torque JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1730 of 1803

EVAPORATIVE EMISSIONS

TABLE OF CONTENTS

page page

EVAPORATIVE EMISSIONS

DESCRIPTION - EVAPORATION CONTROL

SYSTEM............................24

SPECIFICATIONS

TORQUE............................26

EVAP/PURGE SOLENOID

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................27

INSTALLATION.........................27

FUEL FILLER CAP

DESCRIPTION.........................27

OPERATION...........................27

LEAK DETECTION PUMP

DESCRIPTION.........................27

OPERATION...........................28

REMOVAL.............................28INSTALLATION.........................28

ORVR

DESCRIPTION.........................29

OPERATION...........................29

P C V VA LV E

DESCRIPTION.........................29

OPERATION...........................31

DIAGNOSIS AND TESTING - PCV VALVE.....31

REMOVAL.............................32

INSTALLATION.........................32

VACUUM LINES

DESCRIPTION.........................33

VAPOR CANISTER

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................33

INSTALLATION.........................33

EVAPORATIVE EMISSIONS

DESCRIPTION - EVAPORATION CONTROL

SYSTEM

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When

fuel evaporates in the fuel tank, the vapors pass

through the control valve located in the top section of

the fuel pump module, through the fuel management

valve, and through vent hoses and tubes to a char-

coal filled evaporative canister. The canister tempo-

rarily holds the vapors. The Powertrain Control

Module (PCM) allows intake manifold vacuum to

draw vapors into the combustion chambers during

certain operating conditions.

Gas powered engines use a duty cycle purge sys-

tem. The PCM controls vapor flow by operating theduty cycle EVAP purge solenoid. Refer to Duty Cycle

EVAP Canister Purge Solenoid.

When equipped with certain emissions packages, a

Leak Detection Pump (LDP) will be used as part of

the evaporative system for OBD II requirements.

Also refer to Leak Detection Pump.

Vehicles powered with gasoline engines are also

equipped with ORVR (On-Board Refueling Vapor

Recovery). Refer to ORVR for additional information.

NOTE: The evaporative system uses specially man-

ufactured lines/hoses. If replacement becomes nec-

essary, only use fuel resistant, low permeation

hose.

Certain components can be found in (Fig. 1).

25 - 24 EVAPORATIVE EMISSIONSKJ

Page 1732 of 1803

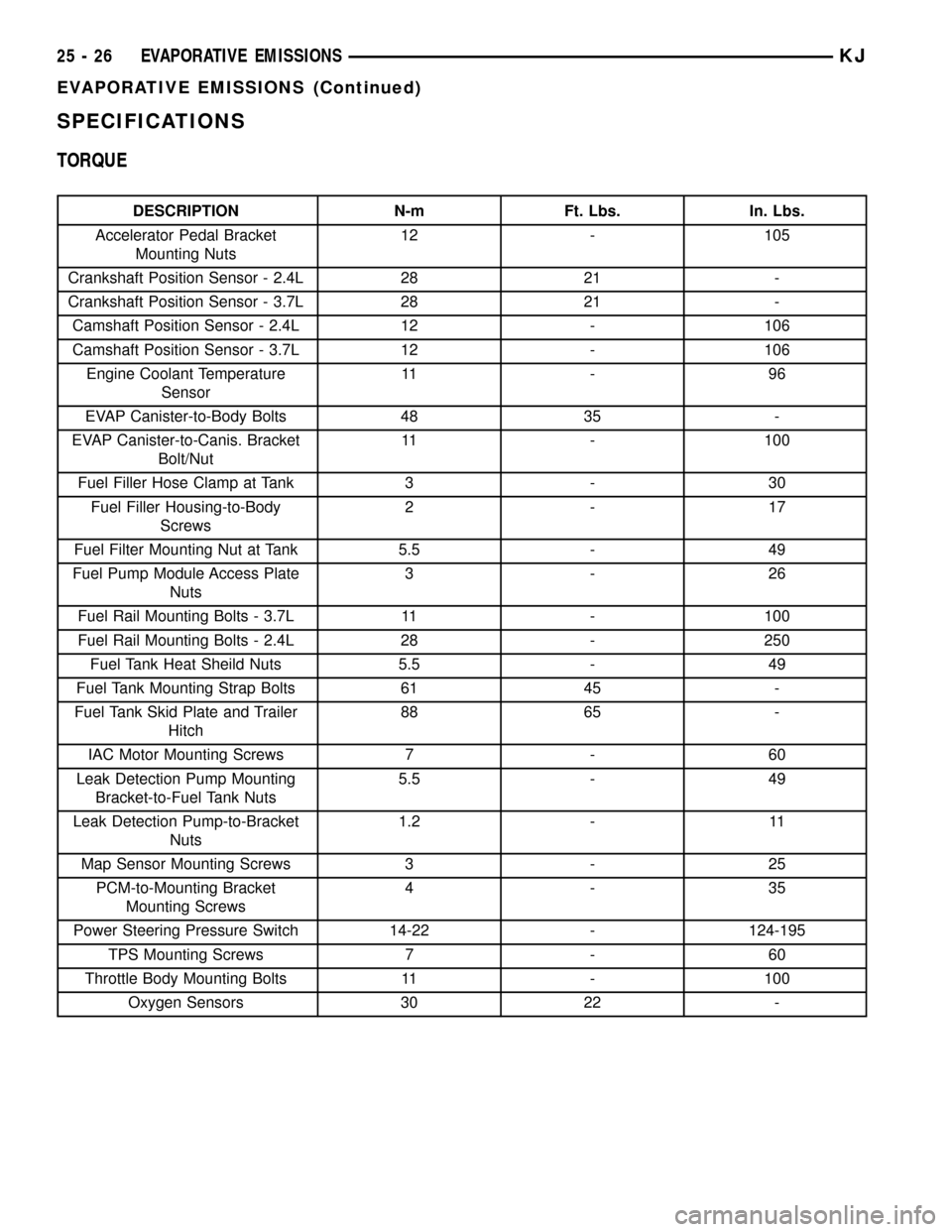

SPECIFICATIONS

TORQUE

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket

Mounting Nuts12 - 105

Crankshaft Position Sensor - 2.4L 28 21 -

Crankshaft Position Sensor - 3.7L 28 21 -

Camshaft Position Sensor - 2.4L 12 - 106

Camshaft Position Sensor - 3.7L 12 - 106

Engine Coolant Temperature

Sensor11 - 9 6

EVAP Canister-to-Body Bolts 48 35 -

EVAP Canister-to-Canis. Bracket

Bolt/Nut11 - 100

Fuel Filler Hose Clamp at Tank 3 - 30

Fuel Filler Housing-to-Body

Screws2-17

Fuel Filter Mounting Nut at Tank 5.5 - 49

Fuel Pump Module Access Plate

Nuts3-26

Fuel Rail Mounting Bolts - 3.7L 11 - 100

Fuel Rail Mounting Bolts - 2.4L 28 - 250

Fuel Tank Heat Sheild Nuts 5.5 - 49

Fuel Tank Mounting Strap Bolts 61 45 -

Fuel Tank Skid Plate and Trailer

Hitch88 65 -

IAC Motor Mounting Screws 7 - 60

Leak Detection Pump Mounting

Bracket-to-Fuel Tank Nuts5.5 - 49

Leak Detection Pump-to-Bracket

Nuts1.2 - 11

Map Sensor Mounting Screws 3 - 25

PCM-to-Mounting Bracket

Mounting Screws4-35

Power Steering Pressure Switch 14-22 - 124-195

TPS Mounting Screws 7 - 60

Throttle Body Mounting Bolts 11 - 100

Oxygen Sensors 30 22 -

25 - 26 EVAPORATIVE EMISSIONSKJ

EVAPORATIVE EMISSIONS (Continued)

Page 1734 of 1803

The pump contains a 3 port solenoid, a pump that

contains a switch, a spring loaded canister vent valve

seal, 2 check valves and a spring/diaphragm.

OPERATION

Immediately after a cold start, engine temperature

between 40ÉF and 86ÉF, the 3 port solenoid is briefly

energized. This initializes the pump by drawing air

into the pump cavity and also closes the vent seal.

During non-test test conditions, the vent seal is held

open by the pump diaphragm assembly which pushes

it open at the full travel position. The vent seal will

remain closed while the pump is cycling. This is due

to the operation of the 3 port solenoid which prevents

the diaphragm assembly from reaching full travel.

After the brief initialization period, the solenoid is

de-energized, allowing atmospheric pressure to enter

the pump cavity. This permits the spring to drive the

diaphragm which forces air out of the pump cavity

and into the vent system. When the solenoid is ener-

gized and de-energized, the cycle is repeated creating

flow in typical diaphragm pump fashion. The pump

is controlled in 2 modes:

PUMP MODE:The pump is cycled at a fixed rate

to achieve a rapid pressure build in order to shorten

the overall test time.

TEST MODE:The solenoid is energized with a

fixed duration pulse. Subsequent fixed pulses occur

when the diaphragm reaches the switch closure

point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5 inches

of water.

When the pump starts, the cycle rate is quite high.

As the system becomes pressurized pump rate drops.

If there is no leak the pump will quit. If there is a

leak, the test is terminated at the end of the test

mode.

If there is no leak, the purge monitor is run. If the

cycle rate increases due to the flow through the

purge system, the test is passed and the diagnostic is

complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.

