relay JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 375 of 1803

REAR WINDOW DEFOGGER

SWITCH

DESCRIPTION

The rear window defogger switch is installed in the

instrument panel HVAC contol head assembly. The

momentary-type switch provides a hard-wired ground

signal to the HVAC control head each time it is

depressed. The instrument cluster rear window

defogger timer and logic circuitry responds by ener-

gizing or de-energizing the rear window defogger

relay.

OPERATION

Energizing the rear window defogger relay pro-

vides electrical current to the rear window defogger

grid and, if the vehicle is so equipped, the outside

rear view mirror heating grids. An amber indicator

lamp in the defogger switch, which lights to indicate

when the defogger system is turned On, is also pow-

ered by the defogger relay output.

The defogger switch illumination lamp and indica-

tor lamp bulbs are serviceable. The defogger switch

cannot be repaired and, if faulty or damaged the

entire HVAC control head assembly must be

replaced.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER SWITCH

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the HVAC control head assembly from

the instrument panel and unplug the defogger switch

wire harness connector-B.

(2) Check for continuity between the ground cir-

cuit cavity of the defogger switch wire harness con-nector and a good ground. There should be

continuity. If OK, go to Step 3. If not OK, repair the

open circuit as required.

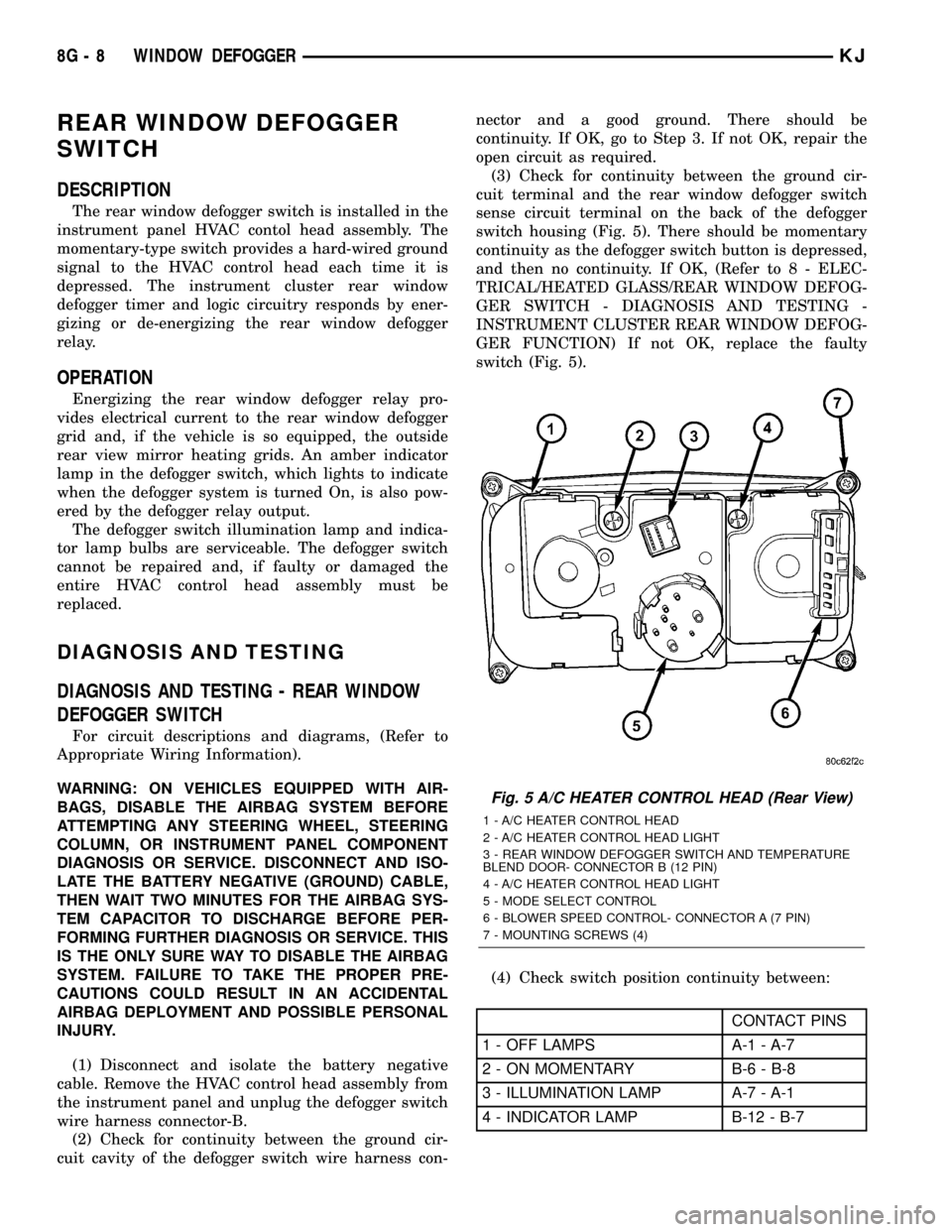

(3) Check for continuity between the ground cir-

cuit terminal and the rear window defogger switch

sense circuit terminal on the back of the defogger

switch housing (Fig. 5). There should be momentary

continuity as the defogger switch button is depressed,

and then no continuity. If OK, (Refer to 8 - ELEC-

TRICAL/HEATED GLASS/REAR WINDOW DEFOG-

GER SWITCH - DIAGNOSIS AND TESTING -

INSTRUMENT CLUSTER REAR WINDOW DEFOG-

GER FUNCTION) If not OK, replace the faulty

switch (Fig. 5).

(4) Check switch position continuity between:

CONTACT PINS

1 - OFF LAMPS A-1 - A-7

2 - ON MOMENTARY B-6 - B-8

3 - ILLUMINATION LAMP A-7 - A-1

4 - INDICATOR LAMP B-12 - B-7

Fig. 5 A/C HEATER CONTROL HEAD (Rear View)

1 - A/C HEATER CONTROL HEAD

2 - A/C HEATER CONTROL HEAD LIGHT

3 - REAR WINDOW DEFOGGER SWITCH AND TEMPERATURE

BLEND DOOR- CONNECTOR B (12 PIN)

4 - A/C HEATER CONTROL HEAD LIGHT

5 - MODE SELECT CONTROL

6 - BLOWER SPEED CONTROL- CONNECTOR A (7 PIN)

7 - MOUNTING SCREWS (4)

8G - 8 WINDOW DEFOGGERKJ

Page 376 of 1803

DIAGNOSIS AND TESTING - REAR HVAC

CONTROL ASSEMBLY WINDOW DEFOGGER

FUNCTION

Before performing this test, complete the Defogger

Switch and Defogger Relay tests as described in this

group. For circuit descriptions and diagrams, (Refer

to Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the defogger relay from the junction

block and unplug the defogger switch wire harness

connector.

(2) Remove the HVAC control head from the

instrument panel. This is accomplished by removing

the ashtray and the screw behind the ashtray and

uncliping the center bezel.

(3) Check for continuity between the rear window

defogger switch sense circuit cavity of the cluster

wire harness connector (connector B) and a good

ground. There should be no continuity. If OK, go to

Step 4. If not OK, repair the short circuit as

required.

(4) Check for continuity between the rear window

defogger switch sense circuit cavity of the right

instrument cluster wire harness connector (connector

B) and the defogger switch wire harness connector.

There should be continuity. If OK, go to Step 5. If not

OK, repair the open circuit as required.

