engine JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1316 of 1803

AIR CLEANER ELEMENT

REMOVAL - 2.4L

Housing removal is not necessary for element (fil-

ter) replacement.

(1) Disconnect air intake duct at side of element

cover.

(2) Pry up 2 spring clips from front of housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs

located on rear of housing, and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

INSTALLATION - 2.4L

(1) Install element into housing.

(2) Position housing cover into housing locating

tabs.

(3) Pry up spring clips and lock cover to housing.

(4) Connect air intake duct.

If any air filter, air resonator, air intake tubes or

air filter housing clamps had been loosened or

removed, tighten them to 5 N´m (40 in. lbs.) torque.

CYLINDER HEAD

DESCRIPTION

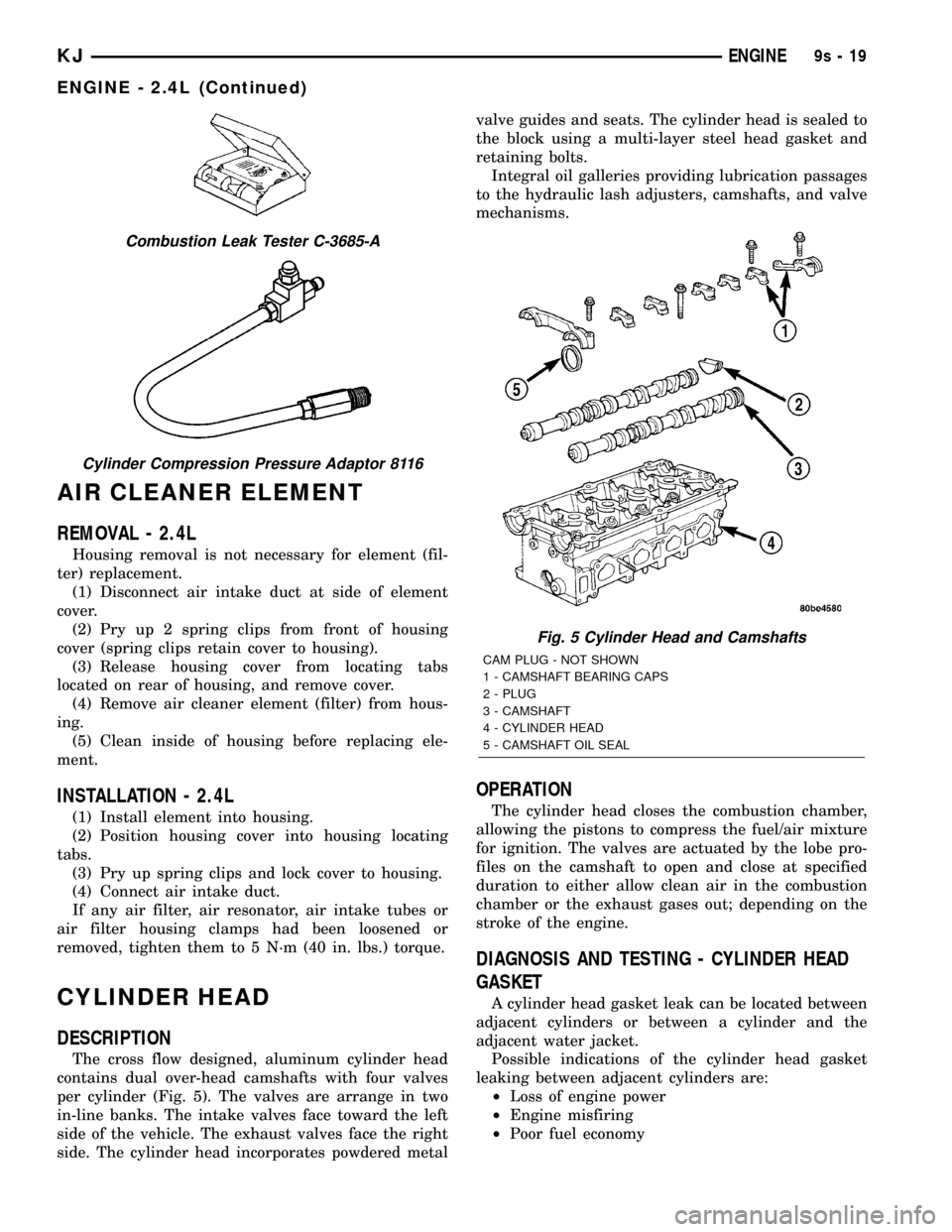

The cross flow designed, aluminum cylinder head

contains dual over-head camshafts with four valves

per cylinder (Fig. 5). The valves are arrange in two

in-line banks. The intake valves face toward the left

side of the vehicle. The exhaust valves face the right

side. The cylinder head incorporates powdered metalvalve guides and seats. The cylinder head is sealed to

the block using a multi-layer steel head gasket and

retaining bolts.

Integral oil galleries providing lubrication passages

to the hydraulic lash adjusters, camshafts, and valve

mechanisms.

OPERATION

The cylinder head closes the combustion chamber,

allowing the pistons to compress the fuel/air mixture

for ignition. The valves are actuated by the lobe pro-

files on the camshaft to open and close at specified

duration to either allow clean air in the combustion

chamber or the exhaust gases out; depending on the

stroke of the engine.

DIAGNOSIS AND TESTING - CYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Combustion Leak Tester C-3685-A

Cylinder Compression Pressure Adaptor 8116

Fig. 5 Cylinder Head and Camshafts

CAM PLUG - NOT SHOWN

1 - CAMSHAFT BEARING CAPS

2 - PLUG

3 - CAMSHAFT

4 - CYLINDER HEAD

5 - CAMSHAFT OIL SEAL

KJENGINE9s-19

ENGINE - 2.4L (Continued)

Page 1317 of 1803

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL - CYLINDER HEAD

(1) Perform fuel system pressure release procedure

before attempting any repairs.(Refer to 14 -FUEL SYSTEM/FUEL DELIVERY - SPECIFICA-

TIONS)

(2) Disconnect battery negative cable.

(3) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(4) Remove air filter housing and inlet tube.

(5) Remove intake manifold.

(6) Remove heater tube support bracket from cyl-

inder head.

(7) Disconnect radiator upper and heater supply

hoses from water outlet connections.

(8) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(9) Raise vehicle and remove exhaust pipe from

manifold.

(10) Remove power steering pump and set aside.

Do not disconnect lines.

(11) Remove accessory drive bracket

(12) Remove ignition coil and wires from engine.

(13) Disconnect cam sensor and fuel injector wir-

ing connectors.

(14) Remove timing belt and camshaft sprockets.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL)

(15) Remove timing belt idler pulley and rear tim-

ing belt cover. (Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT / CHAIN COVER(S) -

REMOVAL)

(16) Remove cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(17) Remove camshafts (Refer to 9 - ENGINE/

CYLINDER HEAD/CAMSHAFT(S) - REMOVAL).

NOTE: Identify rocker arm position to ensure cor-

rect re-installation in original position, if reused.

(18) Remove rocker arms. (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARMS - REMOVAL).

(19) Remove cylinder head bolts in REVERSE

sequence of tightening.

(20) Remove cylinder head from engine block.

