9 Engine JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 723 of 1803

(6) Raise and support the vehicle.

(7) Remove the splash shield from the right front

fender wheel house. (Refer to 23 - BODY/EXTERIOR/

WHEELHOUSE SPLASH SHIELD - REMOVAL).

(8) Release the ªWº clip that secures the front

bumper fascia to the front bumper support. This clip

is located behind the bumper support and below the

right front lamp unit.

(9) Place a clean container on the floor beneath the

washer pump/motor location to catch any washer

fluid that is spilled during the following procedure.

(10) Disconnect the front and rear washer hoses

from the washer pump/motor unit outlet nipples and

allow the washer fluid to drain into the container for

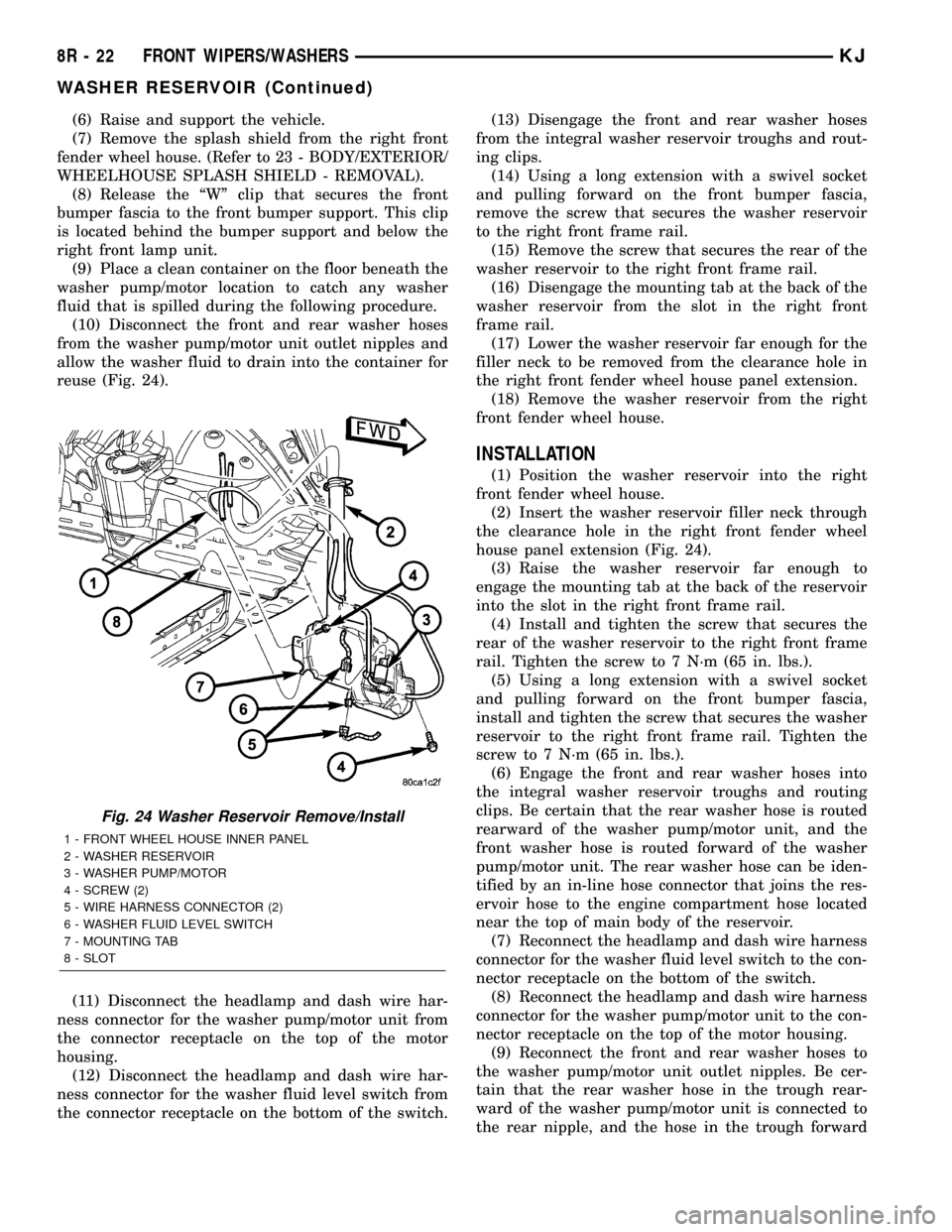

reuse (Fig. 24).

(11) Disconnect the headlamp and dash wire har-

ness connector for the washer pump/motor unit from

the connector receptacle on the top of the motor

housing.

(12) Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the connector receptacle on the bottom of the switch.(13) Disengage the front and rear washer hoses

from the integral washer reservoir troughs and rout-

ing clips.

(14) Using a long extension with a swivel socket

and pulling forward on the front bumper fascia,

remove the screw that secures the washer reservoir

to the right front frame rail.

(15) Remove the screw that secures the rear of the

washer reservoir to the right front frame rail.

(16) Disengage the mounting tab at the back of the

washer reservoir from the slot in the right front

frame rail.

(17) Lower the washer reservoir far enough for the

filler neck to be removed from the clearance hole in

the right front fender wheel house panel extension.

(18) Remove the washer reservoir from the right

front fender wheel house.

INSTALLATION

(1) Position the washer reservoir into the right

front fender wheel house.

(2) Insert the washer reservoir filler neck through

the clearance hole in the right front fender wheel

house panel extension (Fig. 24).

(3) Raise the washer reservoir far enough to

engage the mounting tab at the back of the reservoir

into the slot in the right front frame rail.

(4) Install and tighten the screw that secures the

rear of the washer reservoir to the right front frame

rail. Tighten the screw to 7 N´m (65 in. lbs.).

(5) Using a long extension with a swivel socket

and pulling forward on the front bumper fascia,

install and tighten the screw that secures the washer

reservoir to the right front frame rail. Tighten the

screw to 7 N´m (65 in. lbs.).

(6) Engage the front and rear washer hoses into

the integral washer reservoir troughs and routing

clips. Be certain that the rear washer hose is routed

rearward of the washer pump/motor unit, and the

front washer hose is routed forward of the washer

pump/motor unit. The rear washer hose can be iden-

tified by an in-line hose connector that joins the res-

ervoir hose to the engine compartment hose located

near the top of main body of the reservoir.

(7) Reconnect the headlamp and dash wire harness

connector for the washer fluid level switch to the con-

nector receptacle on the bottom of the switch.

(8) Reconnect the headlamp and dash wire harness

connector for the washer pump/motor unit to the con-

nector receptacle on the top of the motor housing.

(9) Reconnect the front and rear washer hoses to

the washer pump/motor unit outlet nipples. Be cer-

tain that the rear washer hose in the trough rear-

ward of the washer pump/motor unit is connected to

the rear nipple, and the hose in the trough forward

Fig. 24 Washer Reservoir Remove/Install

1 - FRONT WHEEL HOUSE INNER PANEL

2 - WASHER RESERVOIR

3 - WASHER PUMP/MOTOR

4 - SCREW (2)

5 - WIRE HARNESS CONNECTOR (2)

6 - WASHER FLUID LEVEL SWITCH

7 - MOUNTING TAB

8 - SLOT

8R - 22 FRONT WIPERS/WASHERSKJ

WASHER RESERVOIR (Continued)

Page 724 of 1803

of the washer pump/motor unit is connected to the

front nipple.