(5) Check for continuity between the rear window

defogger relay control circuit cavity of the right

instrument cluster wire harness connector (connectorB) and a good ground. There should be no continuity.

If OK, go to Step 6. If not OK, repair the short circuit

as required.

(6) Check for continuity between the rear window

defogger relay control circuit cavities of the right

instrument cluster wire harness connector (connector

B) and the defogger relay receptacle (the cavity for

ISO relay terminal 85) in the junction block. There

should be continuity. If OK, replace the faulty HVAC

control head. If not OK, repair the open circuit as

required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) The Rear Window Defogger switch is part of

the HVAC assembly and if damaged or inoperative

the entire HVAC control assembly must be replace-

d(Refer to 24 - HEATING & AIR CONDITIONING/

CONTROLS/A/C HEATER CONTROL - REMOVAL).

INSTALLATION

(1) The Rear Window Defogger switch is part of

the HVAC control assembly and if damaged or inop-

erative you must replace the entire HVEAC control

head assembly(Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/A/C HEATER CONTROL -

INSTALLATION).

(2) Connect the battery negative cable.

KJWINDOW DEFOGGER 8G - 9

REAR WINDOW DEFOGGER SWITCH (Continued)

Page 384 of 1803

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - HORN SYSTEM . . . 1

HORN

DIAGNOSIS AND TESTING - HORN..........2

REMOVAL.............................3

INSTALLATION..........................3HORN RELAY

DIAGNOSIS AND TESTING - HORN RELAY....3

REMOVAL.............................3

INSTALLATION..........................3

HORN SWITCH

DESCRIPTION..........................4

DIAGNOSIS AND TESTING - HORN SWITCH . . . 4

HORN SYSTEM

DESCRIPTION

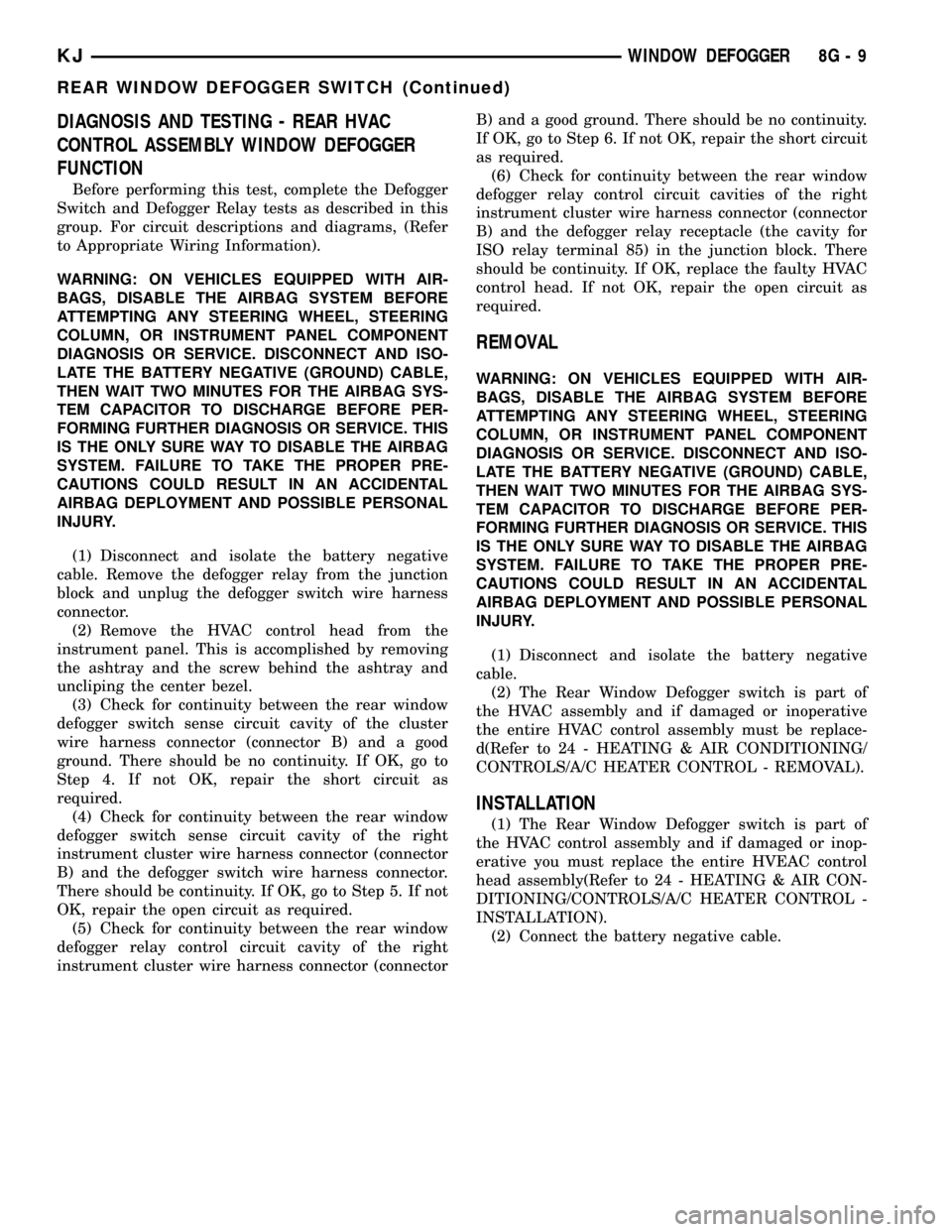

A dual-note electric horn system is standard facto-

ry-installed equipment on this model (Fig. 1).

The dual-note horn system features dual electro-

magnetic horn units. The horn system includes the

following major components:

²Horn- The two horns are located below the

Power Distribution Center (PDC).

²Horn Relay- The horn relay is located in the

Junction Block (JB).²Horn Switch- The horn switch is molded into

the driver airbag assembly.OPERATION

The horn system operates on battery current

received through fuse 3 in the Junction Block (JB).

The horn system circuit is designed so that the sys-

tem will remain operational, regardless of the igni-

tion switch position.

DIAGNOSIS AND TESTING - HORN SYSTEM

In most cases, any problem involving continually

sounding horns can be quickly alleviated by removing

the horn relay from the Junction Block (JB). Refer to

horn relay for the removal procedure. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Fig. 1 HORN LOCATION

