connectors JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 640 of 1803

NOTE: The integral flange on the left side of the

ACM cover is secured to the floor panel transmis-

sion tunnel with a short piece of double-faced tape

as an assembly aid during the manufacturing pro-

cess, but this tape does not require replacement

following service removal.

(7) Reinstall the center console onto the top of the

floor panel transmission tunnel. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - INSTALLATION).

(8) Do not reconnect the battery negative cable at

this time. The airbag system verification test proce-

dure should be performed following service of any

supplemental restraint system component. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - VERIFICATION TEST).

CHILD TETHER ANCHOR

DESCRIPTION

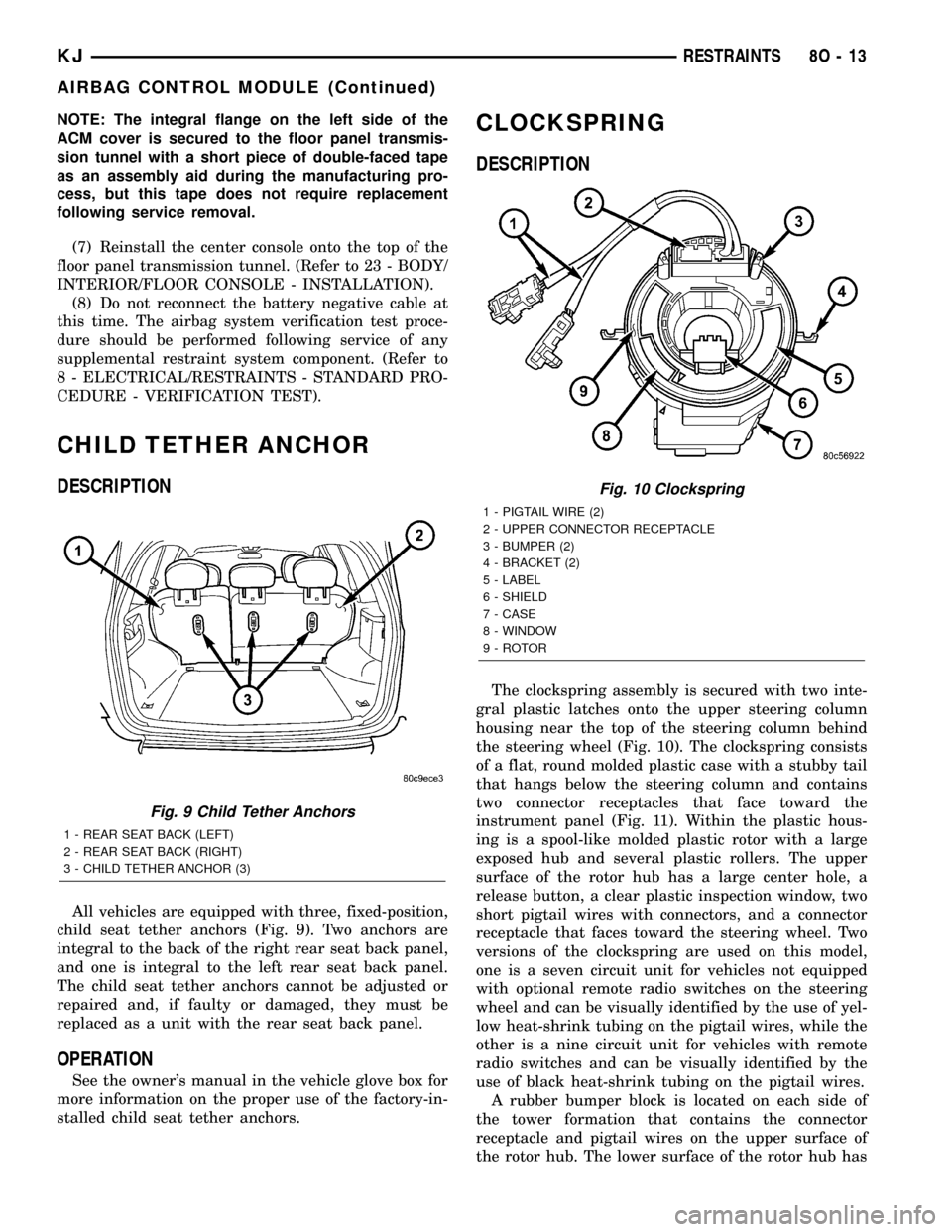

All vehicles are equipped with three, fixed-position,

child seat tether anchors (Fig. 9). Two anchors are

integral to the back of the right rear seat back panel,

and one is integral to the left rear seat back panel.

