Windshield JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1578 of 1803

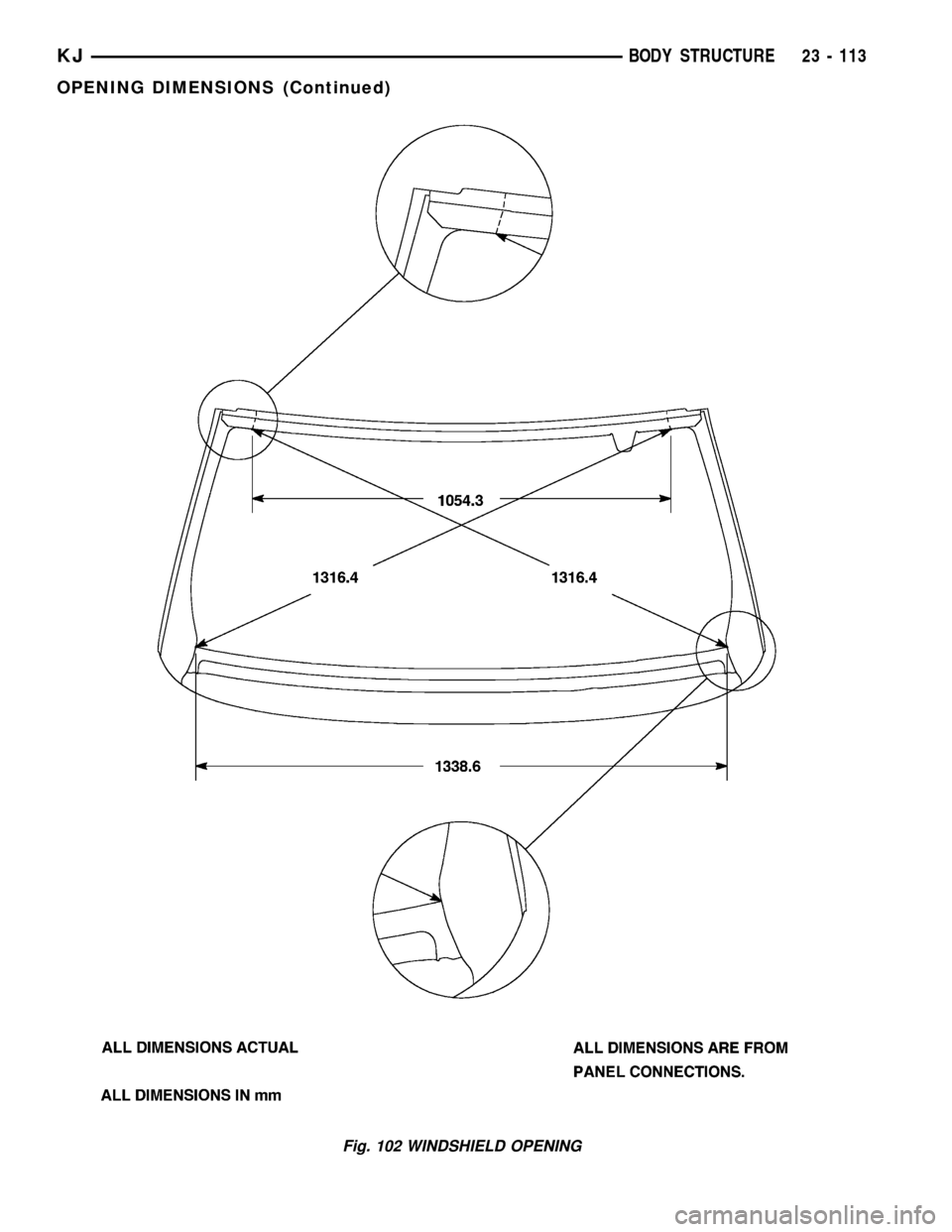

Fig. 102 WINDSHIELD OPENING

KJBODY STRUCTURE 23 - 113

OPENING DIMENSIONS (Continued)

