windshield washer JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 715 of 1803

element where it is gripped by the claws of the

superstructure.

All models have two 47.50 centimeter (18.70 inch)

long front wiper blades with non-replaceable rubber

elements (squeegees). The wiper blades cannot be

adjusted or repaired. If faulty, worn, or damaged the

entire wiper blade unit must be replaced.

OPERATION

The wiper blades are moved back and forth across

the glass by the wiper arms when the wipers are

being operated. The wiper blade superstructure is

the flexible frame that grips the wiper blade element

and evenly distributes the force of the spring-loaded

wiper arm along the length of the element. The com-

bination of the wiper arm force and the flexibility of

the superstructure makes the element conform to

and maintain proper contact with the glass, even as

the blade is moved over the varied curvature that

may be encountered across the glass surface. The

wiper element flexor provides the claws of the blade

superstructure with a rigid, yet flexible component

on the element which can be gripped. The rubber ele-

ment is designed to be stiff enough to maintain an

even cleaning edge as it is drawn across the glass,

yet resilient enough to conform to the glass surface

and flip from one cleaning edge to the other each

time the wiper blade changes directions. The airfoil

used on the driver side wiper blade is designed to

reduce the lifting effect caused by air moving over

the vehicle at higher highway speeds.

REMOVAL

NOTE: The notched end of the wiper element flexor

should always be oriented towards the end of the

wiper blade that is nearest to the wiper pivot.

(1) Lift the front wiper arm to raise the wiper

blade and element off of the glass, until the wiper

arm hinge is in its over-center position.

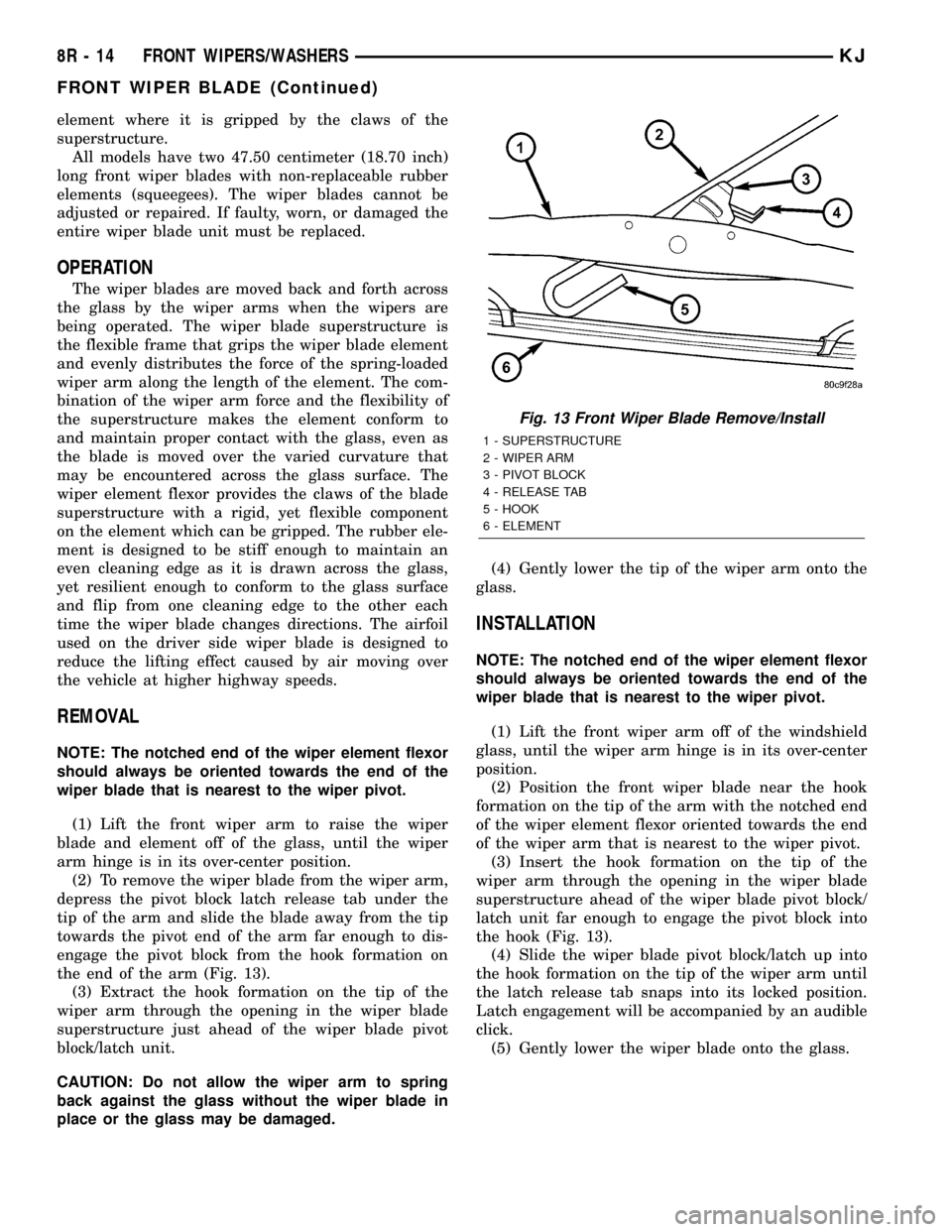

(2) To remove the wiper blade from the wiper arm,

depress the pivot block latch release tab under the

tip of the arm and slide the blade away from the tip

towards the pivot end of the arm far enough to dis-

engage the pivot block from the hook formation on

the end of the arm (Fig. 13).

(3) Extract the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure just ahead of the wiper blade pivot

block/latch unit.

CAUTION: Do not allow the wiper arm to spring

back against the glass without the wiper blade in

place or the glass may be damaged.(4) Gently lower the tip of the wiper arm onto the

glass.

INSTALLATION

NOTE: The notched end of the wiper element flexor

should always be oriented towards the end of the

wiper blade that is nearest to the wiper pivot.

(1) Lift the front wiper arm off of the windshield

glass, until the wiper arm hinge is in its over-center

position.

(2) Position the front wiper blade near the hook

formation on the tip of the arm with the notched end

of the wiper element flexor oriented towards the end

of the wiper arm that is nearest to the wiper pivot.

(3) Insert the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure ahead of the wiper blade pivot block/

latch unit far enough to engage the pivot block into

the hook (Fig. 13).

(4) Slide the wiper blade pivot block/latch up into

the hook formation on the tip of the wiper arm until

the latch release tab snaps into its locked position.

Latch engagement will be accompanied by an audible

click.

(5) Gently lower the wiper blade onto the glass.

Fig. 13 Front Wiper Blade Remove/Install

1 - SUPERSTRUCTURE

2 - WIPER ARM

3 - PIVOT BLOCK

4 - RELEASE TAB

5 - HOOK

6 - ELEMENT

8R - 14 FRONT WIPERS/WASHERSKJ

FRONT WIPER BLADE (Continued)

