Fan relay JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1165 of 1803

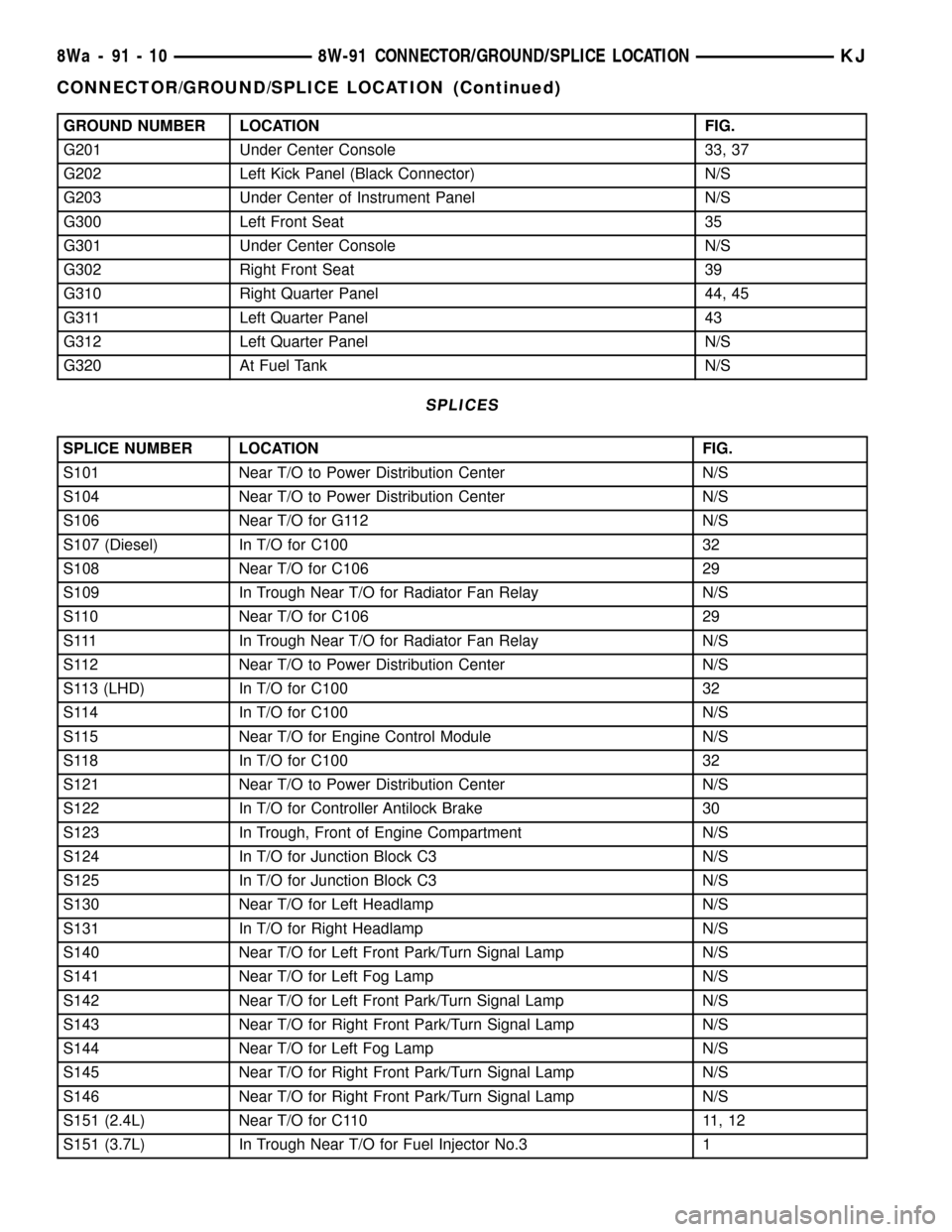

GROUND NUMBER LOCATION FIG.

G201 Under Center Console 33, 37

G202 Left Kick Panel (Black Connector) N/S

G203 Under Center of Instrument Panel N/S

G300 Left Front Seat 35

G301 Under Center Console N/S

G302 Right Front Seat 39

G310 Right Quarter Panel 44, 45

G311 Left Quarter Panel 43

G312 Left Quarter Panel N/S

G320 At Fuel Tank N/S

SPLICES

SPLICE NUMBER LOCATION FIG.

S101 Near T/O to Power Distribution Center N/S

S104 Near T/O to Power Distribution Center N/S

S106 Near T/O for G112 N/S

S107 (Diesel) In T/O for C100 32

S108 Near T/O for C106 29

S109 In Trough Near T/O for Radiator Fan Relay N/S

S110 Near T/O for C106 29

S111 In Trough Near T/O for Radiator Fan Relay N/S

S112 Near T/O to Power Distribution Center N/S

S113 (LHD) In T/O for C100 32

S114 In T/O for C100 N/S

S115 Near T/O for Engine Control Module N/S

S118 In T/O for C100 32

S121 Near T/O to Power Distribution Center N/S

S122 In T/O for Controller Antilock Brake 30

S123 In Trough, Front of Engine Compartment N/S

S124 In T/O for Junction Block C3 N/S

S125 In T/O for Junction Block C3 N/S

S130 Near T/O for Left Headlamp N/S

S131 In T/O for Right Headlamp N/S

S140 Near T/O for Left Front Park/Turn Signal Lamp N/S

S141 Near T/O for Left Fog Lamp N/S

S142 Near T/O for Left Front Park/Turn Signal Lamp N/S

S143 Near T/O for Right Front Park/Turn Signal Lamp N/S

S144 Near T/O for Left Fog Lamp N/S

S145 Near T/O for Right Front Park/Turn Signal Lamp N/S

S146 Near T/O for Right Front Park/Turn Signal Lamp N/S

S151 (2.4L) Near T/O for C110 11, 12

S151 (3.7L) In Trough Near T/O for Fuel Injector No.3 1

8Wa - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONKJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1661 of 1803

(5) Connect the test set hose or probe to the open

end of the leaking circuit. The test set gauge should

return to the 27 kPa (8 in. Hg.) setting shortly after

each connection is made. If OK, replace the faulty

disconnected component. If not OK, go to Step 6.

(6)

To locate a leak in a vacuum line, leave one end

of the line plugged and connect the test set hose or

probe to the other end of the line. Run your fingers

slowly along the line while watching the test set gauge.

The vacuum reading will fluctuate when your fingers

contact the source of the leak. To repair the vacuum

line, cut out the leaking section of the line. Then, insert

the loose ends of the line into a suitable length of 3 mil-

limeter (0.125 inch) inside diameter rubber hose.

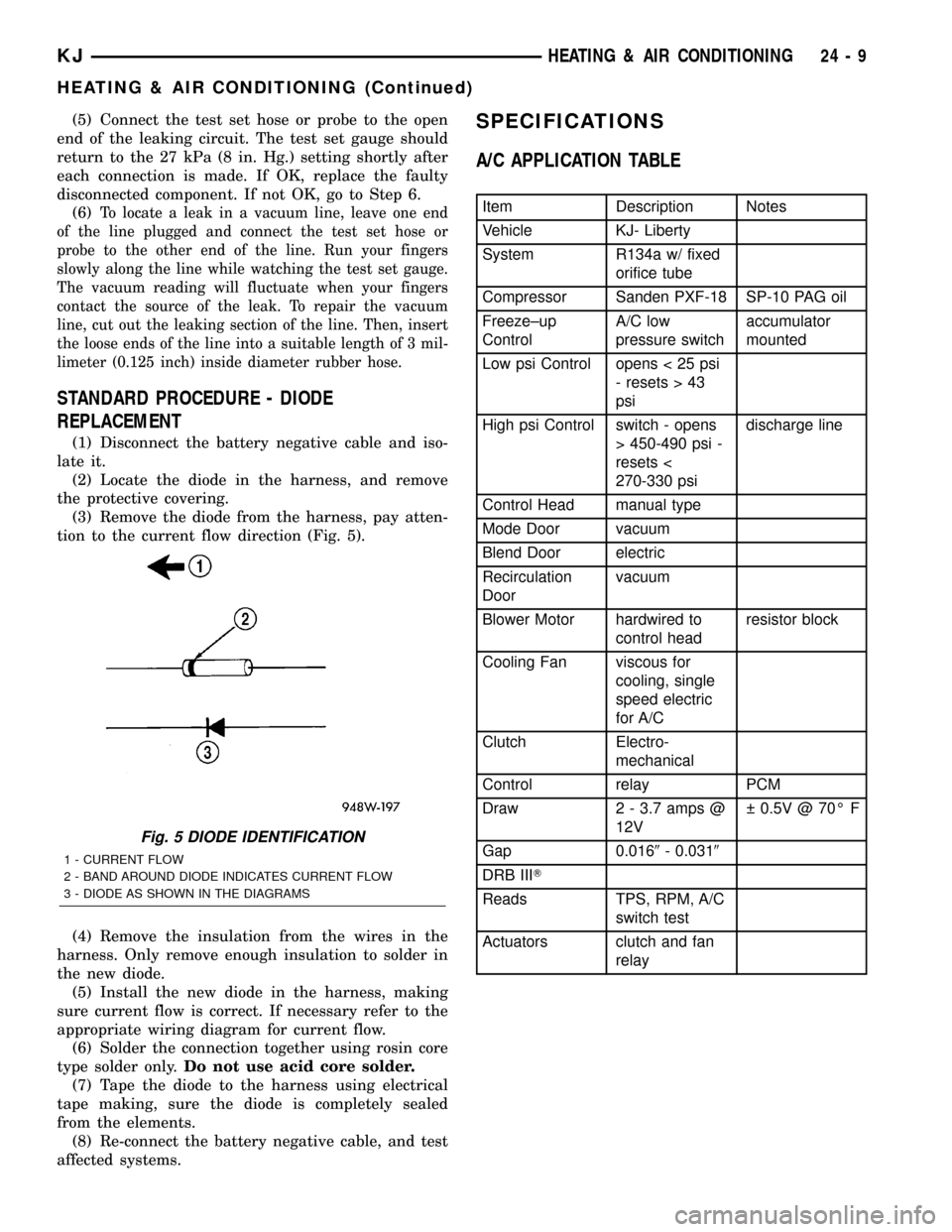

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect the battery negative cable and iso-

late it.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 5).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8) Re-connect the battery negative cable, and test

affected systems.

SPECIFICATIONS

A/C APPLICATION TABLE

Item Description Notes

Vehicle KJ- Liberty

System R134a w/ fixed

orifice tube

Compressor Sanden PXF-18 SP-10 PAG oil

Freeze±up

ControlA/C low

pressure switchaccumulator

mounted

Low psi Control opens < 25 psi

- resets > 43

psi

High psi Control switch - opens

> 450-490 psi -

resets <

270-330 psidischarge line

Control Head manual type

Mode Door vacuum

Blend Door electric

Recirculation

Doorvacuum

Blower Motor hardwired to

control headresistor block

Cooling Fan viscous for

cooling, single

speed electric

for A/C

Clutch Electro-

mechanical

Control relay PCM

Draw 2 - 3.7 amps @

12V 0.5V @ 70É F

Gap 0.0169- 0.0319

DRB IIIT

Reads TPS, RPM, A/C

switch test

Actuators clutch and fan

relay

Fig. 5 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

KJHEATING & AIR CONDITIONING 24 - 9

HEATING & AIR CONDITIONING (Continued)

