service indicator JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 324 of 1803

ENGINE SYSTEMS

TABLE OF CONTENTS

page page

BATTERY SYSTEM......................... 1

CHARGING SYSTEM....................... 22STARTING SYSTEM....................... 32

BATTERY SYSTEM

TABLE OF CONTENTS

page page

BATTERY SYSTEM

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - BATTERY

SYSTEM.............................2

CLEANING.............................5

INSPECTION...........................6

SPECIFICATIONS........................6

SPECIAL TOOLS........................7

BATTERY

DESCRIPTION..........................7

DIAGNOSIS AND TESTING - BATTERY.......8

STANDARD PROCEDURE

STANDARD PROCEDURE - BATTERY

CHARGING...........................8

STANDARD PROCEDURE - BUILT-IN

INDICATOR TEST.....................10

STANDARD PROCEDURE - HYDROMETER

TEST...............................11

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST.......................12

STANDARD PROCEDURE - LOAD TEST....12

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST.........................14STANDARD PROCEDURE - USING

MIDTRONICS ELECTRICAL TESTER.......15

REMOVAL.............................16

INSTALLATION.........................16

BATTERY HOLDDOWN

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................17

BATTERY CABLES

DESCRIPTION.........................18

OPERATION...........................18

DIAGNOSIS AND TESTING - BATTERY

CABLES............................19

THERMAL GUARD

DESCRIPTION.........................20

OPERATION...........................20

REMOVAL.............................20

INSTALLATION.........................20

BATTERY TRAY

DESCRIPTION.........................21

OPERATION...........................21

REMOVAL.............................21

INSTALLATION.........................21

BATTERY SYSTEM

DESCRIPTION

A single 12-volt battery system is standard factory-

installed equipment on this model. All of the compo-

nents of the battery system are located within the

engine compartment of the vehicle. The service infor-

mation for the battery system in this vehicle covers

the following related components, which are covered

in further detail elsewhere in this service manual:²Battery- The storage battery provides a reli-

able means of storing a renewable source of electrical

energy within the vehicle.

²Battery Cable- The battery cables connect the

battery terminal posts to the vehicle electrical sys-

tem.

²Battery Holddown- The battery holddown

hardware secures the battery in the battery tray in

the engine compartment.

KJENGINE SYSTEMS 8F - 1

Page 329 of 1803

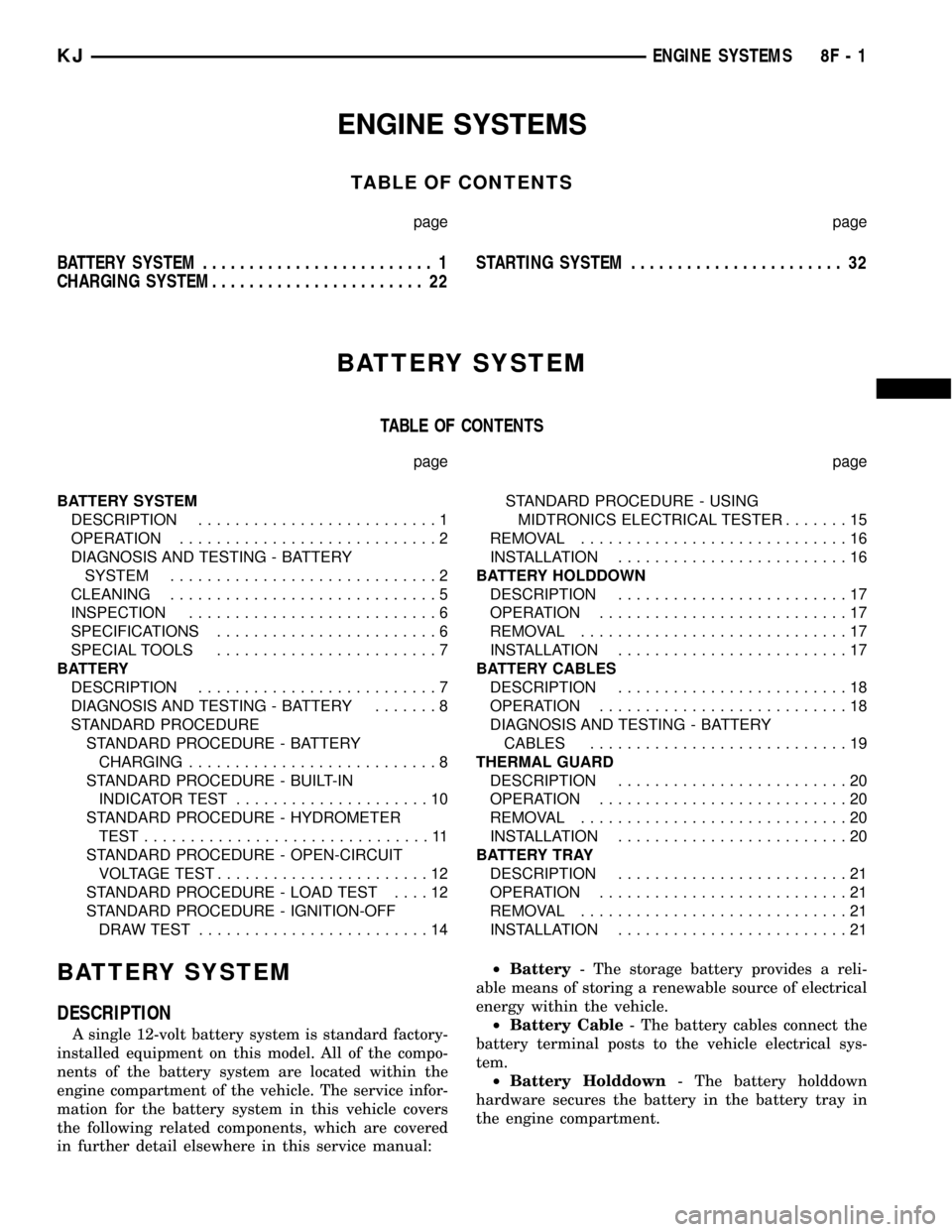

(4) Clean the battery thermal guard with a sodium

bicarbonate (baking soda) and warm water cleaning

solution using a stiff bristle parts cleaning brush to

remove any acid film.

(5) Clean any corrosion from the battery terminal

posts with a wire brush or a post and terminal

cleaner, and a sodium bicarbonate (baking soda) and

warm water cleaning solution (Fig. 3).

INSPECTION

The following information details the recommended

inspection procedures for the battery and related

components. In addition to the maintenance sched-

ules found in this service manual and the owner's

manual, it is recommended that these procedures be

performed any time the battery or related compo-

nents must be removed for vehicle service.

(1) Inspect the battery cable terminal clamps for

damage. Replace any battery cable that has a dam-

aged or deformed terminal clamp.

(2) Inspect the battery tray and battery holddown

hardware for damage. Replace any damaged parts.

(3) Slide the thermal guard off of the battery case.

Inspect the battery case for cracks or other damagethat could result in electrolyte leaks. Also, check the

battery terminal posts for looseness. Batteries with

damaged cases or loose terminal posts must be

replaced.