Page 722 of 1803

WASHER RESERVOIR

DESCRIPTION

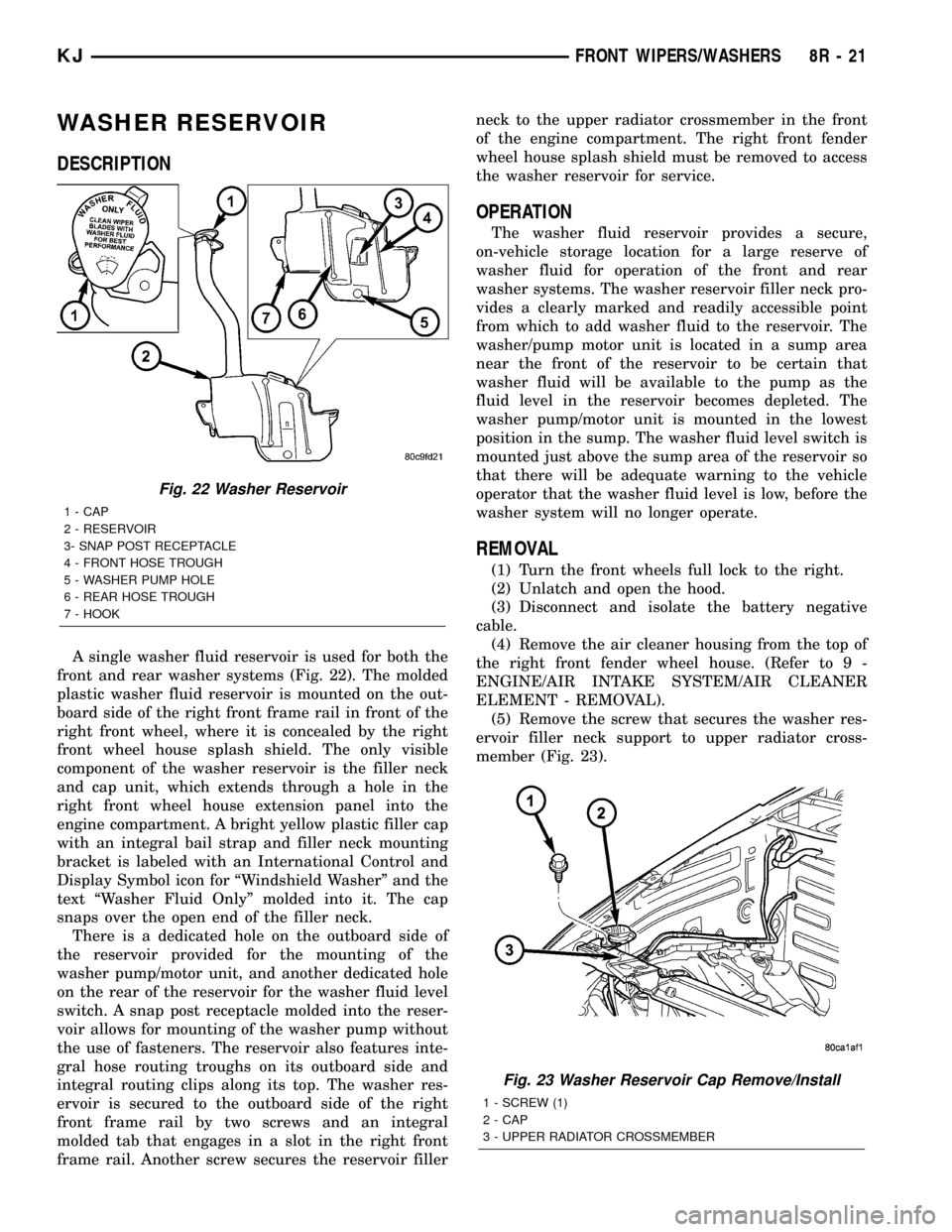

A single washer fluid reservoir is used for both the

front and rear washer systems (Fig. 22). The molded

plastic washer fluid reservoir is mounted on the out-

board side of the right front frame rail in front of the

right front wheel, where it is concealed by the right

front wheel house splash shield. The only visible

component of the washer reservoir is the filler neck

and cap unit, which extends through a hole in the

right front wheel house extension panel into the

engine compartment. A bright yellow plastic filler cap

with an integral bail strap and filler neck mounting

bracket is labeled with an International Control and

Display Symbol icon for ªWindshield Washerº and the

text ªWasher Fluid Onlyº molded into it. The cap

snaps over the open end of the filler neck.

There is a dedicated hole on the outboard side of

the reservoir provided for the mounting of the

washer pump/motor unit, and another dedicated hole

on the rear of the reservoir for the washer fluid level

switch. A snap post receptacle molded into the reser-

voir allows for mounting of the washer pump without

the use of fasteners. The reservoir also features inte-

gral hose routing troughs on its outboard side and

integral routing clips along its top. The washer res-

ervoir is secured to the outboard side of the right

front frame rail by two screws and an integral

molded tab that engages in a slot in the right front

frame rail. Another screw secures the reservoir fillerneck to the upper radiator crossmember in the front

of the engine compartment. The right front fender

wheel house splash shield must be removed to access

the washer reservoir for service.

OPERATION

The washer fluid reservoir provides a secure,

on-vehicle storage location for a large reserve of

washer fluid for operation of the front and rear

washer systems. The washer reservoir filler neck pro-

vides a clearly marked and readily accessible point

from which to add washer fluid to the reservoir. The

washer/pump motor unit is located in a sump area

near the front of the reservoir to be certain that

washer fluid will be available to the pump as the

fluid level in the reservoir becomes depleted. The

washer pump/motor unit is mounted in the lowest

position in the sump. The washer fluid level switch is

mounted just above the sump area of the reservoir so

that there will be adequate warning to the vehicle

operator that the washer fluid level is low, before the

washer system will no longer operate.

REMOVAL

(1) Turn the front wheels full lock to the right.

(2) Unlatch and open the hood.

(3) Disconnect and isolate the battery negative

cable.

(4) Remove the air cleaner housing from the top of

the right front fender wheel house. (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

ELEMENT - REMOVAL).

(5) Remove the screw that secures the washer res-

ervoir filler neck support to upper radiator cross-

member (Fig. 23).

Fig. 22 Washer Reservoir

1 - CAP

2 - RESERVOIR

3- SNAP POST RECEPTACLE

4 - FRONT HOSE TROUGH

5 - WASHER PUMP HOLE

6 - REAR HOSE TROUGH

7 - HOOK

Fig. 23 Washer Reservoir Cap Remove/Install

1 - SCREW (1)

2 - CAP

3 - UPPER RADIATOR CROSSMEMBER

KJFRONT WIPERS/WASHERS 8R - 21

Page 733 of 1803

rear wiper on driver circuit between the rear wiper

module and the multi-function switch as required.

REAR WASHER SYSTEM

The diagnosis found here addresses an electrically

inoperative rear washer system. If the washer pump/

motor operates, but no washer fluid is emitted from

the rear washer nozzle, be certain to check the fluid

level in the reservoir. Also inspect the rear washer

system components as required. (Refer to 8 - ELEC-

TRICAL/REAR WIPERS/WASHERS - INSPECTION).

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Turn the ignition switch to the On position.

Turn the control ring on the right (wiper) control

stalk of the multi-function switch to the On position.

Check whether the rear wiper system is operating. If

OK, go to Step 2. If not OK, test and repair the rear

wiper system before continuing with these tests.

Refer to REAR WIPER SYSTEM .

(2) Pull the right (wiper) control stalk of the multi-

function switch toward the steering wheel. Check

whether the front washer system is operating. If OK,

test the multi-function switch. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/MULTI-

FUNCTION SWITCH - DIAGNOSIS AND

TESTING). If the multi-function switch tests OK, go

to Step 3. If the multi-function switch does not test

OK, replace the faulty switch.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the headlamp and dash wire harness con-

nector for the washer pump/motor unit from the

pump/motor unit connector receptacle. Check for con-

tinuity between the washer pump driver circuit cav-ity of the headlamp and dash wire harness connector

for the washer pump/motor unit and a good ground.

There should be no continuity. If OK, go to Step 4. If

not OK, repair the shorted washer pump driver cir-

cuit between the washer pump/motor unit and the

multi-function switch as required.

(4) Check for continuity between the washer pump

driver circuit cavities of the headlamp and dash wire

harness connector for the washer pump/motor unit

and the instrument panel wire harness connector for

the multi-function switch (Connector C-2). There

should be continuity. If OK, go to Step 5. If not OK,

repair the open washer pump driver circuit between

the washer pump/motor unit and the multi-function

switch as required.

(5) Check for continuity between the washer pump

sense circuit cavity of the headlamp and dash wire

harness connector for the washer pump/motor unit

and a good ground. There should be no continuity. If

OK, go to Step 6. If not OK, repair the shorted

washer pump sense circuit between the washer

pump/motor unit and the multi-function switch as

required.

(6) Check for continuity between the washer pump

sense circuit cavities of the headlamp and dash wire

harness connector for the washer pump/motor unit

and the instrument panel wire harness connector for

the multi-function switch (Connector C-2). There

should be continuity. If OK, replace the faulty washer

pump/motor unit. If not OK, repair the open washer

pump sense circuit between the washer pump/motor

unit and the multi-function switch as required.

CLEANING - REAR WIPER & WASHER SYSTEM

REAR WIPER SYSTEM

The squeegee of a wiper blade exposed to the ele-

ments for a long time tends to lose its wiping effec-

tiveness. Periodic cleaning of the squeegee is

suggested to remove any deposits of salt or road film.

The wiper blade, arm, and rear flip-up glass should

only be cleaned using a sponge or soft cloth and

windshield washer fluid, a mild detergent, or a non-

abrasive cleaner. If the wiper blade continues to

leave streaks, smears, hazing, or beading on the

glass after thorough cleaning of the squeegees and

the glass, the entire wiper blade assembly must be

replaced.

CAUTION: Protect the rubber squeegee of the wiper

blade from any petroleum-based cleaners, solvents,

or contaminants. These products can rapidly deteri-

orate the rubber squeegee.

