service JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 279 of 1803

lating (AM) and Frequency Modulating (FM) com-

mercial frequency ranges.

The audio system components operate on battery

current received through a fuse in the Junction Block

(JB) on a fused ignition switch output (run-acc) cir-

cuit so that the system will only operate when the

ignition switch is in the Run or Accessory positions.

On vehicles that are equipped with the optional

remote radio switches, the Body Control Module

(BCM) receives hard wired resistor multiplexed

inputs from the remote radio switches. The program-

ming in the BCM allows it to process those inputs

and send the proper messages to the radio receiver

over the Programmable Communication Interface

(PCI) bus network to control the radio volume up or

down, station seek up or down, preset station

advance, and mode advance functions.

Refer to the owner's manual for more information

on the features, use and operation of each of the

available audio systems.

DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB diagnostic tool.For information on the use of the DRB, refer to

the appropriate Diagnostic Service Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

AUDIO SYSTEM DIAGNOSIS TABLE

CONDITION POSSIBLE CAUSES CORRECTION

NO AUDIO 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in Junction Block (JB). Replace fuses, if

required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for shorted or open wires. Repair wiring,

if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

6. Speakers faulty. 6. Replace speaker as necessary.

NO RADIO DISPLAY 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in Junction Block (JB). Replace fuses, if

required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector.

Repair wiring, if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

8A - 2 AUDIOKJ

AUDIO (Continued)

Page 280 of 1803

CONDITION POSSIBLE CAUSES CORRECTION

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

CLOCK WILL NOT KEEP

SET TIME1. Fuse faulty. 1. Check Ignition-Off Draw (IOD) fuse in the

Junction Block (JB). Replace fuse, if required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector.

Repair wiring, if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

POOR RADIO RECEPTION 1. Antenna faulty. 1. (Refer to 8 - ELECTRICAL/AUDIO/ANTENNA

BODY & CABLE - DIAGNOSIS AND TESTING).

2. Radio ground faulty. 2. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

3. Radio noise suppression

faulty.3. Repair or replace ground strap as necessary.

4. Radio faulty. 4. Refer to appropriate Diagnostic Service

Manual.

NO/POOR TAPE

OPERATION1. Faulty tape. 1. Insert known good tape and test operation.

2. Foreign objects behind

tape door.2. Remove foreign objects and test operation.

3. Dirty cassette tape head. 3. Clean head with Mopar Cassette Head

Cleaner.

4. Faulty tape deck. 4. Exchange or replace radio, if required.

NO COMPACT DISC

OPERATION1. Faulty CD. 1. Insert known good CD and test operation.

2. Foreign material on CD. 2. Clean CD and test operation.

3. Condensation on CD or

optics.3. Allow temperature of vehicle interior to stabilize

and test operation.

4. Faulty CD player. 4. Refer to appropriate Diagnostic Service

Manual.

AMPLIFIER CHOKE AND

RELAY

DESCRIPTION

Models equipped with the premium speaker pack-

age have a amplifier choke and relay. The amplifier

choke and relay is mounted to the lower instrument

panel above the accelerator pedal.

The amplifier choke and relay should be checked if

there is no sound output from the speakers. The

amplifier choke and relay can not be repaired or

adjusted and, if faulty or damaged, the unit must be

replaced.

OPERATION

The amplifier choke and relay is used to control

the supply of fused battery current to the front door

speaker-mounted dual amplifiers. The speaker relay

is energized by a fused 12 volt output from the radio

receiver whenever the radio is turned on. For com-

plete circuit diagrams, refer to the appropriate wir-

ing information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

KJAUDIO 8A - 3

AUDIO (Continued)

Page 281 of 1803

DIAGNOSIS AND TESTING - AMPLIFIER

CHOKE AND RELAY

Any diagnosis of the Audio system should

begin with the use of the DRB diagnostic tool.

For information on the use of the DRB, refer to

the appropriate Diagnostic Service Manual.

The amplifier choke and relay is used to switch

power to the individual speaker amplifiers used with

the premium speaker package. The amplifier choke

and relay is serviced only as a unit. If all of the

speakers are inoperative the amplifier choke and

relay should be inspected. Before replacement, make

the following inspections of the amplifier choke and

relay circuits. For complete circuit diagrams, refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1)

Check the fused B(+) fuse in the junction block. If

OK, go to Step 2. If not OK, replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the battery as

required.

(3) Disconnect the instrument panel wire harness

connector from the amplifier choke and relay. Check

for battery voltage at the fused B(+) circuit cavity of

the instrument panel wire harness connector for the

amplifier choke and relay. If OK, go to Step 4. If not

OK, repair the open fused B(+) circuit to the junction

block fuse as required.

(4) Probe the ground circuit cavity of the instru-

ment panel wire harness connector for the amplifier

choke and relay. Check for continuity to a good

ground. There should be continuity. If OK, go to Step

5. If not OK, repair the open ground circuit to ground

as required.

(5) Turn the ignition switch to the RUN position

and turn the radio ON. Check for battery voltage at

the radio 12-volt output circuit cavity of the instru-

ment panel wire harness connector for the amplifier

choke and relay. If OK, go to Step 6. If not OK,

repair the open radio 12-volt output circuit to the

radio as required.

(6) Turn the radio and ignition switches to the

OFF position. Reconnect the instrument panel wire

harness connector to the amplifier choke and relay.

Check for battery voltage at the amplified speaker

(+) circuit cavity of the instrument panel wire har-

ness connector for the amplifier choke and relay.

There should be zero volts. Turn the ignition and

radio switches to the ON position. There should now

be battery voltage. If OK, repair the open amplified

speaker (+) circuits to the speaker-mounted amplifi-ers as required. If not OK, replace the faulty ampli-

fier choke and relay.

