6 X57 18DB/OR (BASE)

7 Q23 16DG (MIDLINE II/HIGHLINE)

8 P35 18OR/VT (EXCEPT BASE)

9-

10 Z350 20BK/LG

11 -

8Wa - 80 - 38 8W-80 CONNECTOR PIN-OUTSKJ

Page 1094 of 1803

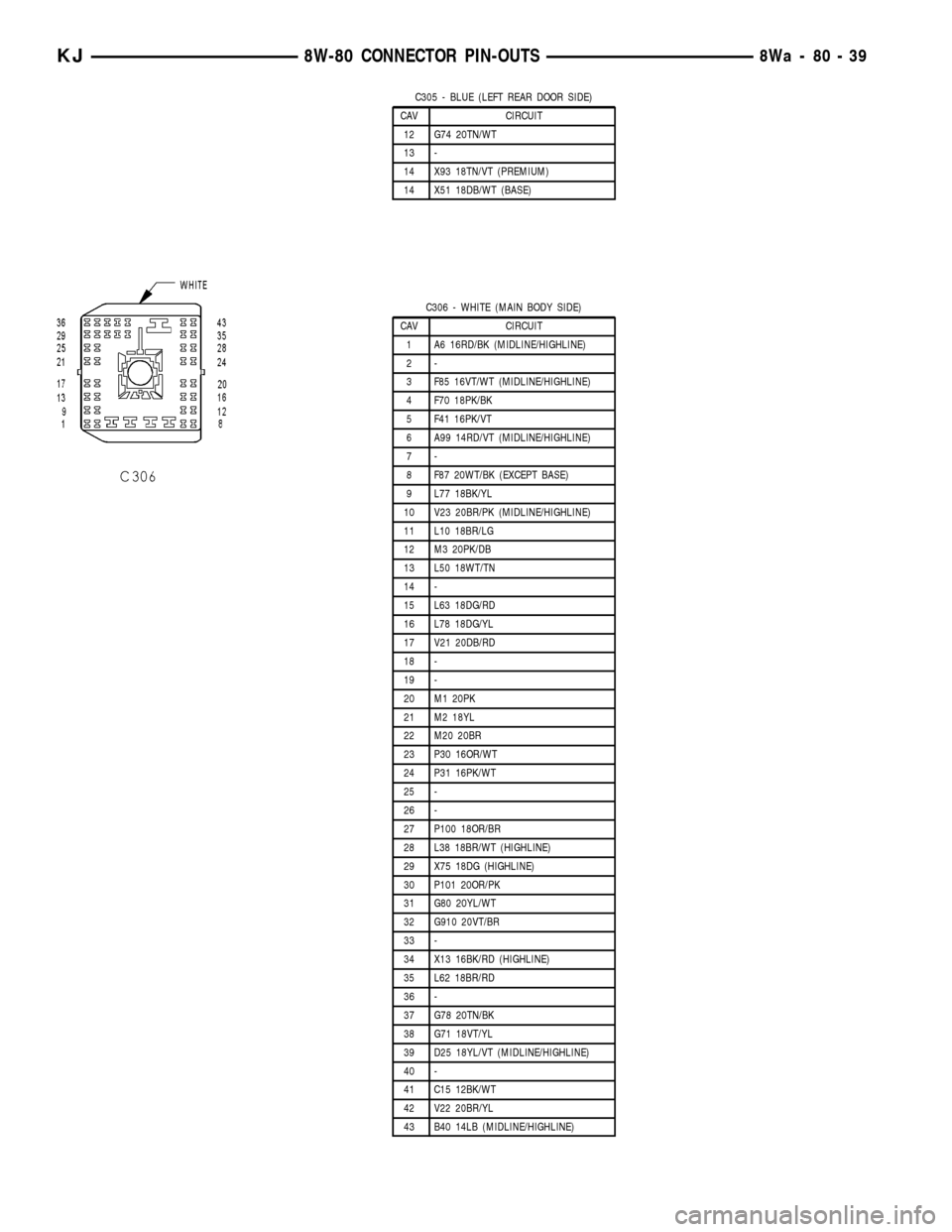

C305 - BLUE (LEFT REAR DOOR SIDE)

CAV CIRCUIT

12 G74 20TN/WT

13 -

14 X93 18TN/VT (PREMIUM)

14 X51 18DB/WT (BASE)

C306 - WHITE (MAIN BODY SIDE)