8R - 32 REAR WIPERS/WASHERSKJ

REAR WIPERS/WASHERS (Continued)

Page 1605 of 1803

EXTERIOR

TABLE OF CONTENTS

page page

BODY SIDE MOLDINGS

REMOVAL............................140

INSTALLATION........................140

COWL GRILLE

REMOVAL............................140

INSTALLATION........................140

EXTERIOR NAME PLATES

REMOVAL............................140

INSTALLATION........................141

FRONT FENDER

REMOVAL............................141

INSTALLATION........................141

FUEL FILL DOOR/HOUSING

REMOVAL............................141

INSTALLATION........................141

GRILLE

REMOVAL............................142

INSTALLATION........................142

GRILLE OPENING REINFORCEMENT

REMOVAL............................142

INSTALLATION........................142FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL............................143

INSTALLATION........................143

LUGGAGE RACK

REMOVAL............................144

INSTALLATION........................144

REAR WHEELHOUSE SPLASH SHIELD

REMOVAL............................144

INSTALLATION........................144

SIDE VIEW MIRROR

REMOVAL............................145

INSTALLATION........................145

FRONT WHEEL OPENING FLARE MOLDINGS

REMOVAL............................145

INSTALLATION........................145

REAR WHEEL OPENING FLARE MOLDINGS

REMOVAL............................145

INSTALLATION........................145

RADIATOR CROSSMEMBER

REMOVAL............................146

INSTALLATION........................146

BODY SIDE MOLDINGS

REMOVAL

(1) Using a trim stick C-4755 or equivalent,

remove and discard the molding from the outside of

the door.

INSTALLATION

(1) Thoroughly clean all residue from the body side

molding attachment area of the door.

(2) Wipe area clean with a 50% solution of water

and alcohol and wipe dry.

(3) Apply new body side molding using the locators

in the door and apply pressure of approximately 40

p.s.i. over the entire surface of the molding.

COWL GRILLE

REMOVAL

(1) Remove the hood seal.

(2) Remove the wiper arms. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER ARMS -

REMOVAL)

(3) Remove the four plastic retainers and remove

the cowl grill.

INSTALLATION

(1) Position the cowl grill and engage the nine

clips to the bottom of the windshield.

(2) Install the five plastic retainers.

(3) Install the wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS - INSTAL-

LATION)

(4) Install the hood seal.

EXTERIOR NAME PLATES

REMOVAL

NOTE: Exterior nameplates are attached to body

panels with adhesive tape.

(1) Apply a length of masking tape on the body,

parallel to the top edge of the nameplate to use as a

guide, if necessary.

(2) If temperature is below 21ÉC (70ÉF) warm

emblem with a heat lamp or gun. Do not exceed 52ÉC

(120ÉF) when heating emblem.

(3) Using a trim stick C-4755 or equivalent, behind

the emblem to separate the adhesive backing from

the body.

23 - 140 EXTERIORKJ

Page 1761 of 1803

RELAY - OPERATION, FRONT FOG LAMP . . 8L-22

RELAY - OPERATION, FUEL PUMP.......14-34

RELAY - OPERATION, HEADLAMP HIGH

BEAM..............................8L-33

RELAY - OPERATION, HEADLAMP LOW

BEAM..............................8L-39

RELAY - OPERATION, PARK LAMP.......8L-54

RELAY - OPERATION, REAR FOG LAMP . . . 8L-57

RELAY - OPERATION, REAR WINDOW

DEFOGGER..........................8G-6

RELAY - OPERATION, STARTER MOTOR . . . 8F-42

RELAY - OPERATION, TRAILER TOW.....8L-62

RELAY - OPERATION, TRANSMISSION

CONTROL.........................21-168

RELAY - OPERATION, WIPER HIGH/LOW . . 8R-23

RELAY - OPERATION, WIPER ON/OFF....8R-25

RELAY - REMOVAL................8W-97-14

RELAY - REMOVAL, A/C COMPRESSOR

CLUTCH............................24-16

RELAY - REMOVAL, AMPLIFIER CHOKE....8A-4

RELAY - REMOVAL, BLOWER MOTOR....24-21

RELAY - REMOVAL, CLUTCH SWITCH

OVERRIDE...........................6-10

RELAY - REMOVAL, DAYTIME RUNNING

LAMP..............................8L-21

RELAY - REMOVAL, DOOR LOCK.........8N-6

RELAY - REMOVAL, FRONT FOG LAMP . . . 8L-24

RELAY - REMOVAL, FUEL PUMP........14-34

RELAY - REMOVAL, HEADLAMP HIGH

BEAM..............................8L-34

RELAY - REMOVAL, HEADLAMP LOW

BEAM..............................8L-40

RELAY - REMOVAL, HORN..............8H-3

RELAY - REMOVAL, PARK LAMP........8L-55

RELAY - REMOVAL, REAR FOG LAMP....8L-58

RELAY - REMOVAL, REAR WINDOW

DEFOGGER..........................8G-7

RELAY - REMOVAL, STARTER MOTOR....8F-43

RELAY - REMOVAL, TRAILER TOW.......8L-63

RELAY - REMOVAL, WIPER HIGH/LOW . . . 8R-24

RELAY - REMOVAL, WIPER ON/OFF......8R-26

RELAYS - DIAGNOSIS AND TESTING,

ASD AND FUEL PUMP..................8I-4

RELEASE - STANDARD PROCEDURE,

FUEL SYSTEM PRESSURE..............14-4

RELEASE BEARING - INSTALLATION,

CLUTCH..............................6-6

RELEASE BEARING - REMOVAL, CLUTCH . . . 6-6

RELEASE CABLE - INSTALLATION, LATCH . 23-120

RELEASE CABLE - REMOVAL, LATCH....23-120

RELEASE HANDLE - INSTALLATION,

LATCH ............................23-120

RELEASE HANDLE - REMOVAL, LATCH . . 23-120

RELEASE SWITCH - DIAGNOSIS AND

TESTING, FLIP-UP GLASS..............8N-5

RELIEF VALVE - DESCRIPTION, HIGH

PRESSURE.........................24-42

RELIEF VALVE - OPERATION, HIGH

PRESSURE.........................24-42

REMOTE KEYLESS ENTRY MODULE -

DESCRIPTION........................8N-7

REMOTE KEYLESS ENTRY MODULE -

DIAGNOSIS AND TESTING..............8N-7

REMOTE KEYLESS ENTRY MODULE -

INSTALLATION.......................8N-7

REMOTE KEYLESS ENTRY MODULE -

OPERATION..........................8N-7

REMOTE KEYLESS ENTRY MODULE -

REMOVAL...........................8N-7

REMOTE KEYLESS ENTRY

TRANSMITTER - DIAGNOSIS AND

TESTING............................8N-8

REMOTE KEYLESS ENTRY

TRANSMITTER - SPECIFICATIONS........8N-9

REMOTE SWITCHES - DESCRIPTION.....8A-11

REMOTE SWITCHES - DIAGNOSIS AND

TESTING...........................8A-12

REMOTE SWITCHES - INSTALLATION.....8A-13

REMOTE SWITCHES - OPERATION.......8A-12

REMOTE SWITCHES - REMOVAL

........8A-13

REPAIR - DESCRIPTION, THREADED

HOLE

.............................Intro.-4

REPAIR - STANDARD PROCEDURE,

ALUMINUM THREAD

..................21-81

REPAIR - STANDARD PROCEDURE,

REAR GLASS HEATING GRID

............8G-4

REPAIR DAMAGED OR WORN THREADS

- STANDARD PROCEDURE

...............9-9REPAIRING LEAKS - STANDARD

PROCEDURE.........................22-8

REPEATER LAMP BULB - INSTALLATION . . 8L-60

REPEATER LAMP BULB - REMOVAL......8L-60

REPEATER LAMP UNIT - INSTALLATION . . 8L-61

REPEATER LAMP UNIT - REMOVAL......8L-60

REQUIREMENTS - DESCRIPTION,

COOLING SYSTEM....................24-1

RESERVOIR - DESCRIPTION, VACUUM....8P-7

RESERVOIR - DESCRIPTION, WASHER . . . 8R-21

RESERVOIR - DIAGNOSIS AND TESTING,

VACUUM............................8P-7

RESERVOIR - INSTALLATION, FLUID......5-26

RESERVOIR - INSTALLATION, VACUUM....8P-8

RESERVOIR - INSTALLATION, WASHER . . . 8R-22

RESERVOIR - OPERATION, VACUUM......8P-7

RESERVOIR - OPERATION, WASHER.....8R-21

RESERVOIR - REMOVAL, FLUID..........5-26

RESERVOIR - REMOVAL, VACUUM........8P-7

RESERVOIR - REMOVAL, WASHER......8R-21

RESISTANCE, 2.4L - IGNITION COIL.......8I-2

RESISTANCE, 2.4L - SPARK PLUG CABLE . . . 8I-3

RESISTANCE, 3.7L V-6 - IGNITION COIL....8I-3

RESISTOR - DESCRIPTION, BLOWER

MOTOR............................24-22

RESISTOR - DIAGNOSIS AND TESTING,

BLOWER MOTOR....................24-22

RESISTOR - INSTALLATION, BLOWER

MOTOR............................24-22

RESISTOR - OPERATION, BLOWER

MOTOR............................24-22

RESISTOR - REMOVAL, BLOWER

MOTOR............................24-22

RESTRAINT DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL......................8O-6