(21) Inspect and clean cylinder head. (Refer to 9 -

ENGINE/CYLINDER HEAD - INSPECTION) (Refer

to 9 - ENGINE/CYLINDER HEAD - CLEANING)

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

9s - 20 ENGINEKJ

CYLINDER HEAD (Continued)

Page 1318 of 1803

Remove all gasket material from cylinder head and

block (Refer to 9 - ENGINE - STANDARD PROCE-

DURE). Be careful not to gouge or scratch the alumi-

num head sealing surface.

Clean all engine oil passages.

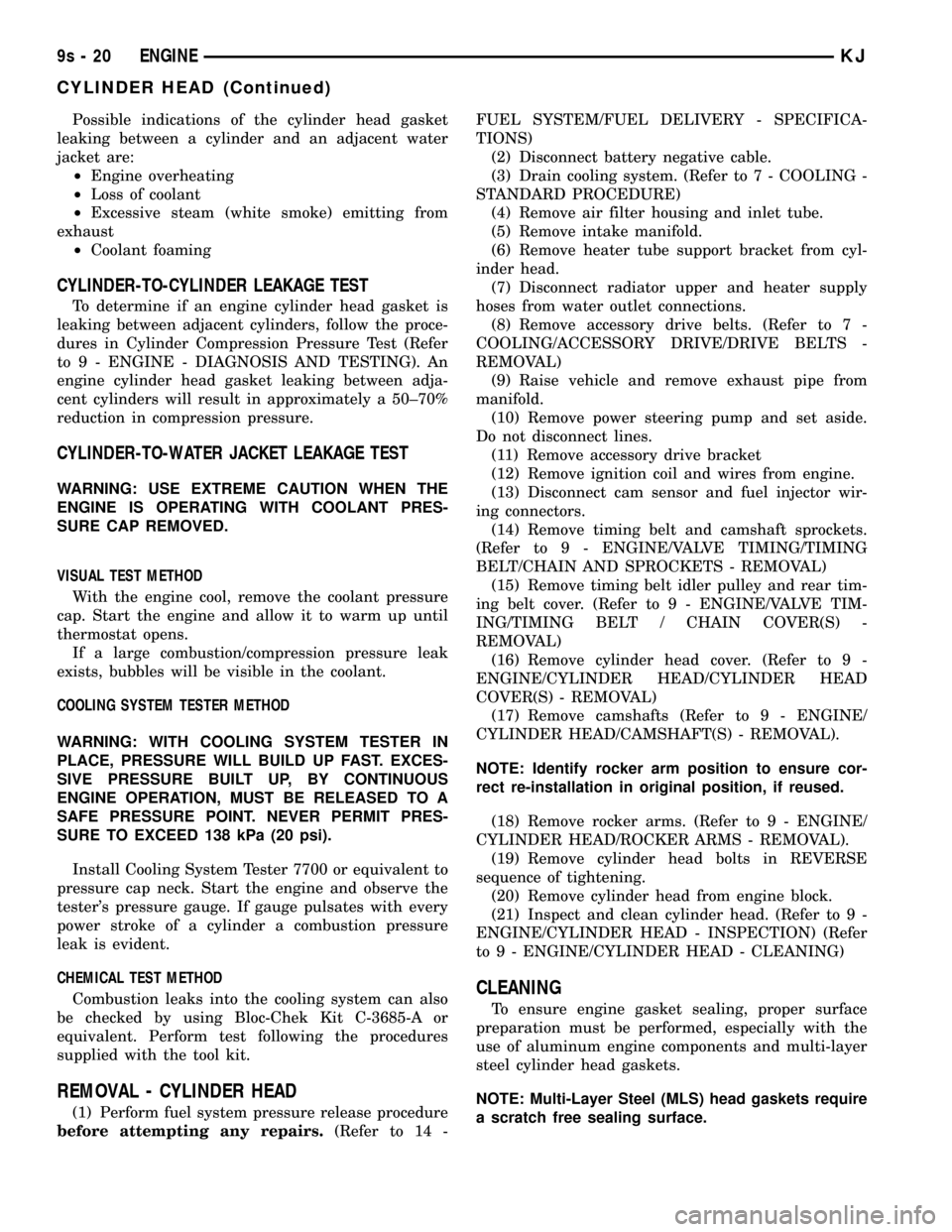

INSPECTION

(1) Cylinder head must be flat within 0.1 mm

(0.004 in.) (Fig. 6).

(2) Inspect camshaft bearing journals for scoring.

(3) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(4) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 7). (Refer to 9 - ENGINE - SPECIFICA-

TIONS) Replace guides if they are not within

specification.

(5) Check valve guide height (Fig. 8).

