removal JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1648 of 1803

(4) Test sunroof operation, adjust as necessary.

(5) Install headliner. (Refer to 23 - BODY/INTERI-

OR/HEADLINER - INSTALLATION)

CONTROL MODULE

REMOVAL

(1) Remove the module assembly. (Refer to 23 -

BODY/SUNROOF/MODULE ASSEMBLY -

REMOVAL)

(2) Remove three motor assembly retaining screws

from bottom side of motor, and remove motor assem-

bly (Fig. 11).

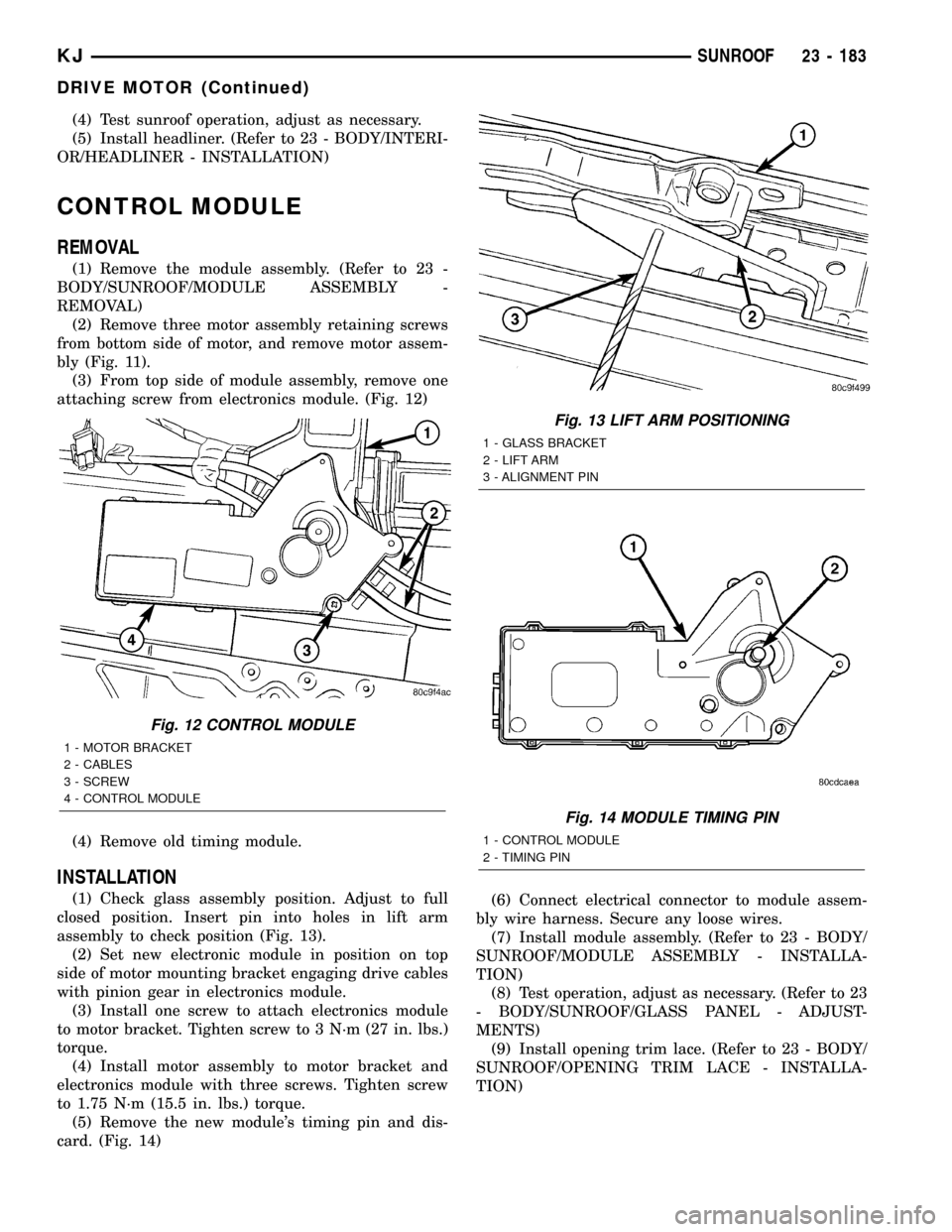

(3) From top side of module assembly, remove one

attaching screw from electronics module. (Fig. 12)

(4) Remove old timing module.

