Timing chain JEEP LIBERTY 2002 KJ / 1.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1317 of 1803

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL - CYLINDER HEAD

(1) Perform fuel system pressure release procedure

before attempting any repairs.(Refer to 14 -FUEL SYSTEM/FUEL DELIVERY - SPECIFICA-

TIONS)

(2) Disconnect battery negative cable.

(3) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(4) Remove air filter housing and inlet tube.

(5) Remove intake manifold.

(6) Remove heater tube support bracket from cyl-

inder head.

(7) Disconnect radiator upper and heater supply

hoses from water outlet connections.

(8) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(9) Raise vehicle and remove exhaust pipe from

manifold.

(10) Remove power steering pump and set aside.

Do not disconnect lines.

(11) Remove accessory drive bracket

(12) Remove ignition coil and wires from engine.

(13) Disconnect cam sensor and fuel injector wir-

ing connectors.

(14) Remove timing belt and camshaft sprockets.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL)

(15) Remove timing belt idler pulley and rear tim-

ing belt cover. (Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT / CHAIN COVER(S) -

REMOVAL)

(16) Remove cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(17) Remove camshafts (Refer to 9 - ENGINE/

CYLINDER HEAD/CAMSHAFT(S) - REMOVAL).

NOTE: Identify rocker arm position to ensure cor-

rect re-installation in original position, if reused.

(18) Remove rocker arms. (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARMS - REMOVAL).

(19) Remove cylinder head bolts in REVERSE

sequence of tightening.

(20) Remove cylinder head from engine block.

(21) Inspect and clean cylinder head. (Refer to 9 -

ENGINE/CYLINDER HEAD - INSPECTION) (Refer

to 9 - ENGINE/CYLINDER HEAD - CLEANING)

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

9s - 20 ENGINEKJ

CYLINDER HEAD (Continued)

Page 1319 of 1803

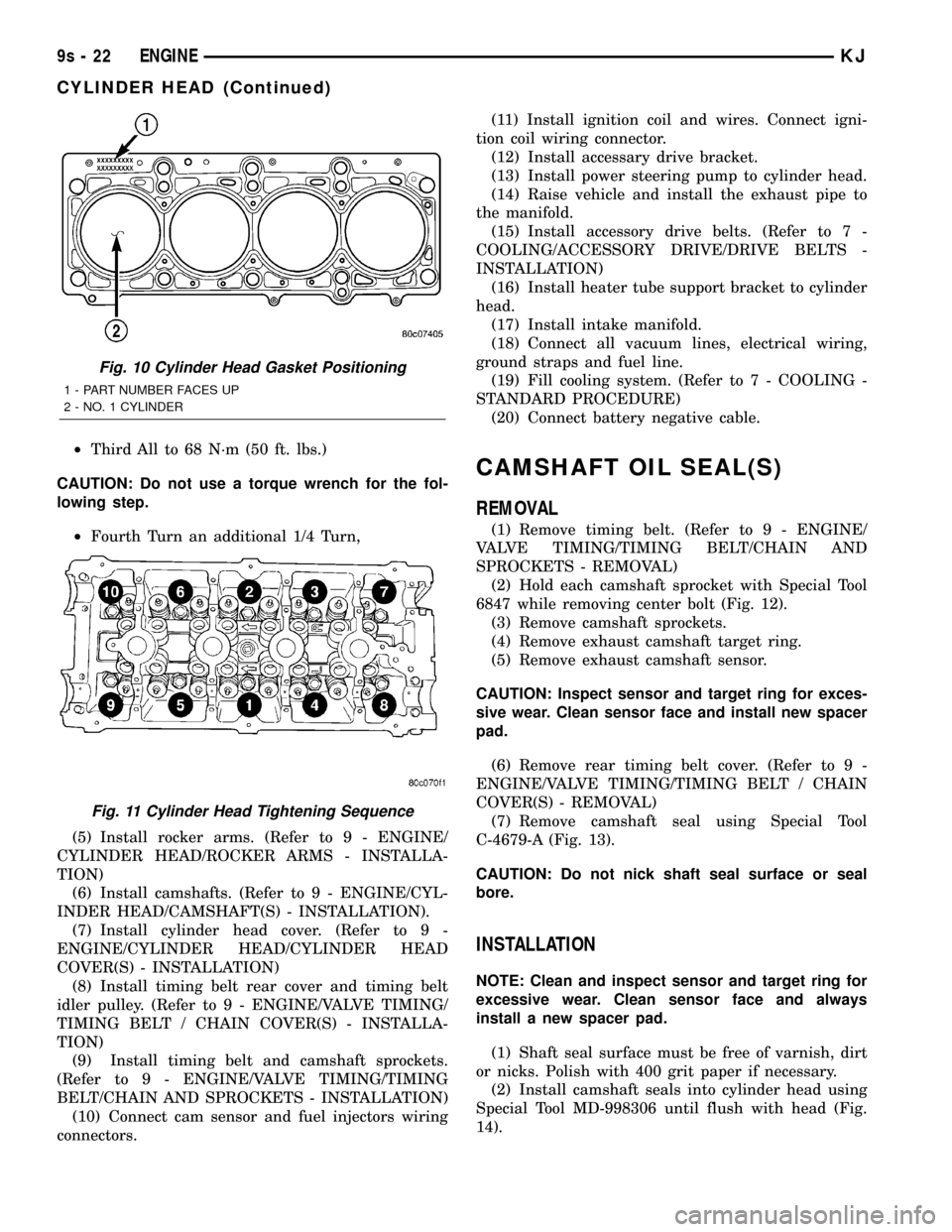

²Third All to 68 N´m (50 ft. lbs.)

CAUTION: Do not use a torque wrench for the fol-

lowing step.

²Fourth Turn an additional 1/4 Turn,

(5) Install rocker arms. (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARMS - INSTALLA-

TION)

(6) Install camshafts. (Refer to 9 - ENGINE/CYL-

INDER HEAD/CAMSHAFT(S) - INSTALLATION).

(7) Install cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(8) Install timing belt rear cover and timing belt

idler pulley. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - INSTALLA-

TION)

(9) Install timing belt and camshaft sprockets.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - INSTALLATION)

(10) Connect cam sensor and fuel injectors wiring

connectors.(11) Install ignition coil and wires. Connect igni-

tion coil wiring connector.

(12) Install accessary drive bracket.

(13) Install power steering pump to cylinder head.

(14) Raise vehicle and install the exhaust pipe to

the manifold.

(15) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(16) Install heater tube support bracket to cylinder

head.

(17) Install intake manifold.

(18) Connect all vacuum lines, electrical wiring,

ground straps and fuel line.

(19) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(20) Connect battery negative cable.