Page 1605 of 1803

EXTERIOR

TABLE OF CONTENTS

page page

BODY SIDE MOLDINGS

REMOVAL............................140

INSTALLATION........................140

COWL GRILLE

REMOVAL............................140

INSTALLATION........................140

EXTERIOR NAME PLATES

REMOVAL............................140

INSTALLATION........................141

FRONT FENDER

REMOVAL............................141

INSTALLATION........................141

FUEL FILL DOOR/HOUSING

REMOVAL............................141

INSTALLATION........................141

GRILLE

REMOVAL............................142

INSTALLATION........................142

GRILLE OPENING REINFORCEMENT

REMOVAL............................142

INSTALLATION........................142FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL............................143

INSTALLATION........................143

LUGGAGE RACK

REMOVAL............................144

INSTALLATION........................144

REAR WHEELHOUSE SPLASH SHIELD

REMOVAL............................144

INSTALLATION........................144

SIDE VIEW MIRROR

REMOVAL............................145

INSTALLATION........................145

FRONT WHEEL OPENING FLARE MOLDINGS

REMOVAL............................145

INSTALLATION........................145

REAR WHEEL OPENING FLARE MOLDINGS

REMOVAL............................145

INSTALLATION........................145

RADIATOR CROSSMEMBER

REMOVAL............................146

INSTALLATION........................146

BODY SIDE MOLDINGS

REMOVAL

(1) Using a trim stick C-4755 or equivalent,

remove and discard the molding from the outside of

the door.

INSTALLATION

(1) Thoroughly clean all residue from the body side

molding attachment area of the door.

(2) Wipe area clean with a 50% solution of water

and alcohol and wipe dry.

(3) Apply new body side molding using the locators

in the door and apply pressure of approximately 40

p.s.i. over the entire surface of the molding.

COWL GRILLE

REMOVAL

(1) Remove the hood seal.

(2) Remove the wiper arms. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER ARMS -

REMOVAL)

(3) Remove the four plastic retainers and remove

the cowl grill.

INSTALLATION

(1) Position the cowl grill and engage the nine

clips to the bottom of the windshield.

(2) Install the five plastic retainers.

(3) Install the wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS - INSTAL-

LATION)

(4) Install the hood seal.

EXTERIOR NAME PLATES

REMOVAL

NOTE: Exterior nameplates are attached to body

panels with adhesive tape.

(1) Apply a length of masking tape on the body,

parallel to the top edge of the nameplate to use as a

guide, if necessary.

(2) If temperature is below 21ÉC (70ÉF) warm

emblem with a heat lamp or gun. Do not exceed 52ÉC

(120ÉF) when heating emblem.

(3) Using a trim stick C-4755 or equivalent, behind

the emblem to separate the adhesive backing from

the body.

