Turn JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1256 of 1803

Misaligned or bent connecting rods can cause

abnormal wear on pistons, piston rings, cylinder

walls, connecting rod bearings and crankshaft con-

necting rod journals. If wear patterns or damage to

any of these components indicate the probability of a

misaligned connecting rod, inspect it for correct rod

alignment. Replace misaligned, bent or twisted con-

necting rods.

(1) Wipe the oil from the connecting rod journal.

(2) Lubricate the upper bearing insert and install

in connecting rod.

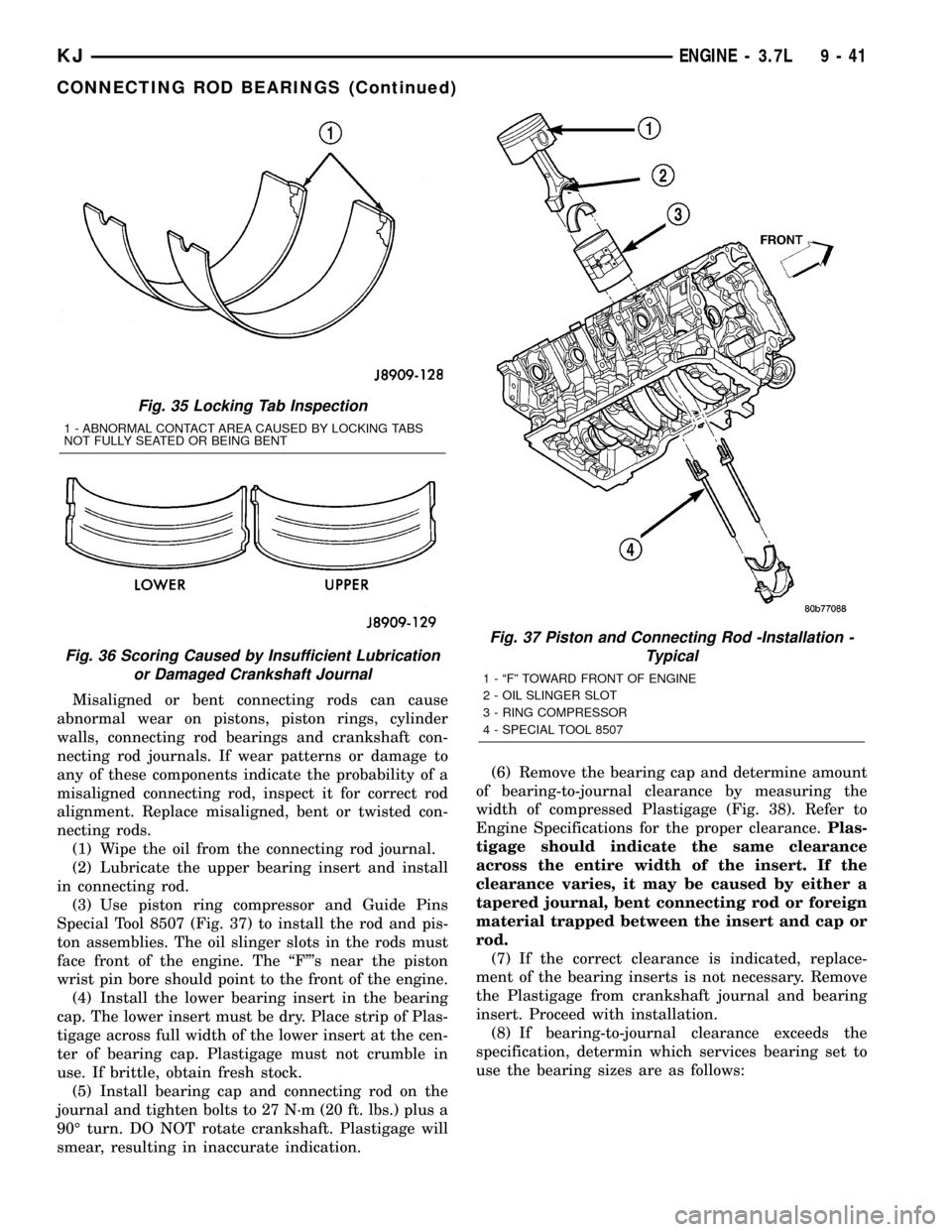

(3) Use piston ring compressor and Guide Pins

Special Tool 8507 (Fig. 37) to install the rod and pis-

ton assemblies. The oil slinger slots in the rods must

face front of the engine. The ªFº's near the piston

wrist pin bore should point to the front of the engine.

(4) Install the lower bearing insert in the bearing

cap. The lower insert must be dry. Place strip of Plas-

tigage across full width of the lower insert at the cen-

ter of bearing cap. Plastigage must not crumble in

use. If brittle, obtain fresh stock.