CAMSHAFT OIL SEAL(S)

REMOVAL

(1) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

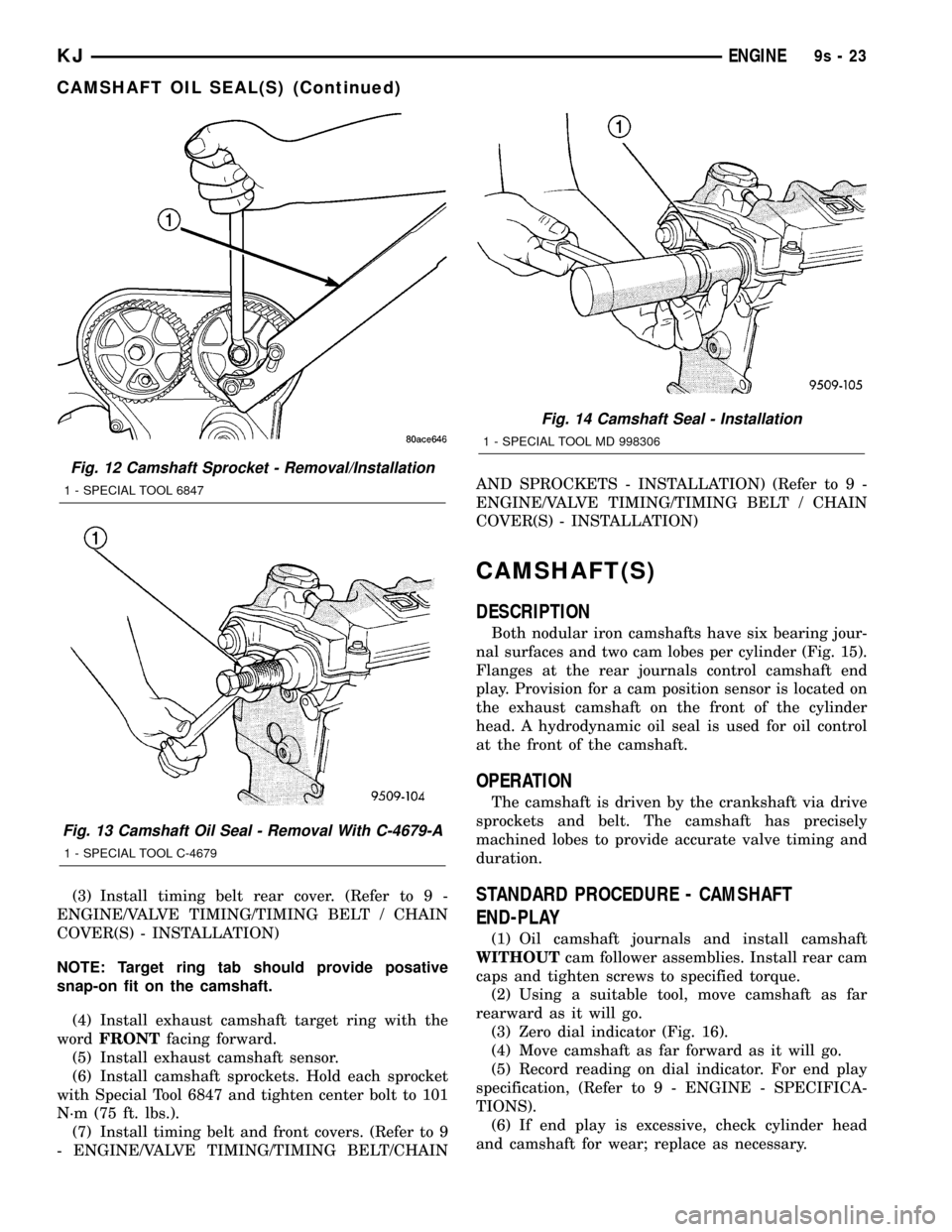

(2) Hold each camshaft sprocket with Special Tool

6847 while removing center bolt (Fig. 12).

(3) Remove camshaft sprockets.

(4) Remove exhaust camshaft target ring.

(5) Remove exhaust camshaft sensor.

CAUTION: Inspect sensor and target ring for exces-

sive wear. Clean sensor face and install new spacer

pad.

(6) Remove rear timing belt cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

(7) Remove camshaft seal using Special Tool

C-4679-A (Fig. 13).

CAUTION: Do not nick shaft seal surface or seal

bore.

INSTALLATION

NOTE: Clean and inspect sensor and target ring for

excessive wear. Clean sensor face and always

install a new spacer pad.

(1) Shaft seal surface must be free of varnish, dirt

or nicks. Polish with 400 grit paper if necessary.

(2) Install camshaft seals into cylinder head using

Special Tool MD-998306 until flush with head (Fig.

14).