Page 1719 of 1803

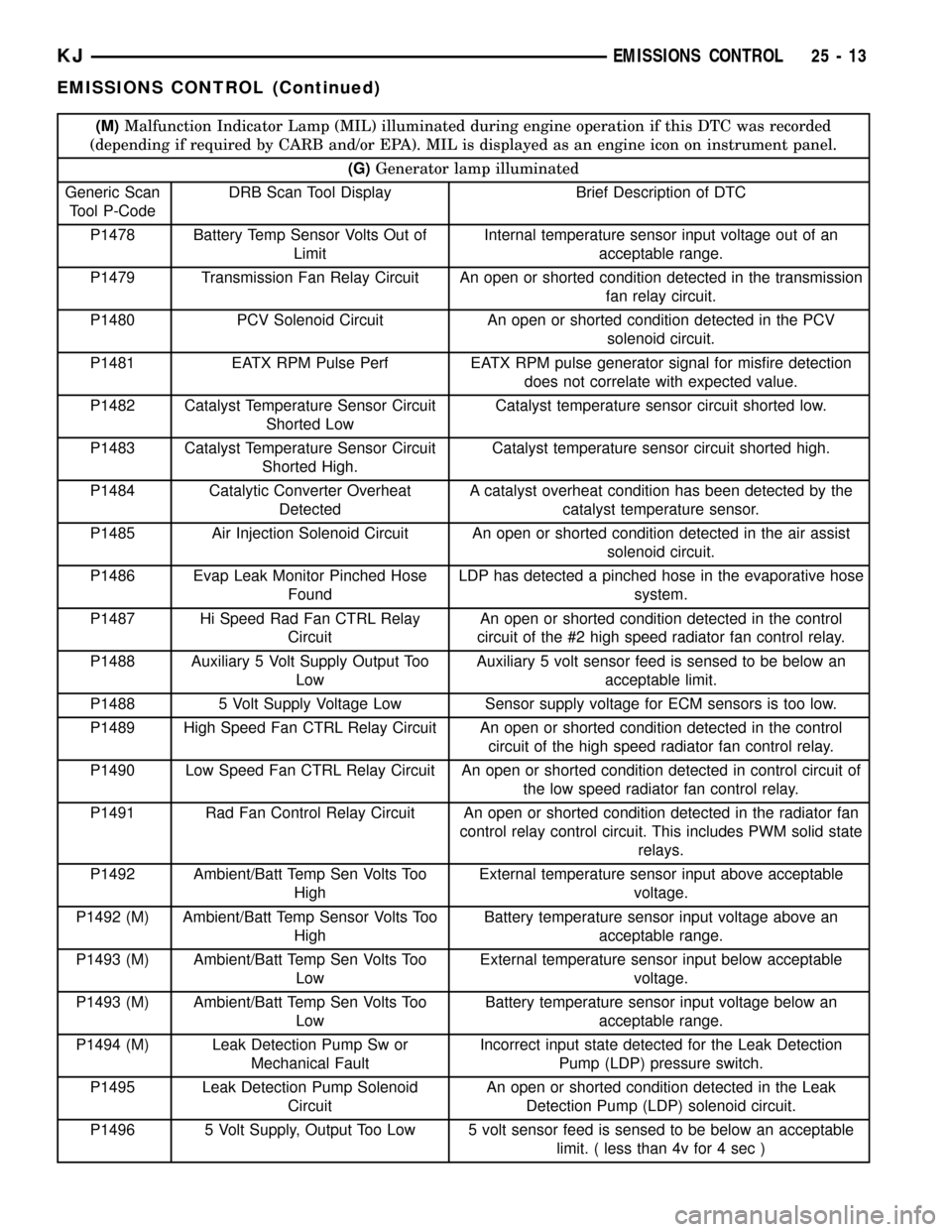

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P1478 Battery Temp Sensor Volts Out of

LimitInternal temperature sensor input voltage out of an

acceptable range.

P1479 Transmission Fan Relay Circuit An open or shorted condition detected in the transmission

fan relay circuit.

P1480 PCV Solenoid Circuit An open or shorted condition detected in the PCV

solenoid circuit.

P1481 EATX RPM Pulse Perf EATX RPM pulse generator signal for misfire detection

does not correlate with expected value.

P1482 Catalyst Temperature Sensor Circuit

Shorted LowCatalyst temperature sensor circuit shorted low.

P1483 Catalyst Temperature Sensor Circuit

Shorted High.Catalyst temperature sensor circuit shorted high.

P1484 Catalytic Converter Overheat

DetectedA catalyst overheat condition has been detected by the

catalyst temperature sensor.

P1485 Air Injection Solenoid Circuit An open or shorted condition detected in the air assist

solenoid circuit.

P1486 Evap Leak Monitor Pinched Hose

FoundLDP has detected a pinched hose in the evaporative hose

system.

P1487 Hi Speed Rad Fan CTRL Relay

CircuitAn open or shorted condition detected in the control

circuit of the #2 high speed radiator fan control relay.

P1488 Auxiliary 5 Volt Supply Output Too

LowAuxiliary 5 volt sensor feed is sensed to be below an

acceptable limit.

P1488 5 Volt Supply Voltage Low Sensor supply voltage for ECM sensors is too low.

P1489 High Speed Fan CTRL Relay Circuit An open or shorted condition detected in the control

circuit of the high speed radiator fan control relay.

P1490 Low Speed Fan CTRL Relay Circuit An open or shorted condition detected in control circuit of

the low speed radiator fan control relay.

P1491 Rad Fan Control Relay Circuit An open or shorted condition detected in the radiator fan

control relay control circuit. This includes PWM solid state

relays.

P1492 Ambient/Batt Temp Sen Volts Too

HighExternal temperature sensor input above acceptable

voltage.

P1492 (M) Ambient/Batt Temp Sensor Volts Too

HighBattery temperature sensor input voltage above an

acceptable range.

P1493 (M) Ambient/Batt Temp Sen Volts Too

LowExternal temperature sensor input below acceptable

voltage.

P1493 (M) Ambient/Batt Temp Sen Volts Too

LowBattery temperature sensor input voltage below an

acceptable range.

P1494 (M) Leak Detection Pump Sw or

Mechanical FaultIncorrect input state detected for the Leak Detection

Pump (LDP) pressure switch.

P1495 Leak Detection Pump Solenoid

CircuitAn open or shorted condition detected in the Leak

Detection Pump (LDP) solenoid circuit.

P1496 5 Volt Supply, Output Too Low 5 volt sensor feed is sensed to be below an acceptable

limit. ( less than 4v for 4 sec )

KJEMISSIONS CONTROL 25 - 13

EMISSIONS CONTROL (Continued)

Page 1720 of 1803

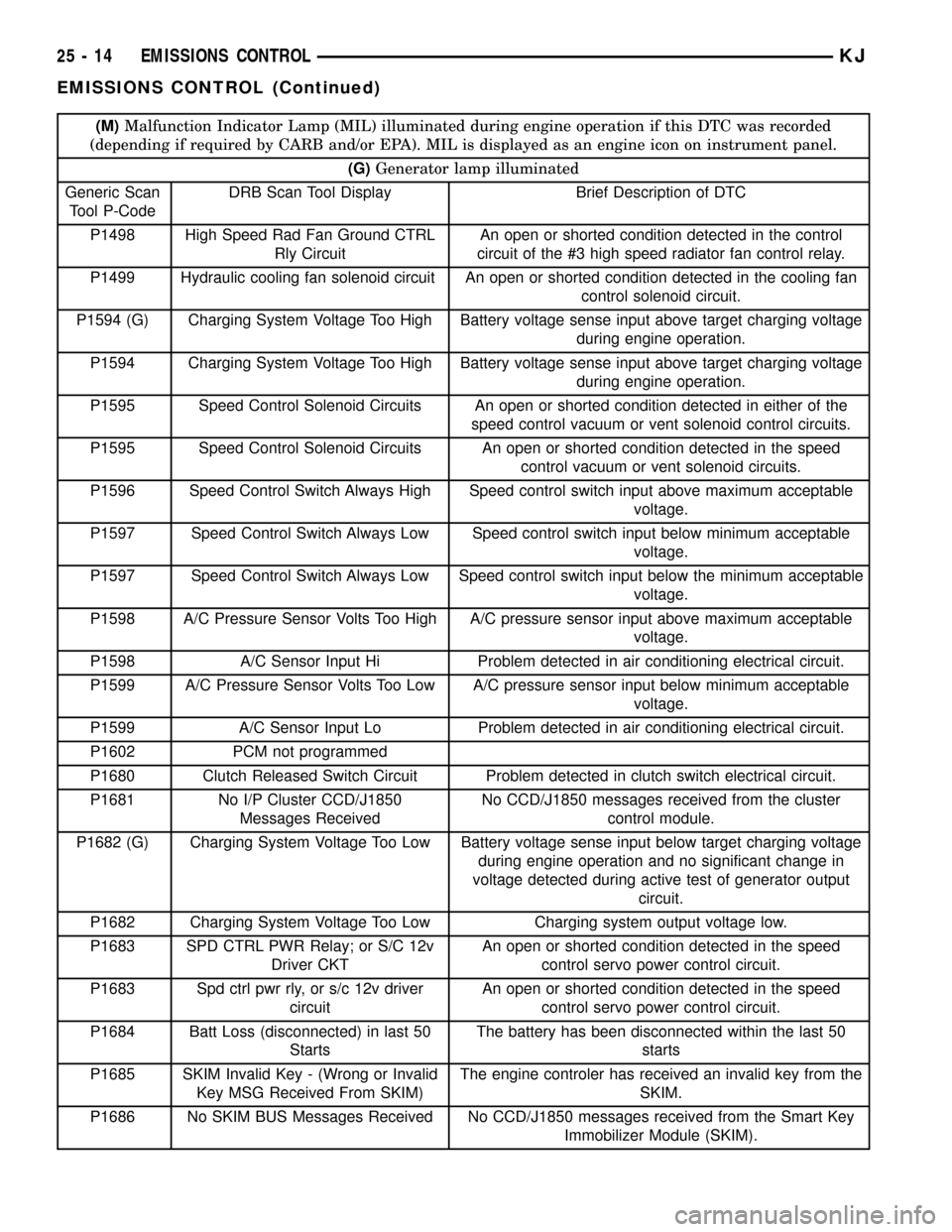

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P1498 High Speed Rad Fan Ground CTRL

Rly CircuitAn open or shorted condition detected in the control

circuit of the #3 high speed radiator fan control relay.

P1499 Hydraulic cooling fan solenoid circuit An open or shorted condition detected in the cooling fan

control solenoid circuit.

P1594 (G) Charging System Voltage Too High Battery voltage sense input above target charging voltage

during engine operation.

P1594 Charging System Voltage Too High Battery voltage sense input above target charging voltage

during engine operation.

P1595 Speed Control Solenoid Circuits An open or shorted condition detected in either of the

speed control vacuum or vent solenoid control circuits.

P1595 Speed Control Solenoid Circuits An open or shorted condition detected in the speed

control vacuum or vent solenoid circuits.

P1596 Speed Control Switch Always High Speed control switch input above maximum acceptable

voltage.

P1597 Speed Control Switch Always Low Speed control switch input below minimum acceptable

voltage.

P1597 Speed Control Switch Always Low Speed control switch input below the minimum acceptable

voltage.

P1598 A/C Pressure Sensor Volts Too High A/C pressure sensor input above maximum acceptable

voltage.

P1598 A/C Sensor Input Hi Problem detected in air conditioning electrical circuit.

P1599 A/C Pressure Sensor Volts Too Low A/C pressure sensor input below minimum acceptable

voltage.

P1599 A/C Sensor Input Lo Problem detected in air conditioning electrical circuit.

P1602 PCM not programmed

P1680 Clutch Released Switch Circuit Problem detected in clutch switch electrical circuit.

P1681 No I/P Cluster CCD/J1850

Messages ReceivedNo CCD/J1850 messages received from the cluster

control module.

P1682 (G) Charging System Voltage Too Low Battery voltage sense input below target charging voltage

during engine operation and no significant change in

voltage detected during active test of generator output

circuit.

P1682 Charging System Voltage Too Low Charging system output voltage low.

P1683 SPD CTRL PWR Relay; or S/C 12v

Driver CKTAn open or shorted condition detected in the speed

control servo power control circuit.

P1683 Spd ctrl pwr rly, or s/c 12v driver

circuitAn open or shorted condition detected in the speed

control servo power control circuit.

P1684 Batt Loss (disconnected) in last 50

StartsThe battery has been disconnected within the last 50

starts

P1685 SKIM Invalid Key - (Wrong or Invalid

Key MSG Received From SKIM)The engine controler has received an invalid key from the

SKIM.

P1686 No SKIM BUS Messages Received No CCD/J1850 messages received from the Smart Key

Immobilizer Module (SKIM).