(5) Install bearing cap and connecting rod on the

journal and tighten bolts to 27 N´m (20 ft. lbs.) plus a

90É turn. DO NOT rotate crankshaft. Plastigage will

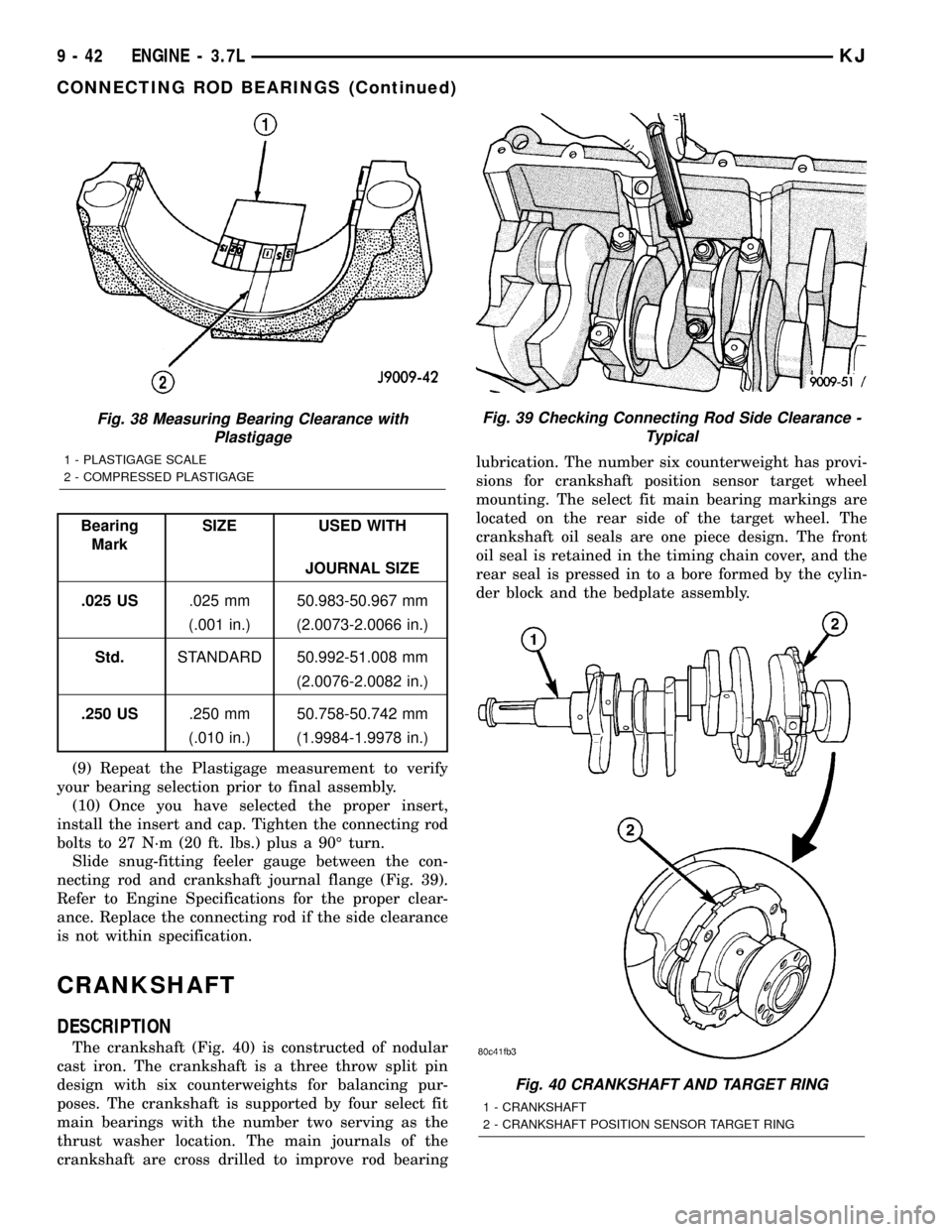

smear, resulting in inaccurate indication.(6) Remove the bearing cap and determine amount

of bearing-to-journal clearance by measuring the

width of compressed Plastigage (Fig. 38). Refer to

Engine Specifications for the proper clearance.Plas-

tigage should indicate the same clearance

across the entire width of the insert. If the

clearance varies, it may be caused by either a

tapered journal, bent connecting rod or foreign

material trapped between the insert and cap or

rod.

(7) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(8) If bearing-to-journal clearance exceeds the

specification, determin which services bearing set to

use the bearing sizes are as follows:

Fig. 35 Locking Tab Inspection

1 - ABNORMAL CONTACT AREA CAUSED BY LOCKING TABS

NOT FULLY SEATED OR BEING BENT

Fig. 36 Scoring Caused by Insufficient Lubrication

or Damaged Crankshaft Journal

Fig. 37 Piston and Connecting Rod -Installation -

Typical

1 - ªFº TOWARD FRONT OF ENGINE

2 - OIL SLINGER SLOT

3 - RING COMPRESSOR

4 - SPECIAL TOOL 8507

KJENGINE - 3.7L 9 - 41

CONNECTING ROD BEARINGS (Continued)

Page 1257 of 1803

Bearing

MarkSIZE USED WITH

JOURNAL SIZE

.025 US.025 mm 50.983-50.967 mm

(.001 in.) (2.0073-2.0066 in.)

Std.STANDARD 50.992-51.008 mm

(2.0076-2.0082 in.)

.250 US.250 mm 50.758-50.742 mm

(.010 in.) (1.9984-1.9978 in.)

(9) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(10) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 27 N´m (20 ft. lbs.) plus a 90É turn.

Slide snug-fitting feeler gauge between the con-

necting rod and crankshaft journal flange (Fig. 39).

Refer to Engine Specifications for the proper clear-

ance. Replace the connecting rod if the side clearance

is not within specification.