The child seat tether anchors cannot be adjusted or

repaired and, if faulty or damaged, they must be

replaced as a unit with the rear seat back panel.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the proper use of the factory-in-

stalled child seat tether anchors.

CLOCKSPRING

DESCRIPTION

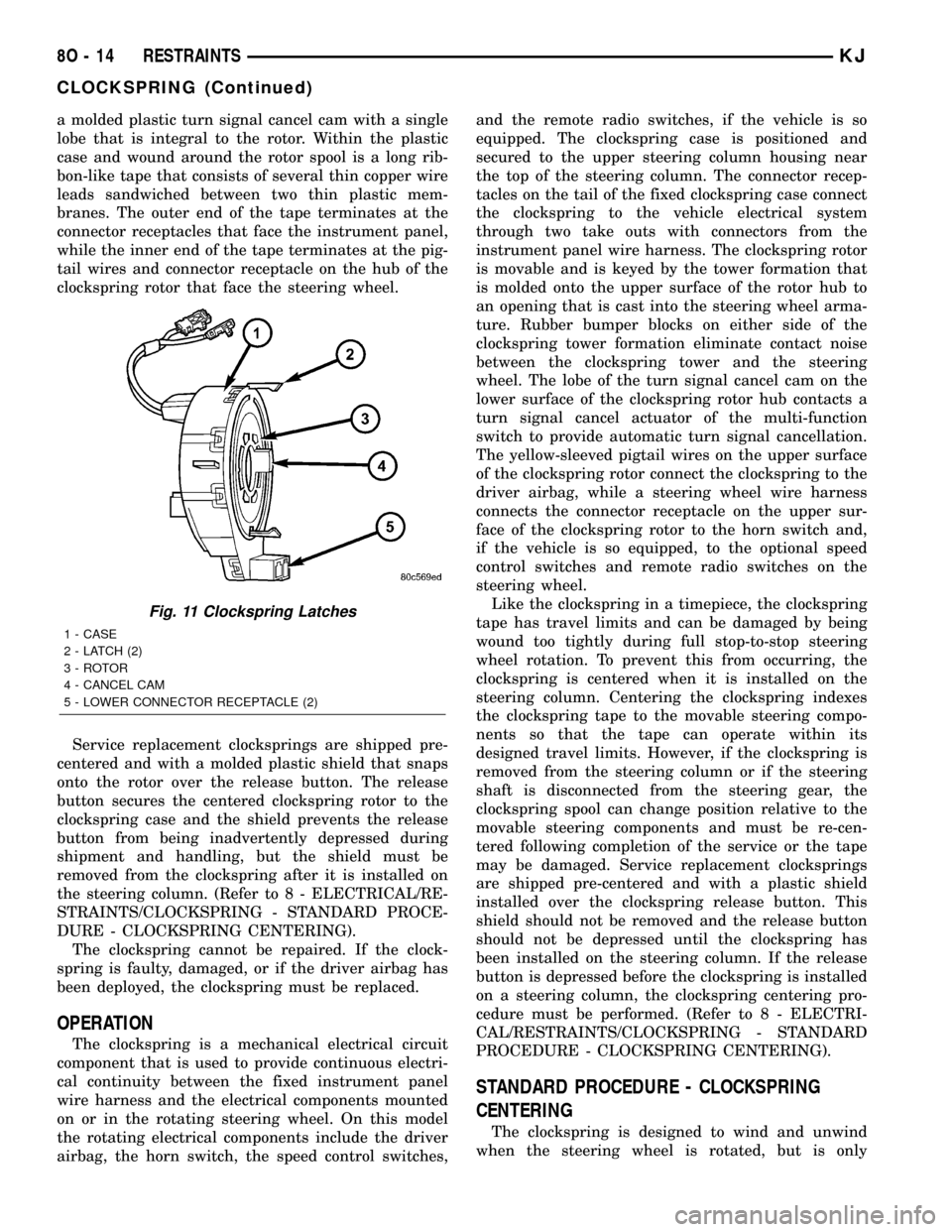

The clockspring assembly is secured with two inte-

gral plastic latches onto the upper steering column

housing near the top of the steering column behind

the steering wheel (Fig. 10). The clockspring consists

of a flat, round molded plastic case with a stubby tail

that hangs below the steering column and contains

two connector receptacles that face toward the

instrument panel (Fig. 11). Within the plastic hous-

ing is a spool-like molded plastic rotor with a large

exposed hub and several plastic rollers. The upper

surface of the rotor hub has a large center hole, a

release button, a clear plastic inspection window, two

short pigtail wires with connectors, and a connector

receptacle that faces toward the steering wheel. Two

versions of the clockspring are used on this model,

one is a seven circuit unit for vehicles not equipped

with optional remote radio switches on the steering

wheel and can be visually identified by the use of yel-

low heat-shrink tubing on the pigtail wires, while the

other is a nine circuit unit for vehicles with remote

radio switches and can be visually identified by the

use of black heat-shrink tubing on the pigtail wires.

A rubber bumper block is located on each side of

the tower formation that contains the connector

receptacle and pigtail wires on the upper surface of

the rotor hub. The lower surface of the rotor hub has

Fig. 9 Child Tether Anchors

1 - REAR SEAT BACK (LEFT)

2 - REAR SEAT BACK (RIGHT)

3 - CHILD TETHER ANCHOR (3)

Fig. 10 Clockspring

1 - PIGTAIL WIRE (2)

2 - UPPER CONNECTOR RECEPTACLE

3 - BUMPER (2)

4 - BRACKET (2)

5 - LABEL

6 - SHIELD

7 - CASE

8 - WINDOW

9 - ROTOR

KJRESTRAINTS 8O - 13

AIRBAG CONTROL MODULE (Continued)

Page 641 of 1803

a molded plastic turn signal cancel cam with a single

lobe that is integral to the rotor. Within the plastic

case and wound around the rotor spool is a long rib-

bon-like tape that consists of several thin copper wire

leads sandwiched between two thin plastic mem-

branes. The outer end of the tape terminates at the

connector receptacles that face the instrument panel,

while the inner end of the tape terminates at the pig-

