Oil JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1696 of 1803

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

The compressor may be removed and repositioned

without disconnecting the refrigerant lines or dis-

charging the refrigerant system. Discharging is not

necessary if servicing the compressor clutch or clutch

coil, the engine, the cylinder head, or the generator.

NOTE: If a replacement compressor is being

installed, be certain to check the refrigerant oil

level. (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - STANDARD PRO-

CEDURE - REFRIGERANT OIL LEVEL) Use only

refrigerant oil of the type recommended for the

compressor in the vehicle. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/REFRIGERANT OIL -

DESCRIPTION)(1) Install the compressor to the mounting bracket.

Tighten the three mounting bolts to 27 N´m (20 ft.

lbs.), (2.4L gasoline and 2.5L diesel engines only).

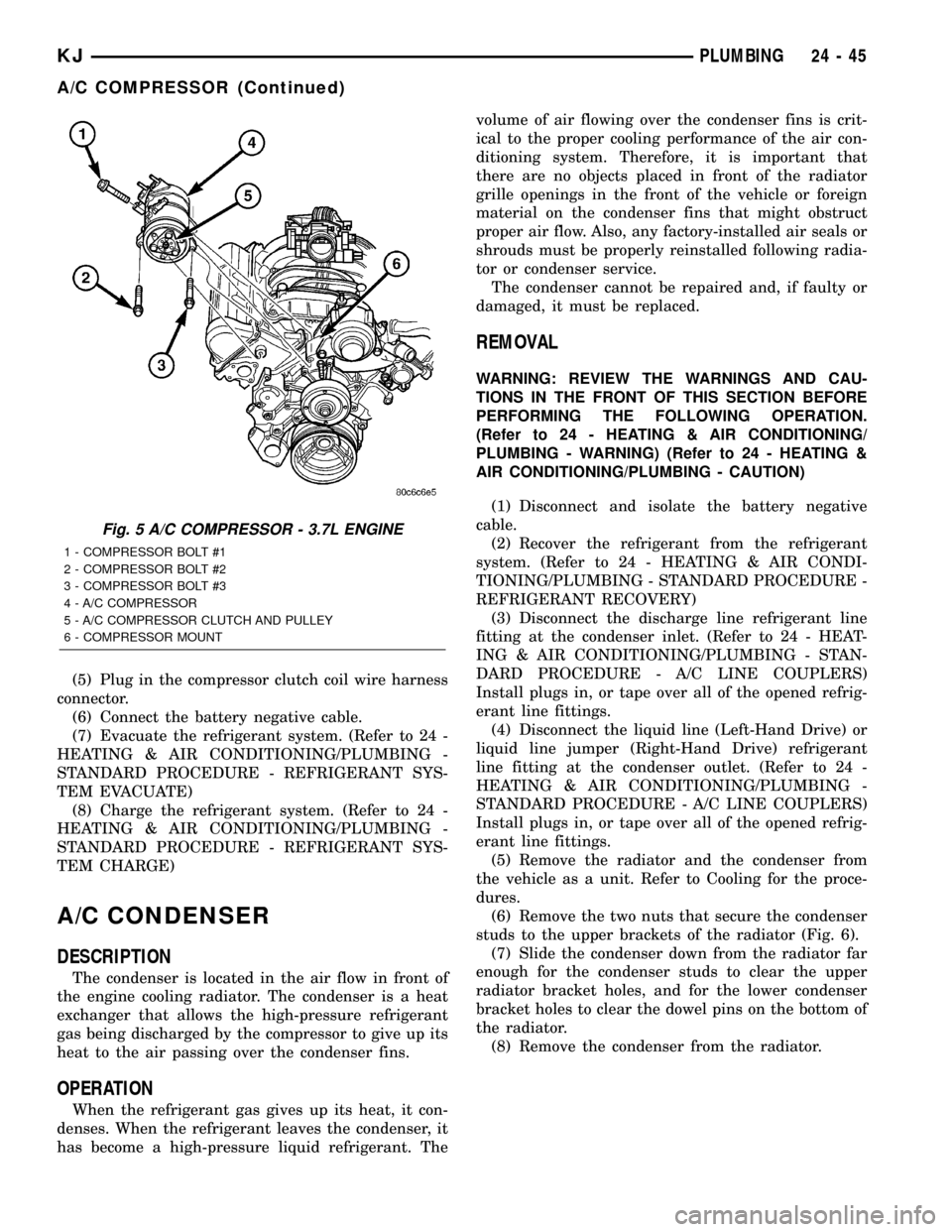

(2) On the 3.7L gasoline engine install and tighten

the bolts in the following sequence (Fig. 5):

²The number one bolt (rear) is hand tightened

first then tightened to 55 N´m (41 ft. lbs.)

²The number three bolt is then hand tightened

and torqued to 40 N´m ( 30 ft. lbs.)

²The number two bolt is also hand tightened and

torqued to 55 N´m ( 41 ft. lbs.)

(3) Remove the tape or plugs from all of the

opened refrigerant line fittings. Install the suction

and discharge line manifold to the compressor.

Tighten the fastener to 28 N´m (250 in. lbs.).(Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/

SUCTION LINE - INSTALLATION) (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

DISCHARGE LINE - INSTALLATION)

(4) Install the serpentine drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