(10) Engage the ªWº clip that secures the front

bumper fascia to the front bumper support. This clip

is located behind the bumper support and below the

right front lamp unit.

(11) Reinstall the splash shield into the right front

fender wheel house. (Refer to 23 - BODY/EXTERIOR/

WHEELHOUSE SPLASH SHIELD - INSTALLA-

TION).

(12) Lower the vehicle.

(13) Install and tighten the screw that secures the

washer reservoir filler neck support to upper radiator

crossmember (Fig. 23). Tighten the screw to 7 N´m

(65 in. lbs.).

(14) Reinstall the air cleaner housing onto the top

of the right front fender wheel house. (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

ELEMENT - INSTALLATION).

(15) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(16) Reconnect the battery negative cable.

WIPER HIGH/LOW RELAY

DESCRIPTION

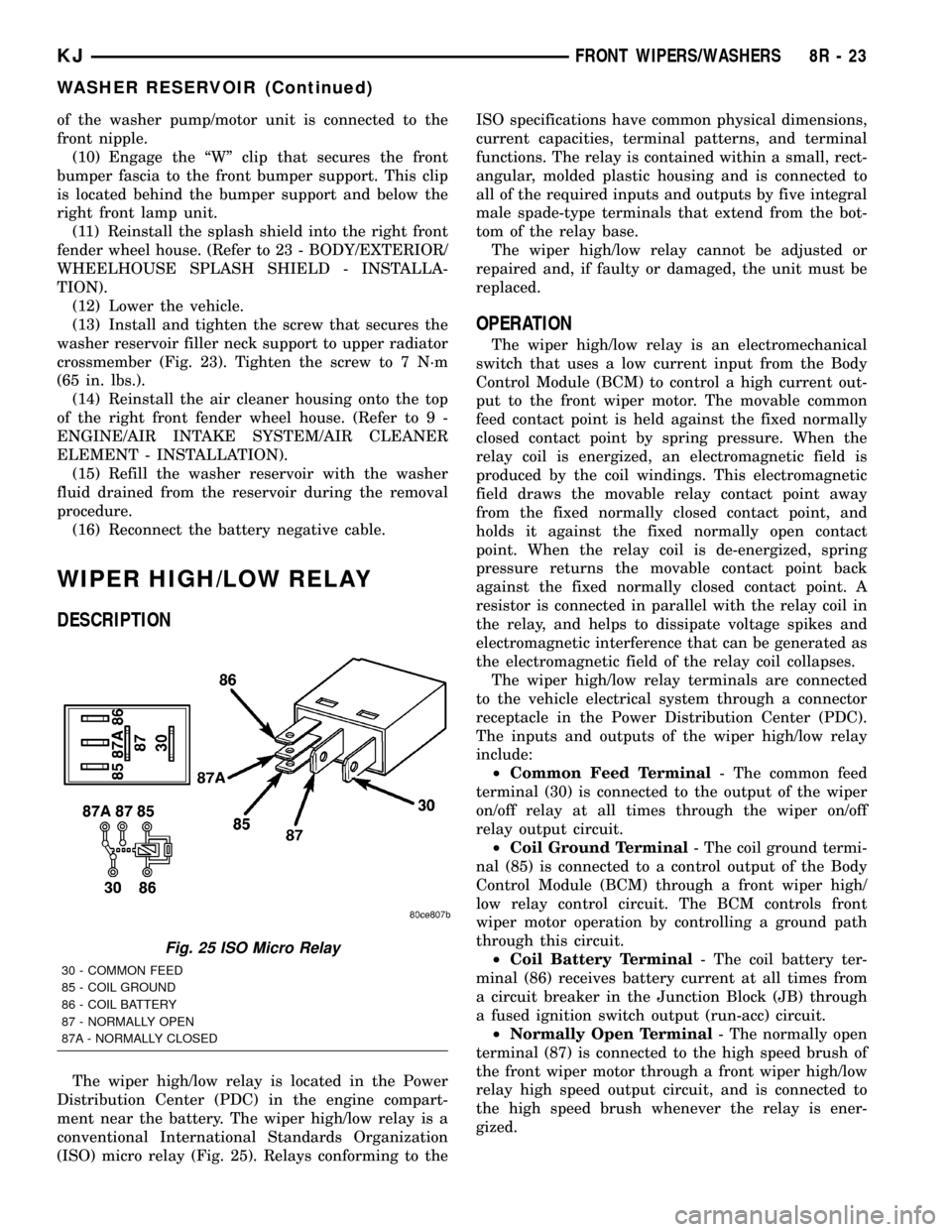

The wiper high/low relay is located in the Power

Distribution Center (PDC) in the engine compart-

ment near the battery. The wiper high/low relay is a

conventional International Standards Organization

(ISO) micro relay (Fig. 25). Relays conforming to theISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions. The relay is contained within a small, rect-

angular, molded plastic housing and is connected to

all of the required inputs and outputs by five integral

male spade-type terminals that extend from the bot-

tom of the relay base.

The wiper high/low relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper high/low relay is an electromechanical

switch that uses a low current input from the Body

Control Module (BCM) to control a high current out-

put to the front wiper motor. The movable common

feed contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The wiper high/low relay terminals are connected

to the vehicle electrical system through a connector

receptacle in the Power Distribution Center (PDC).

The inputs and outputs of the wiper high/low relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the output of the wiper

on/off relay at all times through the wiper on/off

relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Body

Control Module (BCM) through a front wiper high/

low relay control circuit. The BCM controls front

wiper motor operation by controlling a ground path

through this circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a circuit breaker in the Junction Block (JB) through

a fused ignition switch output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) is connected to the high speed brush of

the front wiper motor through a front wiper high/low

relay high speed output circuit, and is connected to

the high speed brush whenever the relay is ener-

gized.

Fig. 25 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJFRONT WIPERS/WASHERS 8R - 23

WASHER RESERVOIR (Continued)

Page 725 of 1803

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to the low speed

brush of the front wiper motor through a front wiper

high/low relay low speed output circuit, and is con-

nected to the low speed brush whenever the relay is

de-energized.