tail wires and connector receptacle on the hub of the

clockspring rotor that face the steering wheel.

Service replacement clocksprings are shipped pre-

centered and with a molded plastic shield that snaps

onto the rotor over the release button. The release

button secures the centered clockspring rotor to the

clockspring case and the shield prevents the release

button from being inadvertently depressed during

shipment and handling, but the shield must be

removed from the clockspring after it is installed on

the steering column. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/CLOCKSPRING - STANDARD PROCE-

DURE - CLOCKSPRING CENTERING).

The clockspring cannot be repaired. If the clock-

spring is faulty, damaged, or if the driver airbag has

been deployed, the clockspring must be replaced.

OPERATION

The clockspring is a mechanical electrical circuit

component that is used to provide continuous electri-

cal continuity between the fixed instrument panel

wire harness and the electrical components mounted

on or in the rotating steering wheel. On this model

the rotating electrical components include the driver

airbag, the horn switch, the speed control switches,and the remote radio switches, if the vehicle is so

equipped. The clockspring case is positioned and

secured to the upper steering column housing near

the top of the steering column. The connector recep-

tacles on the tail of the fixed clockspring case connect

the clockspring to the vehicle electrical system

through two take outs with connectors from the

instrument panel wire harness. The clockspring rotor

is movable and is keyed by the tower formation that

is molded onto the upper surface of the rotor hub to

an opening that is cast into the steering wheel arma-

ture. Rubber bumper blocks on either side of the

clockspring tower formation eliminate contact noise

between the clockspring tower and the steering

wheel. The lobe of the turn signal cancel cam on the

lower surface of the clockspring rotor hub contacts a

turn signal cancel actuator of the multi-function

switch to provide automatic turn signal cancellation.

The yellow-sleeved pigtail wires on the upper surface

of the clockspring rotor connect the clockspring to the

driver airbag, while a steering wheel wire harness

connects the connector receptacle on the upper sur-

face of the clockspring rotor to the horn switch and,

if the vehicle is so equipped, to the optional speed

control switches and remote radio switches on the

steering wheel.