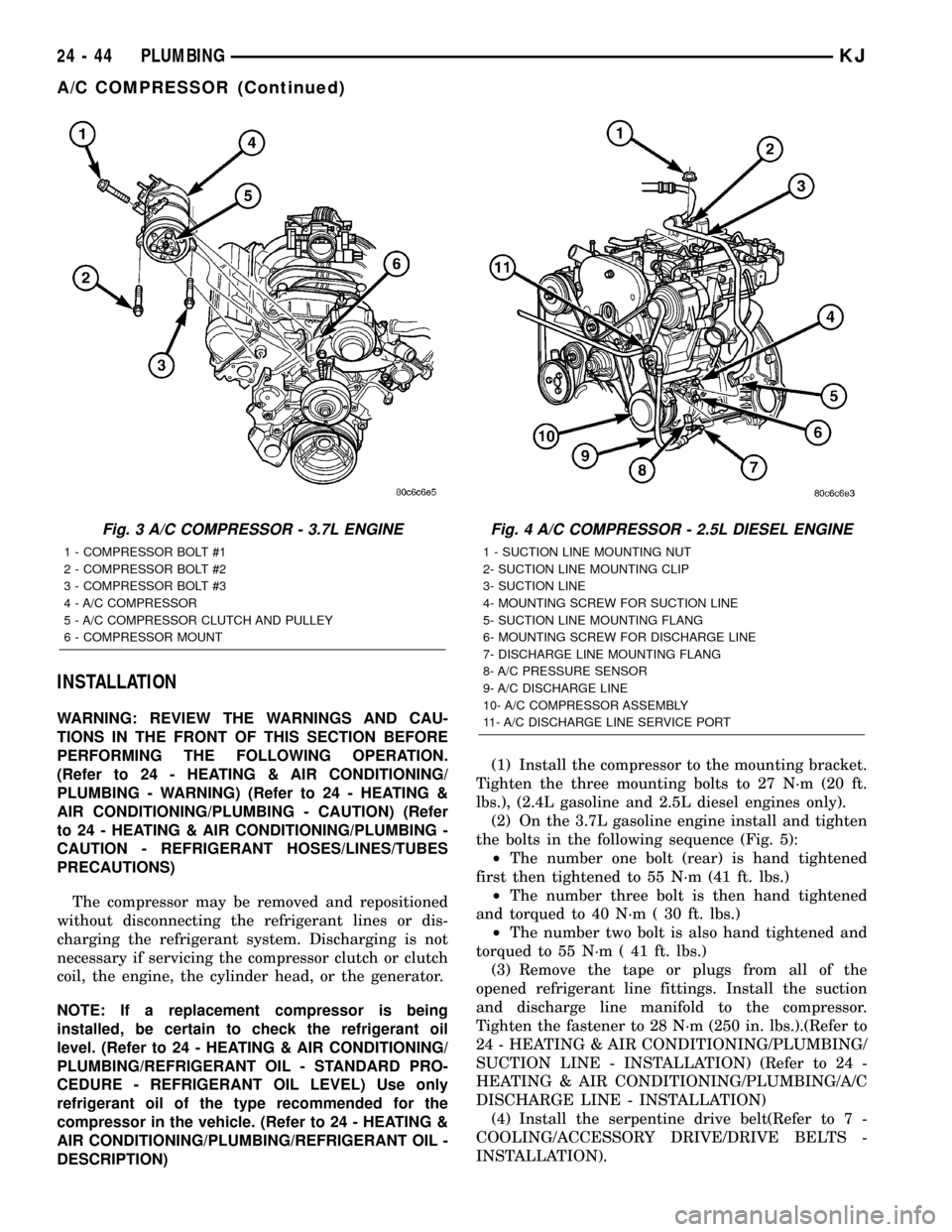

Fig. 3 A/C COMPRESSOR - 3.7L ENGINE

1 - COMPRESSOR BOLT #1

2 - COMPRESSOR BOLT #2

3 - COMPRESSOR BOLT #3

4 - A/C COMPRESSOR

5 - A/C COMPRESSOR CLUTCH AND PULLEY

6 - COMPRESSOR MOUNT

Fig. 4 A/C COMPRESSOR - 2.5L DIESEL ENGINE

1 - SUCTION LINE MOUNTING NUT

2- SUCTION LINE MOUNTING CLIP

3- SUCTION LINE

4- MOUNTING SCREW FOR SUCTION LINE

5- SUCTION LINE MOUNTING FLANG

6- MOUNTING SCREW FOR DISCHARGE LINE

7- DISCHARGE LINE MOUNTING FLANG

8- A/C PRESSURE SENSOR

9- A/C DISCHARGE LINE

10- A/C COMPRESSOR ASSEMBLY

11- A/C DISCHARGE LINE SERVICE PORT

24 - 44 PLUMBINGKJ

A/C COMPRESSOR (Continued)

Page 1697 of 1803

(5) Plug in the compressor clutch coil wire harness

connector.

(6) Connect the battery negative cable.

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

A/C CONDENSER

DESCRIPTION

The condenser is located in the air flow in front of

the engine cooling radiator. The condenser is a heat

exchanger that allows the high-pressure refrigerant

gas being discharged by the compressor to give up its

heat to the air passing over the condenser fins.

OPERATION

When the refrigerant gas gives up its heat, it con-

denses. When the refrigerant leaves the condenser, it

has become a high-pressure liquid refrigerant. Thevolume of air flowing over the condenser fins is crit-

ical to the proper cooling performance of the air con-

ditioning system. Therefore, it is important that

there are no objects placed in front of the radiator

grille openings in the front of the vehicle or foreign

material on the condenser fins that might obstruct

proper air flow. Also, any factory-installed air seals or

shrouds must be properly reinstalled following radia-

tor or condenser service.

The condenser cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Disconnect the discharge line refrigerant line

fitting at the condenser inlet. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

(4) Disconnect the liquid line (Left-Hand Drive) or

liquid line jumper (Right-Hand Drive) refrigerant

line fitting at the condenser outlet. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

(5) Remove the radiator and the condenser from

the vehicle as a unit. Refer to Cooling for the proce-

dures.

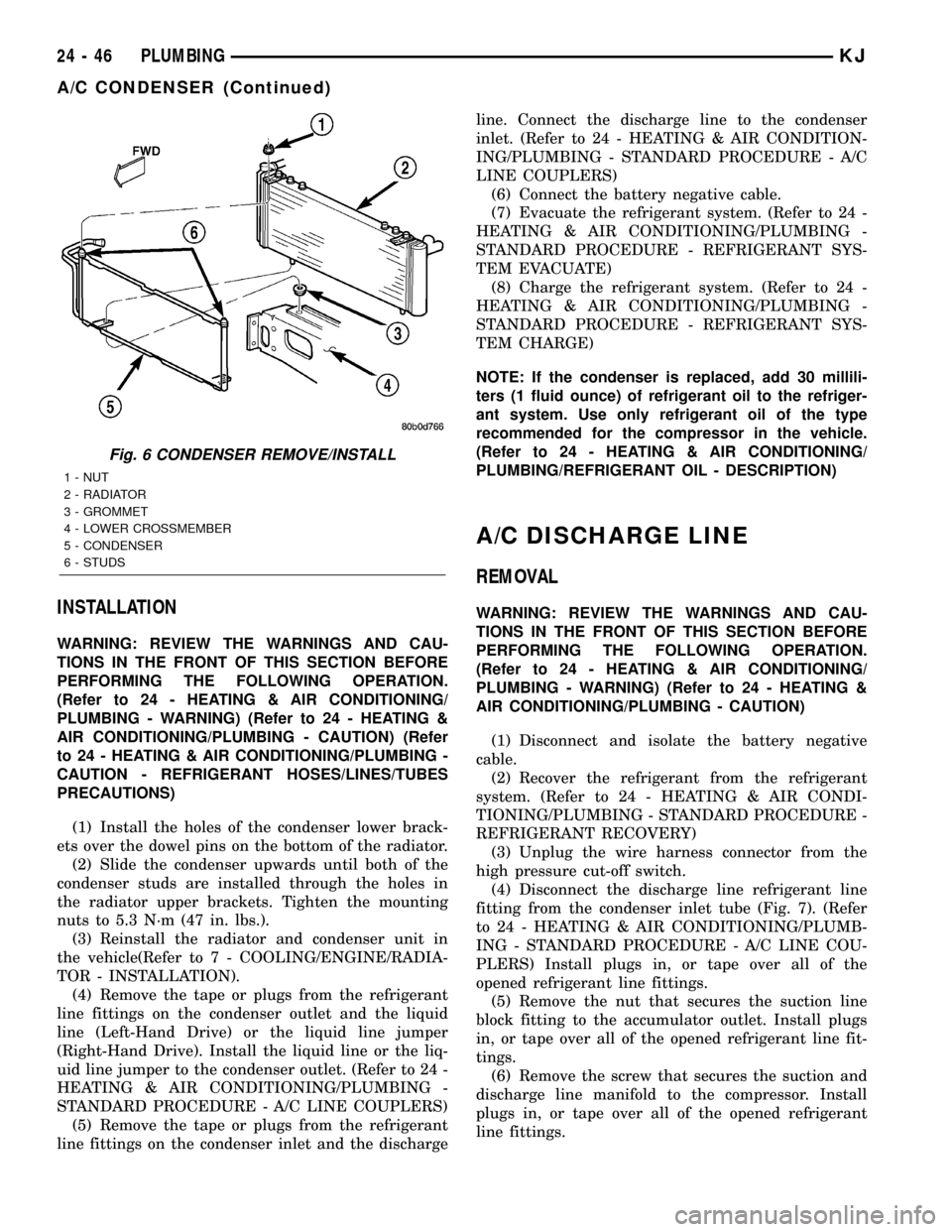

(6) Remove the two nuts that secure the condenser

studs to the upper brackets of the radiator (Fig. 6).