(4) Inspect the battery thermal guard for tears,

cracks, deformation or other damage. Replace any

battery thermal guard that has been damaged.

(5) Inspect the battery built-in test indicator sight

glass for an indication of the battery condition. If the

battery is discharged, charge as required. Refer to

Standard Procedures for the proper battery built-in

indicator test procedures. Also refer to Standard Pro-

cedures for the proper battery charging procedures.

SPECIFICATIONS

The battery Group Size number, the Cold Cranking

Amperage (CCA) rating, and the Reserve Capacity

(RC) rating or Ampere-Hours (AH) rating can be

found on the original equipment battery label. Be

certain that a replacement battery has the correct

Group Size number, as well as CCA, and RC or AH

ratings that equal or exceed the original equipment

specification for the vehicle being serviced. Battery

sizes and ratings are discussed in more detail below.

²Group Size- The outside dimensions and ter-

minal placement of the battery conform to standards

established by the Battery Council International

(BCI). Each battery is assigned a BCI Group Size

number to help identify a correctly-sized replace-

ment.

²Cold Cranking Amperage- The Cold Crank-

ing Amperage (CCA) rating specifies how much cur-

rent (in amperes) the battery can deliver for thirty

seconds at -18É C (0É F). Terminal voltage must not

fall below 7.2 volts during or after the thirty second

discharge period. The CCA required is generally

higher as engine displacement increases, depending

also upon the starter current draw requirements.

²Reserve Capacity- The Reserve Capacity (RC)

rating specifies the time (in minutes) it takes for bat-

tery terminal voltage to fall below 10.5 volts, at a

discharge rate of 25 amperes. RC is determined with

the battery fully-charged at 26.7É C (80É F). This rat-

ing estimates how long the battery might last after a

charging system failure, under minimum electrical

load.

²Ampere-Hours- The Ampere-Hours (AH) rat-

ing specifies the current (in amperes) that a battery

can deliver steadily for twenty hours, with the volt-

age in the battery not falling below 10.5 volts. This

rating is also sometimes identified as the twenty-

hour discharge rating.

Fig. 3 Clean Battery Terminal Post - Typical

1 - TERMINAL BRUSH

2 - BATTERY CABLE

3 - BATTERY

8F - 6 BATTERY SYSTEMKJ

BATTERY SYSTEM (Continued)

Page 331 of 1803

battery reduces battery gassing and water loss, at

normal charge and discharge rates. Therefore, the

battery should not require additional water in nor-

mal service. If the electrolyte level in this battery

does become low, water must be added. However,

rapid loss of electrolyte can be caused by an over-

charging condition. Be certain to diagnose the charg-

ing system after replenishing the water in the

battery for a low electrolyte condition and before

returning the vehicle to service. Refer to Charging

System for the proper charging system diagnosis and

testing procedures.

DIAGNOSIS AND TESTING - BATTERY

The battery must be completely charged and the

top, posts and terminal clamps should be properly

cleaned and inspected before diagnostic procedures

are performed. Refer to Battery System Cleaning for

the proper cleaning procedures, and Battery System

Inspection for the proper battery inspection proce-

dures. Refer to Standard Procedures for the proper

battery charging procedures.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING OR LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS ARE IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

The condition of a battery is determined by two cri-

teria:

²State-Of-Charge- This can be determined by

checking the specific gravity of the battery electrolyte

(built-in indicator test or hydrometer test), or bychecking the battery voltage (open-circuit voltage

test).

²Cranking Capacity- This can be determined

by performing a battery load test, which measures

the ability of the battery to supply high-amperage

current.

First, determine the battery state-of-charge. This

can be done in one of three ways. If the battery has a

built-in test indicator, perform the built-in indicator

test to determine the state-of-charge. If the battery

has no built-in test indicator but does have remov-

able cell caps, perform the hydrometer test to deter-

mine the state-of-charge. If the battery cell caps are

not removable, or a hydrometer is not available, per-

form the open-circuit voltage test to determine the

state-of-charge. Refer to open-circuit voltage test in

the Standard Procedures section of this group.

Second, determine the battery cranking capacity by

performing a load test. The battery must be charged

before proceeding with a load test if:

²The battery built-in test indicator has a black or

dark color visible.

²The temperature corrected specific gravity of the

battery electrolyte is less than 1.235.

²The battery open-circuit voltage is less than 12.4

volts.

A battery that will not accept a charge is faulty,

and must be replaced. Further testing is not

required. A fully-charged battery must be load tested

to determine its cranking capacity. A battery that is

fully-charged, but does not pass the load test, is

faulty and must be replaced.

NOTE: Completely discharged batteries may take

several hours to accept a charge. Refer to Standard

Procedures for the proper battery charging proce-

dures.

A battery is fully-charged when:

²All battery cells are gassing freely during charg-

ing.

²A green color is visible in the sight glass of the

battery built-in test indicator.

²Three corrected specific gravity tests, taken at

one-hour intervals, indicate no increase in the spe-

cific gravity of the battery electrolyte.

²Open-circuit voltage of the battery is 12.4 volts

or greater.

STANDARD PROCEDURE

STANDARD PROCEDURE - BATTERY

CHARGING

Battery charging can be performed fast or slow, it

terms of time.Slowbattery charging is the best

means of restoring a battery to full potential. Fast

8F - 8 BATTERY SYSTEMKJ

BATTERY (Continued)

Page 332 of 1803

battery charging should only be performed when

absolutely necessary due to time restraints. A battery

is fully-charged when:

²All of the battery cells are gassing freely during

battery charging.

²A green color is visible in the sight glass of the

battery built-in test indicator.

²Three hydrometer tests, taken at one-hour inter-

vals, indicate no increase in the temperature-cor-

rected specific gravity of the battery electrolyte.

²Open-circuit voltage of the battery is 12.65 volts

or above.

WARNING: NEVER EXCEED TWENTY AMPERES

WHEN CHARGING A COLD (-1É C [30É F] OR

LOWER) BATTERY. THE BATTERY MAY ARC INTER-

NALLY AND EXPLODE. PERSONAL INJURY AND/OR

VEHICLE DAMAGE MAY RESULT.

CAUTION: Always disconnect and isolate the bat-

tery negative cable before charging a battery. Do

not exceed sixteen volts while charging a battery.

Damage to the vehicle electrical system compo-

nents may result.

CAUTION: Battery electrolyte will bubble inside the

battery case during normal battery charging. Elec-

trolyte boiling or being discharged from the battery

vents indicates a battery overcharging condition.

Immediately reduce the charging rate or turn off the

charger to evaluate the battery condition. Damage

to the battery may result from overcharging.

CAUTION: The battery should not be hot to the

touch. If the battery feels hot to the touch, turn off

the charger and let the battery cool before continu-

ing the charging operation. Damage to the battery

may result.

NOTE: Models equipped with the diesel engine

option are equipped with two 12-volt batteries, con-

nected in parallel (positive-to-positive and negative-

to-negative). In order to ensure proper charging of

each battery, these batteries MUST be disconnected

from each other, as well as from the vehicle electri-

cal system, while being charged.