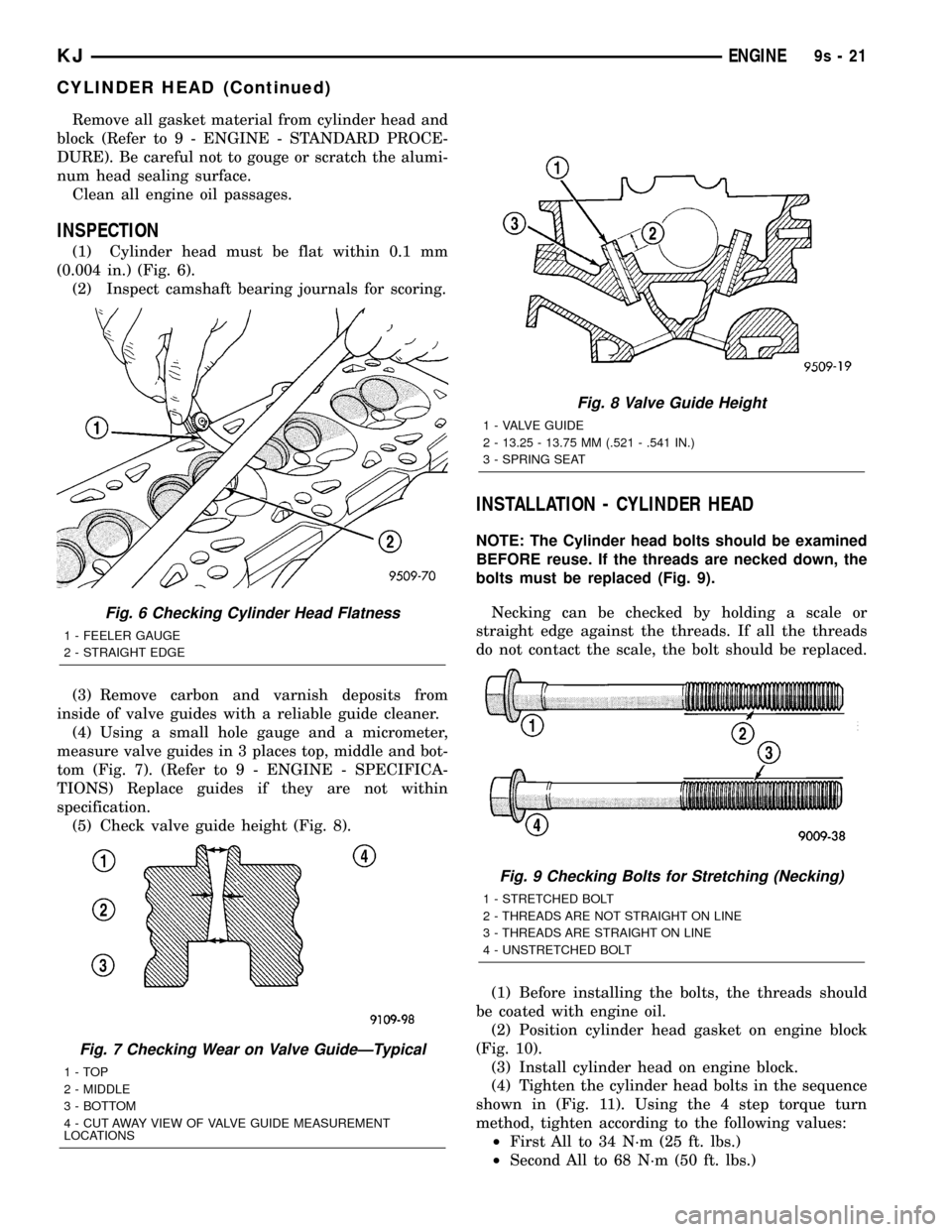

INSTALLATION - CYLINDER HEAD

NOTE: The Cylinder head bolts should be examined

BEFORE reuse. If the threads are necked down, the

bolts must be replaced (Fig. 9).

Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale, the bolt should be replaced.

(1) Before installing the bolts, the threads should

be coated with engine oil.

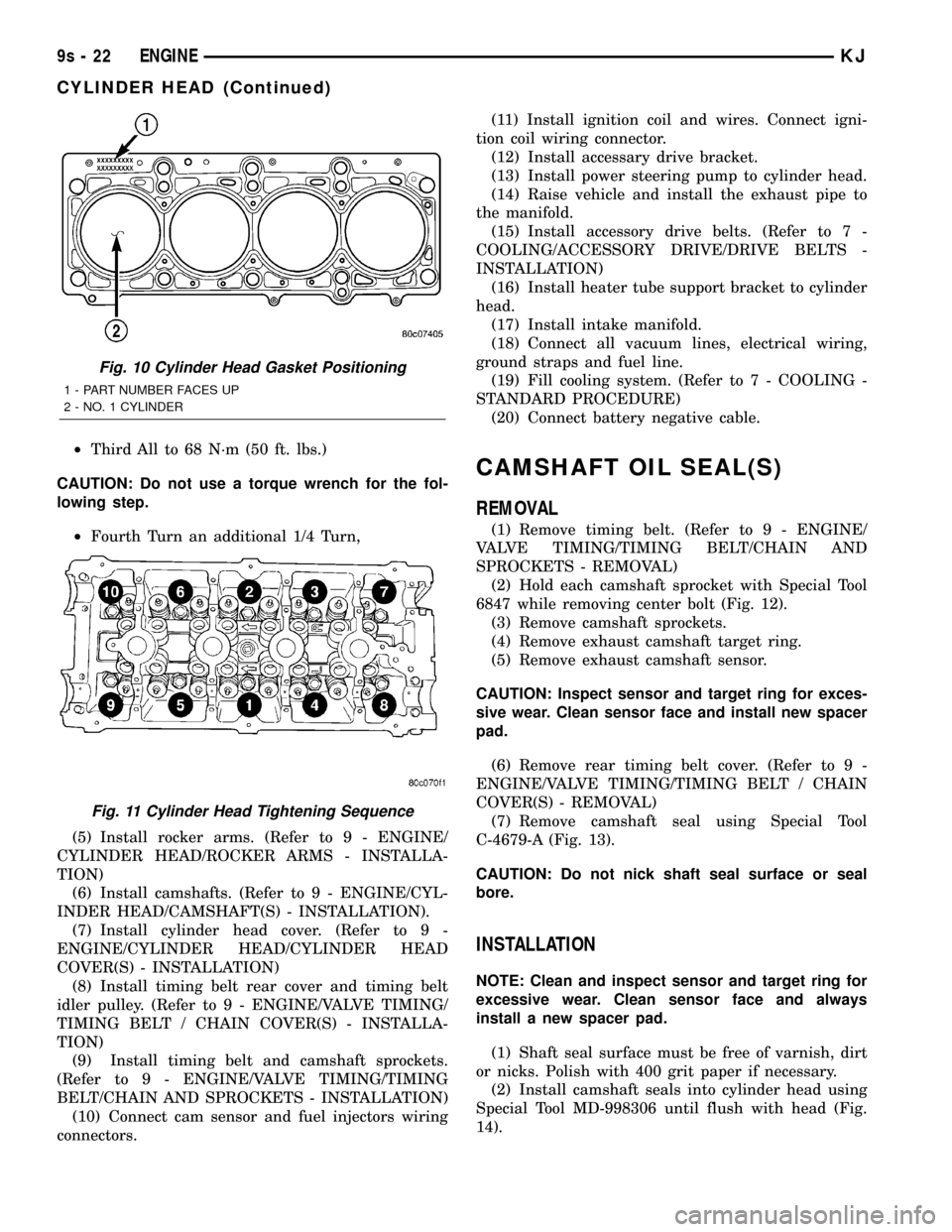

(2) Position cylinder head gasket on engine block

(Fig. 10).

(3) Install cylinder head on engine block.

(4) Tighten the cylinder head bolts in the sequence

shown in (Fig. 11). Using the 4 step torque turn

method, tighten according to the following values:

²First All to 34 N´m (25 ft. lbs.)

²Second All to 68 N´m (50 ft. lbs.)

Fig. 6 Checking Cylinder Head Flatness

1 - FEELER GAUGE

2 - STRAIGHT EDGE

Fig. 7 Checking Wear on Valve GuideÐTypical

1-TOP

2 - MIDDLE

3 - BOTTOM

4 - CUT AWAY VIEW OF VALVE GUIDE MEASUREMENT

LOCATIONS

Fig. 8 Valve Guide Height

1 - VALVE GUIDE

2 - 13.25 - 13.75 MM (.521 - .541 IN.)

3 - SPRING SEAT

Fig. 9 Checking Bolts for Stretching (Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

KJENGINE9s-21

CYLINDER HEAD (Continued)

Page 1319 of 1803

²Third All to 68 N´m (50 ft. lbs.)

CAUTION: Do not use a torque wrench for the fol-

lowing step.

²Fourth Turn an additional 1/4 Turn,

(5) Install rocker arms. (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARMS - INSTALLA-

TION)

(6) Install camshafts. (Refer to 9 - ENGINE/CYL-

INDER HEAD/CAMSHAFT(S) - INSTALLATION).

(7) Install cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(8) Install timing belt rear cover and timing belt

idler pulley. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - INSTALLA-

TION)

(9) Install timing belt and camshaft sprockets.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - INSTALLATION)

(10) Connect cam sensor and fuel injectors wiring

connectors.(11) Install ignition coil and wires. Connect igni-

tion coil wiring connector.

(12) Install accessary drive bracket.

(13) Install power steering pump to cylinder head.

(14) Raise vehicle and install the exhaust pipe to

the manifold.

(15) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(16) Install heater tube support bracket to cylinder

head.