INSTALLATION

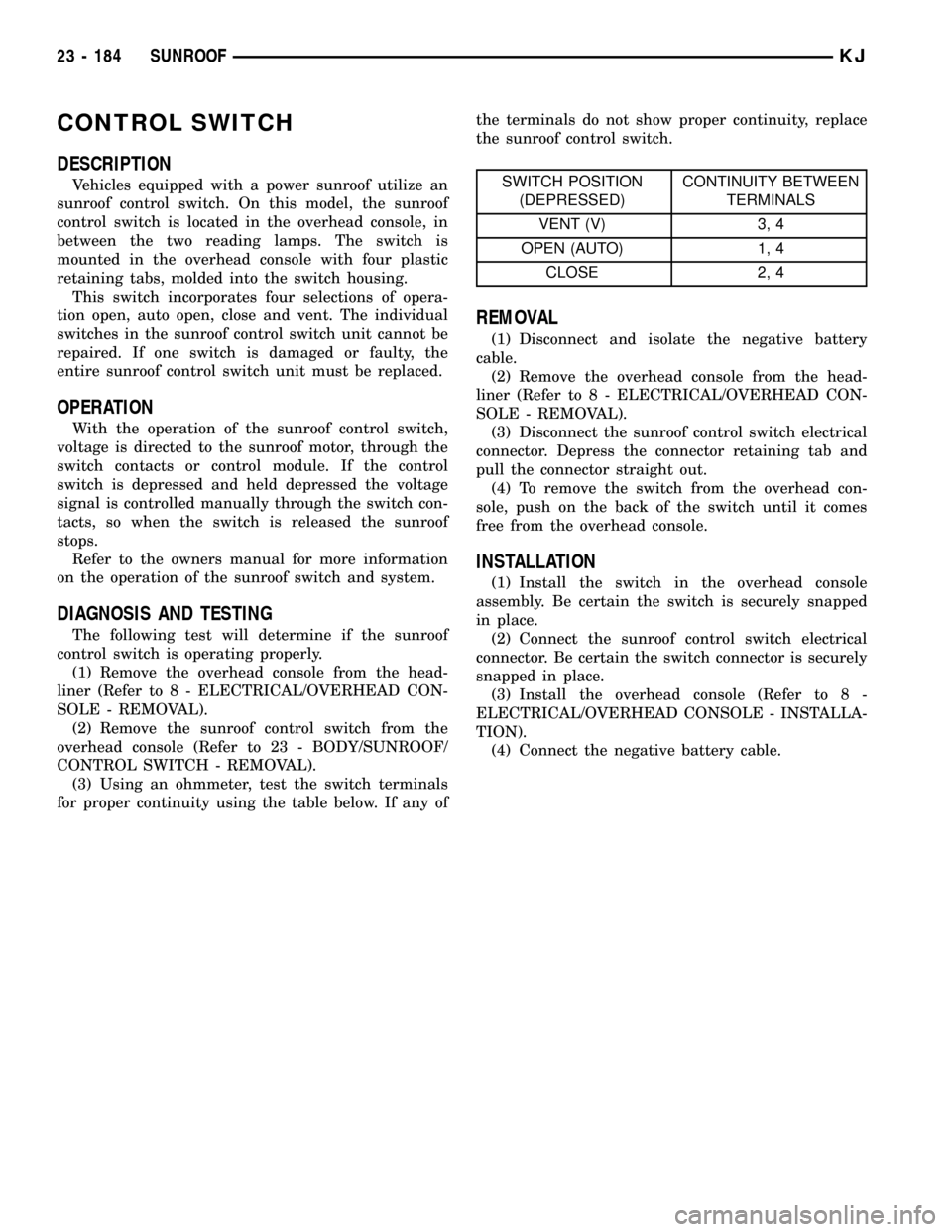

(1) Check glass assembly position. Adjust to full

closed position. Insert pin into holes in lift arm

assembly to check position (Fig. 13).

(2) Set new electronic module in position on top

side of motor mounting bracket engaging drive cables

with pinion gear in electronics module.

(3) Install one screw to attach electronics module

to motor bracket. Tighten screw to 3 N´m (27 in. lbs.)

torque.

(4) Install motor assembly to motor bracket and

electronics module with three screws. Tighten screw

to 1.75 N´m (15.5 in. lbs.) torque.

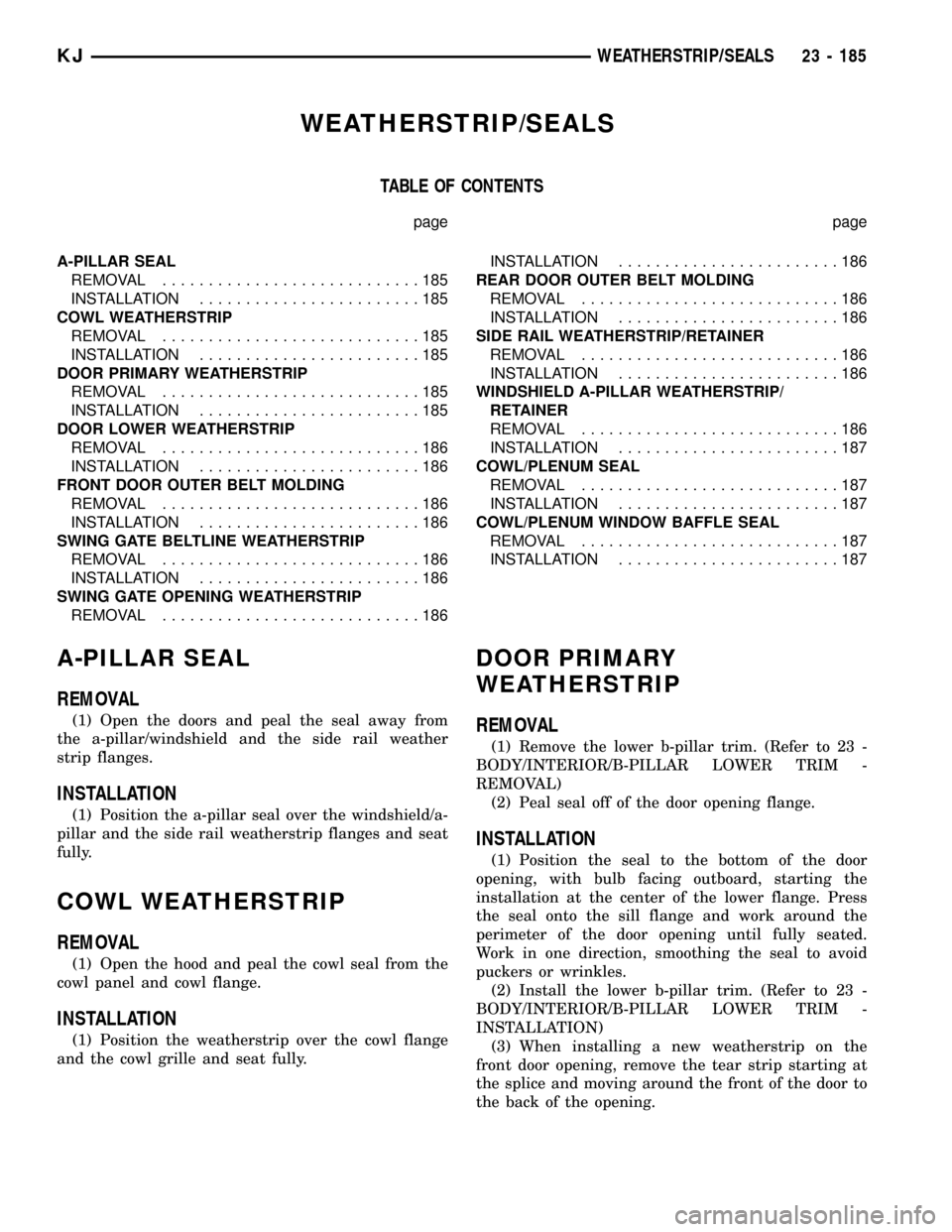

(5) Remove the new module's timing pin and dis-

card. (Fig. 14)(6) Connect electrical connector to module assem-

bly wire harness. Secure any loose wires.