(7) Slide the condenser down from the radiator far

enough for the condenser studs to clear the upper

radiator bracket holes, and for the lower condenser

bracket holes to clear the dowel pins on the bottom of

the radiator.

(8) Remove the condenser from the radiator.

Fig. 5 A/C COMPRESSOR - 3.7L ENGINE

1 - COMPRESSOR BOLT #1

2 - COMPRESSOR BOLT #2

3 - COMPRESSOR BOLT #3

4 - A/C COMPRESSOR

5 - A/C COMPRESSOR CLUTCH AND PULLEY

6 - COMPRESSOR MOUNT

KJPLUMBING 24 - 45

A/C COMPRESSOR (Continued)

Page 1698 of 1803

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Install the holes of the condenser lower brack-

ets over the dowel pins on the bottom of the radiator.

(2) Slide the condenser upwards until both of the

condenser studs are installed through the holes in

the radiator upper brackets. Tighten the mounting

nuts to 5.3 N´m (47 in. lbs.).

(3) Reinstall the radiator and condenser unit in

the vehicle(Refer to 7 - COOLING/ENGINE/RADIA-

TOR - INSTALLATION).

(4) Remove the tape or plugs from the refrigerant

line fittings on the condenser outlet and the liquid

line (Left-Hand Drive) or the liquid line jumper

(Right-Hand Drive). Install the liquid line or the liq-

uid line jumper to the condenser outlet. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

(5) Remove the tape or plugs from the refrigerant

line fittings on the condenser inlet and the dischargeline. Connect the discharge line to the condenser

inlet. (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE - A/C

LINE COUPLERS)

(6) Connect the battery negative cable.

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

NOTE: If the condenser is replaced, add 30 millili-

ters (1 fluid ounce) of refrigerant oil to the refriger-

ant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - DESCRIPTION)

A/C DISCHARGE LINE

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Unplug the wire harness connector from the

high pressure cut-off switch.

(4) Disconnect the discharge line refrigerant line

fitting from the condenser inlet tube (Fig. 7). (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE - A/C LINE COU-

PLERS) Install plugs in, or tape over all of the

opened refrigerant line fittings.

(5) Remove the nut that secures the suction line

block fitting to the accumulator outlet. Install plugs

in, or tape over all of the opened refrigerant line fit-

tings.

(6) Remove the screw that secures the suction and

discharge line manifold to the compressor. Install

plugs in, or tape over all of the opened refrigerant

line fittings.

Fig. 6 CONDENSER REMOVE/INSTALL

1 - NUT

2 - RADIATOR

3 - GROMMET

4 - LOWER CROSSMEMBER

5 - CONDENSER

6 - STUDS

24 - 46 PLUMBINGKJ

A/C CONDENSER (Continued)

Page 1701 of 1803

(7) Remove the suction and discharge line assem-

bly from the vehicle.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT IF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Remove the tape or plugs from the suction and

discharge line manifold and the compressor. Install

the suction and discharge line manifold to the com-

pressor. Tighten the fastener to 28 N´m (250 in. lbs.).

(2) Remove the tape or plugs from the suction line

and the accumulator outlet block fittings. Install the

suction line to the accumulator outlet and tighten the

mounting nut to 9 N´m (80 in. lbs.).

(3) Remove the tape or plugs from the refrigerant

line fittings on the discharge line and the condenser

inlet tube. Connect the discharge line refrigerant line

coupler to the condenser inlet tube. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

(4) Plug in the wire harness connector on the a/c

high pressure switch.

(5) Connect the battery negative cable.

(6) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(7) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

(8) Check the affected areas of the system for

leaks.

A/C EVAPORATOR

DESCRIPTION

The evaporator coil is located in the HVAC hous-

ing, under the instrument panel. The evaporator coil

is positioned in the HVAC housing so that all air that

enters the housing must pass over the fins of the

evaporator before it is distributed through the sys-

tem ducts and outlets. However, air passing over the

evaporator coil fins will only be conditioned when the

compressor is engaged and circulating refrigerant

through the evaporator coil tubes.

OPERATION

Refrigerant enters the evaporator from the fixed

orifice tube as a low-temperature, low-pressure liq-

uid. As air flows over the fins of the evaporator, the

humidity in the air condenses on the fins, and the

heat from the air is absorbed by the refrigerant. Heat

absorption causes the refrigerant to boil and vapor-

ize. The refrigerant becomes a low-pressure gas when

it leaves the evaporator.

The evaporator coil cannot be repaired and, if

faulty or damaged, it must be replaced.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Remove and disassemble the HVAC housing.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - DISASSEMBLY)