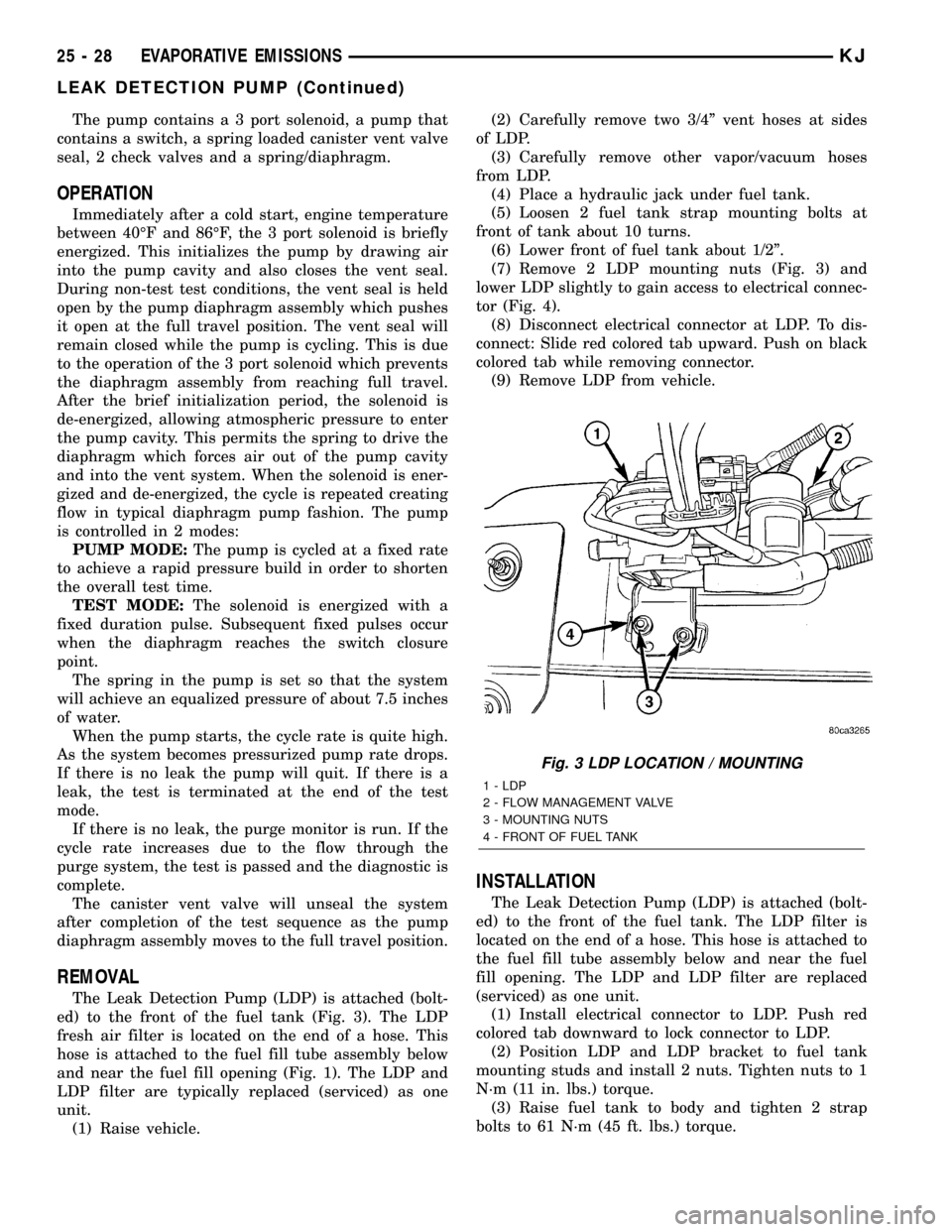

REMOVAL

The Leak Detection Pump (LDP) is attached (bolt-

ed) to the front of the fuel tank (Fig. 3). The LDP

fresh air filter is located on the end of a hose. This

hose is attached to the fuel fill tube assembly below

and near the fuel fill opening (Fig. 1). The LDP and

LDP filter are typically replaced (serviced) as one

unit.

(1) Raise vehicle.(2) Carefully remove two 3/4º vent hoses at sides

of LDP.

(3) Carefully remove other vapor/vacuum hoses

from LDP.

(4) Place a hydraulic jack under fuel tank.

(5) Loosen 2 fuel tank strap mounting bolts at

front of tank about 10 turns.

(6) Lower front of fuel tank about 1/2º.

(7) Remove 2 LDP mounting nuts (Fig. 3) and

lower LDP slightly to gain access to electrical connec-

tor (Fig. 4).

(8) Disconnect electrical connector at LDP. To dis-

connect: Slide red colored tab upward. Push on black

colored tab while removing connector.

(9) Remove LDP from vehicle.

INSTALLATION

The Leak Detection Pump (LDP) is attached (bolt-

ed) to the front of the fuel tank. The LDP filter is

located on the end of a hose. This hose is attached to

the fuel fill tube assembly below and near the fuel

fill opening. The LDP and LDP filter are replaced

(serviced) as one unit.

(1) Install electrical connector to LDP. Push red

colored tab downward to lock connector to LDP.

(2) Position LDP and LDP bracket to fuel tank

mounting studs and install 2 nuts. Tighten nuts to 1

N´m (11 in. lbs.) torque.

(3) Raise fuel tank to body and tighten 2 strap

bolts to 61 N´m (45 ft. lbs.) torque.

Fig. 3 LDP LOCATION / MOUNTING

1 - LDP

2 - FLOW MANAGEMENT VALVE

3 - MOUNTING NUTS

4 - FRONT OF FUEL TANK

25 - 28 EVAPORATIVE EMISSIONSKJ

LEAK DETECTION PUMP (Continued)

Page 1738 of 1803

(13) If vacuum is not present, disconnect each PCV

system hose at top of each crankcase breather (Fig.

8). Check for obstructions or restrictions.

(14) If vacuum is still not present, remove each

PCV system crankcase breather (Fig. 8) from each

cylinder head. Check for obstructions or restrictions.

If plugged, replace breather. Tighten breather to 12

N´m (106 in. lbs.) torque. Do not attempt to clean

breather

(15) If vacuum is still not present, disconnect each

PCV system hose at each fitting and check for

obstructions or restrictions.

REMOVAL

2.4L

The PCV valve is attached to the left/front side of

the valve cover (Fig. 5). It is secured with 1 bolt. An

o-ring is used to seal valve to valve cover (Fig. 6).

(1) Remove hose from valve (Fig. 5). Check condi-

tion of hose.

(2) Remove 1 bolt.

(3) Remove PCV valve from valve cover.

(4) Check condition of valve o-ring.

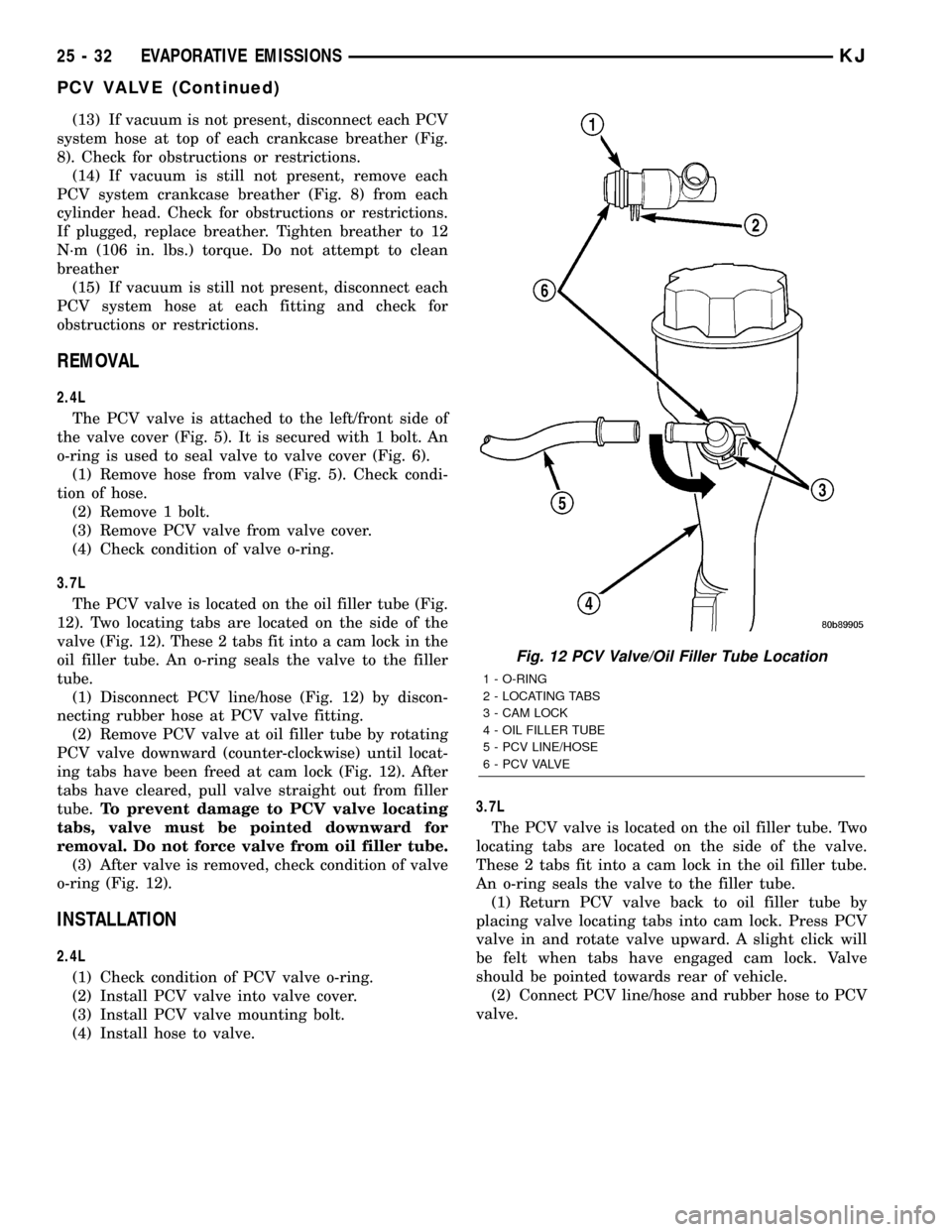

3.7L

The PCV valve is located on the oil filler tube (Fig.

12). Two locating tabs are located on the side of the

valve (Fig. 12). These 2 tabs fit into a cam lock in the

oil filler tube. An o-ring seals the valve to the filler

tube.

(1) Disconnect PCV line/hose (Fig. 12) by discon-

necting rubber hose at PCV valve fitting.

(2) Remove PCV valve at oil filler tube by rotating

PCV valve downward (counter-clockwise) until locat-

ing tabs have been freed at cam lock (Fig. 12). After

tabs have cleared, pull valve straight out from filler

tube.To prevent damage to PCV valve locating

tabs, valve must be pointed downward for

removal. Do not force valve from oil filler tube.

(3) After valve is removed, check condition of valve

o-ring (Fig. 12).

INSTALLATION

2.4L

(1) Check condition of PCV valve o-ring.

(2) Install PCV valve into valve cover.

(3) Install PCV valve mounting bolt.

(4) Install hose to valve.3.7L

The PCV valve is located on the oil filler tube. Two

locating tabs are located on the side of the valve.

These 2 tabs fit into a cam lock in the oil filler tube.

An o-ring seals the valve to the filler tube.

(1) Return PCV valve back to oil filler tube by

placing valve locating tabs into cam lock. Press PCV

valve in and rotate valve upward. A slight click will

be felt when tabs have engaged cam lock. Valve

should be pointed towards rear of vehicle.

(2) Connect PCV line/hose and rubber hose to PCV

valve.

Fig. 12 PCV Valve/Oil Filler Tube Location

1 - O-RING

2 - LOCATING TABS

3 - CAM LOCK

4 - OIL FILLER TUBE

5 - PCV LINE/HOSE

6 - P C V VA LV E

25 - 32 EVAPORATIVE EMISSIONSKJ

PCV VALVE (Continued)

Page 1739 of 1803

VACUUM LINES

DESCRIPTION

A vacuum schematic for emission related items can

be found on the VECI label. Refer to Vehicle Emis-

sion Control Information (VECI) Label for label loca-

tion.

VAPOR CANISTER

DESCRIPTION

A maintenance free, EVAP canister is used on all

gasoline powered models. The EVAP canister is

located near the left/front corner of the fuel tank.

OPERATION

The EVAP canister is filled with granules of an

activated carbon mixture. Fuel vapors entering the

EVAP canister are absorbed by the charcoal granules.

The canister serves two functions: as a temporary

fuel vapor storage point while refueling the vehicle

for the ORVR system, as a temporary vapor storage

point while the engine is running.

Fuel tank pressure vents into the EVAP canister.

Fuel vapors are temporarily held in the canister until

they can be drawn into the intake manifold. The duty

cycle EVAP canister purge solenoid allows the EVAP

canister to be purged at predetermined times and at

certain engine operating conditions.

Refer to ORVR for additional information.