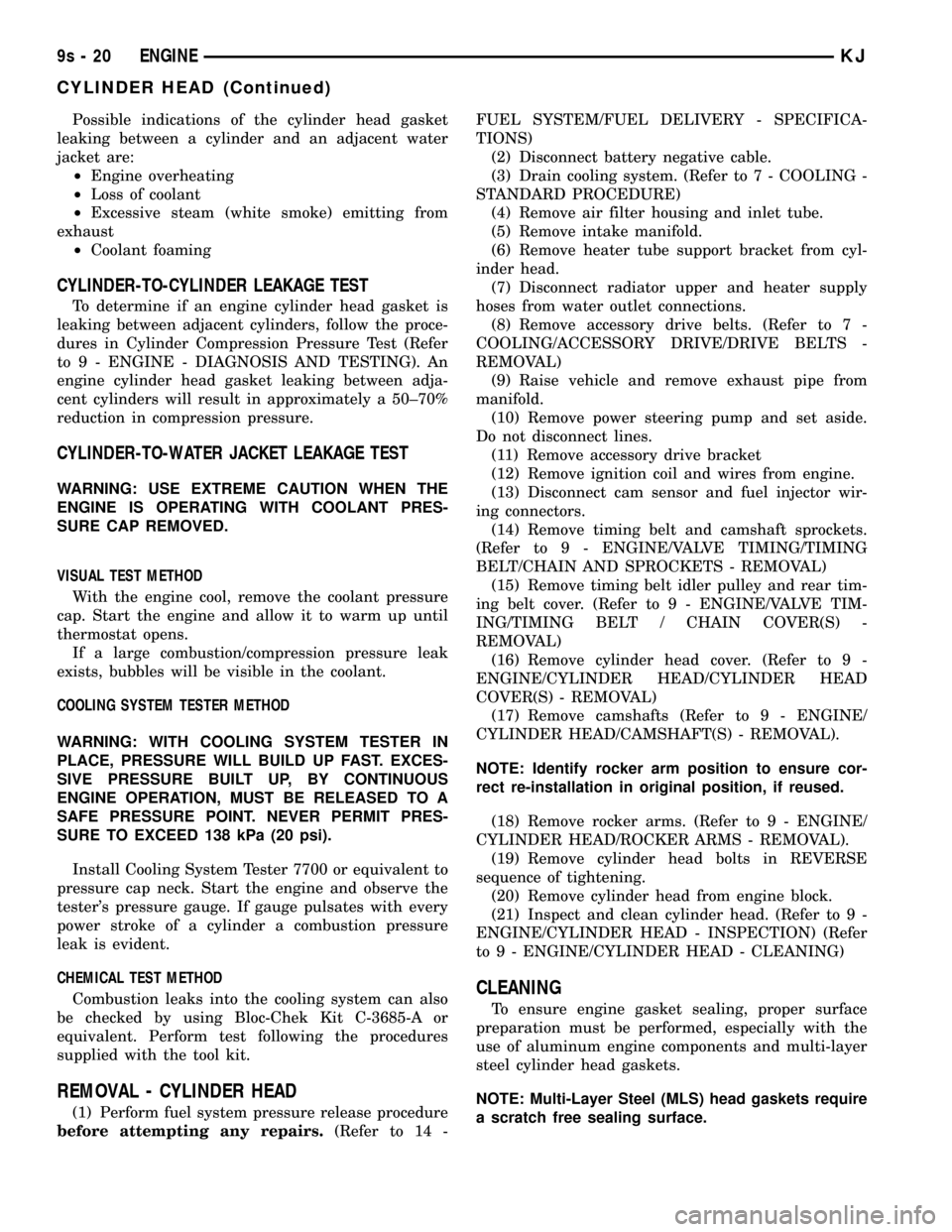

Fig. 10 Cylinder Head Gasket Positioning

1 - PART NUMBER FACES UP

2 - NO. 1 CYLINDER

Fig. 11 Cylinder Head Tightening Sequence

9s - 22 ENGINEKJ

CYLINDER HEAD (Continued)

Page 1320 of 1803

(3) Install timing belt rear cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

NOTE: Target ring tab should provide posative

snap-on fit on the camshaft.

(4) Install exhaust camshaft target ring with the

wordFRONTfacing forward.

(5) Install exhaust camshaft sensor.

(6) Install camshaft sprockets. Hold each sprocket

with Special Tool 6847 and tighten center bolt to 101

N´m (75 ft. lbs.).

(7) Install timing belt and front covers. (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT/CHAINAND SPROCKETS - INSTALLATION) (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

CAMSHAFT(S)

DESCRIPTION

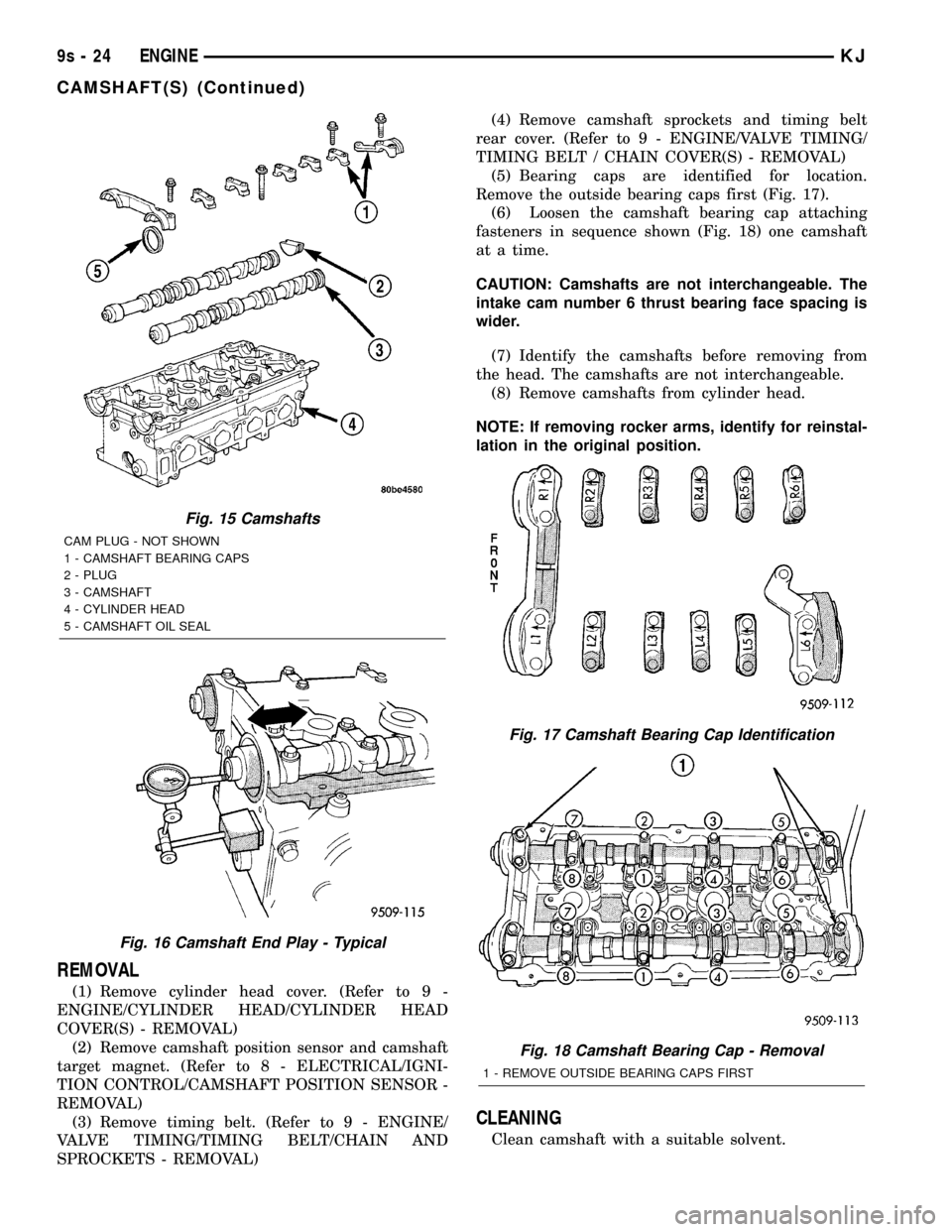

Both nodular iron camshafts have six bearing jour-

nal surfaces and two cam lobes per cylinder (Fig. 15).

Flanges at the rear journals control camshaft end

play. Provision for a cam position sensor is located on

the exhaust camshaft on the front of the cylinder

head. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

OPERATION

The camshaft is driven by the crankshaft via drive

sprockets and belt. The camshaft has precisely

machined lobes to provide accurate valve timing and

duration.

STANDARD PROCEDURE - CAMSHAFT

END-PLAY

(1) Oil camshaft journals and install camshaft

WITHOUTcam follower assemblies. Install rear cam

caps and tighten screws to specified torque.

(2) Using a suitable tool, move camshaft as far

rearward as it will go.

(3) Zero dial indicator (Fig. 16).

(4) Move camshaft as far forward as it will go.

(5) Record reading on dial indicator. For end play

specification, (Refer to 9 - ENGINE - SPECIFICA-

TIONS).

(6) If end play is excessive, check cylinder head

and camshaft for wear; replace as necessary.