23 - 140 EXTERIORKJ

Page 1626 of 1803

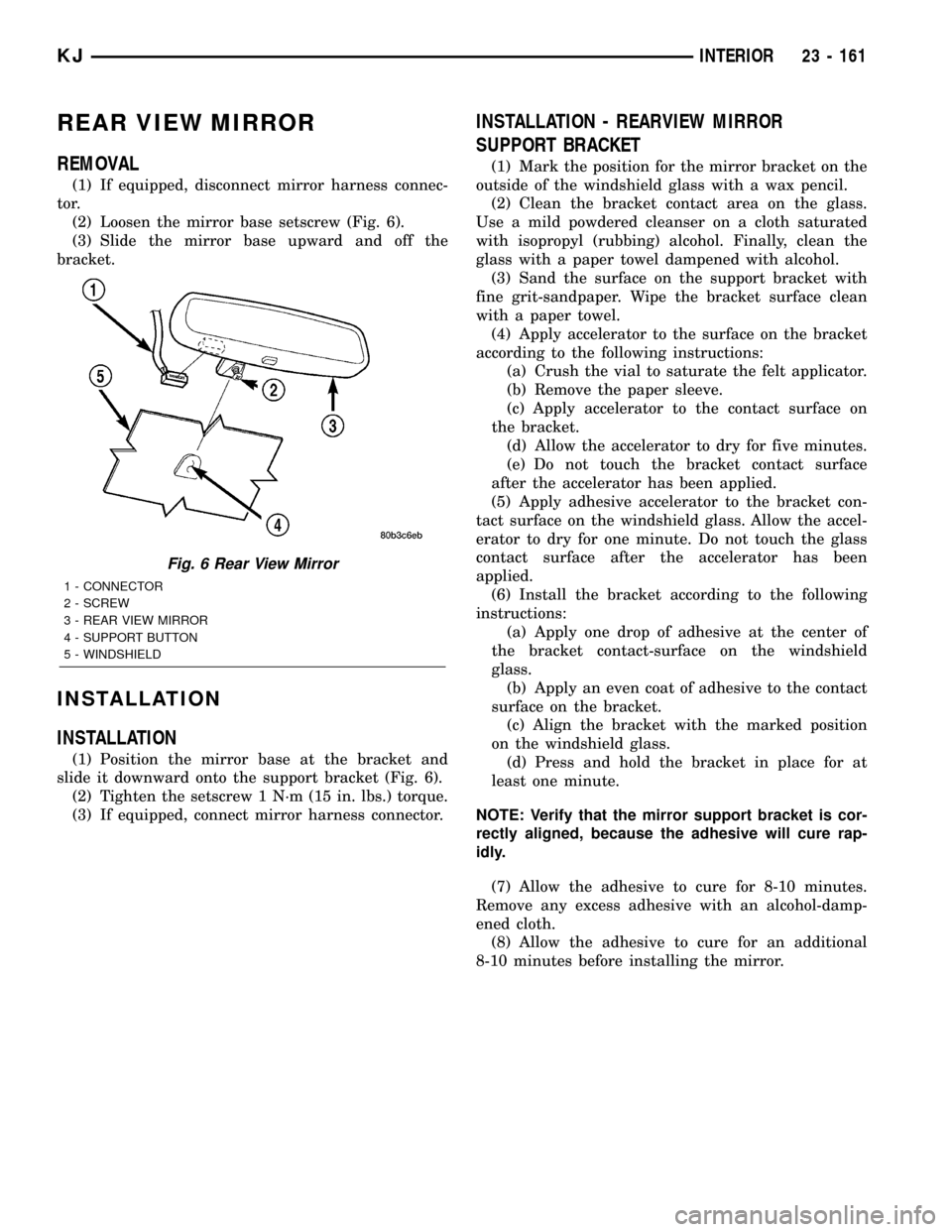

REAR VIEW MIRROR

REMOVAL

(1) If equipped, disconnect mirror harness connec-

tor.

(2) Loosen the mirror base setscrew (Fig. 6).

(3) Slide the mirror base upward and off the

bracket.

INSTALLATION

INSTALLATION

(1) Position the mirror base at the bracket and

slide it downward onto the support bracket (Fig. 6).

(2) Tighten the setscrew 1 N´m (15 in. lbs.) torque.

(3) If equipped, connect mirror harness connector.

INSTALLATION - REARVIEW MIRROR

SUPPORT BRACKET

(1) Mark the position for the mirror bracket on the

outside of the windshield glass with a wax pencil.

(2) Clean the bracket contact area on the glass.

Use a mild powdered cleanser on a cloth saturated

with isopropyl (rubbing) alcohol. Finally, clean the

glass with a paper towel dampened with alcohol.

(3) Sand the surface on the support bracket with

fine grit-sandpaper. Wipe the bracket surface clean

with a paper towel.

(4) Apply accelerator to the surface on the bracket

according to the following instructions:

(a) Crush the vial to saturate the felt applicator.

(b) Remove the paper sleeve.

(c) Apply accelerator to the contact surface on

the bracket.

(d) Allow the accelerator to dry for five minutes.

(e) Do not touch the bracket contact surface

after the accelerator has been applied.

(5) Apply adhesive accelerator to the bracket con-

tact surface on the windshield glass. Allow the accel-

erator to dry for one minute. Do not touch the glass

contact surface after the accelerator has been

applied.

(6) Install the bracket according to the following

instructions:

(a) Apply one drop of adhesive at the center of

the bracket contact-surface on the windshield

glass.

(b) Apply an even coat of adhesive to the contact

surface on the bracket.

(c) Align the bracket with the marked position

on the windshield glass.