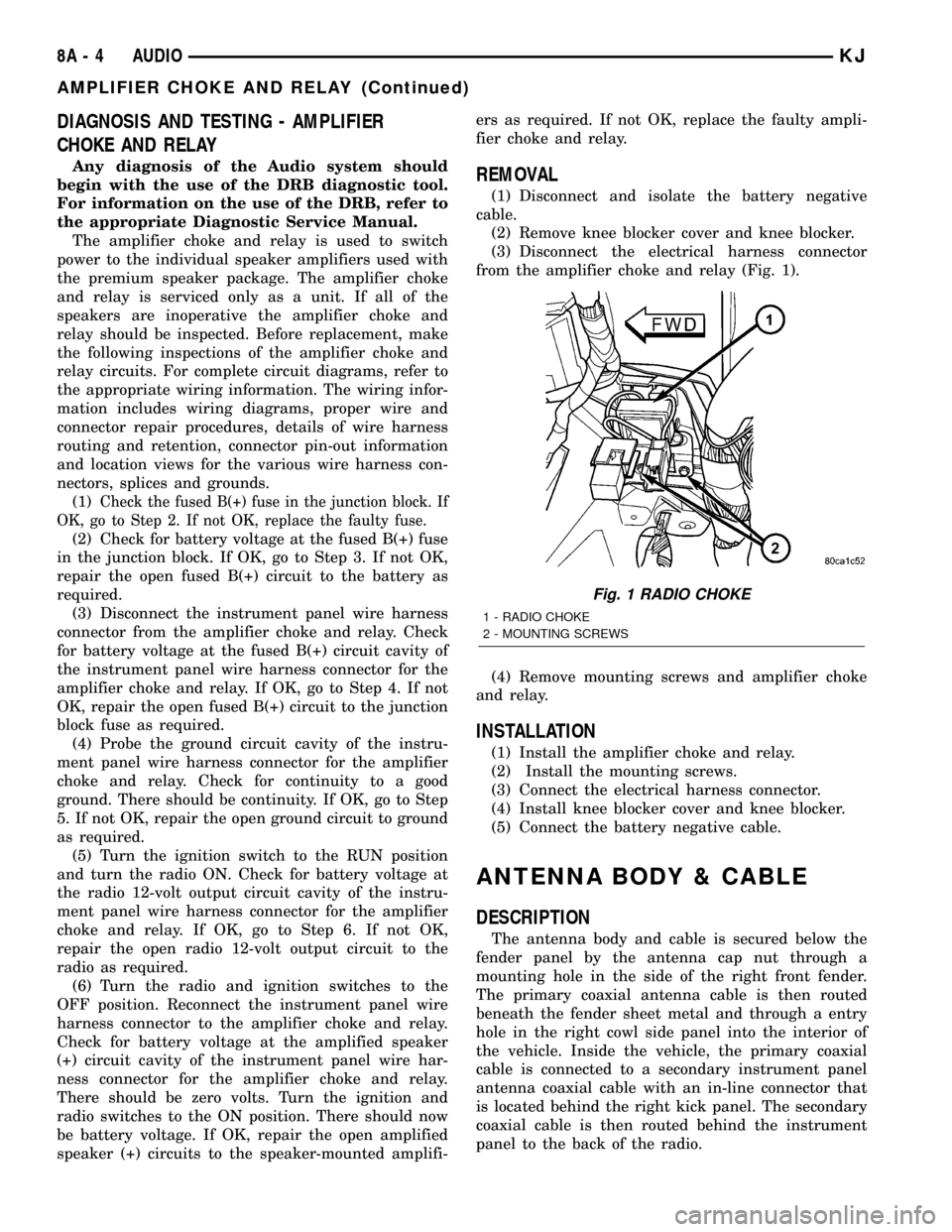

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove knee blocker cover and knee blocker.

(3) Disconnect the electrical harness connector

from the amplifier choke and relay (Fig. 1).

(4) Remove mounting screws and amplifier choke

and relay.

INSTALLATION

(1) Install the amplifier choke and relay.

(2) Install the mounting screws.

(3) Connect the electrical harness connector.

(4) Install knee blocker cover and knee blocker.

(5) Connect the battery negative cable.

ANTENNA BODY & CABLE

DESCRIPTION

The antenna body and cable is secured below the

fender panel by the antenna cap nut through a

mounting hole in the side of the right front fender.

The primary coaxial antenna cable is then routed

beneath the fender sheet metal and through a entry

hole in the right cowl side panel into the interior of

the vehicle. Inside the vehicle, the primary coaxial

cable is connected to a secondary instrument panel

antenna coaxial cable with an in-line connector that

is located behind the right kick panel. The secondary

coaxial cable is then routed behind the instrument

panel to the back of the radio.

Fig. 1 RADIO CHOKE

1 - RADIO CHOKE

2 - MOUNTING SCREWS

8A - 4 AUDIOKJ

AMPLIFIER CHOKE AND RELAY (Continued)

Page 282 of 1803

OPERATION

The antenna body and cable connects the antenna

mast to the radio. The radio antenna is an electro-

magnetic circuit component used to capture radio fre-

quency signals that are broadcast by local

commercial radio stations in both the Amplitude

Modulating (AM) and Frequency Modulating (FM)

frequency ranges. These electromagnetic radio fre-

quency signals induce small electrical modulations

into the antenna as they move past the mast. The

antenna body transfers the weak electromagnetic

radio waves induced into the rigid antenna mast into

the center conductor of the flexible primary antenna

coaxial cable. The braided outer shield of the

antenna coaxial cable is grounded through both the

antenna body and the radio chassis, effectively

shielding the radio waves as they are conducted to

the radio. The radio then tunes and amplifies the

weak radio signals into stronger electrical signals in

order to operate the audio system speakers.