(7) Install module assembly. (Refer to 23 - BODY/

SUNROOF/MODULE ASSEMBLY - INSTALLA-

TION)

(8) Test operation, adjust as necessary. (Refer to 23

- BODY/SUNROOF/GLASS PANEL - ADJUST-

MENTS)

(9) Install opening trim lace. (Refer to 23 - BODY/

SUNROOF/OPENING TRIM LACE - INSTALLA-

TION)

Fig. 12 CONTROL MODULE

1 - MOTOR BRACKET

2 - CABLES

3 - SCREW

4 - CONTROL MODULE

Fig. 13 LIFT ARM POSITIONING

1 - GLASS BRACKET

2 - LIFT ARM

3 - ALIGNMENT PIN

Fig. 14 MODULE TIMING PIN

1 - CONTROL MODULE

2 - TIMING PIN

KJSUNROOF 23 - 183

DRIVE MOTOR (Continued)

Page 1649 of 1803

CONTROL SWITCH

DESCRIPTION

Vehicles equipped with a power sunroof utilize an

sunroof control switch. On this model, the sunroof

control switch is located in the overhead console, in

between the two reading lamps. The switch is

mounted in the overhead console with four plastic

retaining tabs, molded into the switch housing.

This switch incorporates four selections of opera-

tion open, auto open, close and vent. The individual

switches in the sunroof control switch unit cannot be

repaired. If one switch is damaged or faulty, the

entire sunroof control switch unit must be replaced.

OPERATION

With the operation of the sunroof control switch,

voltage is directed to the sunroof motor, through the

switch contacts or control module. If the control

switch is depressed and held depressed the voltage

signal is controlled manually through the switch con-

tacts, so when the switch is released the sunroof

stops.

Refer to the owners manual for more information

on the operation of the sunroof switch and system.

DIAGNOSIS AND TESTING

The following test will determine if the sunroof

control switch is operating properly.

(1) Remove the overhead console from the head-

liner (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

(2) Remove the sunroof control switch from the

overhead console (Refer to 23 - BODY/SUNROOF/

CONTROL SWITCH - REMOVAL).

(3) Using an ohmmeter, test the switch terminals

for proper continuity using the table below. If any ofthe terminals do not show proper continuity, replace

the sunroof control switch.

SWITCH POSITION

(DEPRESSED)CONTINUITY BETWEEN

TERMINALS

VENT (V) 3, 4

OPEN (AUTO) 1, 4

CLOSE 2, 4

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the overhead console from the head-

liner (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

(3) Disconnect the sunroof control switch electrical

connector. Depress the connector retaining tab and

pull the connector straight out.

(4) To remove the switch from the overhead con-

sole, push on the back of the switch until it comes

free from the overhead console.

INSTALLATION

(1) Install the switch in the overhead console

assembly. Be certain the switch is securely snapped

in place.

(2) Connect the sunroof control switch electrical

connector. Be certain the switch connector is securely

snapped in place.

(3) Install the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - INSTALLA-

TION).

(4) Connect the negative battery cable.

23 - 184 SUNROOFKJ

Page 1650 of 1803

WEATHERSTRIP/SEALS

TABLE OF CONTENTS

page page

A-PILLAR SEAL

REMOVAL............................185

INSTALLATION........................185

COWL WEATHERSTRIP

REMOVAL............................185

INSTALLATION........................185

DOOR PRIMARY WEATHERSTRIP

REMOVAL............................185

INSTALLATION........................185

DOOR LOWER WEATHERSTRIP

REMOVAL............................186

INSTALLATION........................186

FRONT DOOR OUTER BELT MOLDING

REMOVAL............................186

INSTALLATION........................186

SWING GATE BELTLINE WEATHERSTRIP

REMOVAL............................186

INSTALLATION........................186

SWING GATE OPENING WEATHERSTRIP

REMOVAL............................186INSTALLATION........................186

REAR DOOR OUTER BELT MOLDING

REMOVAL............................186

INSTALLATION........................186

SIDE RAIL WEATHERSTRIP/RETAINER

REMOVAL............................186

INSTALLATION........................186

WINDSHIELD A-PILLAR WEATHERSTRIP/

RETAINER

REMOVAL............................186

INSTALLATION........................187

COWL/PLENUM SEAL

REMOVAL............................187

INSTALLATION........................187

COWL/PLENUM WINDOW BAFFLE SEAL

REMOVAL............................187

INSTALLATION........................187

A-PILLAR SEAL

REMOVAL

(1) Open the doors and peal the seal away from

the a-pillar/windshield and the side rail weather

strip flanges.

INSTALLATION

(1) Position the a-pillar seal over the windshield/a-

pillar and the side rail weatherstrip flanges and seat

fully.

COWL WEATHERSTRIP

REMOVAL

(1) Open the hood and peal the cowl seal from the

cowl panel and cowl flange.

INSTALLATION

(1) Position the weatherstrip over the cowl flange

and the cowl grille and seat fully.

DOOR PRIMARY

WEATHERSTRIP

REMOVAL

(1) Remove the lower b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR LOWER TRIM -

REMOVAL)

(2) Peal seal off of the door opening flange.

INSTALLATION

(1) Position the seal to the bottom of the door

opening, with bulb facing outboard, starting the

installation at the center of the lower flange. Press

the seal onto the sill flange and work around the

perimeter of the door opening until fully seated.

Work in one direction, smoothing the seal to avoid

puckers or wrinkles.

(2) Install the lower b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR LOWER TRIM -

INSTALLATION)

(3) When installing a new weatherstrip on the

front door opening, remove the tear strip starting at

the splice and moving around the front of the door to

the back of the opening.