Some battery chargers are equipped with polarity-

sensing circuitry. This circuitry protects the battery

charger and the battery from being damaged if they

are improperly connected. If the battery state-of-

charge is too low for the polarity-sensing circuitry to

detect, the battery charger will not operate. This

makes it appear that the battery will not acceptcharging current. See the instructions provided by

the manufacturer of the battery charger for details

on how to bypass the polarity-sensing circuitry.

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine the battery

cranking capacity. Refer to Standard Procedures for

the proper battery load test procedures. If the battery

will endure a load test, return the battery to service.

If the battery will not endure a load test, it is faulty

and must be replaced.

Clean and inspect the battery hold downs, tray,

terminals, posts, and top before completing battery

service. Refer to Battery System Cleaning for the

proper battery system cleaning procedures, and Bat-

tery System Inspection for the proper battery system

inspection procedures.

CHARGING A COMPLETELY DISCHARGED

BATTERY

The following procedure should be used to recharge

a completely discharged battery. Unless this proce-

dure is properly followed, a good battery may be

needlessly replaced.

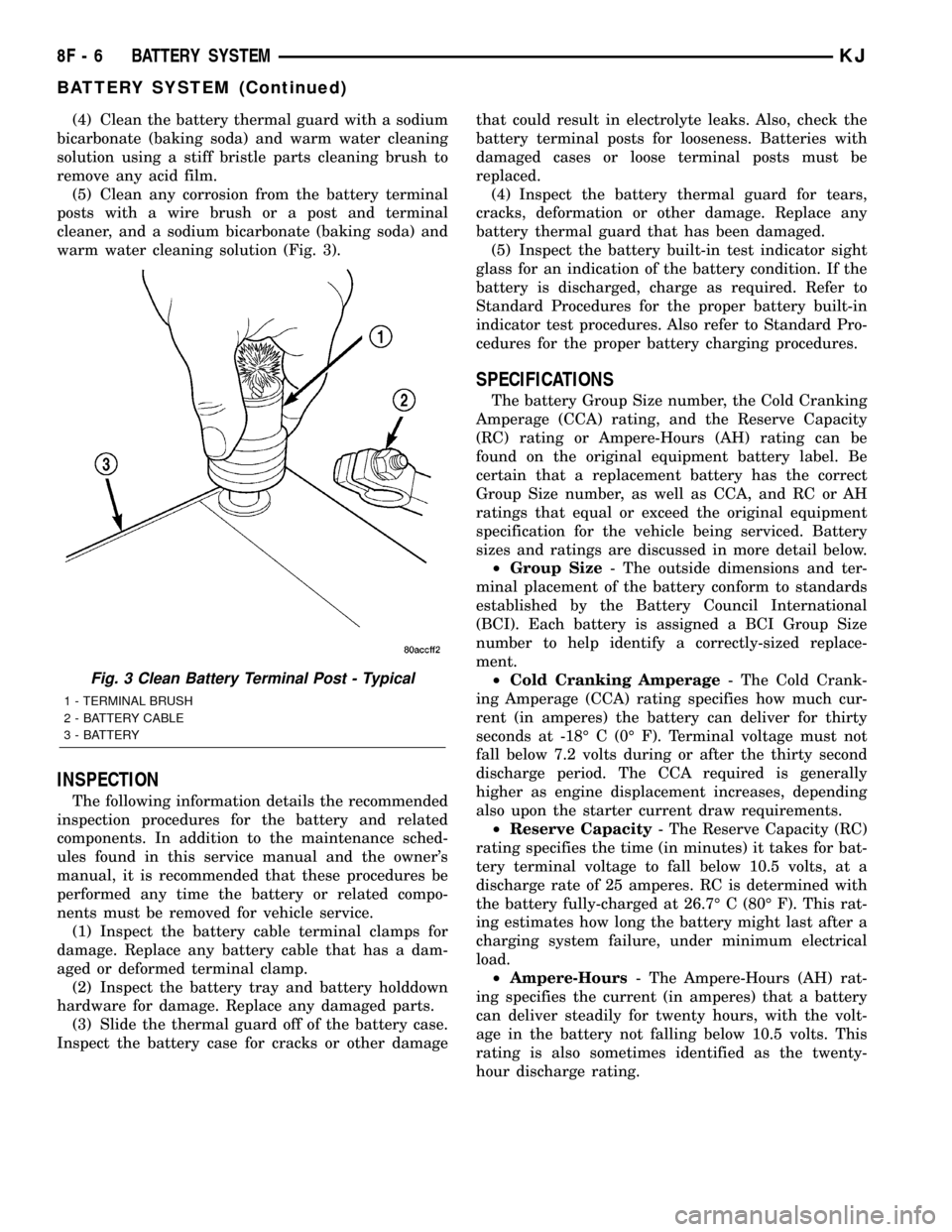

(1) Measure the voltage at the battery posts with a

voltmeter, accurate to 1/10 (0.10) volt (Fig. 6). If the

reading is below ten volts, the battery charging cur-

rent will be low. It could take some time before the

battery accepts a current greater than a few milliam-

peres. Such low current may not be detectable on the

ammeters built into many battery chargers.

(2) Disconnect and isolate the battery negative

cable. Connect the battery charger leads. Some bat-

tery chargers are equipped with polarity-sensing cir-

cuitry. This circuitry protects the battery charger and

the battery from being damaged if they are improp-

erly connected. If the battery state-of-charge is too

low for the polarity-sensing circuitry to detect, the

battery charger will not operate. This makes it

appear that the battery will not accept charging cur-

rent. See the instructions provided by the manufac-

Fig. 6 Voltmeter - Typical

KJBATTERY SYSTEM 8F - 9

BATTERY (Continued)