Like the clockspring in a timepiece, the clockspring

tape has travel limits and can be damaged by being

wound too tightly during full stop-to-stop steering

wheel rotation. To prevent this from occurring, the

clockspring is centered when it is installed on the

steering column. Centering the clockspring indexes

the clockspring tape to the movable steering compo-

nents so that the tape can operate within its

designed travel limits. However, if the clockspring is

removed from the steering column or if the steering

shaft is disconnected from the steering gear, the

clockspring spool can change position relative to the

movable steering components and must be re-cen-

tered following completion of the service or the tape

may be damaged. Service replacement clocksprings

are shipped pre-centered and with a plastic shield

installed over the clockspring release button. This

shield should not be removed and the release button

should not be depressed until the clockspring has

been installed on the steering column. If the release

button is depressed before the clockspring is installed

on a steering column, the clockspring centering pro-

cedure must be performed. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - STANDARD

PROCEDURE - CLOCKSPRING CENTERING).

STANDARD PROCEDURE - CLOCKSPRING

CENTERING

The clockspring is designed to wind and unwind

when the steering wheel is rotated, but is only

Fig. 11 Clockspring Latches

1 - CASE

2 - LATCH (2)

3 - ROTOR

4 - CANCEL CAM

5 - LOWER CONNECTOR RECEPTACLE (2)

8O - 14 RESTRAINTSKJ

CLOCKSPRING (Continued)