KJWEATHERSTRIP/SEALS 23 - 185

Page 1651 of 1803

(4) When installing a new weatherstrip on the rear

door opening, remove the tear strip starting at the

splice and moving around the back of the door to the

front of the opening.

DOOR LOWER WEATHERSTRIP

REMOVAL

(1) Carefully disengage the push pin fasteners and

remove the seal.

INSTALLATION

(1) Position the seal and seat the push pin fasten-

ers.

FRONT DOOR OUTER BELT

MOLDING

REMOVAL

(1) Lower the window.

(2) Pull the outer belt molding off of the door

flange starting at the rear and moving forward.

INSTALLATION

(1) Press the belt molding onto the outer door win-

dow flange starting at the rear and working forward.

SWING GATE BELTLINE

WEATHERSTRIP

REMOVAL

(1) Remove the swing gate trim panel. (Refer to 23

- BODY/SWING GATE/TRIM PANEL - REMOVAL)

(2) Pull seal away from the corner tabs and

remove from the swing gate flange.

INSTALLATION

(1) Install the seal over the swing gate flange and

seat the corner tabs.

(2) Install the swing gate trim panel. (Refer to 23 -

BODY/SWING GATE/TRIM PANEL - INSTALLA-

TION)

SWING GATE OPENING

WEATHERSTRIP

REMOVAL

(1) Open the swing gate and peal seal off of the

gate opening flange.

INSTALLATION

(1) Position the seal to the bottom of the gate

opening starting the installation at the center of the

flange. Press the seal onto the sill flange and work

around the perimeter of the door opening until fully

seated. Work in one direction, smoothing the seal to

avoid puckers or wrinkles.

REAR DOOR OUTER BELT

MOLDING

REMOVAL

(1) Lower the window.

(2) Pull the outer belt molding off of the door

flange starting at the rear and moving forward.

INSTALLATION

(1) Press the belt molding onto the outer door win-

dow flange starting at the front and working back.

SIDE RAIL WEATHERSTRIP/

RETAINER

REMOVAL

(1) Remove the windshield weatherstrip retainer.

(Refer to 23 - BODY/WEATHERSTRIP/SEALS/

WINDSHIELD A-PILLAR WEATHERSTRIP/RE-

TAINER - REMOVAL)

(2) Remove the two screws.

(3) Using a trim stick C-4755 or equivalent,

release the push in fasteners and remove the weath-

erstrip.

INSTALLATION

(1) Position the weatherstrip and seat the push in

fasteners.

(2) Install the two screws.

(3) Install the windshield weatherstrip. (Refer to

23 - BODY/WEATHERSTRIP/SEALS/WINDSHIELD

A-PILLAR WEATHERSTRIP/RETAINER - INSTAL-

LATION)

WINDSHIELD A-PILLAR

WEATHERSTRIP/RETAINER

REMOVAL

(1) Open the doors and peal the a-pillar seal away

from the a-pillar/windshield and the side rail

weather strip flanges.

(2) Remove the seven screws and remove the

weatherstrip.

23 - 186 WEATHERSTRIP/SEALSKJ

DOOR PRIMARY WEATHERSTRIP (Continued)

Page 1652 of 1803

INSTALLATION

(1) Position the weatherstrip and install the seven

screws.

(2) Position the a-pillar seal over the windshield/a-

pillar and the side rail weatherstrip flanges and seat

fully.

COWL/PLENUM SEAL

REMOVAL

(1) Remove the cowl grille. (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL)

(2) Remove the seal from the plenum flange above

the air inlet duct.

INSTALLATION

NOTE: Seal should not be touching the plenum baf-

fle flange seal.

(1) Position the seal on the plenum flange and seat

fully.(2) Install the cowl grille. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION)

COWL/PLENUM WINDOW

BAFFLE SEAL

REMOVAL

(1) Remove the cowl grille. (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL)

(2) Remove the seal from the window below the

cowl/plenum seal.

INSTALLATION

(1) Position the seal against the upper flange of

the inner plenum window below the cowl/plenum seal

and seat fully.

(2) Install the cowl grille. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION)

KJWEATHERSTRIP/SEALS 23 - 187

WINDSHIELD A-PILLAR WEATHERSTRIP/RETAINER (Continued)