RESTRAINT SYSTEM - DIAGNOSIS AND

TESTING, SUPPLEMENTAL..............8O-6

RESTRAINT SYSTEM - WARNING........8O-5

RESTRAINTS - DESCRIPTION............8O-2

RESTRAINTS - OPERATION.............8O-4

RESTRAINTS - STANDARD PROCEDURE,

HANDLING NON-DEPLOYED

SUPPLEMENTAL......................8O-6

RETAINER/BULKHEAD - ASSEMBLY, 4C . . 21-123

RETAINER/BULKHEAD - DISASSEMBLY,

4C ...............................21-122

RETRACTOR - INSTALLATION, FRONT

SEAT BELT .........................8O-24

RETRACTOR - INSTALLATION, REAR

CENTER SEAT BELT..................8O-33

RETRACTOR - INSTALLATION, REAR

OUTBOARD SEAT BELT................8O-34

RETRACTOR - REMOVAL, FRONT SEAT

BELT ..............................8O-23

RETRACTOR - REMOVAL, REAR CENTER

SEAT BELT .........................8O-32

RETRACTOR - REMOVAL, REAR

OUTBOARD SEAT BELT................8O-33

RETURN - DESCRIPTION, SENSOR.......8E-14

RETURN HOSE (GEAR TO THE COOLER)

- INSTALLATION.....................19-22

RETURN HOSE (GEAR TO THE COOLER)