Page 334 of 1803

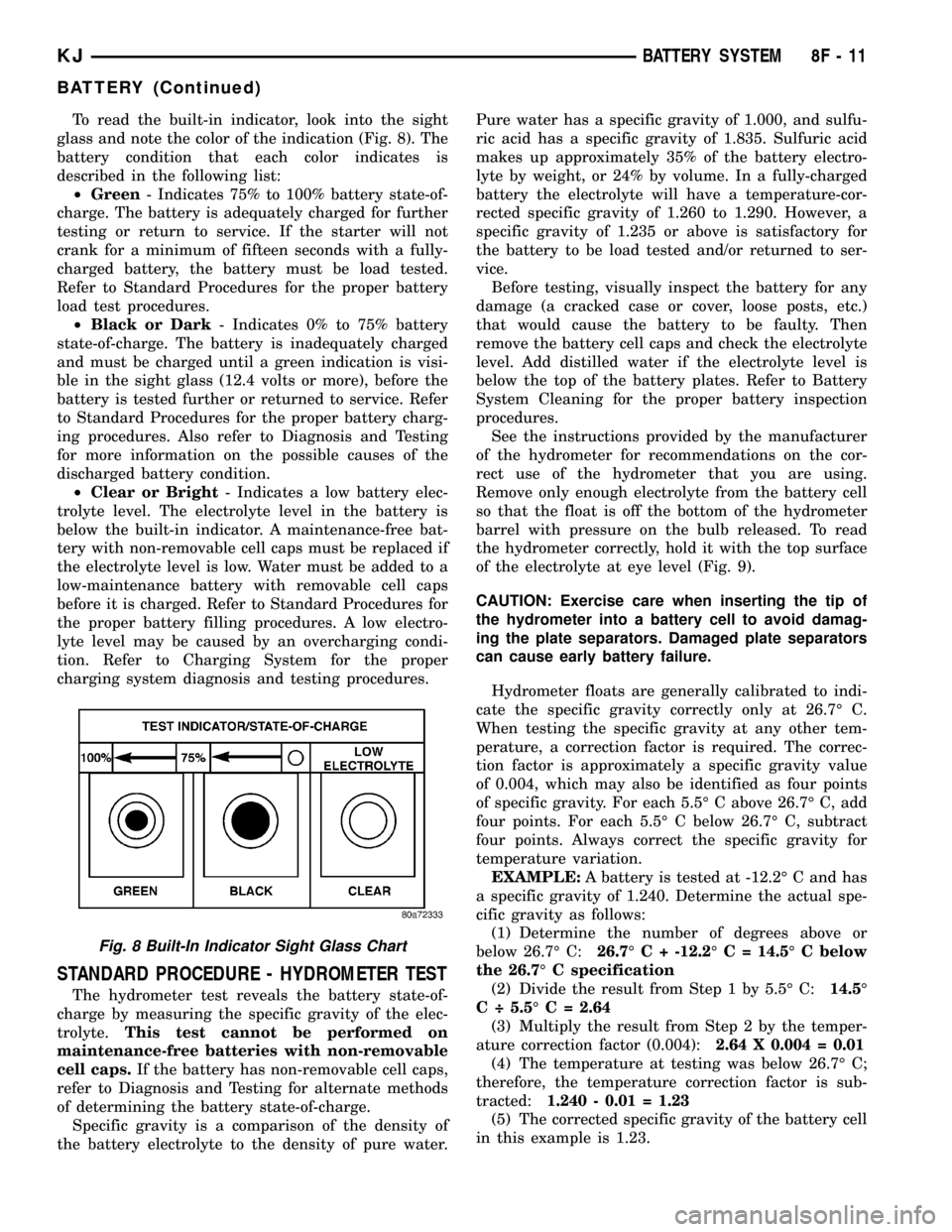

To read the built-in indicator, look into the sight

glass and note the color of the indication (Fig. 8). The

battery condition that each color indicates is

described in the following list:

²Green- Indicates 75% to 100% battery state-of-

charge. The battery is adequately charged for further

testing or return to service. If the starter will not

crank for a minimum of fifteen seconds with a fully-

charged battery, the battery must be load tested.

Refer to Standard Procedures for the proper battery

load test procedures.

²Black or Dark- Indicates 0% to 75% battery

state-of-charge. The battery is inadequately charged

and must be charged until a green indication is visi-

ble in the sight glass (12.4 volts or more), before the

battery is tested further or returned to service. Refer

to Standard Procedures for the proper battery charg-

ing procedures. Also refer to Diagnosis and Testing

for more information on the possible causes of the

discharged battery condition.

²Clear or Bright- Indicates a low battery elec-

trolyte level. The electrolyte level in the battery is

below the built-in indicator. A maintenance-free bat-

tery with non-removable cell caps must be replaced if

the electrolyte level is low. Water must be added to a

low-maintenance battery with removable cell caps

before it is charged. Refer to Standard Procedures for

the proper battery filling procedures. A low electro-

lyte level may be caused by an overcharging condi-

tion. Refer to Charging System for the proper

charging system diagnosis and testing procedures.

STANDARD PROCEDURE - HYDROMETER TEST

The hydrometer test reveals the battery state-of-

charge by measuring the specific gravity of the elec-

trolyte.This test cannot be performed on

maintenance-free batteries with non-removable

cell caps.If the battery has non-removable cell caps,

refer to Diagnosis and Testing for alternate methods

of determining the battery state-of-charge.

Specific gravity is a comparison of the density of

the battery electrolyte to the density of pure water.Pure water has a specific gravity of 1.000, and sulfu-

ric acid has a specific gravity of 1.835. Sulfuric acid

makes up approximately 35% of the battery electro-

lyte by weight, or 24% by volume. In a fully-charged

battery the electrolyte will have a temperature-cor-

rected specific gravity of 1.260 to 1.290. However, a

specific gravity of 1.235 or above is satisfactory for

the battery to be load tested and/or returned to ser-

vice.

Before testing, visually inspect the battery for any

damage (a cracked case or cover, loose posts, etc.)

that would cause the battery to be faulty. Then

remove the battery cell caps and check the electrolyte

level. Add distilled water if the electrolyte level is

below the top of the battery plates. Refer to Battery

System Cleaning for the proper battery inspection

procedures.

See the instructions provided by the manufacturer

of the hydrometer for recommendations on the cor-

rect use of the hydrometer that you are using.

Remove only enough electrolyte from the battery cell

so that the float is off the bottom of the hydrometer

barrel with pressure on the bulb released. To read

the hydrometer correctly, hold it with the top surface

of the electrolyte at eye level (Fig. 9).

CAUTION: Exercise care when inserting the tip of

the hydrometer into a battery cell to avoid damag-

ing the plate separators. Damaged plate separators

can cause early battery failure.

Hydrometer floats are generally calibrated to indi-

cate the specific gravity correctly only at 26.7É C.

When testing the specific gravity at any other tem-

perature, a correction factor is required. The correc-

tion factor is approximately a specific gravity value

of 0.004, which may also be identified as four points

of specific gravity. For each 5.5É C above 26.7É C, add

four points. For each 5.5É C below 26.7É C, subtract

four points. Always correct the specific gravity for

temperature variation.

EXAMPLE:A battery is tested at -12.2É C and has

a specific gravity of 1.240. Determine the actual spe-

cific gravity as follows:

(1) Determine the number of degrees above or

below 26.7É C:26.7É C + -12.2É C = 14.5É C below

the 26.7É C specification

(2) Divide the result from Step 1 by 5.5É C:14.5É

C ÷ 5.5É C = 2.64

(3) Multiply the result from Step 2 by the temper-

ature correction factor (0.004):2.64 X 0.004 = 0.01

(4) The temperature at testing was below 26.7É C;

therefore, the temperature correction factor is sub-

tracted:1.240 - 0.01 = 1.23

(5) The corrected specific gravity of the battery cell

in this example is 1.23.