CAV CIRCUIT

1 A6 16RD/BK (MIDLINE/HIGHLINE)

2-

3 F85 16VT/WT (MIDLINE/HIGHLINE)

4 F70 18PK/BK

5 F41 16PK/VT

6 A99 14RD/VT (MIDLINE/HIGHLINE)

7-

8 F87 20WT/BK (EXCEPT BASE)

9 L77 18BK/YL

10 V23 20BR/PK (MIDLINE/HIGHLINE)

11 L10 18BR/LG

12 M3 20PK/DB

13 L50 18WT/TN

14 -

15 L63 18DG/RD

16 L78 18DG/YL

17 V21 20DB/RD

18 -

19 -

20 M1 20PK

21 M2 18YL

22 M20 20BR

23 P30 16OR/WT

24 P31 16PK/WT

25 -

26 -

27 P100 18OR/BR

28 L38 18BR/WT (HIGHLINE)

29 X75 18DG (HIGHLINE)

30 P101 20OR/PK

31 G80 20YL/WT

32 G910 20VT/BR

33 -

34 X13 16BK/RD (HIGHLINE)

35 L62 18BR/RD

36 -

37 G78 20TN/BK

38 G71 18VT/YL

39 D25 18YL/VT (MIDLINE/HIGHLINE)

40 -

41 C15 12BK/WT

42 V22 20BR/YL

43 B40 14LB (MIDLINE/HIGHLINE)

KJ8W-80 CONNECTOR PIN-OUTS8Wa-80-39

Page 1097 of 1803

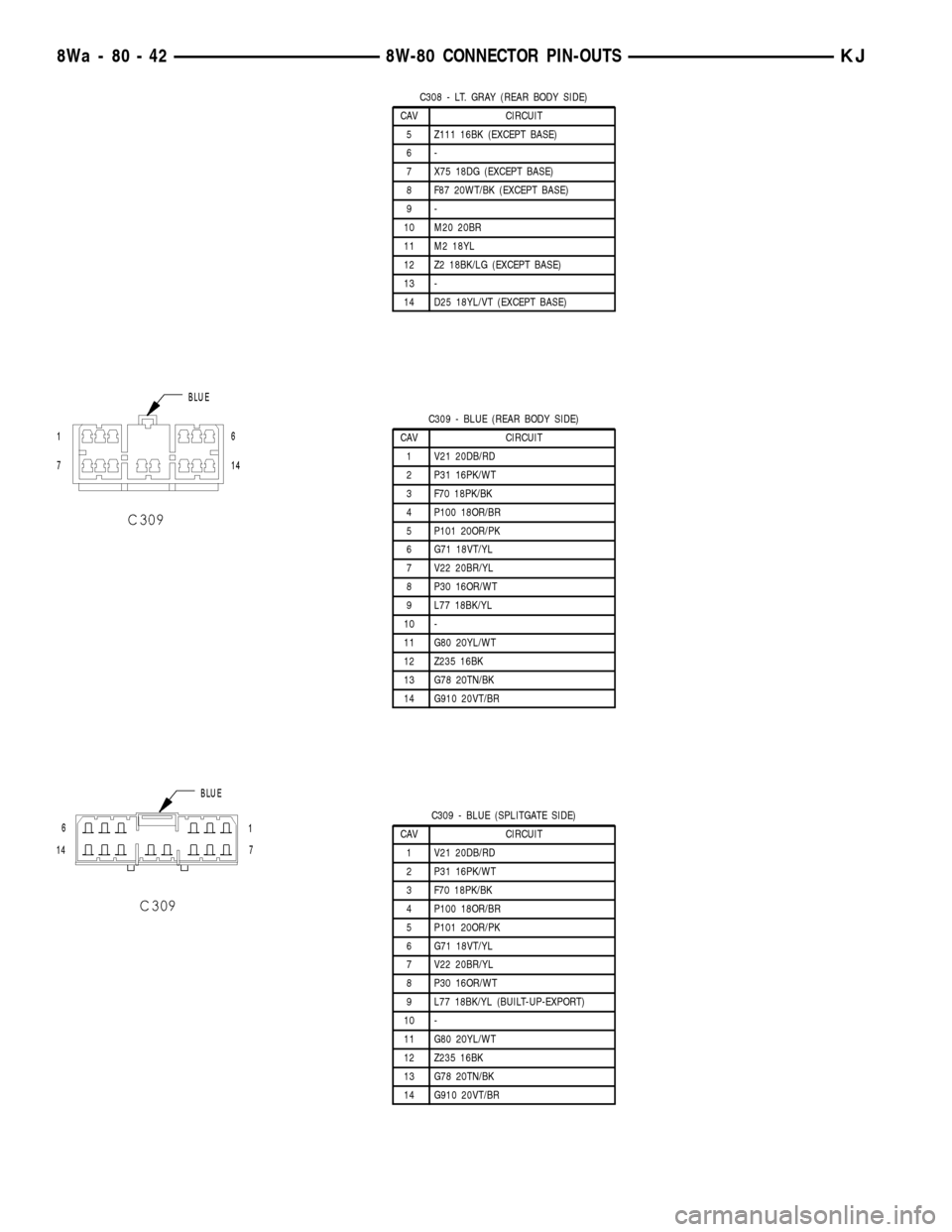

C308 - LT. GRAY (REAR BODY SIDE)