1 - HIGH NOTE HORN

2 - LOW NOTE HORN

KJHORN 8H - 1

Page 385 of 1803

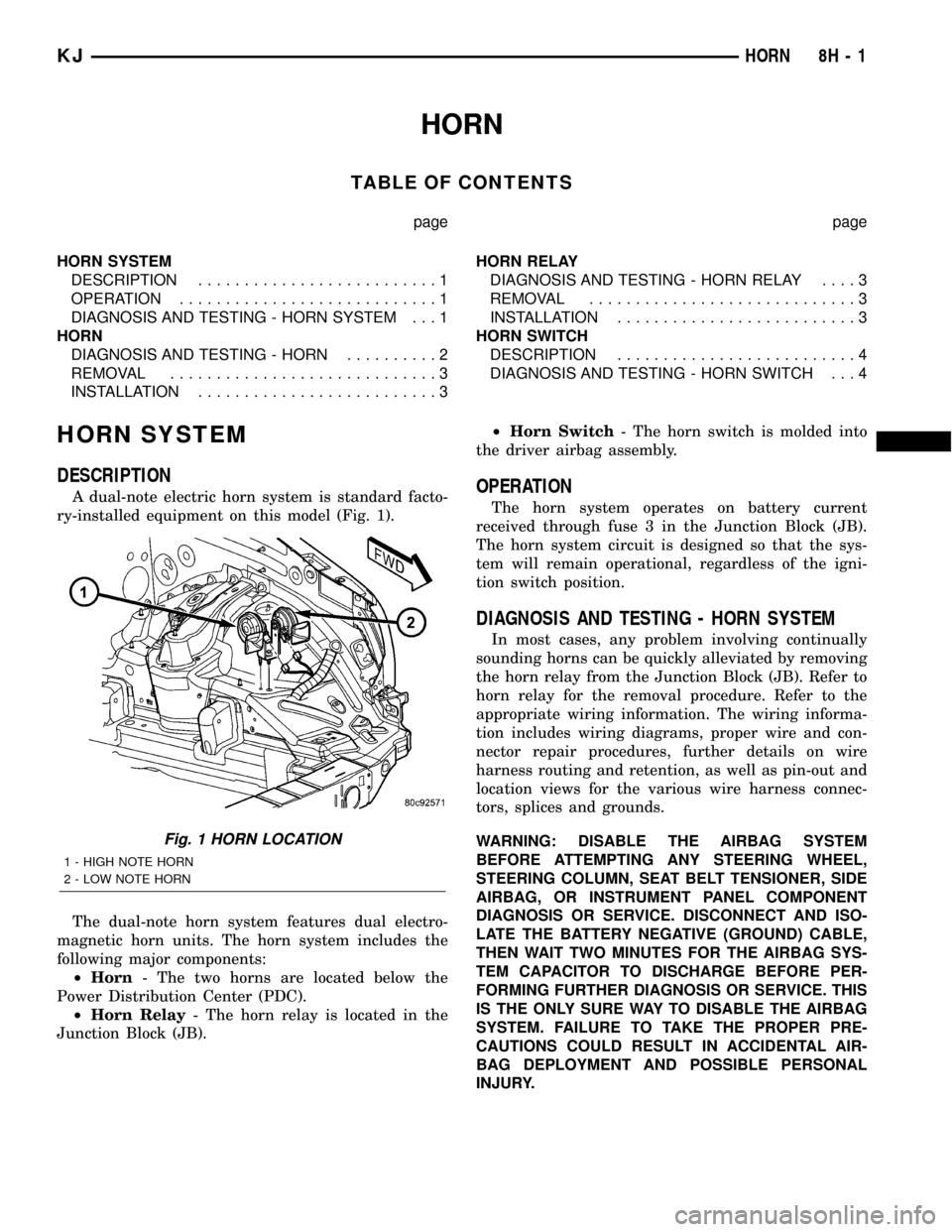

HORN SYSTEM DIAGNOSIS TABLE

CONDITION POSSIBLE CAUSES CORRECTION

BOTH HORNS

INOPERATIVE1. Faulty fuse. 1. Check the fuse in the Junction Block (JB).

Replace the fuse and repair the shorted circuit or

component, if required.

2. Faulty horn relay. 2. Refer to horn relay for the proper diagnosis

and testing procedures. Replace the horn relay or

repair the open horn relay circuit, if required.

3. Faulty horn switch. 3. Refer to horn switch for the proper diagnosis

and testing procedure. Replace the horn switch or

repair the open horn switch circuit, if required.

4. Faulty horns. 4. Refer to horn for the proper diagnosis and

testing procedure. Replace the horns or repair the

open horn circuit, if required.

ONE HORN INOPERATIVE 1. Faulty horn. 1. Refer to horn for the proper diagnosis and

testing procedures. Replace the horn or repair the

open horn circuit, if required.

HORN SOUNDS

CONTINUOUSLY1. Faulty horn relay. 1. Refer to horn relay for the proper diagnosis

and testing procedure. Replace the horn relay or

repair the shorted horn relay control circuit, if

required.

2. Faulty horn switch. 2. Refer to horn switch for the proper diagnosis

and testing procedure. Replace the horn switch or

repair the shorted horn switch circuit, if required.

HORN

DIAGNOSIS AND TESTING - HORN

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.(1) Disconnect the wire harness connector from the

horn. Measure the resistance between the horn

ground circuit cavity of the wire harness connector

and a good ground. There should be no measurable

resistance. If OK, go to Step 2. If not OK, replace

wiring as necessary.

(2) Check for battery voltage at the horn relay out-

put circuit cavity of the wire harness connector for

the horn. There should be zero volts. If OK, go to

Step 3. If not OK, refer to horn relay and horn relay

circuit for the proper diagnosis and testing proce-

dures.

(3) Depress the horn switch. There should now be

battery voltage at the horn relay output circuit cavity

of the wire harness connector for the horn. If OK, but

the horn does not sound, replace the faulty horn. If

not OK, refer to horn relay and horn relay circuit for

the proper diagnosis and testing procedures.

8H - 2 HORNKJ

HORN SYSTEM (Continued)