(17) Install intake manifold.

(18) Connect all vacuum lines, electrical wiring,

ground straps and fuel line.

(19) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(20) Connect battery negative cable.

CAMSHAFT OIL SEAL(S)

REMOVAL

(1) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

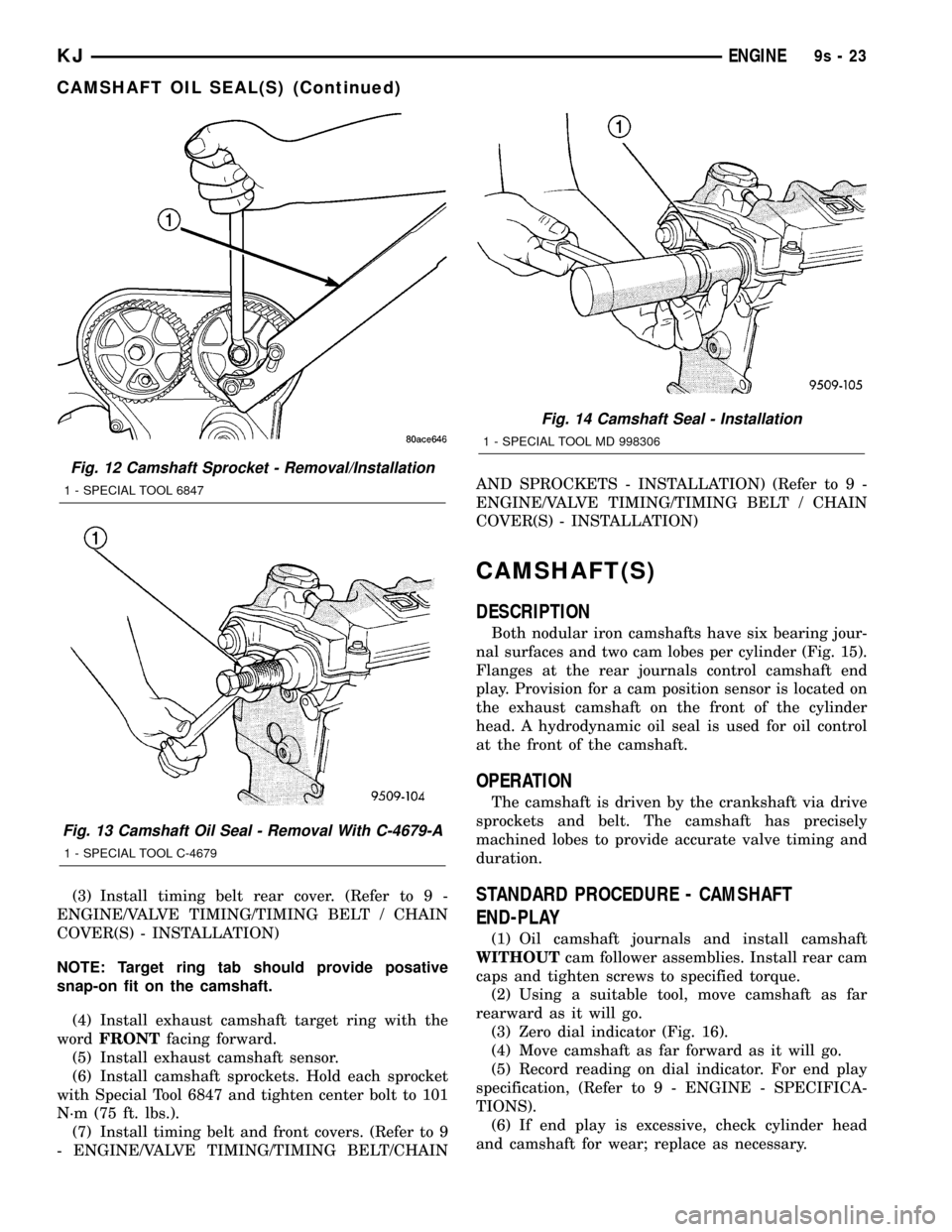

(2) Hold each camshaft sprocket with Special Tool

6847 while removing center bolt (Fig. 12).

(3) Remove camshaft sprockets.

(4) Remove exhaust camshaft target ring.

(5) Remove exhaust camshaft sensor.

CAUTION: Inspect sensor and target ring for exces-

sive wear. Clean sensor face and install new spacer

pad.

(6) Remove rear timing belt cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

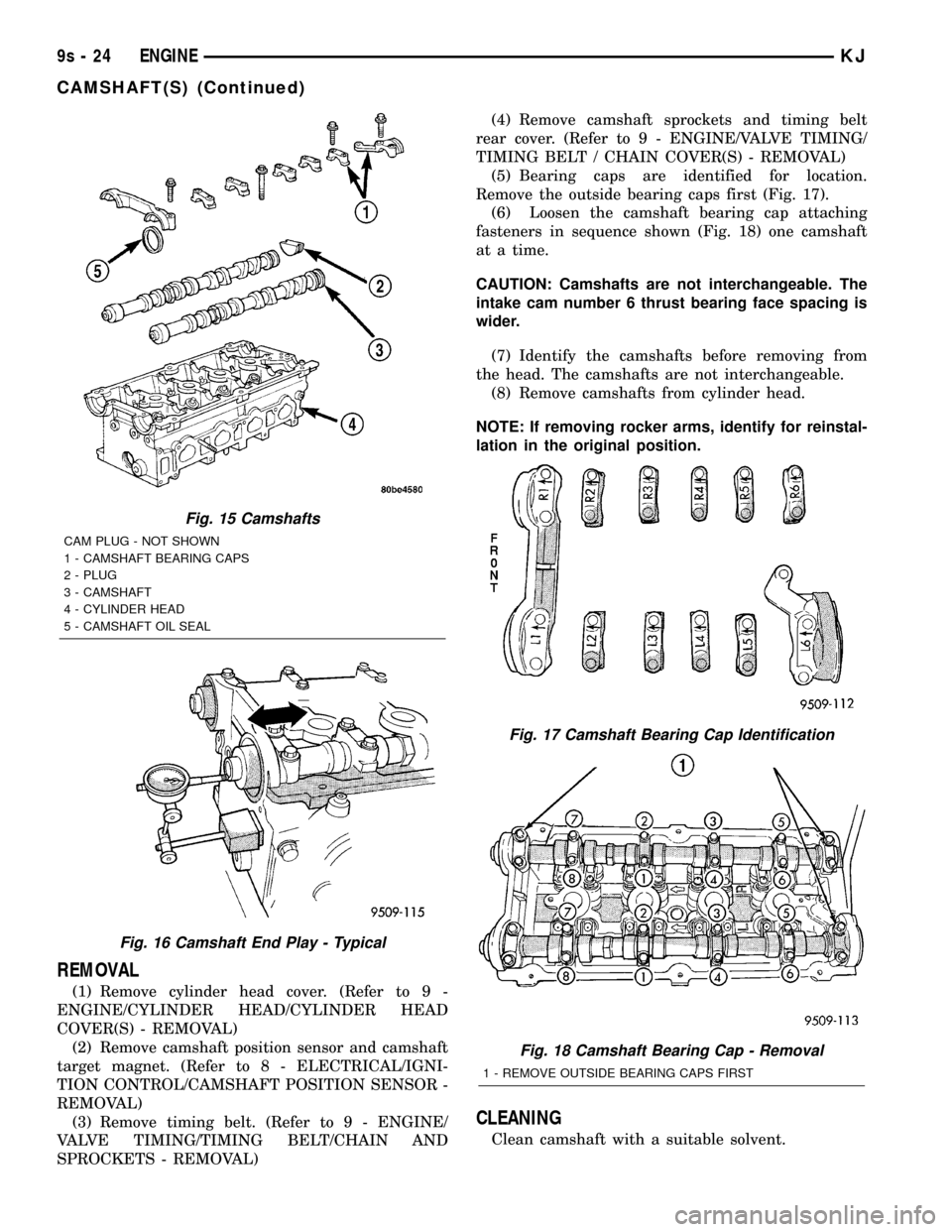

(7) Remove camshaft seal using Special Tool

C-4679-A (Fig. 13).