CRANKSHAFT

DESCRIPTION

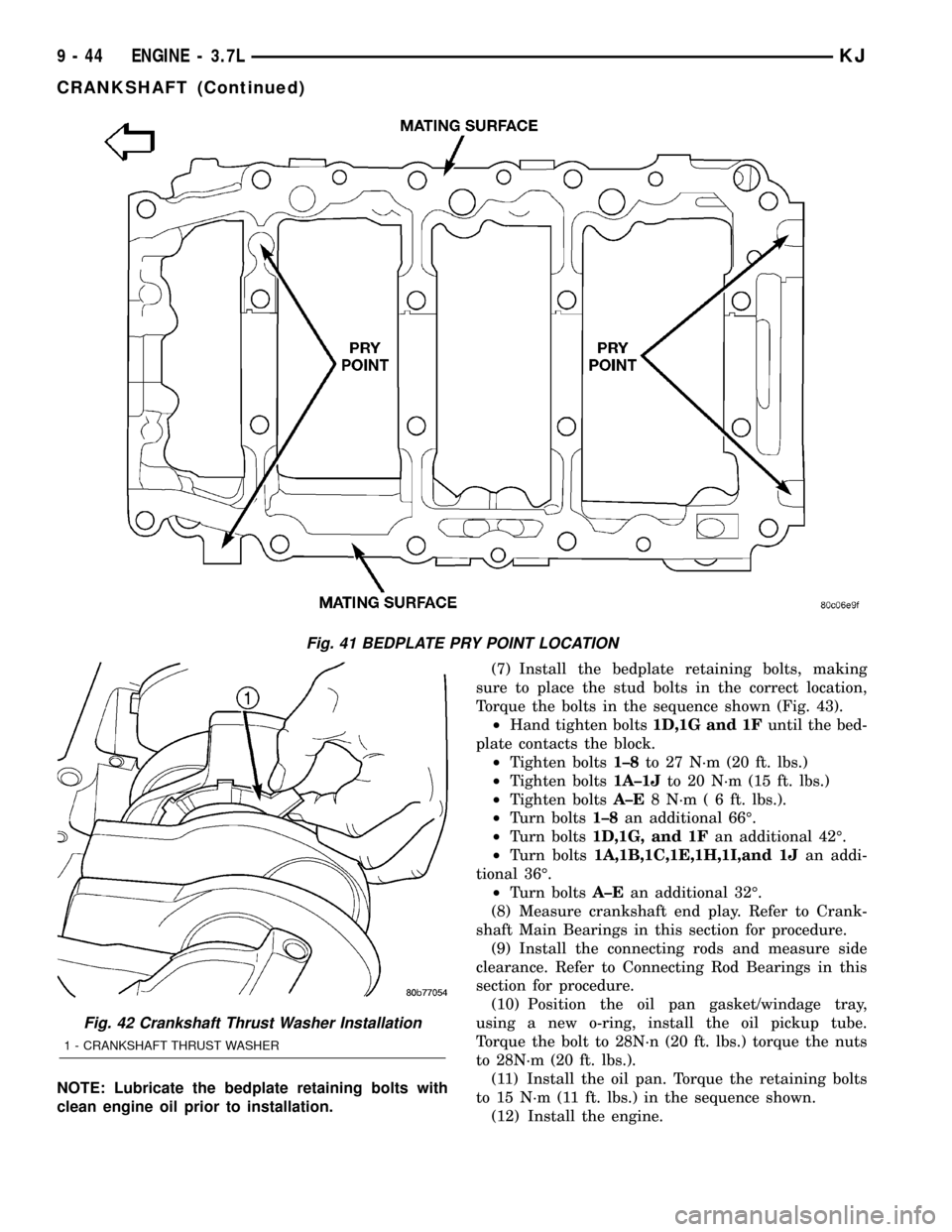

The crankshaft (Fig. 40) is constructed of nodular

cast iron. The crankshaft is a three throw split pin

design with six counterweights for balancing pur-

poses. The crankshaft is supported by four select fit

main bearings with the number two serving as the

thrust washer location. The main journals of the

crankshaft are cross drilled to improve rod bearinglubrication. The number six counterweight has provi-

sions for crankshaft position sensor target wheel

mounting. The select fit main bearing markings are

located on the rear side of the target wheel. The

crankshaft oil seals are one piece design. The front

oil seal is retained in the timing chain cover, and the

rear seal is pressed in to a bore formed by the cylin-

der block and the bedplate assembly.

Fig. 38 Measuring Bearing Clearance with

Plastigage

1 - PLASTIGAGE SCALE

2 - COMPRESSED PLASTIGAGE

Fig. 39 Checking Connecting Rod Side Clearance -

Typical

Fig. 40 CRANKSHAFT AND TARGET RING

1 - CRANKSHAFT

2 - CRANKSHAFT POSITION SENSOR TARGET RING

9 - 42 ENGINE - 3.7LKJ

CONNECTING ROD BEARINGS (Continued)

Page 1259 of 1803

NOTE: Lubricate the bedplate retaining bolts with

clean engine oil prior to installation.(7) Install the bedplate retaining bolts, making

sure to place the stud bolts in the correct location,

Torque the bolts in the sequence shown (Fig. 43).

²Hand tighten bolts1D,1G and 1Funtil the bed-

plate contacts the block.

²Tighten bolts1±8to 27 N´m (20 ft. lbs.)

²Tighten bolts1A±1Jto 20 N´m (15 ft. lbs.)

²Tighten boltsA±E8 N´m ( 6 ft. lbs.).

²Turn bolts1±8an additional 66É.

²Turn bolts1D,1G, and 1Fan additional 42É.

²Turn bolts1A,1B,1C,1E,1H,1I,and 1Jan addi-

tional 36É.

²Turn boltsA±Ean additional 32É.

(8) Measure crankshaft end play. Refer to Crank-

shaft Main Bearings in this section for procedure.

(9) Install the connecting rods and measure side

clearance. Refer to Connecting Rod Bearings in this

section for procedure.

(10) Position the oil pan gasket/windage tray,

using a new o-ring, install the oil pickup tube.

Torque the bolt to 28N´n (20 ft. lbs.) torque the nuts

to 28N´m (20 ft. lbs.).

(11) Install the oil pan. Torque the retaining bolts

to 15 N´m (11 ft. lbs.) in the sequence shown.

(12) Install the engine.

Fig. 41 BEDPLATE PRY POINT LOCATION

Fig. 42 Crankshaft Thrust Washer Installation

1 - CRANKSHAFT THRUST WASHER

9 - 44 ENGINE - 3.7LKJ

CRANKSHAFT (Continued)

Page 1263 of 1803

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

NOTE: This procedure can be performed in vehicle.