Page 386 of 1803

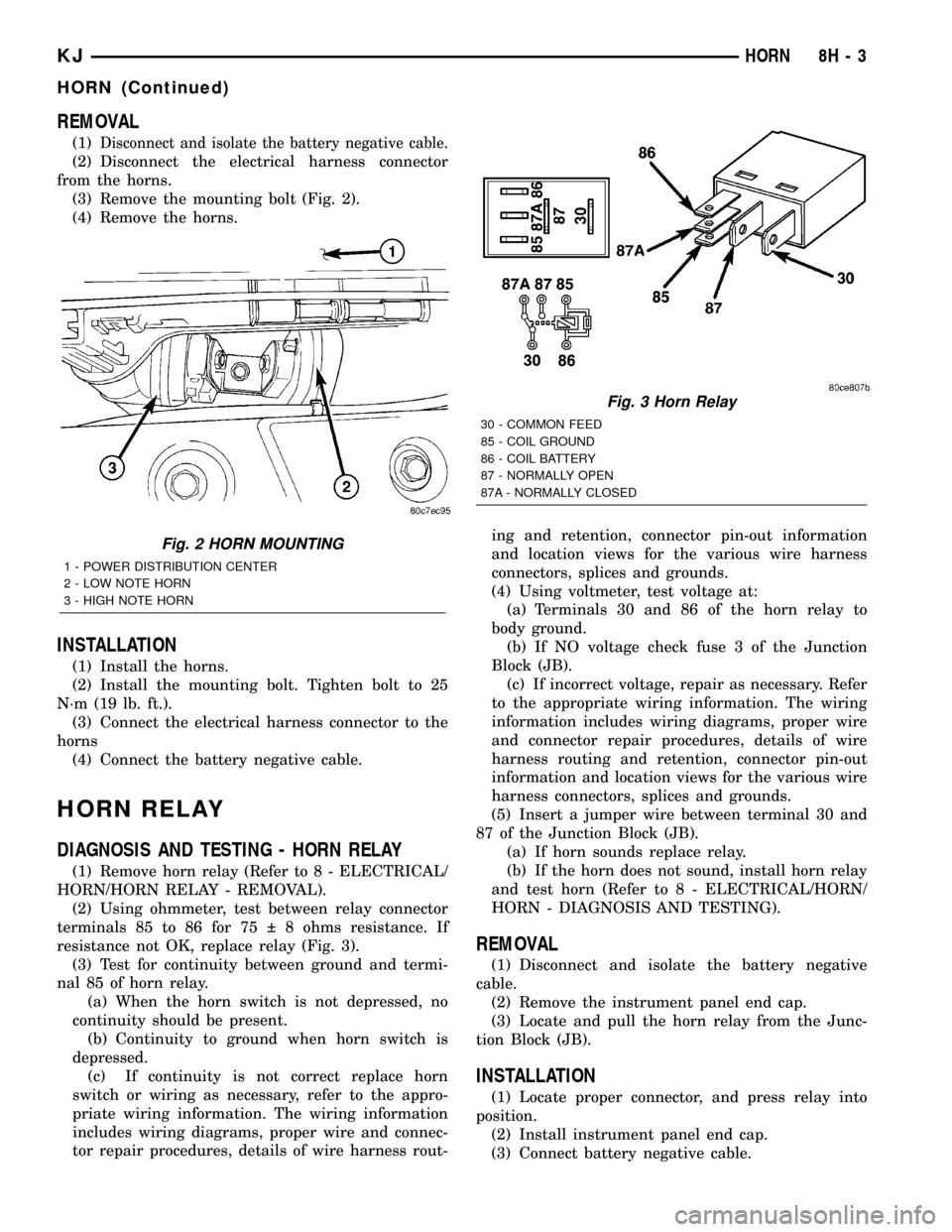

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Disconnect the electrical harness connector

from the horns.

(3) Remove the mounting bolt (Fig. 2).

(4) Remove the horns.

INSTALLATION

(1) Install the horns.

(2) Install the mounting bolt. Tighten bolt to 25

N´m (19 lb. ft.).

(3) Connect the electrical harness connector to the

horns

(4) Connect the battery negative cable.

HORN RELAY

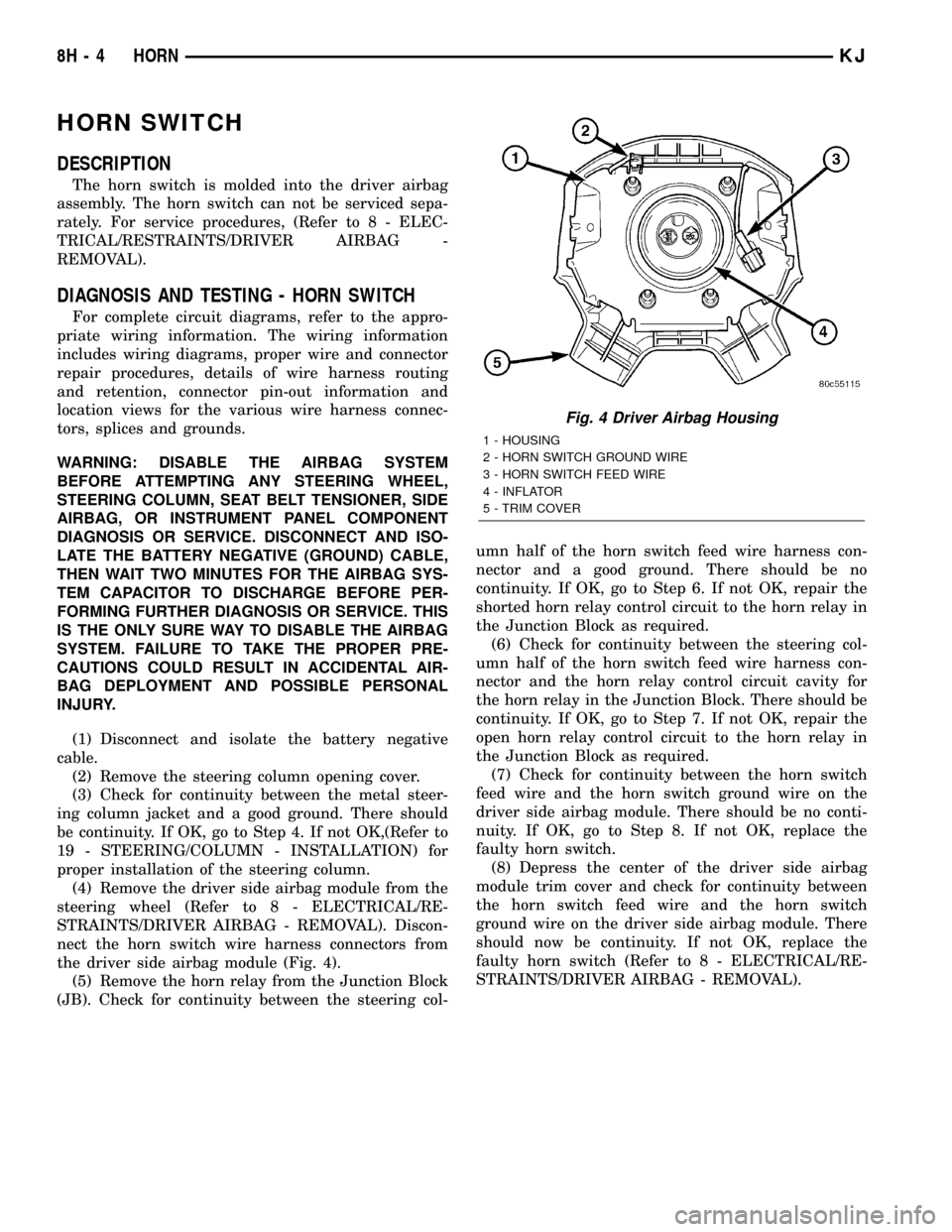

DIAGNOSIS AND TESTING - HORN RELAY

(1) Remove horn relay (Refer to 8 - ELECTRICAL/

HORN/HORN RELAY - REMOVAL).

(2) Using ohmmeter, test between relay connector

terminals 85 to 86 for 75 8 ohms resistance. If

resistance not OK, replace relay (Fig. 3).

(3) Test for continuity between ground and termi-

nal 85 of horn relay.

(a) When the horn switch is not depressed, no

continuity should be present.

(b) Continuity to ground when horn switch is

depressed.

(c) If continuity is not correct replace horn

switch or wiring as necessary, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connec-

tor repair procedures, details of wire harness rout-ing and retention, connector pin-out information

and location views for the various wire harness

connectors, splices and grounds.

(4) Using voltmeter, test voltage at:

(a) Terminals 30 and 86 of the horn relay to

body ground.

(b) If NO voltage check fuse 3 of the Junction

Block (JB).

(c) If incorrect voltage, repair as necessary. Refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

(5) Insert a jumper wire between terminal 30 and

87 of the Junction Block (JB).

(a) If horn sounds replace relay.

(b) If the horn does not sound, install horn relay

and test horn (Refer to 8 - ELECTRICAL/HORN/

HORN - DIAGNOSIS AND TESTING).

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel end cap.

(3) Locate and pull the horn relay from the Junc-

tion Block (JB).

INSTALLATION

(1) Locate proper connector, and press relay into

position.

(2) Install instrument panel end cap.

(3) Connect battery negative cable.