25 - 14 EMISSIONS CONTROLKJ

EMISSIONS CONTROL (Continued)

Page 1747 of 1803

DIFFERENTIAL - TRAC-LOK - CLEANING . . 3-109,

3-77

DIFFERENTIAL - TRAC-LOK -

DISASSEMBLY...................3-107,3-75

DIFFERENTIAL - TRAC-LOK -

INSPECTION....................3-109,3-77

DIFFERENTIAL CASE BEARINGS -

INSTALLATION...............3-110,3-44,3-79

DIFFERENTIAL CASE BEARINGS -

REMOVAL..................3-110,3-43,3-79

DIMENSIONS - SPECIFICATIONS, FRAME . . . 13-3

DIMENSIONS - SPECIFICATIONS,

OPENING..........................23-111

DIODE - INSTALLATION............8W-01-14

DIODE - REMOVAL................8W-01-14

DIODE REPLACEMENT - STANDARD

PROCEDURE.........................24-9

DISASSEMBLY - POWER DISTRIBUTION

CENTER DISASSEMBLY.............8W-97-7

DISASSEMBLY, 4C RETAINER/BULKHEAD . 21-122

DISASSEMBLY, DIAGNOSIS AND

TESTING...........................21-83

DISASSEMBLY, DIFFERENTIAL......3-105,3-41

DISASSEMBLY, DIFFERENTIAL -

TRAC-LOK......................3-107,3-75

DISASSEMBLY, DISASSEMBLY - POWER

DISTRIBUTION CENTER.............8W-97-7

DISASSEMBLY, DISC BRAKE CALIPERS....5-14

DISASSEMBLY, HVAC HOUSING.........24-34

DISASSEMBLY, INPUT CLUTCH

ASSEMBLY.........................21-135

DISASSEMBLY, INSTRUMENT CLUSTER....8J-9

DISASSEMBLY, LOW/REVERSE CLUTCH . . 21-145

DISASSEMBLY, MANUAL - NV1500........21-4

DISASSEMBLY, MANUAL - NV3550.......21-35

DISASSEMBLY, OIL PUMP...............9-65

DISASSEMBLY, OIL PUMP.............21-149

DISASSEMBLY, PLANETARY GEARTRAIN . 21-159

DISASSEMBLY, SINGLE CARDAN

UNIVERSAL JOINTS....................3-8

DISASSEMBLY, TRANSFER CASE -

NV231............................21-182

DISASSEMBLY, TRANSFER CASE -

NV242............................21-218

DISASSEMBLY, VALVE BODY...........21-173

DISASSEMBLY, WHEEL CYLINDERS.......5-28

DISC - INSTALLATION, CLUTCH...........6-6

DISC - REMOVAL, CLUTCH...............6-6

DISC BRAKE CALIPER ADAPTER -

INSTALLATION........................5-18

DISC BRAKE CALIPER ADAPTER -

REMOVAL...........................5-18

DISC BRAKE CALIPERS - ASSEMBLY......5-16

DISC BRAKE CALIPERS - CLEANING......5-16

DISC BRAKE CALIPERS - DESCRIPTION....5-13

DISC BRAKE CALIPERS - DISASSEMBLY . . . 5-14

DISC BRAKE CALIPERS - INSPECTION.....5-16

DISC BRAKE CALIPERS - INSTALLATION . . . 5-17

DISC BRAKE CALIPERS - OPERATION.....5-14

DISC BRAKE CALIPERS - REMOVAL.......5-14

DISC BRAKE ROTOR - DIAGNOSIS AND

TESTING............................5-18

DISC BRAKE ROTOR - STANDARD

PROCEDURE.........................5-19

DISCHARGE (ESD) SENSITIVE DEVICES -

STANDARD PROCEDURE,

ELECTROSTATIC...................8W-01-8

DISCHARGE LINE - INSTALLATION, A/C . . . 24-47

DISCHARGE LINE - REMOVAL, A/C.......24-46

DISPLAY TEST MODE - DESCRIPTION,

STATE ..............................25-2

DISTRIBUTION - DESCRIPTION, POWER . 8W-97-1

DISTRIBUTION - OPERATION, POWER . . 8W-97-1

DISTRIBUTION CENTER - DESCRIPTION,

POWER..........................8W-97-6

DISTRIBUTION CENTER - OPERATION,

POWER..........................8W-97-7

DISTRIBUTION CENTER - REMOVAL,

POWER..........................8W-97-7

DISTRIBUTION CENTER ASSEMBLY,

ASSEMBLY - POWER

..............8W-97-10

DISTRIBUTION CENTER DISASSEMBLY,

DISASSEMBLY - POWER

............8W-97-7

DISTRIBUTION SYSTEMS, SPECIAL

TOOLS - POWER

...................8W-97-2

DOO - INSTALLATION, FLOOR -

DEFROST

...........................24-37

DOOR - INSTALLATION

.........23-122,23-129DOOR - INSTALLATION, BLEND.........24-35

DOOR - INSTALLATION, PANEL..........24-36

DOOR - INSTALLATION, PASSENGER

AIRBAG............................8O-30

DOOR - INSTALLATION, RECIRC.........24-37

DOOR - REMOVAL.............23-122,23-129

DOOR - REMOVAL, BLEND.............24-35

DOOR - REMOVAL, DEFROST...........24-35

DOOR - REMOVAL, FLOOR - DEFROST....24-36

DOOR - REMOVAL, PASSENGER AIRBAG . . 8O-29

DOOR - REMOVAL, RECIRC............24-37

DOOR ACTUATOR - INSTALLATION,

BLEND.............................24-20

DOOR ACTUATOR - INSTALLATION,

FLOOR - DEFROST...................24-25

DOOR ACTUATOR - INSTALLATION,

PANEL.............................24-25

DOOR ACTUATOR - INSTALLATION,

RECIRCULATION.....................24-26

DOOR ACTUATOR - REMOVAL, BLEND....24-20

DOOR ACTUATOR - REMOVAL, FLOOR -

DEFROST...........................24-24

DOOR ACTUATOR - REMOVAL, PANEL....24-24

DOOR ACTUATOR - REMOVAL,

RECIRCULATION.....................24-26

DOOR AJAR INDICATOR - DESCRIPTION . . 8J-17

DOOR AJAR INDICATOR - OPERATION....8J-17

DOOR AJAR SWITCH - DESCRIPTION....8L-77

DOOR AJAR SWITCH - OPERATION........8L-77

DOOR CYLINDER LOCK SWITCH -

DESCRIPTION........................8Q-9

DOOR CYLINDER LOCK SWITCH -

DIAGNOSIS AND TESTING.............8Q-10

DOOR CYLINDER LOCK SWITCH -

INSTALLATION......................8Q-10

DOOR CYLINDER LOCK SWITCH -

OPERATION.........................8Q-10

DOOR CYLINDER LOCK SWITCH -

REMOVAL..........................8Q-10

DOOR GLASS - INSTALLATION . . 23-122,23-129,

23-172

DOOR GLASS - REMOVAL......23-122,23-129,

23-172

DOOR LOCK / UNLOCK SWITCH -

INSTALLATION.......................8N-5

DOOR LOCK / UNLOCK SWITCH -

REMOVAL...........................8N-4

DOOR LOCK MOTOR - DESCRIPTION......8N-5

DOOR LOCK MOTOR - DIAGNOSIS AND

TESTING............................8N-5

DOOR LOCK MOTOR - OPERATION.......8N-5

DOOR LOCK RELAY - DESCRIPTION......8N-6

DOOR LOCK RELAY - DIAGNOSIS AND

TESTING............................8N-6

DOOR LOCK RELAY - INSTALLATION......8N-7

DOOR LOCK RELAY - OPERATION........8N-6

DOOR LOCK RELAY - REMOVAL.........8N-6

DOOR LOCK/UNLOCK SWITCH -

DIAGNOSIS AND TESTING..............8N-4

DOOR LOWER WEATHERSTRIP -

INSTALLATION......................23-186

DOOR LOWER WEATHERSTRIP -

REMOVAL.........................23-186

DOOR OUTER BELT MOLDING -

INSTALLATION, FRONT...............23-186

DOOR OUTER BELT MOLDING -

INSTALLATION, REAR................23-186

DOOR OUTER BELT MOLDING -

REMOVAL, FRONT...................23-186

DOOR OUTER BELT MOLDING -

REMOVAL, REAR....................23-186

DOOR PRIMARY WEATHERSTRIP -

INSTALLATION......................23-185

DOOR PRIMARY WEATHERSTRIP -

REMOVAL.........................23-185

DOOR SCUFF PLATE - INSTALLATION,

REAR.............................23-160

DOOR SCUFF PLATE - REMOVAL, REAR . . 23-160

DOOR SILL SCUFF PLATE -

INSTALLATION......................23-157

DOOR SILL SCUFF PLATE - REMOVAL

. . . 23-157

DOOR/HOUSING - INSTALLATION, FUEL

FILL

..............................23-141

DOOR/HOUSING - REMOVAL, FUEL FILL

. 23-141

DOUBLE INVERTED FLARING -

STANDARD PROCEDURE

.................5-8

DRAIN AND FILL - STANDARD

PROCEDURE, FLUID

...........21-208,21-246DRAIN TUBE - INSTALLATION..........23-181

DRAIN TUBE - REMOVAL.............23-180

DRAINAGE AND WIND NOISE

DIAGNOSIS, DIAGNOSIS AND TESTING

- WATER ..........................23-176

DRAINING COOLING SYSTEM 3.7L

ENGINE - STANDARD PROCEDURE........7-12

DRAW TEST - STANDARD PROCEDURE,

IGNITION-OFF.......................8F-14

DRIVE - DIAGNOSIS AND TESTING,

VISCOUS FAN........................7-28

DRIVE BELT - DIAGNOSIS AND TESTING,

SERPENTINE.........................7-15

DRIVE MOTOR - INSTALLATION........23-182

DRIVE MOTOR - REMOVAL............23-182

DRIVER AIRBAG - DESCRIPTION........8O-17

DRIVER AIRBAG - INSTALLATION.......8O-20

DRIVER AIRBAG - OPERATION..........8O-18

DRIVER AIRBAG - REMOVAL...........8O-19

DRIVER SEAT HEATER SWITCH -

DESCRIPTION.......................8G-11

DRIVER SEAT HEATER SWITCH -

INSTALLATION......................8G-13

DRIVER SEAT HEATER SWITCH -

OPERATION.........................8G-12

DRIVER SEAT HEATER SWITCH -

REMOVAL..........................8G-13

DRIVER SIDE BEZELS - INSTALLATION,

INSTRUMENT PANEL.................23-154

DRIVER SIDE BEZELS - REMOVAL,

INSTRUMENT PANEL.................23-153

DROP - STANDARD PROCEDURE,

TESTING FOR A VOLTAGE...........8W-01-10

DRUM - DIAGNOSIS AND TESTING,

BRAKE..............................5-27

DRUM BRAKE - ADJUSTMENT, REAR......5-12

DRUM BRAKE - DESCRIPTION, REAR.....5-10

DRUM BRAKE - OPERATION, REAR.......5-11

DRUM BRAKE SHOES - INSTALLATION....5-11

DRUM BRAKE SHOES - REMOVAL........5-11

DRUM MACHINING - STANDARD

PROCEDURES, BRAKE.................5-27

DUCT - INSTALLATION, DEFROST/

DEMISTER..........................24-32

DUCT - INSTALLATION, FLOOR..........24-32

DUCT - INSTALLATION, FLOOR CONSOLE . 24-31

DUCT - REMOVAL, FLOOR.............24-32

DUCT - REMOVAL, FLOOR CONSOLE.....24-31

DUCT/DEMISTER ADAPTOR - REMOVAL,

DEFROST...........................24-32

EFFECTS OF INCORRECT FLUID LEVEL -

DIAGNOSIS AND TESTING............21-125

ELECTRIC - DESCRIPTION, RADIATOR

FAN ................................7-26

ELECTRIC - INSTALLATION, RADIATOR

FAN ................................7-27

ELECTRIC - INSTALLATION, WINDOW

REGULATOR.................23-126,23-134

ELECTRIC - OPERATION, RADIATOR FAN . . . 7-26

ELECTRIC - REMOVAL, RADIATOR FAN....7-26

ELECTRIC - REMOVAL, WINDOW

REGULATOR.................23-126,23-134

ELECTRICAL - DESCRIPTION............5-34

ELECTRICAL - OPERATION..............5-34

ELECTRICAL TESTER - STANDARD

PROCEDURE, USING MIDTRONICS.......8F-15

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES - STANDARD

PROCEDURE......................8W-01-8

ELEMENT - DESCRIPTION, HEATED SEAT . 8G-13

ELEMENT - DIAGNOSIS AND TESTING,

HEATED SEAT .......................8G-13

ELEMENT - OPERATION, HEATED SEAT . . . 8G-13

EMISSION CONTROL INFORMATION

(VECI) LABEL - DESCRIPTION,

VEHICLE..........................Intro.-8

EMISSION CONTROL SYSTEM -

DESCRIPTION........................25-1

END - INSTALLATION, TIE ROD.........19-16

END - REMOVAL, TIE ROD.............19-16

END CAP - INSTALLATION, INSTRUMENT

PANEL

............................23-153

END CAP - REMOVAL, INSTRUMENT

PANEL

............................23-153

END REMOVAL TOOL, SPECIAL TOOLS -

OUTER TIE ROD

.....................19-15

ENGINE - 3.7L - DESCRIPTION

............9-3

ENGINE - DESCRIPTION, 3.7L

............7-21

8 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1759 of 1803

PRIMARY WEATHERSTRIP - REMOVAL,

DOOR............................23-185

PROGRAMING - STANDARD

PROCEDURE, RKE TRANSMITTER........8N-9

PROGRAMMING - STANDARD

PROCEDURE, PCM/SKIM................8E-1

PROGRAMMING - STANDARD

PROCEDURE, SENTRY KEY

TRANSPONDER.......................8Q-8

PROPELLER SHAFT - DIAGNOSIS AND

TESTING.............................3-1

PROPELLER SHAFT - FRONT -

INSTALLATION.........................3-6