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE

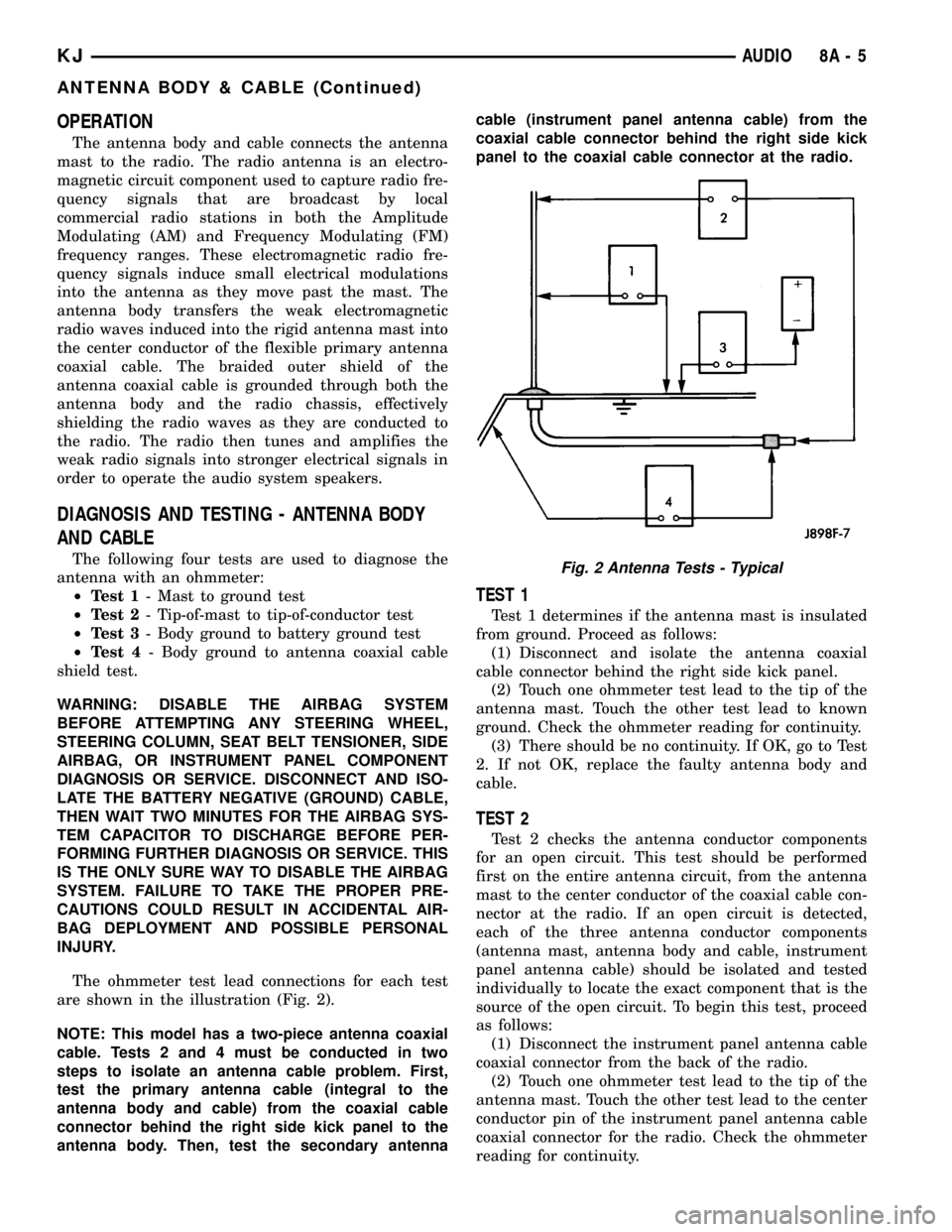

The following four tests are used to diagnose the

antenna with an ohmmeter:

²Test 1- Mast to ground test

²Test 2- Tip-of-mast to tip-of-conductor test

²Test 3- Body ground to battery ground test

²Test 4- Body ground to antenna coaxial cable

shield test.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The ohmmeter test lead connections for each test

are shown in the illustration (Fig. 2).

NOTE: This model has a two-piece antenna coaxial

cable. Tests 2 and 4 must be conducted in two

steps to isolate an antenna cable problem. First,

test the primary antenna cable (integral to the

antenna body and cable) from the coaxial cable

connector behind the right side kick panel to the

antenna body. Then, test the secondary antennacable (instrument panel antenna cable) from the

coaxial cable connector behind the right side kick

panel to the coaxial cable connector at the radio.

TEST 1

Test 1 determines if the antenna mast is insulated

from ground. Proceed as follows:

(1) Disconnect and isolate the antenna coaxial

cable connector behind the right side kick panel.

(2) Touch one ohmmeter test lead to the tip of the

antenna mast. Touch the other test lead to known

ground. Check the ohmmeter reading for continuity.

(3) There should be no continuity. If OK, go to Test

2. If not OK, replace the faulty antenna body and

cable.

TEST 2

Test 2 checks the antenna conductor components

for an open circuit. This test should be performed

first on the entire antenna circuit, from the antenna

mast to the center conductor of the coaxial cable con-

nector at the radio. If an open circuit is detected,

each of the three antenna conductor components

(antenna mast, antenna body and cable, instrument

panel antenna cable) should be isolated and tested

individually to locate the exact component that is the

source of the open circuit. To begin this test, proceed

as follows:

(1) Disconnect the instrument panel antenna cable

coaxial connector from the back of the radio.

(2) Touch one ohmmeter test lead to the tip of the

antenna mast. Touch the other test lead to the center

conductor pin of the instrument panel antenna cable

coaxial connector for the radio. Check the ohmmeter

reading for continuity.

Fig. 2 Antenna Tests - Typical

KJAUDIO 8A - 5

ANTENNA BODY & CABLE (Continued)

Page 284 of 1803

(8) Install antenna mast.

(9) Tighten fender mounting bolts near door hinge

area.

(10) Install and tighten the upper fender mounting

bolts (Refer to 23 - BODY/EXTERIOR/FRONT

FENDER - INSTALLATION).

(11) Connect the battery negative cable.

CD CHANGER

DESCRIPTION

A factory-installed Compact Disc (CD) changer fea-

turing a six-CD magazine is an available option on

this model. The CD changer is mounted in the cargo

area of the passenger compartment on the right rear

quarter panel.

The controls on the radio receiver operate the CD

changer through messages sent over the Programma-

ble Communications Interface (PCI) data bus net-

work. For diagnosis of the messaging functions of the

radio receiver and the CD changer, or of the PCI data

bus, a DRB scan tool and the proper Diagnostic Pro-

cedures manual are required.

The CD changer can only be serviced by an autho-

rized radio repair station. See the latest Warranty

Policies and Procedures manual for a current listing

of authorized radio repair stations. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

OPERATION

The CD changer will only operate when the igni-

tion switch is in the On or Accessory positions, and

the radio is turned on. The six-CD magazine may be

ejected with the ignition in the Off position. For more

information on the features, loading procedures and

radio control functions for the operation of the CD

changer, refer to the owner's manual.