- REMOVAL.........................19-21

RETURN HOSE (RESERVOIR TO THE

COOLER) - INSTALLATION.............19-22

RETURN HOSE (RESERVOIR TO THE

COOLER) - REMOVAL

.................19-21

REVERSE FLUSHING - STANDARD

PROCEDURE, COOLING SYSTEM

.........7-12

RFE TRANSMISSION, SPECIAL TOOLS

. . . 21-120

RHD - INSTALLATION

...............8W-97-6

RHD - REMOVAL

...................8W-97-5

RIGHT POWER SEAT SWITCH -

DESCRIPTION

.......................8N-19

RIGHT POWER SEAT SWITCH -

DIAGNOSIS AND TESTING

.............8N-19

RIGHT POWER SEAT SWITCH -

INSTALLATION

......................8N-20

RIGHT POWER SEAT SWITCH -

OPERATION

.........................8N-19

RIGHT POWER SEAT SWITCH -

REMOVAL

..........................8N-20

RIGHT SIDE - INSTALLATION

........2-12,2-15

RIGHT SIDE - REMOVAL

............2-11,2-14

RING - INSTALLATION, PINION

GEAR/RING GEAR/TONE

...........3-112,3-82RING - REMOVAL, PINION GEAR/RING

GEAR/TONE.....................3-110,3-79

RING FITTING - STANDARD

PROCEDURE, PISTON..................9-52

RISER - INSTALLATION, MANUAL SEAT . . 23-168

RISER - REMOVAL, MANUAL SEAT......23-167

RKE TRANSMITTER BATTERIES -

STANDARD PROCEDURE...............8N-8

RKE TRANSMITTER CUSTOMER

PREFERENCES - STANDARD

PROCEDURE.........................8N-8

RKE TRANSMITTER PROGRAMING -

STANDARD PROCEDURE...............8N-9

ROAD TEST - DIAGNOSIS AND TESTING . . . 8P-2

ROAD TESTING - DIAGNOSIS AND

TESTING...........................21-78

ROCKER ARM - DESCRIPTION.......9-29,9-37

ROCKER ARM - INSTALLATION..........9-37

ROCKER ARM - REMOVAL..............9-37

ROD - DESCRIPTION, PISTON &

CONNECTING.........................9-49

ROD BEARING - FITTING - STANDARD

PROCEDURE, CONNECTING.............9-40

ROD BEARING, FITTING - CONNECTING....9-49

ROD END - INSTALLATION, TIE.........19-16

ROD END - REMOVAL, TIE.............19-16

ROD END REMOVAL TOOL, SPECIAL

TOOLS - OUTER TIE..................19-15

ROTATION - STANDARD PROCEDURE,

TIRE................................22-2

ROTOR - DIAGNOSIS AND TESTING,

DISC BRAKE.........................5-18

ROTOR - STANDARD PROCEDURE, DISC

BRAKE..............................5-19

ROTORS - INSTALLATION...............5-19

ROTORS - REMOVAL..................5-19

ROUTING 3.7L ENGINE - DESCRIPTION,

COOLING SYSTEM.....................7-2

RUN CHANNEL - INSTALLATION, GLASS . 23-123,

23-130

RUN CHANNEL - REMOVAL, GLASS....23-123,

23-130

RUNNING LAMP RELAY - DESCRIPTION,

DAYTIME...........................8L-20

RUNNING LAMP RELAY - INSTALLATION,

DAYTIME...........................8L-21

RUNNING LAMP RELAY - OPERATION,

DAYTIME...........................8L-20

RUNNING LAMP RELAY - REMOVAL,

DAYTIME...........................8L-21

RUNOUT - DIAGNOSIS AND TESTING,

TIRES AND WHEEL....................22-1

SAFETY CERTIFICATION LABEL -

DESCRIPTION, VEHICLE..............Intro.-9

SAFETY PRECAUTIONS AND WARNINGS,

WARNING...........................23-1

SAFETY PRECAUTIONS, WARNING -

WINDSHIELD.......................23-173

SANDING/BUFFING & POLISHING -

DESCRIPTION, FINESSE..............23-163

SCHEDULES - DESCRIPTION,

MAINTENANCE........................0-4

SCHEMATICS AND DIAGRAMS -

HYDRAULIC SCHEMATICS.............21-100

SCHEMATICS, SCHEMATICS AND

DIAGRAMS - HYDRAULIC.............21-100

SCUFF PLATE - INSTALLATION, DOOR

SILL..............................23-157

SCUFF PLATE - INSTALLATION, REAR

DOOR............................23-160

SCUFF PLATE - REMOVAL, DOOR SILL . . . 23-157

SCUFF PLATE - REMOVAL, REAR DOOR . . 23-160

SEAL - FRONT - INSTALLATION,

CRANKSHAFT OIL.....................9-47

SEAL - FRONT - REMOVAL,

CRANKSHAFT OIL.....................9-46

SEAL - INSTALLATION, ADAPTER

HOUSING..........................21-124

SEAL - INSTALLATION, A-PILLAR.......23-185

SEAL - INSTALLATION, COWL/PLENUM . . 23-187

SEAL - INSTALLATION, COWL/PLENUM

WINDOW BAFFLE

...................23-187

SEAL - INSTALLATION, FRONT OUTPUT

SHAFT

......................21-208,21-246

SEAL - INSTALLATION, GLASS PANEL

. . . 23-178

SEAL - INSTALLATION, OIL PUMP

FRONT

............................21-152

SEAL - INSTALLATION, PINION

. . 3-103,3-39,3-68

22 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1768 of 1803

VALVE - INSTALLATION, FLOW

MANAGEMENT.......................14-7

VALVE - INSTALLATION, FRONT CHECK....8R-9

VALVE - INSTALLATION, FUEL TANK

CHECK.............................14-28

VALVE - INSTALLATION, PCV...........25-32

VALVE - INSTALLATION, REAR CHECK....8R-35

VALVE - INSTALLATION, VACUUM CHECK . 24-28

VALVE - OPERATION, FLOW

MANAGEMENT.......................14-6

VALVE - OPERATION, FRONT CHECK......8R-9

VALVE - OPERATION, FUEL TANK CHECK . . 14-28

VALVE - OPERATION, HIGH PRESSURE

RELIEF.............................24-42

VALVE - OPERATION, PCV..............25-31

VALVE - OPERATION, REAR CHECK......8R-34

VALVE - OPERATION, SOLENOID SWITCH . 21-161

VALVE - OPERATION, VACUUM CHECK....24-28

VALVE - REMOVAL, FLOW

MANAGEMENT.......................14-6

VALVE - REMOVAL, FRONT CHECK.......8R-9

VALVE - REMOVAL, FUEL TANK CHECK . . . 14-28

VALVE - REMOVAL, PCV...............25-32

VALVE - REMOVAL, REAR CHECK.......8R-34

VALVE - REMOVAL, VACUUM CHECK.....24-28

VALVE BODY - ASSEMBLY............21-176

VALVE BODY - CLEANING.............21-175

VALVE BODY - DESCRIPTION............21-171

VALVE BODY - DISASSEMBLY..........21-173

VALVE BODY - INSPECTION...........21-175

VALVE BODY - INSTALLATION..........21-177

VALVE BODY - OPERATION............21-171

VALVE BODY - REMOVAL.............21-172

VALVE GUIDE SEALS - DESCRIPTION . . 9-29,9-38

VALVE GUIDES - DESCRIPTION......9-19,9-30

VALVE SPRINGS - DESCRIPTION.....9-29,9-38

VALVE SPRINGS - INSTALLATION.....9-29,9-38

VALVE SPRINGS - REMOVAL........9-29,9-38

VALVE TIMING - DESCRIPTION...........9-71

VALVE TIMING - OPERATION............9-71

VALVES & SEATS - DESCRIPTION,

INTAKE/EXHAUST.....................9-26

VALVES & SEATS - INSTALLATION,

INTAKE/EXHAUST.................9-28,9-36

VALVES & SEATS - REMOVAL,

INTAKE/EXHAUST.................9-27,9-35

VANITY LAMP BULB - INSTALLATION.....8L-84

VANITY LAMP BULB - REMOVAL........8L-83

VAPOR CANISTER - DESCRIPTION.......25-33

VAPOR CANISTER - INSTALLATION......25-33

VAPOR CANISTER - OPERATION.........25-33

VAPOR CANISTER - REMOVAL..........25-33

VARIATION ADJUSTMENT - STANDARD

PROCEDURE, COMPASS...............8M-3

VEHICLE EMISSION CONTROL

INFORMATION (VECI) LABEL -

DESCRIPTION......................Intro.-8

VEHICLE IDENTIFICATION NUMBER -

DESCRIPTION......................Intro.-8

VEHICLE SAFETY CERTIFICATION LABEL

- DESCRIPTION.....................Intro.-9

VEHICLE THEFT SECURITY -

DESCRIPTION........................8Q-1

VEHICLE THEFT SECURITY - OPERATION . . 8Q-3

VEHICLE THEFT SECURITY SYSTEM -

DIAGNOSIS AND TESTING..............8Q-6

VERIFICATION TEST - STANDARD

PROCEDURE.........................8O-8

VIBRATION - DIAGNOSIS AND TESTING,

TIRE NOISE OR.......................22-8

VIBRATION DAMPER - INSTALLATION.....9-55

VIBRATION DAMPER - REMOVAL.........9-54

VIEW MIRROR - INSTALLATION, SIDE . . . 23-145

VIEW MIRROR - REMOVAL, REAR......23-161

VIEW MIRROR - REMOVAL, SIDE.......23-145

VISCOUS - CLEANING, RADIATOR - FAN . . . 7-29

VISCOUS - DESCRIPTION, RADIATOR -

FAN ................................7-27

VISCOUS - INSPECTION, RADIATOR -

FAN ................................7-29

VISCOUS - INSTALLATION, RADIATOR -

FAN

................................7-29

VISCOUS - OPERATION, RADIATOR -

FAN

................................7-27

VISCOUS - REMOVAL, RADIATOR - FAN

....7-28

VISCOUS FAN DRIVE - DIAGNOSIS AND

TESTING

............................7-28

VISOR - INSTALLATION, SUN

..........23-160VISOR - REMOVAL, SUN..............23-160

VISOR SUPPORT - INSTALLATION, SUN . . 23-160

VISOR SUPPORT - REMOVAL, SUN.....23-160

VOLT SUPPLIES - DESCRIPTION, 5......8E-13

VOLT SUPPLIES - OPERATION, 5........8E-15

VOLTAGE DROP - STANDARD

PROCEDURE, TESTING FOR A.......8W-01-10

VOLTAGE POTENTIAL - STANDARD

PROCEDURE, TESTING OF...........8W-01-9

VOLTAGE REGULATOR - DESCRIPTION....8F-31