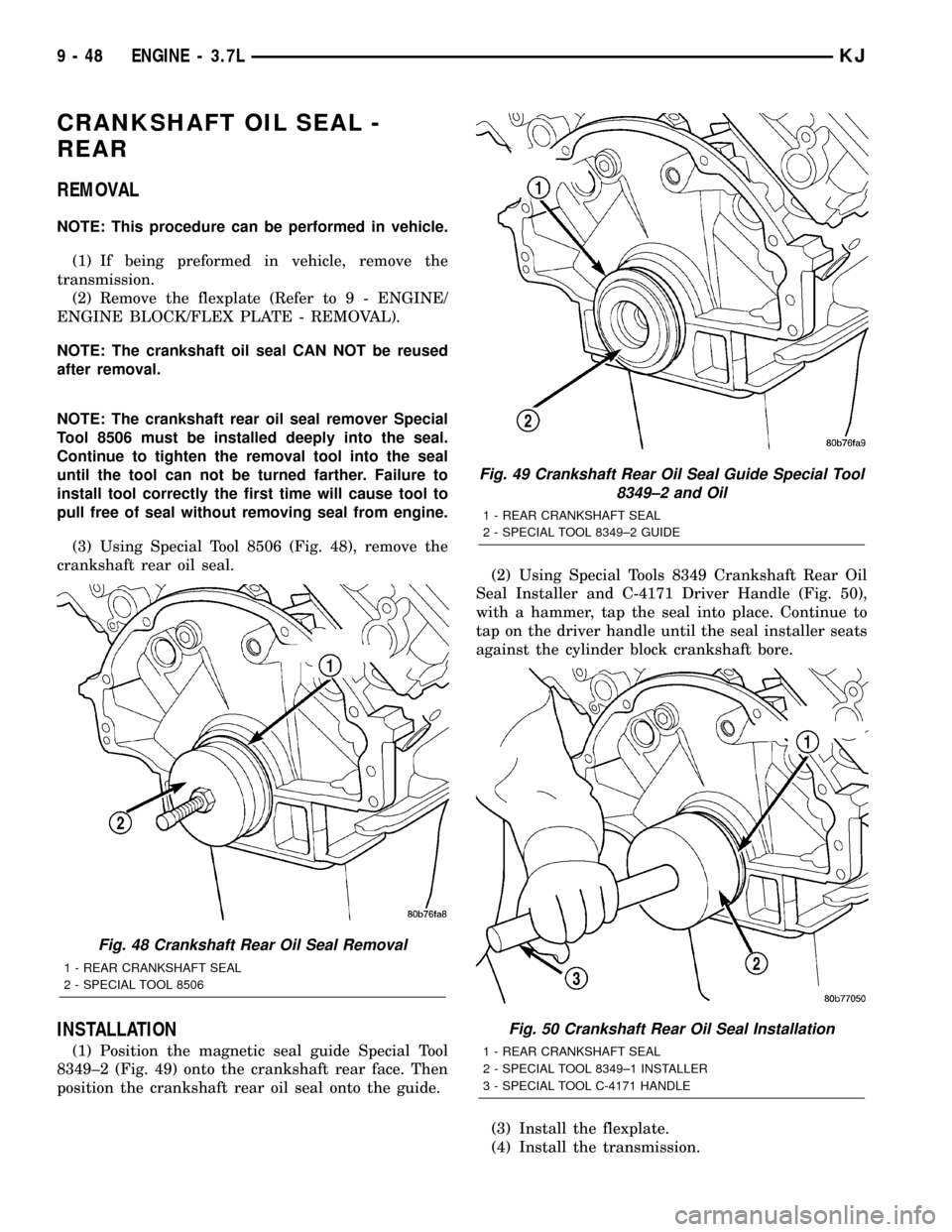

(1) If being preformed in vehicle, remove the

transmission.

(2) Remove the flexplate (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL).

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Special

Tool 8506 must be installed deeply into the seal.

Continue to tighten the removal tool into the seal

until the tool can not be turned farther. Failure to

install tool correctly the first time will cause tool to

pull free of seal without removing seal from engine.

(3) Using Special Tool 8506 (Fig. 48), remove the

crankshaft rear oil seal.

INSTALLATION

(1) Position the magnetic seal guide Special Tool

8349±2 (Fig. 49) onto the crankshaft rear face. Then

position the crankshaft rear oil seal onto the guide.(2) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle (Fig. 50),

with a hammer, tap the seal into place. Continue to

tap on the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(3) Install the flexplate.

(4) Install the transmission.

Fig. 48 Crankshaft Rear Oil Seal Removal

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8506

Fig. 49 Crankshaft Rear Oil Seal Guide Special Tool

8349±2 and Oil

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8349±2 GUIDE

Fig. 50 Crankshaft Rear Oil Seal Installation

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8349±1 INSTALLER

3 - SPECIAL TOOL C-4171 HANDLE

9 - 48 ENGINE - 3.7LKJ

Page 1265 of 1803

90É turn. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

(6) Remove the bearing cap and determine amount

of bearing-to-journal clearance by measuring the

width of compressed Plastigage. Refer to Engine

Specifications for the proper clearance.Plastigage

should indicate the same clearance across the

entire width of the insert. If the clearance var-

ies, it may be caused by either a tapered jour-

nal, bent connecting rod or foreign material

trapped between the insert and cap or rod.

(7) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(8) If bearing-to-journal clearance exceeds the

specification, determin which services bearing set to

use the bearing sizes are as follows:

Bearing

MarkSIZE USED WITH

JOURNAL SIZE

.025 US.025 mm 57.871-57.879 mm

(.001 in.) (2.2783-2.2786 in.)

Std.STANDARD 57.896-57.904 mm

(2.2793-2.2810 in.)

.250 US.250 mm 57.646-57.654 mm

(.010 in.) (2.2695-2.2698 in.)

(9) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(10) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 27 N´m (20 ft. lbs.) plus a 90É turn.

Slide snug-fitting feeler gauge between the con-

necting rod and crankshaft journal flange. Refer to

Engine Specifications for the proper clearance.

Replace the connecting rod if the side clearance is

not within specification.

STANDARD PROCEDURE - PISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm (

.0001 in.) INCREMENTS is required. If a bore gauge

is not available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at a point 38.0 mm (1.5 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 54).