Fig. 12 Camshaft Sprocket - Removal/Installation

1 - SPECIAL TOOL 6847

Fig. 13 Camshaft Oil Seal - Removal With C-4679-A

1 - SPECIAL TOOL C-4679

Fig. 14 Camshaft Seal - Installation

1 - SPECIAL TOOL MD 998306

KJENGINE9s-23

CAMSHAFT OIL SEAL(S) (Continued)

Page 1321 of 1803

REMOVAL

(1) Remove cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(2) Remove camshaft position sensor and camshaft

target magnet. (Refer to 8 - ELECTRICAL/IGNI-

TION CONTROL/CAMSHAFT POSITION SENSOR -

REMOVAL)

(3) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)(4) Remove camshaft sprockets and timing belt

rear cover. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - REMOVAL)

(5) Bearing caps are identified for location.

Remove the outside bearing caps first (Fig. 17).

(6) Loosen the camshaft bearing cap attaching

fasteners in sequence shown (Fig. 18) one camshaft

at a time.

CAUTION: Camshafts are not interchangeable. The

intake cam number 6 thrust bearing face spacing is

wider.

(7) Identify the camshafts before removing from

the head. The camshafts are not interchangeable.

(8) Remove camshafts from cylinder head.

NOTE: If removing rocker arms, identify for reinstal-

lation in the original position.

CLEANING

Clean camshaft with a suitable solvent.

Fig. 15 Camshafts

CAM PLUG - NOT SHOWN

1 - CAMSHAFT BEARING CAPS

2 - PLUG

3 - CAMSHAFT

4 - CYLINDER HEAD

5 - CAMSHAFT OIL SEAL

Fig. 16 Camshaft End Play - Typical

Fig. 17 Camshaft Bearing Cap Identification

Fig. 18 Camshaft Bearing Cap - Removal

1 - REMOVE OUTSIDE BEARING CAPS FIRST

9s - 24 ENGINEKJ

CAMSHAFT(S) (Continued)

Page 1322 of 1803

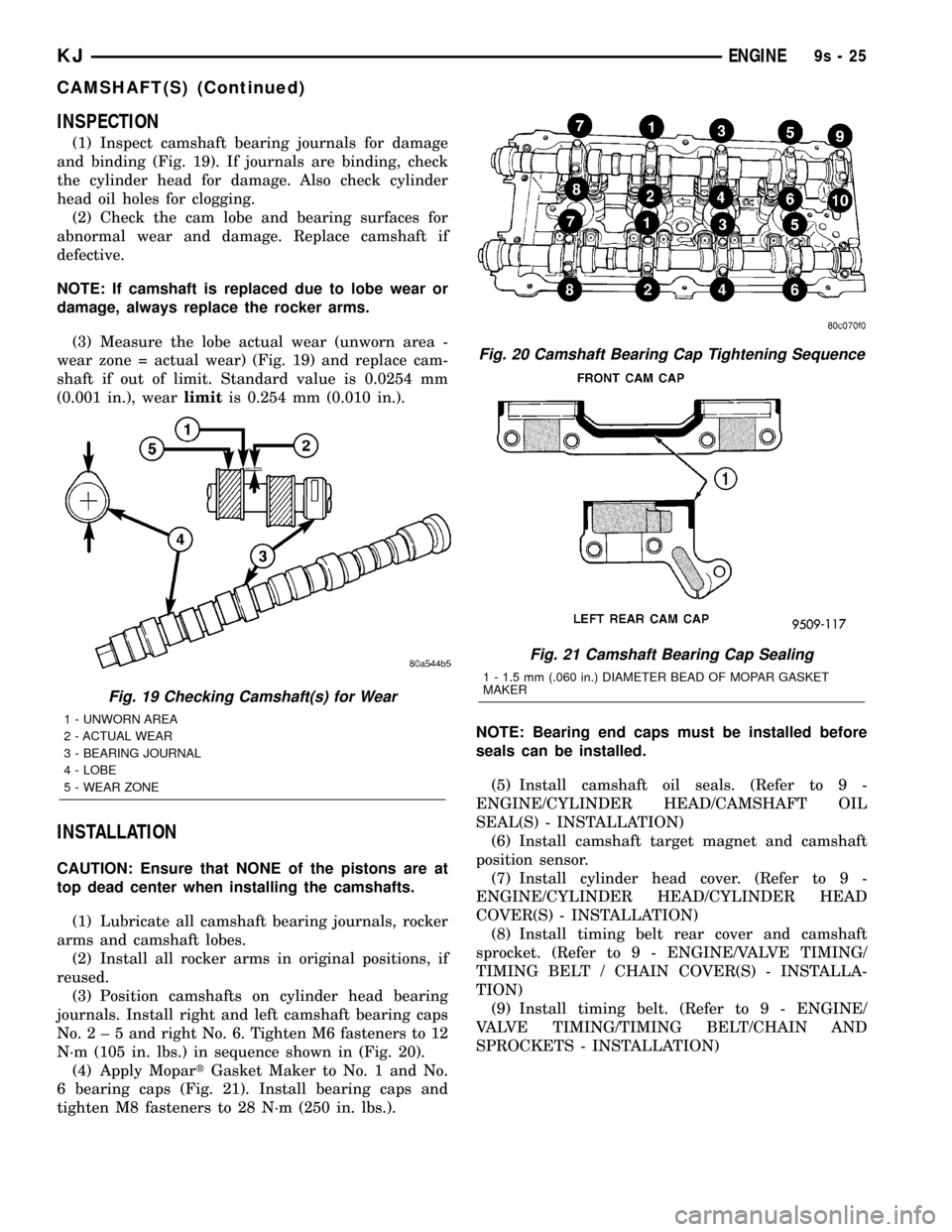

INSPECTION

(1) Inspect camshaft bearing journals for damage

and binding (Fig. 19). If journals are binding, check

the cylinder head for damage. Also check cylinder

head oil holes for clogging.

(2) Check the cam lobe and bearing surfaces for

abnormal wear and damage. Replace camshaft if

defective.

NOTE: If camshaft is replaced due to lobe wear or

damage, always replace the rocker arms.

(3) Measure the lobe actual wear (unworn area -

wear zone = actual wear) (Fig. 19) and replace cam-

shaft if out of limit. Standard value is 0.0254 mm

(0.001 in.), wearlimitis 0.254 mm (0.010 in.).

INSTALLATION

CAUTION: Ensure that NONE of the pistons are at

top dead center when installing the camshafts.

(1) Lubricate all camshaft bearing journals, rocker

arms and camshaft lobes.

(2) Install all rocker arms in original positions, if

reused.

(3) Position camshafts on cylinder head bearing

journals. Install right and left camshaft bearing caps

No.2±5andright No. 6. Tighten M6 fasteners to 12

N´m (105 in. lbs.) in sequence shown in (Fig. 20).

(4) Apply MopartGasket Maker to No. 1 and No.

6 bearing caps (Fig. 21). Install bearing caps and

tighten M8 fasteners to 28 N´m (250 in. lbs.).NOTE: Bearing end caps must be installed before

seals can be installed.

(5) Install camshaft oil seals. (Refer to 9 -

ENGINE/CYLINDER HEAD/CAMSHAFT OIL

SEAL(S) - INSTALLATION)

(6) Install camshaft target magnet and camshaft

position sensor.