Page 1659 of 1803

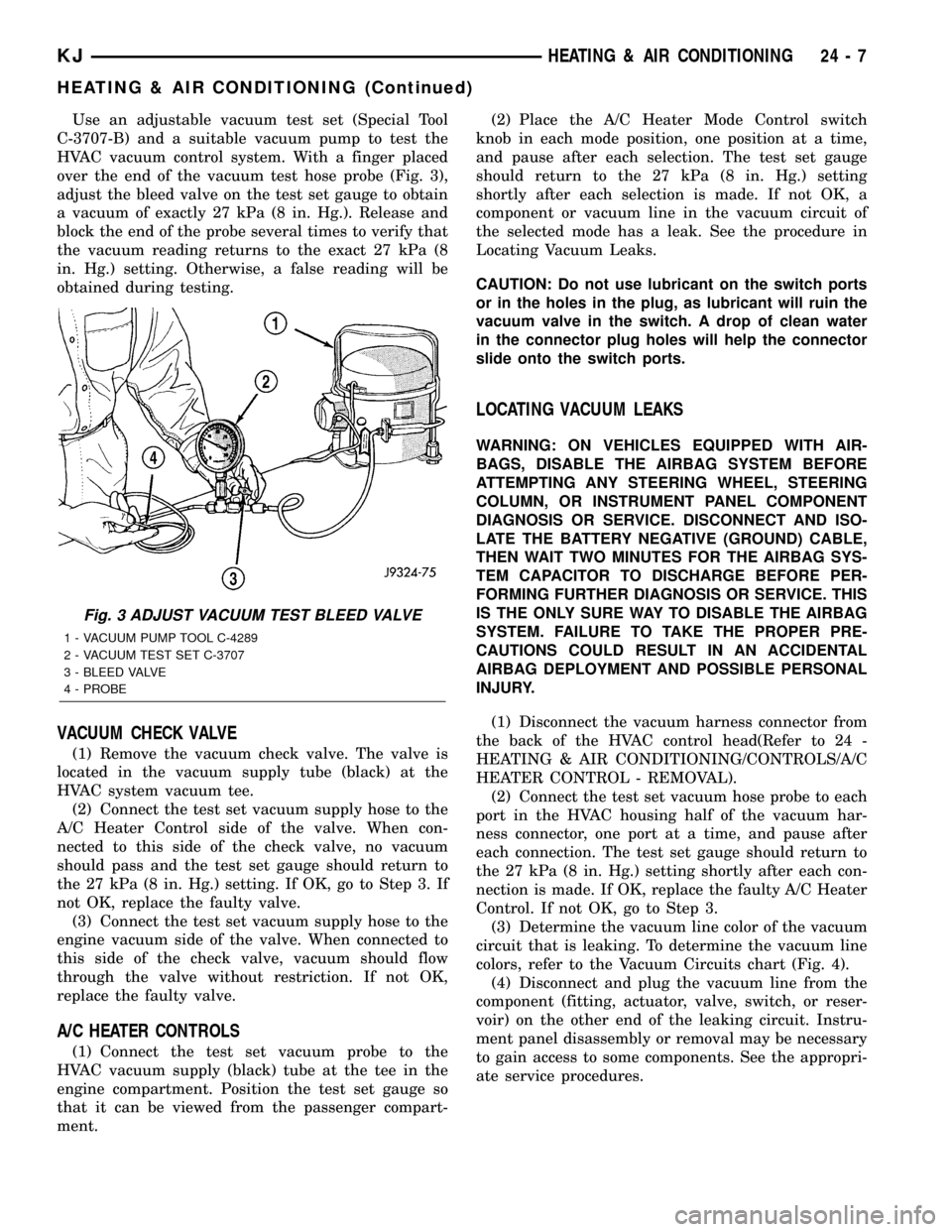

Use an adjustable vacuum test set (Special Tool

C-3707-B) and a suitable vacuum pump to test the

HVAC vacuum control system. With a finger placed

over the end of the vacuum test hose probe (Fig. 3),

adjust the bleed valve on the test set gauge to obtain

a vacuum of exactly 27 kPa (8 in. Hg.). Release and

block the end of the probe several times to verify that

the vacuum reading returns to the exact 27 kPa (8

in. Hg.) setting. Otherwise, a false reading will be

obtained during testing.

VACUUM CHECK VALVE

(1) Remove the vacuum check valve. The valve is

located in the vacuum supply tube (black) at the

HVAC system vacuum tee.

(2) Connect the test set vacuum supply hose to the

A/C Heater Control side of the valve. When con-

nected to this side of the check valve, no vacuum

should pass and the test set gauge should return to

the 27 kPa (8 in. Hg.) setting. If OK, go to Step 3. If

not OK, replace the faulty valve.

(3) Connect the test set vacuum supply hose to the

engine vacuum side of the valve. When connected to

this side of the check valve, vacuum should flow

through the valve without restriction. If not OK,

replace the faulty valve.

A/C HEATER CONTROLS

(1) Connect the test set vacuum probe to the

HVAC vacuum supply (black) tube at the tee in the

engine compartment. Position the test set gauge so

that it can be viewed from the passenger compart-

ment.(2) Place the A/C Heater Mode Control switch

knob in each mode position, one position at a time,

and pause after each selection. The test set gauge

should return to the 27 kPa (8 in. Hg.) setting

shortly after each selection is made. If not OK, a

component or vacuum line in the vacuum circuit of

the selected mode has a leak. See the procedure in

Locating Vacuum Leaks.

CAUTION: Do not use lubricant on the switch ports

or in the holes in the plug, as lubricant will ruin the

vacuum valve in the switch. A drop of clean water

in the connector plug holes will help the connector

slide onto the switch ports.

LOCATING VACUUM LEAKS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect the vacuum harness connector from

the back of the HVAC control head(Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - REMOVAL).

(2) Connect the test set vacuum hose probe to each

port in the HVAC housing half of the vacuum har-

ness connector, one port at a time, and pause after

each connection. The test set gauge should return to

the 27 kPa (8 in. Hg.) setting shortly after each con-

nection is made. If OK, replace the faulty A/C Heater

Control. If not OK, go to Step 3.

(3) Determine the vacuum line color of the vacuum

circuit that is leaking. To determine the vacuum line

colors, refer to the Vacuum Circuits chart (Fig. 4).

(4) Disconnect and plug the vacuum line from the

component (fitting, actuator, valve, switch, or reser-

voir) on the other end of the leaking circuit. Instru-

ment panel disassembly or removal may be necessary

to gain access to some components. See the appropri-

ate service procedures.

Fig. 3 ADJUST VACUUM TEST BLEED VALVE

1 - VACUUM PUMP TOOL C-4289

2 - VACUUM TEST SET C-3707

3 - BLEED VALVE

4 - PROBE

KJHEATING & AIR CONDITIONING 24 - 7

HEATING & AIR CONDITIONING (Continued)

Page 1663 of 1803

CONTROLS

TABLE OF CONTENTS

page page

A/C COMPRESSOR CLUTCH

DESCRIPTION - 3.7L and 2.4L.............12

OPERATION - 3.7L and 2.4L...............12

DIAGNOSIS AND TESTING - A/C

COMPRESSOR CLUTCH COIL...........12

STANDARD PROCEDURE - A/C

COMPRESSOR CLUTCH BREAK-IN.......12

REMOVAL.............................13

INSPECTION..........................14

INSTALLATION.........................14

A/C COMPRESSOR CLUTCH RELAY

DESCRIPTION.........................15

OPERATION...........................15

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH RELAY......................15