The wiper high/low relay can be diagnosed using

conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - WIPER HIGH/LOW

RELAY

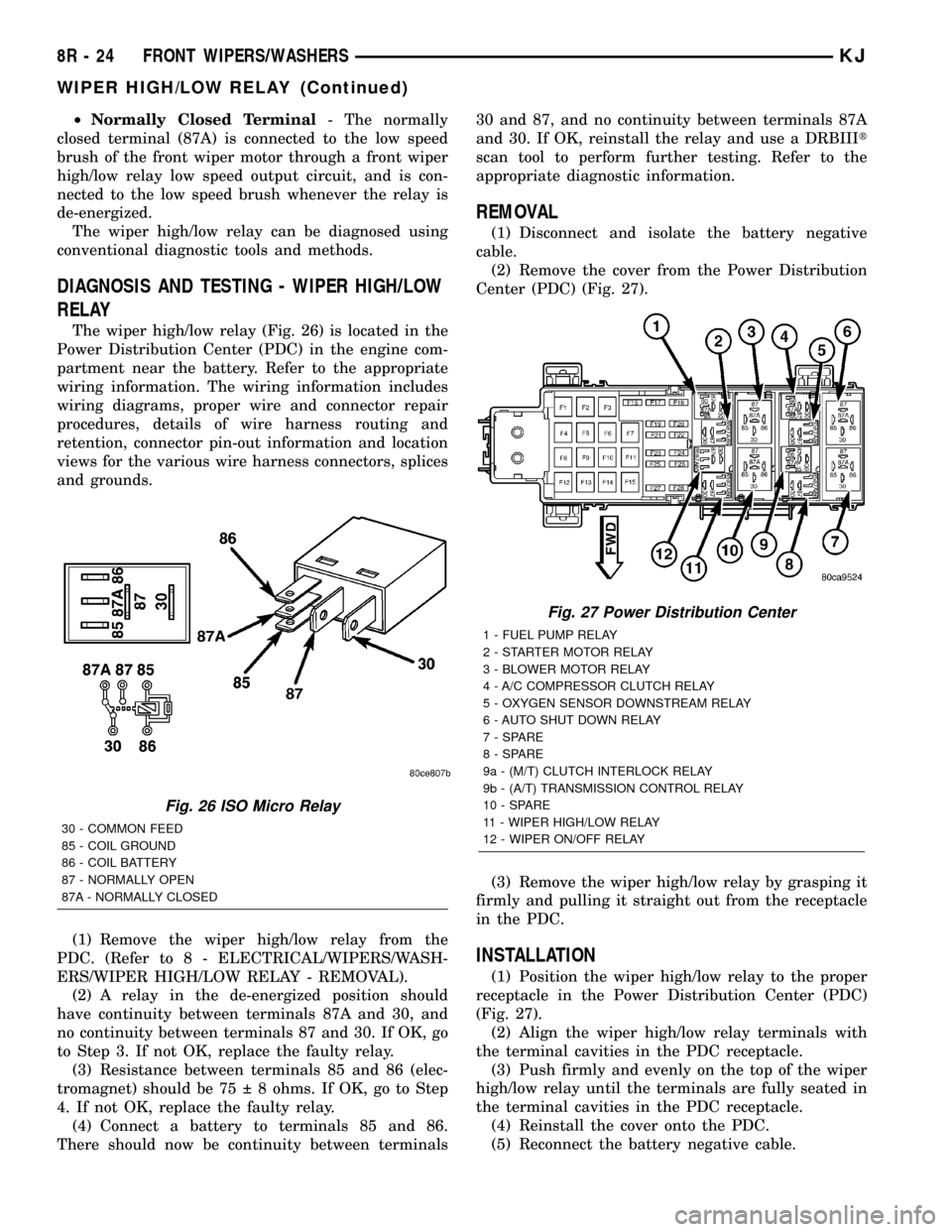

The wiper high/low relay (Fig. 26) is located in the

Power Distribution Center (PDC) in the engine com-

partment near the battery. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

(1) Remove the wiper high/low relay from the

PDC. (Refer to 8 - ELECTRICAL/WIPERS/WASH-

ERS/WIPER HIGH/LOW RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 27).

(3) Remove the wiper high/low relay by grasping it

firmly and pulling it straight out from the receptacle

in the PDC.

INSTALLATION

(1) Position the wiper high/low relay to the proper

receptacle in the Power Distribution Center (PDC)

(Fig. 27).

(2) Align the wiper high/low relay terminals with

the terminal cavities in the PDC receptacle.

(3) Push firmly and evenly on the top of the wiper

high/low relay until the terminals are fully seated in

the terminal cavities in the PDC receptacle.

(4) Reinstall the cover onto the PDC.

(5) Reconnect the battery negative cable.

Fig. 26 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 27 Power Distribution Center

1 - FUEL PUMP RELAY

2 - STARTER MOTOR RELAY

3 - BLOWER MOTOR RELAY

4 - A/C COMPRESSOR CLUTCH RELAY

5 - OXYGEN SENSOR DOWNSTREAM RELAY

6 - AUTO SHUT DOWN RELAY

7-SPARE

8-SPARE

9a - (M/T) CLUTCH INTERLOCK RELAY

9b - (A/T) TRANSMISSION CONTROL RELAY

10 - SPARE

11 - WIPER HIGH/LOW RELAY

12 - WIPER ON/OFF RELAY

8R - 24 FRONT WIPERS/WASHERSKJ

WIPER HIGH/LOW RELAY (Continued)