CAV CIRCUIT

5 Z111 16BK (EXCEPT BASE)

6-

7 X75 18DG (EXCEPT BASE)

8 F87 20WT/BK (EXCEPT BASE)

9-

10 M20 20BR

11 M2 18YL

12 Z2 18BK/LG (EXCEPT BASE)

13 -

14 D25 18YL/VT (EXCEPT BASE)

C309 - BLUE (REAR BODY SIDE)

CAV CIRCUIT

1 V21 20DB/RD

2 P31 16PK/WT

3 F70 18PK/BK

4 P100 18OR/BR

5 P101 20OR/PK

6 G71 18VT/YL

7 V22 20BR/YL

8 P30 16OR/WT

9 L77 18BK/YL

10 -

11 G80 20YL/WT

12 Z235 16BK

13 G78 20TN/BK

14 G910 20VT/BR

C309 - BLUE (SPLITGATE SIDE)

CAV CIRCUIT

1 V21 20DB/RD

2 P31 16PK/WT

3 F70 18PK/BK

4 P100 18OR/BR

5 P101 20OR/PK

6 G71 18VT/YL

7 V22 20BR/YL

8 P30 16OR/WT

9 L77 18BK/YL (BUILT-UP-EXPORT)

10 -

11 G80 20YL/WT

12 Z235 16BK

13 G78 20TN/BK

14 G910 20VT/BR

8Wa - 80 - 42 8W-80 CONNECTOR PIN-OUTSKJ

Page 1123 of 1803

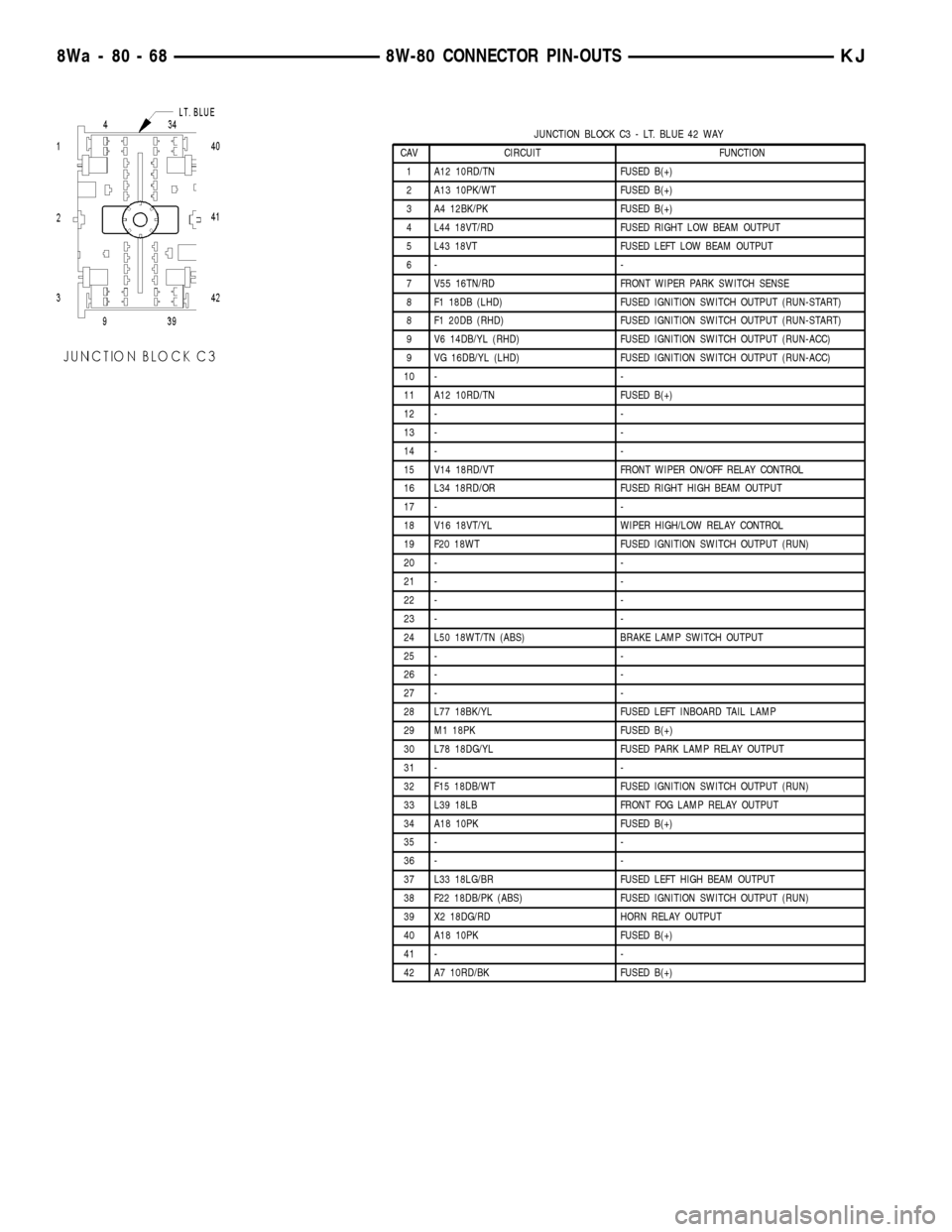

JUNCTION BLOCK C3 - LT. BLUE 42 WAY

CAV CIRCUIT FUNCTION

1 A12 10RD/TN FUSED B(+)

2 A13 10PK/WT FUSED B(+)

3 A4 12BK/PK FUSED B(+)

4 L44 18VT/RD FUSED RIGHT LOW BEAM OUTPUT

5 L43 18VT FUSED LEFT LOW BEAM OUTPUT

6- -

7 V55 16TN/RD FRONT WIPER PARK SWITCH SENSE

8 F1 18DB (LHD) FUSED IGNITION SWITCH OUTPUT (RUN-START)