Fig. 8 Built-In Indicator Sight Glass Chart

KJBATTERY SYSTEM 8F - 11

BATTERY (Continued)

Page 373 of 1803

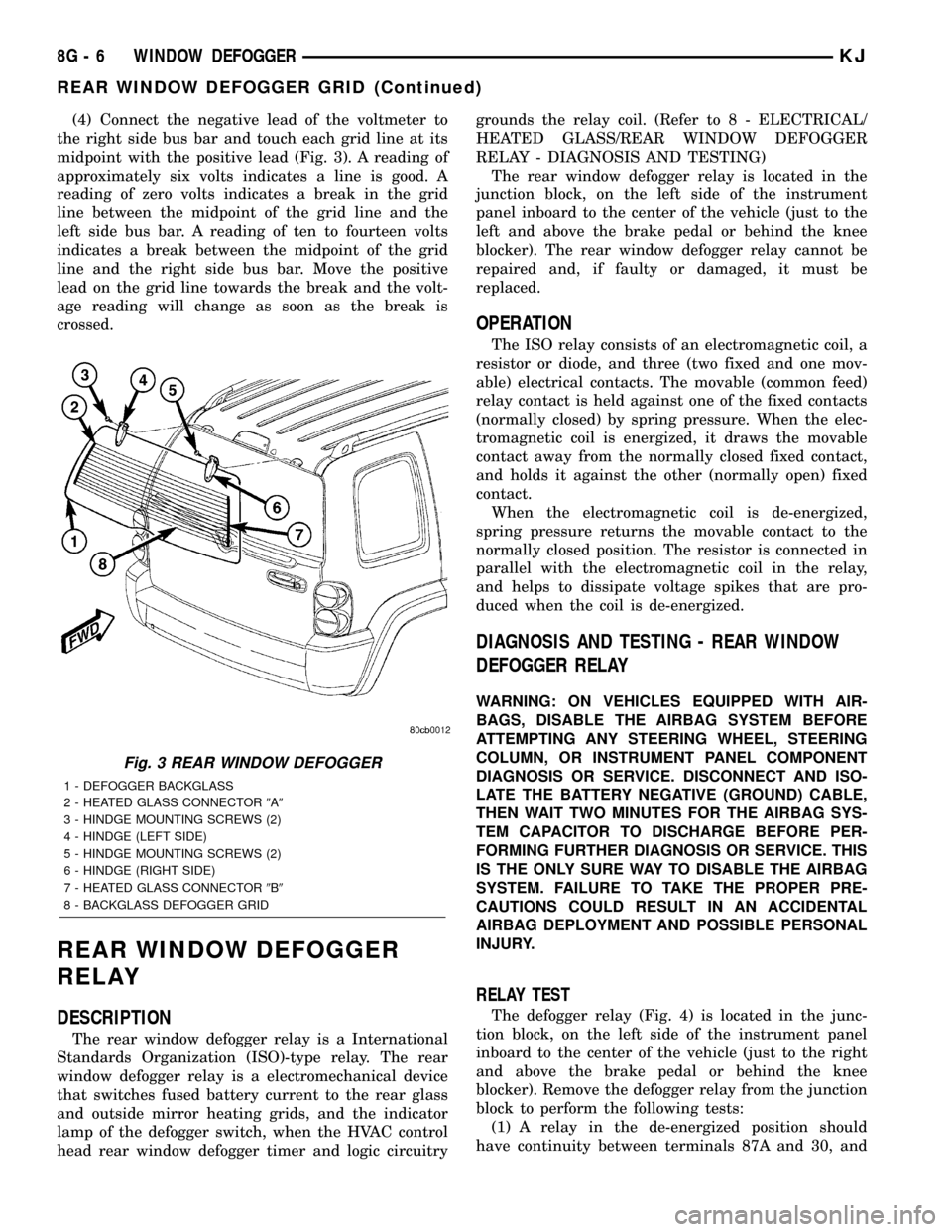

(4) Connect the negative lead of the voltmeter to

the right side bus bar and touch each grid line at its

midpoint with the positive lead (Fig. 3). A reading of

approximately six volts indicates a line is good. A

reading of zero volts indicates a break in the grid

line between the midpoint of the grid line and the

left side bus bar. A reading of ten to fourteen volts

indicates a break between the midpoint of the grid

line and the right side bus bar. Move the positive

lead on the grid line towards the break and the volt-

age reading will change as soon as the break is

crossed.

REAR WINDOW DEFOGGER

RELAY

DESCRIPTION

The rear window defogger relay is a International

Standards Organization (ISO)-type relay. The rear

window defogger relay is a electromechanical device

that switches fused battery current to the rear glass

and outside mirror heating grids, and the indicator

lamp of the defogger switch, when the HVAC control

head rear window defogger timer and logic circuitrygrounds the relay coil. (Refer to 8 - ELECTRICAL/

HEATED GLASS/REAR WINDOW DEFOGGER

RELAY - DIAGNOSIS AND TESTING)

The rear window defogger relay is located in the

junction block, on the left side of the instrument

panel inboard to the center of the vehicle (just to the

left and above the brake pedal or behind the knee

blocker). The rear window defogger relay cannot be

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor is connected in

parallel with the electromagnetic coil in the relay,

and helps to dissipate voltage spikes that are pro-

duced when the coil is de-energized.