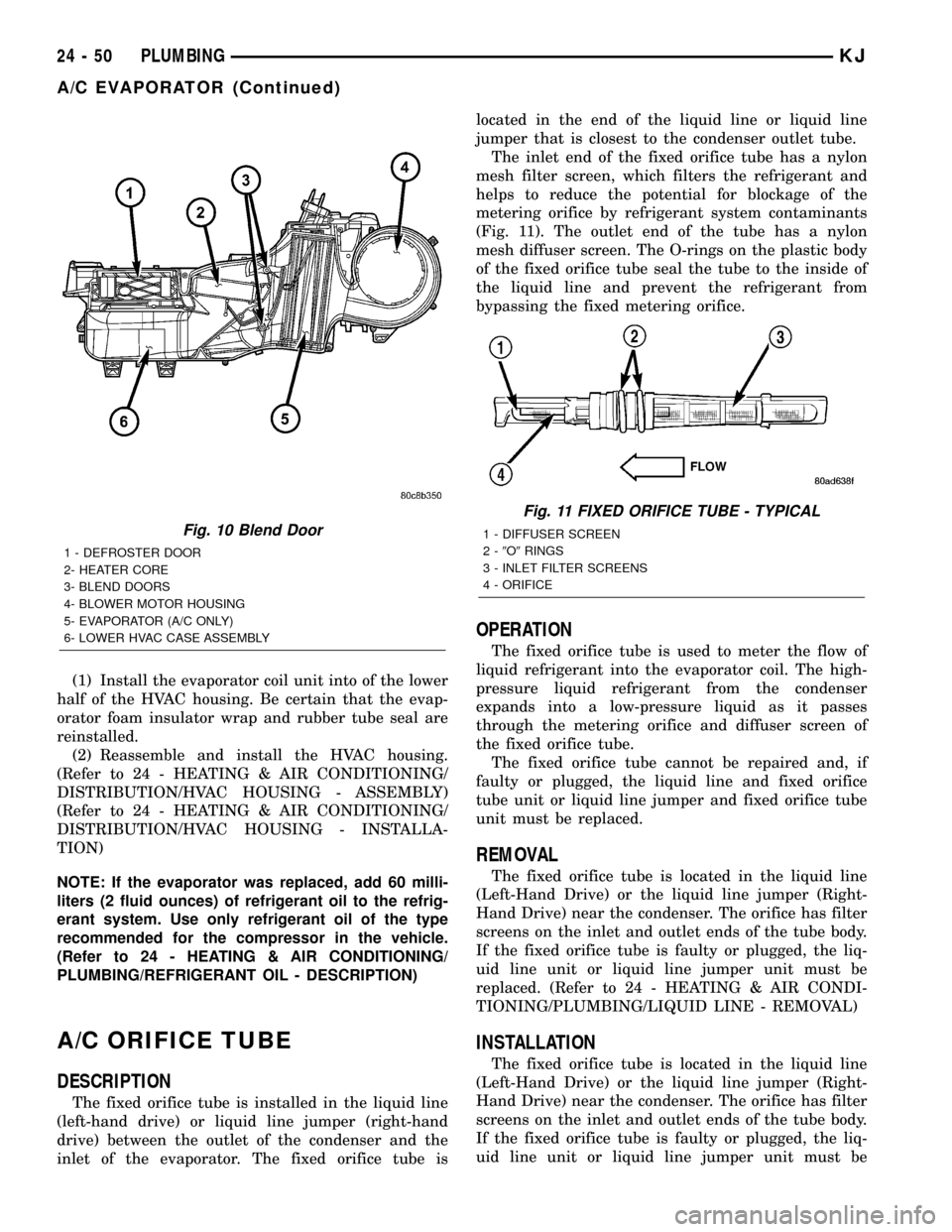

(2) Lift the evaporator coil unit out of the lower

half of the HVAC housing. (Fig. 10).

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

KJPLUMBING 24 - 49

A/C SUCTION LINE (Continued)

Page 1702 of 1803

(1) Install the evaporator coil unit into of the lower

half of the HVAC housing. Be certain that the evap-

orator foam insulator wrap and rubber tube seal are

reinstalled.

(2) Reassemble and install the HVAC housing.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - ASSEMBLY)

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - INSTALLA-

TION)

NOTE: If the evaporator was replaced, add 60 milli-

liters (2 fluid ounces) of refrigerant oil to the refrig-

erant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - DESCRIPTION)

A/C ORIFICE TUBE

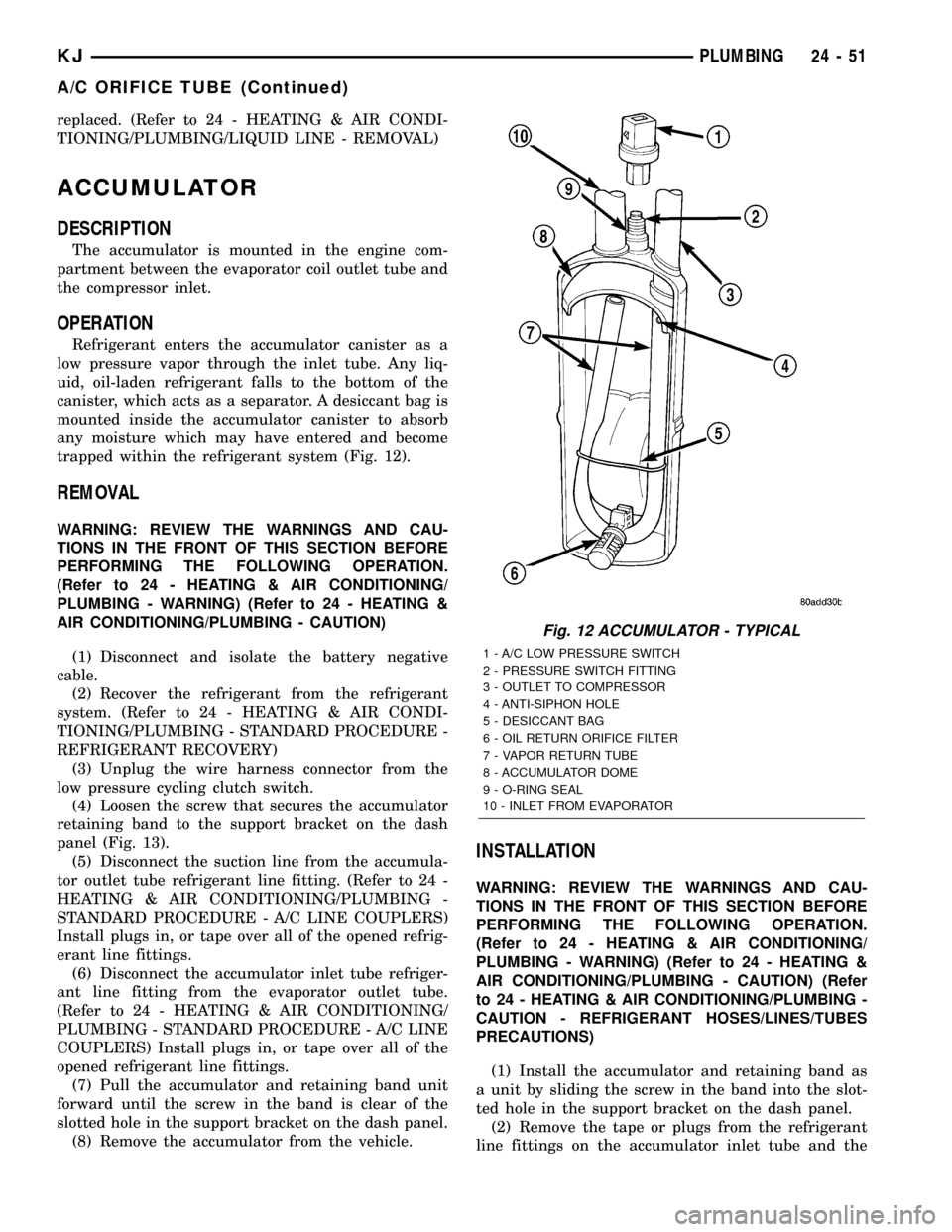

DESCRIPTION

The fixed orifice tube is installed in the liquid line

(left-hand drive) or liquid line jumper (right-hand

drive) between the outlet of the condenser and the

inlet of the evaporator. The fixed orifice tube islocated in the end of the liquid line or liquid line

jumper that is closest to the condenser outlet tube.