Page 643 of 1803

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

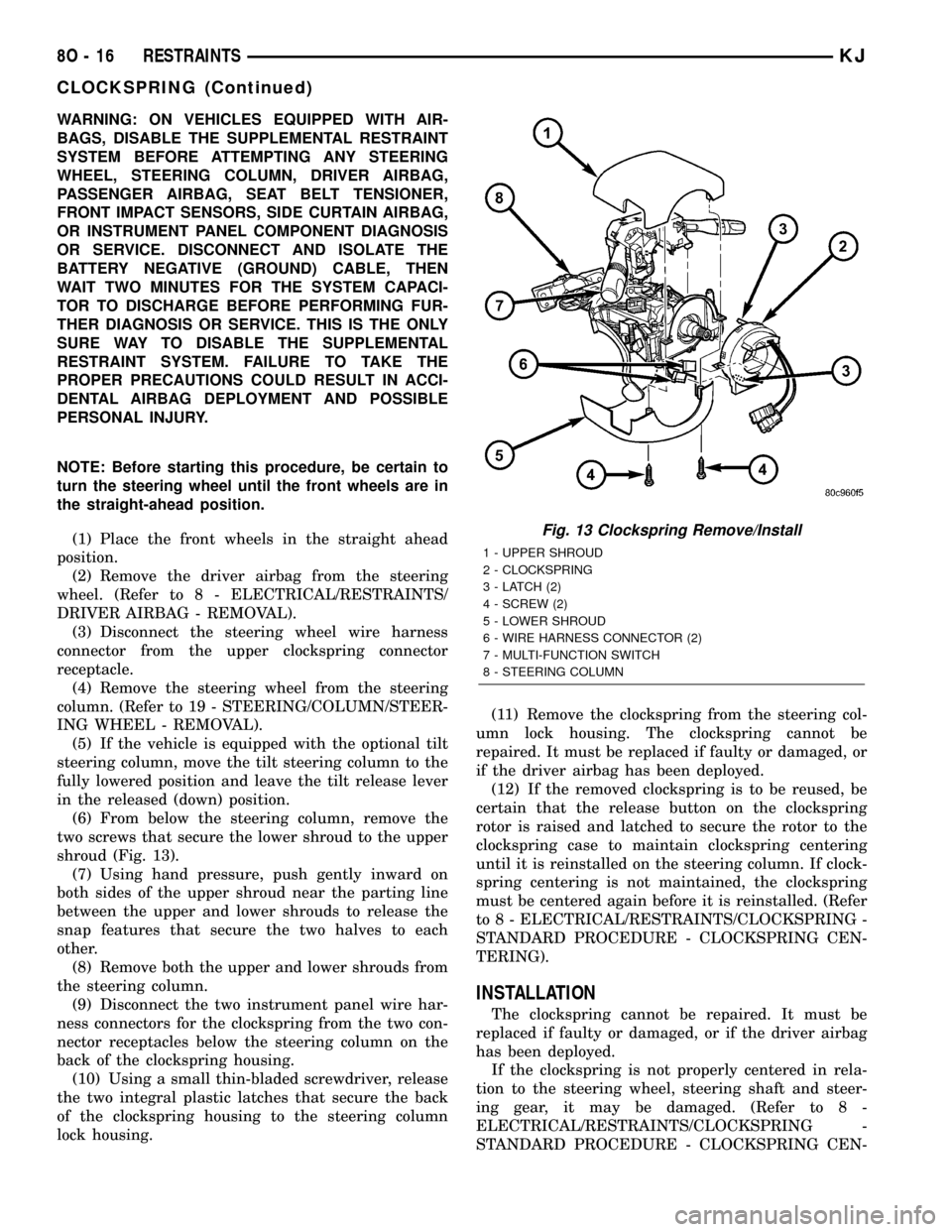

(1) Place the front wheels in the straight ahead

position.

(2) Remove the driver airbag from the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(3) Disconnect the steering wheel wire harness

connector from the upper clockspring connector

receptacle.

(4) Remove the steering wheel from the steering

column. (Refer to 19 - STEERING/COLUMN/STEER-

ING WHEEL - REMOVAL).

(5) If the vehicle is equipped with the optional tilt

steering column, move the tilt steering column to the

fully lowered position and leave the tilt release lever

in the released (down) position.

(6) From below the steering column, remove the

two screws that secure the lower shroud to the upper

shroud (Fig. 13).

(7) Using hand pressure, push gently inward on

both sides of the upper shroud near the parting line

between the upper and lower shrouds to release the

snap features that secure the two halves to each

other.

(8) Remove both the upper and lower shrouds from

the steering column.

(9) Disconnect the two instrument panel wire har-

ness connectors for the clockspring from the two con-

nector receptacles below the steering column on the

back of the clockspring housing.

(10) Using a small thin-bladed screwdriver, release

the two integral plastic latches that secure the back

of the clockspring housing to the steering column

lock housing.(11) Remove the clockspring from the steering col-

umn lock housing. The clockspring cannot be

repaired. It must be replaced if faulty or damaged, or

if the driver airbag has been deployed.

(12) If the removed clockspring is to be reused, be

certain that the release button on the clockspring

rotor is raised and latched to secure the rotor to the

clockspring case to maintain clockspring centering

until it is reinstalled on the steering column. If clock-

spring centering is not maintained, the clockspring

must be centered again before it is reinstalled. (Refer

to 8 - ELECTRICAL/RESTRAINTS/CLOCKSPRING -

STANDARD PROCEDURE - CLOCKSPRING CEN-

TERING).

INSTALLATION

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

If the clockspring is not properly centered in rela-

tion to the steering wheel, steering shaft and steer-

ing gear, it may be damaged. (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

STANDARD PROCEDURE - CLOCKSPRING CEN-

Fig. 13 Clockspring Remove/Install

1 - UPPER SHROUD

2 - CLOCKSPRING

3 - LATCH (2)

4 - SCREW (2)

5 - LOWER SHROUD

6 - WIRE HARNESS CONNECTOR (2)

7 - MULTI-FUNCTION SWITCH

8 - STEERING COLUMN

8O - 16 RESTRAINTSKJ

CLOCKSPRING (Continued)

Page 644 of 1803

TERING). Service replacement clocksprings are

shipped pre-centered, with the release button

engaged (raised) and a molded plastic shield installed

over the release button. This release button should

not be disengaged and the shield should not be

removed until the clockspring has been installed on

the steering column. If the release button is disen-

gaged before the clockspring is installed on a steering

column, the clockspring centering procedure must be

performed.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Carefully slide the centered clockspring down

over the steering column upper shaft until the two

integral plastic latches on the back of the clockspring

housing are fully engaged through their openings in

the steering column lock housing (Fig. 13).

(2) Reconnect the two instrument panel wire har-

ness connectors for the clockspring to the two connec-

tor receptacles below the steering column on the back

of the clockspring housing.