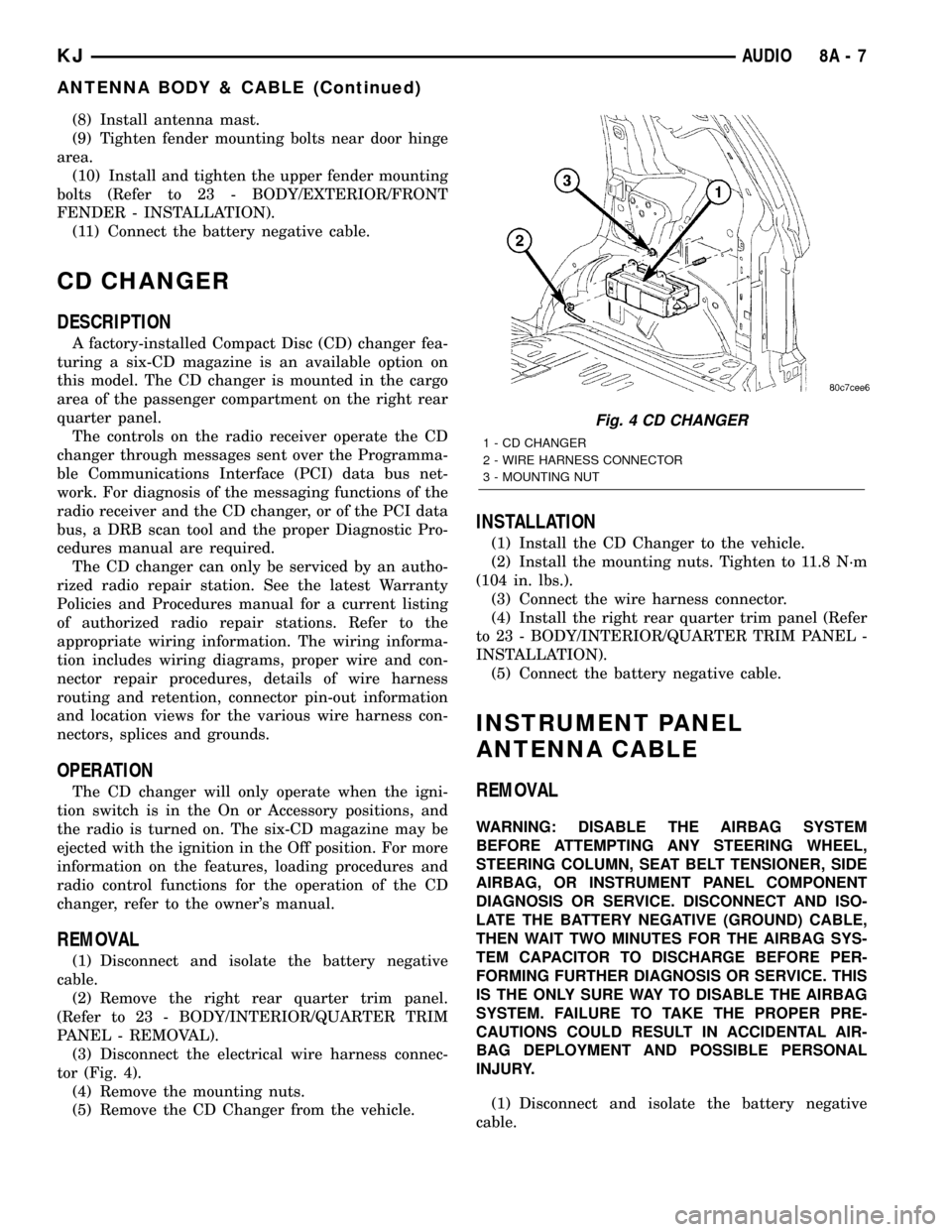

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the right rear quarter trim panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - REMOVAL).

(3) Disconnect the electrical wire harness connec-

tor (Fig. 4).

(4) Remove the mounting nuts.

(5) Remove the CD Changer from the vehicle.

INSTALLATION

(1) Install the CD Changer to the vehicle.

(2) Install the mounting nuts. Tighten to 11.8 N´m

(104 in. lbs.).

(3) Connect the wire harness connector.

(4) Install the right rear quarter trim panel (Refer

to 23 - BODY/INTERIOR/QUARTER TRIM PANEL -

INSTALLATION).

(5) Connect the battery negative cable.

INSTRUMENT PANEL

ANTENNA CABLE

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

Fig. 4 CD CHANGER

1 - CD CHANGER

2 - WIRE HARNESS CONNECTOR

3 - MOUNTING NUT

KJAUDIO 8A - 7

ANTENNA BODY & CABLE (Continued)

Page 285 of 1803

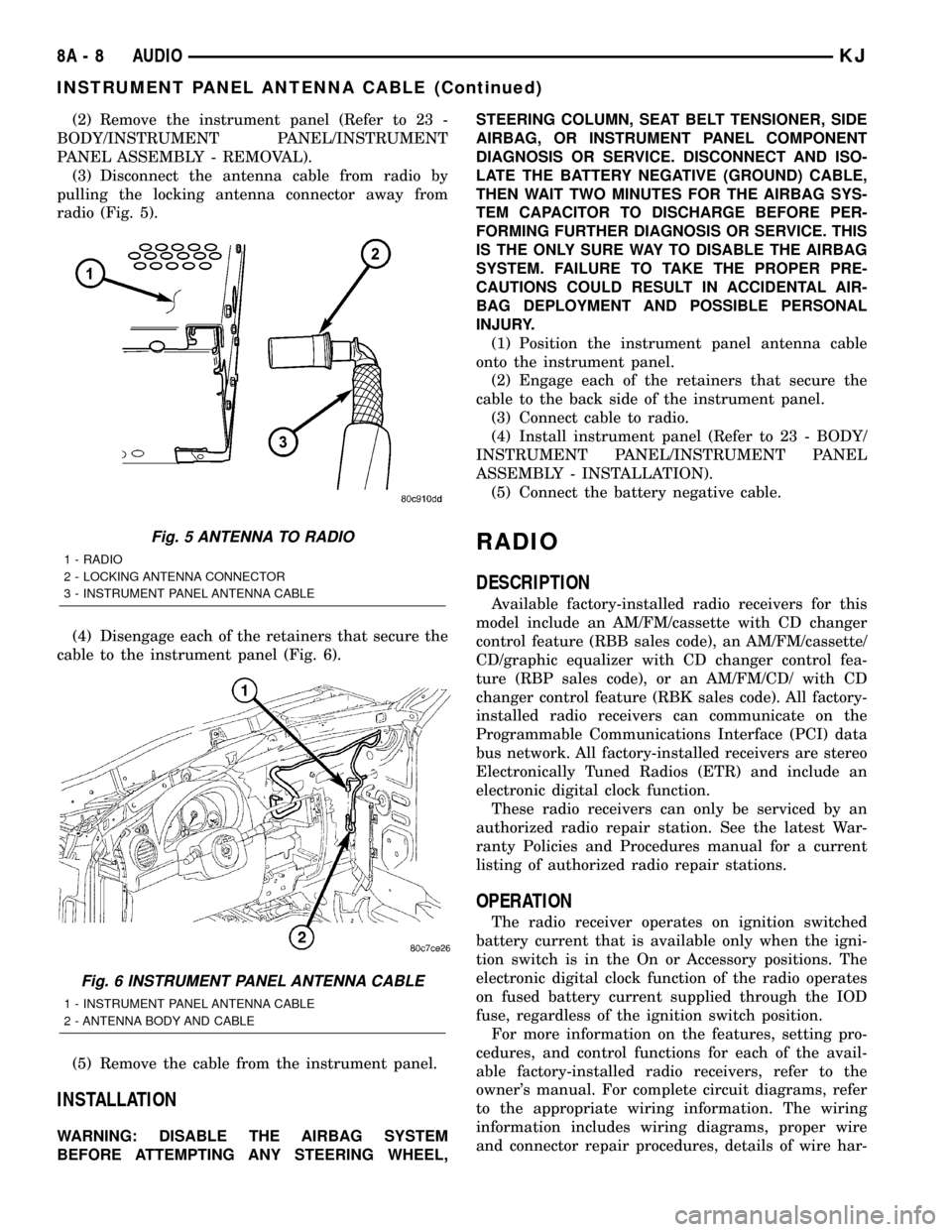

(2) Remove the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL).