8 F1 20DB (RHD) FUSED IGNITION SWITCH OUTPUT (RUN-START)

9 V6 14DB/YL (RHD) FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

9 VG 16DB/YL (LHD) FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

10 - -

11 A12 10RD/TN FUSED B(+)

12 - -

13 - -

14 - -

15 V14 18RD/VT FRONT WIPER ON/OFF RELAY CONTROL

16 L34 18RD/OR FUSED RIGHT HIGH BEAM OUTPUT

17 - -

18 V16 18VT/YL WIPER HIGH/LOW RELAY CONTROL

19 F20 18WT FUSED IGNITION SWITCH OUTPUT (RUN)

20 - -

21 - -

22 - -

23 - -

24 L50 18WT/TN (ABS) BRAKE LAMP SWITCH OUTPUT

25 - -

26 - -

27 - -

28 L77 18BK/YL FUSED LEFT INBOARD TAIL LAMP

29 M1 18PK FUSED B(+)

30 L78 18DG/YL FUSED PARK LAMP RELAY OUTPUT

31 - -

32 F15 18DB/WT FUSED IGNITION SWITCH OUTPUT (RUN)

33 L39 18LB FRONT FOG LAMP RELAY OUTPUT

34 A18 10PK FUSED B(+)

35 - -

36 - -

37 L33 18LG/BR FUSED LEFT HIGH BEAM OUTPUT

38 F22 18DB/PK (ABS) FUSED IGNITION SWITCH OUTPUT (RUN)

39 X2 18DG/RD HORN RELAY OUTPUT

40 A18 10PK FUSED B(+)

41 - -

42 A7 10RD/BK FUSED B(+)

8Wa - 80 - 68 8W-80 CONNECTOR PIN-OUTSKJ

Page 1127 of 1803

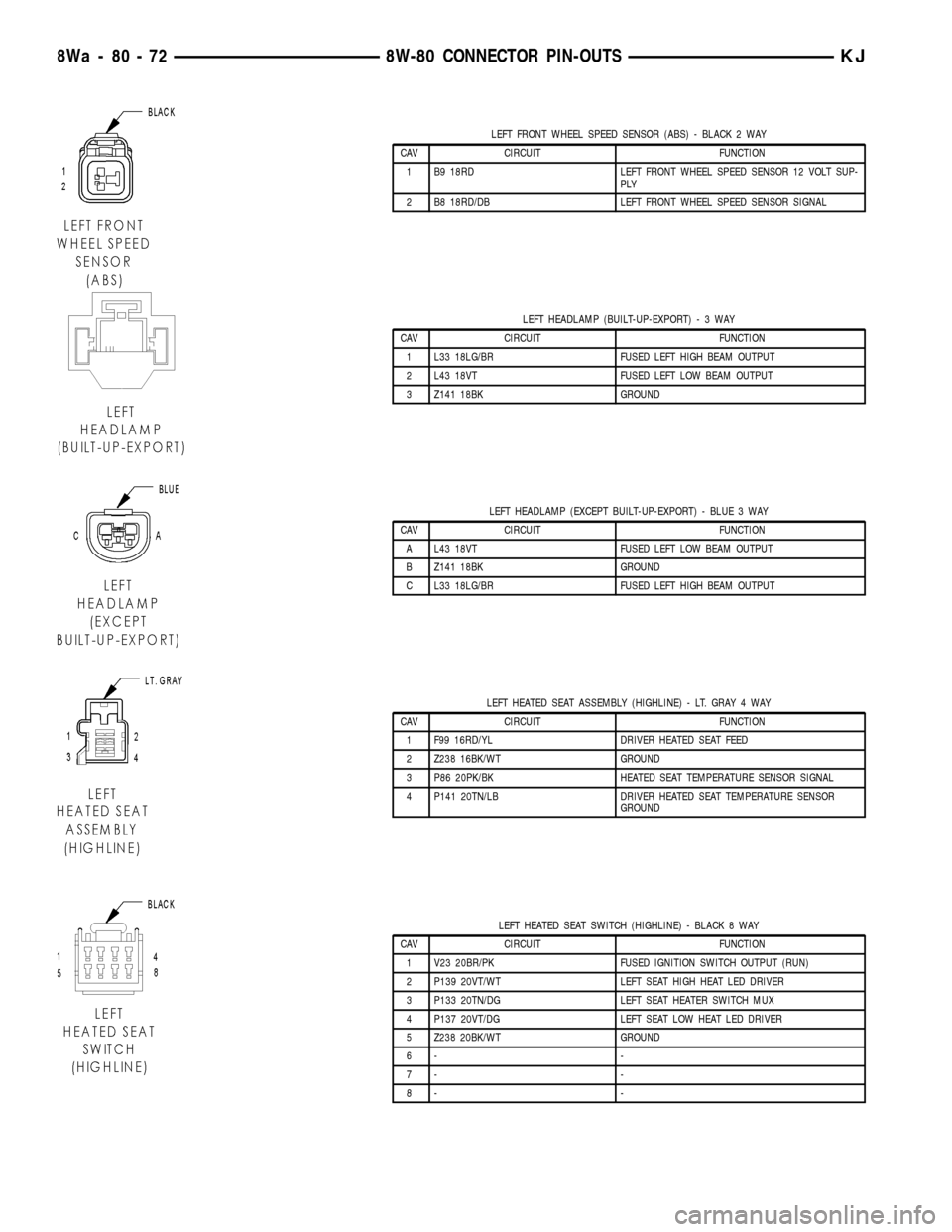