PROPELLER SHAFT - FRONT - REMOVAL . . . 3-6

PROPELLER SHAFT - REAR -

INSTALLATION.........................3-7

PROPELLER SHAFT - REAR - REMOVAL....3-7

PROPELLER SHAFT ANGLE - STANDARD

PROCEDURES.........................3-3

PROPELLER SHAFT, SPECIFICATIONS.......3-6

PROPORTIONING VALVE - DIAGNOSIS

AND TESTING........................5-20

PULLEY - DESCRIPTION, GENERATOR

DECOUPLER........................8F-26

PULLEY - INSTALLATION..............19-23

PULLEY - INSTALLATION, GENERATOR

DECOUPLER........................8F-30

PULLEY - OPERATION, GENERATOR

DECOUPLER........................8F-27

PULLEY - REMOVAL..................19-23

PULLEY - REMOVAL, GENERATOR

DECOUPLER........................8F-27

PUMP - ASSEMBLY, OIL................9-67

PUMP - ASSEMBLY, OIL..............21-151

PUMP - CLEANING, OIL..............21-150

PUMP - DESCRIPTION................19-17

PUMP - DESCRIPTION, FUEL...........14-15

PUMP - DESCRIPTION, LEAK DETECTION . 25-27

PUMP - DESCRIPTION, OIL............21-147

PUMP - DESCRIPTION, WATER..........7-29

PUMP - DISASSEMBLY, OIL.............9-65

PUMP - DISASSEMBLY, OIL...........21-149

PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER

STEERING..........................19-18

PUMP - INSPECTION, OIL...............9-66

PUMP - INSPECTION, OIL.............21-150

PUMP - INSTALLATION, LEAK

DETECTION.........................25-28

PUMP - INSTALLATION, OIL.............9-67

PUMP - OPERATION..................19-17

PUMP - OPERATION, FUEL.............14-15

PUMP - OPERATION, LEAK DETECTION . . . 25-28

PUMP - OPERATION, OIL.............21-147

PUMP - OPERATION, WATER............7-30

PUMP - REMOVAL, LEAK DETECTION....25-28

PUMP - REMOVAL, OIL.................9-65

PUMP AMPERAGE TEST - DIAGNOSIS

AND TESTING, FUEL..................14-16

PUMP CAPACITY TEST - DIAGNOSIS

AND TESTING, FUEL..................14-15

PUMP FRONT SEAL - INSTALLATION,

OIL...............................21-152

PUMP FRONT SEAL - REMOVAL, OIL....21-152

PUMP MODULE - DESCRIPTION, FUEL....14-18

PUMP MODULE - INSTALLATION, FUEL . . . 14-19

PUMP MODULE - OPERATION, FUEL.....14-18

PUMP MODULE - REMOVAL, FUEL.......14-18

PUMP PRESSURE TEST - DIAGNOSIS

AND TESTING, FUEL..................14-15

PUMP RELAY - DESCRIPTION, FUEL.....14-34

PUMP RELAY - DIAGNOSIS AND

TESTING, FUEL......................14-34

PUMP RELAY - INSTALLATION, FUEL.....14-34

PUMP RELAY - OPERATION, FUEL.......14-34

PUMP RELAY - REMOVAL, FUEL........14-34

PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD AND FUEL...............8I-4

PUMP, SPECIAL TOOLS - POWER

STEERING..........................19-20

PUMP VOLUME CHECK - STANDARD

PROCEDURE, OIL...................21-148

PUMP/MOTOR - DESCRIPTION, WASHER

. 8R-18

PUMP/MOTOR - INSTALLATION,

WASHER

...........................8R-20

PUMP/MOTOR - OPERATION, WASHER

. . . 8R-19

PUMP/MOTOR - REMOVAL, WASHER

....8R-19

QUARTER TRIM PANEL - INSTALLATION

. 23-159QUARTER TRIM PANEL - REMOVAL.....23-159

QUARTER WINDOW - INSTALLATION....23-172

QUARTER WINDOW - REMOVAL........23-172

QUICK CONNECT FITTING -

DESCRIPTION.......................14-10

QUICK LEARN - STANDARD

PROCEDURE, TCM...................8E-21

QUICK-CONNECT FITTINGS - STANDARD

PROCEDURE........................14-10

RACK - INSTALLATION, LUGGAGE......23-144

RACK - REMOVAL, LUGGAGE..........23-144

RADIAL-PLY TIRES - DESCRIPTION.......22-6

RADIATOR - CLEANING.................7-24

RADIATOR - DESCRIPTION..............7-22

RADIATOR - FAN - VISCOUS - CLEANING . . 7-29

RADIATOR - FAN - VISCOUS -

DESCRIPTION........................7-27

RADIATOR - FAN - VISCOUS -

INSPECTION.........................7-29

RADIATOR - FAN - VISCOUS -

INSTALLATION........................7-29

RADIATOR - FAN - VISCOUS -

OPERATION..........................7-27

RADIATOR - FAN - VISCOUS - REMOVAL . . . 7-28

RADIATOR - INSPECTION...............7-24

RADIATOR - INSTALLATION.............7-24

RADIATOR - REMOVAL.................7-23

RADIATOR CROSSMEMBER -

INSTALLATION......................23-146

RADIATOR CROSSMEMBER - REMOVAL . 23-146

RADIATOR FAN - ELECTRIC -

DESCRIPTION........................7-26

RADIATOR FAN - ELECTRIC -

INSTALLATION........................7-27

RADIATOR FAN - ELECTRIC -

OPERATION..........................7-26

RADIATOR FAN - ELECTRIC - REMOVAL . . . 7-26

RADIATOR PRESSURE CAP - CLEANING . . . 7-25

RADIATOR PRESSURE CAP -

DESCRIPTION........................7-25

RADIATOR PRESSURE CAP - DIAGNOSIS

AND TESTING........................7-25

RADIATOR PRESSURE CAP -

INSPECTION.........................7-25

RADIATOR PRESSURE CAP - OPERATION . . 7-25

RADIO - DESCRIPTION.................8A-8

RADIO - INSTALLATION................8A-9

RADIO - OPERATION...................8A-8

RADIO - REMOVAL....................8A-9

RADIO NOISE SUPPRESSION GROUND

STRAP - DESCRIPTION.................8A-9

RADIO NOISE SUPPRESSION GROUND

STRAP - INSTALLATION...............8A-11

RADIO NOISE SUPPRESSION GROUND

STRAP - OPERATION.................8A-10

RADIO NOISE SUPPRESSION GROUND

STRAP - REMOVAL...................8A-10

RAIL - DESCRIPTION, FUEL............14-21

RAIL - INSTALLATION, FUEL............14-24

RAIL - OPERATION, FUEL..............14-21

RAIL - REMOVAL, FUEL...............14-22

RAIL WEATHERSTRIP/RETAINER -

INSTALLATION, SIDE.................23-186

RAIL WEATHERSTRIP/RETAINER -

REMOVAL, SIDE....................23-186

RAMP - INSTALLATION, WIPER ARM

PARK..............................8R-43

RAMP - REMOVAL, WIPER ARM PARK . . . 8R-43

RANGE INDICATOR ILLUMINATION BULB

- INSTALLATION, TRANSMISSION........8L-83

RANGE INDICATOR ILLUMINATION BULB

- REMOVAL, TRANSMISSION

...........8L-82

RANGE SENSOR - DESCRIPTION,

TRANSMISSION

.....................21-168

RANGE SENSOR - OPERATION,

TRANSMISSION

.....................21-168

RATINGS, GAS ENGINES - GENERATOR

. . . 8F-23

RBI AXLE - INSTALLATION, 198

..........5-28

RBI AXLE - REMOVAL, 198

..............5-27

READING LAMP BULB - INSTALLATION

. . . 8L-79

READING LAMP BULB - REMOVAL

.......8L-79

READING LAMP SWITCH -

INSTALLATION

.......................8L-80

READING LAMP SWITCH - REMOVAL

.....8L-80

READING LAMP UNIT - INSTALLATION

. . . 8L-81

READING LAMP UNIT - REMOVAL

.......8L-81

REAR - DESCRIPTION

..................2-16REAR - INSTALLATION, CRANKSHAFT

OIL SEAL............................9-48

REAR - INSTALLATION, PROPELLER

SHAFT...............................3-7

REAR - INSTALLATION, SEAT..........23-168

REAR - INSTALLATION, SEAT BACK.....23-168

REAR - INSTALLATION, SEAT BACK

COVER............................23-169

REAR - INSTALLATION, SEAT BACK

CUSHION..........................23-170

REAR - INSTALLATION, SEAT BACK

FRAME............................23-171

REAR - INSTALLATION, SEAT CUSHION . . 23-171

REAR - REMOVAL, CRANKSHAFT OIL

SEAL...............................9-48

REAR AXLE - 198RBI - DESCRIPTION.....3-49

REAR AXLE - 198RBI - INSTALLATION.....3-54

REAR AXLE - 198RBI - OPERATION.......3-49

REAR AXLE - 198RBI - REMOVAL........3-54

REAR AXLE - 8 1/4 - ADJUSTMENTS......3-92

REAR AXLE - 8 1/4 - DESCRIPTION.......3-86

REAR AXLE - 8 1/4 - INSTALLATION......3-91

REAR AXLE - 8 1/4 - OPERATION.........3-86

REAR AXLE - 8 1/4 - REMOVAL..........3-91

REAR AXLE - SPECIFICATIONS...........3-62

REAR AXLE, SPECIAL TOOLS............3-63

REAR AXLE, SPECIFICATIONS............3-98

REAR BRAKE HOSE - INSTALLATION......5-10

REAR BRAKE HOSE - REMOVAL...........5-9

REAR CENTER SEAT BELT &

RETRACTOR - INSTALLATION...........8O-33

REAR CENTER SEAT BELT &

RETRACTOR - REMOVAL..............8O-32

REAR CHECK VALVE - DESCRIPTION.....8R-34

REAR CHECK VALVE - INSTALLATION....8R-35

REAR CHECK VALVE - OPERATION.......8R-34

REAR CHECK VALVE - REMOVAL........8R-34

REAR CROSSMEMBER - INSTALLATION....13-7

REAR CROSSMEMBER - REMOVAL.......13-7

REAR DOOR OUTER BELT MOLDING -

INSTALLATION......................23-186

REAR DOOR OUTER BELT MOLDING -

REMOVAL.........................23-186

REAR DOOR SCUFF PLATE -

INSTALLATION......................23-160

REAR DOOR SCUFF PLATE - REMOVAL . . 23-160

REAR DRUM BRAKE - ADJUSTMENT......5-12

REAR DRUM BRAKE - DESCRIPTION......5-10

REAR DRUM BRAKE - OPERATION........5-11

REAR FASCIA - INSTALLATION...........13-2

REAR FASCIA - REMOVAL...............13-2

REAR FASCIA SUPPORT - INSTALLATION . . 13-3

REAR FASCIA SUPPORT - REMOVAL......13-3

REAR FOG LAMP INDICATOR -

DESCRIPTION.......................8J-27

REAR FOG LAMP INDICATOR -

OPERATION.........................8J-27

REAR FOG LAMP RELAY - DESCRIPTION . . 8L-56

REAR FOG LAMP RELAY - DIAGNOSIS

AND TESTING.......................8L-57

REAR FOG LAMP RELAY -

INSTALLATION.......................8L-58

REAR FOG LAMP RELAY - OPERATION . . . 8L-57

REAR FOG LAMP RELAY - REMOVAL.....8L-58

REAR GLASS HEATING GRID REPAIR -

STANDARD PROCEDURE...............8G-4

REAR HVAC CONTROL ASSEMBLY

WINDOW DEFOGGER FUNCTION -

DIAGNOSIS AND TESTING..............8G-9

REAR LAMP BULB - INSTALLATION......8L-59

REAR LAMP BULB - REMOVAL..........8L-58

REAR LAMP UNIT - INSTALLATION......8L-60

REAR LAMP UNIT - REMOVAL..........8L-59

REAR MOUNT - INSTALLATION..........9-57

REAR MOUNT - REMOVAL..............9-57

REAR OUTBOARD SEAT BELT &

RETRACTOR - INSTALLATION...........8O-34

REAR OUTBOARD SEAT BELT &

RETRACTOR - REMOVAL..............8O-33

REAR OUTPUT SHAFT SEAL -

INSTALLATION

......................21-212

REAR OUTPUT SHAFT SEAL - REMOVAL

. 21-210

REAR SEAL AREA LEAKS - DIAGNOSIS

AND TESTING

........................9-61

REAR SEAT BACK LATCH / LOCK -

INSTALLATION, FOLDING

.............23-170

REAR SEAT BACK LATCH / LOCK -

REMOVAL, FOLDING

.................23-170

20 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1771 of 1803

COOLANT TEMPERATURE SENSOR -

OPERATION, ENGINE...................7-21

COOLANT TEMPERATURE SENSOR -

REMOVAL, ENGINE....................7-21

COOLER - DESCRIPTION, TRANS.........7-30

COOLERS AND TUBES - STANDARD

PROCEDURE, FLUSHING................7-30

COOLING, SPECIAL TOOLS..............7-13

COOLING SYSTEM - OPERATION..........7-2

COOLING SYSTEM - REVERSE

FLUSHING - STANDARD PROCEDURE.....7-12

COOLING SYSTEM - STANDARD

PROCEDURE, DRAINING................7-11

COOLING SYSTEM - STANDARD

PROCEDURE, REFILLING................7-11

COOLING SYSTEM 2.4L ENGINE -

DESCRIPTION.........................7-1

COOLING SYSTEM DIAGNOSIS CHART -

DIAGNOSIS AND TESTING...............7-5

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING.........................7-2