Fig. 2 HORN MOUNTING

1 - POWER DISTRIBUTION CENTER

2 - LOW NOTE HORN

3 - HIGH NOTE HORN

Fig. 3 Horn Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJHORN 8H - 3

HORN (Continued)

Page 387 of 1803

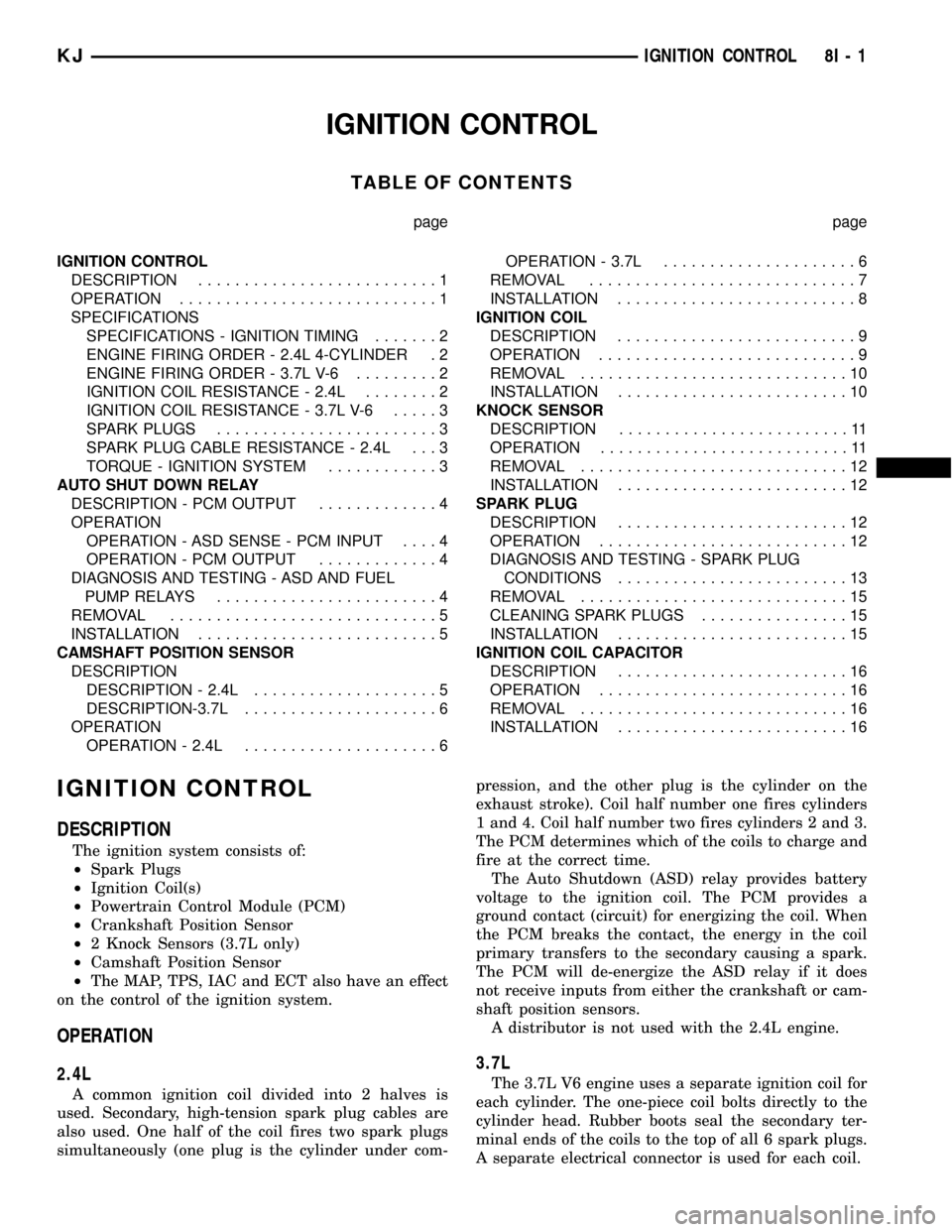

HORN SWITCH

DESCRIPTION

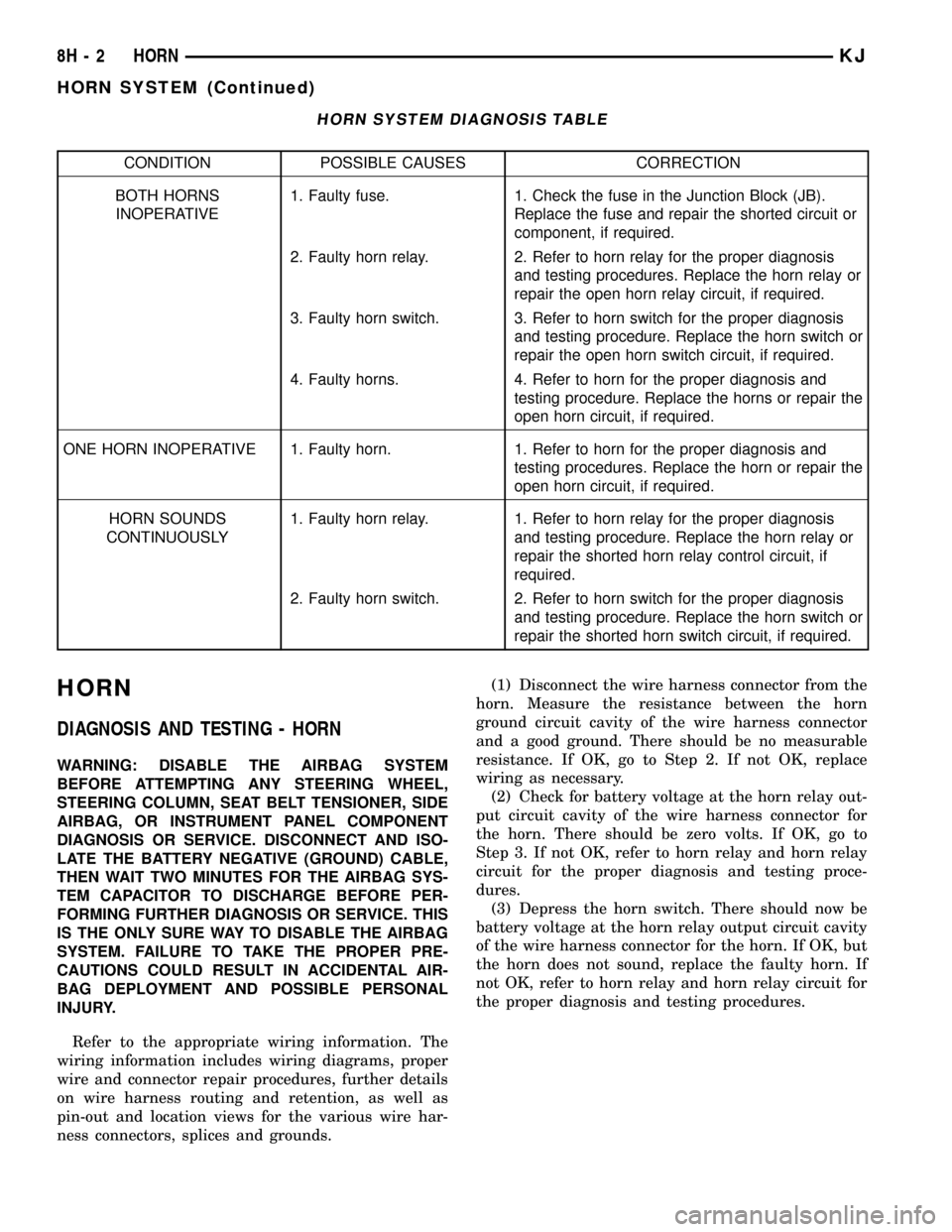

The horn switch is molded into the driver airbag

assembly. The horn switch can not be serviced sepa-

rately. For service procedures, (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG -

REMOVAL).

DIAGNOSIS AND TESTING - HORN SWITCH

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column opening cover.