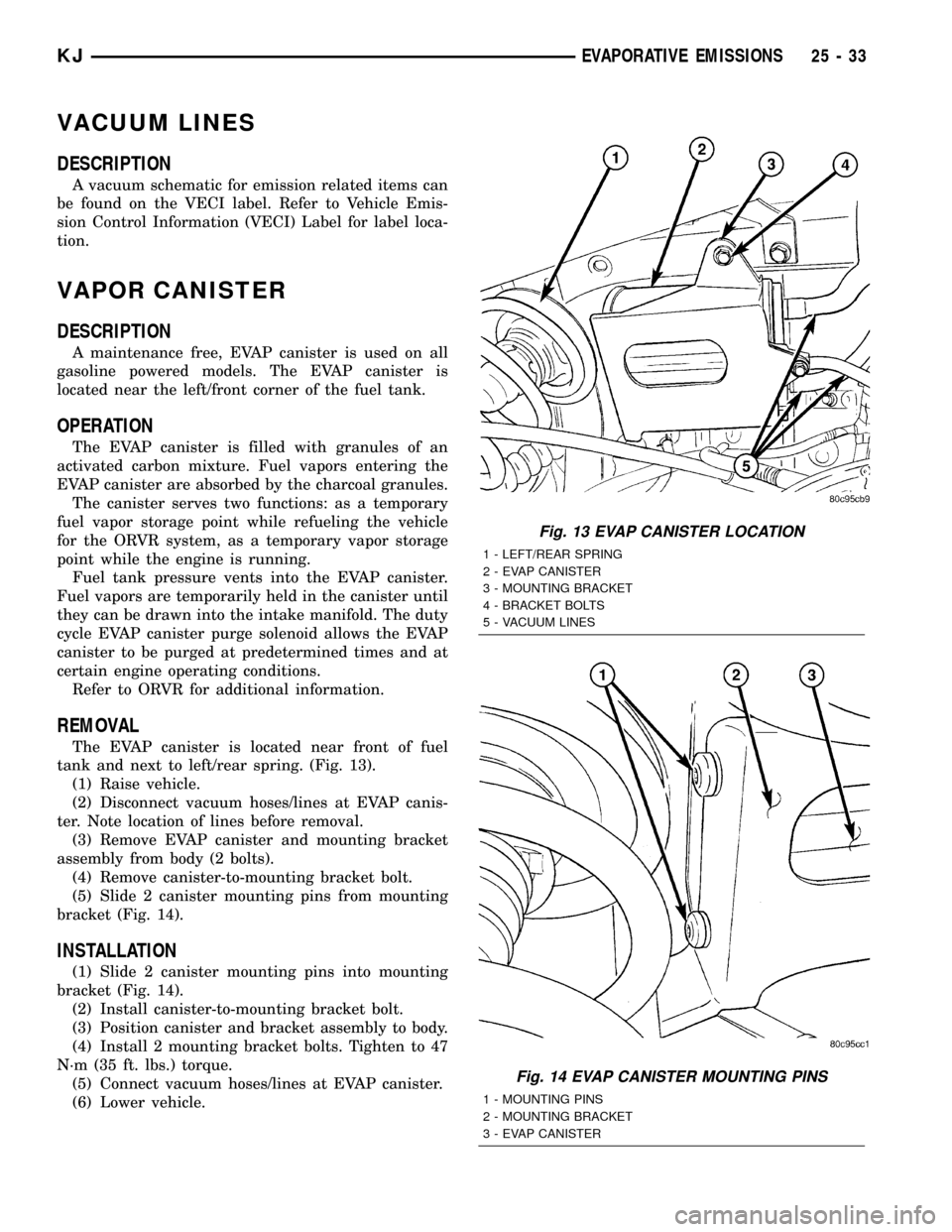

REMOVAL

The EVAP canister is located near front of fuel

tank and next to left/rear spring. (Fig. 13).

(1) Raise vehicle.

(2) Disconnect vacuum hoses/lines at EVAP canis-

ter. Note location of lines before removal.

(3) Remove EVAP canister and mounting bracket

assembly from body (2 bolts).

(4) Remove canister-to-mounting bracket bolt.

(5) Slide 2 canister mounting pins from mounting

bracket (Fig. 14).

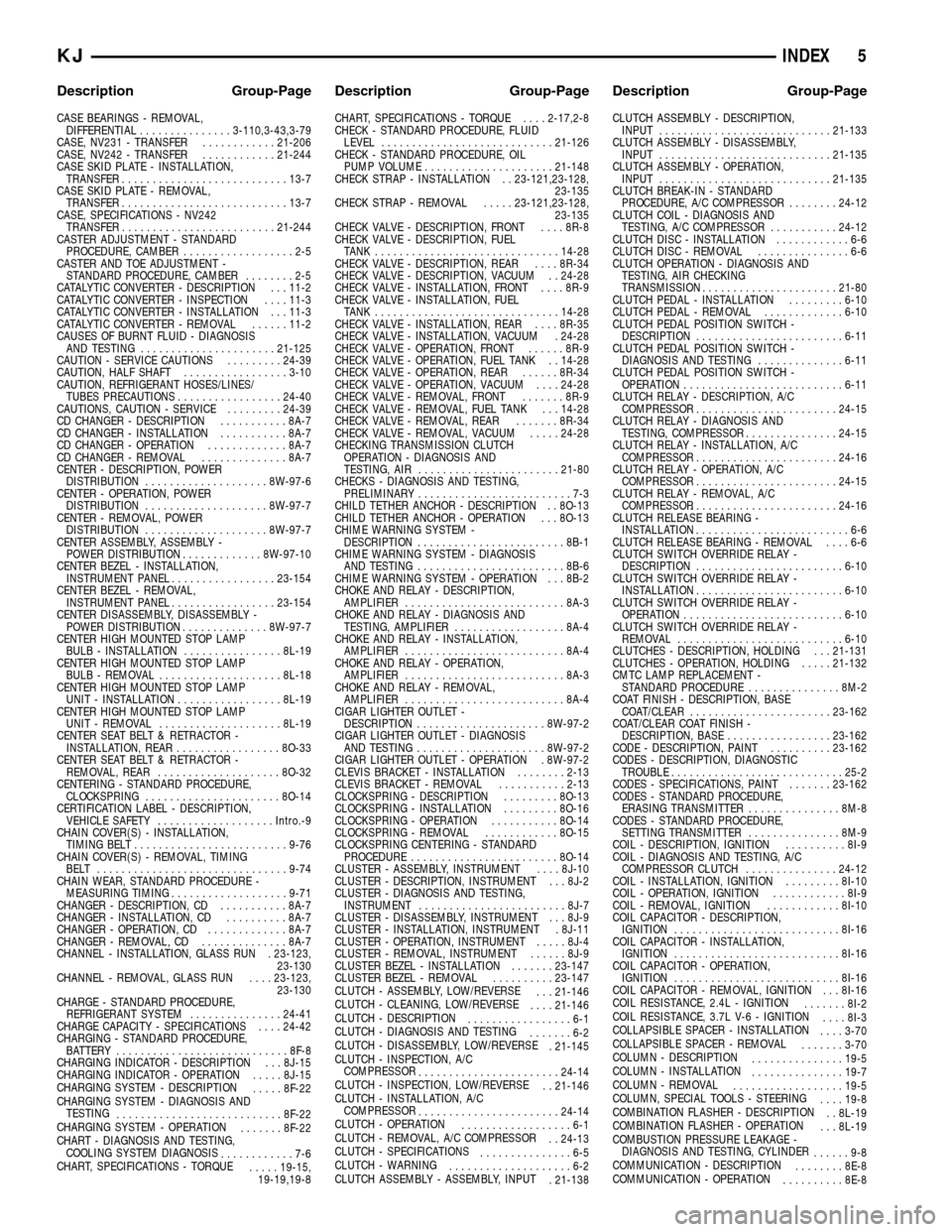

INSTALLATION

(1) Slide 2 canister mounting pins into mounting

bracket (Fig. 14).

(2) Install canister-to-mounting bracket bolt.

(3) Position canister and bracket assembly to body.

(4) Install 2 mounting bracket bolts. Tighten to 47

N´m (35 ft. lbs.) torque.

(5) Connect vacuum hoses/lines at EVAP canister.

(6) Lower vehicle.