Page 726 of 1803

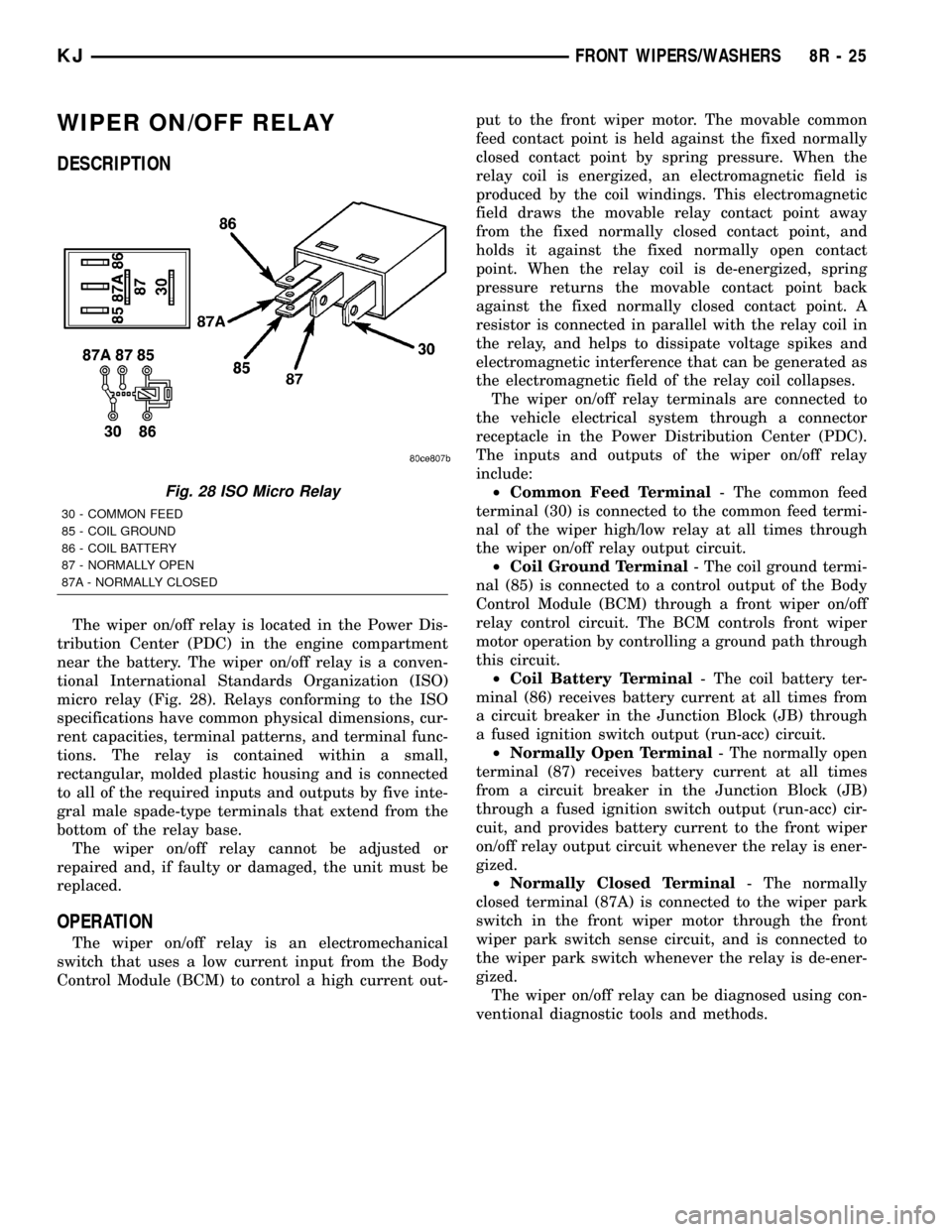

WIPER ON/OFF RELAY

DESCRIPTION

The wiper on/off relay is located in the Power Dis-

tribution Center (PDC) in the engine compartment

near the battery. The wiper on/off relay is a conven-

tional International Standards Organization (ISO)

micro relay (Fig. 28). Relays conforming to the ISO

specifications have common physical dimensions, cur-

rent capacities, terminal patterns, and terminal func-

tions. The relay is contained within a small,

rectangular, molded plastic housing and is connected

to all of the required inputs and outputs by five inte-

gral male spade-type terminals that extend from the

bottom of the relay base.

The wiper on/off relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper on/off relay is an electromechanical

switch that uses a low current input from the Body

Control Module (BCM) to control a high current out-put to the front wiper motor. The movable common

feed contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The wiper on/off relay terminals are connected to

the vehicle electrical system through a connector

receptacle in the Power Distribution Center (PDC).

The inputs and outputs of the wiper on/off relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the common feed termi-

nal of the wiper high/low relay at all times through

the wiper on/off relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Body

Control Module (BCM) through a front wiper on/off

relay control circuit. The BCM controls front wiper

motor operation by controlling a ground path through

this circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a circuit breaker in the Junction Block (JB) through

a fused ignition switch output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) receives battery current at all times

from a circuit breaker in the Junction Block (JB)

through a fused ignition switch output (run-acc) cir-

cuit, and provides battery current to the front wiper

on/off relay output circuit whenever the relay is ener-

gized.

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to the wiper park

switch in the front wiper motor through the front

wiper park switch sense circuit, and is connected to

the wiper park switch whenever the relay is de-ener-

gized.

The wiper on/off relay can be diagnosed using con-

ventional diagnostic tools and methods.

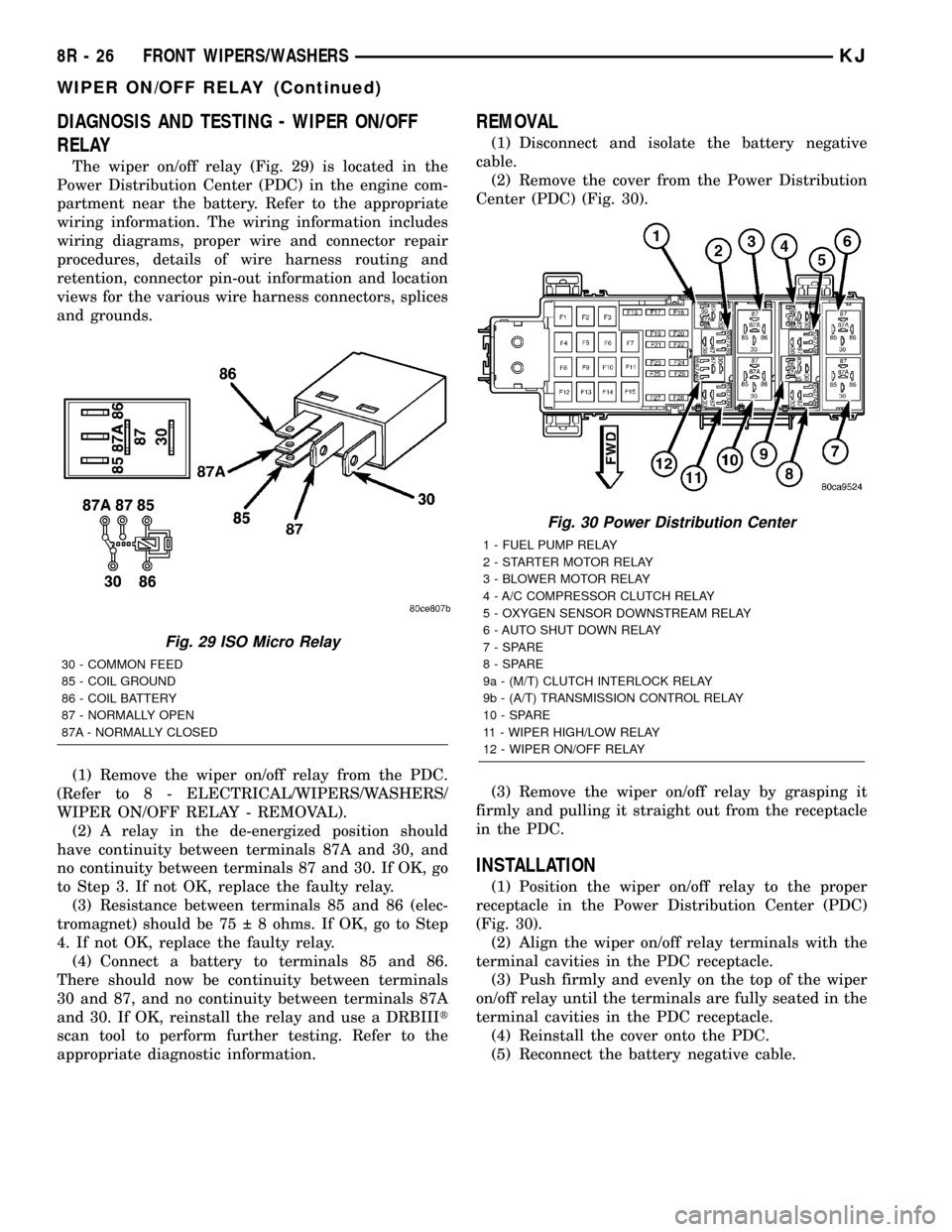

Fig. 28 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJFRONT WIPERS/WASHERS 8R - 25

Page 727 of 1803

DIAGNOSIS AND TESTING - WIPER ON/OFF

RELAY

The wiper on/off relay (Fig. 29) is located in the

Power Distribution Center (PDC) in the engine com-

partment near the battery. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

(1) Remove the wiper on/off relay from the PDC.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ON/OFF RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