VOLTAGE REGULATOR - OPERATION.....8F-31

VOLTAGE TEST - STANDARD

PROCEDURE, OPEN-CIRCUIT...........8F-12

VOLUME CHECK - STANDARD

PROCEDURE, OIL PUMP..............21-148

WAIT-TO-START INDICATOR -

DESCRIPTION.......................8J-35

WAIT-TO-START INDICATOR -

OPERATION.........................8J-35

WARNING - INSTALLATION............23-173

WARNING - REMOVAL...............23-173

WARNING - SAFETY PRECAUTIONS AND

WARNINGS..........................23-1

WARNING - SERVICE WARNINGS........24-39

WARNING - WINDSHIELD SAFETY

PRECAUTIONS......................23-173

WARNING, BRAKES - BASE..............5-2

WARNING, CLUTCH.....................6-2

WARNING, FRONT......................2-7

WARNING, REAR......................2-16

WARNING, RESTRAINT SYSTEM.........8O-5

WARNING SYSTEM - DESCRIPTION,

CHIME..............................8B-1

WARNING SYSTEM - DIAGNOSIS AND

TESTING, CHIME......................8B-6

WARNING SYSTEM - OPERATION,

CHIME..............................8B-2

WARNINGS, GENERAL..............8W-01-7

WARNINGS, WARNING - SAFETY

PRECAUTIONS........................23-1

WARNINGS, WARNING - SERVICE.......24-39

WASHER FLUID INDICATOR -

DESCRIPTION.......................8J-35

WASHER FLUID INDICATOR -

DIAGNOSIS AND TESTING..............8J-36

WASHER FLUID INDICATOR -

OPERATION.........................8J-36

WASHER FLUID LEVEL SWITCH -

DESCRIPTION.......................8R-17

WASHER FLUID LEVEL SWITCH -

INSTALLATION......................8R-18

WASHER FLUID LEVEL SWITCH -

OPERATION.........................8R-17

WASHER FLUID LEVEL SWITCH -

REMOVAL..........................8R-17

WASHER HOSES/TUBES - DESCRIPTION,

FRONT.............................8R-10

WASHER HOSES/TUBES - DESCRIPTION,

REAR..............................8R-35

WASHER HOSES/TUBES - OPERATION,

FRONT.............................8R-10

WASHER HOSES/TUBES - OPERATION,

REAR..............................8R-36

WASHER NOZZLE - DESCRIPTION,

FRONT.............................8R-11

WASHER NOZZLE - DESCRIPTION, REAR . 8R-36

WASHER NOZZLE - INSTALLATION,

FRONT.............................8R-11

WASHER NOZZLE - INSTALLATION,

REAR..............................8R-37

WASHER NOZZLE - OPERATION, FRONT . . 8R-11

WASHER NOZZLE - OPERATION, REAR . . . 8R-36

WASHER NOZZLE - REMOVAL, FRONT....8R-11

WASHER NOZZLE - REMOVAL, REAR....8R-36

WASHER PUMP/MOTOR - DESCRIPTION . . 8R-18

WASHER PUMP/MOTOR - INSTALLATION . 8R-20

WASHER PUMP/MOTOR - OPERATION . . . 8R-19

WASHER PUMP/MOTOR - REMOVAL.....8R-19

WASHER RESERVOIR - DESCRIPTION....8R-21

WASHER RESERVOIR - INSTALLATION . . . 8R-22

WASHER RESERVOIR - OPERATION

......8R-21

WASHER RESERVOIR - REMOVAL

.......8R-21

WASHER SYSTEM - CLEANING, FRONT

WIPER

..............................8R-7

WASHER SYSTEM - CLEANING, REAR

WIPER

.............................8R-32

WASHER SYSTEM - DIAGNOSIS AND

TESTING, FRONT WIPER

...............8R-6WASHER SYSTEM - DIAGNOSIS AND

TESTING, REAR WIPER...............8R-30

WASHER SYSTEM - INSPECTION, FRONT

WIPER..............................8R-7

WASHER SYSTEM - INSPECTION, REAR

WIPER.............................8R-33

WATER DRAINAGE AND WIND NOISE

DIAGNOSIS, DIAGNOSIS AND TESTING . . 23-176

WATER LEAKS - DIAGNOSIS AND

TESTING............................23-2

WATER PUMP - DESCRIPTION...........7-29

WATER PUMP - OPERATION.............7-30

WATERDAM - INSTALLATION....23-126,23-133

WATERDAM - REMOVAL........23-126,23-133

WATER-IN-FUEL INDICATOR -

DESCRIPTION.......................8J-37

WATER-IN-FUEL INDICATOR -

OPERATION.........................8J-37

WEAR INDICATORS - DIAGNOSIS AND

TESTING, TREAD......................22-8

WEAR PATTERNS - DIAGNOSIS AND

TESTING, TIRE.......................22-8

WEAR, STANDARD PROCEDURE -

MEASURING TIMING CHAIN.............9-71

WEATHERSTRIP - INSTALLATION, COWL . 23-185

WEATHERSTRIP - INSTALLATION, DOOR

LOWER...........................23-186

WEATHERSTRIP - INSTALLATION, DOOR

PRIMARY..........................23-185

WEATHERSTRIP - INSTALLATION,

SWING GATE BELTLINE...............23-186

WEATHERSTRIP - INSTALLATION,

SWING GATE OPENING...............23-186

WEATHERSTRIP - REMOVAL, COWL.....23-185

WEATHERSTRIP - REMOVAL, DOOR

LOWER...........................23-186

WEATHERSTRIP - REMOVAL, DOOR

PRIMARY..........................23-185

WEATHERSTRIP - REMOVAL, SWING

GATE BELTLINE.....................23-186

WEATHERSTRIP - REMOVAL, SWING

GATE OPENING.....................23-186

WEATHERSTRIP/RETAINER -

INSTALLATION, SIDE RAIL............23-186

WEATHERSTRIP/RETAINER -

INSTALLATION, WINDSHIELD A-PILLAR . . 23-187

WEATHERSTRIP/RETAINER - REMOVAL,

SIDE RAIL.........................23-186

WEATHERSTRIP/RETAINER - REMOVAL,

WINDSHIELD A-PILLAR...............23-186

WELD AND STRUCTURAL ADHESIVE

LOCATIONS - SPECIFICATIONS...........23-9

WHEEL - INSTALLATION, STEERING......19-12

WHEEL - REMOVAL, STEERING.........19-12

WHEEL ALIGNMENT - DESCRIPTION.......2-3

WHEEL ALIGNMENT - OPERATION.........2-3

WHEEL BALANCING - STANDARD

PROCEDURE.........................22-4

WHEEL CYLINDERS - ASSEMBLY.........5-29

WHEEL CYLINDERS - CLEANING.........5-28

WHEEL CYLINDERS - DISASSEMBLY......5-28

WHEEL CYLINDERS - INSPECTION........5-29

WHEEL CYLINDERS - INSTALLATION......5-29

WHEEL CYLINDERS - REMOVAL..........5-28

WHEEL MOUNTING - STANDARD

PROCEDURE........................22-10

WHEEL OPENING FLARE MOLDINGS -

INSTALLATION, FRONT...............23-145

WHEEL OPENING FLARE MOLDINGS -

INSTALLATION, REAR................23-145

WHEEL OPENING FLARE MOLDINGS -

REMOVAL, FRONT...................23-145

WHEEL OPENING FLARE MOLDINGS -

REMOVAL, REAR....................23-145

WHEEL REPLACEMENT - STANDARD

PROCEDURE........................22-10

WHEEL RUNOUT - DIAGNOSIS AND

TESTING, TIRES......................22-1

WHEEL SPEED SENSOR -

INSTALLATION, FRONT

.................5-34

WHEEL SPEED SENSOR -

INSTALLATION, REAR

..................5-35

WHEEL SPEED SENSOR - REMOVAL,

FRONT

..............................5-34

WHEEL SPEED SENSOR - REMOVAL,

REAR

...............................5-35

WHEELHOUSE SPLASH SHIELD -

INSTALLATION, FRONT

...............23-143

KJINDEX 29

Description Group-Page Description Group-Page Description Group-Page

Page 1769 of 1803

WHEELHOUSE SPLASH SHIELD -

INSTALLATION, REAR................23-144

WHEELHOUSE SPLASH SHIELD -

REMOVAL, FRONT...................23-143

WHEELHOUSE SPLASH SHIELD -

REMOVAL, REAR....................23-144

WHEELS - DESCRIPTION...............22-9

WHEELS - DIAGNOSIS AND TESTING.....22-10

WIND DEFLECTOR - INSTALLATION.....23-180

WIND DEFLECTOR - REMOVAL.........23-180

WIND NOISE - DIAGNOSIS AND TESTING . . 23-3

WIND NOISE DIAGNOSIS, DIAGNOSIS

AND TESTING - WATER DRAINAGE.....23-176

WINDOW - INSTALLATION, QUARTER . . . 23-172

WINDOW - REMOVAL, QUARTER.......23-172

WINDOW BAFFLE SEAL - INSTALLATION,

COWL/PLENUM.....................23-187

WINDOW BAFFLE SEAL - REMOVAL,

COWL/PLENUM.....................23-187

WINDOW DEFOGGER - DESCRIPTION,

REAR...............................8G-3

WINDOW DEFOGGER - OPERATION,

REAR...............................8G-3

WINDOW DEFOGGER FUNCTION -

DIAGNOSIS AND TESTING, REAR HVAC

CONTROL ASSEMBLY..................8G-9

WINDOW DEFOGGER GRID -

DESCRIPTION, REAR..................8G-5

WINDOW DEFOGGER GRID - DIAGNOSIS

AND TESTING, REAR..................8G-5

WINDOW DEFOGGER GRID -

OPERATION, REAR......................8G-5

WINDOW DEFOGGER RELAY -

DESCRIPTION, REAR..................8G-6

WINDOW DEFOGGER RELAY -

DIAGNOSIS AND TESTING, REAR.........8G-6

WINDOW DEFOGGER RELAY -

INSTALLATION, REAR..................8G-7

WINDOW DEFOGGER RELAY -

OPERATION, REAR....................8G-6

WINDOW DEFOGGER RELAY -

REMOVAL, REAR.....................8G-7

WINDOW DEFOGGER SWITCH -

DESCRIPTION, REAR..................8G-8

WINDOW DEFOGGER SWITCH -

DIAGNOSIS AND TESTING, REAR.........8G-8

WINDOW DEFOGGER SWITCH -

OPERATION, REAR....................8G-8

WINDOW DEFOGGER SYSTEM -

DIAGNOSIS AND TESTING, REAR.........8G-4

WINDOW MOTOR - REMOVAL..........8N-22WINDOW REGULATOR - ELECTRIC -

INSTALLATION................23-126,23-134