Fig. 13 EVAP CANISTER LOCATION

1 - LEFT/REAR SPRING

2 - EVAP CANISTER

3 - MOUNTING BRACKET

4 - BRACKET BOLTS

5 - VACUUM LINES

Fig. 14 EVAP CANISTER MOUNTING PINS

1 - MOUNTING PINS

2 - MOUNTING BRACKET

3 - EVAP CANISTER

KJEVAPORATIVE EMISSIONS 25 - 33

Page 1744 of 1803

CASE BEARINGS - REMOVAL,

DIFFERENTIAL...............3-110,3-43,3-79

CASE, NV231 - TRANSFER............21-206

CASE, NV242 - TRANSFER............21-244

CASE SKID PLATE - INSTALLATION,

TRANSFER...........................13-7

CASE SKID PLATE - REMOVAL,

TRANSFER...........................13-7

CASE, SPECIFICATIONS - NV242

TRANSFER.........................21-244

CASTER ADJUSTMENT - STANDARD

PROCEDURE, CAMBER..................2-5

CASTER AND TOE ADJUSTMENT -

STANDARD PROCEDURE, CAMBER........2-5

CATALYTIC CONVERTER - DESCRIPTION . . . 11-2

CATALYTIC CONVERTER - INSPECTION....11-3

CATALYTIC CONVERTER - INSTALLATION . . . 11-3

CATALYTIC CONVERTER - REMOVAL......11-2

CAUSES OF BURNT FLUID - DIAGNOSIS

AND TESTING......................21-125

CAUTION - SERVICE CAUTIONS.........24-39

CAUTION, HALF SHAFT.................3-10

CAUTION, REFRIGERANT HOSES/LINES/

TUBES PRECAUTIONS.................24-40

CAUTIONS, CAUTION - SERVICE.........24-39

CD CHANGER - DESCRIPTION...........8A-7

CD CHANGER - INSTALLATION...........8A-7

CD CHANGER - OPERATION.............8A-7

CD CHANGER - REMOVAL..............8A-7

CENTER - DESCRIPTION, POWER

DISTRIBUTION....................8W-97-6

CENTER - OPERATION, POWER

DISTRIBUTION....................8W-97-7

CENTER - REMOVAL, POWER

DISTRIBUTION....................8W-97-7

CENTER ASSEMBLY, ASSEMBLY -

POWER DISTRIBUTION.............8W-97-10

CENTER BEZEL - INSTALLATION,

INSTRUMENT PANEL.................23-154

CENTER BEZEL - REMOVAL,

INSTRUMENT PANEL.................23-154

CENTER DISASSEMBLY, DISASSEMBLY -

POWER DISTRIBUTION..............8W-97-7

CENTER HIGH MOUNTED STOP LAMP

BULB - INSTALLATION................8L-19

CENTER HIGH MOUNTED STOP LAMP

BULB - REMOVAL....................8L-18

CENTER HIGH MOUNTED STOP LAMP

UNIT - INSTALLATION.................8L-19

CENTER HIGH MOUNTED STOP LAMP

UNIT - REMOVAL....................8L-19

CENTER SEAT BELT & RETRACTOR -

INSTALLATION, REAR.................8O-33

CENTER SEAT BELT & RETRACTOR -

REMOVAL, REAR....................8O-32

CENTERING - STANDARD PROCEDURE,

CLOCKSPRING......................8O-14

CERTIFICATION LABEL - DESCRIPTION,

VEHICLE SAFETY...................Intro.-9

CHAIN COVER(S) - INSTALLATION,

TIMING BELT.........................9-76

CHAIN COVER(S) - REMOVAL, TIMING

BELT ...............................9-74

CHAIN WEAR, STANDARD PROCEDURE -

MEASURING TIMING...................9-71

CHANGER - DESCRIPTION, CD...........8A-7

CHANGER - INSTALLATION, CD..........8A-7

CHANGER - OPERATION, CD.............8A-7

CHANGER - REMOVAL, CD..............8A-7

CHANNEL - INSTALLATION, GLASS RUN . 23-123,

23-130

CHANNEL - REMOVAL, GLASS RUN....23-123,

23-130

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-41

CHARGE CAPACITY - SPECIFICATIONS....24-42

CHARGING - STANDARD PROCEDURE,

BATTERY............................8F-8

CHARGING INDICATOR - DESCRIPTION . . . 8J-15

CHARGING INDICATOR - OPERATION.....8J-15

CHARGING SYSTEM - DESCRIPTION

.....8F-22

CHARGING SYSTEM - DIAGNOSIS AND

TESTING

...........................8F-22

CHARGING SYSTEM - OPERATION

.......8F-22

CHART - DIAGNOSIS AND TESTING,

COOLING SYSTEM DIAGNOSIS

............7-6

CHART, SPECIFICATIONS - TORQUE

.....19-15,

19-19,19-8CHART, SPECIFICATIONS - TORQUE....2-17,2-8

CHECK - STANDARD PROCEDURE, FLUID

LEVEL............................21-126

CHECK - STANDARD PROCEDURE, OIL

PUMP VOLUME.....................21-148

CHECK STRAP - INSTALLATION . . 23-121,23-128,

23-135

CHECK STRAP - REMOVAL.....23-121,23-128,

23-135

CHECK VALVE - DESCRIPTION, FRONT....8R-8

CHECK VALVE - DESCRIPTION, FUEL

TANK ..............................14-28

CHECK VALVE - DESCRIPTION, REAR....8R-34

CHECK VALVE - DESCRIPTION, VACUUM . . 24-28

CHECK VALVE - INSTALLATION, FRONT....8R-9

CHECK VALVE - INSTALLATION, FUEL

TANK ..............................14-28

CHECK VALVE - INSTALLATION, REAR....8R-35

CHECK VALVE - INSTALLATION, VACUUM . 24-28

CHECK VALVE - OPERATION, FRONT......8R-9

CHECK VALVE - OPERATION, FUEL TANK . . 14-28

CHECK VALVE - OPERATION, REAR......8R-34

CHECK VALVE - OPERATION, VACUUM....24-28

CHECK VALVE - REMOVAL, FRONT.......8R-9

CHECK VALVE - REMOVAL, FUEL TANK . . . 14-28

CHECK VALVE - REMOVAL, REAR.......8R-34

CHECK VALVE - REMOVAL, VACUUM.....24-28

CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING, AIR.......................21-80

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY.........................7-3

CHILD TETHER ANCHOR - DESCRIPTION . . 8O-13

CHILD TETHER ANCHOR - OPERATION . . . 8O-13

CHIME WARNING SYSTEM -

DESCRIPTION........................8B-1

CHIME WARNING SYSTEM - DIAGNOSIS

AND TESTING........................8B-6

CHIME WARNING SYSTEM - OPERATION . . . 8B-2

CHOKE AND RELAY - DESCRIPTION,

AMPLIFIER..........................8A-3

CHOKE AND RELAY - DIAGNOSIS AND

TESTING, AMPLIFIER..................8A-4

CHOKE AND RELAY - INSTALLATION,

AMPLIFIER..........................8A-4

CHOKE AND RELAY - OPERATION,

AMPLIFIER..........................8A-3

CHOKE AND RELAY - REMOVAL,

AMPLIFIER..........................8A-4

CIGAR LIGHTER OUTLET -

DESCRIPTION.....................8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CLEVIS BRACKET - INSTALLATION........2-13

CLEVIS BRACKET - REMOVAL...........2-13

CLOCKSPRING - DESCRIPTION.........8O-13

CLOCKSPRING - INSTALLATION.........8O-16

CLOCKSPRING - OPERATION...........8O-14

CLOCKSPRING - REMOVAL............8O-15

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-14

CLUSTER - ASSEMBLY, INSTRUMENT....8J-10

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-7

CLUSTER - DISASSEMBLY, INSTRUMENT . . . 8J-9

CLUSTER - INSTALLATION, INSTRUMENT . 8J-11

CLUSTER - OPERATION, INSTRUMENT.....8J-4

CLUSTER - REMOVAL, INSTRUMENT......8J-9

CLUSTER BEZEL - INSTALLATION.......23-147

CLUSTER BEZEL - REMOVAL..........23-147

CLUTCH - ASSEMBLY, LOW/REVERSE

. . . 21-146

CLUTCH - CLEANING, LOW/REVERSE

....21-146

CLUTCH - DESCRIPTION

.................6-1

CLUTCH - DIAGNOSIS AND TESTING

.......6-2

CLUTCH - DISASSEMBLY, LOW/REVERSE

. 21-145

CLUTCH - INSPECTION, A/C

COMPRESSOR

.......................24-14

CLUTCH - INSPECTION, LOW/REVERSE

. . 21-146

CLUTCH - INSTALLATION, A/C

COMPRESSOR

.......................24-14

CLUTCH - OPERATION

..................6-1

CLUTCH - REMOVAL, A/C COMPRESSOR

. . 24-13

CLUTCH - SPECIFICATIONS

...............6-5

CLUTCH - WARNING

....................6-2

CLUTCH ASSEMBLY - ASSEMBLY, INPUT

. 21-138CLUTCH ASSEMBLY - DESCRIPTION,

INPUT............................21-133

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT............................21-135

CLUTCH ASSEMBLY - OPERATION,

INPUT............................21-135

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR........24-12

CLUTCH COIL - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-12

CLUTCH DISC - INSTALLATION............6-6

CLUTCH DISC - REMOVAL...............6-6

CLUTCH OPERATION - DIAGNOSIS AND

TESTING, AIR CHECKING

TRANSMISSION......................21-80

CLUTCH PEDAL - INSTALLATION.........6-10

CLUTCH PEDAL - REMOVAL.............6-10

CLUTCH PEDAL POSITION SWITCH -

DESCRIPTION........................6-11

CLUTCH PEDAL POSITION SWITCH -

DIAGNOSIS AND TESTING..............6-11

CLUTCH PEDAL POSITION SWITCH -

OPERATION..........................6-11

CLUTCH RELAY - DESCRIPTION, A/C

COMPRESSOR.......................24-15

CLUTCH RELAY - DIAGNOSIS AND

TESTING, COMPRESSOR...............24-15

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR.......................24-16

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR.......................24-15

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR........................24-16

CLUTCH RELEASE BEARING -

INSTALLATION.........................6-6

CLUTCH RELEASE BEARING - REMOVAL....6-6

CLUTCH SWITCH OVERRIDE RELAY -

DESCRIPTION........................6-10

CLUTCH SWITCH OVERRIDE RELAY -

INSTALLATION........................6-10

CLUTCH SWITCH OVERRIDE RELAY -

OPERATION..........................6-10

CLUTCH SWITCH OVERRIDE RELAY -

REMOVAL...........................6-10

CLUTCHES - DESCRIPTION, HOLDING . . . 21-131

CLUTCHES - OPERATION, HOLDING.....21-132

CMTC LAMP REPLACEMENT -

STANDARD PROCEDURE...............8M-2

COAT FINISH - DESCRIPTION, BASE

COAT/CLEAR.......................23-162

COAT/CLEAR COAT FINISH -

DESCRIPTION, BASE.................23-162

CODE - DESCRIPTION, PAINT..........23-162

CODES - DESCRIPTION, DIAGNOSTIC

TROUBLE............................25-2

CODES - SPECIFICATIONS, PAINT.......23-162

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER...............8M-8

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER...............8M-9

COIL - DESCRIPTION, IGNITION..........8I-9

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-12

COIL - INSTALLATION, IGNITION.........8I-10

COIL - OPERATION, IGNITION............8I-9

COIL - REMOVAL, IGNITION............8I-10

COIL CAPACITOR - DESCRIPTION,

IGNITION...........................8I-16

COIL CAPACITOR - INSTALLATION,

IGNITION...........................8I-16

COIL CAPACITOR - OPERATION,

IGNITION...........................8I-16

COIL CAPACITOR - REMOVAL, IGNITION . . . 8I-16

COIL RESISTANCE, 2.4L - IGNITION

.......8I-2

COIL RESISTANCE, 3.7L V-6 - IGNITION

....8I-3

COLLAPSIBLE SPACER - INSTALLATION

....3-70

COLLAPSIBLE SPACER - REMOVAL

.......3-70

COLUMN - DESCRIPTION

...............19-5

COLUMN - INSTALLATION

...............19-7

COLUMN - REMOVAL

..................19-5

COLUMN, SPECIAL TOOLS - STEERING

....19-8

COMBINATION FLASHER - DESCRIPTION

. . 8L-19

COMBINATION FLASHER - OPERATION

. . . 8L-19

COMBUSTION PRESSURE LEAKAGE -

DIAGNOSIS AND TESTING, CYLINDER

......9-8

COMMUNICATION - DESCRIPTION

........8E-8

COMMUNICATION - OPERATION

..........8E-8

KJINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 1745 of 1803

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-2

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-2

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING..............8M-6

COMPASS MINI-TRIP ILLUMINATION

BULB - INSTALLATION................8L-75

COMPASS MINI-TRIP ILLUMINATION

BULB - REMOVAL....................8L-74

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-3

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-4

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION.......................8M-8

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-5

COMPASS/MINI-TRIP COMPUTER -

REMOVAL...........................8M-7

COMPRESSION PRESSURE - DIAGNOSIS

AND TESTING, CYLINDER................9-8

COMPRESSOR CLUTCH - INSPECTION,

A/C................................24-14

COMPRESSOR CLUTCH - INSTALLATION,

A/C................................24-14

COMPRESSOR CLUTCH - REMOVAL, A/C . . 24-13

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE, A/C...........24-12

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C..........24-12

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C...................24-15

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING.............24-15

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C...................24-16

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C.....................24-15

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C......................24-16

COMPRESSOR NOISE - DIAGNOSIS AND

TESTING, A/C.......................24-42

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP..........................8M-4

COMPUTER - DIAGNOSIS AND TESTING,

COMPASS MINI-TRIP..................8M-6

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP..........................8M-8

COMPUTER - OPERATION, COMPASS/

MINI-TRIP..........................8M-5

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP..........................8M-7