REMOVAL.............................16

INSTALLATION.........................16

A/C HEATER CONTROL

DESCRIPTION.........................16

REMOVAL.............................17

INSTALLATION.........................17

A/C HIGH PRESSURE SWITCH

DESCRIPTION.........................17

OPERATION...........................18

DIAGNOSIS AND TESTING - A/C HIGH

PRESSURE SWITCH...................18

REMOVAL.............................18

INSTALLATION.........................18

A/C LOW PRESSURE SWITCH

DESCRIPTION.........................18

OPERATION...........................18

DIAGNOSIS AND TESTING - A/C LOW

PRESSURE SWITCH...................19

REMOVAL.............................19

INSTALLATION.........................19

BLEND DOOR ACTUATOR

REMOVAL.............................20

INSTALLATION.........................20BLOWER MOTOR RELAY

DESCRIPTION.........................20

OPERATION...........................20

DIAGNOSIS AND TESTING - BLOWER

MOTOR RELAY.......................21

REMOVAL.............................21

INSTALLATION.........................22

BLOWER MOTOR RESISTOR

DESCRIPTION.........................22

OPERATION...........................22

DIAGNOSIS AND TESTING - BLOWER

MOTOR RESISTOR....................22

REMOVAL.............................22

INSTALLATION.........................22

BLOWER MOTOR SWITCH

DESCRIPTION.........................23

OPERATION...........................23

DIAGNOSIS AND TESTING - BLOWER

MOTOR SWITCH......................23

REMOVAL.............................23

INSTALLATION.........................23

MODE DOOR ACTUATOR

REMOVAL

REMOVAL - PANEL DOOR ACTUATOR.....24

REMOVAL - FLOOR - DEFROST DOOR

ACTUATOR..........................24

INSTALLATION

INSTALLATION - PANEL DOOR ACTUATOR . 25

INSTALLATION - FLOOR - DEFROST DOOR

ACTUATOR..........................25

RECIRCULATION DOOR ACTUATOR

REMOVAL.............................26

INSTALLATION.........................26

VACUUM CHECK VALVE

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................28

INSTALLATION.........................28

KJCONTROLS 24 - 11

Page 1665 of 1803

to 2000 rpm. This procedure (burnishing) will seat

the opposing friction surfaces and provide a higher

compressor clutch torque capability.

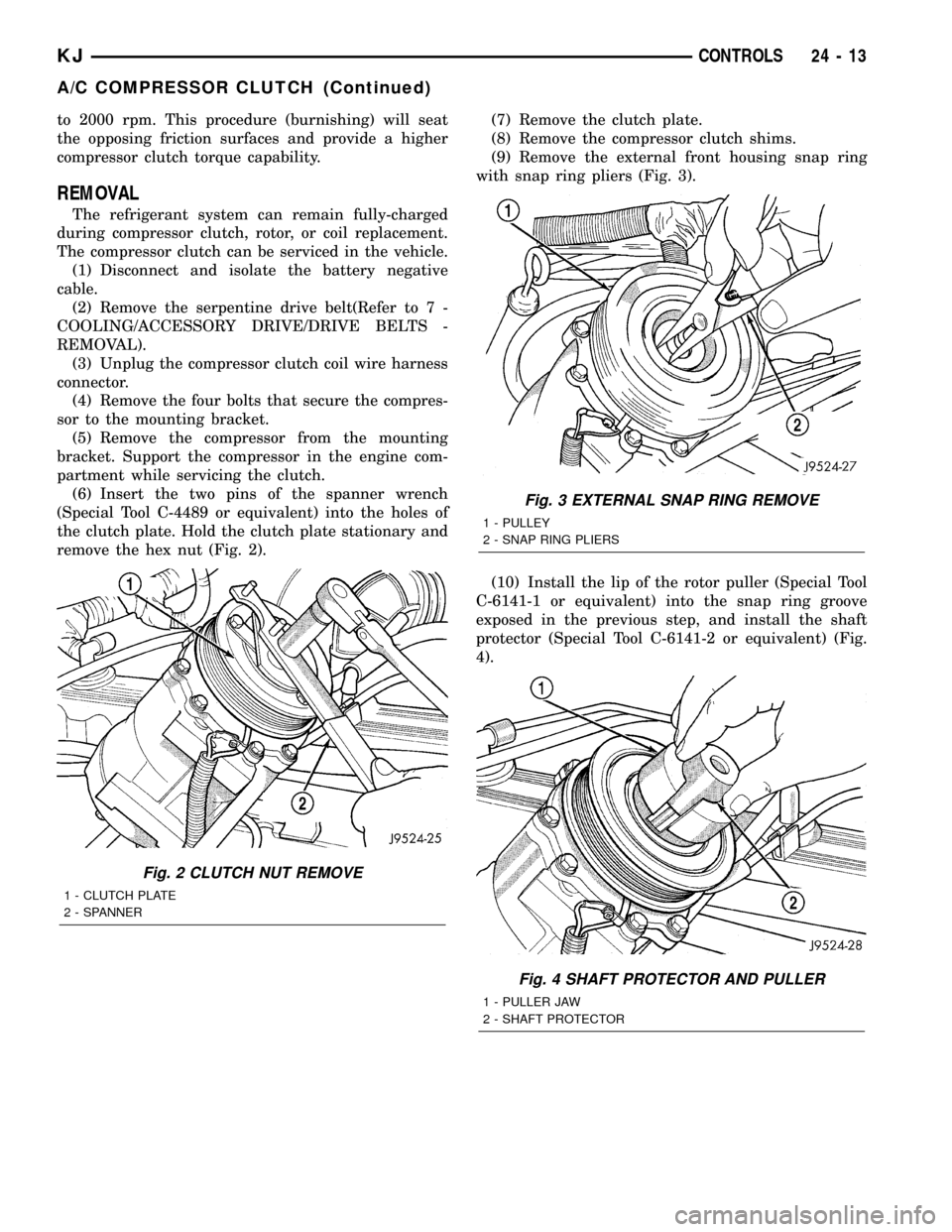

REMOVAL

The refrigerant system can remain fully-charged

during compressor clutch, rotor, or coil replacement.

The compressor clutch can be serviced in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Unplug the compressor clutch coil wire harness

connector.

(4) Remove the four bolts that secure the compres-

sor to the mounting bracket.

(5) Remove the compressor from the mounting

bracket. Support the compressor in the engine com-

partment while servicing the clutch.