(7) Install cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(8) Install timing belt rear cover and camshaft

sprocket. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - INSTALLA-

TION)

(9) Install timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

Fig. 19 Checking Camshaft(s) for Wear

1 - UNWORN AREA

2 - ACTUAL WEAR

3 - BEARING JOURNAL

4 - LOBE

5 - WEAR ZONE

Fig. 20 Camshaft Bearing Cap Tightening Sequence

Fig. 21 Camshaft Bearing Cap Sealing

1 - 1.5 mm (.060 in.) DIAMETER BEAD OF MOPAR GASKET

MAKER

KJENGINE9s-25

CAMSHAFT(S) (Continued)

Page 1330 of 1803

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder to the flywheel or flex-

plate.

STANDARD PROCEDURE - CRANKSHAFT END

PLAY

(1) Using Dial Indicator C-3339 and Mounting

Post L-4438, attach to front of engine, locating probe

perpendicular on nose of crankshaft (Fig. 40).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Engine Specifica-

tions.

REMOVAL

NOTE: Crankshaft can not be removed when engine

is in vehicle.

(1) Remove engine assembly from vehicle. (Refer to

9 - ENGINE - REMOVAL)

(2) Remove flex plate and crankshaft rear oil seal.

(3) Mount engine on a repair stand.

(4) Drain engine oil and remove oil filter.

(5) Remove the oil pan. (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL)

(6) Remove the timing belt covers. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)(7) Remove the timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(8) Remove the oil pump. (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - REMOVAL)

(9) Remove balance shafts and housing assembly.

(Refer to 9 - ENGINE/VALVE TIMING/BALANCE

SHAFT - REMOVAL)

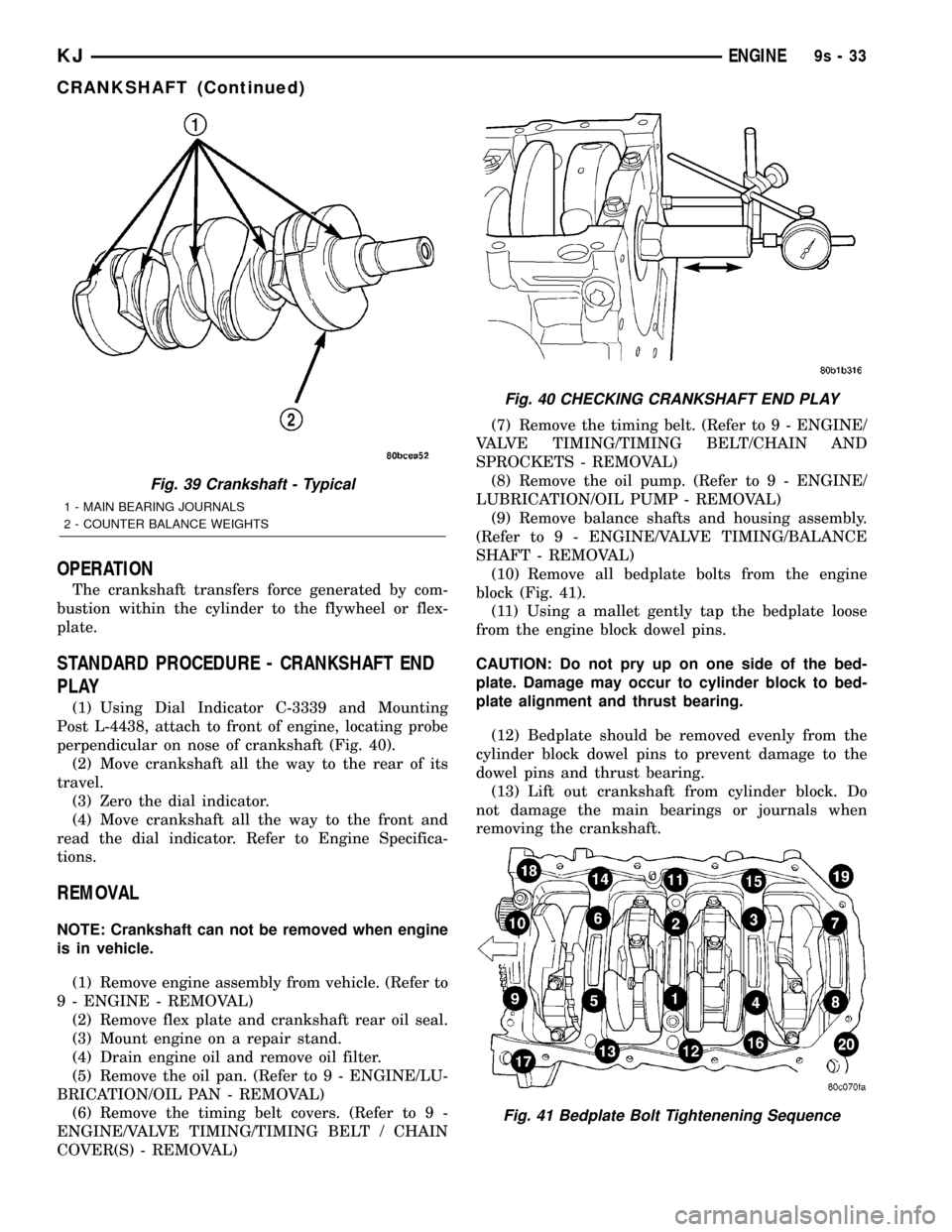

(10) Remove all bedplate bolts from the engine

block (Fig. 41).

(11) Using a mallet gently tap the bedplate loose

from the engine block dowel pins.

CAUTION: Do not pry up on one side of the bed-

plate. Damage may occur to cylinder block to bed-

plate alignment and thrust bearing.

(12) Bedplate should be removed evenly from the

cylinder block dowel pins to prevent damage to the

dowel pins and thrust bearing.

(13) Lift out crankshaft from cylinder block. Do

not damage the main bearings or journals when

removing the crankshaft.

Fig. 39 Crankshaft - Typical

1 - MAIN BEARING JOURNALS

2 - COUNTER BALANCE WEIGHTS

Fig. 40 CHECKING CRANKSHAFT END PLAY

Fig. 41 Bedplate Bolt Tightenening Sequence

KJENGINE9s-33

CRANKSHAFT (Continued)

Page 1332 of 1803

(6) Before installing the bolts the threads should

be oiled with clean engine oil, wipe off any excess oil.

(7) Install main bearing bedplate to engine block

bolts 11, 17, and 20 finger tight. Tighten these bolts

down together until the bedplate contacts the cylin-

der block.

(8) To ensure correct thrust bearing alignment,

perform the following steps:

²Step 1: Rotate crankshaft until number 4 piston

is at TDC.

²Step 2: Move crankshaft rearward to limits of

travel.

²Step 3: Then, move crankshaft forward to limits

of travel.

²Step 4: Wedge an appropriate tool between the

rear of the cylinder block(NOT BED PLATE)and

the rear crankshaft counterweight. This will hold the

crankshaft in it's furthest forward position.