CAUTION: Do not nick shaft seal surface or seal

bore.

INSTALLATION

NOTE: Clean and inspect sensor and target ring for

excessive wear. Clean sensor face and always

install a new spacer pad.

(1) Shaft seal surface must be free of varnish, dirt

or nicks. Polish with 400 grit paper if necessary.

(2) Install camshaft seals into cylinder head using

Special Tool MD-998306 until flush with head (Fig.

14).

Fig. 10 Cylinder Head Gasket Positioning

1 - PART NUMBER FACES UP

2 - NO. 1 CYLINDER

Fig. 11 Cylinder Head Tightening Sequence

9s - 22 ENGINEKJ

CYLINDER HEAD (Continued)

Page 1320 of 1803

(3) Install timing belt rear cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

NOTE: Target ring tab should provide posative

snap-on fit on the camshaft.

(4) Install exhaust camshaft target ring with the

wordFRONTfacing forward.

(5) Install exhaust camshaft sensor.

(6) Install camshaft sprockets. Hold each sprocket

with Special Tool 6847 and tighten center bolt to 101

N´m (75 ft. lbs.).

(7) Install timing belt and front covers. (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT/CHAINAND SPROCKETS - INSTALLATION) (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

CAMSHAFT(S)

DESCRIPTION

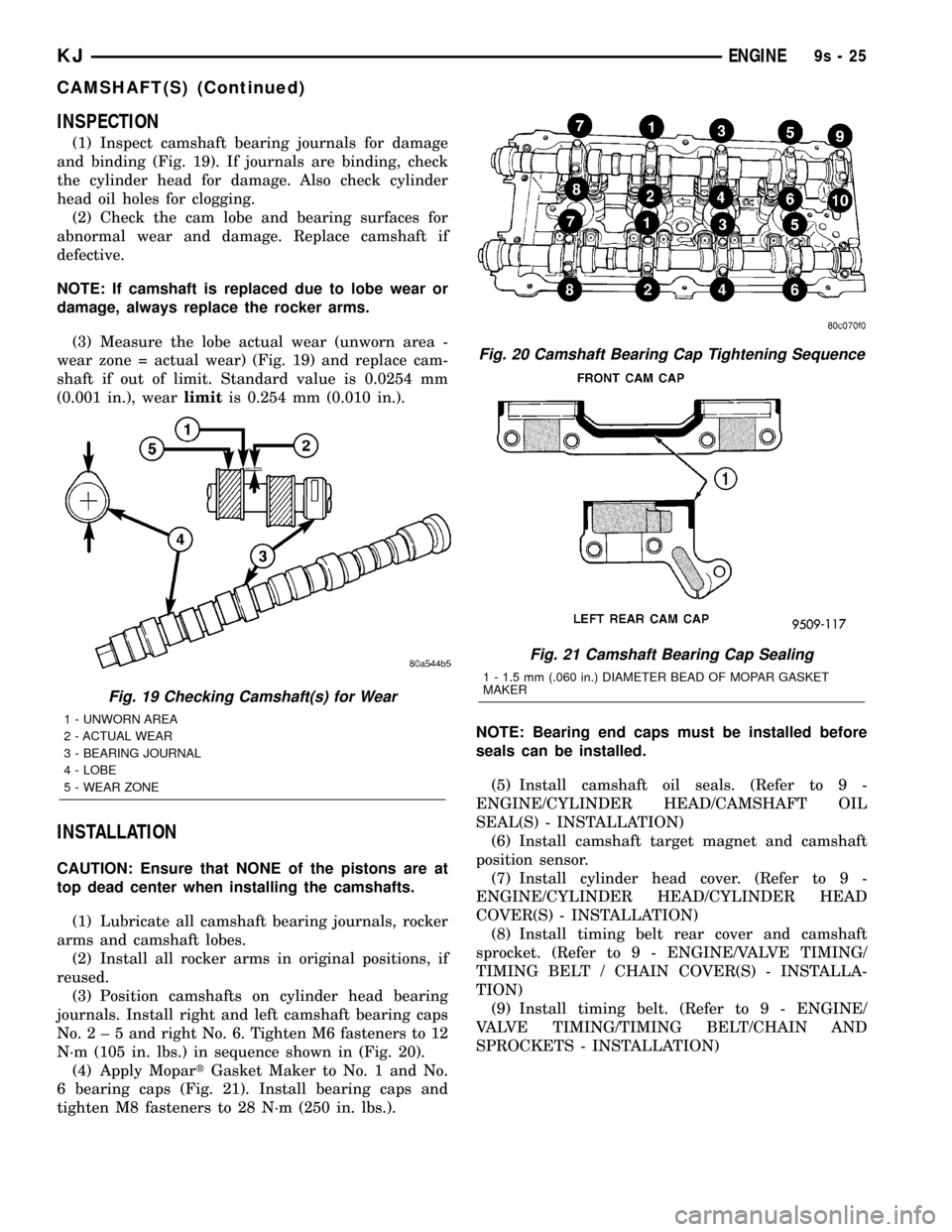

Both nodular iron camshafts have six bearing jour-

nal surfaces and two cam lobes per cylinder (Fig. 15).

Flanges at the rear journals control camshaft end

play. Provision for a cam position sensor is located on

the exhaust camshaft on the front of the cylinder

head. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

OPERATION

The camshaft is driven by the crankshaft via drive

sprockets and belt. The camshaft has precisely

machined lobes to provide accurate valve timing and

duration.

STANDARD PROCEDURE - CAMSHAFT

END-PLAY

(1) Oil camshaft journals and install camshaft

WITHOUTcam follower assemblies. Install rear cam

caps and tighten screws to specified torque.

(2) Using a suitable tool, move camshaft as far

rearward as it will go.

(3) Zero dial indicator (Fig. 16).

(4) Move camshaft as far forward as it will go.

(5) Record reading on dial indicator. For end play

specification, (Refer to 9 - ENGINE - SPECIFICA-

TIONS).

(6) If end play is excessive, check cylinder head

and camshaft for wear; replace as necessary.