(d) Press and hold the bracket in place for at

least one minute.

NOTE: Verify that the mirror support bracket is cor-

rectly aligned, because the adhesive will cure rap-

idly.

(7) Allow the adhesive to cure for 8-10 minutes.

Remove any excess adhesive with an alcohol-damp-

ened cloth.

(8) Allow the adhesive to cure for an additional

8-10 minutes before installing the mirror.

Fig. 6 Rear View Mirror

1 - CONNECTOR

2 - SCREW

3 - REAR VIEW MIRROR

4 - SUPPORT BUTTON

5 - WINDSHIELD

KJINTERIOR 23 - 161

Page 1637 of 1803

STATIONARY GLASS

TABLE OF CONTENTS

page page

DOOR GLASS

REMOVAL............................172

INSTALLATION........................172

QUARTER WINDOW

REMOVAL............................172

INSTALLATION........................172WINDSHIELD

WARNING

WINDSHIELD SAFETY PRECAUTIONS....173

REMOVAL............................173

INSTALLATION........................173

DOOR GLASS

REMOVAL

(1) Remove the rear door glass run channel. (Refer

to 23 - BODY/DOORS - REAR/GLASS RUN CHAN-

NEL - REMOVAL)

INSTALLATION

(1) Install the rear door glass run channel. (Refer

to 23 - BODY/DOORS - REAR/GLASS RUN CHAN-

NEL - INSTALLATION)

QUARTER WINDOW

REMOVAL

(1) Remove the headliner as necessary to gain

access to the glass seal from the inside. (Refer to 23 -

BODY/INTERIOR/HEADLINER - REMOVAL)

(2) Cut urethane bonding from around quarter

window glass using a suitable sharp cold knife. A

pneumatic cutting device can be used if available.

(3) Separate glass from vehicle.

INSTALLATION

CAUTION: Open a window before installing glass.

This will avoid pressurizing the passenger compart-

ment. If a door or swing gate flip-up glass is

slammed before urethane is cured, water leaks can

result.

The window opening fence should be cleaned of old

urethane bonding material.

(1) Install the headliner as necessary. (Refer to 23

- BODY/INTERIOR/HEADLINER - INSTALLATION)

(2) Clean inside of glass with Mopar Glass Cleaner

and lint-free cloth.

(3) Apply PVC (vinyl) primer 25 mm (1 in.) wide

around edge of glass. Wipe with clean/dry lint-free

cloth.

(4) Apply fence primer around edge of fence. Allow

at least eighteen minutes drying time.

(5) Apply a 10 mm (0.4 in.) bead of urethane

around window vinyl border location.

(6)

Position glass into window opening and lock clips

into place.

23 - 172 STATIONARY GLASSKJ

Page 1638 of 1803

WINDSHIELD

WARNING

WINDSHIELD SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

²URETHANE ADHESIVES ARE APPLIED AS A

SYSTEM. USE GLASS CLEANER, GLASS PREP

SOLVENT, GLASS PRIMER, PVC (VINYL) PRIMER

AND PINCH WELD (FENCE) PRIMER PROVIDED BY

THE ADHESIVE MANUFACTURER. IF NOT, STRUC-

TURAL INTEGRITY COULD BE COMPROMISED.

²DAIMLERCHRYSLER DOES NOT RECOMMEND

GLASS ADHESIVE BY BRAND. TECHNICIANS

SHOULD REVIEW PRODUCT LABELS AND TECHNI-

CAL DATA SHEETS, AND USE ONLY ADHESIVES

THAT THEIR MANUFACTURES WARRANT WILL

RESTORE A VEHICLE TO THE REQUIREMENTS OF

FMVSS 212. TECHNICIANS SHOULD ALSO INSURE

THAT PRIMERS AND CLEANERS ARE COMPATIBLE

WITH THE PARTICULAR ADHESIVE USED.

²BE SURE TO REFER TO THE URETHANE MAN-

UFACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

²VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

²SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

²ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

REMOVAL

(1) Remove inside rear view mirror. (Refer to 23 -

BODY/INTERIOR/REAR VIEW MIRROR -

REMOVAL)

(2) Remove cowl cover. (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - REMOVAL)(3) Remove screws attaching windshield side mold-

ing to A-pillar.