CONDENSER - DESCRIPTION, A/C.......24-45

CONDENSER - INSTALLATION, A/C.......24-46

CONDENSER - OPERATION, A/C.........24-45

CONDENSER - REMOVAL, A/C..........24-45

CONDITIONER - DESCRIPTION, HEATER

AND AIR ............................24-1

CONDITIONER - OPERATION, HEATER

AND AIR ............................24-2

CONDITIONS - DIAGNOSIS AND

TESTING, SPARK PLUG................8I-13

CONNECT FITTING - DESCRIPTION,

QUICK.............................14-10

CONNECTING ROD - DESCRIPTION,

PISTON.............................9-49

CONNECTING ROD BEARING - FITTING -

STANDARD PROCEDURE................9-40

CONNECTING ROD BEARING, FITTING.....9-49

CONNECTOR - DESCRIPTION, DATA LINK . 8E-10

CONNECTOR - INSTALLATION

.......8W-01-11

CONNECTOR - INSTALLATION, TRAILER

TOW

..............................8L-61

CONNECTOR - OPERATION, DATA LINK

. . . 8E-10

CONNECTOR - REMOVAL

...........8W-01-11

CONNECTOR - REMOVAL, TRAILER TOW

. . 8L-61

CONNECTOR, GROUND AND SPLICE

INFORMATION - DESCRIPTION

........8W-01-7

CONNECTOR/GROUND/SPLICE LOCATION

- DESCRIPTION

....................8W-91-1

CONSOLE - DESCRIPTION, OVERHEAD

....8M-1

CONSOLE - INSTALLATION, FLOOR

.....23-158

CONSOLE - OPERATION, OVERHEAD

......8M-2

CONSOLE - REMOVAL, FLOOR

.........23-158

CONSOLE DUCT - INSTALLATION, FLOOR

. 24-31

CONSOLE DUCT - REMOVAL, FLOOR

.....24-31CONSOLE LID LATCH - INSTALLATION,

FLOOR............................23-158

CONSOLE LID LATCH - REMOVAL,

FLOOR............................23-158

CONSOLE, REMOVAL - OVERHEAD.......8M-4

CONTAINER - DESCRIPTION, COOLANT

RECOVERY PRESS....................7-19

CONTAINER - OPERATION, COOLANT

RECOVERY PRESS....................7-19

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID................5-26

CONTAMINATION - DIAGNOSIS AND

TESTING, FLUID....................21-125

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-9

CONTROL - DESCRIPTION, A/C HEATER . . . 24-16

CONTROL - DESCRIPTION, IGNITION......8I-1

CONTROL - DESCRIPTION, SPEED........8P-1

CONTROL - INSTALLATION, A/C HEATER . . 24-17

CONTROL - OPERATION, IGNITION........8I-1

CONTROL - OPERATION, SPEED..........8P-1

CONTROL - REMOVAL, A/C HEATER......24-17

CONTROL - TORQUE, SPEED............8P-2

CONTROL ARM - DESCRIPTION, LOWER . . . 2-21

CONTROL ARM - INSTALLATION, LOWER . . 2-10,

2-21

CONTROL ARM - INSTALLATION, UPPER . . . 2-21

CONTROL ARM - OPERATION, LOWER.....2-21

CONTROL ARM - REMOVAL, LOWER . . 2-10,2-21

CONTROL ARM - REMOVAL, UPPER......2-20

CONTROL ASSEMBLY WINDOW

DEFOGGER FUNCTION - DIAGNOSIS

AND TESTING, REAR HVAC.............8G-9

CONTROL CABLE - INSTALLATION,

THROTTLE..........................14-46

CONTROL CABLE - REMOVAL,

THROTTLE..........................14-45

CONTROL ILLUMINATION BULB -

INSTALLATION, HEATER-A/C............8L-78

CONTROL ILLUMINATION BULB -

REMOVAL, HEATER-A/C...............8L-78

CONTROL INFORMATION (VECI) LABEL -

DESCRIPTION, VEHICLE EMISSION.....Intro.-8

CONTROL MODULE - DESCRIPTION,

AIRBAG.............................8O-9

CONTROL MODULE - DESCRIPTION,

BODY...............................8E-2

CONTROL MODULE - DESCRIPTION,

SIDE IMPACT AIRBAG.................8O-43

CONTROL MODULE - DESCRIPTION,

TRANSMISSION......................8E-18

CONTROL MODULE - DIAGNOSIS AND

TESTING, BODY.......................8E-7

CONTROL MODULE - INSTALLATION....23-183

CONTROL MODULE - INSTALLATION,

AIRBAG............................8O-12

CONTROL MODULE - INSTALLATION,

BODY...............................8E-7

CONTROL MODULE - INSTALLATION,

SIDE IMPACT AIRBAG.................8O-45

CONTROL MODULE - OPERATION,

AIRBAG............................8O-10

CONTROL MODULE - OPERATION, BODY . . . 8E-5

CONTROL MODULE - OPERATION, SIDE

IMPACT AIRBAG.....................8O-43

CONTROL MODULE - OPERATION,

TRANSMISSION......................8E-18

CONTROL MODULE - REMOVAL........23-183

CONTROL MODULE - REMOVAL, AIRBAG . 8O-11

CONTROL MODULE - REMOVAL, BODY....8E-7

CONTROL MODULE - REMOVAL, SIDE

IMPACT AIRBAG.....................8O-44

CONTROL MOTOR - DESCRIPTION, IDLE

AIR ...............................14-35

CONTROL MOTOR - INSTALLATION, IDLE

AIR ...............................14-36

CONTROL MOTOR - OPERATION, IDLE

AIR ...............................14-35

CONTROL MOTOR - REMOVAL, IDLE AIR . . 14-36

CONTROL RELAY - DESCRIPTION,

TRANSMISSION.....................21-168

CONTROL RELAY - OPERATION,

TRANSMISSION

.....................21-168

CONTROL SWITCH - DESCRIPTION

.....23-184

CONTROL SWITCH - DIAGNOSIS AND

TESTING

..........................23-184

CONTROL SWITCH - INSTALLATION

.....23-184

CONTROL SWITCH - OPERATION

.......23-184CONTROL SWITCH - REMOVAL........23-184

CONTROL SYSTEM - DESCRIPTION,

EMISSION...........................25-1

CONTROL SYSTEM - DESCRIPTION,

EVAPORATION.......................25-24

CONTROLLER ANTILOCK BRAKE -

INSTALLATION.......................8E-10

CONTROLLER ANTILOCK BRAKE -

REMOVAL..........................8E-10

CONVERTER - DESCRIPTION, CATALYTIC . . . 11-2

CONVERTER - DESCRIPTION, TORQUE . . . 21-162

CONVERTER - INSPECTION, CATALYTIC....11-3

CONVERTER - INSTALLATION, CATALYTIC . . 11-3

CONVERTER - INSTALLATION, TORQUE . . 21-167

CONVERTER - OPERATION, TORQUE....21-166

CONVERTER - REMOVAL, CATALYTIC......11-2

CONVERTER - REMOVAL, TORQUE......21-167

CONVERTER HOUSING FLUID LEAK -

DIAGNOSIS AND TESTING.............21-80

COOLANT - DESCRIPTION, ENGINE........0-3

COOLANT LOW INDICATOR -

DESCRIPTION.......................8J-15

COOLANT LOW INDICATOR - OPERATION . 8J-16

COOLANT RECOVERY PRESS

CONTAINER - DESCRIPTION.............7-19

COOLANT RECOVERY PRESS

CONTAINER - OPERATION...............7-19

COOLANT TEMPERATURE SENSOR -

DESCRIPTION, ENGINE.................7-19

COOLANT TEMPERATURE SENSOR -

INSTALLATION, ENGINE................7-21

COOLANT TEMPERATURE SENSOR -

OPERATION, ENGINE...................7-20

COOLANT TEMPERATURE SENSOR -

REMOVAL, ENGINE....................7-20

COOLANT THERMOSTAT - OPERATION,

ENGINE.............................7-21

COOLER - DESCRIPTION, FLUID.........19-20

COOLER - DESCRIPTION, TRANS.........7-32

COOLER - INSTALLATION, FLUID........19-20

COOLER - OPERATION, FLUID..........19-20

COOLER - REMOVAL, FLUID............19-20

COOLING, SPECIAL TOOLS..............7-14

COOLING SYSTEM - OPERATION..........7-2

COOLING SYSTEM - REVERSE

FLUSHING - STANDARD PROCEDURE.....7-12

COOLING SYSTEM 3.7L ENGINE -

DESCRIPTION.........................7-1

COOLING SYSTEM 3.7L ENGINE -

STANDARD PROCEDURE, DRAINING......7-12

COOLING SYSTEM 3.7L ENGINE -

STANDARD PROCEDURE, REFILLING......7-12

COOLING SYSTEM DIAGNOSIS CHART -

DIAGNOSIS AND TESTING...............7-6

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING.........................7-4

COOLING SYSTEM REQUIREMENTS -

DESCRIPTION........................24-1

COOLING SYSTEM ROUTING 3.7L

ENGINE - DESCRIPTION.................7-2

CORE - DESCRIPTION, HEATER.........24-52

CORE - INSTALLATION, HEATER.........24-53

CORE - OPERATION, HEATER...........24-52

CORE - REMOVAL, HEATER............24-52

CORE AND OIL GALLERY PLUGS -

STANDARD PROCEDURE, ENGINE........9-10

COURTESY LAMP BULB - INSTALLATION . . 8L-76

COURTESY LAMP BULB - REMOVAL.....8L-75

COURTESY LAMP REPLACEMENT -

STANDARD PROCEDURE...............8M-2

COURTESY LAMP UNIT - INSTALLATION . . 8L-77

COURTESY LAMP UNIT - REMOVAL......8L-76

COVER - DESCRIPTION, STRUCTURAL.....9-55

COVER - FRONT - INSTALLATION, SEAT

BACK.............................23-167

COVER - FRONT - INSTALLATION, SEAT

CUSHION..........................23-167

COVER - FRONT - REMOVAL, SEAT BACK . 23-166

COVER - FRONT - REMOVAL, SEAT

CUSHION..........................23-167

COVER - INSTALLATION, COWL TRIM . . . 23-157

COVER - INSTALLATION, INSTRUMENT

PANEL TOP

........................23-153

COVER - INSTALLATION, STRUCTURAL

....9-55

COVER - OPERATION, STRUCTURAL

......9-55

COVER - REAR - INSTALLATION, SEAT

BACK

.............................23-169

COVER - REAR - REMOVAL, SEAT BACK

. 23-169

6 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1746 of 1803

COVER - REMOVAL, COWL TRIM.......23-157

COVER - REMOVAL, INSTRUMENT

PANEL TOP........................23-152

COVER - REMOVAL, STRUCTURAL........9-55

COVER(S) - DESCRIPTION, CYLINDER

HEAD...............................9-25

COVER(S) - INSTALLATION, CYLINDER

HEAD...........................9-26,9-34

COVER(S) - INSTALLATION, TIMING

BELT / CHAIN........................9-76

COVER(S) - REMOVAL, CYLINDER HEAD . . 9-25,

9-34

COVER(S) - REMOVAL, TIMING BELT /

CHAIN..............................9-74

COWL GRILLE - INSTALLATION........23-140

COWL GRILLE - REMOVAL............23-140

COWL TRIM COVER - INSTALLATION....23-157

COWL TRIM COVER - REMOVAL.......23-157

COWL WEATHERSTRIP - INSTALLATION . 23-185

COWL WEATHERSTRIP - REMOVAL.....23-185

COWL/PLENUM SEAL - INSTALLATION . . . 23-187

COWL/PLENUM SEAL - REMOVAL......23-187

COWL/PLENUM WINDOW BAFFLE SEAL -

INSTALLATION......................23-187

COWL/PLENUM WINDOW BAFFLE SEAL -

REMOVAL.........................23-187

CRADLE CROSSMEMBER -

INSTALLATION, ENGINE................13-6

CRADLE CROSSMEMBER - REMOVAL,

ENGINE.............................13-6

CRANKSHAFT - DESCRIPTION...........9-42

CRANKSHAFT - INSPECTION.............9-43

CRANKSHAFT - INSTALLATION...........9-43

CRANKSHAFT - REMOVAL..............9-43

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION........................9-47

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL...........................9-46

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION........................9-48