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER RELAY

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

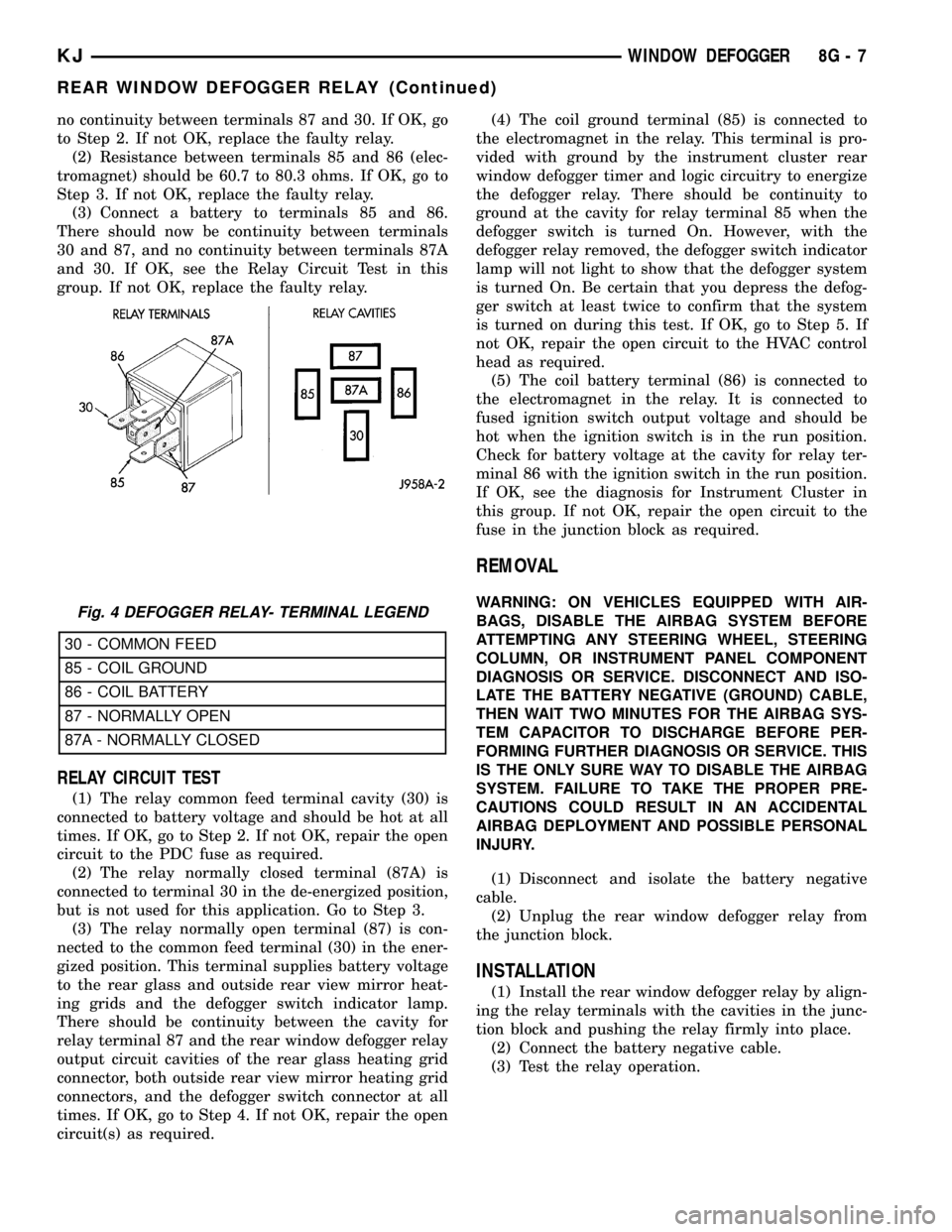

RELAY TEST

The defogger relay (Fig. 4) is located in the junc-

tion block, on the left side of the instrument panel

inboard to the center of the vehicle (just to the right

and above the brake pedal or behind the knee

blocker). Remove the defogger relay from the junction

block to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

Fig. 3 REAR WINDOW DEFOGGER

1 - DEFOGGER BACKGLASS

2 - HEATED GLASS CONNECTOR9A9

3 - HINDGE MOUNTING SCREWS (2)

4 - HINDGE (LEFT SIDE)

5 - HINDGE MOUNTING SCREWS (2)

6 - HINDGE (RIGHT SIDE)

7 - HEATED GLASS CONNECTOR9B9

8 - BACKGLASS DEFOGGER GRID

8G - 6 WINDOW DEFOGGERKJ

REAR WINDOW DEFOGGER GRID (Continued)

Page 374 of 1803

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 60.7 to 80.3 ohms. If OK, go to

Step 3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see the Relay Circuit Test in this

group. If not OK, replace the faulty relay.

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the PDC fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the rear glass and outside rear view mirror heat-

ing grids and the defogger switch indicator lamp.

There should be continuity between the cavity for

relay terminal 87 and the rear window defogger relay

output circuit cavities of the rear glass heating grid

connector, both outside rear view mirror heating grid

connectors, and the defogger switch connector at all

times. If OK, go to Step 4. If not OK, repair the open

circuit(s) as required.(4) The coil ground terminal (85) is connected to

the electromagnet in the relay. This terminal is pro-

vided with ground by the instrument cluster rear

window defogger timer and logic circuitry to energize

the defogger relay. There should be continuity to

ground at the cavity for relay terminal 85 when the

defogger switch is turned On. However, with the

defogger relay removed, the defogger switch indicator

lamp will not light to show that the defogger system

is turned On. Be certain that you depress the defog-

ger switch at least twice to confirm that the system

is turned on during this test. If OK, go to Step 5. If

not OK, repair the open circuit to the HVAC control

head as required.

(5) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is connected to

fused ignition switch output voltage and should be

hot when the ignition switch is in the run position.

Check for battery voltage at the cavity for relay ter-

minal 86 with the ignition switch in the run position.

If OK, see the diagnosis for Instrument Cluster in

this group. If not OK, repair the open circuit to the

fuse in the junction block as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the rear window defogger relay from

the junction block.

INSTALLATION

(1) Install the rear window defogger relay by align-

ing the relay terminals with the cavities in the junc-

tion block and pushing the relay firmly into place.

(2) Connect the battery negative cable.

(3) Test the relay operation.

Fig. 4 DEFOGGER RELAY- TERMINAL LEGEND

KJWINDOW DEFOGGER 8G - 7

REAR WINDOW DEFOGGER RELAY (Continued)

Page 375 of 1803

REAR WINDOW DEFOGGER

SWITCH

DESCRIPTION

The rear window defogger switch is installed in the

instrument panel HVAC contol head assembly. The

momentary-type switch provides a hard-wired ground

signal to the HVAC control head each time it is

depressed. The instrument cluster rear window

defogger timer and logic circuitry responds by ener-

gizing or de-energizing the rear window defogger

relay.

OPERATION

Energizing the rear window defogger relay pro-

vides electrical current to the rear window defogger

grid and, if the vehicle is so equipped, the outside

rear view mirror heating grids. An amber indicator

lamp in the defogger switch, which lights to indicate

when the defogger system is turned On, is also pow-

ered by the defogger relay output.