CORE AND OIL GALLERY PLUGS -

STANDARD PROCEDURE, ENGINE.........9-9

COVER - CLEANING, CYLINDER HEAD.....9-26

COVER - INSPECTION, CYLINDER HEAD . . . 9-26

COVER - INSTALLATION, CYLINDER

HEAD...............................9-26

COVER - REMOVAL, CYLINDER HEAD.....9-26

COVER(S) - INSTALLATION, TIMING

BELT ...............................9-53

COVER(S) - REMOVAL, TIMING BELT......9-53

CRANKSHAFT - DESCRIPTION...........9-32

CRANKSHAFT - INSPECTION.............9-34

CRANKSHAFT - INSTALLATION...........9-34

CRANKSHAFT - OPERATION.............9-33

CRANKSHAFT - REMOVAL..............9-33

CRANKSHAFT END PLAY - STANDARD

PROCEDURE.........................9-33

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION........................9-37

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL...........................9-37

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION........................9-39

CRANKSHAFT OIL SEAL - REAR -

REMOVAL...........................9-38

CRANKSHAFT SPROCKET -

INSTALLATION........................9-56

CRANKSHAFT SPROCKET - REMOVAL.....9-55

CROSS-OVER PIPE - INSTALLATION.......11-4

CROSS-OVER PIPE - REMOVAL..........11-4

CYLINDER BORE FITTING - STANDARD

PROCEDURE, PISTON TO...............9-30

CYLINDER BORE HONING - STANDARD

PROCEDURE.........................9-31

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST - DIAGNOSIS AND

TESTING.............................9-3

CYLINDER COMPRESSION PRESSURE

TEST - DIAGNOSIS AND TESTING.........9-3

CYLINDER HEAD - CLEANING............9-20

CYLINDER HEAD - DESCRIPTION.........9-19

CYLINDER HEAD - INSPECTION..........9-21

CYLINDER HEAD - INSTALLATION........9-21

CYLINDER HEAD - OPERATION...........9-19

CYLINDER HEAD - REMOVAL............9-20

CYLINDER HEAD COVER - CLEANING......9-26

CYLINDER HEAD COVER - INSPECTION....9-26

CYLINDER HEAD COVER -

INSTALLATION

........................9-26

CYLINDER HEAD COVER - REMOVAL

......9-26

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING

........................9-19

CYLINDER HEAD OFF - INSTALLATION

.....9-28

CYLINDER HEAD OFF - REMOVAL

........9-27

CYLINDER HEAD ON - INSTALLATION

.....9-28

CYLINDER HEAD ON - REMOVAL

.........9-27

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR OF

.......9-9

DAMPER - INSTALLATION, VIBRATION

.....9-43

DAMPER - REMOVAL, VIBRATION

........9-43

DAYTIME RUNNING LAMP RELAY -

DESCRIPTION

.......................8L-20

DAYTIME RUNNING LAMP RELAY -

INSTALLATION

.......................8L-21

DAYTIME RUNNING LAMP RELAY -

OPERATION

.........................8L-20DAYTIME RUNNING LAMP RELAY -

REMOVAL..........................8L-21

DESCRIPTION - OPERATION.............7-20

DESCRIPTION, BACKUP LAMP SWITCH . . . 8L-15

DESCRIPTION, BALANCE SHAFT..........9-59

DESCRIPTION, BRAKE LAMP SWITCH....8L-16

DESCRIPTION, CAMSHAFT(S)............9-23

DESCRIPTION, CATALYTIC CONVERTER....11-2

DESCRIPTION, COMBINATION FLASHER . . . 8L-19

DESCRIPTION, COOLANT RECOVERY

PRESS CONTAINER....................7-20

DESCRIPTION, COOLING SYSTEM 2.4L

ENGINE..............................7-1

DESCRIPTION, CRANKSHAFT............9-32

DESCRIPTION, CYLINDER HEAD..........9-19

DESCRIPTION, DAYTIME RUNNING

LAMP RELAY........................8L-20

DESCRIPTION, ENGINE - 2.4L.............9-3

DESCRIPTION, ENGINE BLOCK...........9-30

DESCRIPTION, ENGINE BLOCK HEATER -

2.4L................................7-20

DESCRIPTION, ENGINE COOLANT.........7-19

DESCRIPTION, ENGINE COOLANT

TEMPERATURE SENSOR................7-21

DESCRIPTION, ENGINE MOUNTING.......9-44

DESCRIPTION, EXHAUST MANIFOLD......9-53

DESCRIPTION, EXHAUST SYSTEM........11-1

DESCRIPTION, FRONT FOG LAMP RELAY . . 8L-22

DESCRIPTION, HAZARD SWITCH........8L-28

DESCRIPTION, HEADLAMP HIGH BEAM

RELAY.............................8L-33

DESCRIPTION, HEADLAMP LEVELING

MOTOR............................8L-35

DESCRIPTION, HEADLAMP LEVELING

SWITCH............................8L-37

DESCRIPTION, HEADLAMP LOW BEAM

RELAY.............................8L-39

DESCRIPTION, HEAT SHIELDS...........11-4

DESCRIPTION, HOAT COOLANT..........7-18

DESCRIPTION, HOSE CLAMPS............7-1

DESCRIPTION, INTAKE MANIFOLD........9-51

DESCRIPTION, INTAKE/EXHAUST VALVES

& SEATS ............................9-27

DESCRIPTION, LAMP BAR.............8L-65

DESCRIPTION, LAMP BAR SWITCH......8L-67

DESCRIPTION, LAMPS/LIGHTING -

EXTERIOR...........................8L-2

DESCRIPTION, LUBRICATION............9-46

DESCRIPTION, MUFFLER...............11-4

DESCRIPTION, MULTI-FUNCTION

SWITCH............................8L-46

DESCRIPTION, OIL FILTER..............9-47

DESCRIPTION, OIL PRESSURE

SENSOR/SWITCH.....................9-48

DESCRIPTION, PARK LAMP RELAY.......8L-54

DESCRIPTION, PISTON & CONNECTING

ROD................................9-40

DESCRIPTION, RADIATOR...............7-22

DESCRIPTION, RADIATOR FAN -

ELECTRIC...........................7-26

DESCRIPTION, RADIATOR PRESSURE

CAP ................................7-25

DESCRIPTION, REAR FOG LAMP RELAY . . . 8L-56

DESCRIPTION, TRAILER TOW RELAY.....8L-62

DESCRIPTION, TRAILER TOW WIRING....8L-64

DESCRIPTION, TRANS COOLER..........7-30

DESCRIPTION, WATER PUMP - 2.4L......7-27

DIAGNOSIS - DIAGNOSIS AND TESTING,

LASH ADJUSTER (TAPPET) NOISE........9-28

DIAGNOSIS - DIAGNOSIS AND TESTING,

SERPENTINE DRIVE BELT...............7-15

DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING, ENGINE........9-5

DIAGNOSIS AND TESTING, BACKUP

LAMP SWITCH......................8L-15

DIAGNOSIS AND TESTING, BRAKE LAMP

SWITCH............................8L-17

DIAGNOSIS AND TESTING, COOLING

SYSTEM DIAGNOSIS CHART

..............7-5

DIAGNOSIS AND TESTING, COOLING

SYSTEM LEAKS

........................7-2

DIAGNOSIS AND TESTING, CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST

................................9-3

DIAGNOSIS AND TESTING, CYLINDER

COMPRESSION PRESSURE TEST

..........9-3

DIAGNOSIS AND TESTING, CYLINDER

HEAD GASKET

........................9-19DIAGNOSIS AND TESTING, ENGINE........9-5

DIAGNOSIS AND TESTING, ENGINE

DIAGNOSIS - PERFORMANCE.............9-5

DIAGNOSIS AND TESTING, ENGINE

MECHANICAL.........................9-7

DIAGNOSIS AND TESTING, ENGINE OIL

LEAK INSPECTION......................9-4

DIAGNOSIS AND TESTING, ENGINE OIL

PRESSURE CHECKING.................9-46

DIAGNOSIS AND TESTING, EXHAUST

SYSTEM............................11-2

DIAGNOSIS AND TESTING, FRONT FOG

LAMP RELAY........................8L-23

DIAGNOSIS AND TESTING, HEADLAMP

HIGH BEAM RELAY...................8L-34

DIAGNOSIS AND TESTING, HEADLAMP

LEVELING SWITCH...................8L-37

DIAGNOSIS AND TESTING, HEADLAMP

LOW BEAM RELAY...................8L-40

DIAGNOSIS AND TESTING, INTAKE

MANIFOLD LEAKS.....................9-51

DIAGNOSIS AND TESTING, LAMP BAR....8L-65

DIAGNOSIS AND TESTING, LAMPS/

LIGHTING - EXTERIOR.................8L-7

DIAGNOSIS AND TESTING, LASH

ADJUSTER (TAPPET) NOISE

DIAGNOSIS..........................9-28

DIAGNOSIS AND TESTING, MULTI-

FUNCTION SWITCH...................8L-50

DIAGNOSIS AND TESTING, ON-BOARD

DIAGNOSTICS (OBD)....................7-2

DIAGNOSIS AND TESTING, PARK LAMP

RELAY.............................8L-55

DIAGNOSIS AND TESTING,

PRELIMINARY CHECKS..................7-2

DIAGNOSIS AND TESTING, RADIATOR

PRESSURE CAP.......................7-25

DIAGNOSIS AND TESTING, REAR FOG

LAMP RELAY........................8L-57

DIAGNOSIS AND TESTING, SERPENTINE

DRIVE BELT DIAGNOSIS................7-15

DIAGNOSIS AND TESTING, TRAILER

TOW RELAY.........................8L-62

DIAGNOSIS CHART - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-5

DIAGNOSTICS (OBD) - DIAGNOSIS AND

TESTING, ON-BOARD...................7-2

DISASSEMBLY, OIL PUMP...............9-49

DRAINING COOLING SYSTEM -

STANDARD PROCEDURE................7-11

DRIVE BELT DIAGNOSIS - DIAGNOSIS

AND TESTING, SERPENTINE.............7-15

ELECTRIC - DESCRIPTION, RADIATOR

FAN ................................7-26

ELECTRIC - INSTALLATION, RADIATOR

FAN ................................7-27

ELECTRIC - OPERATION, RADIATOR FAN . . . 7-26

ELECTRIC - REMOVAL, RADIATOR FAN....7-26

END PLAY - STANDARD PROCEDURE,

CRANKSHAFT........................9-33

END-PLAY - STANDARD PROCEDURE,

CAMSHAFT..........................9-23

ENGINE - 2.4L - DESCRIPTION............9-3

ENGINE - DESCRIPTION, COOLING

SYSTEM 2.4L.........................7-1

ENGINE - DIAGNOSIS AND TESTING.......9-5

ENGINE - INSTALLATION, 2.4L . . 7-14,7-17,7-22,

7-28

ENGINE - REMOVAL, 2.4L . . . 7-14,7-16,7-22,7-27

ENGINE - SPECIFICATIONS, 2.4L.........9-13

ENGINE - STANDARD PROCEDURE,

HYDROSTATIC LOCKED..................9-9

ENGINE ASSEMBLY - INSTALLATION......9-12

ENGINE ASSEMBLY - REMOVAL..........9-12

ENGINE BLOCK - DESCRIPTION..........9-30

ENGINE BLOCK HEATER - 2.4L -

DESCRIPTION........................7-20

ENGINE BLOCK HEATER - 2.4L -

OPERATION..........................7-20

ENGINE COOLANT - DESCRIPTION

........7-19

ENGINE COOLANT TEMPERATURE

SENSOR - DESCRIPTION

...............7-21

ENGINE COOLANT TEMPERATURE

SENSOR - INSTALLATION

...............7-22

ENGINE COOLANT TEMPERATURE

SENSOR - OPERATION

.................7-21

ENGINE COOLANT TEMPERATURE

SENSOR - REMOVAL

...................7-21

2 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1772 of 1803

ENGINE CORE AND OIL GALLERY PLUGS

- STANDARD PROCEDURE...............9-9

ENGINE DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING...............9-5