WINDOW REGULATOR - ELECTRIC -

REMOVAL...................23-126,23-134

WINDOW REGULATOR - MANUAL -

INSTALLATION................23-126,23-133

WINDOW REGULATOR - MANUAL -

REMOVAL...................23-126,23-133

WINDOW SWITCH - DIAGNOSIS AND

TESTING...........................8N-22

WINDOW SWITCH - INSTALLATION......8N-23

WINDOW SWITCH - REMOVAL..........8N-23

WINDOWS - DESCRIPTION, POWER.....8N-21

WINDOWS - DIAGNOSIS AND TESTING,

POWER............................8N-21

WINDOWS - OPERATION, POWER.......8N-21

WINDSHIELD A-PILLAR WEATHERSTRIP/

RETAINER - INSTALLATION............23-187

WINDSHIELD A-PILLAR WEATHERSTRIP/

RETAINER - REMOVAL...............23-186

WINDSHIELD SAFETY PRECAUTIONS,

WARNING.........................23-173

WIPER & WASHER SYSTEM -

CLEANING, FRONT....................8R-7

WIPER & WASHER SYSTEM -

CLEANING, REAR....................8R-32

WIPER & WASHER SYSTEM -

DIAGNOSIS AND TESTING, FRONT........8R-6

WIPER & WASHER SYSTEM -

DIAGNOSIS AND TESTING, REAR........8R-30

WIPER & WASHER SYSTEM -

INSPECTION, FRONT...................8R-7

WIPER & WASHER SYSTEM -

INSPECTION, REAR...................8R-33

WIPER ARM - DESCRIPTION, FRONT.....8R-12

WIPER ARM - DESCRIPTION, REAR......8R-37

WIPER ARM - INSTALLATION, FRONT....8R-13

WIPER ARM - INSTALLATION, REAR.....8R-38

WIPER ARM - OPERATION, FRONT......8R-12

WIPER ARM - OPERATION, REAR.......8R-38

WIPER ARM - REMOVAL, FRONT........8R-12

WIPER ARM - REMOVAL, REAR.........8R-38

WIPER ARM PARK RAMP -

INSTALLATION......................8R-43

WIPER ARM PARK RAMP - REMOVAL....8R-43

WIPER BLADE - DESCRIPTION, FRONT . . . 8R-13

WIPER BLADE - DESCRIPTION, REAR....8R-39

WIPER BLADE - INSTALLATION, FRONT . . . 8R-14

WIPER BLADE - INSTALLATION, REAR....8R-40

WIPER BLADE - OPERATION, FRONT.....8R-14

WIPER BLADE - OPERATION, REAR......8R-39WIPER BLADE - REMOVAL, FRONT......8R-14

WIPER BLADE - REMOVAL, REAR.......8R-40

WIPER HIGH/LOW RELAY -

DESCRIPTION.......................8R-23

WIPER HIGH/LOW RELAY - DIAGNOSIS

AND TESTING.......................8R-24

WIPER HIGH/LOW RELAY -

INSTALLATION......................8R-24

WIPER HIGH/LOW RELAY - OPERATION . . 8R-23

WIPER HIGH/LOW RELAY - REMOVAL....8R-24

WIPER MODULE - DESCRIPTION, FRONT . 8R-15

WIPER MODULE - INSTALLATION,

FRONT.............................8R-16

WIPER MODULE - OPERATION, FRONT . . . 8R-15

WIPER MODULE - REMOVAL, FRONT....8R-16

WIPER MOTOR - DESCRIPTION, REAR . . . 8R-41

WIPER MOTOR - INSTALLATION, REAR . . . 8R-42

WIPER MOTOR - OPERATION, REAR.....8R-41

WIPER MOTOR - REMOVAL, REAR......8R-42

WIPER ON/OFF RELAY - DESCRIPTION . . . 8R-25

WIPER ON/OFF RELAY - DIAGNOSIS AND

TESTING...........................8R-26

WIPER ON/OFF RELAY - INSTALLATION . . . 8R-26

WIPER ON/OFF RELAY - OPERATION.....8R-25

WIPER ON/OFF RELAY - REMOVAL......8R-26

WIPERS/WASHERS - DESCRIPTION,

FRONT..............................8R-2

WIPERS/WASHERS - DESCRIPTION,

REAR...............................8R-27

WIPERS/WASHERS - OPERATION,

FRONT..............................8R-4

WIPERS/WASHERS - OPERATION, REAR . . 8R-29

WIPER/WASHER SWITCH -

DESCRIPTION, FRONT................8R-16

WIPER/WASHER SWITCH -

DESCRIPTION, REAR.................8R-43

WIPER/WASHER SWITCH - OPERATION,

FRONT.............................8R-16

WIPER/WASHER SWITCH - OPERATION,

REAR..............................8R-43

WIRE SPLICING - STANDARD

PROCEDURE.....................8W-01-14

WIRING - DESCRIPTION, TRAILER TOW . . 8L-64

WIRING DIAGRAMS - DESCRIPTION,

HOW TO USE .....................8W-01-1

WIRING HARNESS - DIAGNOSIS AND

TESTING.........................8W-01-7

WIRING/TERMINAL, SPECIAL TOOLS . . 8W-01-10

WORN THREADS - STANDARD

PROCEDURE, REPAIR DAMAGED OR.......9-9

30 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1784 of 1803

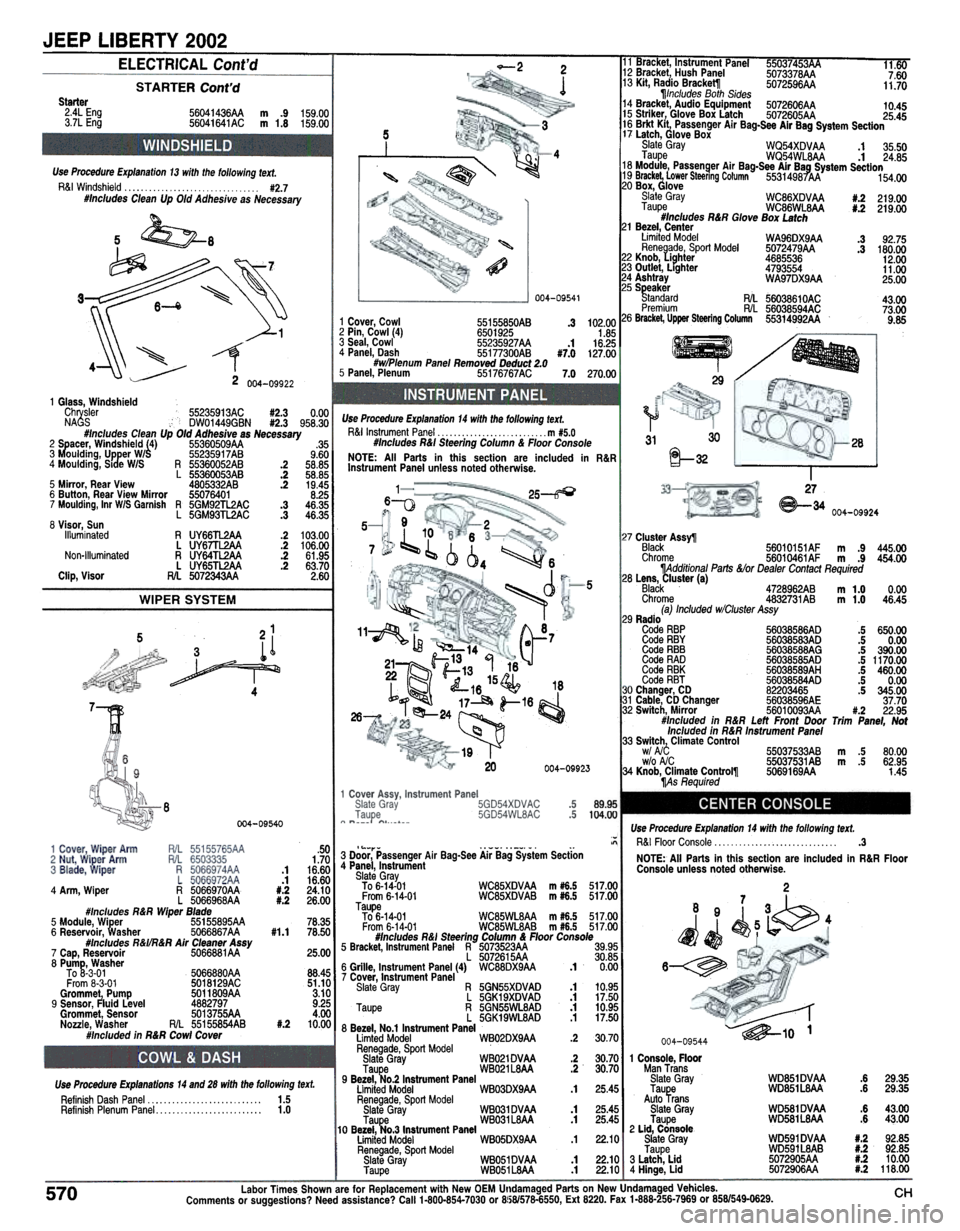

Starter2.4L Eng3.7L Eng

STARTER Cont'd

56041436M m .9 159.0056041641AC m 1.8 159.0035 I-

r~..:::---~ ~;i:i~:~'"

4~

Use Procedure Explanation 13 with the following tex!.R&IWindshield ...#2.7#Includes Clean Up Old Adhesive as Necessary

5 ~8

~~~~ -,

S-(::~:~~::~~:::::::~ ,,~(" p-~~ ~

\\\

f,

~

'~

):1

004-09541

1 Cover, Cowl 55155850AB.3 102.002 Pin, Cowl (4) 6501925 1.853 Seal, Cowl 55235927AA.1 16.254 Panel, Dash 55177300AB #7.0 127.00#W/Plenum Panel Removed Deduct 2.05 Panel, Plenum 55176767AC 7.0 270.00

\\\

4~1'"~

JEEP LIBERTY 2002

ELECTRICALCont'd2211 racket, Instrument anel9- 12 Bracket, Hush Panel 78 7.60

113 Kit, Radio Bracke~ 5072596M 11.701]lncludes Both Sides14 Bracket, Audio Equipment 5072606M 10.4515 Striker} Glove Box Latch 5072605M 25.4516 Brk! KI!t Passenger Air Bag-See Air Bag System Section11 Latch, ulove BoxSlate Gray WQ54XDVM.1 35.50Taupe WQ54WL8AA.1 24.8518 Module, PassenQer Air Bag-See Air Bag System Section19 Bracket, Lower Steeling Column 5531498TAA 154.0020 Box, GloveSlate Gray WC86XDVAA #.2 219.00Taupe WC86WL8AA #.2 219.00#Includes R&R Glove Box Latch21 Bezel, CenterLimited Model WA96DX9AA.3 92.75Renegade, Sport Model 5072479AA .3 180.0022 Knob, Li9hter 4685536 12.0023 Outlet, Lighter 4793554 11.0024 Ashtray WA97DX9AA 25.0025 SpeakerStandard AiL 56038610AC 43.00Premium AiL 56038594AC 73.0026 Bracket, UpperSt~ring Column 55314992AA 9.85

~/-

~313028

r:l-32I27

8-34 004-09924

2

7

5WIPER SYSTEM

213 I!

""""",~~~~-~~~4

5

~,..~6

,--d

~ :: 1

11~~~ ~ 19 ~14 .7

21~h13 4 1822 r:13 IIII ~ L16 15~ 18!Jj,j17~ 'j;--16 ~-" ~24 ~ ~

1~20 004-09923

7lf26--

?7 Cluster Ass~Black 56010151AF m .9 445.00Chrome 56010461AF m .9 454.00llAdditional Palts &/or Dealer Contact Required28 Lens, Cluster (a)Black 4728962AB m 1.0 0.00Chrome 4832731AB m 1.0 46.45la) Included wlCluster Assy29 RadioCode RBP 56038586AD.5 650.00Code RBY 56038583AD.5 0.00Code RBB 56038588AG.5 390.00Code RAD 56038585AD.5 1170.00Code RBK 56038589AH.5 460.00Code RBT 56038584AD.5 0.0030 Changer, CD 82203465 .5 345.00131 Cable, CD Changer 56038596AE 37.7032 Switch, Mirror 56010093AA #.2 22.95#Included in R&R Left Front Door Trim Panel, NotIncluded in R&R Instrument Panel33 Switch;, Climate ControlI wi Nv 55037533AB m .5 80.00wlo NC 55037531AB m .5 62.95134 Knob, Climate Controlll 5069169AA 1.451]As Required

8004-09540

on

6--<:~

#1.1

,-"-;:;;;;;;::~4~10 1

WD851DVAAWD851LSAA

WD581DVAAWD581L8AA

WD591DVAAWD591L8AB5072905AA5072906AA

.6 29.35.6 29.35

.6 43.00.6 43.00

#.2 92.85#.2 92.85#.2 10.00#.2 118.00

Use Procedure Explanations 14 and 28 with the following text.Refinish Dash Panel 1.5Refinish Plenum Panel 1.0

Labor Times Shown are for Replacement with New OEM Undamaged Parts on New Undamaged Vehicles.Comments or suggestions? Need assistance? Call 1.800-854-7030 or 8!;8/578-6550, Ext 8220. Fax 1-888-256-7969 or 858/549-0629.570CH

' 2 004-09922

1 Glass, WindshieldChrysler 55235913AC #2.3 0.00 ...NAGS c DW01449GBN #2.3 958.30 Use Procedure Explanation 14 with the following text.#Includes Clean Up Otd Adhesive as Necessary R&llnstrument Panel.. m #5.02 Spacer, Windshield /4) 55360509AA .35 #tncludes R&I Steering Column & Floor Console3 Mould!ng. Upper W/$ 55235917AB 9.60 NOTE: All Parts in this section are included in R&R4 Moulding. Side WIS R 55360052AB .2 58.85 Instrument Panel unless noted otherwiseL 55360053AB .2 58.85 .

5 Mirror, Rear View 4805332AB .2 19.45 16 Button, Rear View Mirror 55076401 8.25 25-{!:Q7 Moulding, Inr W/S Garnish R 5GM92TL2AC .3 46.35 6-0L 5GM93TL2AC .3 46.3598 Visor, Sun 5Illuminated R UY66TL2AA .2 103.00 I 10 6L UY67TL2AA .2 106.00 ~Non-Illuminated R UY64TL2AA .2 61.95 ~ 6 1L UY65TL2AA .2 63.70 ()\4Clip, Visor R/L 5072343AA 2.60

4 Arm, Wiper R 5666970AAL 5066968AA#Includes R&R Wiper Blade5 Module, Wiper 55155895AA6 Reservoir, Washer 5066867AA#Includes R&I/R&R Air Cleaner Assy7 Cap, Reservoir 5066881AA8 Pump, WasherTo 8-3-01 5066880AAFrom 8-3-01 5018129ACGrommet Pump 5011809AA9 Sensor, Fluid Level 4882797Grommet, Sensor 5013755AANozzle, Washer AiL 55155854AB#Included in R&R Cowl Cover

Use Procedure Explanation 14 with the following text.R&IFloorConsole .3

NOTE: All Parts in this section are included in R&R FloorConsole unless noted otherwise.

2