The defogger switch illumination lamp and indica-

tor lamp bulbs are serviceable. The defogger switch

cannot be repaired and, if faulty or damaged the

entire HVAC control head assembly must be

replaced.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER SWITCH

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

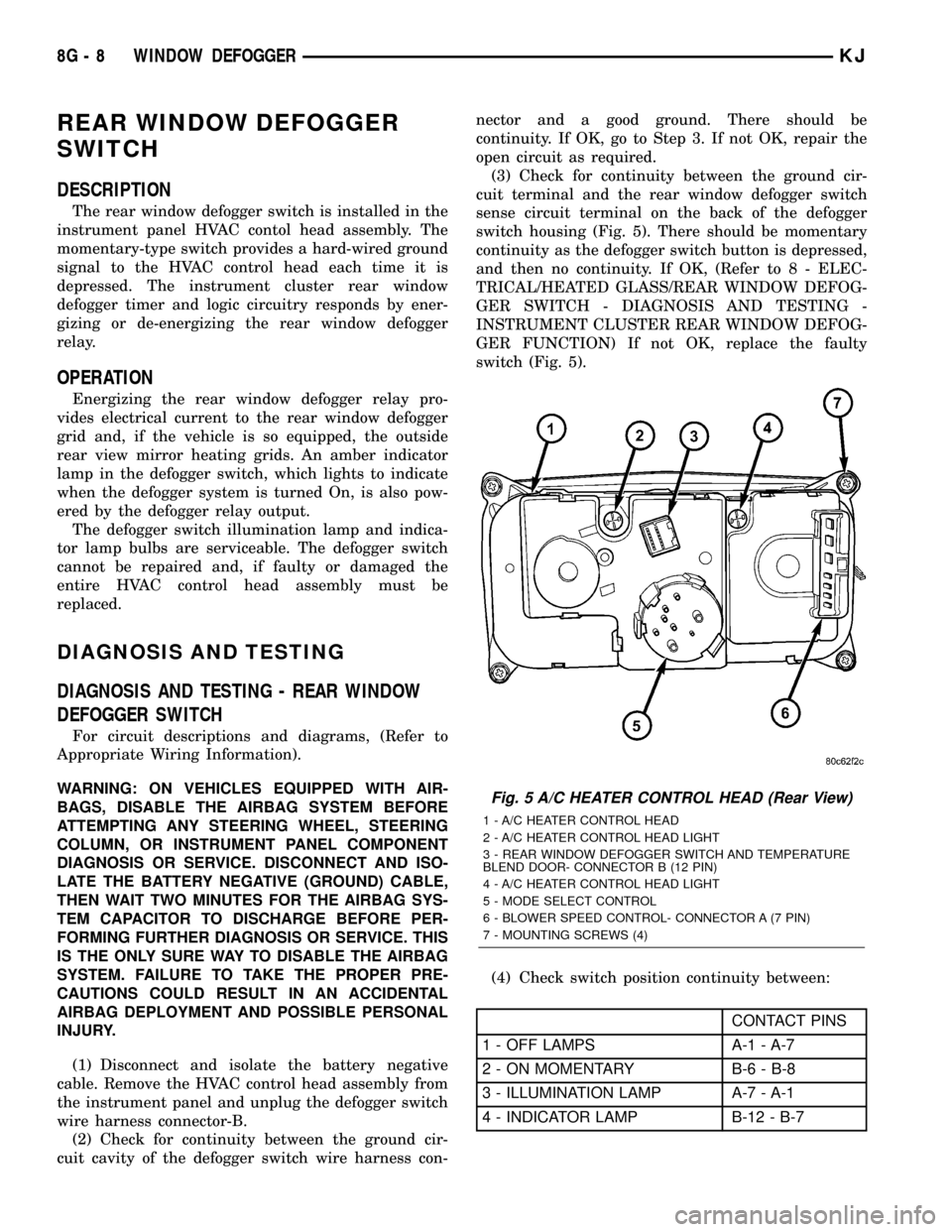

(1) Disconnect and isolate the battery negative

cable. Remove the HVAC control head assembly from

the instrument panel and unplug the defogger switch

wire harness connector-B.

(2) Check for continuity between the ground cir-

cuit cavity of the defogger switch wire harness con-nector and a good ground. There should be

continuity. If OK, go to Step 3. If not OK, repair the

open circuit as required.

(3) Check for continuity between the ground cir-

cuit terminal and the rear window defogger switch

sense circuit terminal on the back of the defogger

switch housing (Fig. 5). There should be momentary

continuity as the defogger switch button is depressed,

and then no continuity. If OK, (Refer to 8 - ELEC-

TRICAL/HEATED GLASS/REAR WINDOW DEFOG-

GER SWITCH - DIAGNOSIS AND TESTING -

INSTRUMENT CLUSTER REAR WINDOW DEFOG-

GER FUNCTION) If not OK, replace the faulty

switch (Fig. 5).

(4) Check switch position continuity between:

CONTACT PINS

1 - OFF LAMPS A-1 - A-7

2 - ON MOMENTARY B-6 - B-8

3 - ILLUMINATION LAMP A-7 - A-1

4 - INDICATOR LAMP B-12 - B-7

Fig. 5 A/C HEATER CONTROL HEAD (Rear View)

1 - A/C HEATER CONTROL HEAD

2 - A/C HEATER CONTROL HEAD LIGHT

3 - REAR WINDOW DEFOGGER SWITCH AND TEMPERATURE

BLEND DOOR- CONNECTOR B (12 PIN)

4 - A/C HEATER CONTROL HEAD LIGHT

5 - MODE SELECT CONTROL

6 - BLOWER SPEED CONTROL- CONNECTOR A (7 PIN)

7 - MOUNTING SCREWS (4)

8G - 8 WINDOW DEFOGGERKJ

Page 377 of 1803

HEATED SEAT SYSTEM

TABLE OF CONTENTS

page page

HEATED SEAT SYSTEM

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM............................11

DRIVER SEAT HEATER SWITCH

DESCRIPTION.........................11

OPERATION...........................12

DIAGNOSIS AND TESTING - HEATED SEAT

SWITCH............................12

REMOVAL.............................13

INSTALLATION.........................13

HEATED SEAT ELEMENT

DESCRIPTION.........................13OPERATION...........................13

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT...........................13

HEATED SEAT SENSOR

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR............................14

PASSENGER SEAT HEATER SWITCH

DESCRIPTION.........................14

OPERATION...........................14

DIAGNOSIS AND TESTING - HEATED SEAT

SWITCH............................14

REMOVAL.............................15

INSTALLATION.........................15

HEATED SEAT SYSTEM

DESCRIPTION

Individually controlled electrically heated front

seats are available on models that are also equipped

with the optional leather trim package. Vehicles with

this option can be visually identified by the two sep-

arate heated seat switches mounted on the outboard

seat cushion side shields. The heated seat system

allows the front seat driver and passenger to select

from two different levels of supplemental electrical

seat heating, or no seat heating to suit their individ-

ual comfort requirements. The heated seat system for

this vehicle includes the following major components:

²Heated Seat Switches- Two heated seat

switches are used per vehicle, including two Light-

Emitting Diode (LED) indicator lamps and an incan-

descent back lighting bulb for each switch. One

switch for the driver and one for the passenger front

seats. The switches are mounted on the outboard

seat cushion side shields.

²Heated Seat Module- also referred to as the

Seat Heat Interface Module (SHIM), this module con-

tains the solid state electronic control and diagnostic

logic circuitry for the heated seat system. One heated

seat module is used per vehicle and is mounted

under the left front seat cushion. Refer to the Elec-

tronic Control Modules section of the service manual

for heated seat module information.

²Heated Seat Elements- Four heated seat ele-

ments are used per vehicle, one for each front seat

back and one for each front seat cushion. The ele-

ments are integral to the individual front seat andseat back cushions and cannot be removed from the

cushions, once installed at the factory.

²Heated Seat Sensors- Two heated seat sen-

sors are used per vehicle, one for each front seat. The

sensors are integral to the individual front seat heat-

ing elements.

Following are general descriptions of the major

components in the heated seat system. See the own-

er's manual in the vehicle glove box for more infor-

mation on the features, use and operation of the

heated seat system. Refer toWiring Diagramsfor

the location of complete heated seat system wiring

diagrams.

OPERATION

The heated seat module receives fused battery cur-

rent through fuse #29 in the Junction Block (JB)

when the ignition switch is in the ªONº position. The

heated seat switches receive battery current through

fuse #25 in the Junction Block also, when the igni-

tion switch is in the ªONº position. The heated seat

module shares a common ground circuit with each of

the heated seat elements. The heated seat elements

will only operate when the surface temperature of

the seat cushion is below the designed temperature

set points of the system.

The heated seat system will also be turned off

automatically whenever the ignition switch is turned

to any position except On. If the ignition switch is

turned to the Off position while a heated seat is

turned ON, the heated seat will remain Off after the

ignition switch is turned back ªONº until a heated

seat switch is depressed again.