ENGINE GASKET SURFACE

PREPARATION - STANDARD

PROCEDURE.........................9-11

ENGINE MECHANICAL - DIAGNOSIS AND

TESTING.............................9-7

ENGINE MOUNTING - DESCRIPTION......9-44

ENGINE OIL AND FILTER CHANGE -

STANDARD PROCEDURE................9-47

ENGINE OIL LEAK INSPECTION -

DIAGNOSIS AND TESTING...............9-4

ENGINE OIL LEVEL CHECK, STANDARD

PROCEDURE.........................9-47

ENGINE OIL PRESSURE CHECKING -

DIAGNOSIS AND TESTING..............9-46

ENGINE, SPECIAL TOOLS - 2.4L..........9-17

EXHAUST MANIFOLD - CLEANING........9-53

EXHAUST MANIFOLD - DESCRIPTION.....9-53

EXHAUST MANIFOLD - INSPECTION.......9-53

EXHAUST MANIFOLD - INSTALLATION.....9-53

EXHAUST MANIFOLD - OPERATION.......9-53

EXHAUST MANIFOLD - REMOVAL.........9-53

EXHAUST SYSTEM - DESCRIPTION.......11-1

EXHAUST SYSTEM - DIAGNOSIS AND

TESTING............................11-2

EXTERIOR - DESCRIPTION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR - DIAGNOSIS AND TESTING,

LAMPS/LIGHTING.....................8L-7

EXTERIOR - OPERATION, LAMPS/

LIGHTING...........................8L-5

EXTERIOR - SPECIFICATIONS,

LAMPS/LIGHTING....................8L-15

FAN - ELECTRIC - DESCRIPTION,

RADIATOR...........................7-26

FAN - ELECTRIC - INSTALLATION,

RADIATOR...........................7-27

FAN - ELECTRIC - OPERATION,

RADIATOR...........................7-26

FAN - ELECTRIC - REMOVAL, RADIATOR . . . 7-26

FILTER - DESCRIPTION, OIL.............9-47

FILTER - INSTALLATION, OIL............9-47

FILTER - REMOVAL, OIL................9-47

FILTER CHANGE - STANDARD

PROCEDURE, ENGINE OIL...............9-47

FITTING - CONNECTING ROD............9-32

FITTING - PISTON RING................9-42

FITTING - STANDARD PROCEDURE,

MAIN BEARING.......................9-35

FITTING - STANDARD PROCEDURE,

PISTON TO CYLINDER BORE............9-30

FLASHER - DESCRIPTION, COMBINATION . 8L-19

FLASHER - OPERATION, COMBINATION . . . 8L-19

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM - REVERSE...........7-12

FLUSHING COOLERS AND TUBES -

STANDARD PROCEDURE................7-30

FOG LAMP BULB - INSTALLATION,

FRONT.............................8L-22

FOG LAMP BULB - REMOVAL, FRONT....8L-21

FOG LAMP RELAY - DESCRIPTION,

FRONT.............................8L-22

FOG LAMP RELAY - DESCRIPTION, REAR . 8L-56

FOG LAMP RELAY - DIAGNOSIS AND

TESTING, FRONT.....................8L-23

FOG LAMP RELAY - DIAGNOSIS AND

TESTING, REAR......................8L-57

FOG LAMP RELAY - INSTALLATION,

FRONT.............................8L-24

FOG LAMP RELAY - INSTALLATION,

REAR..............................8L-58

FOG LAMP RELAY - OPERATION, FRONT . . 8L-22

FOG LAMP RELAY - OPERATION, REAR . . . 8L-57

FOG LAMP RELAY - REMOVAL, FRONT . . . 8L-24

FOG LAMP RELAY - REMOVAL, REAR....8L-58

FOG LAMP UNIT - ADJUSTMENT, FRONT . . 8L-25

FOG LAMP UNIT - INSTALLATION,

FRONT

.............................8L-25

FOG LAMP UNIT - REMOVAL, FRONT

.....8L-24

FORM-IN-PLACE GASKETS AND

SEALERS - STANDARD PROCEDURE

......9-10

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL

............................9-37

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL

...............................9-37FRONT FOG LAMP BULB -

INSTALLATION.......................8L-22

FRONT FOG LAMP BULB - REMOVAL.....8L-21

FRONT FOG LAMP RELAY -

DESCRIPTION.......................8L-22

FRONT FOG LAMP RELAY - DIAGNOSIS

AND TESTING.......................8L-23

FRONT FOG LAMP RELAY -

INSTALLATION.......................8L-24

FRONT FOG LAMP RELAY - OPERATION . . 8L-22

FRONT FOG LAMP RELAY - REMOVAL....8L-24

FRONT FOG LAMP UNIT - ADJUSTMENT . . 8L-25

FRONT FOG LAMP UNIT - INSTALLATION . . 8L-25

FRONT FOG LAMP UNIT - REMOVAL.....8L-24

FRONT LAMP BULB - INSTALLATION.....8L-27

FRONT LAMP BULB - REMOVAL.........8L-27

FRONT LAMP UNIT - INSTALLATION.....8L-28

FRONT LAMP UNIT - REMOVAL.........8L-27

FRONT MOUNT - INSTALLATION..........9-44

FRONT MOUNT - REMOVAL.............9-44

FRONT POSITION LAMP BULB -

INSTALLATION.......................8L-28

FRONT POSITION LAMP BULB -

REMOVAL..........................8L-28

FRONT SUSPENSION, SPECIAL TOOLS.....2-1

GALLERY PLUGS - STANDARD

PROCEDURE, ENGINE CORE AND OIL......9-9

GASKET - DIAGNOSIS AND TESTING,

CYLINDER HEAD......................9-19

GASKET SURFACE PREPARATION -

STANDARD PROCEDURE, ENGINE........9-11

GASKETS AND SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE...........9-10