LEFT FRONT WHEEL SPEED SENSOR (ABS) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 B9 18RD LEFT FRONT WHEEL SPEED SENSOR 12 VOLT SUP-

PLY

2 B8 18RD/DB LEFT FRONT WHEEL SPEED SENSOR SIGNAL

LEFT HEADLAMP (BUILT-UP-EXPORT)-3WAY

CAV CIRCUIT FUNCTION

1 L33 18LG/BR FUSED LEFT HIGH BEAM OUTPUT

2 L43 18VT FUSED LEFT LOW BEAM OUTPUT

3 Z141 18BK GROUND

LEFT HEADLAMP (EXCEPT BUILT-UP-EXPORT) - BLUE 3 WAY

CAV CIRCUIT FUNCTION

A L43 18VT FUSED LEFT LOW BEAM OUTPUT

B Z141 18BK GROUND

C L33 18LG/BR FUSED LEFT HIGH BEAM OUTPUT

LEFT HEATED SEAT ASSEMBLY (HIGHLINE) - LT. GRAY 4 WAY

CAV CIRCUIT FUNCTION

1 F99 16RD/YL DRIVER HEATED SEAT FEED

2 Z238 16BK/WT GROUND

3 P86 20PK/BK HEATED SEAT TEMPERATURE SENSOR SIGNAL

4 P141 20TN/LB DRIVER HEATED SEAT TEMPERATURE SENSOR

GROUND

LEFT HEATED SEAT SWITCH (HIGHLINE) - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1 V23 20BR/PK FUSED IGNITION SWITCH OUTPUT (RUN)

2 P139 20VT/WT LEFT SEAT HIGH HEAT LED DRIVER

3 P133 20TN/DG LEFT SEAT HEATER SWITCH MUX

4 P137 20VT/DG LEFT SEAT LOW HEAT LED DRIVER

5 Z238 20BK/WT GROUND

6- -

7- -

8- -

8Wa - 80 - 72 8W-80 CONNECTOR PIN-OUTSKJ