(3) Disconnect the antenna cable from radio by

pulling the locking antenna connector away from

radio (Fig. 5).

(4) Disengage each of the retainers that secure the

cable to the instrument panel (Fig. 6).

(5) Remove the cable from the instrument panel.

INSTALLATION

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the instrument panel antenna cable

onto the instrument panel.

(2) Engage each of the retainers that secure the

cable to the back side of the instrument panel.

(3) Connect cable to radio.

(4) Install instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - INSTALLATION).

(5) Connect the battery negative cable.

RADIO

DESCRIPTION

Available factory-installed radio receivers for this

model include an AM/FM/cassette with CD changer

control feature (RBB sales code), an AM/FM/cassette/

CD/graphic equalizer with CD changer control fea-

ture (RBP sales code), or an AM/FM/CD/ with CD

changer control feature (RBK sales code). All factory-

installed radio receivers can communicate on the

Programmable Communications Interface (PCI) data

bus network. All factory-installed receivers are stereo

Electronically Tuned Radios (ETR) and include an

electronic digital clock function.

These radio receivers can only be serviced by an

authorized radio repair station. See the latest War-

ranty Policies and Procedures manual for a current

listing of authorized radio repair stations.

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory positions. The

electronic digital clock function of the radio operates

on fused battery current supplied through the IOD

fuse, regardless of the ignition switch position.

For more information on the features, setting pro-

cedures, and control functions for each of the avail-

able factory-installed radio receivers, refer to the

owner's manual. For complete circuit diagrams, refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire har-

Fig. 5 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

Fig. 6 INSTRUMENT PANEL ANTENNA CABLE

1 - INSTRUMENT PANEL ANTENNA CABLE

2 - ANTENNA BODY AND CABLE

8A - 8 AUDIOKJ

INSTRUMENT PANEL ANTENNA CABLE (Continued)

Page 286 of 1803

ness routing and retention, connector pin-out infor-

mation and location views for the various wire

harness connectors, splices and grounds.

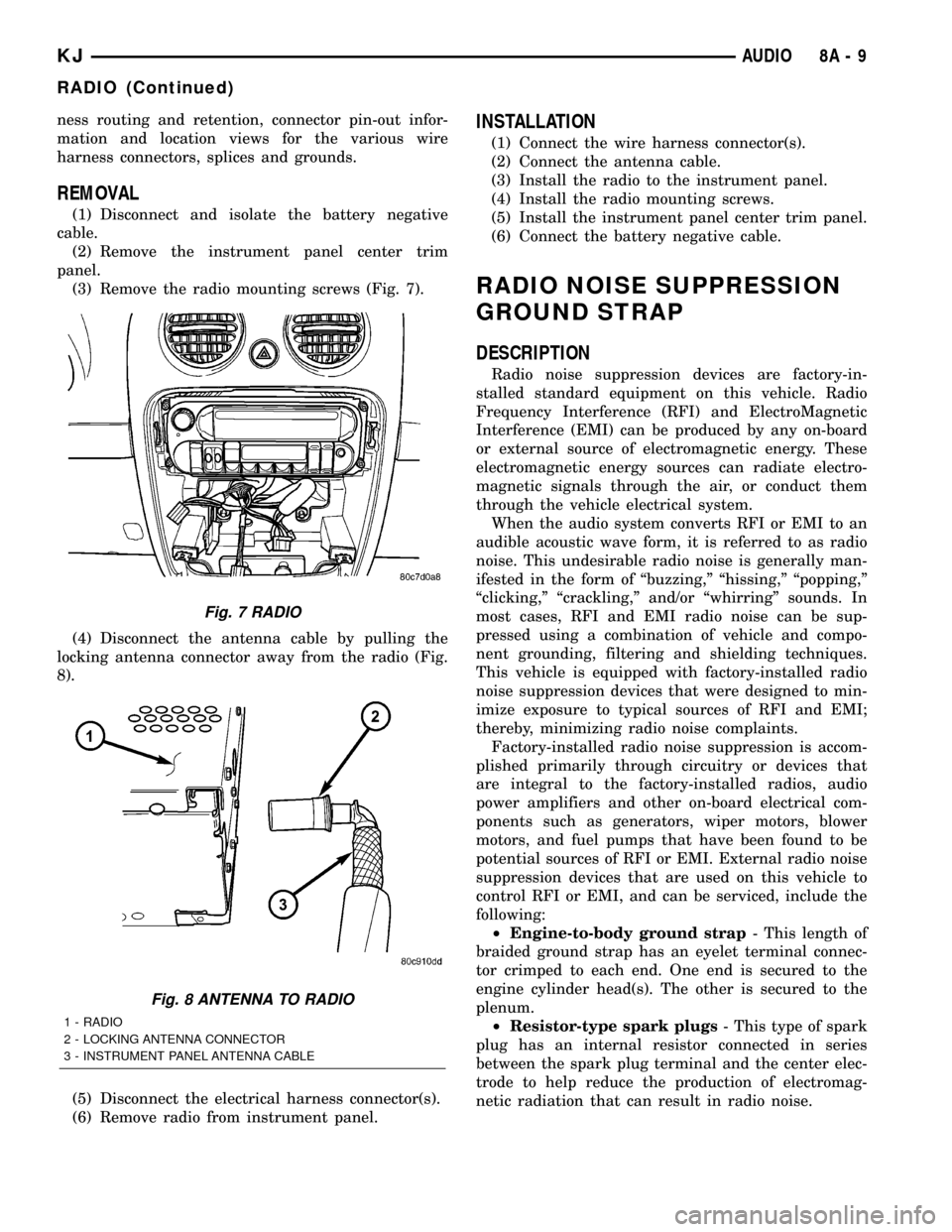

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center trim

panel.

(3) Remove the radio mounting screws (Fig. 7).