(3) Position the upper and lower shrouds onto the

steering column.

(4) Align the snap features on the lower shroud

with the receptacles on the upper shroud and apply

hand pressure to snap them together.

(5) From below the steering column, install and

tighten the two screws that secure the lower shroud

to the upper shroud. Tighten the screws to 2 N´m (18

in. lbs.).

(6) If the vehicle is equipped with the optional tilt

steering column, move the tilt steering column back

to the fully raised position and move the tilt release

lever back to the locked (up) position.(7) Reinstall the steering wheel onto the steering

column. (Refer to 19 - STEERING/COLUMN/STEER-

ING WHEEL - INSTALLATION).

NOTE: Be certain that the steering wheel mounting

screw is tightened to the proper torque specifica-

tion to ensure proper clockspring operation.

(8) Reconnect the steering wheel wire harness con-

nector to the upper clockspring connector receptacle.

(9) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

DRIVER AIRBAG

DESCRIPTION

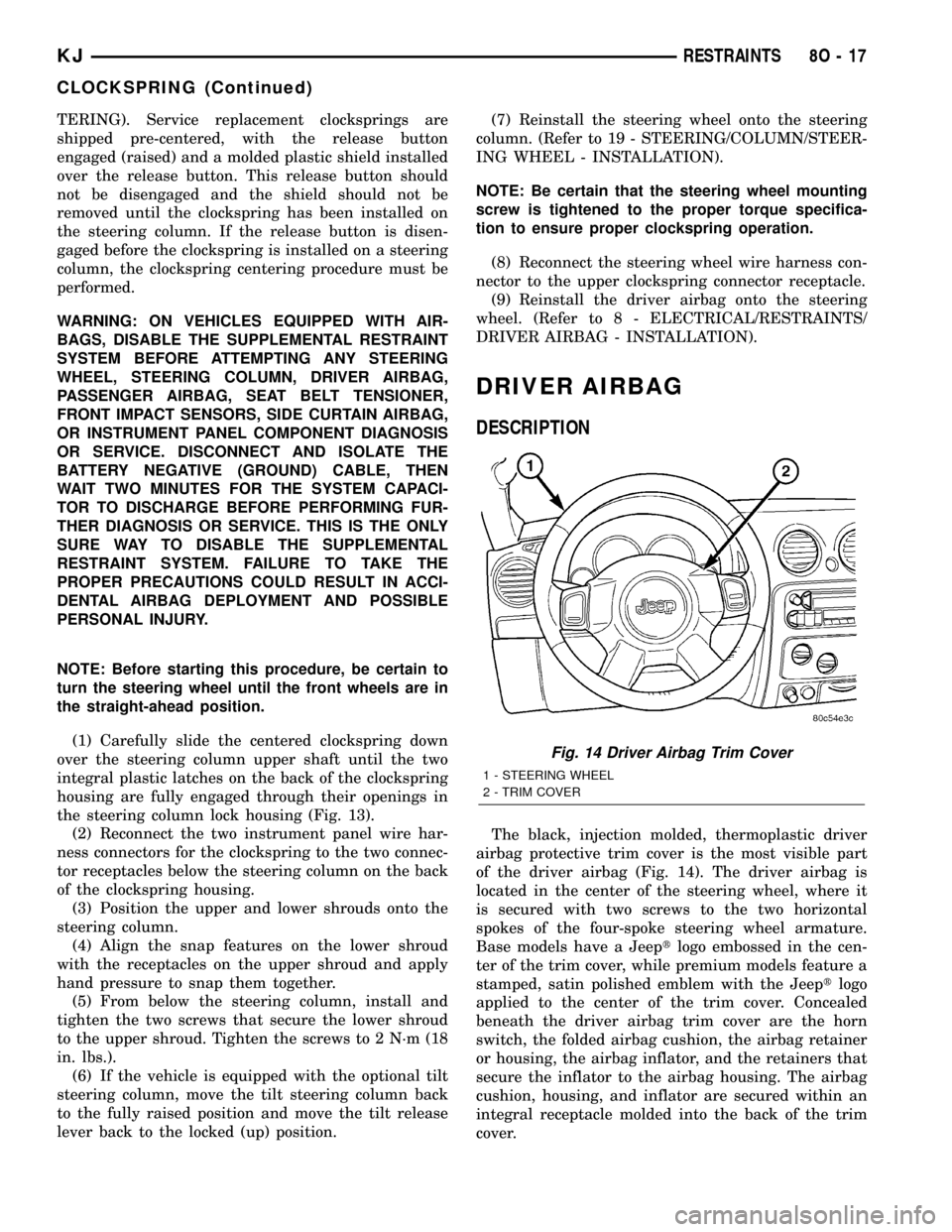

The black, injection molded, thermoplastic driver

airbag protective trim cover is the most visible part

of the driver airbag (Fig. 14). The driver airbag is

located in the center of the steering wheel, where it

is secured with two screws to the two horizontal

spokes of the four-spoke steering wheel armature.

Base models have a Jeeptlogo embossed in the cen-

ter of the trim cover, while premium models feature a

stamped, satin polished emblem with the Jeeptlogo

applied to the center of the trim cover. Concealed

beneath the driver airbag trim cover are the horn

switch, the folded airbag cushion, the airbag retainer

or housing, the airbag inflator, and the retainers that

secure the inflator to the airbag housing. The airbag

cushion, housing, and inflator are secured within an

integral receptacle molded into the back of the trim

cover.

Fig. 14 Driver Airbag Trim Cover

1 - STEERING WHEEL

2 - TRIM COVER

KJRESTRAINTS 8O - 17

CLOCKSPRING (Continued)

Page 647 of 1803

(4) Disconnect the steering wheel wire harness

connector for the horn switch from the horn switch

feed pigtail wire connector, which is located on the

back of the driver airbag housing.

CAUTION: Do not pull on the clockspring pigtail

wires or pry on the connector insulator to disen-

gage the connector from the driver airbag inflator

connector receptacle. Improper removal of these