(3) The coated pistons will be serviced with the

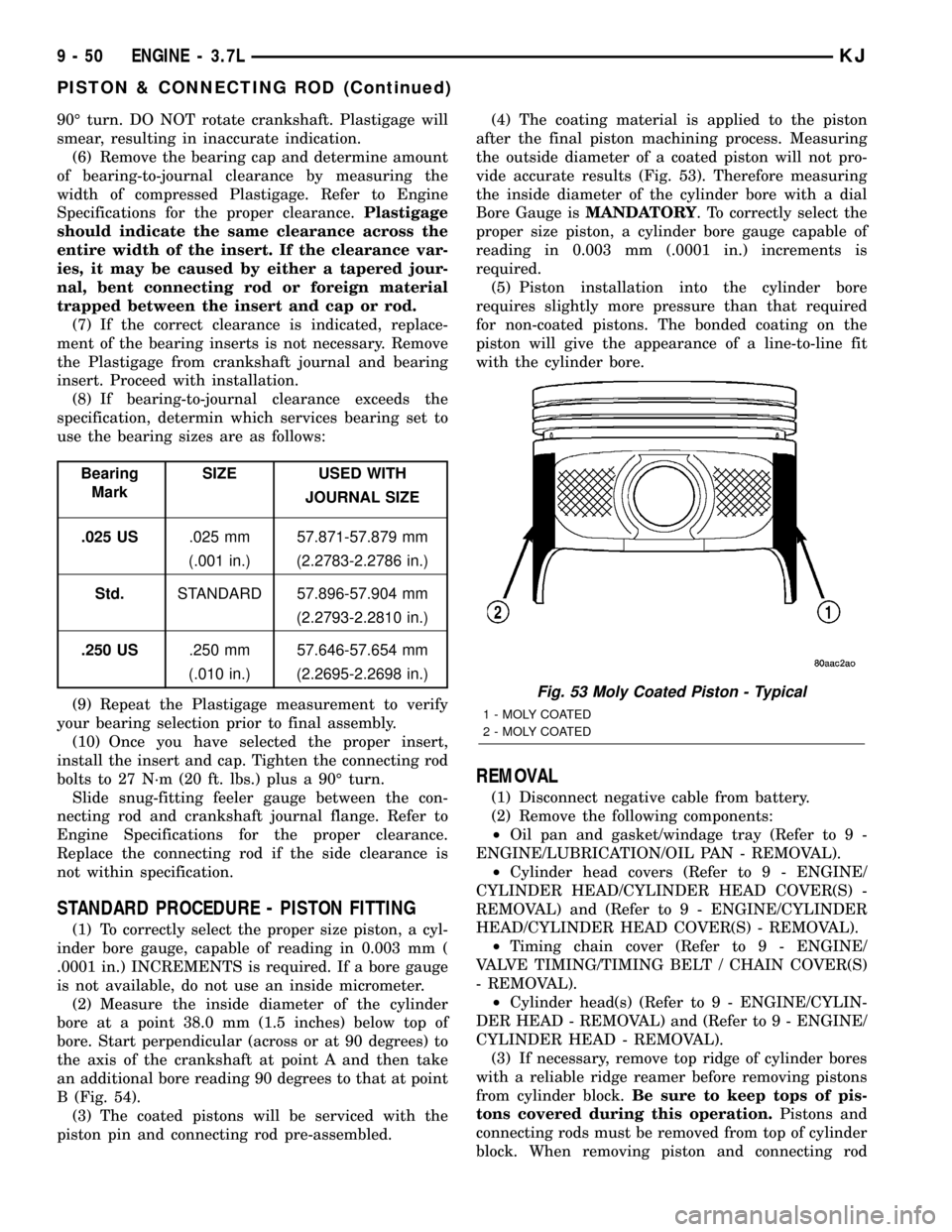

piston pin and connecting rod pre-assembled.(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not pro-

vide accurate results (Fig. 53). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the following components:

²Oil pan and gasket/windage tray (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - REMOVAL).

²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL) and (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

²Timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- REMOVAL).

²Cylinder head(s) (Refer to 9 - ENGINE/CYLIN-

DER HEAD - REMOVAL) and (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(3) If necessary, remove top ridge of cylinder bores

with a reliable ridge reamer before removing pistons

from cylinder block.Be sure to keep tops of pis-

tons covered during this operation.Pistons and

connecting rods must be removed from top of cylinder

block. When removing piston and connecting rod

Fig. 53 Moly Coated Piston - Typical

1 - MOLY COATED

2 - MOLY COATED

9 - 50 ENGINE - 3.7LKJ

PISTON & CONNECTING ROD (Continued)

Page 1273 of 1803

OPERATION

Oil from the oil pan is pumped by a gerotor type oil

pump directly mounted to the crankshaft nose. Oil

pressure is controlled by a relief valve mounted

inside the oil pump housing. For lubrication flow

refer to (Fig. 69)

The camshaft exhaust valve lobes and rocker arms

are lubricated through a small hole in the rocker

arm; oil flows through the lash adjuster then through

the rocker arm and onto the camshaft lobe. Due to

the orentation of the rocker arm, the camshaft intakelobes are not lubed in the same manner as the

exhaust lobes. The intake lobes are lubed through

internal passages in the camshaft. Oil flows through

a bore in the number 3 camshaft bearing bore, and

as the camshaft turns, a hole in the camshaft aligns

with the hole in the camshaft bore allowing engine

oil to enter the camshaft tube. The oil then exits

through 1.6mm (0.063 in.) holes drilled into the

intake lobes, lubricating the lobes and the rocker

arms.