HAZARD SWITCH - DESCRIPTION.......8L-28

HAZARD SWITCH - INSTALLATION.......8L-30

HAZARD SWITCH - OPERATION.........8L-29

HAZARD SWITCH - REMOVAL..........8L-29

HEAD - CLEANING, CYLINDER...........9-20

HEAD - DESCRIPTION, CYLINDER........9-19

HEAD - INSPECTION, CYLINDER..........9-21

HEAD - INSTALLATION, CYLINDER........9-21

HEAD - OPERATION, CYLINDER..........9-19

HEAD - REMOVAL, CYLINDER...........9-20

HEAD COVER - CLEANING, CYLINDER.....9-26

HEAD COVER - INSPECTION, CYLINDER . . . 9-26

HEAD COVER - INSTALLATION,

CYLINDER...........................9-26

HEAD COVER - REMOVAL, CYLINDER.....9-26

HEAD GASKET - DIAGNOSIS AND

TESTING, CYLINDER...................9-19

HEAD OFF - INSTALLATION, CYLINDER....9-28

HEAD OFF - REMOVAL, CYLINDER........9-27

HEAD ON - INSTALLATION, CYLINDER.....9-28

HEAD ON - REMOVAL, CYLINDER........9-27

HEADLAMP BULB - INSTALLATION.......8L-32

HEADLAMP BULB - REMOVAL..........8L-30

HEADLAMP HIGH BEAM RELAY -

DESCRIPTION.......................8L-33

HEADLAMP HIGH BEAM RELAY -

DIAGNOSIS AND TESTING.............8L-34

HEADLAMP HIGH BEAM RELAY -

INSTALLATION.......................8L-35

HEADLAMP HIGH BEAM RELAY -

OPERATION.........................8L-33

HEADLAMP HIGH BEAM RELAY -

REMOVAL..........................8L-34

HEADLAMP LEVELING MOTOR -

DESCRIPTION.......................8L-35

HEADLAMP LEVELING MOTOR -

INSTALLATION.......................8L-36

HEADLAMP LEVELING MOTOR -

OPERATION.........................8L-36

HEADLAMP LEVELING MOTOR -

REMOVAL..........................8L-36

HEADLAMP LEVELING SWITCH -

DESCRIPTION.......................8L-37

HEADLAMP LEVELING SWITCH -

DIAGNOSIS AND TESTING.............8L-37

HEADLAMP LEVELING SWITCH -

INSTALLATION

.......................8L-38

HEADLAMP LEVELING SWITCH -

OPERATION

.........................8L-37

HEADLAMP LEVELING SWITCH -

REMOVAL

..........................8L-38

HEADLAMP LOW BEAM RELAY -

DESCRIPTION

.......................8L-39

HEADLAMP LOW BEAM RELAY -

DIAGNOSIS AND TESTING

.............8L-40HEADLAMP LOW BEAM RELAY -

INSTALLATION.......................8L-41

HEADLAMP LOW BEAM RELAY -

OPERATION.........................8L-39

HEADLAMP LOW BEAM RELAY -

REMOVAL..........................8L-40

HEADLAMP UNIT - ADJUSTMENT........8L-42

HEADLAMP UNIT - INSTALLATION.......8L-42

HEADLAMP UNIT - REMOVAL...........8L-41

HEAT SHIELDS - DESCRIPTION..........11-4

HEATER - 2.4L - DESCRIPTION, ENGINE

BLOCK..............................7-20

HEATER - 2.4L - OPERATION, ENGINE

BLOCK..............................7-20

HIGH BEAM RELAY - DESCRIPTION,

HEADLAMP.........................8L-33

HIGH BEAM RELAY - DIAGNOSIS AND

TESTING, HEADLAMP.................8L-34

HIGH BEAM RELAY - INSTALLATION,

HEADLAMP.........................8L-35

HIGH BEAM RELAY - OPERATION,

HEADLAMP.........................8L-33

HIGH BEAM RELAY - REMOVAL,

HEADLAMP.........................8L-34

HIGH MOUNTED STOP LAMP BULB -

INSTALLATION, CENTER...............8L-19

HIGH MOUNTED STOP LAMP BULB -

REMOVAL, CENTER...................8L-18

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER...............8L-19

HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER...................8L-19

HOAT COOLANT - DESCRIPTION..........7-18

HONING - STANDARD PROCEDURE,

CYLINDER BORE......................9-31

HOSE CLAMPS - DESCRIPTION...........7-1

HOSE CLAMPS - OPERATION.............7-2

HYDRAULIC LIFTERS - INSTALLATION.....9-29

HYDRAULIC LIFTERS - REMOVAL.........9-29

HYDROSTATIC LOCKED ENGINE -

STANDARD PROCEDURE.................9-9

INSPECTION - DIAGNOSIS AND

TESTING, ENGINE OIL LEAK..............9-4

INSPECTION, CAMSHAFT(S).............9-25

INSPECTION, CATALYTIC CONVERTER.....11-3

INSPECTION, CRANKSHAFT.............9-34

INSPECTION, CYLINDER HEAD...........9-21

INSPECTION, CYLINDER HEAD COVER.....9-26

INSPECTION, EXHAUST MANIFOLD.......9-53

INSPECTION, INTAKE MANIFOLD.........9-52

INSPECTION, OIL PUMP................9-50

INSPECTION, RADIATOR................7-24

INSPECTION, RADIATOR PRESSURE CAP . . . 7-25

INSPECTION, REMOVAL................9-28

INSPECTION, ROCKER ARMS............9-30

INSPECTION, STANDARD PROCEDURE.....9-32

INSPECTION, WATER PUMP - 2.4L........7-28

INSTALLATION - BALANCE SHAFT

TIMING.............................9-61

INSTALLATION, 2.4L...................7-20

INSTALLATION, 2.4L...................9-19

INSTALLATION, 2.4L ENGINE....7-14,7-17,7-22,

7-28

INSTALLATION, BALANCE SHAFT

CARRIER............................9-64

INSTALLATION, BALANCE SHAFT CHAIN . . . 9-64

INSTALLATION, BRAKE LAMP SWITCH....8L-18

INSTALLATION, CAMSHAFT OIL SEAL(S) . . . 9-22

INSTALLATION, CAMSHAFT(S)...........9-25

INSTALLATION, CATALYTIC CONVERTER

....11-3

INSTALLATION, CENTER HIGH MOUNTED

STOP LAMP BULB

....................8L-19

INSTALLATION, CENTER HIGH MOUNTED

STOP LAMP UNIT

....................8L-19

INSTALLATION, CLEVIS BRACKET

BUSHING

.............................2-4

INSTALLATION, CRANKSHAFT

............9-34

INSTALLATION, CRANKSHAFT OIL SEAL -

FRONT

..............................9-37

INSTALLATION, CRANKSHAFT OIL SEAL -

REAR

...............................9-39

INSTALLATION, CRANKSHAFT SPROCKET

. . 9-56

INSTALLATION, CROSS-OVER PIPE

.......11-4

INSTALLATION, CYLINDER HEAD

.........9-21

INSTALLATION, CYLINDER HEAD COVER

. . . 9-26

INSTALLATION, CYLINDER HEAD OFF

......9-28

INSTALLATION, CYLINDER HEAD ON

......9-28

KJINDEX 3

Description Group-Page Description Group-Page Description Group-Page

Page 1773 of 1803

INSTALLATION, DAYTIME RUNNING

LAMP RELAY........................8L-21

INSTALLATION, ENGINE ASSEMBLY.......9-12

INSTALLATION, ENGINE COOLANT

TEMPERATURE SENSOR................7-22

INSTALLATION, EXHAUST MANIFOLD......9-53

INSTALLATION, FRONT FOG LAMP BULB . . 8L-22

INSTALLATION, FRONT FOG LAMP

RELAY.............................8L-24

INSTALLATION, FRONT FOG LAMP UNIT . . 8L-25

INSTALLATION, FRONT LAMP BULB......8L-27

INSTALLATION, FRONT LAMP UNIT......8L-28

INSTALLATION, FRONT MOUNT..........9-44

INSTALLATION, FRONT POSITION LAMP

BULB..............................8L-28

INSTALLATION, HAZARD SWITCH........8L-30

INSTALLATION, HEADLAMP BULB.......8L-32

INSTALLATION, HEADLAMP HIGH BEAM

RELAY.............................8L-35

INSTALLATION, HEADLAMP LEVELING

MOTOR............................8L-36

INSTALLATION, HEADLAMP LEVELING

SWITCH............................8L-38

INSTALLATION, HEADLAMP LOW BEAM

RELAY.............................8L-41

INSTALLATION, HEADLAMP UNIT........8L-42

INSTALLATION, HYDRAULIC LIFTERS......9-29

INSTALLATION, INTAKE MANIFOLD........9-52

INSTALLATION, LAMP.................8L-66

INSTALLATION, LAMP BAR.............8L-66

INSTALLATION, LAMP BAR SWITCH......8L-67

INSTALLATION, LICENSE PLATE LAMP

BULB..............................8L-45

INSTALLATION, LICENSE PLATE LAMP

UNIT..............................8L-46

INSTALLATION, LOWER BALL JOINT.......2-5

INSTALLATION, LOWER CONTROL ARM

BUSHING.............................2-3

INSTALLATION, LOWER SUSPENSION

ARM BUSHING........................2-8

INSTALLATION, MUFFLER...............11-5

INSTALLATION, MULTI-FUNCTION

SWITCH............................8L-53

INSTALLATION, OIL FILTER..............9-47

INSTALLATION, OIL PAN................9-48

INSTALLATION, OIL PUMP..............9-50

INSTALLATION, PARK LAMP RELAY......8L-56

INSTALLATION, PISTON & CONNECTING

ROD................................9-41

INSTALLATION, RADIATOR..............7-24

INSTALLATION, RADIATOR FAN -

ELECTRIC...........................7-27

INSTALLATION, REAR FOG LAMP RELAY . . 8L-58

INSTALLATION, REAR LAMP BULB.......8L-59

INSTALLATION, REAR LAMP UNIT.......8L-60

INSTALLATION, REAR MOUNT...........9-45

INSTALLATION, REPEATER LAMP BULB . . . 8L-60

INSTALLATION, REPEATER LAMP UNIT . . . 8L-61

INSTALLATION, RHD....................5-1

INSTALLATION, ROCKER ARMS..........9-30

INSTALLATION, STRUCTURAL COLLAR....9-44

INSTALLATION, TIMING BELT............9-56

INSTALLATION, TIMING BELT COVER(S) . . . 9-53

INSTALLATION, TIMING BELT

TENSIONER & PULLEY.................9-59

INSTALLATION, TRAILER TOW

CONNECTOR........................8L-61

INSTALLATION, TRAILER TOW RELAY....8L-63

INSTALLATION, UPPER BALL JOINT........2-6

INSTALLATION, UPPER CONTROL ARM

BUSHINGS............................2-4

INSTALLATION, UPPER SUSPENSION

ARM BUSHING........................2-8

INSTALLATION, VIBRATION DAMPER......9-43

INTAKE MANIFOLD - DESCRIPTION.......9-51

INTAKE MANIFOLD - INSPECTION........9-52

INTAKE MANIFOLD - INSTALLATION.......9-52

INTAKE MANIFOLD - OPERATION.........9-51

INTAKE MANIFOLD - REMOVAL..........9-52

INTAKE MANIFOLD LEAKS - DIAGNOSIS

AND TESTING........................9-51

INTAKE/EXHAUST VALVES & SEATS -

CLEANING

...........................9-27

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION

........................9-27

JOINT - INSTALLATION, LOWER BALL

......2-5

JOINT - INSTALLATION, UPPER BALL

......2-6

JOINT - REMOVAL, LOWER BALL

..........2-5JOINT - REMOVAL, UPPER BALL..........2-6

LAMP - INSTALLATION................8L-66

LAMP - REMOVAL....................8L-66

LAMP BAR - DESCRIPTION.............8L-65

LAMP BAR - DIAGNOSIS AND TESTING . . . 8L-65

LAMP BAR - INSTALLATION............8L-66

LAMP BAR - OPERATION..............8L-65

LAMP BAR - REMOVAL................8L-65

LAMP BAR AIMING - STANDARD

PROCEDURE........................8L-65

LAMP BAR SWITCH - DESCRIPTION.....8L-67

LAMP BAR SWITCH - INSTALLATION.....8L-67

LAMP BAR SWITCH - REMOVAL.........8L-67

LAMP BULB - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-19

LAMP BULB - INSTALLATION, FRONT....8L-27

LAMP BULB - INSTALLATION, FRONT

FOG ...............................8L-22

LAMP BULB - INSTALLATION, FRONT

POSITION..........................8L-28

LAMP BULB - INSTALLATION, LICENSE

PLATE .............................8L-45

LAMP BULB - INSTALLATION, REAR.....8L-59

LAMP BULB - INSTALLATION, REPEATER . . 8L-60

LAMP BULB - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-18

LAMP BULB - REMOVAL, FRONT........8L-27

LAMP BULB - REMOVAL, FRONT FOG....8L-21

LAMP BULB - REMOVAL, FRONT

POSITION..........................8L-28

LAMP BULB - REMOVAL, LICENSE

PLATE .............................8L-44

LAMP BULB - REMOVAL, REAR.........8L-59

LAMP BULB - REMOVAL, REPEATER.....8L-60

LAMP RELAY - DESCRIPTION, DAYTIME

RUNNING...........................8L-20

LAMP RELAY - DESCRIPTION, FRONT

FOG ...............................8L-22

LAMP RELAY - DESCRIPTION, PARK.....8L-54

LAMP RELAY - DESCRIPTION, REAR FOG . 8L-56

LAMP RELAY - DIAGNOSIS AND

TESTING, FRONT FOG.................8L-23

LAMP RELAY - DIAGNOSIS AND

TESTING, PARK......................8L-55

LAMP RELAY - DIAGNOSIS AND

TESTING, REAR FOG..................8L-57

LAMP RELAY - INSTALLATION, DAYTIME

RUNNING...........................8L-21

LAMP RELAY - INSTALLATION, FRONT

FOG ...............................8L-24

LAMP RELAY - INSTALLATION, PARK.....8L-56

LAMP RELAY - INSTALLATION, REAR

FOG ...............................8L-58

LAMP RELAY - OPERATION, DAYTIME

RUNNING...........................8L-20

LAMP RELAY - OPERATION, FRONT FOG . . 8L-22

LAMP RELAY - OPERATION, PARK.......8L-54

LAMP RELAY - OPERATION, REAR FOG . . . 8L-57

LAMP RELAY - REMOVAL, DAYTIME

RUNNING...........................8L-21

LAMP RELAY - REMOVAL, FRONT FOG . . . 8L-24

LAMP RELAY - REMOVAL, PARK........8L-55

LAMP RELAY - REMOVAL, REAR FOG....8L-58

LAMP SWITCH - DESCRIPTION, BACKUP . . 8L-15

LAMP SWITCH - DESCRIPTION, BRAKE . . . 8L-16

LAMP SWITCH - DIAGNOSIS AND

TESTING, BACKUP....................8L-15

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE.....................8L-17

LAMP SWITCH - INSTALLATION, BRAKE . . 8L-18

LAMP SWITCH - OPERATION, BACKUP . . . 8L-15

LAMP SWITCH - OPERATION, BRAKE.....8L-16

LAMP SWITCH - REMOVAL, BRAKE......8L-17

LAMP UNIT - ADJUSTMENT, FRONT FOG . . 8L-25

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-19

LAMP UNIT - INSTALLATION, FRONT.....8L-28

LAMP UNIT - INSTALLATION, FRONT

FOG ...............................8L-25

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-46

LAMP UNIT - INSTALLATION, REAR......8L-60

LAMP UNIT - INSTALLATION, REPEATER

. . 8L-61

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP

.....................8L-19

LAMP UNIT - REMOVAL, FRONT

.........8L-27

LAMP UNIT - REMOVAL, FRONT FOG

.....8L-24

LAMP UNIT - REMOVAL, LICENSE PLATE

. . 8L-45LAMP UNIT - REMOVAL, REAR..........8L-59

LAMP UNIT - REMOVAL, REPEATER......8L-61

LAMPS/LIGHTING - EXTERIOR -

DESCRIPTION........................8L-2

LAMPS/LIGHTING - EXTERIOR -

DIAGNOSIS AND TESTING..............8L-7

LAMPS/LIGHTING - EXTERIOR -

OPERATION..........................8L-5

LAMPS/LIGHTING - EXTERIOR -

SPECIFICATIONS.....................8L-15

LASH ADJUSTER (TAPPET) NOISE

DIAGNOSIS - DIAGNOSIS AND

TESTING............................9-28

LEAK INSPECTION - DIAGNOSIS AND

TESTING, ENGINE OIL...................9-4

LEAKAGE TEST - DIAGNOSIS AND

TESTING, CYLINDER COMBUSTION

PRESSURE...........................9-3

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM.....................7-2

LEAKS - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD....................9-51