(3) Check for continuity between the metal steer-

ing column jacket and a good ground. There should

be continuity. If OK, go to Step 4. If not OK,(Refer to

19 - STEERING/COLUMN - INSTALLATION) for

proper installation of the steering column.

(4) Remove the driver side airbag module from the

steering wheel (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL). Discon-

nect the horn switch wire harness connectors from

the driver side airbag module (Fig. 4).

(5) Remove the horn relay from the Junction Block

(JB). Check for continuity between the steering col-umn half of the horn switch feed wire harness con-

nector and a good ground. There should be no

continuity. If OK, go to Step 6. If not OK, repair the

shorted horn relay control circuit to the horn relay in

the Junction Block as required.

(6) Check for continuity between the steering col-

umn half of the horn switch feed wire harness con-

nector and the horn relay control circuit cavity for

the horn relay in the Junction Block. There should be

continuity. If OK, go to Step 7. If not OK, repair the

open horn relay control circuit to the horn relay in

the Junction Block as required.

(7) Check for continuity between the horn switch

feed wire and the horn switch ground wire on the

driver side airbag module. There should be no conti-

nuity. If OK, go to Step 8. If not OK, replace the

faulty horn switch.

(8) Depress the center of the driver side airbag

module trim cover and check for continuity between

the horn switch feed wire and the horn switch

ground wire on the driver side airbag module. There

should now be continuity. If not OK, replace the

faulty horn switch (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL).

Fig. 4 Driver Airbag Housing

1 - HOUSING

2 - HORN SWITCH GROUND WIRE

3 - HORN SWITCH FEED WIRE

4 - INFLATOR

5 - TRIM COVER

8H - 4 HORNKJ

Page 388 of 1803

IGNITION CONTROL

TABLE OF CONTENTS

page page

IGNITION CONTROL

DESCRIPTION..........................1

OPERATION............................1

SPECIFICATIONS

SPECIFICATIONS - IGNITION TIMING.......2

ENGINE FIRING ORDER - 2.4L 4-CYLINDER . 2

ENGINE FIRING ORDER - 3.7L V-6.........2

IGNITION COIL RESISTANCE - 2.4L........2

IGNITION COIL RESISTANCE - 3.7L V-6.....3

SPARK PLUGS........................3

SPARK PLUG CABLE RESISTANCE - 2.4L . . . 3

TORQUE - IGNITION SYSTEM............3

AUTO SHUT DOWN RELAY

DESCRIPTION - PCM OUTPUT.............4

OPERATION

OPERATION - ASD SENSE - PCM INPUT....4

OPERATION - PCM OUTPUT.............4

DIAGNOSIS AND TESTING - ASD AND FUEL

PUMP RELAYS........................4

REMOVAL.............................5

INSTALLATION..........................5

CAMSHAFT POSITION SENSOR

DESCRIPTION

DESCRIPTION - 2.4L....................5

DESCRIPTION-3.7L.....................6

OPERATION

OPERATION - 2.4L.....................6OPERATION - 3.7L.....................6

REMOVAL.............................7

INSTALLATION..........................8

IGNITION COIL

DESCRIPTION..........................9

OPERATION............................9

REMOVAL.............................10

INSTALLATION.........................10

KNOCK SENSOR

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................12

INSTALLATION.........................12

SPARK PLUG

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS.........................13

REMOVAL.............................15

CLEANING SPARK PLUGS................15

INSTALLATION.........................15

IGNITION COIL CAPACITOR

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

IGNITION CONTROL

DESCRIPTION

The ignition system consists of:

²Spark Plugs

²Ignition Coil(s)

²Powertrain Control Module (PCM)

²Crankshaft Position Sensor

²2 Knock Sensors (3.7L only)

²Camshaft Position Sensor

²The MAP, TPS, IAC and ECT also have an effect

on the control of the ignition system.

OPERATION

2.4L

A common ignition coil divided into 2 halves is

used. Secondary, high-tension spark plug cables are

also used. One half of the coil fires two spark plugs

simultaneously (one plug is the cylinder under com-pression, and the other plug is the cylinder on the

exhaust stroke). Coil half number one fires cylinders

1 and 4. Coil half number two fires cylinders 2 and 3.

The PCM determines which of the coils to charge and

fire at the correct time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing a spark.

The PCM will de-energize the ASD relay if it does

not receive inputs from either the crankshaft or cam-

shaft position sensors.

A distributor is not used with the 2.4L engine.

3.7L

The 3.7L V6 engine uses a separate ignition coil for

each cylinder. The one-piece coil bolts directly to the

cylinder head. Rubber boots seal the secondary ter-

minal ends of the coils to the top of all 6 spark plugs.

A separate electrical connector is used for each coil.

KJIGNITION CONTROL 8I - 1

Page 389 of 1803

Because of coil design, spark plug cables (second-

ary cables) are not used. A distributor is not used

with the 3.7L engine.

Two knock sensors (one for each cylinder bank) are

used to help control spark knock.

The Auto Shutdown (ASD) relay provides battery

voltage to each ignition coil. The Powertrain Control

Module (PCM) provides a ground contact (circuit) for

energizing each coil. When the PCM breaks the con-

tact, the energy in the coil primary transfers to the

secondary causing a spark. The PCM will de-energize

the ASD relay if it does not receive inputs from

either the crankshaft or camshaft position sensors.