(4) Disconnect the antenna cable by pulling the

locking antenna connector away from the radio (Fig.

8).

(5) Disconnect the electrical harness connector(s).

(6) Remove radio from instrument panel.

INSTALLATION

(1) Connect the wire harness connector(s).

(2) Connect the antenna cable.

(3) Install the radio to the instrument panel.

(4) Install the radio mounting screws.

(5) Install the instrument panel center trim panel.

(6) Connect the battery negative cable.

RADIO NOISE SUPPRESSION

GROUND STRAP

DESCRIPTION

Radio noise suppression devices are factory-in-

stalled standard equipment on this vehicle. Radio

Frequency Interference (RFI) and ElectroMagnetic

Interference (EMI) can be produced by any on-board

or external source of electromagnetic energy. These

electromagnetic energy sources can radiate electro-

magnetic signals through the air, or conduct them

through the vehicle electrical system.

When the audio system converts RFI or EMI to an

audible acoustic wave form, it is referred to as radio

noise. This undesirable radio noise is generally man-

ifested in the form of ªbuzzing,º ªhissing,º ªpopping,º

ªclicking,º ªcrackling,º and/or ªwhirringº sounds. In

most cases, RFI and EMI radio noise can be sup-

pressed using a combination of vehicle and compo-

nent grounding, filtering and shielding techniques.

This vehicle is equipped with factory-installed radio

noise suppression devices that were designed to min-

imize exposure to typical sources of RFI and EMI;

thereby, minimizing radio noise complaints.

Factory-installed radio noise suppression is accom-

plished primarily through circuitry or devices that

are integral to the factory-installed radios, audio

power amplifiers and other on-board electrical com-

ponents such as generators, wiper motors, blower

motors, and fuel pumps that have been found to be

potential sources of RFI or EMI. External radio noise

suppression devices that are used on this vehicle to

control RFI or EMI, and can be serviced, include the

following:

²Engine-to-body ground strap- This length of

braided ground strap has an eyelet terminal connec-

tor crimped to each end. One end is secured to the

engine cylinder head(s). The other is secured to the

plenum.

²Resistor-type spark plugs- This type of spark

plug has an internal resistor connected in series

between the spark plug terminal and the center elec-

trode to help reduce the production of electromag-

netic radiation that can result in radio noise.

Fig. 7 RADIO

Fig. 8 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

KJAUDIO 8A - 9

RADIO (Continued)

Page 289 of 1803

OPERATION

The six switches in the two remote radio switch units

are normally open, resistor multiplexed momentary

switches that are hard wired to the Body Control Mod-

ule (BCM) through the clockspring. The BCM sends a

five volt reference signal to both switch units on one

circuit, and senses the status of all of the switches by

reading the voltage drop on a second circuit.

When the BCM senses an input (voltage drop) from

any one of the remote radio switches, it sends the

proper switch status messages on the Programmable

Communication Interface (PCI) data bus network to

the radio receiver. The electronic circuitry within the

radio receiver is programmed to respond to these

remote radio switch status messages by adjusting the

radio settings as requested. For diagnosis of the

BCM or the PCI data bus, the use of a DRB scan tool

and the proper Diagnostic Procedures manual are

recommended.

For more information on the features and control

functions for each of the remote radio switches, refer

to the owner's manual.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

Any diagnosis of the Audio system should

begin with the use of the DRB diagnostic tool.

For information on the use of the DRB, refer to

the appropriate Diagnostic Service Manual.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

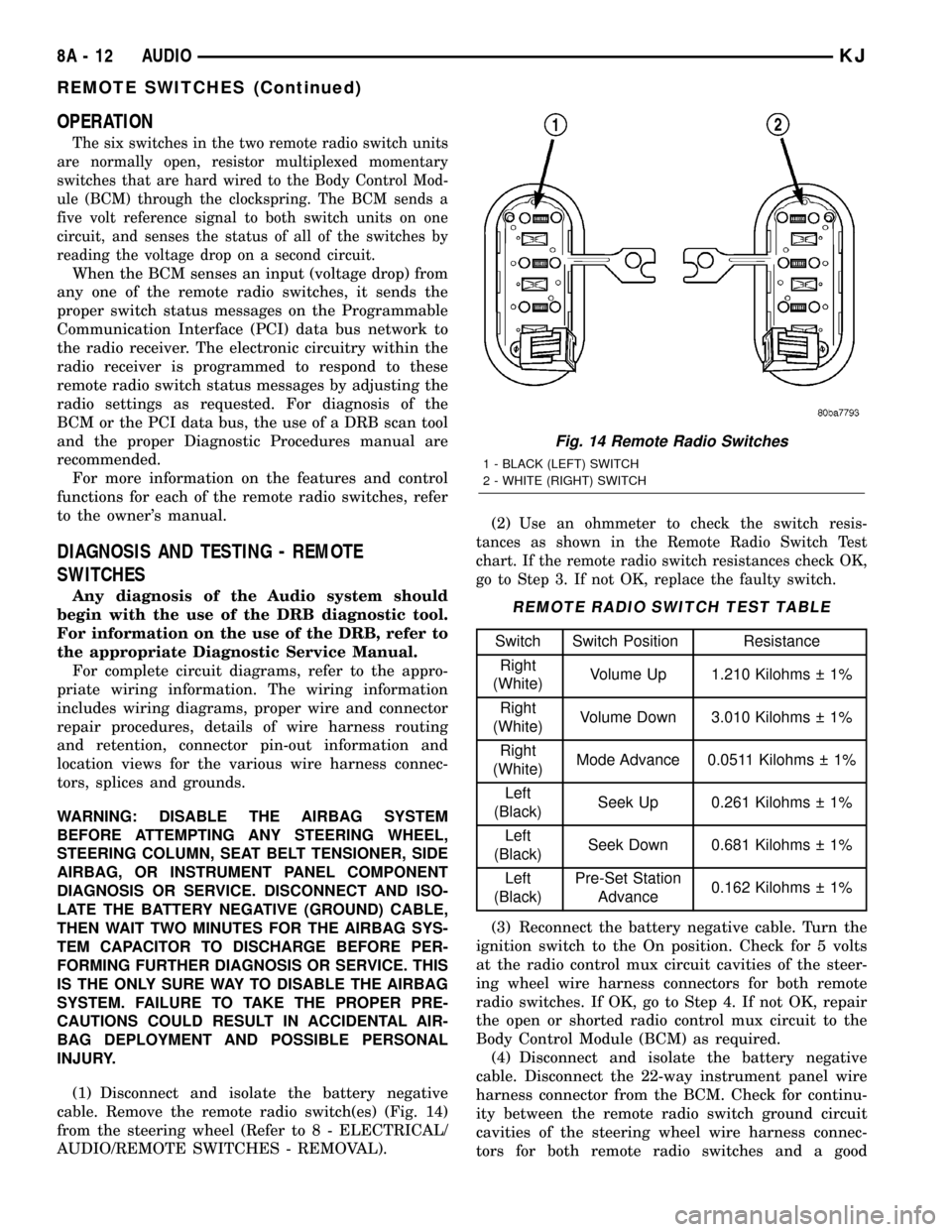

(1) Disconnect and isolate the battery negative

cable. Remove the remote radio switch(es) (Fig. 14)

from the steering wheel (Refer to 8 - ELECTRICAL/

AUDIO/REMOTE SWITCHES - REMOVAL).(2)