(6) Insert the two pins of the spanner wrench

(Special Tool C-4489 or equivalent) into the holes of

the clutch plate. Hold the clutch plate stationary and

remove the hex nut (Fig. 2).(7) Remove the clutch plate.

(8) Remove the compressor clutch shims.

(9) Remove the external front housing snap ring

with snap ring pliers (Fig. 3).

(10) Install the lip of the rotor puller (Special Tool

C-6141-1 or equivalent) into the snap ring groove

exposed in the previous step, and install the shaft

protector (Special Tool C-6141-2 or equivalent) (Fig.

4).

Fig. 2 CLUTCH NUT REMOVE

1 - CLUTCH PLATE

2 - SPANNER

Fig. 3 EXTERNAL SNAP RING REMOVE

1 - PULLEY

2 - SNAP RING PLIERS

Fig. 4 SHAFT PROTECTOR AND PULLER

1 - PULLER JAW

2 - SHAFT PROTECTOR

KJCONTROLS 24 - 13

A/C COMPRESSOR CLUTCH (Continued)

Page 1668 of 1803

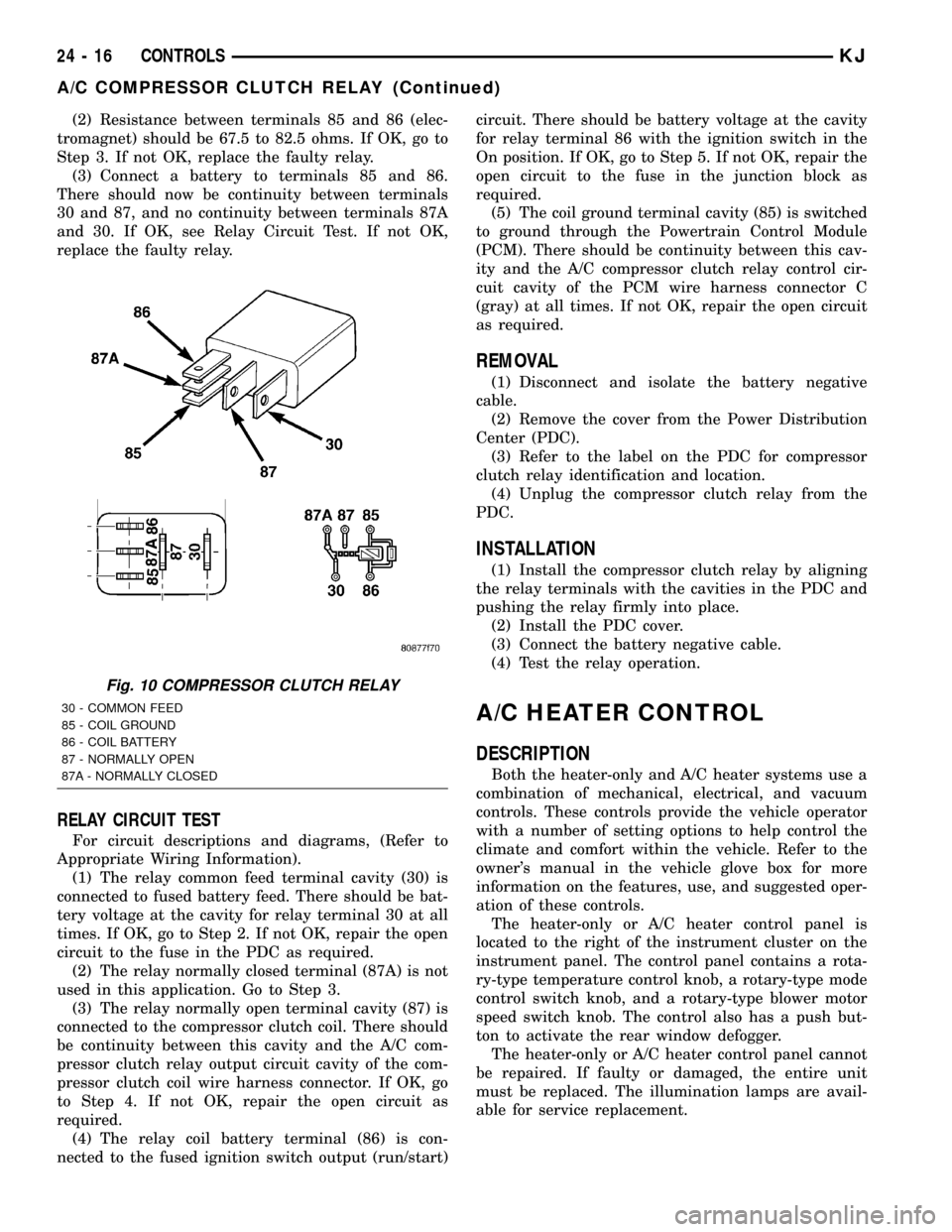

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 67.5 to 82.5 ohms. If OK, go to

Step 3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see Relay Circuit Test. If not OK,

replace the faulty relay.

RELAY CIRCUIT TEST

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed. There should be bat-

tery voltage at the cavity for relay terminal 30 at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is not

used in this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the compressor clutch coil. There should

be continuity between this cavity and the A/C com-

pressor clutch relay output circuit cavity of the com-

pressor clutch coil wire harness connector. If OK, go

to Step 4. If not OK, repair the open circuit as

required.

(4) The relay coil battery terminal (86) is con-

nected to the fused ignition switch output (run/start)circuit. There should be battery voltage at the cavity

for relay terminal 86 with the ignition switch in the

On position. If OK, go to Step 5. If not OK, repair the

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

Both the heater-only and A/C heater systems use a

combination of mechanical, electrical, and vacuum

controls. These controls provide the vehicle operator

with a number of setting options to help control the

climate and comfort within the vehicle. Refer to the

owner's manual in the vehicle glove box for more

information on the features, use, and suggested oper-

ation of these controls.