Fig. 12 Camshaft Sprocket - Removal/Installation

1 - SPECIAL TOOL 6847

Fig. 13 Camshaft Oil Seal - Removal With C-4679-A

1 - SPECIAL TOOL C-4679

Fig. 14 Camshaft Seal - Installation

1 - SPECIAL TOOL MD 998306

KJENGINE9s-23

CAMSHAFT OIL SEAL(S) (Continued)

Page 1321 of 1803

REMOVAL

(1) Remove cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(2) Remove camshaft position sensor and camshaft

target magnet. (Refer to 8 - ELECTRICAL/IGNI-

TION CONTROL/CAMSHAFT POSITION SENSOR -

REMOVAL)

(3) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)(4) Remove camshaft sprockets and timing belt

rear cover. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - REMOVAL)

(5) Bearing caps are identified for location.

Remove the outside bearing caps first (Fig. 17).

(6) Loosen the camshaft bearing cap attaching

fasteners in sequence shown (Fig. 18) one camshaft

at a time.

CAUTION: Camshafts are not interchangeable. The

intake cam number 6 thrust bearing face spacing is

wider.

(7) Identify the camshafts before removing from

the head. The camshafts are not interchangeable.

(8) Remove camshafts from cylinder head.

NOTE: If removing rocker arms, identify for reinstal-

lation in the original position.

CLEANING

Clean camshaft with a suitable solvent.

Fig. 15 Camshafts

CAM PLUG - NOT SHOWN

1 - CAMSHAFT BEARING CAPS

2 - PLUG

3 - CAMSHAFT

4 - CYLINDER HEAD

5 - CAMSHAFT OIL SEAL

Fig. 16 Camshaft End Play - Typical

Fig. 17 Camshaft Bearing Cap Identification

Fig. 18 Camshaft Bearing Cap - Removal

1 - REMOVE OUTSIDE BEARING CAPS FIRST

9s - 24 ENGINEKJ

CAMSHAFT(S) (Continued)

Page 1322 of 1803

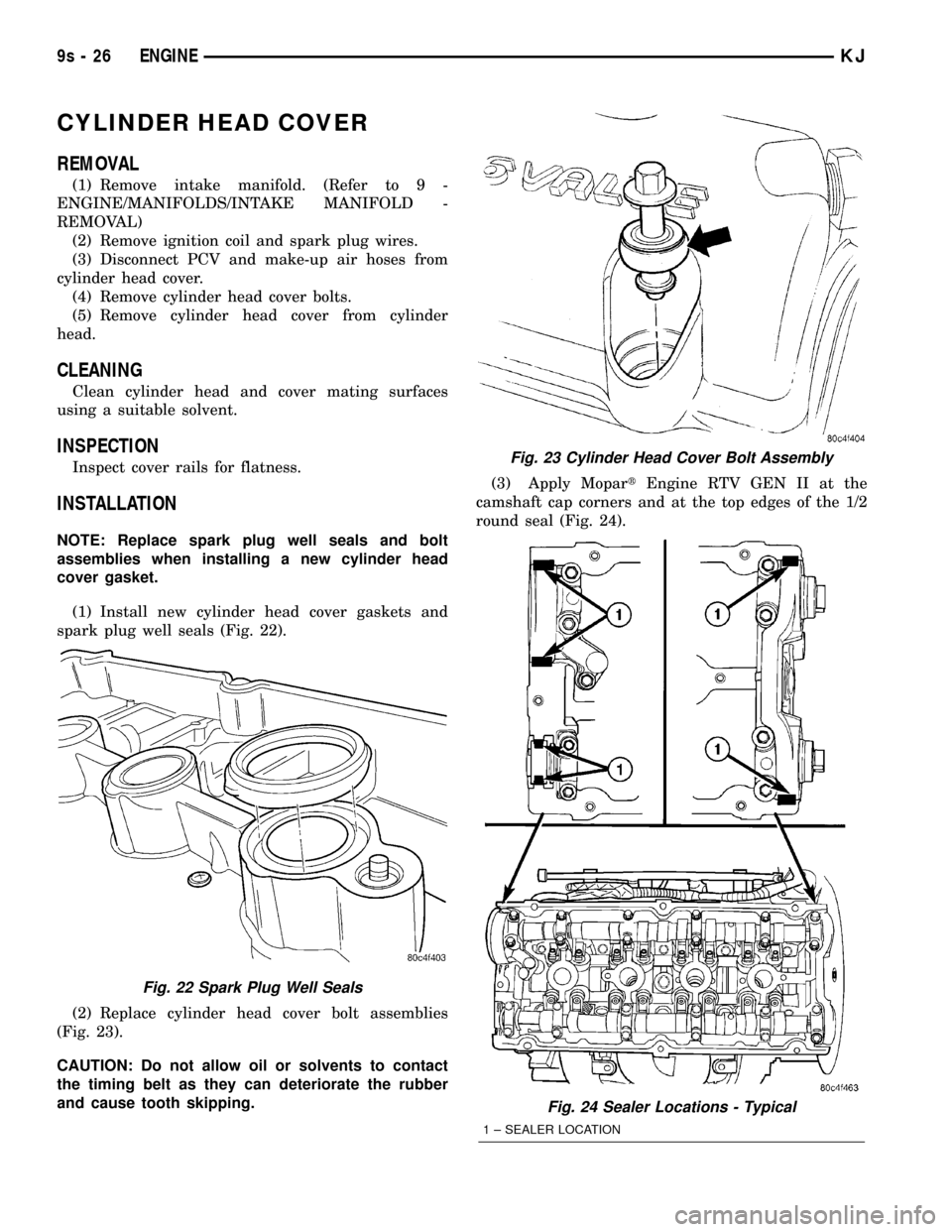

INSPECTION

(1) Inspect camshaft bearing journals for damage

and binding (Fig. 19). If journals are binding, check

the cylinder head for damage. Also check cylinder

head oil holes for clogging.

(2) Check the cam lobe and bearing surfaces for

abnormal wear and damage. Replace camshaft if

defective.

NOTE: If camshaft is replaced due to lobe wear or

damage, always replace the rocker arms.

(3) Measure the lobe actual wear (unworn area -

wear zone = actual wear) (Fig. 19) and replace cam-

shaft if out of limit. Standard value is 0.0254 mm

(0.001 in.), wearlimitis 0.254 mm (0.010 in.).

INSTALLATION

CAUTION: Ensure that NONE of the pistons are at

top dead center when installing the camshafts.

(1) Lubricate all camshaft bearing journals, rocker

arms and camshaft lobes.

(2) Install all rocker arms in original positions, if

reused.

(3) Position camshafts on cylinder head bearing

journals. Install right and left camshaft bearing caps

No.2±5andright No. 6. Tighten M6 fasteners to 12

N´m (105 in. lbs.) in sequence shown in (Fig. 20).

(4) Apply MopartGasket Maker to No. 1 and No.

6 bearing caps (Fig. 21). Install bearing caps and

tighten M8 fasteners to 28 N´m (250 in. lbs.).NOTE: Bearing end caps must be installed before

seals can be installed.

(5) Install camshaft oil seals. (Refer to 9 -

ENGINE/CYLINDER HEAD/CAMSHAFT OIL

SEAL(S) - INSTALLATION)

(6) Install camshaft target magnet and camshaft

position sensor.