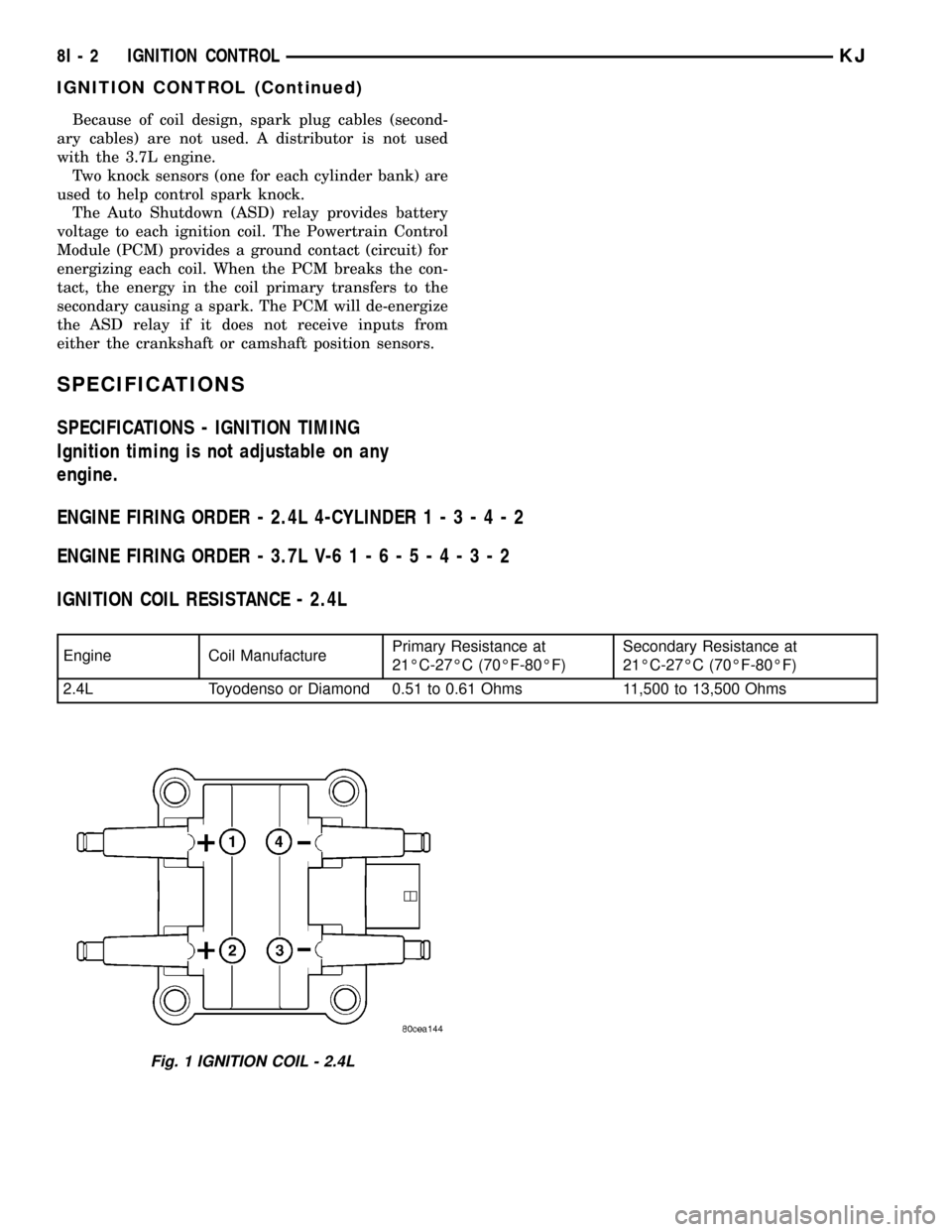

SPECIFICATIONS

SPECIFICATIONS - IGNITION TIMING

Ignition timing is not adjustable on any

engine.

ENGINE FIRING ORDER - 2.4L 4-CYLINDER1-3-4-2

ENGINE FIRING ORDER - 3.7L V-61-6-5-4-3-2

IGNITION COIL RESISTANCE - 2.4L

Engine Coil ManufacturePrimary Resistance at

21ÉC-27ÉC (70ÉF-80ÉF)Secondary Resistance at

21ÉC-27ÉC (70ÉF-80ÉF)

2.4L Toyodenso or Diamond 0.51 to 0.61 Ohms 11,500 to 13,500 Ohms

Fig. 1 IGNITION COIL - 2.4L

8I - 2 IGNITION CONTROLKJ

IGNITION CONTROL (Continued)

Page 391 of 1803

AUTO SHUT DOWN RELAY

DESCRIPTION - PCM OUTPUT

The 5±pin, 12±volt, Automatic Shutdown (ASD)

relay is located in the Power Distribution Center

(PDC). Refer to label on PDC cover for relay location.

OPERATION

OPERATION - ASD SENSE - PCM INPUT

A 12 volt signal at this input indicates to the PCM

that the ASD has been activated. The relay is used to

connect the oxygen sensor heater elements, oxygen

sensor heater relay, ignition coil and fuel injectors to

12 volt + power supply.

This input is used only to sense that the ASD relay

is energized. If the Powertrain Control Module

(PCM) does not see 12 volts at this input when the

ASD should be activated, it will set a Diagnostic

Trouble Code (DTC).

OPERATION - PCM OUTPUT

The ASD relay supplies battery voltage (12+ volts)

to the fuel injectors and ignition coil(s). With certain

emissions packages it also supplies 12±volts to the

oxygen sensor heating elements and the oxygen sen-

sor heater relay.

The ground circuit for the coil within the ASD

relay is controlled by the Powertrain Control Module

(PCM). The PCM operates the ASD relay by switch-

ing its ground circuit on and off.

The ASD relay will be shut±down, meaning the

12±volt power supply to the ASD relay will be de-ac-

tivated by the PCM if the ignition key is left in the

ON position. This is if the engine has not been run-

ning for approximately 1.8 seconds.

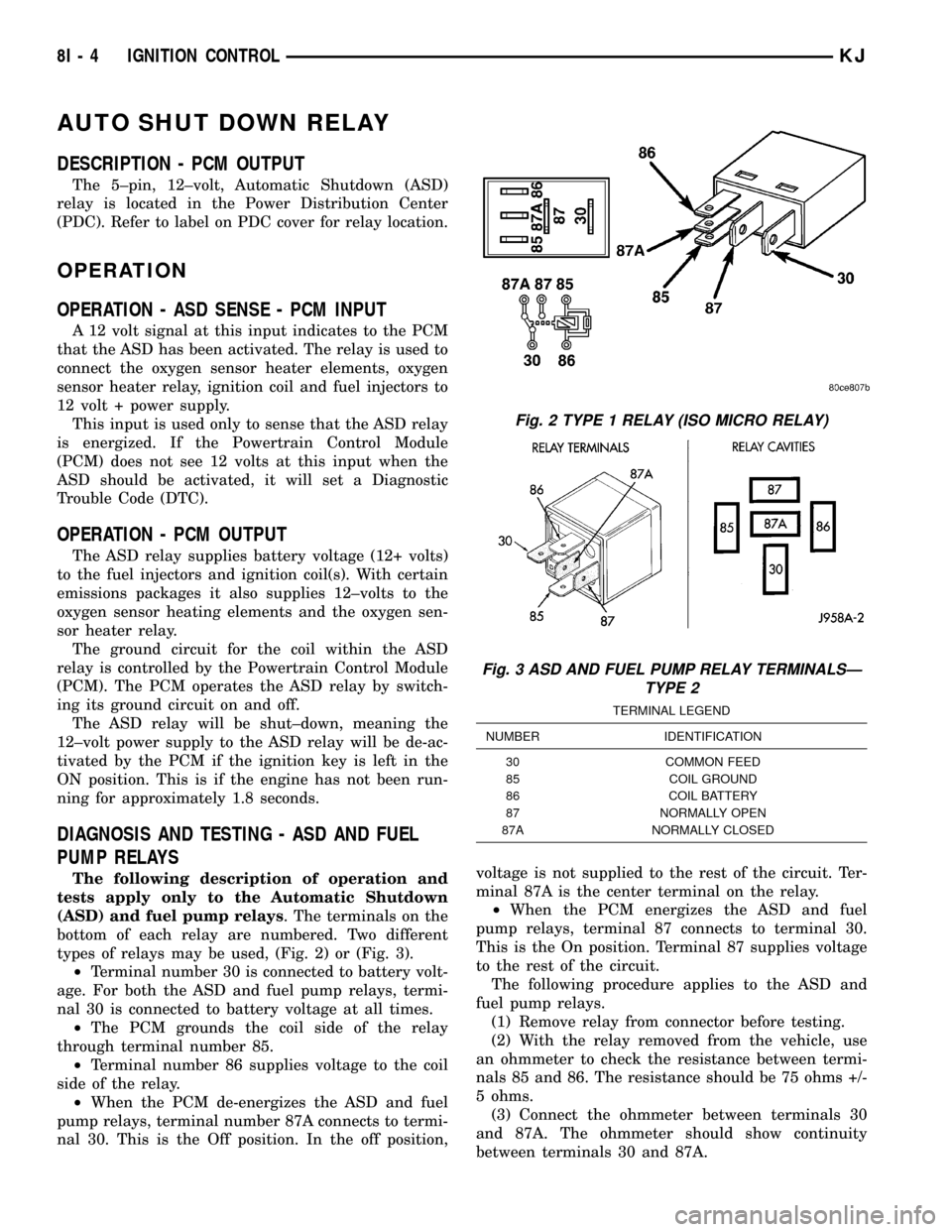

DIAGNOSIS AND TESTING - ASD AND FUEL

PUMP RELAYS

The following description of operation and

tests apply only to the Automatic Shutdown

(ASD) and fuel pump relays. The terminals on the

bottom of each relay are numbered. Two different

types of relays may be used, (Fig. 2) or (Fig. 3).