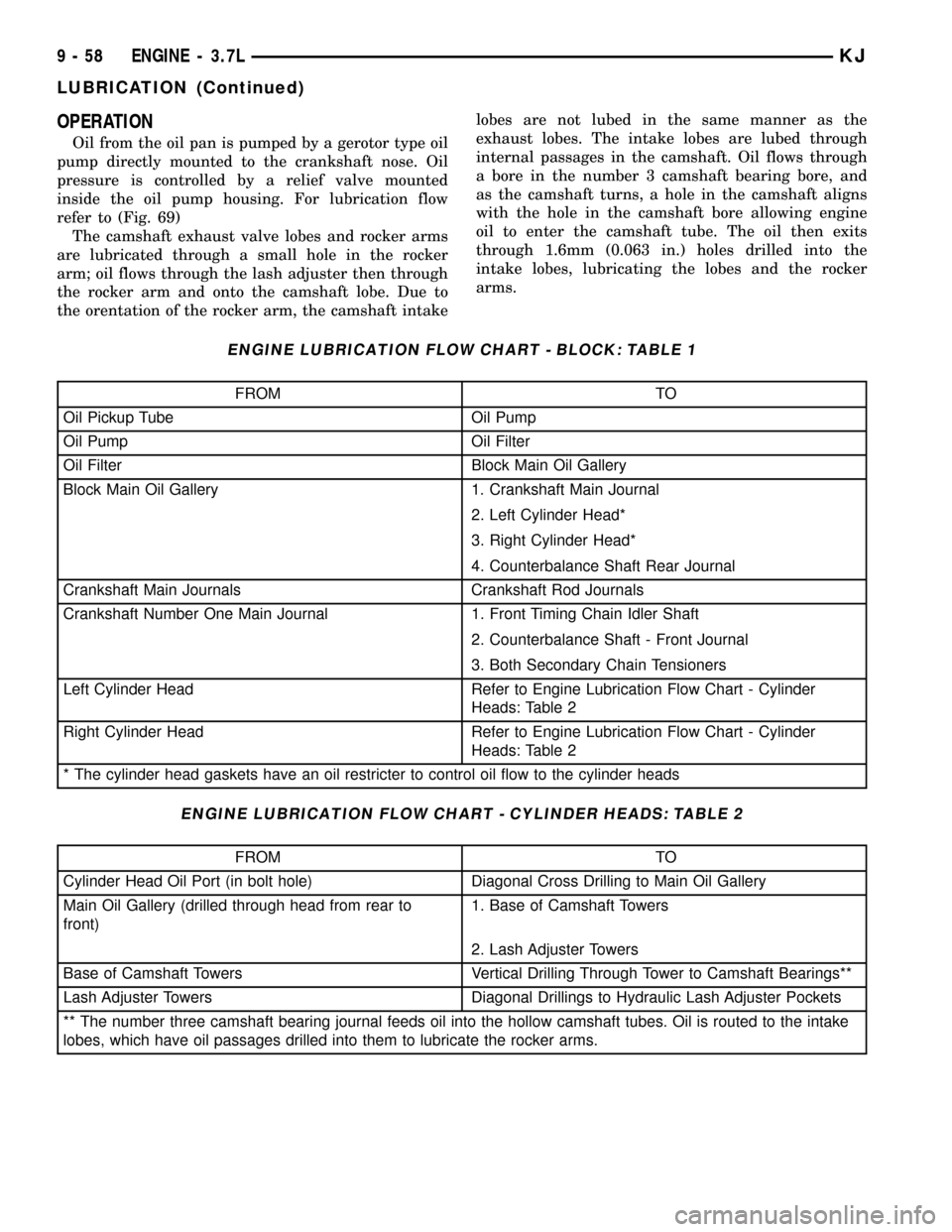

ENGINE LUBRICATION FLOW CHART - BLOCK: TABLE 1

FROM TO

Oil Pickup Tube Oil Pump

Oil Pump Oil Filter

Oil Filter Block Main Oil Gallery

Block Main Oil Gallery 1. Crankshaft Main Journal

2. Left Cylinder Head*

3. Right Cylinder Head*

4. Counterbalance Shaft Rear Journal

Crankshaft Main Journals Crankshaft Rod Journals

Crankshaft Number One Main Journal 1. Front Timing Chain Idler Shaft

2. Counterbalance Shaft - Front Journal

3. Both Secondary Chain Tensioners

Left Cylinder Head Refer to Engine Lubrication Flow Chart - Cylinder

Heads: Table 2

Right Cylinder Head Refer to Engine Lubrication Flow Chart - Cylinder

Heads: Table 2

* The cylinder head gaskets have an oil restricter to control oil flow to the cylinder heads

ENGINE LUBRICATION FLOW CHART - CYLINDER HEADS: TABLE 2

FROM TO

Cylinder Head Oil Port (in bolt hole) Diagonal Cross Drilling to Main Oil Gallery

Main Oil Gallery (drilled through head from rear to

front)1. Base of Camshaft Towers

2. Lash Adjuster Towers

Base of Camshaft Towers Vertical Drilling Through Tower to Camshaft Bearings**

Lash Adjuster Towers Diagonal Drillings to Hydraulic Lash Adjuster Pockets

** The number three camshaft bearing journal feeds oil into the hollow camshaft tubes. Oil is routed to the intake

lobes, which have oil passages drilled into them to lubricate the rocker arms.

9 - 58 ENGINE - 3.7LKJ

LUBRICATION (Continued)

Page 1275 of 1803

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat inspection.If the oil leak source is not pos-

itively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, camshaft bore

cup plugs oil galley pipe plugs, oil filter runoff, and

main bearing cap to cylinder block mating sur-

faces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

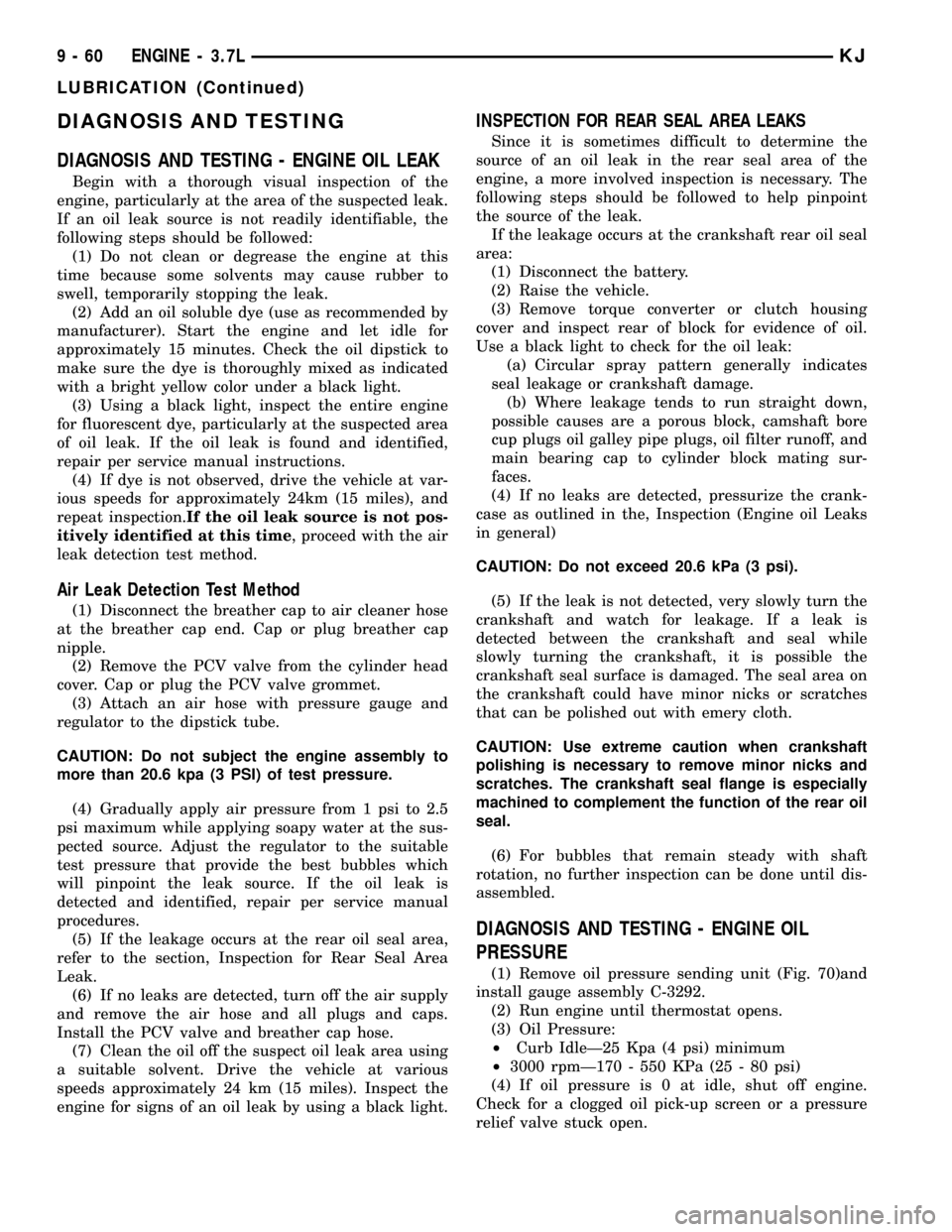

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE

(1) Remove oil pressure sending unit (Fig. 70)and

install gauge assembly C-3292.