(7) Install cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(8) Install timing belt rear cover and camshaft

sprocket. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - INSTALLA-

TION)

(9) Install timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

Fig. 19 Checking Camshaft(s) for Wear

1 - UNWORN AREA

2 - ACTUAL WEAR

3 - BEARING JOURNAL

4 - LOBE

5 - WEAR ZONE

Fig. 20 Camshaft Bearing Cap Tightening Sequence

Fig. 21 Camshaft Bearing Cap Sealing

1 - 1.5 mm (.060 in.) DIAMETER BEAD OF MOPAR GASKET

MAKER

KJENGINE9s-25

CAMSHAFT(S) (Continued)

Page 1323 of 1803

CYLINDER HEAD COVER

REMOVAL

(1) Remove intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL)

(2) Remove ignition coil and spark plug wires.

(3) Disconnect PCV and make-up air hoses from

cylinder head cover.

(4) Remove cylinder head cover bolts.

(5) Remove cylinder head cover from cylinder

head.

CLEANING

Clean cylinder head and cover mating surfaces

using a suitable solvent.

INSPECTION

Inspect cover rails for flatness.

INSTALLATION

NOTE: Replace spark plug well seals and bolt

assemblies when installing a new cylinder head

cover gasket.

(1) Install new cylinder head cover gaskets and

spark plug well seals (Fig. 22).

(2) Replace cylinder head cover bolt assemblies

(Fig. 23).

CAUTION: Do not allow oil or solvents to contact

the timing belt as they can deteriorate the rubber

and cause tooth skipping.(3) Apply MopartEngine RTV GEN II at the

camshaft cap corners and at the top edges of the 1/2

round seal (Fig. 24).

Fig. 22 Spark Plug Well Seals

Fig. 23 Cylinder Head Cover Bolt Assembly

Fig. 24 Sealer Locations - Typical

1 ± SEALER LOCATION

9s - 26 ENGINEKJ

Page 1324 of 1803

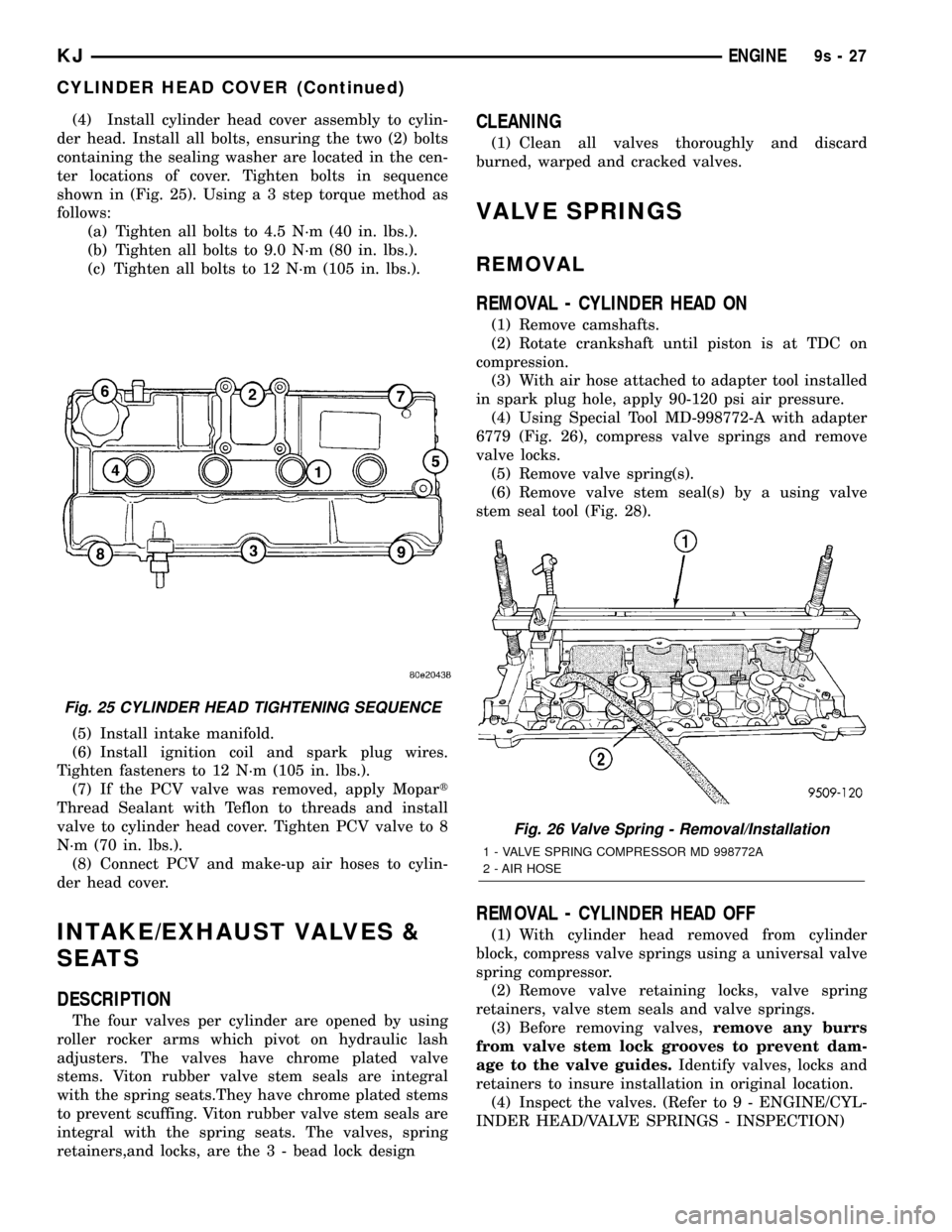

(4) Install cylinder head cover assembly to cylin-

der head. Install all bolts, ensuring the two (2) bolts

containing the sealing washer are located in the cen-

ter locations of cover. Tighten bolts in sequence

shown in (Fig. 25). Using a 3 step torque method as

follows:

(a) Tighten all bolts to 4.5 N´m (40 in. lbs.).

(b) Tighten all bolts to 9.0 N´m (80 in. lbs.).

(c) Tighten all bolts to 12 N´m (105 in. lbs.).

(5) Install intake manifold.

(6) Install ignition coil and spark plug wires.

Tighten fasteners to 12 N´m (105 in. lbs.).

(7) If the PCV valve was removed, apply Mopart

Thread Sealant with Teflon to threads and install

valve to cylinder head cover. Tighten PCV valve to 8

N´m (70 in. lbs.).

(8) Connect PCV and make-up air hoses to cylin-

der head cover.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The four valves per cylinder are opened by using

roller rocker arms which pivot on hydraulic lash

adjusters. The valves have chrome plated valve

stems. Viton rubber valve stem seals are integral

with the spring seats.They have chrome plated stems

to prevent scuffing. Viton rubber valve stem seals are

integral with the spring seats. The valves, spring

retainers,and locks, are the 3 - bead lock design

CLEANING

(1) Clean all valves thoroughly and discard

burned, warped and cracked valves.