The inlet end of the fixed orifice tube has a nylon

mesh filter screen, which filters the refrigerant and

helps to reduce the potential for blockage of the

metering orifice by refrigerant system contaminants

(Fig. 11). The outlet end of the tube has a nylon

mesh diffuser screen. The O-rings on the plastic body

of the fixed orifice tube seal the tube to the inside of

the liquid line and prevent the refrigerant from

bypassing the fixed metering orifice.

OPERATION

The fixed orifice tube is used to meter the flow of

liquid refrigerant into the evaporator coil. The high-

pressure liquid refrigerant from the condenser

expands into a low-pressure liquid as it passes

through the metering orifice and diffuser screen of

the fixed orifice tube.

The fixed orifice tube cannot be repaired and, if

faulty or plugged, the liquid line and fixed orifice

tube unit or liquid line jumper and fixed orifice tube

unit must be replaced.

REMOVAL

The fixed orifice tube is located in the liquid line

(Left-Hand Drive) or the liquid line jumper (Right-

Hand Drive) near the condenser. The orifice has filter

screens on the inlet and outlet ends of the tube body.

If the fixed orifice tube is faulty or plugged, the liq-

uid line unit or liquid line jumper unit must be

replaced. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/LIQUID LINE - REMOVAL)

INSTALLATION

The fixed orifice tube is located in the liquid line

(Left-Hand Drive) or the liquid line jumper (Right-

Hand Drive) near the condenser. The orifice has filter

screens on the inlet and outlet ends of the tube body.

If the fixed orifice tube is faulty or plugged, the liq-

uid line unit or liquid line jumper unit must be

Fig. 10 Blend Door

1 - DEFROSTER DOOR

2- HEATER CORE

3- BLEND DOORS

4- BLOWER MOTOR HOUSING

5- EVAPORATOR (A/C ONLY)

6- LOWER HVAC CASE ASSEMBLY

Fig. 11 FIXED ORIFICE TUBE - TYPICAL

1 - DIFFUSER SCREEN

2-9O9RINGS

3 - INLET FILTER SCREENS

4 - ORIFICE

24 - 50 PLUMBINGKJ

A/C EVAPORATOR (Continued)

Page 1703 of 1803

replaced. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/LIQUID LINE - REMOVAL)

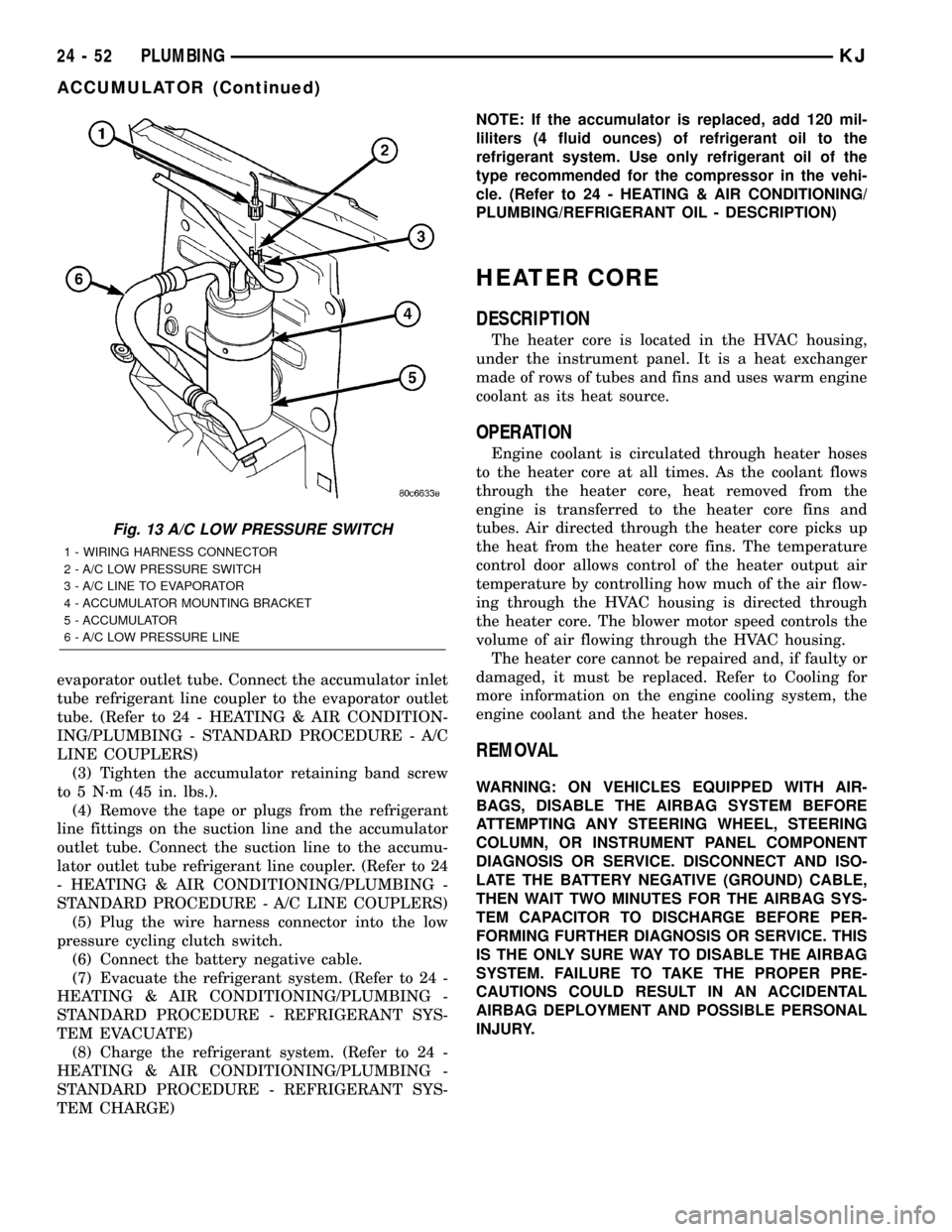

ACCUMULATOR

DESCRIPTION

The accumulator is mounted in the engine com-

partment between the evaporator coil outlet tube and

the compressor inlet.

OPERATION

Refrigerant enters the accumulator canister as a

low pressure vapor through the inlet tube. Any liq-

uid, oil-laden refrigerant falls to the bottom of the

canister, which acts as a separator. A desiccant bag is

mounted inside the accumulator canister to absorb

any moisture which may have entered and become

trapped within the refrigerant system (Fig. 12).

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Unplug the wire harness connector from the

low pressure cycling clutch switch.