²Step 5: Install and tighten bolts (1±10) in

sequence shown in (Fig. 45) to 41 N´m (30 ft. lbs.).

²Step 6: Remove wedge tool used to hold crank-

shaft.

(9) Tighten bolts (1±10) again to 41 N´m (30 ft.

lbs.) +1/4 turn in sequence shown in (Fig. 45).

(10) Install main bearing bedplate to engine block

bolts (11±20), and torque each bolt to 28 N´m (20 ft.

lbs.) in sequence shown in (Fig. 45).

(11) After the main bearing bedplate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 N´m (50 in. lbs.).

(12) Install balance shafts and housing assembly.

(Refer to 9 - ENGINE/VALVE TIMING/BALANCE

SHAFT - INSTALLATION)

(13) Install the oil pump and pickup tube. (Refer

to 9 - ENGINE/LUBRICATION/OIL PUMP -

INSTALLATION)

(14) Install the timing belt rear cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

(15) Install the timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

(16) Install the timing belt front covers. (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

(17) Install engine support bracket.

(18) Install the oil pan. (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION)

(19) Install the oil filter.

(20) Install crankshaft rear oil seal. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - INSTALLATION)

(21) Install flex plate. Apply MopartLock & Seal

Adhesive to bolt threads and tighten to 95 N´m (70

ft. lbs.).(22) Install the engine assembly. (Refer to 9 -

ENGINE - INSTALLATION)

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE - MAIN BEARING -

FITTING

For crankshaft specifications (Refer to 9 - ENGINE

- SPECIFICATIONS).

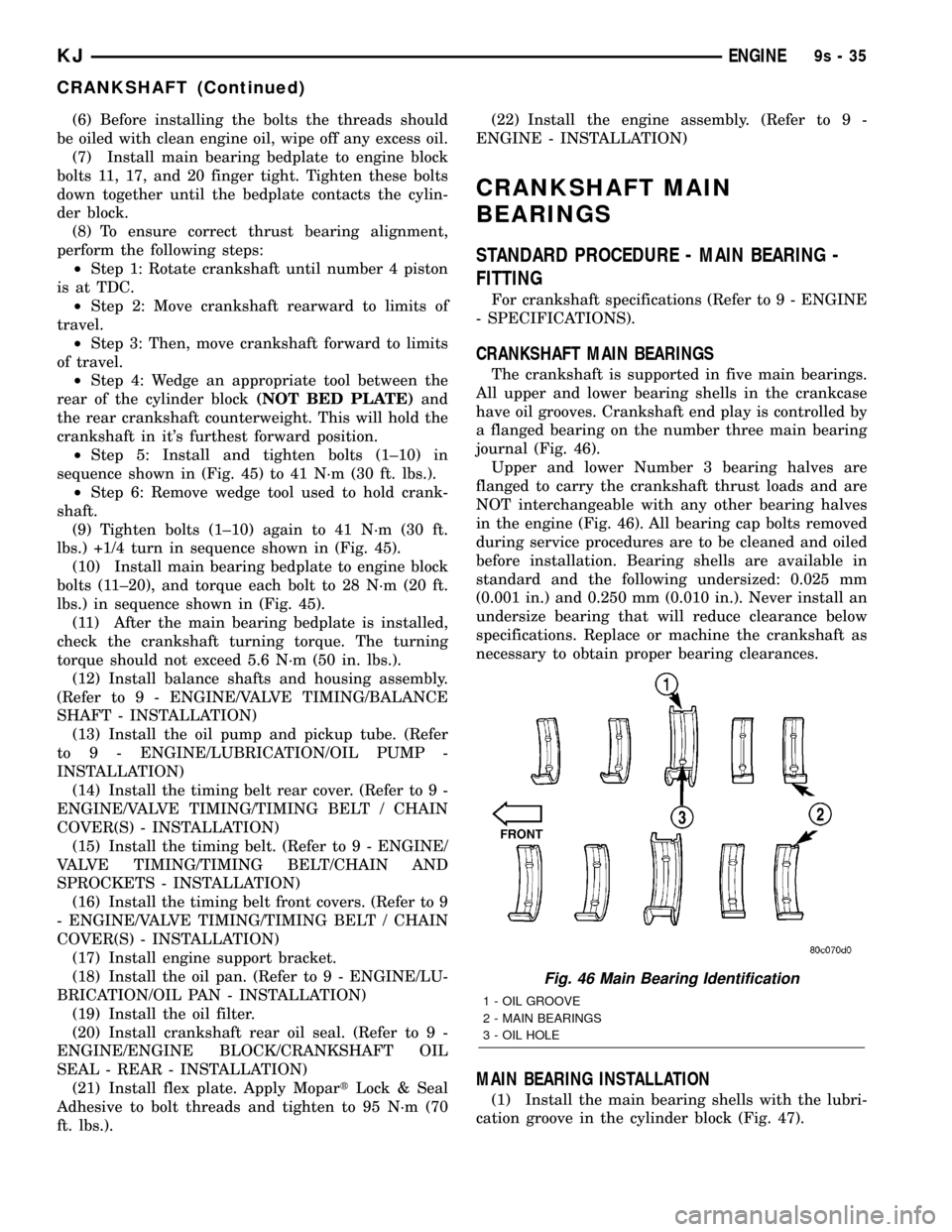

CRANKSHAFT MAIN BEARINGS

The crankshaft is supported in five main bearings.

All upper and lower bearing shells in the crankcase

have oil grooves. Crankshaft end play is controlled by

a flanged bearing on the number three main bearing

journal (Fig. 46).

Upper and lower Number 3 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 46). All bearing cap bolts removed

during service procedures are to be cleaned and oiled

before installation. Bearing shells are available in

standard and the following undersized: 0.025 mm

(0.001 in.) and 0.250 mm (0.010 in.). Never install an

undersize bearing that will reduce clearance below

specifications. Replace or machine the crankshaft as

necessary to obtain proper bearing clearances.

MAIN BEARING INSTALLATION

(1) Install the main bearing shells with the lubri-

cation groove in the cylinder block (Fig. 47).