VALVE SPRINGS

REMOVAL

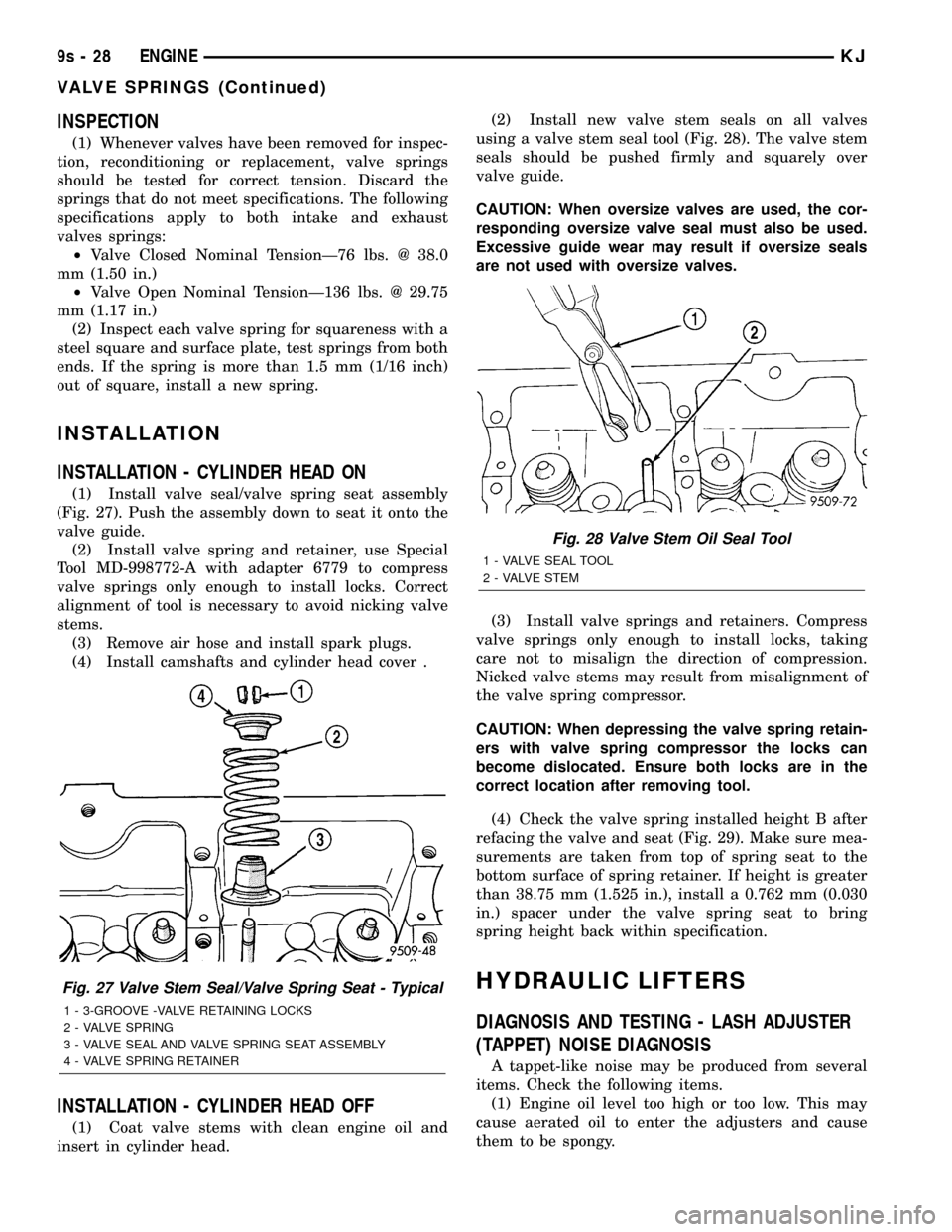

REMOVAL - CYLINDER HEAD ON

(1) Remove camshafts.

(2) Rotate crankshaft until piston is at TDC on

compression.

(3) With air hose attached to adapter tool installed

in spark plug hole, apply 90-120 psi air pressure.

(4) Using Special Tool MD-998772-A with adapter

6779 (Fig. 26), compress valve springs and remove

valve locks.

(5) Remove valve spring(s).

(6) Remove valve stem seal(s) by a using valve

stem seal tool (Fig. 28).

REMOVAL - CYLINDER HEAD OFF

(1) With cylinder head removed from cylinder

block, compress valve springs using a universal valve

spring compressor.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves, locks and

retainers to insure installation in original location.

(4) Inspect the valves. (Refer to 9 - ENGINE/CYL-

INDER HEAD/VALVE SPRINGS - INSPECTION)

Fig. 25 CYLINDER HEAD TIGHTENING SEQUENCE

Fig. 26 Valve Spring - Removal/Installation

1 - VALVE SPRING COMPRESSOR MD 998772A

2 - AIR HOSE

KJENGINE9s-27

CYLINDER HEAD COVER (Continued)

Page 1325 of 1803

INSPECTION

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested for correct tension. Discard the

springs that do not meet specifications. The following

specifications apply to both intake and exhaust

valves springs:

²Valve Closed Nominal TensionÐ76 lbs. @ 38.0

mm (1.50 in.)

²Valve Open Nominal TensionÐ136 lbs. @ 29.75

mm (1.17 in.)

(2) Inspect each valve spring for squareness with a

steel square and surface plate, test springs from both

ends. If the spring is more than 1.5 mm (1/16 inch)

out of square, install a new spring.

INSTALLATION

INSTALLATION - CYLINDER HEAD ON

(1) Install valve seal/valve spring seat assembly

(Fig. 27). Push the assembly down to seat it onto the

valve guide.

(2) Install valve spring and retainer, use Special

Tool MD-998772-A with adapter 6779 to compress

valve springs only enough to install locks. Correct

alignment of tool is necessary to avoid nicking valve

stems.

(3) Remove air hose and install spark plugs.

(4) Install camshafts and cylinder head cover .

INSTALLATION - CYLINDER HEAD OFF

(1) Coat valve stems with clean engine oil and

insert in cylinder head.(2) Install new valve stem seals on all valves

using a valve stem seal tool (Fig. 28). The valve stem

seals should be pushed firmly and squarely over

valve guide.

CAUTION: When oversize valves are used, the cor-

responding oversize valve seal must also be used.

Excessive guide wear may result if oversize seals

are not used with oversize valves.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring retain-

ers with valve spring compressor the locks can

become dislocated. Ensure both locks are in the

correct location after removing tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 29). Make sure mea-

surements are taken from top of spring seat to the

bottom surface of spring retainer. If height is greater

than 38.75 mm (1.525 in.), install a 0.762 mm (0.030

in.) spacer under the valve spring seat to bring

spring height back within specification.

HYDRAULIC LIFTERS

DIAGNOSIS AND TESTING - LASH ADJUSTER

(TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

Fig. 27 Valve Stem Seal/Valve Spring Seat - Typical

1 - 3-GROOVE -VALVE RETAINING LOCKS

2 - VALVE SPRING

3 - VALVE SEAL AND VALVE SPRING SEAT ASSEMBLY

4 - VALVE SPRING RETAINER

Fig. 28 Valve Stem Oil Seal Tool

1 - VALVE SEAL TOOL

2 - VALVE STEM

9s - 28 ENGINEKJ

VALVE SPRINGS (Continued)