(2) Run engine until thermostat opens.

(3) Oil Pressure:

²Curb IdleÐ25 Kpa (4 psi) minimum

²3000 rpmÐ170 - 550 KPa (25 - 80 psi)

(4) If oil pressure is 0 at idle, shut off engine.

Check for a clogged oil pick-up screen or a pressure

relief valve stuck open.

9 - 60 ENGINE - 3.7LKJ

LUBRICATION (Continued)

Page 1276 of 1803

DIAGNOSIS AND TESTING - REAR SEAL AREA

LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, camshaft bore

cup plugs, oil galley pipe plugs, oil filter runoff,

and main bearing cap to cylinder block mating sur-

faces. See Engine, for proper repair procedures of

these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the section, Inspection (Engine oil

Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. (Refer to 9 - ENGINE - DIAGNOSIS AND

TESTING), under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

OIL

STANDARD PROCEDURE - ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conform to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

Fig. 70 Oil Pressure Sending Unit -Typical

1 - BELT

2 - OIL PRESSURE SENSOR

3 - OIL FILTER

4 - ELEC. CONNECTOR

KJENGINE - 3.7L 9 - 61

LUBRICATION (Continued)

Page 1277 of 1803

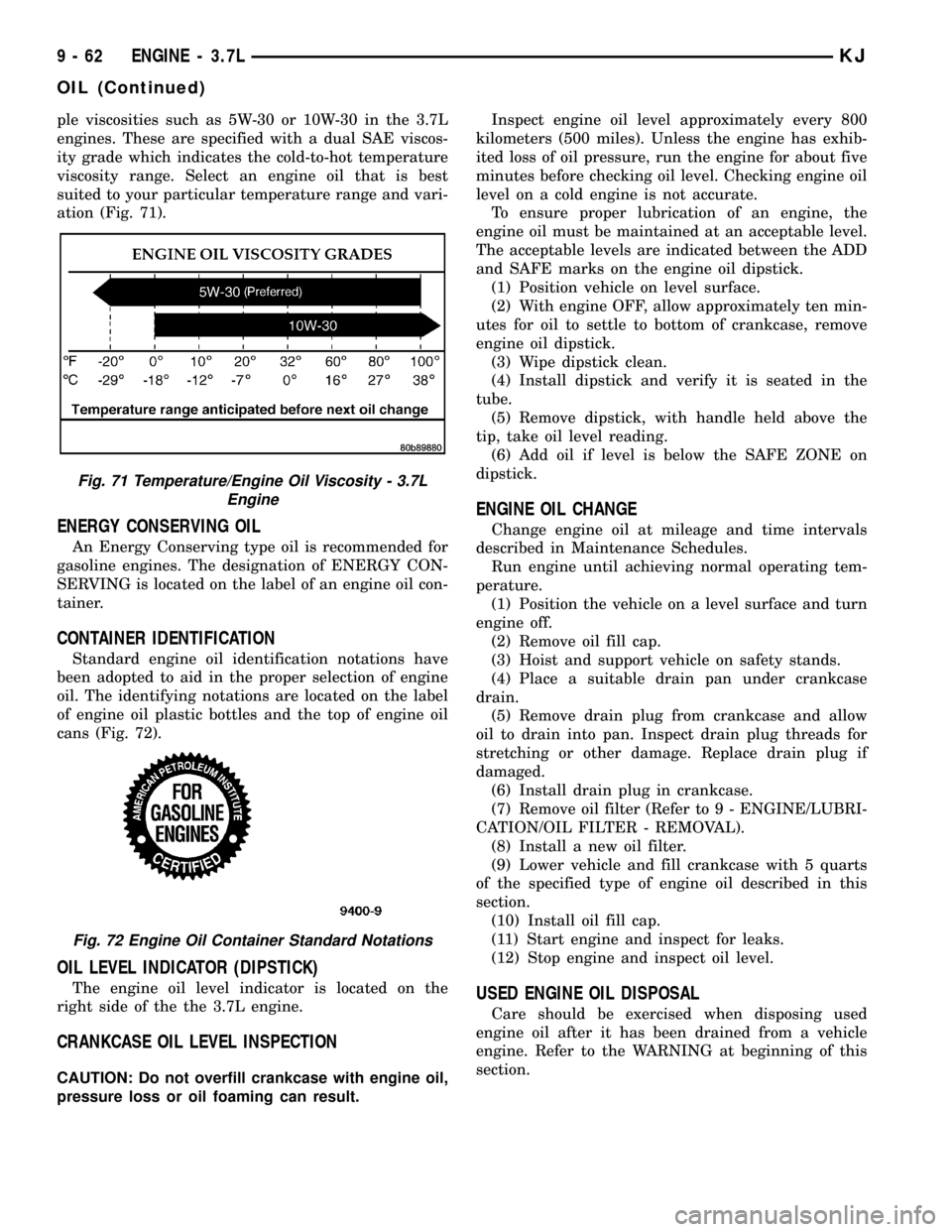

ple viscosities such as 5W-30 or 10W-30 in the 3.7L

engines. These are specified with a dual SAE viscos-

ity grade which indicates the cold-to-hot temperature

viscosity range. Select an engine oil that is best

suited to your particular temperature range and vari-

ation (Fig. 71).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

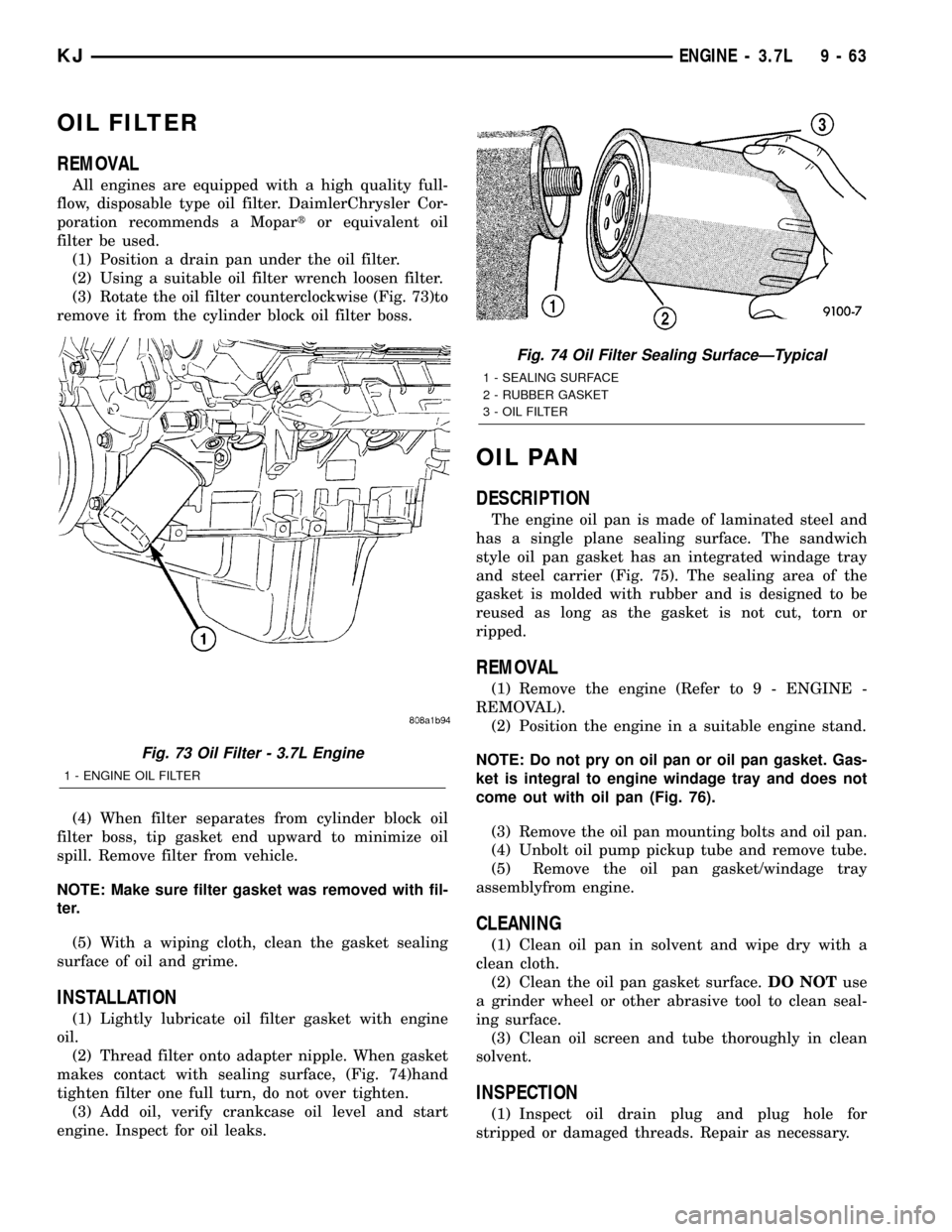

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 72).

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located on the

right side of the the 3.7L engine.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.Inspect engine oil level approximately every 800

kilometers (500 miles). Unless the engine has exhib-

ited loss of oil pressure, run the engine for about five

minutes before checking oil level. Checking engine oil

level on a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil if level is below the SAFE ZONE on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Remove oil fill cap.

(3) Hoist and support vehicle on safety stands.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug if

damaged.

(6) Install drain plug in crankcase.