LEVEL CHECK, STANDARD PROCEDURE

- ENGINE OIL........................9-47

LEVELING MOTOR - DESCRIPTION,

HEADLAMP.........................8L-35

LEVELING MOTOR - INSTALLATION,

HEADLAMP.........................8L-36

LEVELING MOTOR - OPERATION,

HEADLAMP.........................8L-36

LEVELING MOTOR - REMOVAL,

HEADLAMP.........................8L-36

LEVELING SWITCH - DESCRIPTION,

HEADLAMP...........................8L-37

LEVELING SWITCH - DIAGNOSIS AND

TESTING, HEADLAMP.................8L-37

LEVELING SWITCH - INSTALLATION,

HEADLAMP.........................8L-38

LEVELING SWITCH - OPERATION,

HEADLAMP.........................8L-37

LEVELING SWITCH - REMOVAL,

HEADLAMP.........................8L-38

LICENSE PLATE LAMP BULB -

INSTALLATION.......................8L-45

LICENSE PLATE LAMP BULB - REMOVAL . . 8L-44

LICENSE PLATE LAMP UNIT -

INSTALLATION.......................8L-46

LICENSE PLATE LAMP UNIT - REMOVAL . . 8L-45

LIFTERS - INSTALLATION, HYDRAULIC....9-29

LIFTERS - REMOVAL, HYDRAULIC........9-29

LOCKED ENGINE - STANDARD

PROCEDURE, HYDROSTATIC..............9-9

LOW BEAM RELAY - DESCRIPTION,

HEADLAMP.........................8L-39

LOW BEAM RELAY - DIAGNOSIS AND

TESTING, HEADLAMP.................8L-40

LOW BEAM RELAY - INSTALLATION,

HEADLAMP.........................8L-41

LOW BEAM RELAY - OPERATION,

HEADLAMP.........................8L-39

LOW BEAM RELAY - REMOVAL,

HEADLAMP.........................8L-40

LOWER BALL JOINT - INSTALLATION......2-5

LOWER BALL JOINT - REMOVAL..........2-5

LOWER CONTROL ARM BUSHING -

INSTALLATION.........................2-3

LOWER CONTROL ARM BUSHING -

REMOVAL............................2-2

LOWER SUSPENSION ARM BUSHING -

INSTALLATION.........................2-8

LOWER SUSPENSION ARM BUSHING -

REMOVAL............................2-7

LUBRICATION - DESCRIPTION...........9-46

LUBRICATION - OPERATION

.............9-46

MAIN BEARING - FITTING - STANDARD

PROCEDURE

.........................9-35

MANIFOLD - CLEANING, EXHAUST

........9-53

MANIFOLD - DESCRIPTION, EXHAUST

.....9-53

MANIFOLD - DESCRIPTION, INTAKE

.......9-51

MANIFOLD - INSPECTION, EXHAUST

......9-53

MANIFOLD - INSPECTION, INTAKE

........9-52

MANIFOLD - INSTALLATION, EXHAUST

....9-53

MANIFOLD - INSTALLATION, INTAKE

......9-52

MANIFOLD - OPERATION, EXHAUST

.......9-53

MANIFOLD - OPERATION, INTAKE

........9-51

MANIFOLD - REMOVAL, EXHAUST

........9-53

MANIFOLD - REMOVAL, INTAKE

..........9-52

4 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1774 of 1803

MANIFOLD LEAKS - DIAGNOSIS AND

TESTING, INTAKE.....................9-51

MEASURING BEARING CLEARANCE

USING PLASTIGAGE - STANDARD

PROCEDURE.........................9-11

MECHANICAL - DIAGNOSIS AND

TESTING, ENGINE......................9-7

MOTOR - DESCRIPTION, HEADLAMP

LEVELING..........................8L-35

MOTOR - INSTALLATION, HEADLAMP

LEVELING..........................8L-36

MOTOR - OPERATION, HEADLAMP

LEVELING..........................8L-36

MOTOR - REMOVAL, HEADLAMP

LEVELING..........................8L-36

MOUNT - INSTALLATION, FRONT.........9-44

MOUNT - INSTALLATION, REAR..........9-45

MOUNT - REMOVAL, FRONT.............9-44

MOUNT - REMOVAL, REAR..............9-45

MOUNTED STOP LAMP BULB -

INSTALLATION, CENTER HIGH..........8L-19

MOUNTED STOP LAMP BULB -

REMOVAL, CENTER HIGH..............8L-18

MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER HIGH..........8L-19

MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER HIGH..............8L-19

MOUNTING - DESCRIPTION, ENGINE......9-44

MUFFLER - DESCRIPTION...............11-4

MUFFLER - INSTALLATION..............11-5

MUFFLER - REMOVAL..................11-4

MULTI-FUNCTION SWITCH -

DESCRIPTION.......................8L-46

MULTI-FUNCTION SWITCH - DIAGNOSIS

AND TESTING.......................8L-50

MULTI-FUNCTION SWITCH -

INSTALLATION.......................8L-53

MULTI-FUNCTION SWITCH - OPERATION . . 8L-48

MULTI-FUNCTION SWITCH - REMOVAL . . . 8L-53

NOISE DIAGNOSIS - DIAGNOSIS AND

TESTING, LASH ADJUSTER (TAPPET)......9-28

OFF - INSTALLATION, CYLINDER HEAD....9-28

OFF - REMOVAL, CYLINDER HEAD........9-27

OIL AND FILTER CHANGE - STANDARD

PROCEDURE, ENGINE..................9-47

OIL FILTER - DESCRIPTION.............9-47

OIL FILTER - INSTALLATION.............9-47

OIL FILTER - REMOVAL.................9-47

OIL GALLERY PLUGS - STANDARD

PROCEDURE, ENGINE CORE..............9-9

OIL LEAK INSPECTION - DIAGNOSIS

AND TESTING, ENGINE..................9-4

OIL LEVEL CHECK, STANDARD

PROCEDURE - ENGINE.................9-47

OIL PAN - INSTALLATION...............9-48

OIL PAN - REMOVAL...................9-48

OIL PRESSURE CHECKING - DIAGNOSIS

AND TESTING, ENGINE.................9-46

OIL PRESSURE SENSOR/SWITCH -

DESCRIPTION........................9-48

OIL PRESSURE SENSOR/SWITCH -

OPERATION..........................9-48

OIL PUMP - ASSEMBLY................9-50

OIL PUMP - CLEANING.................9-49

OIL PUMP - DISASSEMBLY.............9-49

OIL PUMP - INSPECTION...............9-50

OIL PUMP - INSTALLATION.............9-50

OIL PUMP - REMOVAL.................9-49

OIL SEAL - FRONT - INSTALLATION,

CRANKSHAFT........................9-37

OIL SEAL - FRONT - REMOVAL,

CRANKSHAFT........................9-37

OIL SEAL - REAR - INSTALLATION,

CRANKSHAFT........................9-39

OIL SEAL - REAR - REMOVAL,

CRANKSHAFT........................9-38

OIL SEAL(S) - INSTALLATION,

CAMSHAFT..........................9-22

OIL SEAL(S) - REMOVAL, CAMSHAFT.....9-22

ON-BOARD DIAGNOSTICS (OBD) -

DIAGNOSIS AND TESTING...............7-2

OPERATION, BACKUP LAMP SWITCH.....8L-15

OPERATION, BALANCE SHAFT

...........9-59

OPERATION, BRAKE LAMP SWITCH

......8L-16

OPERATION, CAMSHAFT(S)

.............9-23

OPERATION, COMBINATION FLASHER

....8L-19

OPERATION, COOLANT RECOVERY

PRESS CONTAINER

....................7-20OPERATION, COOLING SYSTEM...........7-2

OPERATION, CRANKSHAFT..............9-33

OPERATION, CYLINDER HEAD...........9-19

OPERATION, DAYTIME RUNNING LAMP

RELAY.............................8L-20

OPERATION, DESCRIPTION..............7-20

OPERATION, ENGINE BLOCK HEATER -

2.4L................................7-20

OPERATION, ENGINE COOLANT

TEMPERATURE SENSOR................7-21

OPERATION, EXHAUST MANIFOLD........9-53

OPERATION, FRONT FOG LAMP RELAY . . . 8L-22

OPERATION, HAZARD SWITCH..........8L-29

OPERATION, HEADLAMP HIGH BEAM

RELAY.............................8L-33

OPERATION, HEADLAMP LEVELING

MOTOR............................8L-36

OPERATION, HEADLAMP LEVELING

SWITCH............................8L-37

OPERATION, HEADLAMP LOW BEAM

RELAY.............................8L-39

OPERATION, HOSE CLAMPS..............7-2

OPERATION, INTAKE MANIFOLD..........9-51

OPERATION, LAMP BAR...............8L-65

OPERATION, LAMPS/LIGHTING -

EXTERIOR...........................8L-5

OPERATION, LUBRICATION..............9-46

OPERATION, MULTI-FUNCTION SWITCH . . . 8L-48

OPERATION, OIL PRESSURE SENSOR/

SWITCH..............................9-48

OPERATION, PARK LAMP RELAY........8L-54

OPERATION, PISTON & CONNECTING

ROD................................9-40

OPERATION, RADIATOR FAN - ELECTRIC . . . 7-26

OPERATION, RADIATOR PRESSURE CAP . . . 7-25

OPERATION, REAR FOG LAMP RELAY....8L-57

OPERATION, TRAILER TOW RELAY.......8L-62

OPERATION, WATER PUMP - 2.4L........7-27

PAN - INSTALLATION, OIL...............9-48

PAN - REMOVAL, OIL..................9-48

PARK LAMP RELAY - DESCRIPTION......8L-54

PARK LAMP RELAY - DIAGNOSIS AND

TESTING...........................8L-55

PARK LAMP RELAY - INSTALLATION.....8L-56

PARK LAMP RELAY - OPERATION.......8L-54

PARK LAMP RELAY - REMOVAL.........8L-55

PERFORMANCE - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS............9-5

PIPE - INSTALLATION, CROSS-OVER......11-4

PIPE - REMOVAL, CROSS-OVER..........11-4

PISTON & CONNECTING ROD -

DESCRIPTION........................9-40

PISTON & CONNECTING ROD -

INSTALLATION........................9-41

PISTON & CONNECTING ROD -

OPERATION..........................9-40

PISTON & CONNECTING ROD -

REMOVAL...........................9-40

PISTON RING, FITTING.................9-42

PISTON TO CYLINDER BORE FITTING -

STANDARD PROCEDURE................9-30

PLASTIGAGE - STANDARD PROCEDURE,

MEASURING BEARING CLEARANCE

USING..............................9-11

PLATE LAMP BULB - INSTALLATION,

LICENSE...........................8L-45

PLATE LAMP BULB - REMOVAL,

LICENSE...........................8L-44

PLATE LAMP UNIT - INSTALLATION,

LICENSE...........................8L-46

PLATE LAMP UNIT - REMOVAL, LICENSE . . 8L-45

PLAY - STANDARD PROCEDURE,

CRANKSHAFT END....................9-33

PLUGS - STANDARD PROCEDURE,

ENGINE CORE AND OIL GALLERY.........9-9

POSITION LAMP BULB - INSTALLATION,

FRONT.............................8L-28

POSITION LAMP BULB - REMOVAL,

FRONT

.............................8L-28

PRELIMINARY CHECKS - DIAGNOSIS

AND TESTING

.........................7-2

PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET

SURFACE

............................9-11

PRESS CONTAINER - DESCRIPTION,

COOLANT RECOVERY

..................7-20

PRESS CONTAINER - OPERATION,

COOLANT RECOVERY

..................7-20PRESSURE CAP - CLEANING, RADIATOR . . . 7-25

PRESSURE CAP - DESCRIPTION,

RADIATOR...........................7-25

PRESSURE CAP - DIAGNOSIS AND

TESTING, RADIATOR...................7-25

PRESSURE CAP - INSPECTION,

RADIATOR...........................7-25

PRESSURE CAP - OPERATION,

RADIATOR...........................7-25

PRESSURE CHECKING - DIAGNOSIS AND

TESTING, ENGINE OIL..................9-46

PRESSURE LEAKAGE TEST - DIAGNOSIS

AND TESTING, CYLINDER

COMBUSTION.........................9-3

PRESSURE SENSOR/SWITCH -

DESCRIPTION, OIL....................9-48

PRESSURE SENSOR/SWITCH -

OPERATION, OIL......................9-48

PRESSURE TEST - DIAGNOSIS AND

TESTING, CYLINDER COMPRESSION.......9-3

PULLEY - INSTALLATION, TIMING BELT

TENSIONER..........................9-59

PULLEY - REMOVAL, TIMING BELT

TENSIONER..........................9-59

PUMP - 2.4L - DESCRIPTION, WATER.....7-27

PUMP - 2.4L - INSPECTION, WATER......7-28

PUMP - 2.4L - OPERATION, WATER.......7-27

PUMP - ASSEMBLY, OIL................9-50

PUMP - CLEANING, OIL................9-49

PUMP - DISASSEMBLY, OIL.............9-49

PUMP - INSPECTION, OIL...............9-50

PUMP - INSTALLATION, OIL.............9-50

PUMP - REMOVAL, OIL.................9-49

RADIATOR - CLEANING.................7-24

RADIATOR - DESCRIPTION..............7-22

RADIATOR - INSPECTION...............7-24

RADIATOR - INSTALLATION.............7-24

RADIATOR - REMOVAL.................7-22

RADIATOR FAN - ELECTRIC -

DESCRIPTION........................7-26

RADIATOR FAN - ELECTRIC -

INSTALLATION........................7-27

RADIATOR FAN - ELECTRIC -