~~~~~~

,~-.- ,-,..1'70 3 Door, Passenger Air Bag-See Air Bag System Section1 16'60 4 Panel, Instrument.116'60Slate Gray..To 6-14-01 WC85XDVAA m #6.5 517.00#.2 24.10 From 6-14-01 WC85XDVAB m#6.5 517.00#.2 26.00 Taupe

To 6-14-01 WC85WL8AA m #6.5 517,0078,35 From 6-14-01 WC85WL8AB m #6.5 517,0078.50 #Includes R&I Steering Column & Floor Console25005 Bracket, Instrument Panel R 5073523AA 39.95, L 5072615AA 30,8588 45 6 Grille, Instrument Panel (4) WC88DX9AA .1 0,00.7 Cover, Instrument Panel531.1100Slate Gray R 5GN55XDVAD .1 10,95, L 5GK19XDVAD .1 17,5094,2005 Taupe R 5GN55WL8AD .1 10.95, L 5GK19WL8AD .1 17,50#.2 10,00 8 Bezel, No.1 Instrument PanelLimted Model WB02DX9AA.2 30,70 004-09544Renegade, Sport ModelSlate Gray WB021DVAA.2 30.70 1 Console, FloorTaupe WB021L8AA.2 30,70 Man Trans9 Bezel, No.2 Instrument Panel Slate GrayLimited Model WB03DX9AA.1 25,45 TaupeRenegade, Sport Model Auto TransSlate Gray WB031DVAA.1 25.45 Slate GrayTaupe WB031 L8AA .1 25.45 Taupe10 Bezel, No.3 Instrument Panel 2 Lid, ConsoleLimited Model WB05DX9AA.1 22.10 Slate Grayi Renegade, Sport Model TaupeISlate Gray WB051DVAA.1 22.10 3 Latch, LidTaupe WB051l8AA.1 22.10 4 Hinge, Lid

Page 1798 of 1803

FASTENER USAGE

DESCRIPTION

DESCRIPTION

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

DESCRIPTION

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

THREADED HOLE REPAIR

DESCRIPTION

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

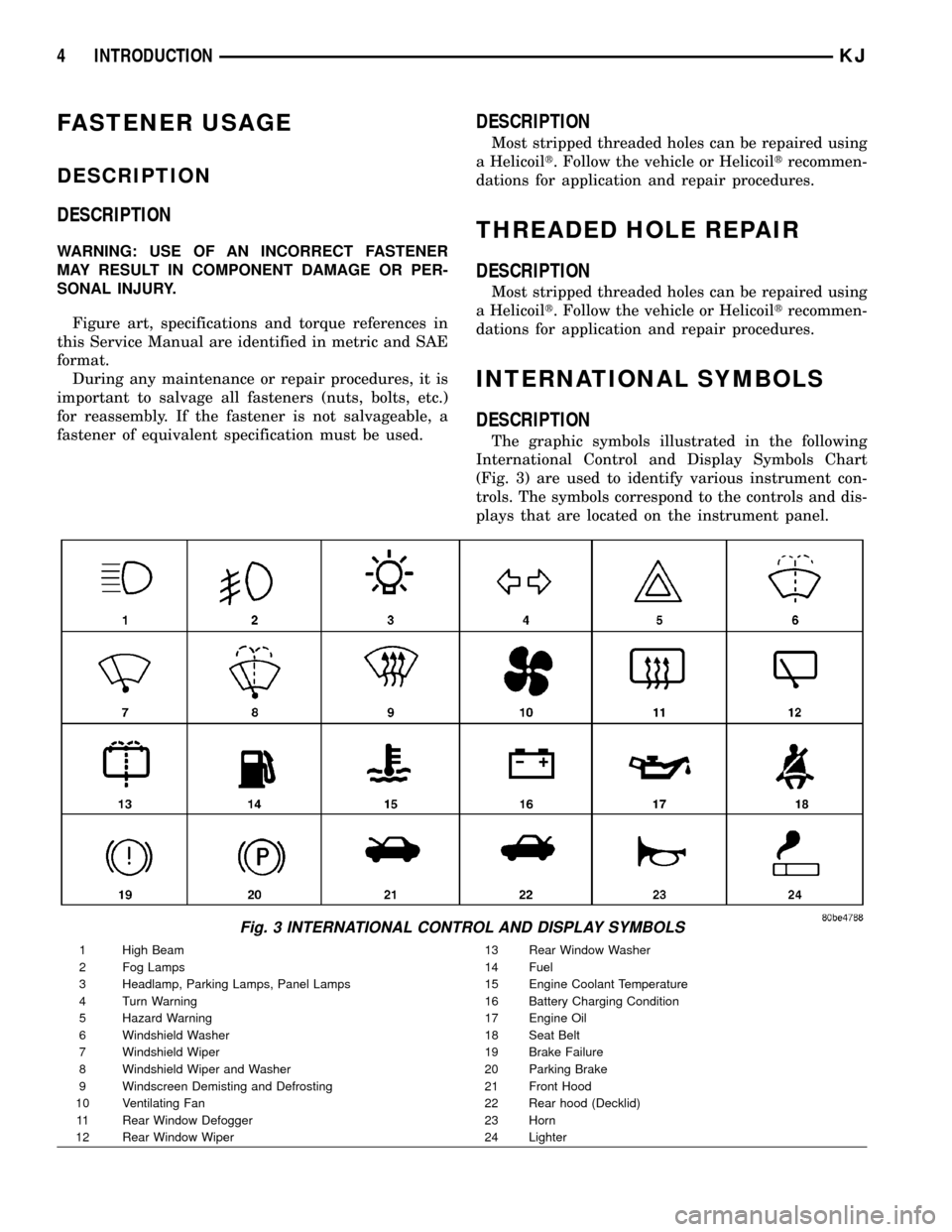

INTERNATIONAL SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart

(Fig. 3) are used to identify various instrument con-

trols. The symbols correspond to the controls and dis-

plays that are located on the instrument panel.

Fig. 3 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

4 INTRODUCTIONKJ