Fig. 46 Main Bearing Identification

1 - OIL GROOVE

2 - MAIN BEARINGS

3 - OIL HOLE

KJENGINE9s-35

CRANKSHAFT (Continued)

Page 1334 of 1803

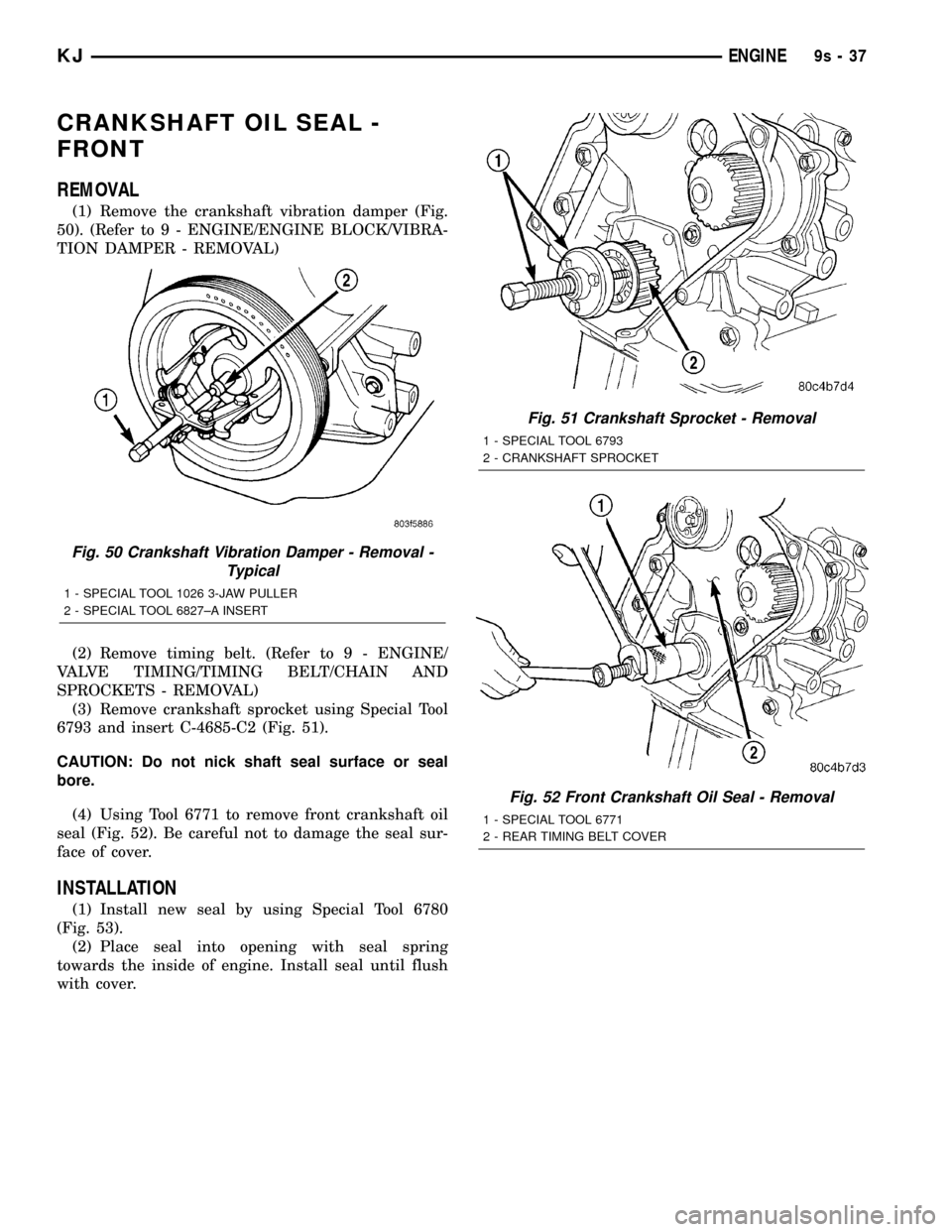

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Remove the crankshaft vibration damper (Fig.

50). (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRA-

TION DAMPER - REMOVAL)

(2) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(3) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 51).

CAUTION: Do not nick shaft seal surface or seal

bore.

(4) Using Tool 6771 to remove front crankshaft oil

seal (Fig. 52). Be careful not to damage the seal sur-

face of cover.

INSTALLATION

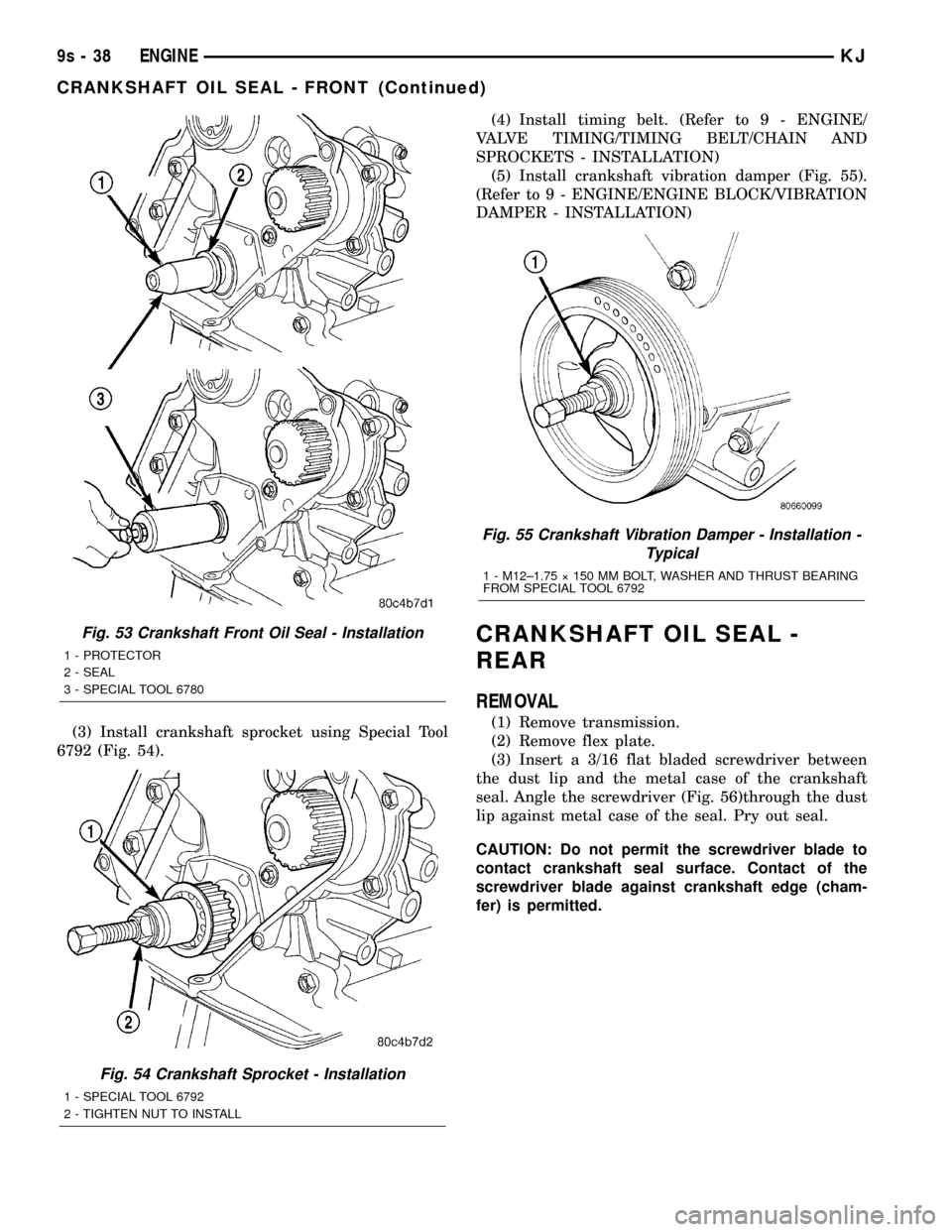

(1) Install new seal by using Special Tool 6780

(Fig. 53).