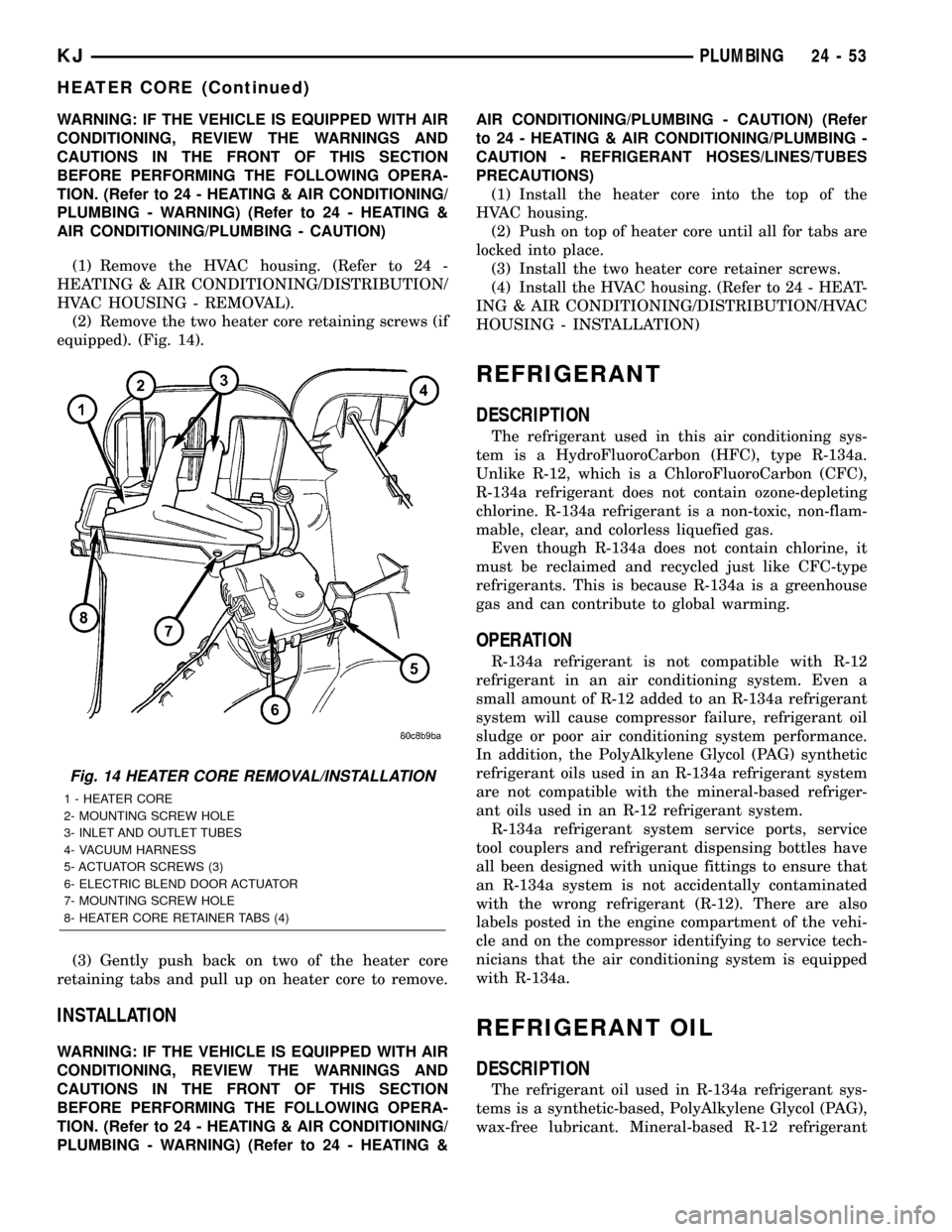

(4) Loosen the screw that secures the accumulator

retaining band to the support bracket on the dash

panel (Fig. 13).

(5) Disconnect the suction line from the accumula-

tor outlet tube refrigerant line fitting. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

(6) Disconnect the accumulator inlet tube refriger-

ant line fitting from the evaporator outlet tube.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE - A/C LINE

COUPLERS) Install plugs in, or tape over all of the

opened refrigerant line fittings.

(7) Pull the accumulator and retaining band unit

forward until the screw in the band is clear of the

slotted hole in the support bracket on the dash panel.

(8) Remove the accumulator from the vehicle.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Install the accumulator and retaining band as

a unit by sliding the screw in the band into the slot-

ted hole in the support bracket on the dash panel.

(2) Remove the tape or plugs from the refrigerant

line fittings on the accumulator inlet tube and the

Fig. 12 ACCUMULATOR - TYPICAL

1 - A/C LOW PRESSURE SWITCH

2 - PRESSURE SWITCH FITTING

3 - OUTLET TO COMPRESSOR

4 - ANTI-SIPHON HOLE

5 - DESICCANT BAG

6 - OIL RETURN ORIFICE FILTER

7 - VAPOR RETURN TUBE

8 - ACCUMULATOR DOME

9 - O-RING SEAL

10 - INLET FROM EVAPORATOR

KJPLUMBING 24 - 51

A/C ORIFICE TUBE (Continued)

Page 1704 of 1803

evaporator outlet tube. Connect the accumulator inlet

tube refrigerant line coupler to the evaporator outlet

tube. (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE - A/C

LINE COUPLERS)

(3) Tighten the accumulator retaining band screw

to 5 N´m (45 in. lbs.).

(4) Remove the tape or plugs from the refrigerant

line fittings on the suction line and the accumulator

outlet tube. Connect the suction line to the accumu-

lator outlet tube refrigerant line coupler. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

(5) Plug the wire harness connector into the low

pressure cycling clutch switch.

(6) Connect the battery negative cable.

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)NOTE: If the accumulator is replaced, add 120 mil-

liliters (4 fluid ounces) of refrigerant oil to the

refrigerant system. Use only refrigerant oil of the

type recommended for the compressor in the vehi-

cle. (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - DESCRIPTION)

HEATER CORE

DESCRIPTION

The heater core is located in the HVAC housing,

under the instrument panel. It is a heat exchanger

made of rows of tubes and fins and uses warm engine

coolant as its heat source.

OPERATION

Engine coolant is circulated through heater hoses

to the heater core at all times. As the coolant flows

through the heater core, heat removed from the

engine is transferred to the heater core fins and

tubes. Air directed through the heater core picks up

the heat from the heater core fins. The temperature

control door allows control of the heater output air

temperature by controlling how much of the air flow-

ing through the HVAC housing is directed through

the heater core. The blower motor speed controls the

volume of air flowing through the HVAC housing.

The heater core cannot be repaired and, if faulty or

damaged, it must be replaced. Refer to Cooling for

more information on the engine cooling system, the

engine coolant and the heater hoses.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Fig. 13 A/C LOW PRESSURE SWITCH

1 - WIRING HARNESS CONNECTOR

2 - A/C LOW PRESSURE SWITCH

3 - A/C LINE TO EVAPORATOR

4 - ACCUMULATOR MOUNTING BRACKET

5 - ACCUMULATOR

6 - A/C LOW PRESSURE LINE

24 - 52 PLUMBINGKJ

ACCUMULATOR (Continued)

Page 1705 of 1803

WARNING: IF THE VEHICLE IS EQUIPPED WITH AIR

CONDITIONING, REVIEW THE WARNINGS AND

CAUTIONS IN THE FRONT OF THIS SECTION

BEFORE PERFORMING THE FOLLOWING OPERA-

TION. (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Remove the HVAC housing. (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL).

(2) Remove the two heater core retaining screws (if

equipped). (Fig. 14).

(3) Gently push back on two of the heater core

retaining tabs and pull up on heater core to remove.