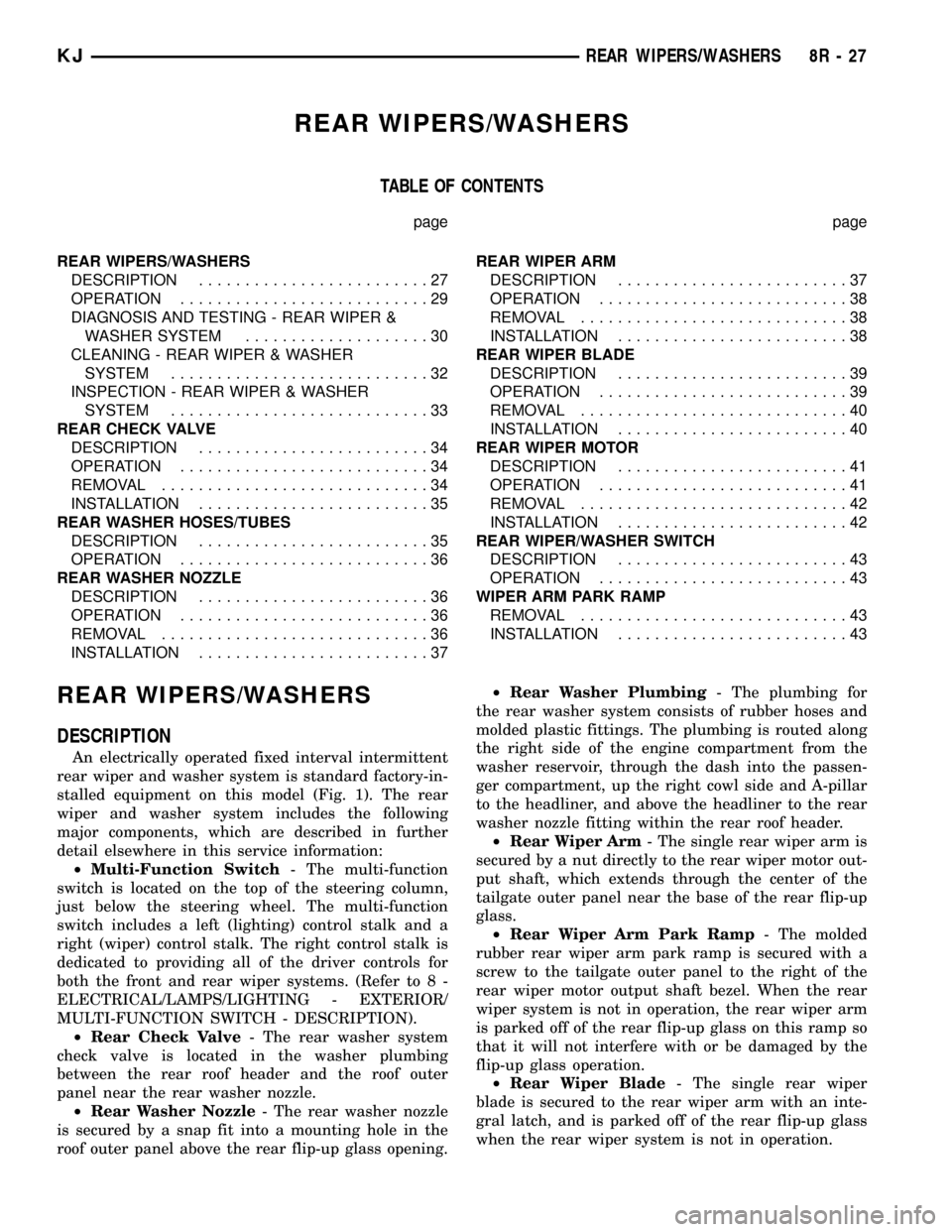

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 30).

(3) Remove the wiper on/off relay by grasping it

firmly and pulling it straight out from the receptacle

in the PDC.

INSTALLATION

(1) Position the wiper on/off relay to the proper

receptacle in the Power Distribution Center (PDC)

(Fig. 30).

(2) Align the wiper on/off relay terminals with the

terminal cavities in the PDC receptacle.

(3) Push firmly and evenly on the top of the wiper

on/off relay until the terminals are fully seated in the

terminal cavities in the PDC receptacle.

(4) Reinstall the cover onto the PDC.

(5) Reconnect the battery negative cable.

Fig. 29 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 30 Power Distribution Center

1 - FUEL PUMP RELAY

2 - STARTER MOTOR RELAY

3 - BLOWER MOTOR RELAY

4 - A/C COMPRESSOR CLUTCH RELAY

5 - OXYGEN SENSOR DOWNSTREAM RELAY

6 - AUTO SHUT DOWN RELAY

7-SPARE

8-SPARE

9a - (M/T) CLUTCH INTERLOCK RELAY

9b - (A/T) TRANSMISSION CONTROL RELAY

10 - SPARE

11 - WIPER HIGH/LOW RELAY

12 - WIPER ON/OFF RELAY

8R - 26 FRONT WIPERS/WASHERSKJ

WIPER ON/OFF RELAY (Continued)

Page 728 of 1803

REAR WIPERS/WASHERS

TABLE OF CONTENTS

page page

REAR WIPERS/WASHERS

DESCRIPTION.........................27

OPERATION...........................29

DIAGNOSIS AND TESTING - REAR WIPER &

WASHER SYSTEM....................30

CLEANING - REAR WIPER & WASHER

SYSTEM............................32

INSPECTION - REAR WIPER & WASHER

SYSTEM............................33

REAR CHECK VALVE

DESCRIPTION.........................34

OPERATION...........................34

REMOVAL.............................34

INSTALLATION.........................35

REAR WASHER HOSES/TUBES

DESCRIPTION.........................35

OPERATION...........................36

REAR WASHER NOZZLE

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................37REAR WIPER ARM

DESCRIPTION.........................37

OPERATION...........................38

REMOVAL.............................38

INSTALLATION.........................38

REAR WIPER BLADE

DESCRIPTION.........................39

OPERATION...........................39

REMOVAL.............................40

INSTALLATION.........................40

REAR WIPER MOTOR

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................42

INSTALLATION.........................42

REAR WIPER/WASHER SWITCH

DESCRIPTION.........................43

OPERATION...........................43

WIPER ARM PARK RAMP

REMOVAL.............................43

INSTALLATION.........................43

REAR WIPERS/WASHERS

DESCRIPTION

An electrically operated fixed interval intermittent

rear wiper and washer system is standard factory-in-

stalled equipment on this model (Fig. 1). The rear

wiper and washer system includes the following

major components, which are described in further

detail elsewhere in this service information:

²Multi-Function Switch- The multi-function

switch is located on the top of the steering column,

just below the steering wheel. The multi-function

switch includes a left (lighting) control stalk and a

right (wiper) control stalk. The right control stalk is

dedicated to providing all of the driver controls for

both the front and rear wiper systems. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

MULTI-FUNCTION SWITCH - DESCRIPTION).

²Rear Check Valve- The rear washer system

check valve is located in the washer plumbing

between the rear roof header and the roof outer

panel near the rear washer nozzle.

²Rear Washer Nozzle- The rear washer nozzle

is secured by a snap fit into a mounting hole in the

roof outer panel above the rear flip-up glass opening.²Rear Washer Plumbing- The plumbing for

the rear washer system consists of rubber hoses and

molded plastic fittings. The plumbing is routed along

the right side of the engine compartment from the

washer reservoir, through the dash into the passen-

ger compartment, up the right cowl side and A-pillar

to the headliner, and above the headliner to the rear

washer nozzle fitting within the rear roof header.