(4) Remove upper windshield molding.

(5) Cut urethane bonding from around windshield

using a suitable sharp cold knife. A pneumatic cut-

ting device can be used if available.

(6) Separate windshield from vehicle.

INSTALLATION

WARNING: REVIEW ALL WARNINGS AND CAU-

TIONS IN THIS GROUP BEFORE PRECEDING WITH

INSTALLATION.

CAUTION: Open a window before installing wind-

shield. This will avoid pressurizing the passenger

compartment. If a door or swing gate flip-up glass

is slammed before urethane is cured, water leaks

can result.

The windshield fence should be cleaned of old ure-

thane bonding material. Support spacers should be

cleaned and properly installed on weld studs or

repair screws at bottom of windshield opening.

(1) Place replacement windshield into windshield

opening. Position glass in the center of the opening

against the support spacers. Mark the glass at the

support spacers with a grease pencil or masking tape

and ink pen to use as a reference for installation.

Remove replacement windshield from windshield

opening.

(2) Position the windshield inside up on a suitable

work surface with two padded, wood 10 cm by 10 cm

by 50 cm (4 in. by 4 in. by 20 in.) blocks, placed par-

allel 75 cm (2.5 ft.) apart.

(3) Clean inside of windshield with Mopar Glass

Cleaner and lint-free cloth.

(4) Apply clear glass primer 25 mm (1 in.) wide

around edge of windshield. Wipe with clean/dry lint-

free cloth.

(5) Apply black-out primer 15 mm (.75 in.) wide on

top and sides of windshield and 25 mm (1 in.) on bot-

tom of windshield. Allow at least three minutes dry-

ing time.

(6) Position windshield spacers on lower fence

above support spacers at the edge of the windshield

opening.

(7) Align the dot on the upper molding to the tick

mark in the center of the glass and install upper

molding onto windshield.

(8) Apply a 10 mm (0.4 in.) bead of urethane

around perimeter of windshield along the inside of

the moldings. Apply two beads along the bottom

edge.

KJSTATIONARY GLASS 23 - 173

Page 1639 of 1803

(9) Apply fence primer around the perimeter of the

windshield opening fence. Allow at least 18 minutes

drying time.

(10) With aid of a helper, position windshield over

windshield opening. Align reference marks at bottom

of windshield to support spacers.

(11) Slowly lower windshield glass to windshield

opening fence. Guide top molding into proper position

if necessary. Push windshield inward to fence spacers

at bottom and until top molding is flush to roof line.

(12) Clean excess urethane from exterior with

Mopar Super Clean or equivalent.(13) Install windshield side moldings. (Refer to 23

- BODY/WEATHERSTRIP/SEALS/WINDSHIELD

A-PILLAR WEATHERSTRIP - INSTALLATION)

(14) Install cowl grille. (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - INSTALLATION)

(15) Install inside rear view mirror. (Refer to 23 -

BODY/INTERIOR/REAR VIEW MIRROR - INSTAL-

LATION)

(16) After urethane has cured, water test wind-

shield to verify repair.

23 - 174 STATIONARY GLASSKJ

WINDSHIELD (Continued)