CRANKSHAFT OIL SEAL - REAR -

REMOVAL...........................9-48

CRANKSHAFT POSITION SENSOR -

DESCRIPTION.......................14-30

CRANKSHAFT POSITION SENSOR -

INSTALLATION.......................14-32

CRANKSHAFT POSITION SENSOR -

OPERATION.........................14-31

CRANKSHAFT POSITION SENSOR -

REMOVAL..........................14-31

CROSSMEMBER - INSTALLATION,

ENGINE CRADLE......................13-6

CROSSMEMBER - INSTALLATION,

RADIATOR.........................23-146

CROSSMEMBER - INSTALLATION, REAR . . . 13-7

CROSSMEMBER - REMOVAL, ENGINE

CRADLE.............................13-6

CROSSMEMBER - REMOVAL, RADIATOR . 23-146

CROSSMEMBER - REMOVAL, REAR.......13-7

CROSS-OVER PIPE - INSTALLATION.......11-3

CROSS-OVER PIPE - REMOVAL..........11-3

CRUISE INDICATOR - DESCRIPTION......8J-16

CRUISE INDICATOR - OPERATION.......8J-17

CURTAIN AIRBAG - DESCRIPTION, SIDE . . 8O-38

CURTAIN AIRBAG - INSTALLATION, SIDE . . 8O-41

CURTAIN AIRBAG - OPERATION, SIDE....8O-39

CURTAIN AIRBAG - REMOVAL, SIDE.....8O-40

CUSHION - FRONT - INSTALLATION,

SEAT .............................23-167

CUSHION - FRONT - INSTALLATION,

SEAT BACK........................23-167

CUSHION - FRONT - REMOVAL, SEAT . . . 23-167

CUSHION - FRONT - REMOVAL, SEAT

BACK.............................23-167

CUSHION - REAR - INSTALLATION, SEAT . 23-171

CUSHION - REAR - INSTALLATION, SEAT

BACK.............................23-170

CUSHION - REAR - REMOVAL, SEAT....23-171

CUSHION - REAR - REMOVAL, SEAT

BACK

.............................23-170

CUSHION COVER - FRONT -

INSTALLATION, SEAT

.................23-167

CUSHION COVER - FRONT - REMOVAL,

SEAT

.............................23-167

CUSHION SIDE SHIELDS -

INSTALLATION, SEAT

.................23-167

CUSHION SIDE SHIELDS - REMOVAL,

SEAT

.............................23-167CUSTOMER PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER........8N-8

CV JOINT/BOOT-INNER - INSTALLATION . . . 3-17

CV JOINT/BOOT-INNER - REMOVAL.......3-15

CV JOINT/BOOT-OUTER - INSTALLATION . . . 3-13

CV JOINT/BOOT-OUTER - REMOVAL.......3-12

CYLINDER - DESCRIPTION, MASTER......5-24

CYLINDER - INSPECTION, MASTER........6-9

CYLINDER - INSTALLATION, FLIP-UP

GLASS SUPPORT...................23-139

CYLINDER - INSTALLATION, LOCK......23-125,

23-138

CYLINDER - INSTALLATION, LOCK.......19-11

CYLINDER - INSTALLATION, MASTER.....5-25

CYLINDER - INSTALLATION, SUPPORT . . . 23-120

CYLINDER - OPERATION, MASTER........5-24

CYLINDER - REMOVAL, FLIP-UP GLASS

SUPPORT.........................23-139

CYLINDER - REMOVAL, LOCK....23-125,23-137

CYLINDER - REMOVAL, LOCK...........19-10

CYLINDER - REMOVAL, MASTER.........5-25

CYLINDER - REMOVAL, SUPPORT......23-120

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-24

CYLINDER BORE HONING - STANDARD

PROCEDURE.........................9-39

CYLINDER COMBUSTION PRESSURE

LEAKAGE - DIAGNOSIS AND TESTING......9-8

CYLINDER COMPRESSION PRESSURE -

DIAGNOSIS AND TESTING...............9-8

CYLINDER FLUID LEVEL - STANDARD

PROCEDURES, MASTER................5-26

CYLINDER HEAD - DESCRIPTION.........9-30

CYLINDER HEAD COVER(S) -

DESCRIPTION........................9-25

CYLINDER HEAD COVER(S) -

INSTALLATION....................9-26,9-34

CYLINDER HEAD COVER(S) - REMOVAL . . . 9-25,

9-34

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING....................9-19,9-30

CYLINDER LOCK SWITCH -

DESCRIPTION, DOOR..................8Q-9

CYLINDER LOCK SWITCH -

DESCRIPTION, TAILGATE...............8N-9

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, DOOR.................8Q-10

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, TAILGATE...............8N-9

CYLINDER LOCK SWITCH -

INSTALLATION, DOOR.................8Q-10

CYLINDER LOCK SWITCH -

INSTALLATION, TAILGATE..............8N-10

CYLINDER LOCK SWITCH - OPERATION,

DOOR.............................8Q-10

CYLINDER LOCK SWITCH - OPERATION,

TAILGATE...........................8N-9

CYLINDER LOCK SWITCH - REMOVAL,

DOOR.............................8Q-10

CYLINDER LOCK SWITCH - REMOVAL,

TAILGATE..........................8N-10

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER . . 5-21,5-24

CYLINDERS - ASSEMBLY, WHEEL.........5-29

CYLINDERS - CLEANING, WHEEL.........5-28

CYLINDERS - DISASSEMBLY, WHEEL......5-28

CYLINDERS - INSPECTION, WHEEL.......5-29

CYLINDERS - INSTALLATION, WHEEL

.....5-29

CYLINDERS - REMOVAL, WHEEL

.........5-28

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR

.........9-9

DAMPER - INSTALLATION, VIBRATION

.....9-55

DAMPER - REMOVAL, VIBRATION

........9-54

DATA LINK CONNECTOR - DESCRIPTION

. . 8E-10

DATA LINK CONNECTOR - OPERATION

....8E-10

DAYTIME RUNNING LAMP RELAY -

DESCRIPTION

.......................8L-20

DAYTIME RUNNING LAMP RELAY -

INSTALLATION

.......................8L-21

DAYTIME RUNNING LAMP RELAY -

OPERATION

.........................8L-20

DAYTIME RUNNING LAMP RELAY -

REMOVAL

..........................8L-21

DECOUPLER - DIAGNOSIS AND

TESTING, GENERATOR

................8F-27

DECOUPLER PULLEY - DESCRIPTION,

GENERATOR

........................8F-26DECOUPLER PULLEY - INSTALLATION,

GENERATOR........................8F-30

DECOUPLER PULLEY - OPERATION,

GENERATOR........................8F-27

DECOUPLER PULLEY - REMOVAL,

GENERATOR........................8F-27

DEFINITION - DESCRIPTION, TRIP.......25-19

DEFLECTOR - INSTALLATION, WIND.....23-180

DEFLECTOR - REMOVAL, WIND........23-180

DEFOGGER - DESCRIPTION, REAR

WINDOW............................8G-3

DEFOGGER - OPERATION, REAR

WINDOW............................8G-3

DEFOGGER FUNCTION - DIAGNOSIS AND

TESTING, REAR HVAC CONTROL

ASSEMBLY WINDOW..................8G-9

DEFOGGER GRID - DESCRIPTION, REAR

WINDOW............................8G-5

DEFOGGER GRID - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-5

DEFOGGER GRID - OPERATION, REAR

WINDOW............................8G-5

DEFOGGER RELAY - DESCRIPTION,

REAR WINDOW.......................8G-6

DEFOGGER RELAY - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-6

DEFOGGER RELAY - INSTALLATION,

REAR WINDOW.......................8G-7

DEFOGGER RELAY - OPERATION, REAR

WINDOW............................8G-6

DEFOGGER RELAY - REMOVAL, REAR

WINDOW............................8G-7

DEFOGGER SWITCH - DESCRIPTION,

REAR WINDOW.......................8G-8

DEFOGGER SWITCH - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-8

DEFOGGER SWITCH - OPERATION, REAR

WINDOW............................8G-8

DEFOGGER SYSTEM - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-4

DEFROST DOO - INSTALLATION, FLOOR . . 24-37

DEFROST DOOR - REMOVAL...........24-35

DEFROST DOOR - REMOVAL, FLOOR.....24-36

DEFROST DOOR ACTUATOR -

INSTALLATION, FLOOR................24-25

DEFROST DOOR ACTUATOR - REMOVAL,

FLOOR.............................24-24

DEFROST DUCT/DEMISTER ADAPTOR -

REMOVAL..........................24-32

DEFROST/DEMISTER DUCT -

INSTALLATION.......................24-32

DELIVERY - DESCRIPTION, FUEL.........14-2

DELIVERY - OPERATION, FUEL...........14-3

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS...............8M-2

DEMISTER OUTLETS - DESCRIPTION.....24-29

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL RESTRAINT............8O-6

DETECTION PUMP - DESCRIPTION, LEAK . 25-27

DETECTION PUMP - INSTALLATION,

LEAK..............................25-28

DETECTION PUMP - OPERATION, LEAK . . . 25-28

DETECTION PUMP - REMOVAL, LEAK....25-28

DEVICES - STANDARD PROCEDURE,

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE........................8W-01-8

DIAGNOSIS CHART - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-6

DIAGNOSIS, DIAGNOSIS AND TESTING -

WATER DRAINAGE AND WIND NOISE . . . 23-176

DIAGNOSTIC PROCEDURES, DIAGNOSIS

AND TESTING......................23-176

DIAGNOSTIC TROUBLE CODES -

DESCRIPTION........................25-2

DIAGNOSTICS (OBD) - DIAGNOSIS AND

TESTING, ON-BOARD...................7-3

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIAGRAMS - HYDRAULIC SCHEMATICS,

SCHEMATICS.......................21-100

DIESEL - TORQUE, EXCEPT.............8F-23

DIFFERENTIAL - ASSEMBLY

........3-105,3-41

DIFFERENTIAL - DISASSEMBLY

.....3-105,3-41

DIFFERENTIAL - INSTALLATION

. 3-105,3-42,3-73

DIFFERENTIAL - REMOVAL

.....3-104,3-40,3-71

DIFFERENTIAL - TRAC-LOK - ASSEMBLY

. . 3-109,

3-77

KJINDEX 7

Description Group-Page Description Group-Page Description Group-Page

Page 1748 of 1803

ENGINE - DESCRIPTION, COOLING

SYSTEM 3.7L.........................7-1

ENGINE - DESCRIPTION, COOLING

SYSTEM ROUTING 3.7L.................7-2

ENGINE - INSTALLATION, 3.7L . . . 7-17,7-18,7-22

ENGINE - REMOVAL, 3.7L...........7-17,7-21

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM 3.7L........7-12

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM 3.7L.......7-12

ENGINE BLOCK - CLEANING.............9-39

ENGINE BLOCK - DESCRIPTION..........9-39

ENGINE BLOCK - INSPECTION...........9-40

ENGINE COOLANT - DESCRIPTION.........0-3

ENGINE COOLANT TEMPERATURE

SENSOR - DESCRIPTION...............7-19

ENGINE COOLANT TEMPERATURE

SENSOR - INSTALLATION...............7-21

ENGINE COOLANT TEMPERATURE

SENSOR - OPERATION.................7-20

ENGINE COOLANT TEMPERATURE

SENSOR - REMOVAL...................7-20

ENGINE COOLANT THERMOSTAT -

OPERATION..........................7-21

ENGINE CORE AND OIL GALLERY PLUGS

- STANDARD PROCEDURE..............9-10

ENGINE CRADLE CROSSMEMBER -

INSTALLATION........................13-6

ENGINE CRADLE CROSSMEMBER -

REMOVAL...........................13-6

ENGINE DIAGNOSIS - INTRODUCTION -

DIAGNOSIS AND TESTING.................9-4

ENGINE DIAGNOSIS - LUBRICATION -

DIAGNOSIS AND TESTING...............9-7

ENGINE DIAGNOSIS - MECHANICAL -

DIAGNOSIS AND TESTING...............9-6

ENGINE DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING...............9-4