(7) Remove oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Install a new oil filter.

(9) Lower vehicle and fill crankcase with 5 quarts

of the specified type of engine oil described in this

section.

(10) Install oil fill cap.

(11) Start engine and inspect for leaks.

(12) Stop engine and inspect oil level.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine. Refer to the WARNING at beginning of this

section.

Fig. 71 Temperature/Engine Oil Viscosity - 3.7L

Engine

Fig. 72 Engine Oil Container Standard Notations

9 - 62 ENGINE - 3.7LKJ

OIL (Continued)

Page 1278 of 1803

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise (Fig. 73)to

remove it from the cylinder block oil filter boss.

(4) When filter separates from cylinder block oil

filter boss, tip gasket end upward to minimize oil

spill. Remove filter from vehicle.

NOTE: Make sure filter gasket was removed with fil-

ter.

(5) With a wiping cloth, clean the gasket sealing

surface of oil and grime.

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 74)hand

tighten filter one full turn, do not over tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

OIL PAN

DESCRIPTION

The engine oil pan is made of laminated steel and

has a single plane sealing surface. The sandwich

style oil pan gasket has an integrated windage tray

and steel carrier (Fig. 75). The sealing area of the

gasket is molded with rubber and is designed to be

reused as long as the gasket is not cut, torn or

ripped.

REMOVAL

(1) Remove the engine (Refer to 9 - ENGINE -

REMOVAL).

(2) Position the engine in a suitable engine stand.

NOTE: Do not pry on oil pan or oil pan gasket. Gas-

ket is integral to engine windage tray and does not

come out with oil pan (Fig. 76).

(3) Remove the oil pan mounting bolts and oil pan.

(4) Unbolt oil pump pickup tube and remove tube.

(5) Remove the oil pan gasket/windage tray

assemblyfrom engine.

CLEANING

(1) Clean oil pan in solvent and wipe dry with a

clean cloth.

(2) Clean the oil pan gasket surface.DO NOTuse

a grinder wheel or other abrasive tool to clean seal-

ing surface.

(3) Clean oil screen and tube thoroughly in clean

solvent.

INSPECTION

(1) Inspect oil drain plug and plug hole for

stripped or damaged threads. Repair as necessary.

Fig. 73 Oil Filter - 3.7L Engine

1 - ENGINE OIL FILTER

Fig. 74 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

KJENGINE - 3.7L 9 - 63