²Terminal number 30 is connected to battery volt-

age. For both the ASD and fuel pump relays, termi-

nal 30 is connected to battery voltage at all times.

²The PCM grounds the coil side of the relay

through terminal number 85.

²Terminal number 86 supplies voltage to the coil

side of the relay.

²When the PCM de-energizes the ASD and fuel

pump relays, terminal number 87A connects to termi-

nal 30. This is the Off position. In the off position,voltage is not supplied to the rest of the circuit. Ter-

minal 87A is the center terminal on the relay.

²When the PCM energizes the ASD and fuel

pump relays, terminal 87 connects to terminal 30.

This is the On position. Terminal 87 supplies voltage

to the rest of the circuit.

The following procedure applies to the ASD and

fuel pump relays.

(1) Remove relay from connector before testing.

(2) With the relay removed from the vehicle, use

an ohmmeter to check the resistance between termi-

nals 85 and 86. The resistance should be 75 ohms +/-

5 ohms.

(3) Connect the ohmmeter between terminals 30

and 87A. The ohmmeter should show continuity

between terminals 30 and 87A.

Fig. 2 TYPE 1 RELAY (ISO MICRO RELAY)

Fig. 3 ASD AND FUEL PUMP RELAY TERMINALSÐ

TYPE 2

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8I - 4 IGNITION CONTROLKJ

Page 392 of 1803

(4) Connect the ohmmeter between terminals 87

and 30. The ohmmeter should not show continuity at

this time.

(5) Connect one end of a jumper wire (16 gauge or

smaller) to relay terminal 85. Connect the other end

of the jumper wire to the ground side of a 12 volt

power source.

(6) Connect one end of another jumper wire (16

gauge or smaller) to the power side of the 12 volt

power source.Do not attach the other end of the

jumper wire to the relay at this time.

WARNING: DO NOT ALLOW OHMMETER TO CON-

TACT TERMINALS 85 OR 86 DURING THIS TEST.

DAMAGE TO OHMMETER MAY RESULT.

(7) Attach the other end of the jumper wire to

relay terminal 86. This activates the relay. The ohm-

meter should now show continuity between relay ter-

minals 87 and 30. The ohmmeter should not show

continuity between relay terminals 87A and 30.

(8) Disconnect jumper wires.

(9) Replace the relay if it did not pass the continu-

ity and resistance tests. If the relay passed the tests,

it operates properly. Check the remainder of the ASD

and fuel pump relay circuits. Refer to 8, Wiring Dia-

grams.

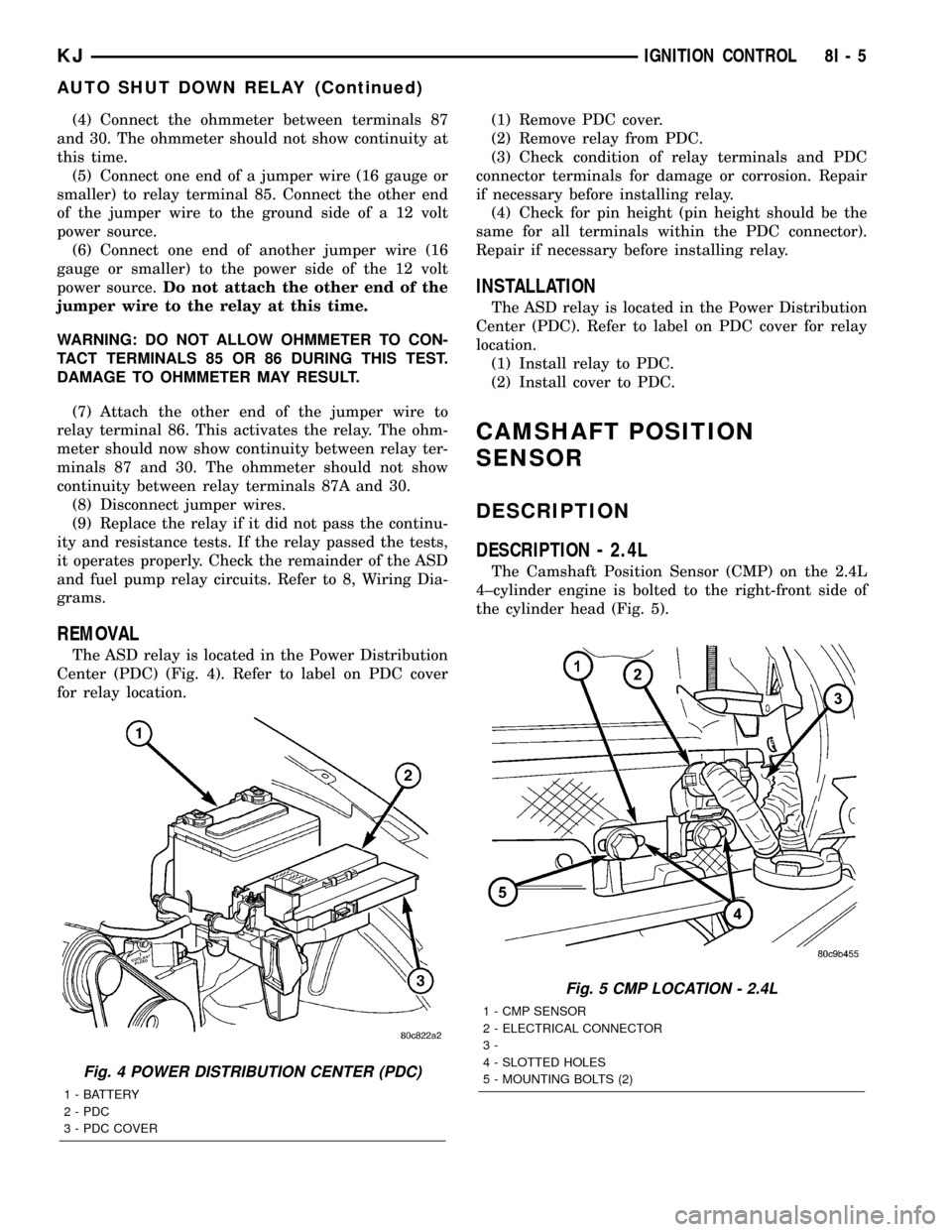

REMOVAL

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 4). Refer to label on PDC cover

for relay location.(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The ASD relay is located in the Power Distribution

Center (PDC). Refer to label on PDC cover for relay

location.

(1) Install relay to PDC.

(2) Install cover to PDC.

CAMSHAFT POSITION

SENSOR

DESCRIPTION

DESCRIPTION - 2.4L

The Camshaft Position Sensor (CMP) on the 2.4L

4±cylinder engine is bolted to the right-front side of

the cylinder head (Fig. 5).

Fig. 4 POWER DISTRIBUTION CENTER (PDC)

1 - BATTERY

2 - PDC

3 - PDC COVER

Fig. 5 CMP LOCATION - 2.4L

1 - CMP SENSOR

2 - ELECTRICAL CONNECTOR

3-

4 - SLOTTED HOLES

5 - MOUNTING BOLTS (2)

KJIGNITION CONTROL 8I - 5

AUTO SHUT DOWN RELAY (Continued)