ENGINE FIRING ORDER, 2.4L 4-

CYLINDER...........................8I-2

ENGINE FIRING ORDER, 3.7L V-6.........8I-2

ENGINE GASKET SURFACE

PREPARATION - STANDARD

PROCEDURE..........................9-9

ENGINE OIL - STANDARD PROCEDURE....9-61

ENGINE OIL LEAK - DIAGNOSIS AND

TESTING............................9-60

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING........................9-60

ENGINE, SPECIAL TOOLS - 3.7L..........9-15

ENGINE, SPECIFICATIONS - 3.7L.........9-12

ENGINE TEMPERATURE GAUGE -

DESCRIPTION.......................8J-18

ENGINE TEMPERATURE GAUGE -

OPERATION.........................8J-18

ENGINES - GENERATOR RATINGS, GAS . . . 8F-23

ENTRY MODULE - DESCRIPTION,

REMOTE KEYLESS....................8N-7

ENTRY MODULE - DIAGNOSIS AND

TESTING, REMOTE KEYLESS............8N-7

ENTRY MODULE - INSTALLATION,

REMOTE KEYLESS....................8N-7

ENTRY MODULE - OPERATION, REMOTE

KEYLESS............................8N-7

ENTRY MODULE - REMOVAL, REMOTE

KEYLESS............................8N-7

ENTRY TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS............8N-8

ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE KEYLESS......8N-9

EQUIPMENT - STANDARD PROCEDURE,

REFRIGERANT SYSTEM SERVICE........24-40

ERASING TRANSMITTER CODES -

STANDARD PROCEDURE...............8M-8

EVACUATE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-41

EVAPORATION CONTROL SYSTEM -

DESCRIPTION.......................25-24

EVAPORATOR - DESCRIPTION, A/C.......24-49

EVAPORATOR - INSTALLATION, A/C......24-49

EVAPORATOR - OPERATION, A/C........24-49

EVAPORATOR - REMOVAL, A/C..........24-49

EVAP/PURGE SOLENOID - DESCRIPTION . . 25-27

EVAP/PURGE SOLENOID - INSTALLATION

. 25-27

EVAP/PURGE SOLENOID - OPERATION

....25-27

EVAP/PURGE SOLENOID - REMOVAL

.....25-27

EXCEPT DIESEL - TORQUE

.............8F-23

EXHAUST MANIFOLD - DESCRIPTION

.....9-69EXHAUST MANIFOLD - INSTALLATION.....9-70

EXHAUST MANIFOLD - REMOVAL.........9-69

EXHAUST SYSTEM - DESCRIPTION.......11-1

EXHAUST SYSTEM - DIAGNOSIS AND

TESTING............................11-2

EXTENSION HOUSING BUSHING -

NV3550 - INSTALLATION...............21-74

EXTENSION HOUSING BUSHING -

NV3550 - REMOVAL..................21-73

EXTENSION HOUSING SEAL - NV1500 -

INSTALLATION.......................21-32

EXTENSION HOUSING SEAL - NV1500 -

REMOVAL..........................21-32

EXTENSION HOUSING SEAL - NV3550 -

INSTALLATION.......................21-74

EXTENSION HOUSING SEAL - NV3550 -

REMOVAL..........................21-74

EXTERIOR - DESCRIPTION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR - DIAGNOSIS AND TESTING,

LAMPS/LIGHTING.....................8L-7

EXTERIOR - OPERATION, LAMPS/

LIGHTING...........................8L-5

EXTERIOR - SPECIFICATIONS,

LAMPS/LIGHTING....................8L-15

EXTERIOR HANDLE - INSTALLATION....23-123,

23-130,23-136

EXTERIOR HANDLE - REMOVAL . 23-123,23-130,

23-136

EXTERIOR NAME PLATES -

INSTALLATION......................23-141

EXTERIOR NAME PLATES - REMOVAL . . . 23-140

FAN - ELECTRIC - DESCRIPTION,

RADIATOR...........................7-26

FAN - ELECTRIC - INSTALLATION,

RADIATOR...........................7-27

FAN - ELECTRIC - OPERATION,

RADIATOR...........................7-26

FAN - ELECTRIC - REMOVAL, RADIATOR . . . 7-26

FAN - VISCOUS - CLEANING, RADIATOR . . . 7-29

FAN - VISCOUS - DESCRIPTION,

RADIATOR...........................7-27

FAN - VISCOUS - INSPECTION,

RADIATOR...........................7-29

FAN - VISCOUS - INSTALLATION,

RADIATOR...........................7-29

FAN - VISCOUS - OPERATION,

RADIATOR...........................7-27

FAN - VISCOUS - REMOVAL, RADIATOR....7-28

FAN DRIVE - DIAGNOSIS AND TESTING,

VISCOUS............................7-28

FASCIA - INSTALLATION, FRONT.........13-2

FASCIA - INSTALLATION, REAR..........13-2

FASCIA - REMOVAL, FRONT.............13-1

FASCIA - REMOVAL, REAR..............13-2

FASCIA SUPPORT - INSTALLATION,

REAR...............................13-3

FASCIA SUPPORT - REMOVAL, REAR......13-3

FASTENER IDENTIFICATION -

DESCRIPTION......................Intro.-1

FENDER - INSTALLATION, FRONT.......23-141

FENDER - REMOVAL, FRONT..........23-141

FILL - STANDARD PROCEDURE, FLUID

DRAIN......................21-208,21-246

FILL - STANDARD PROCEDURE,

TRANSMISSION.....................21-128

FILL DOOR/HOUSING - INSTALLATION,

FUEL.............................23-141

FILL DOOR/HOUSING - REMOVAL, FUEL . 23-141

FILL/CHECK LOCATIONS - DESCRIPTION,

FLUID...............................0-4

FILLER CAP - DESCRIPTION, FUEL.......25-27

FILLER CAP - OPERATION, FUEL........25-27

FILTER - DESCRIPTION, FUEL............14-7

FILTER - INSTALLATION, FUEL...........14-8

FILTER - INSTALLATION, INLET..........14-28

FILTER - INSTALLATION, OIL............9-63

FILTER - REMOVAL, FUEL...............14-7

FILTER - REMOVAL, INLET.............14-28

FILTER - REMOVAL, OIL

................9-63

FILTER REPLACEMENT - STANDARD

PROCEDURE, FLUID

.................21-126

FINESSE SANDING/BUFFING &

POLISHING - DESCRIPTION

...........23-163

FINISH - DESCRIPTION, BASE

COAT/CLEAR COAT

..................23-162

FIRING ORDER, 2.4L 4-CYLINDER -

ENGINE

..............................8I-2FIRING ORDER, 3.7L V-6 - ENGINE........8I-2

FITTING - CONNECTING ROD BEARING....9-49

FITTING - DESCRIPTION, QUICK

CONNECT...........................14-10

FITTING - MAIN BEARING...............9-45

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING............9-40

FITTING - STANDARD PROCEDURE,

PISTON.............................9-50

FITTING - STANDARD PROCEDURE,

PISTON RING........................9-52

FITTINGS - STANDARD PROCEDURE,

QUICK-CONNECT.....................14-10

FLARE MOLDINGS - INSTALLATION,

FRONT WHEEL OPENING.............23-145

FLARE MOLDINGS - INSTALLATION,

REAR WHEEL OPENING..............23-145

FLARE MOLDINGS - REMOVAL, FRONT

WHEEL OPENING...................23-145

FLARE MOLDINGS - REMOVAL, REAR

WHEEL OPENING...................23-145

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED.....................5-8

FLARING - STANDARD PROCEDURE, ISO....5-8

FLASHER - DESCRIPTION, COMBINATION . 8L-19

FLASHER - OPERATION, COMBINATION . . . 8L-19

FLEX PLATE - INSTALLATION............9-49

FLEX PLATE - REMOVAL................9-49

FLIP-UP GLASS - INSTALLATION.......23-136

FLIP-UP GLASS - REMOVAL...........23-136

FLIP-UP GLASS AJAR SWITCH -

DESCRIPTION.......................8L-77

FLIP-UP GLASS AJAR SWITCH -

OPERATION.........................8L-77

FLIP-UP GLASS LATCH - INSTALLATION . 23-136

FLIP-UP GLASS LATCH - REMOVAL.....23-136

FLIP-UP GLASS RELEASE SWITCH -

DIAGNOSIS AND TESTING..............8N-5

FLIP-UP GLASS SUPPORT CYLINDER -

INSTALLATION......................23-139

FLIP-UP GLASS SUPPORT CYLINDER -

REMOVAL.........................23-139

FLOOR - DEFROST DOO - INSTALLATION . . 24-37

FLOOR - DEFROST DOOR - REMOVAL....24-36

FLOOR - DEFROST DOOR ACTUATOR -

INSTALLATION.......................24-25

FLOOR - DEFROST DOOR ACTUATOR -

REMOVAL..........................24-24

FLOOR CONSOLE - INSTALLATION......23-158

FLOOR CONSOLE - REMOVAL..........23-158

FLOOR CONSOLE DUCT - INSTALLATION . . 24-31

FLOOR CONSOLE DUCT - REMOVAL.....24-31

FLOOR CONSOLE LID LATCH -

INSTALLATION......................23-158

FLOOR CONSOLE LID LATCH - REMOVAL . 23-158

FLOOR DUCT - INSTALLATION..........24-32

FLOOR DUCT - REMOVAL..............24-32

FLOOR MATS - INSTALLATION, CARPETS . 23-158

FLOOR MATS - REMOVAL, CARPETS....23-158

FLOOR SHIFT BOOT - INSTALLATION,

4WD .............................23-156

FLOOR SHIFT BOOT - REMOVAL, 4WD . . . 23-156

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-3

FLOW MANAGEMENT VALVE -

DESCRIPTION........................14-6

FLOW MANAGEMENT VALVE -

INSTALLATION........................14-7

FLOW MANAGEMENT VALVE -

OPERATION..........................14-6

FLOW MANAGEMENT VALVE - REMOVAL . . . 14-6

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-2

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT..................21-125

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-4

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE..............21-126

FLUID CAPACITIES - SPECIFICATIONS......0-4

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING......................21-125

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE

..................5-26

FLUID COOLER - DESCRIPTION

.........19-20

FLUID COOLER - INSTALLATION

.........19-20

FLUID COOLER - OPERATION

...........19-20

FLUID COOLER - REMOVAL

............19-20

KJINDEX 9

Description Group-Page Description Group-Page Description Group-Page

Page 1750 of 1803

FUEL PRESSURE REGULATOR -

DESCRIPTION.......................14-13

FUEL PRESSURE REGULATOR -

INSTALLATION.......................14-14

FUEL PRESSURE REGULATOR -

OPERATION.........................14-14

FUEL PRESSURE REGULATOR -

REMOVAL..........................14-14

FUEL PUMP - DESCRIPTION............14-15

FUEL PUMP - OPERATION.............14-15

FUEL PUMP AMPERAGE TEST -

DIAGNOSIS AND TESTING.............14-16

FUEL PUMP CAPACITY TEST -

DIAGNOSIS AND TESTING.............14-15

FUEL PUMP MODULE - DESCRIPTION....14-18

FUEL PUMP MODULE - INSTALLATION . . . 14-19

FUEL PUMP MODULE - OPERATION......14-18

FUEL PUMP MODULE - REMOVAL.......14-18

FUEL PUMP PRESSURE TEST -

DIAGNOSIS AND TESTING.............14-15

FUEL PUMP RELAY - DESCRIPTION......14-34

FUEL PUMP RELAY - DIAGNOSIS AND

TESTING...........................14-34

FUEL PUMP RELAY - INSTALLATION.....14-34

FUEL PUMP RELAY - OPERATION........14-34

FUEL PUMP RELAY - REMOVAL.........14-34

FUEL PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD........................8I-4