²Rear Wiper Arm- The single rear wiper arm is

secured by a nut directly to the rear wiper motor out-

put shaft, which extends through the center of the

tailgate outer panel near the base of the rear flip-up

glass.

²Rear Wiper Arm Park Ramp- The molded

rubber rear wiper arm park ramp is secured with a

screw to the tailgate outer panel to the right of the

rear wiper motor output shaft bezel. When the rear

wiper system is not in operation, the rear wiper arm

is parked off of the rear flip-up glass on this ramp so

that it will not interfere with or be damaged by the

flip-up glass operation.

²Rear Wiper Blade- The single rear wiper

blade is secured to the rear wiper arm with an inte-

gral latch, and is parked off of the rear flip-up glass

when the rear wiper system is not in operation.

KJREAR WIPERS/WASHERS 8R - 27

Page 730 of 1803

²Rear Wiper Module- The rear wiper motor

output shaft is the only visible component of the rear

wiper module. The remainder of the module is con-

cealed within the tailgate below the rear flip-up glass

opening. The rear wiper module includes the module

bracket, the rear wiper motor, and the rear wiper

electronic control circuitry.

²Washer Pump/Motor- The reversible electric

washer pump/motor unit is located in a dedicated

hole on the lower outboard side of the washer reser-

voir, behind the right front wheel house splash

shield. This single reversible washer pump/motor

provides washer fluid to either the front or rear

washer system plumbing, depending upon the direc-

tion of the pump motor rotation. (Refer to 8 - ELEC-

TRICAL/FRONT WIPERS/WASHERS/WASHER

PUMP MOTOR - DESCRIPTION).

²Washer Reservoir- The washer reservoir is

concealed behind the right front wheel house splash

shield ahead of the right front wheel. The washer

reservoir filler neck is the only visible portion of the

reservoir, and it is accessed from the right front cor-

ner of the engine compartment. This single washer

reservoir is shared by both the front and rear washer

systems. (Refer to 8 - ELECTRICAL/FRONT WIP-

ERS/WASHERS/WASHER RESERVOIR - DESCRIP-

TION).

Hard wired circuitry connects the rear wiper and

washer system components to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the rear wiper and

washer system components through the use of a com-

bination of soldered splices, splice block connectors,

and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, further details on wire harness routing

and retention, as well as pin-out and location views

for the various wire harness connectors, splices and

grounds.

OPERATING MODES The components of the rear

wiper and washer system are designed to work in

concert to provide the following operating modes:

²Continuous Wipe Mode- The control ring on

the right (wiper) control stalk of the multi-function

switch has an On position. When selected, this

switch position will cause the rear wiper motor to

operate in a continuous manner at a fixed wipe cycle

speed.

²Intermittent Wipe Mode- The control ring on

the right (wiper) control stalk of the multi-function

switch has a Delay position. When selected, thisswitch position will cause the rear wiper motor to

operate in an intermittent manner at a fixed interval

wipe cycle speed.

²Washer Mode- The control ring on the right

(wiper) control stalk of the multi-function switch has

two momentary Wash positions, one at the end of

each direction of control ring rotation. When the con-

trol ring is rotated to the downward (counterclock-

wise) Wash position, the rear washer system will

dispense washer fluid onto the flip-up glass and the

rear wiper motor will operate in a continuous mode

for as long as the switch is held closed, then provide

several additional wipe cycles after the washer

switch is released (wipe-after-wash mode). When the

control ring is rotated to the upward (clockwise)

Wash position, the rear washer system will dispense

washer fluid onto the flip-up glass and the rear wiper

motor will operate in a continuous mode for as long

as the switch is held closed, then return to fixed wipe

mode operation after the washer switch is released.

²Wipe-After-Wash Mode- The control ring on

the right (wiper) control stalk of the multi-function

switch has two momentary Wash positions, one at

the end of each direction of control ring rotation.

When the control ring is rotated to the downward

(counterclockwise) Wash position, the rear washer

system will dispense washer fluid onto the flip-up

glass and the rear wiper motor will operate in a con-

tinuous mode for as long as the switch is held closed,

then provide several additional wipe cycles after the

washer switch is released.

OPERATION

The rear wiper and washer system is designed to

provide the vehicle operator with a convenient, safe,

and reliable means of maintaining visibility through

the rear flip-up glass. The various components of this

system are designed to convert electrical energy pro-

duced by the vehicle electrical system into the

mechanical action of the wiper blade to wipe the out-

side surface of the glass, as well as into the hydraulic

action of the washer system to apply washer fluid

stored in an on-board reservoir to the area of the

glass to be wiped. When combined, these components

provide the means to effectively maintain clear visi-

bility for the vehicle operator by removing excess

accumulations of rain, snow, bugs, mud, or other

minor debris from the swing gate flip up glass sur-

face that might be encountered while driving the

vehicle under numerous types of inclement operating

conditions.

The vehicle operator initiates all rear wiper and

washer system functions with the right (wiper) con-

trol stalk of the multi-function switch that extends

from the right side of the steering column, just below

the steering wheel. Rotating the control ring on the

KJREAR WIPERS/WASHERS 8R - 29

REAR WIPERS/WASHERS (Continued)