The heater-only or A/C heater control panel is

located to the right of the instrument cluster on the

instrument panel. The control panel contains a rota-

ry-type temperature control knob, a rotary-type mode

control switch knob, and a rotary-type blower motor

speed switch knob. The control also has a push but-

ton to activate the rear window defogger.

The heater-only or A/C heater control panel cannot

be repaired. If faulty or damaged, the entire unit

must be replaced. The illumination lamps are avail-

able for service replacement.

Fig. 10 COMPRESSOR CLUTCH RELAY

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

24 - 16 CONTROLSKJ

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 1669 of 1803

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

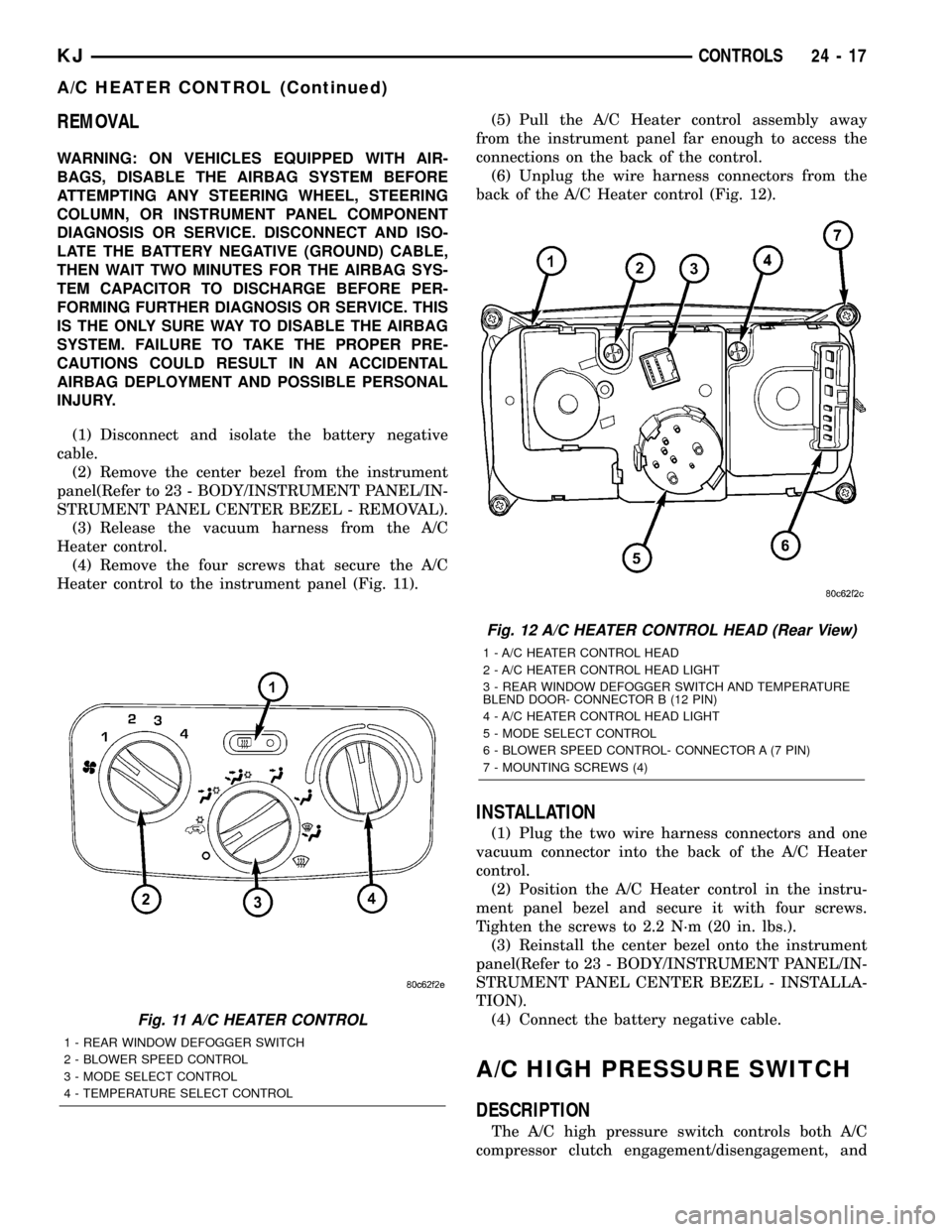

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center bezel from the instrument

panel(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL CENTER BEZEL - REMOVAL).

(3) Release the vacuum harness from the A/C

Heater control.

(4) Remove the four screws that secure the A/C

Heater control to the instrument panel (Fig. 11).(5) Pull the A/C Heater control assembly away

from the instrument panel far enough to access the

connections on the back of the control.

(6) Unplug the wire harness connectors from the

back of the A/C Heater control (Fig. 12).

INSTALLATION

(1) Plug the two wire harness connectors and one

vacuum connector into the back of the A/C Heater

control.

(2) Position the A/C Heater control in the instru-

ment panel bezel and secure it with four screws.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(3) Reinstall the center bezel onto the instrument

panel(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL CENTER BEZEL - INSTALLA-

TION).

(4) Connect the battery negative cable.

A/C HIGH PRESSURE SWITCH

DESCRIPTION

The A/C high pressure switch controls both A/C

compressor clutch engagement/disengagement, and

Fig. 11 A/C HEATER CONTROL

1 - REAR WINDOW DEFOGGER SWITCH

2 - BLOWER SPEED CONTROL

3 - MODE SELECT CONTROL

4 - TEMPERATURE SELECT CONTROL

Fig. 12 A/C HEATER CONTROL HEAD (Rear View)

1 - A/C HEATER CONTROL HEAD

2 - A/C HEATER CONTROL HEAD LIGHT

3 - REAR WINDOW DEFOGGER SWITCH AND TEMPERATURE

BLEND DOOR- CONNECTOR B (12 PIN)

4 - A/C HEATER CONTROL HEAD LIGHT

5 - MODE SELECT CONTROL

6 - BLOWER SPEED CONTROL- CONNECTOR A (7 PIN)

7 - MOUNTING SCREWS (4)

KJCONTROLS 24 - 17

A/C HEATER CONTROL (Continued)