(2) Place seal into opening with seal spring

towards the inside of engine. Install seal until flush

with cover.

Fig. 50 Crankshaft Vibration Damper - Removal -

Typical

1 - SPECIAL TOOL 1026 3-JAW PULLER

2 - SPECIAL TOOL 6827±A INSERT

Fig. 51 Crankshaft Sprocket - Removal

1 - SPECIAL TOOL 6793

2 - CRANKSHAFT SPROCKET

Fig. 52 Front Crankshaft Oil Seal - Removal

1 - SPECIAL TOOL 6771

2 - REAR TIMING BELT COVER

KJENGINE9s-37

Page 1335 of 1803

(3) Install crankshaft sprocket using Special Tool

6792 (Fig. 54).(4) Install timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

(5) Install crankshaft vibration damper (Fig. 55).

(Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION)

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Remove transmission.

(2) Remove flex plate.

(3) Insert a 3/16 flat bladed screwdriver between

the dust lip and the metal case of the crankshaft

seal. Angle the screwdriver (Fig. 56)through the dust

lip against metal case of the seal. Pry out seal.

CAUTION: Do not permit the screwdriver blade to

contact crankshaft seal surface. Contact of the

screwdriver blade against crankshaft edge (cham-

fer) is permitted.

Fig. 53 Crankshaft Front Oil Seal - Installation

1 - PROTECTOR

2 - SEAL

3 - SPECIAL TOOL 6780

Fig. 54 Crankshaft Sprocket - Installation

1 - SPECIAL TOOL 6792

2 - TIGHTEN NUT TO INSTALL

Fig. 55 Crankshaft Vibration Damper - Installation -

Typical

1 - M12±1.75 ý 150 MM BOLT, WASHER AND THRUST BEARING

FROM SPECIAL TOOL 6792

9s - 38 ENGINEKJ

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1346 of 1803

instrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

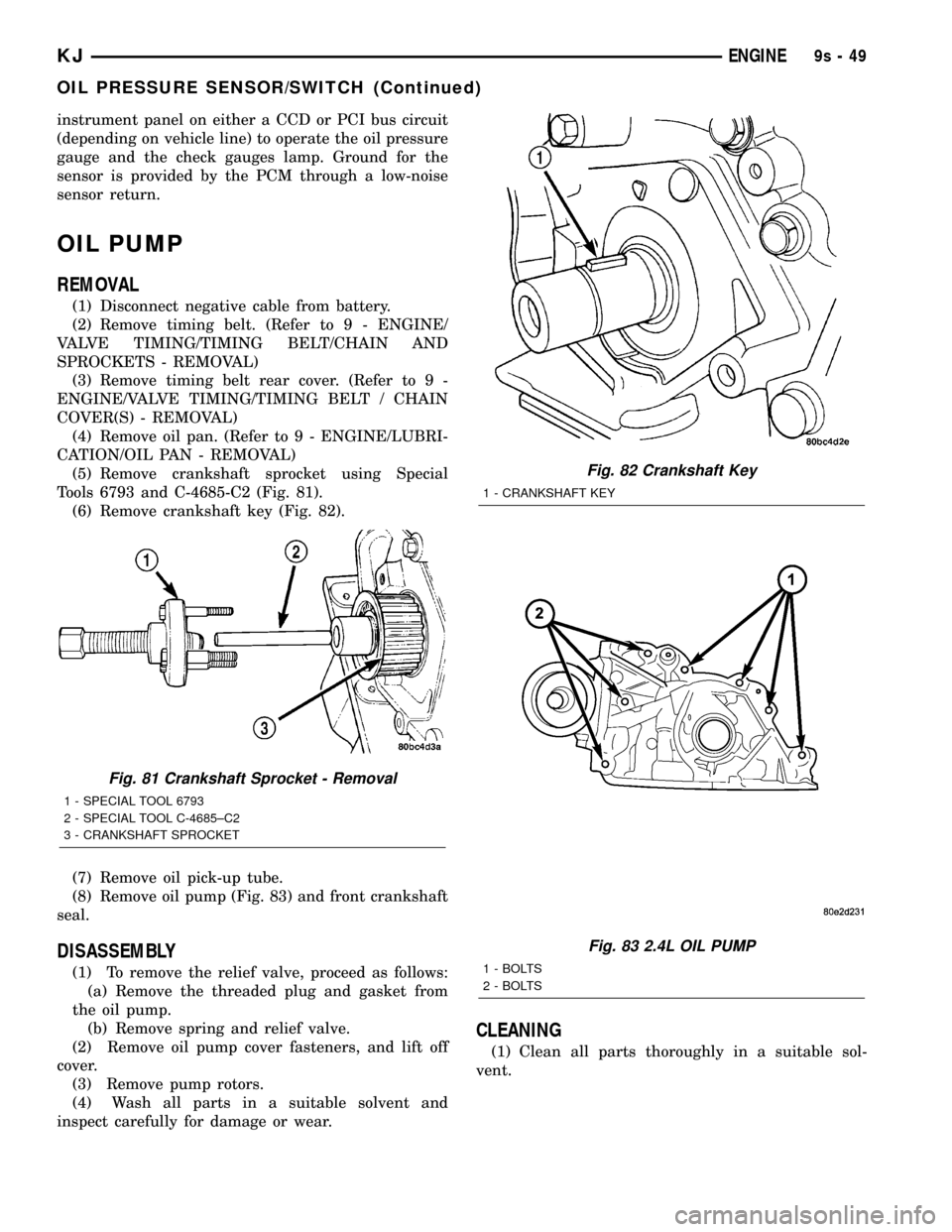

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(3) Remove timing belt rear cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

(4) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL)

(5) Remove crankshaft sprocket using Special

Tools 6793 and C-4685-C2 (Fig. 81).

(6) Remove crankshaft key (Fig. 82).

(7) Remove oil pick-up tube.

(8) Remove oil pump (Fig. 83) and front crankshaft

seal.

DISASSEMBLY

(1) To remove the relief valve, proceed as follows:

(a) Remove the threaded plug and gasket from

the oil pump.

(b) Remove spring and relief valve.

(2) Remove oil pump cover fasteners, and lift off

cover.

(3) Remove pump rotors.

(4) Wash all parts in a suitable solvent and

inspect carefully for damage or wear.

CLEANING

(1) Clean all parts thoroughly in a suitable sol-

vent.

Fig. 81 Crankshaft Sprocket - Removal

1 - SPECIAL TOOL 6793

2 - SPECIAL TOOL C-4685±C2

3 - CRANKSHAFT SPROCKET

Fig. 82 Crankshaft Key

1 - CRANKSHAFT KEY

Fig. 83 2.4L OIL PUMP

1 - BOLTS

2 - BOLTS

KJENGINE9s-49

OIL PRESSURE SENSOR/SWITCH (Continued)