Page 736 of 1803

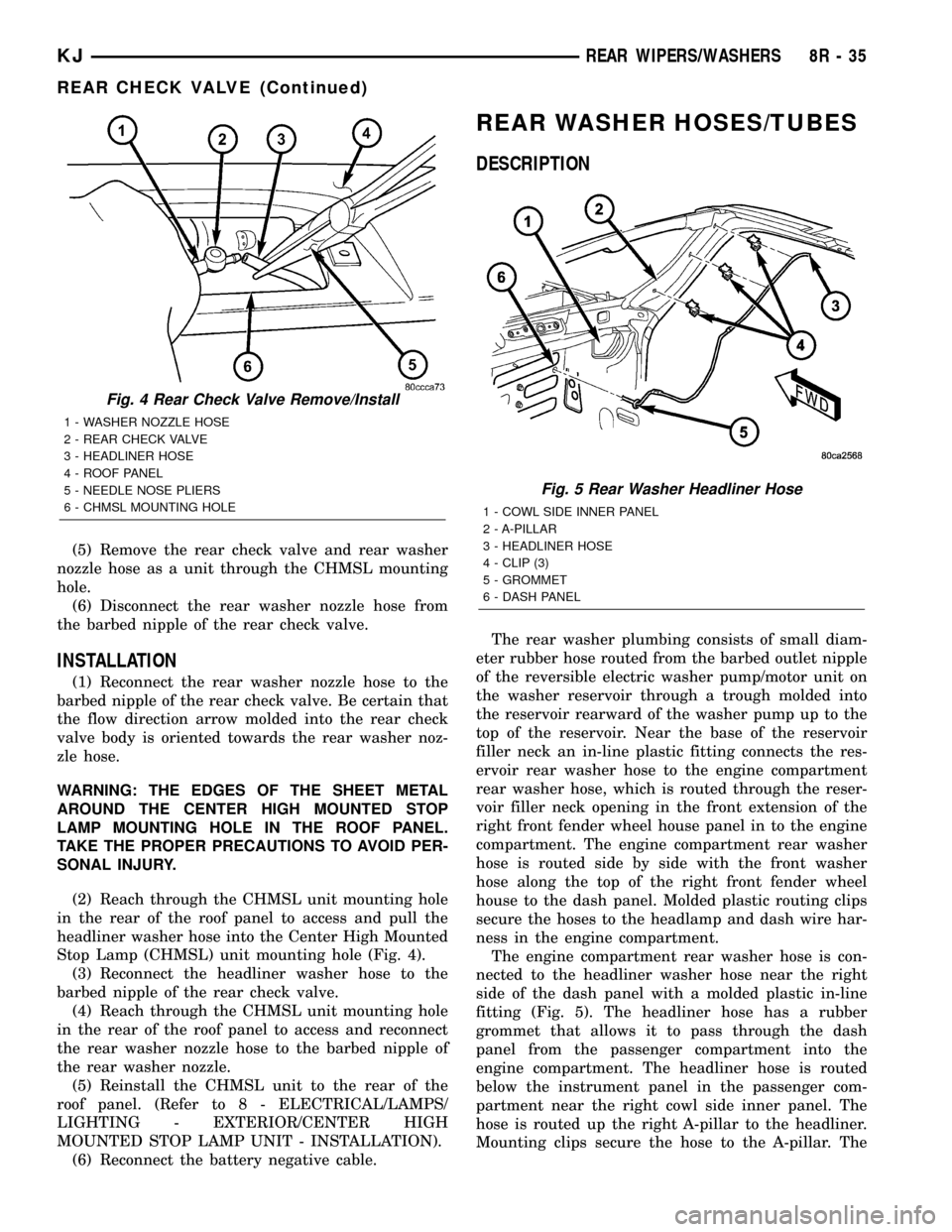

(5) Remove the rear check valve and rear washer

nozzle hose as a unit through the CHMSL mounting

hole.

(6) Disconnect the rear washer nozzle hose from

the barbed nipple of the rear check valve.

INSTALLATION

(1) Reconnect the rear washer nozzle hose to the

barbed nipple of the rear check valve. Be certain that

the flow direction arrow molded into the rear check

valve body is oriented towards the rear washer noz-

zle hose.

WARNING: THE EDGES OF THE SHEET METAL

AROUND THE CENTER HIGH MOUNTED STOP

LAMP MOUNTING HOLE IN THE ROOF PANEL.

TAKE THE PROPER PRECAUTIONS TO AVOID PER-

SONAL INJURY.

(2) Reach through the CHMSL unit mounting hole

in the rear of the roof panel to access and pull the

headliner washer hose into the Center High Mounted

Stop Lamp (CHMSL) unit mounting hole (Fig. 4).

(3) Reconnect the headliner washer hose to the

barbed nipple of the rear check valve.

(4) Reach through the CHMSL unit mounting hole

in the rear of the roof panel to access and reconnect

the rear washer nozzle hose to the barbed nipple of

the rear washer nozzle.

(5) Reinstall the CHMSL unit to the rear of the

roof panel. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/CENTER HIGH

MOUNTED STOP LAMP UNIT - INSTALLATION).

(6) Reconnect the battery negative cable.

REAR WASHER HOSES/TUBES

DESCRIPTION

The rear washer plumbing consists of small diam-

eter rubber hose routed from the barbed outlet nipple

of the reversible electric washer pump/motor unit on

the washer reservoir through a trough molded into

the reservoir rearward of the washer pump up to the

top of the reservoir. Near the base of the reservoir

filler neck an in-line plastic fitting connects the res-

ervoir rear washer hose to the engine compartment

rear washer hose, which is routed through the reser-

voir filler neck opening in the front extension of the

right front fender wheel house panel in to the engine

compartment. The engine compartment rear washer

hose is routed side by side with the front washer

hose along the top of the right front fender wheel

house to the dash panel. Molded plastic routing clips

secure the hoses to the headlamp and dash wire har-

ness in the engine compartment.

The engine compartment rear washer hose is con-

nected to the headliner washer hose near the right

side of the dash panel with a molded plastic in-line

fitting (Fig. 5). The headliner hose has a rubber

grommet that allows it to pass through the dash

panel from the passenger compartment into the

engine compartment. The headliner hose is routed

below the instrument panel in the passenger com-

partment near the right cowl side inner panel. The

hose is routed up the right A-pillar to the headliner.

Mounting clips secure the hose to the A-pillar. The

Fig. 4 Rear Check Valve Remove/Install

1 - WASHER NOZZLE HOSE

2 - REAR CHECK VALVE

3 - HEADLINER HOSE

4 - ROOF PANEL

5 - NEEDLE NOSE PLIERS

6 - CHMSL MOUNTING HOLE

Fig. 5 Rear Washer Headliner Hose

1 - COWL SIDE INNER PANEL

2 - A-PILLAR

3 - HEADLINER HOSE

4 - CLIP (3)

5 - GROMMET

6 - DASH PANEL

KJREAR WIPERS/WASHERS 8R - 35

REAR CHECK VALVE (Continued)

Page 752 of 1803

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD .................Left Hand Drive Vehicles

RHD................Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX....Manual Transmissions-Front Wheel Drive

AT ....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export........ Vehicles Built For Sale In