INSTALLATION

WARNING: IF THE VEHICLE IS EQUIPPED WITH AIR

CONDITIONING, REVIEW THE WARNINGS AND

CAUTIONS IN THE FRONT OF THIS SECTION

BEFORE PERFORMING THE FOLLOWING OPERA-

TION. (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Install the heater core into the top of the

HVAC housing.

(2) Push on top of heater core until all for tabs are

locked into place.

(3) Install the two heater core retainer screws.

(4) Install the HVAC housing. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION)

REFRIGERANT

DESCRIPTION

The refrigerant used in this air conditioning sys-

tem is a HydroFluoroCarbon (HFC), type R-134a.

Unlike R-12, which is a ChloroFluoroCarbon (CFC),

R-134a refrigerant does not contain ozone-depleting

chlorine. R-134a refrigerant is a non-toxic, non-flam-

mable, clear, and colorless liquefied gas.

Even though R-134a does not contain chlorine, it

must be reclaimed and recycled just like CFC-type

refrigerants. This is because R-134a is a greenhouse

gas and can contribute to global warming.

OPERATION

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 added to an R-134a refrigerant

system will cause compressor failure, refrigerant oil

sludge or poor air conditioning system performance.

In addition, the PolyAlkylene Glycol (PAG) synthetic

refrigerant oils used in an R-134a refrigerant system

are not compatible with the mineral-based refriger-

ant oils used in an R-12 refrigerant system.

R-134a refrigerant system service ports, service

tool couplers and refrigerant dispensing bottles have

all been designed with unique fittings to ensure that

an R-134a system is not accidentally contaminated

with the wrong refrigerant (R-12). There are also

labels posted in the engine compartment of the vehi-

cle and on the compressor identifying to service tech-

nicians that the air conditioning system is equipped

with R-134a.

REFRIGERANT OIL

DESCRIPTION

The refrigerant oil used in R-134a refrigerant sys-

tems is a synthetic-based, PolyAlkylene Glycol (PAG),

wax-free lubricant. Mineral-based R-12 refrigerant

Fig. 14 HEATER CORE REMOVAL/INSTALLATION

1 - HEATER CORE

2- MOUNTING SCREW HOLE

3- INLET AND OUTLET TUBES

4- VACUUM HARNESS

5- ACTUATOR SCREWS (3)

6- ELECTRIC BLEND DOOR ACTUATOR

7- MOUNTING SCREW HOLE

8- HEATER CORE RETAINER TABS (4)

KJPLUMBING 24 - 53

HEATER CORE (Continued)

Page 1706 of 1803

oils are not compatible with PAG oils, and should

never be introduced to an R-134a refrigerant system.

There are different PAG oils available, and each

contains a different additive package. The PXF±18

compressor used in this vehicle is designed to use an

SP±10 PAG refrigerant oil. Use only refrigerant oil of

this same type to service the refrigerant system.

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance.

PAG refrigerant oil is much more hygroscopic than

mineral oil, and will absorb any moisture it comes

into contact with, even moisture in the air. The PAG

oil container should always be kept tightly capped

until it is ready to be used. After use, recap the oil

container immediately to prevent moisture contami-

nation.

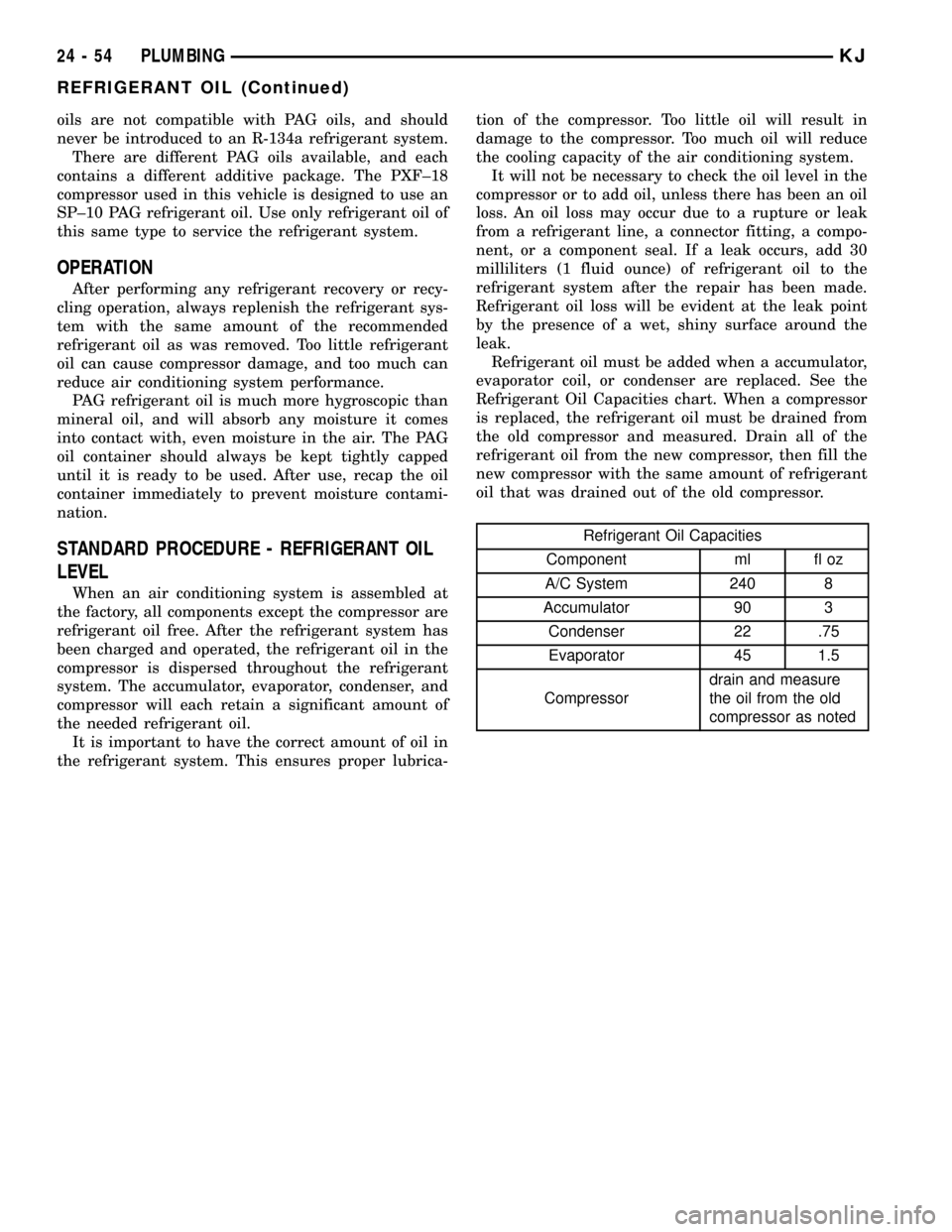

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

When an air conditioning system is assembled at

the factory, all components except the compressor are

refrigerant oil free. After the refrigerant system has

been charged and operated, the refrigerant oil in the

compressor is dispersed throughout the refrigerant

system. The accumulator, evaporator, condenser, and

compressor will each retain a significant amount of

the needed refrigerant oil.