Page 1640 of 1803

SUNROOF

TABLE OF CONTENTS

page page

SUNROOF

DESCRIPTION........................175

DIAGNOSIS AND TESTING

WATER DRAINAGE AND WIND NOISE

DIAGNOSIS.........................176

DIAGNOSTIC PROCEDURES...........176

GLASS PANEL

REMOVAL............................178

INSTALLATION........................178

ADJUSTMENTS

SUNROOF GLASS PANEL ADJUSTMENT . . 178

GLASS PANEL SEAL

REMOVAL............................178

INSTALLATION........................178

SUNSHADE

REMOVAL............................179

INSTALLATION........................179

GUIDE ASSEMBLY

REMOVAL............................179

INSTALLATION........................179

WIND DEFLECTOR

REMOVAL............................180INSTALLATION........................180

OPENING TRIM LACE

REMOVAL............................180

INSTALLATION........................180

DRAIN TUBE

REMOVAL............................180

INSTALLATION........................181

MODULE ASSEMBLY

REMOVAL............................181

INSTALLATION........................181

DRIVE MOTOR

REMOVAL............................182

INSTALLATION........................182

CONTROL MODULE

REMOVAL............................183

INSTALLATION........................183

CONTROL SWITCH

DESCRIPTION........................184

OPERATION..........................184

DIAGNOSIS AND TESTING...............184

REMOVAL............................184

INSTALLATION........................184

SUNROOF

DESCRIPTION

WARNING: Keep fingers and other body parts out

of sunroof opening at all times.

The sunroof features a power sliding glass panel

and a sunshade which can be manually positioned

anywhere along its travel, rearward of glass panel

front edge.

The sunroof is electrically operated from two

switches located on the windshield header, rearwardof the map lamp. To operate the sunroof the ignition

switch must be in either the Accessory or On/Run

position. One switch (vent) is a push button type and

opens the sunroof to the vent position only. The other

switch (open/close) is a rocker type for opening and

closing the sunroof. Pressing and releasing the open

button once the sunroof will express open and the

wind deflector will raise. If the button is pressed a

second time the sunroof will stop in that position.

Pressing and holding the close button will close the

sunroof. If the close button is released the sunroof

will stop in that position.

KJSUNROOF 23 - 175

Page 1650 of 1803

WEATHERSTRIP/SEALS

TABLE OF CONTENTS

page page

A-PILLAR SEAL

REMOVAL............................185

INSTALLATION........................185

COWL WEATHERSTRIP

REMOVAL............................185

INSTALLATION........................185

DOOR PRIMARY WEATHERSTRIP

REMOVAL............................185

INSTALLATION........................185

DOOR LOWER WEATHERSTRIP

REMOVAL............................186

INSTALLATION........................186

FRONT DOOR OUTER BELT MOLDING

REMOVAL............................186

INSTALLATION........................186

SWING GATE BELTLINE WEATHERSTRIP

REMOVAL............................186

INSTALLATION........................186

SWING GATE OPENING WEATHERSTRIP

REMOVAL............................186INSTALLATION........................186

REAR DOOR OUTER BELT MOLDING

REMOVAL............................186

INSTALLATION........................186

SIDE RAIL WEATHERSTRIP/RETAINER

REMOVAL............................186

INSTALLATION........................186

WINDSHIELD A-PILLAR WEATHERSTRIP/

RETAINER

REMOVAL............................186

INSTALLATION........................187

COWL/PLENUM SEAL

REMOVAL............................187

INSTALLATION........................187

COWL/PLENUM WINDOW BAFFLE SEAL

REMOVAL............................187

INSTALLATION........................187

A-PILLAR SEAL

REMOVAL

(1) Open the doors and peal the seal away from

the a-pillar/windshield and the side rail weather

strip flanges.

INSTALLATION

(1) Position the a-pillar seal over the windshield/a-

pillar and the side rail weatherstrip flanges and seat

fully.

COWL WEATHERSTRIP

REMOVAL

(1) Open the hood and peal the cowl seal from the

cowl panel and cowl flange.

INSTALLATION

(1) Position the weatherstrip over the cowl flange

and the cowl grille and seat fully.

DOOR PRIMARY

WEATHERSTRIP

REMOVAL

(1) Remove the lower b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR LOWER TRIM -

REMOVAL)

(2) Peal seal off of the door opening flange.

INSTALLATION

(1) Position the seal to the bottom of the door

opening, with bulb facing outboard, starting the

installation at the center of the lower flange. Press

the seal onto the sill flange and work around the

perimeter of the door opening until fully seated.

Work in one direction, smoothing the seal to avoid

puckers or wrinkles.

(2) Install the lower b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR LOWER TRIM -

INSTALLATION)

(3) When installing a new weatherstrip on the

front door opening, remove the tear strip starting at

the splice and moving around the front of the door to

the back of the opening.

KJWEATHERSTRIP/SEALS 23 - 185

Page 1651 of 1803

(4) When installing a new weatherstrip on the rear

door opening, remove the tear strip starting at the

splice and moving around the back of the door to the

front of the opening.