8G - 10 HEATED SEAT SYSTEMKJ

Page 405 of 1803

TURN SIGNAL INDICATOR

DESCRIPTION.........................34

OPERATION...........................34

WAIT-TO-START INDICATOR

DESCRIPTION.........................35

OPERATION...........................35

WASHER FLUID INDICATOR

DESCRIPTION.........................35OPERATION...........................36

DIAGNOSIS AND TESTING - WASHER FLUID

INDICATOR..........................36

WATER-IN-FUEL INDICATOR

DESCRIPTION.........................37

OPERATION...........................37

INSTRUMENT CLUSTER

DESCRIPTION

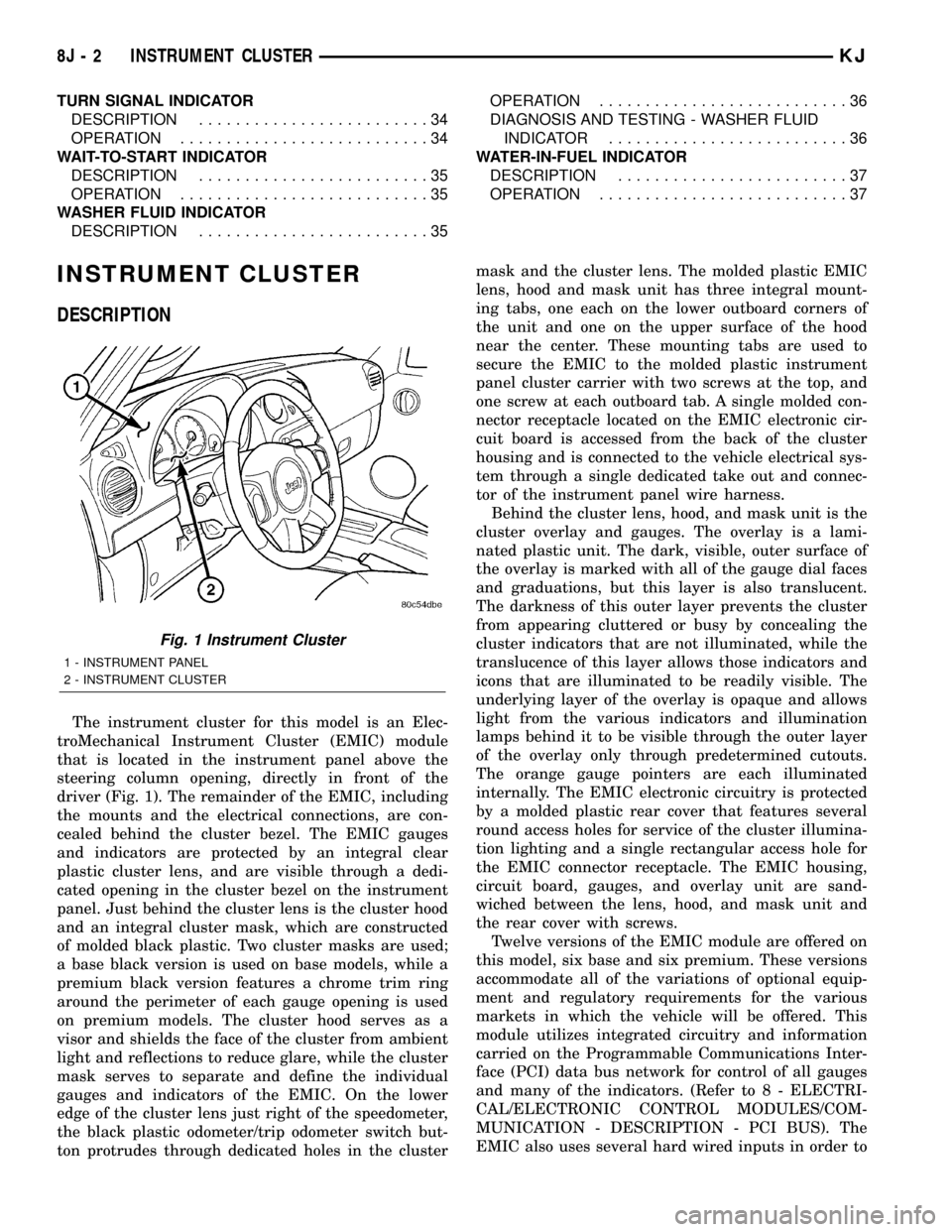

The instrument cluster for this model is an Elec-

troMechanical Instrument Cluster (EMIC) module

that is located in the instrument panel above the

steering column opening, directly in front of the

driver (Fig. 1). The remainder of the EMIC, including

the mounts and the electrical connections, are con-

cealed behind the cluster bezel. The EMIC gauges

and indicators are protected by an integral clear

plastic cluster lens, and are visible through a dedi-

cated opening in the cluster bezel on the instrument

panel. Just behind the cluster lens is the cluster hood

and an integral cluster mask, which are constructed

of molded black plastic. Two cluster masks are used;

a base black version is used on base models, while a

premium black version features a chrome trim ring

around the perimeter of each gauge opening is used

on premium models. The cluster hood serves as a

visor and shields the face of the cluster from ambient

light and reflections to reduce glare, while the cluster

mask serves to separate and define the individual

gauges and indicators of the EMIC. On the lower

edge of the cluster lens just right of the speedometer,

the black plastic odometer/trip odometer switch but-

ton protrudes through dedicated holes in the clustermask and the cluster lens. The molded plastic EMIC

lens, hood and mask unit has three integral mount-

ing tabs, one each on the lower outboard corners of

the unit and one on the upper surface of the hood

near the center. These mounting tabs are used to

secure the EMIC to the molded plastic instrument

panel cluster carrier with two screws at the top, and

one screw at each outboard tab. A single molded con-

nector receptacle located on the EMIC electronic cir-

cuit board is accessed from the back of the cluster

housing and is connected to the vehicle electrical sys-

tem through a single dedicated take out and connec-

tor of the instrument panel wire harness.

Behind the cluster lens, hood, and mask unit is the

cluster overlay and gauges. The overlay is a lami-

nated plastic unit. The dark, visible, outer surface of

the overlay is marked with all of the gauge dial faces

and graduations, but this layer is also translucent.

The darkness of this outer layer prevents the cluster

from appearing cluttered or busy by concealing the

cluster indicators that are not illuminated, while the

translucence of this layer allows those indicators and

icons that are illuminated to be readily visible. The

underlying layer of the overlay is opaque and allows

light from the various indicators and illumination

lamps behind it to be visible through the outer layer

of the overlay only through predetermined cutouts.

The orange gauge pointers are each illuminated

internally. The EMIC electronic circuitry is protected

by a molded plastic rear cover that features several

round access holes for service of the cluster illumina-

tion lighting and a single rectangular access hole for

the EMIC connector receptacle. The EMIC housing,

circuit board, gauges, and overlay unit are sand-

wiched between the lens, hood, and mask unit and

the rear cover with screws.

Twelve versions of the EMIC module are offered on

this model, six base and six premium. These versions

accommodate all of the variations of optional equip-

ment and regulatory requirements for the various

markets in which the vehicle will be offered. This

module utilizes integrated circuitry and information

carried on the Programmable Communications Inter-

face (PCI) data bus network for control of all gauges

and many of the indicators. (Refer to 8 - ELECTRI-

CAL/ELECTRONIC CONTROL MODULES/COM-

MUNICATION - DESCRIPTION - PCI BUS). The

EMIC also uses several hard wired inputs in order to

Fig. 1 Instrument Cluster

1 - INSTRUMENT PANEL

2 - INSTRUMENT CLUSTER

8J - 2 INSTRUMENT CLUSTERKJ