It is important to have the correct amount of oil in

the refrigerant system. This ensures proper lubrica-tion of the compressor. Too little oil will result in

damage to the compressor. Too much oil will reduce

the cooling capacity of the air conditioning system.

It will not be necessary to check the oil level in the

compressor or to add oil, unless there has been an oil

loss. An oil loss may occur due to a rupture or leak

from a refrigerant line, a connector fitting, a compo-

nent, or a component seal. If a leak occurs, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system after the repair has been made.

Refrigerant oil loss will be evident at the leak point

by the presence of a wet, shiny surface around the

leak.

Refrigerant oil must be added when a accumulator,

evaporator coil, or condenser are replaced. See the

Refrigerant Oil Capacities chart. When a compressor

is replaced, the refrigerant oil must be drained from

the old compressor and measured. Drain all of the

refrigerant oil from the new compressor, then fill the

new compressor with the same amount of refrigerant

oil that was drained out of the old compressor.

Refrigerant Oil Capacities

Component ml fl oz

A/C System 240 8

Accumulator 90 3

Condenser 22 .75

Evaporator 45 1.5

Compressordrain and measure

the oil from the old

compressor as noted

24 - 54 PLUMBINGKJ

REFRIGERANT OIL (Continued)

Page 1713 of 1803

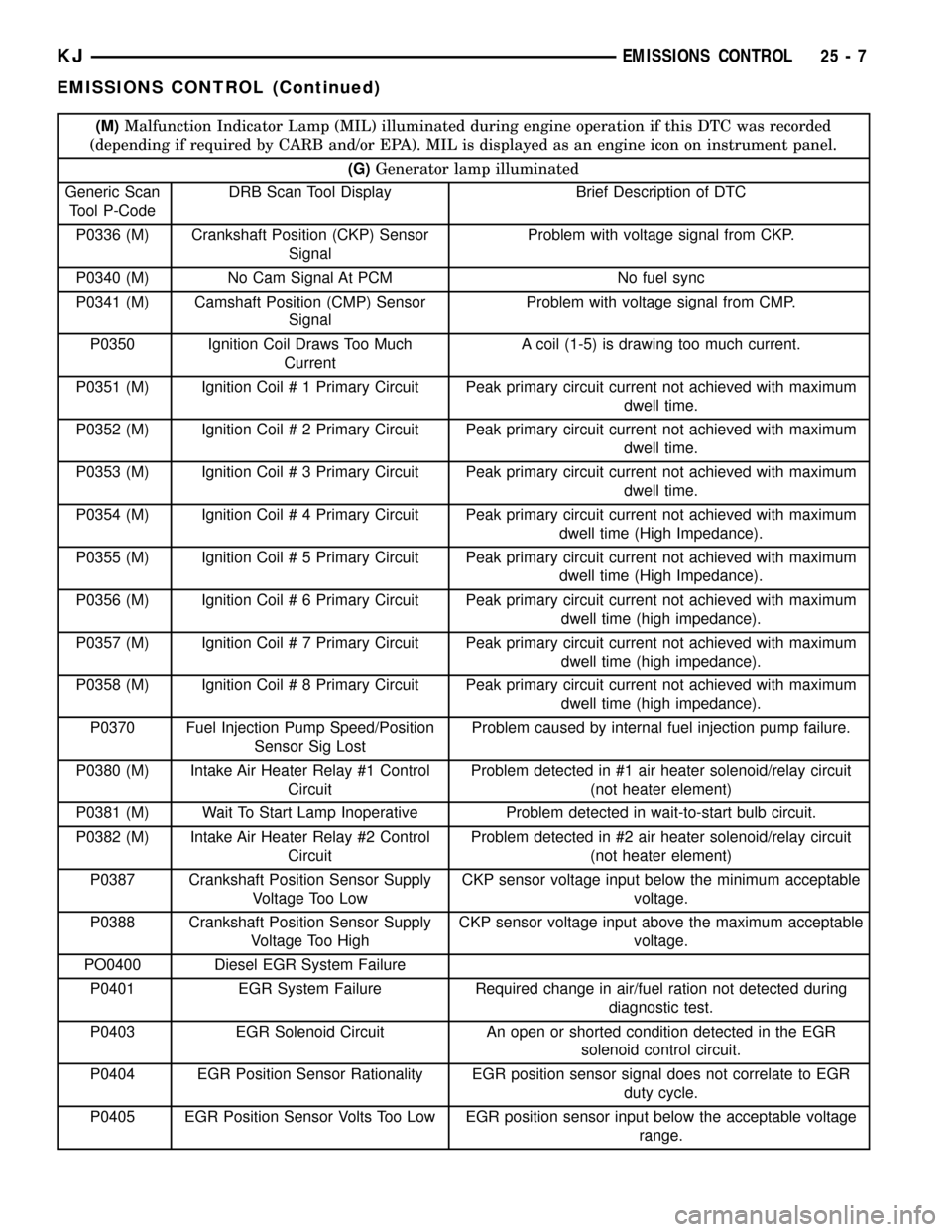

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0336 (M) Crankshaft Position (CKP) Sensor

SignalProblem with voltage signal from CKP.

P0340 (M) No Cam Signal At PCM No fuel sync

P0341 (M) Camshaft Position (CMP) Sensor

SignalProblem with voltage signal from CMP.

P0350 Ignition Coil Draws Too Much

CurrentA coil (1-5) is drawing too much current.

P0351 (M) Ignition Coil # 1 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0352 (M) Ignition Coil # 2 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0353 (M) Ignition Coil # 3 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0354 (M) Ignition Coil # 4 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0355 (M) Ignition Coil # 5 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0356 (M) Ignition Coil # 6 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0357 (M) Ignition Coil # 7 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0358 (M) Ignition Coil # 8 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0370 Fuel Injection Pump Speed/Position

Sensor Sig LostProblem caused by internal fuel injection pump failure.

P0380 (M) Intake Air Heater Relay #1 Control

CircuitProblem detected in #1 air heater solenoid/relay circuit

(not heater element)

P0381 (M) Wait To Start Lamp Inoperative Problem detected in wait-to-start bulb circuit.

P0382 (M) Intake Air Heater Relay #2 Control

CircuitProblem detected in #2 air heater solenoid/relay circuit

(not heater element)

P0387 Crankshaft Position Sensor Supply

Voltage Too LowCKP sensor voltage input below the minimum acceptable

voltage.

P0388 Crankshaft Position Sensor Supply

Voltage Too HighCKP sensor voltage input above the maximum acceptable

voltage.

PO0400 Diesel EGR System Failure

P0401 EGR System Failure Required change in air/fuel ration not detected during

diagnostic test.

P0403 EGR Solenoid Circuit An open or shorted condition detected in the EGR

solenoid control circuit.

P0404 EGR Position Sensor Rationality EGR position sensor signal does not correlate to EGR

duty cycle.

P0405 EGR Position Sensor Volts Too Low EGR position sensor input below the acceptable voltage

range.

KJEMISSIONS CONTROL 25 - 7

EMISSIONS CONTROL (Continued)