DOOR LOWER WEATHERSTRIP

REMOVAL

(1) Carefully disengage the push pin fasteners and

remove the seal.

INSTALLATION

(1) Position the seal and seat the push pin fasten-

ers.

FRONT DOOR OUTER BELT

MOLDING

REMOVAL

(1) Lower the window.

(2) Pull the outer belt molding off of the door

flange starting at the rear and moving forward.

INSTALLATION

(1) Press the belt molding onto the outer door win-

dow flange starting at the rear and working forward.

SWING GATE BELTLINE

WEATHERSTRIP

REMOVAL

(1) Remove the swing gate trim panel. (Refer to 23

- BODY/SWING GATE/TRIM PANEL - REMOVAL)

(2) Pull seal away from the corner tabs and

remove from the swing gate flange.

INSTALLATION

(1) Install the seal over the swing gate flange and

seat the corner tabs.

(2) Install the swing gate trim panel. (Refer to 23 -

BODY/SWING GATE/TRIM PANEL - INSTALLA-

TION)

SWING GATE OPENING

WEATHERSTRIP

REMOVAL

(1) Open the swing gate and peal seal off of the

gate opening flange.

INSTALLATION

(1) Position the seal to the bottom of the gate

opening starting the installation at the center of the

flange. Press the seal onto the sill flange and work

around the perimeter of the door opening until fully

seated. Work in one direction, smoothing the seal to

avoid puckers or wrinkles.

REAR DOOR OUTER BELT

MOLDING

REMOVAL

(1) Lower the window.

(2) Pull the outer belt molding off of the door

flange starting at the rear and moving forward.

INSTALLATION

(1) Press the belt molding onto the outer door win-

dow flange starting at the front and working back.

SIDE RAIL WEATHERSTRIP/

RETAINER

REMOVAL

(1) Remove the windshield weatherstrip retainer.

(Refer to 23 - BODY/WEATHERSTRIP/SEALS/

WINDSHIELD A-PILLAR WEATHERSTRIP/RE-

TAINER - REMOVAL)

(2) Remove the two screws.

(3) Using a trim stick C-4755 or equivalent,

release the push in fasteners and remove the weath-

erstrip.

INSTALLATION

(1) Position the weatherstrip and seat the push in

fasteners.

(2) Install the two screws.

(3) Install the windshield weatherstrip. (Refer to

23 - BODY/WEATHERSTRIP/SEALS/WINDSHIELD

A-PILLAR WEATHERSTRIP/RETAINER - INSTAL-

LATION)

WINDSHIELD A-PILLAR

WEATHERSTRIP/RETAINER

REMOVAL

(1) Open the doors and peal the a-pillar seal away

from the a-pillar/windshield and the side rail

weather strip flanges.

(2) Remove the seven screws and remove the

weatherstrip.

23 - 186 WEATHERSTRIP/SEALSKJ

DOOR PRIMARY WEATHERSTRIP (Continued)

Page 1652 of 1803

INSTALLATION

(1) Position the weatherstrip and install the seven

screws.

(2) Position the a-pillar seal over the windshield/a-

pillar and the side rail weatherstrip flanges and seat

fully.

COWL/PLENUM SEAL

REMOVAL

(1) Remove the cowl grille. (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL)

(2) Remove the seal from the plenum flange above

the air inlet duct.

INSTALLATION

NOTE: Seal should not be touching the plenum baf-

fle flange seal.

(1) Position the seal on the plenum flange and seat

fully.(2) Install the cowl grille. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION)

COWL/PLENUM WINDOW

BAFFLE SEAL

REMOVAL

(1) Remove the cowl grille. (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL)

(2) Remove the seal from the window below the

cowl/plenum seal.

INSTALLATION

(1) Position the seal against the upper flange of

the inner plenum window below the cowl/plenum seal

and seat fully.

(2) Install the cowl grille. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION)

KJWEATHERSTRIP/SEALS 23 - 187

WINDSHIELD A-PILLAR WEATHERSTRIP/RETAINER (Continued)