Use an ohmmeter to check the switch resis-

tances as shown in the Remote Radio Switch Test

chart. If the remote radio switch resistances check OK,

go to Step 3. If not OK, replace the faulty switch.

REMOTE RADIO SWITCH TEST TABLE

Switch Switch Position Resistance

Right

(White)Volume Up 1.210 Kilohms 1%

Right

(White)Volume Down 3.010 Kilohms 1%

Right

(White)Mode Advance 0.0511 Kilohms 1%

Left

(Black)Seek Up 0.261 Kilohms 1%

Left

(Black)Seek Down 0.681 Kilohms 1%

Left

(Black)Pre-Set Station

Advance0.162 Kilohms 1%

(3) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for 5 volts

at the radio control mux circuit cavities of the steer-

ing wheel wire harness connectors for both remote

radio switches. If OK, go to Step 4. If not OK, repair

the open or shorted radio control mux circuit to the

Body Control Module (BCM) as required.

(4) Disconnect and isolate the battery negative

cable. Disconnect the 22-way instrument panel wire

harness connector from the BCM. Check for continu-

ity between the remote radio switch ground circuit

cavities of the steering wheel wire harness connec-

tors for both remote radio switches and a good

Fig. 14 Remote Radio Switches

1 - BLACK (LEFT) SWITCH

2 - WHITE (RIGHT) SWITCH

8A - 12 AUDIOKJ

REMOTE SWITCHES (Continued)

Page 290 of 1803

ground. There should be no continuity. If OK, go to

Step 5. If not OK, repair the shorted remote radio

switch ground circuit to the BCM as required.

(5) Check for continuity between the remote radio

switch ground circuit cavities of the steering wheel

wire harness connectors for both remote radio

switches and the 22-way instrument panel wire har-

ness connector for the BCM. There should be conti-

nuity. If OK, refer to the proper Diagnostic

Procedures manual to test the BCM and the PCI

data bus. If not OK, repair the open remote radio

switch ground circuit as required.

REMOVAL

WARNING:DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, SIDE AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE AIRBAG SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE AIRBAG SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side airbag module from the

vehicle (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

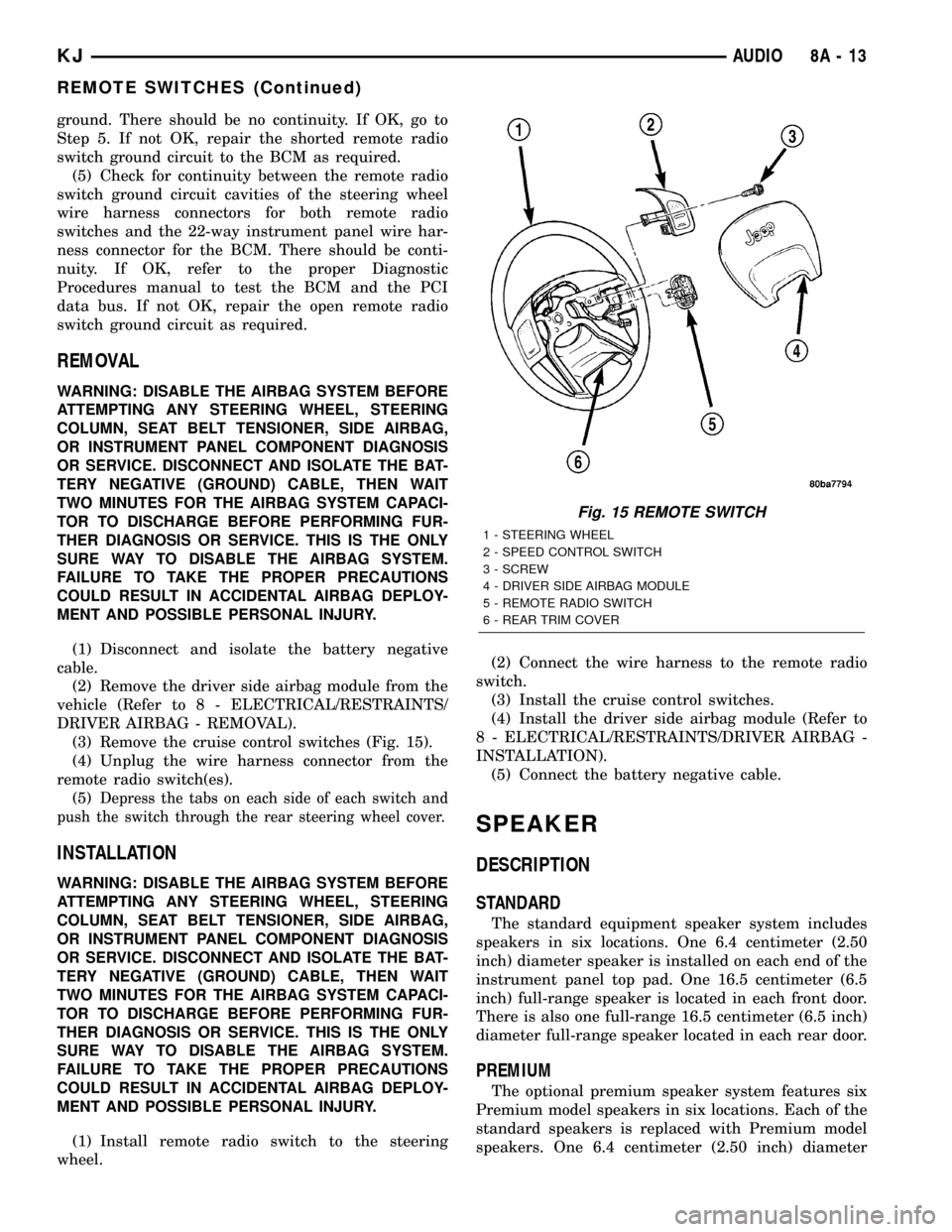

(3) Remove the cruise control switches (Fig. 15).