Markets Other Than North America

Except-Built-Up-Export . . Vehicles Built For Sale In

North America

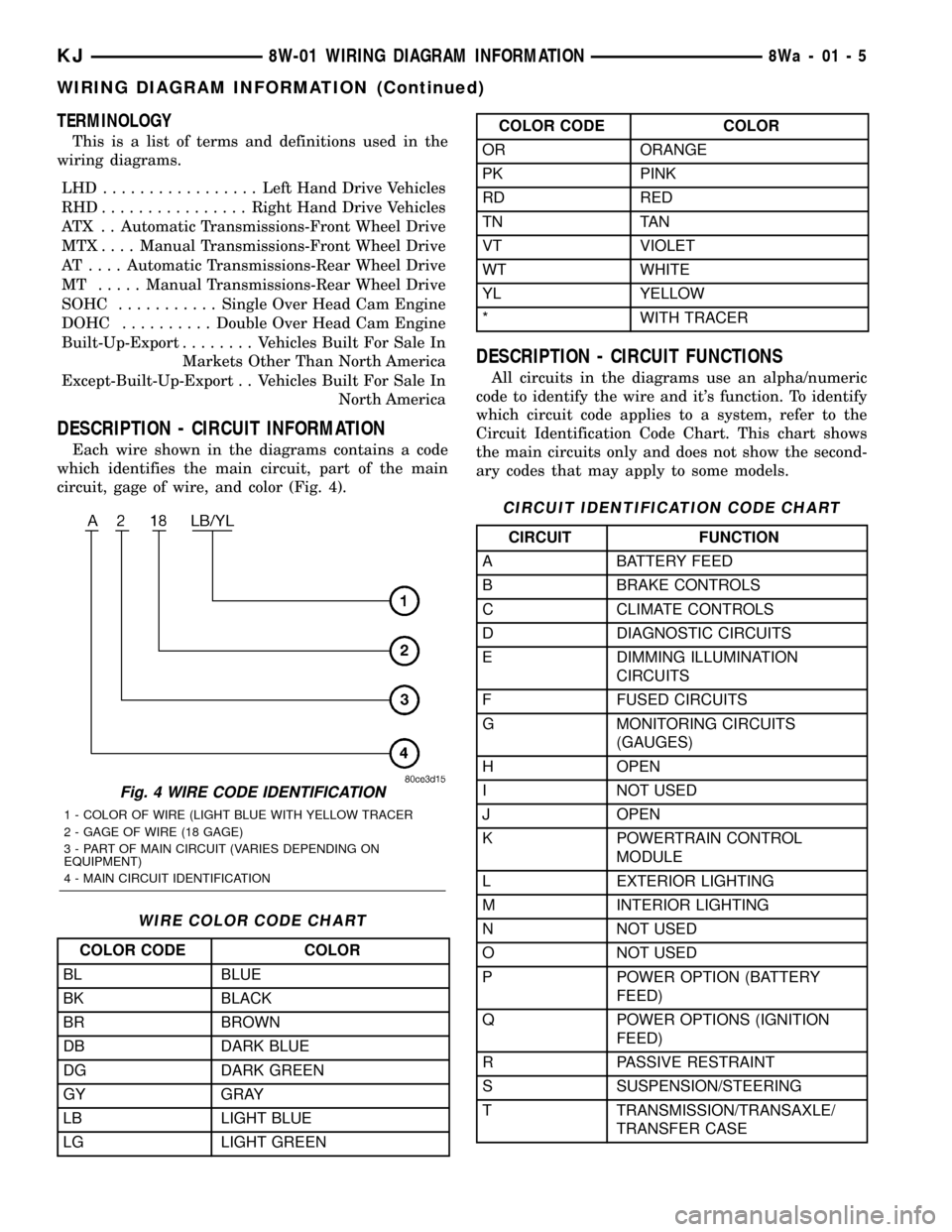

DESCRIPTION - CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 4).

WIRE COLOR CODE CHART

COLOR CODE COLOR

BL BLUE

BK BLACK

BR BROWN

DB DARK BLUE

DG DARK GREEN

GY GRAY

LB LIGHT BLUE

LG LIGHT GREEN

COLOR CODE COLOR

OR ORANGE

PK PINK

RD RED

TN TAN

VT VIOLET

WT WHITE

YL YELLOW

* WITH TRACER

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

Fig. 4 WIRE CODE IDENTIFICATION

1 - COLOR OF WIRE (LIGHT BLUE WITH YELLOW TRACER

2 - GAGE OF WIRE (18 GAGE)

3 - PART OF MAIN CIRCUIT (VARIES DEPENDING ON

EQUIPMENT)

4 - MAIN CIRCUIT IDENTIFICATION

KJ8W-01 WIRING DIAGRAM INFORMATION8Wa-01-5

WIRING DIAGRAM INFORMATION (Continued)

Page 753 of 1803

CIRCUIT FUNCTION

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

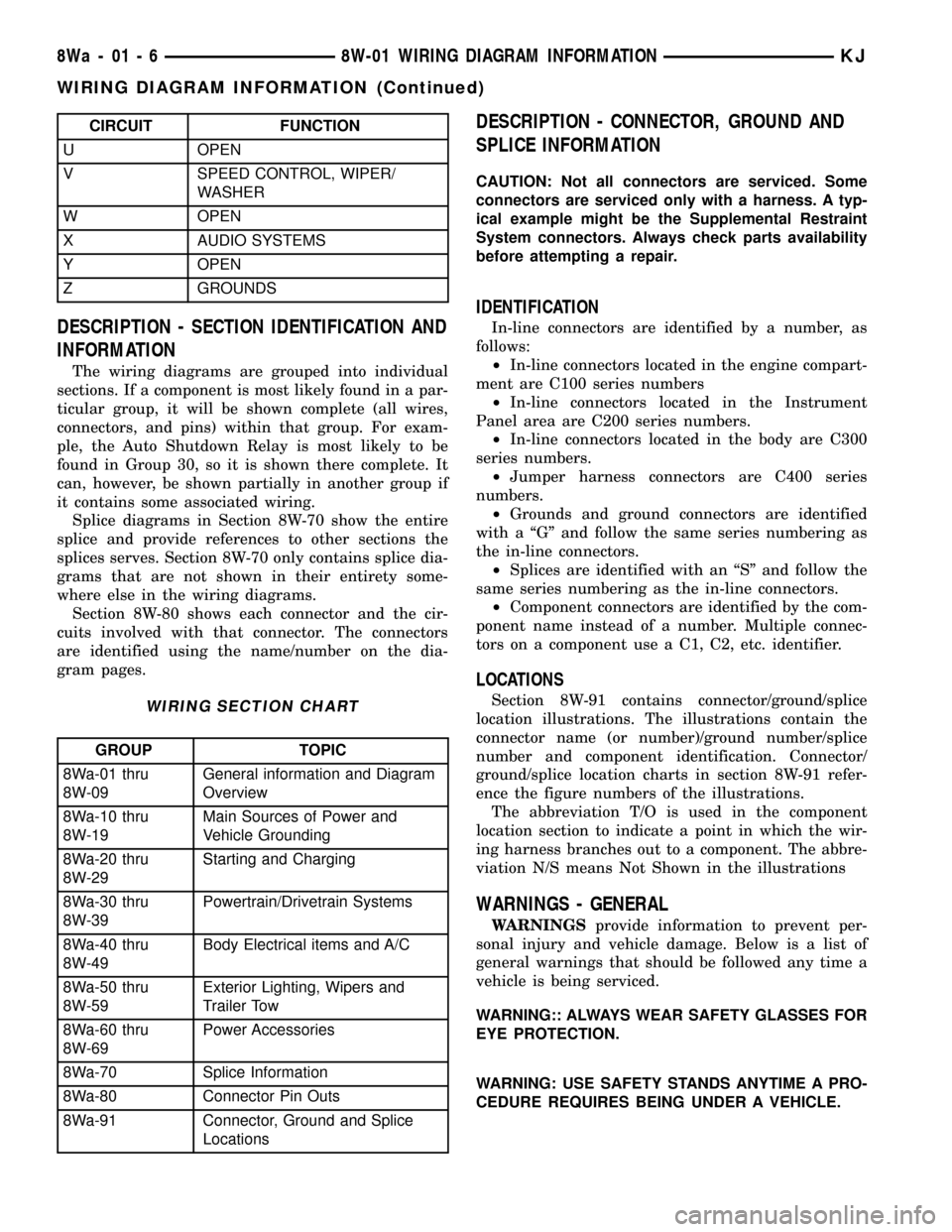

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8Wa-01 thru

8W-09General information and Diagram

Overview

8Wa-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8Wa-20 thru

8W-29Starting and Charging

8Wa-30 thru

8W-39Powertrain/Drivetrain Systems

8Wa-40 thru

8W-49Body Electrical items and A/C

8Wa-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8Wa-60 thru

8W-69Power Accessories

8Wa-70 Splice Information

8Wa-80 Connector Pin Outs

8Wa-91 Connector, Ground and Splice

Locations

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING:: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.

8Wa - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONKJ

WIRING DIAGRAM INFORMATION (Continued)