FUEL RAIL - DESCRIPTION.............14-21

FUEL RAIL - INSTALLATION..............14-24

FUEL RAIL - OPERATION...............14-21

FUEL RAIL - REMOVAL................14-22

FUEL SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE................14-4

FUEL SYSTEM PRESSURE,

SPECIFICATIONS......................14-5

FUEL SYSTEM, SPECIAL TOOLS..........14-6

FUEL TANK - DESCRIPTION............14-24

FUEL TANK - INSTALLATION............14-27

FUEL TANK - OPERATION..............14-24

FUEL TANK - REMOVAL...............14-25

FUEL TANK CHECK VALVE -

DESCRIPTION.......................14-28

FUEL TANK CHECK VALVE -

INSTALLATION.......................14-28

FUEL TANK CHECK VALVE - OPERATION . . 14-28

FUEL TANK CHECK VALVE - REMOVAL....14-28

FUEL TANK SKID PLATE - INSTALLATION . . . 13-9

FUEL TANK SKID PLATE - REMOVAL......13-9

FULL TIME INDICATOR - DESCRIPTION . . . 8J-29

FULL TIME INDICATOR - OPERATION.....8J-30

FUNCTION - DIAGNOSIS AND TESTING,

REAR HVAC CONTROL ASSEMBLY

WINDOW DEFOGGER..................8G-9

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD...........8W-97-3

FUSE - INSTALLATION, IOD..........8W-97-3

FUSE - OPERATION, IOD.............8W-97-3

FUSE - REMOVAL, IOD..............8W-97-3

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON.......8W-01-9

GALLERY PLUGS - STANDARD

PROCEDURE, ENGINE CORE AND OIL.....9-10

GAP AND FLUSH - SPECIFICATIONS.....23-116

GAS ENGINES - GENERATOR RATINGS....8F-23

GAS POWERED - STARTER MOTOR......8F-39

GAS POWERED - TORQUE

.............8F-38

GASKET - DIAGNOSIS AND TESTING,

CYLINDER HEAD

..................9-19,9-30

GASKET SURFACE PREPARATION -

STANDARD PROCEDURE, ENGINE

.........9-9

GATE - INSTALLATION, SWING

.........23-138

GATE - REMOVAL, SWING

............23-138

GATE AJAR INDICATOR - DESCRIPTION

. . . 8J-20

GATE AJAR INDICATOR - OPERATION

.....8J-20

GATE BELTLINE WEATHERSTRIP -

INSTALLATION, SWING

...............23-186

GATE BELTLINE WEATHERSTRIP -

REMOVAL, SWING

...................23-186

GATE OPENING WEATHERSTRIP -

INSTALLATION, SWING

...............23-186

GATE OPENING WEATHERSTRIP -

REMOVAL, SWING

...................23-186

GAUGE - DESCRIPTION, ENGINE

TEMPERATURE

......................8J-18

GAUGE - DESCRIPTION, FUEL

...........8J-19GAUGE - OPERATION, ENGINE

TEMPERATURE......................8J-18

GAUGE - OPERATION, FUEL............8J-20

GEAR - DESCRIPTION.................19-13

GEAR - INSTALLATION, PINION

GEAR/RING..........................3-46

GEAR - OPERATION...................19-13

GEAR - REMOVAL, PINION GEAR/RING....3-44

GEAR/RING GEAR - INSTALLATION,

PINION.............................3-46

GEAR/RING GEAR - REMOVAL, PINION....3-44

GEAR/RING GEAR/TONE RING -

INSTALLATION, PINION............3-112,3-82

GEAR/RING GEAR/TONE RING -

REMOVAL, PINION...............3-110,3-79

GEARSHIFT CABLE - ADJUSTMENTS....21-130

GEARSHIFT CABLE - DIAGNOSIS AND

TESTING..........................21-128

GEARSHIFT CABLE - INSTALLATION.....21-129

GEARSHIFT CABLE - REMOVAL........21-128

GEAR/TONE RING - INSTALLATION,

PINION GEAR/RING...............3-112,3-82

GEAR/TONE RING - REMOVAL, PINION

GEAR/RING.....................3-110,3-79

GEARTRAIN - ASSEMBLY, PLANETARY . . . 21-160

GEARTRAIN - CLEANING, PLANETARY . . . 21-159

GEARTRAIN - DESCRIPTION,

PLANETARY........................21-157

GEARTRAIN - DISASSEMBLY,

PLANETARY........................21-159

GEARTRAIN - INSPECTION, PLANETARY . 21-159

GEARTRAIN - OPERATION, PLANETARY . . 21-157

GENERAL - WARNINGS.............8W-01-7

GENERATOR - DESCRIPTION...........8F-25

GENERATOR - INSTALLATION...........8F-26

GENERATOR - OPERATION.............8F-25

GENERATOR - REMOVAL...............8F-25

GENERATOR DECOUPLER - DIAGNOSIS

AND TESTING.......................8F-27

GENERATOR DECOUPLER PULLEY -

DESCRIPTION.......................8F-26

GENERATOR DECOUPLER PULLEY -

INSTALLATION.......................8F-30

GENERATOR DECOUPLER PULLEY -

OPERATION.........................8F-27

GENERATOR DECOUPLER PULLEY -

REMOVAL..........................8F-27

GENERATOR RATINGS, GAS ENGINES....8F-23

GLASS - INSTALLATION, DOOR . . 23-122,23-129,

23-172

GLASS - INSTALLATION, FLIP-UP.......23-136

GLASS - REMOVAL, DOOR......23-122,23-129,

23-172

GLASS - REMOVAL, FLIP-UP..........23-136

GLASS AJAR INDICATOR - DESCRIPTION . . 8J-21

GLASS AJAR INDICATOR - OPERATION . . . 8J-21

GLASS AJAR SWITCH - DESCRIPTION,

FLIP-UP............................8L-77

GLASS AJAR SWITCH - OPERATION,

FLIP-UP............................8L-77

GLASS HEATING GRID REPAIR -

STANDARD PROCEDURE, REAR..........8G-4

GLASS LATCH - INSTALLATION, FLIP-UP . 23-136

GLASS LATCH - REMOVAL, FLIP-UP.....23-136

GLASS PANEL - INSTALLATION........23-178

GLASS PANEL - REMOVAL............23-178

GLASS PANEL ADJUSTMENT,

ADJUSTMENTS - SUNROOF...........23-178

GLASS PANEL SEAL - INSTALLATION

....23-178

GLASS PANEL SEAL - REMOVAL

.......23-178

GLASS RELEASE SWITCH - DIAGNOSIS

AND TESTING, FLIP-UP

................8N-5

GLASS RUN CHANNEL - INSTALLATION

. 23-123,

23-130

GLASS RUN CHANNEL - REMOVAL

.....23-123,

23-130

GLASS SUPPORT CYLINDER -

INSTALLATION, FLIP-UP

..............23-139

GLASS SUPPORT CYLINDER -

REMOVAL, FLIP-UP

..................23-139

GLOVE BOX - INSTALLATION

..........23-148

GLOVE BOX - REMOVAL

..............23-148

GLOVE BOX LATCH - INSTALLATION

....23-148

GLOVE BOX LATCH - REMOVAL

........23-148

GLOVE BOX LATCH STRIKER -

INSTALLATION

......................23-149

GLOVE BOX LATCH STRIKER - REMOVAL

. 23-148GRAB HANDLE - INSTALLATION,

A-PILLAR TRIM.....................23-156

GRAB HANDLE - REMOVAL, A-PILLAR

TRIM.............................23-156

GRID - DESCRIPTION, REAR WINDOW

DEFOGGER..........................8G-5

GRID - DIAGNOSIS AND TESTING, REAR

WINDOW DEFOGGER..................8G-5

GRID - OPERATION, REAR WINDOW

DEFOGGER..........................8G-5

GRID REPAIR - STANDARD PROCEDURE,

REAR GLASS HEATING.................8G-4

GRILLE - INSTALLATION..............23-142

GRILLE - INSTALLATION, COWL........23-140

GRILLE - REMOVAL..................23-142

GRILLE - REMOVAL, COWL...........23-140

GRILLE OPENING REINFORCEMENT -

INSTALLATION......................23-142

GRILLE OPENING REINFORCEMENT -

REMOVAL.........................23-142

GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT TO..........8W-01-9

GROUND AND SPLICE INFORMATION -

DESCRIPTION, CONNECTOR..........8W-01-7

GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO..............................8W-01-9

GROUND STRAP - DESCRIPTION, RADIO

NOISE SUPPRESSION..................8A-9

GROUND STRAP - INSTALLATION,

RADIO NOISE SUPPRESSION...........8A-11

GROUND STRAP - OPERATION, RADIO

NOISE SUPPRESSION.................8A-10

GROUND STRAP - REMOVAL, RADIO

NOISE SUPPRESSION.................8A-10

GROUNDS - DESCRIPTION, POWER......8E-13

GUARD - DESCRIPTION, THERMAL......8F-20

GUARD - INSTALLATION, THERMAL......8F-20

GUARD - OPERATION, THERMAL........8F-20

GUARD - REMOVAL, THERMAL..........8F-20

GUIDE ASSEMBLY - INSTALLATION.....23-179

GUIDE ASSEMBLY - REMOVAL.........23-179

GUIDE SEALS - DESCRIPTION, VALVE . 9-29,9-38

GUIDES - DESCRIPTION, VALVE......9-19,9-30

HALF SHAFT - CAUTION................3-10

HALF SHAFT - DIAGNOSIS AND TESTING . . 3-10

HALF SHAFT - INSTALLATION............3-11

HALF SHAFT - REMOVAL...............3-10

HALF SHAFT, SPECIFICATIONS...........3-11

HANDLE - INSTALLATION, A-PILLAR

TRIM AND GRAB....................23-156

HANDLE - INSTALLATION, ASSIST......23-157

HANDLE - INSTALLATION, EXTERIOR . . . 23-123,

23-130,23-136

HANDLE - INSTALLATION, LATCH

RELEASE..........................23-120

HANDLE - REMOVAL, A-PILLAR TRIM

AND GRAB.........................23-156

HANDLE - REMOVAL, ASSIST..........23-157

HANDLE - REMOVAL, EXTERIOR . 23-123,23-130,

23-136

HANDLE - REMOVAL, LATCH RELEASE . . 23-120

HANDLING NON-DEPLOYED

SUPPLEMENTAL RESTRAINTS -

STANDARD PROCEDURE...............8O-6

HARNESS - DIAGNOSIS AND TESTING,

WIRING

..........................8W-01-7

HAZARD SWITCH - DESCRIPTION

.......8L-29

HAZARD SWITCH - INSTALLATION

.......8L-30

HAZARD SWITCH - OPERATION

.........8L-29

HAZARD SWITCH - REMOVAL

..........8L-30

HCU (HYDRAULIC CONTROL UNIT) -

DESCRIPTION

........................5-35

HCU (HYDRAULIC CONTROL UNIT) -

INSTALLATION

........................5-36

HCU (HYDRAULIC CONTROL UNIT) -

OPERATION

..........................5-35

HCU (HYDRAULIC CONTROL UNIT) -

REMOVAL

...........................5-36

HEAD - DESCRIPTION, CYLINDER

........9-30

HEAD COVER(S) - DESCRIPTION,

CYLINDER

...........................9-25

HEAD COVER(S) - INSTALLATION,

CYLINDER

.......................9-26,9-34

HEAD COVER(S) - REMOVAL, CYLINDER

. . 9-25,

9-34

KJINDEX 11

Description Group-Page Description Group-Page Description Group-Page