(4) Unplug the wire harness connector from the

remote radio switch(es).

(5)

Depress the tabs on each side of each switch and

push the switch through the rear steering wheel cover.

INSTALLATION

WARNING:DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, SIDE AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE AIRBAG SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE AIRBAG SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY.

(1) Install remote radio switch to the steering

wheel.(2) Connect the wire harness to the remote radio

switch.

(3) Install the cruise control switches.

(4) Install the driver side airbag module (Refer to

8 - ELECTRICAL/RESTRAINTS/DRIVER AIRBAG -

INSTALLATION).

(5) Connect the battery negative cable.

SPEAKER

DESCRIPTION

STANDARD

The standard equipment speaker system includes

speakers in six locations. One 6.4 centimeter (2.50

inch) diameter speaker is installed on each end of the

instrument panel top pad. One 16.5 centimeter (6.5

inch) full-range speaker is located in each front door.

There is also one full-range 16.5 centimeter (6.5 inch)

diameter full-range speaker located in each rear door.

PREMIUM

The optional premium speaker system features six

Premium model speakers in six locations. Each of the

standard speakers is replaced with Premium model

speakers. One 6.4 centimeter (2.50 inch) diameter

Fig. 15 REMOTE SWITCH

1 - STEERING WHEEL

2 - SPEED CONTROL SWITCH

3 - SCREW

4 - DRIVER SIDE AIRBAG MODULE

5 - REMOTE RADIO SWITCH

6 - REAR TRIM COVER

KJAUDIO 8A - 13

REMOTE SWITCHES (Continued)

Page 298 of 1803

ever occurs first. The overspeed warning feature is

only enabled on a BCM that has been programmed

with a Middle East Gulf Coast Country (GCC) coun-

try code.

²No Airbag Indicator Message Warning- The

EMIC chime tone generator will generate one, short,

ªbong-likeº chime tone and turn on the ªAirbagº indi-

cator when the ignition switch is in the On position,

and a PCI data bus ªAirbagº indicator on or off mes-

sage is not received from the ACM for six consecutive

seconds.

²No Antilock Brake Indicator Message Warn-

ing- The EMIC chime tone generator will generate

one, short, ªbong-likeº chime tone and turn on the

ªABSº indicator when the ignition switch is in the On

position, and a PCI data bus ªABSº indicator on or

off message is not received from the CAB for six con-

secutive seconds.

²No Fuel Level Message Warning- The EMIC

chime tone generator will generate one, short, ªbong-

likeº chime tone and turn on the ªLow Fuelº indica-

tor when the ignition switch is in the On position,

and a PCI data bus fuel level message is not received

from the PCM for twelve consecutive seconds.

²Remote Keyless Entry Transmitter Pro-

gramming- On vehicles so equipped, the EMIC

chime tone generator will generate a single ªbong-

likeº chime tone when an electronic message is

received over the PCI data bus from the BCM indi-

cating that a Remote Keyless Entry (RKE) transmit-

ter has been successfully programmed by the

customer into the RKE module memory.

²Sentry Key Immobilizer System Transpon-

der Programming- On vehicles so equipped, the

EMIC chime tone generator will generate a single

ªbong-likeº chime tone when an electronic message is

received over PCI data bus message from the Sentry

Key Immobilizer Module (SKIM) indicating that the

Sentry Key Immobilizer System (SKIS) has been

placed in the ªCustomer Learnº programming mode,

and again each time a new SKIS transponder has

been successfully programmed by the customer.

²Turn Signal Cancel Warning- The EMIC

chime tone generator will generate repetitive ªbong-

likeº chime tones at a slow rate when the vehicle is

driven for a distance of about 3.2 kilometers (about

two miles) with a turn signal indicator flashing. The

EMIC uses an electronic message received over the

PCI data bus from the PCM, and a hard wired input

from the turn signal switch circuitry of the multi-

function switch to determine when to sound the turn

signal cancel warning. The PCM uses internal pro-

gramming and distance pulse information received

over a hard wired vehicle speed pulse input from the

BCM to determine the proper vehicle speed messages

to send to the EMIC. The BCM uses an internallyprogrammed electronic pinion factor and a hard

wired input from the rear wheel speed sensor to cal-

culate the proper distance pulse information to send

to the PCM. The electronic pinion factor represents

the proper tire size and axle ratio information for the

vehicle. These chimes will continue to sound until

the turn signal is turned Off, until the hazard warn-

ing system is turned On, or until the ignition switch

is turned to the Off position, whichever occurs first.

²Water-In-Fuel Warning- On vehicles equipped

with a diesel engine, each time the ignition switch is

turned to the On position, the EMIC chime tone gen-

erator will generate a single ªbong-likeº chime tone

the first time an electronic message is received over

the PCI data bus from the PCM requesting ªWater-

in-Fuelº indicator illumination. The PCM uses inter-

nal programming and a hard wired input from the

water-in-fuel sensor to determine the proper water-

in-fuel messages to send to the EMIC. This warning

will only occur once during an ignition cycle.

The EMIC provides chime service for all available

features in the chime warning system. The EMIC

relies upon its internal programming and hard wired

inputs from the turn signal (multi-function) switch,

the washer fluid level switch, and the engine coolant

level sensor (diesel engine only) to provide chime ser-

vice for the turn signal cancel warning, the low

washer fluid warning, and the low coolant warning

respectively. The EMIC relies upon electronic mes-

sage inputs received from other electronic modules

over the PCI data bus network to provide chime ser-

vice for all of the remaining chime warning system

features. Upon receiving the proper inputs, the EMIC

activates the integral chime tone generator to pro-

vide the audible chime warning to the vehicle opera-

tor. The internal programming of the EMIC

determines the priority of each chime request input

that is received, as well as the rate and duration of

each chime tone that is to be generated. See the own-

er's manual in the vehicle glove box for more infor-

mation on the features provided by the chime

warning system.

The hard wired chime warning system inputs to

the EMIC, as well as other hard wired circuits for

this system may be diagnosed and tested using con-

ventional diagnostic tools and procedures. However,

conventional diagnostic methods may not prove con-

clusive in the diagnosis of the EMIC, the PCI data

bus network, or the electronic message inputs used

by the EMIC to provide chime warning system ser-

vice. The most reliable, efficient, and accurate means

to diagnose the EMIC, the PCI data bus network,

and the electronic message inputs for the chime

warning system requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

KJCHIME/BUZZER 8B - 5

CHIME WARNING SYSTEM (Continued)