pigtail wires and their connector insulators can

result in damage to the airbag circuits or connector

insulators.

(5) The clockspring driver airbag pigtail wire con-

nectors are secured by integral latches to the airbag

inflator connector receptacles, which are located on

the back of the driver airbag housing. Depress the

latches on each side of each connector insulator and

pull the insulators straight out from the airbag infla-

tor to disconnect them from the connector recepta-

cles.

(6) Remove the driver airbag from the steering

wheel.

(7) If the driver airbag has been deployed, the

clockspring must be replaced. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - REMOVAL).

INSTALLATION

The following procedure is for replacement of a

faulty or damaged driver airbag. If the driver airbag

has been deployed, the clockspring must also be

replaced. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - INSTALLATION).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.WARNING: USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE DRIVER

AIRBAG, OR BECOMING ENTRAPPED BETWEEN

THE DRIVER AIRBAG CUSHION AND THE DRIVER

AIRBAG TRIM COVER. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN OCCUPANT INJURIES

UPON AIRBAG DEPLOYMENT.

WARNING: THE DRIVER AIRBAG TRIM COVER

MUST NEVER BE PAINTED. REPLACEMENT AIR-

BAGS ARE SERVICED IN THE ORIGINAL COLORS.

PAINT MAY CHANGE THE WAY IN WHICH THE

MATERIAL OF THE TRIM COVER RESPONDS TO AN

AIRBAG DEPLOYMENT. FAILURE TO OBSERVE

THIS WARNING COULD RESULT IN OCCUPANT

INJURIES UPON AIRBAG DEPLOYMENT.

(1) Position the driver airbag close enough to the

steering wheel to reconnect all three electrical con-

nections on the back of the airbag housing.

(2) When installing the driver airbag, reconnect

the two clockspring driver airbag pigtail wire connec-

tors to the airbag inflator connector receptacles by

pressing straight in on the connectors (Fig. 16). Be

certain to engage each keyed and color-coded connec-

tor to the matching connector receptacle. You can be

certain that each connector is fully engaged in its

receptacle by listening carefully for a distinct, audi-

ble click as the connector latches snap into place.

(3) Reconnect the steering wheel wire harness con-

nector for the horn switch to the horn switch feed

pigtail wire connector, which is located at the back of

the driver airbag housing.

(4) Carefully position the driver airbag in the

steering wheel. Be certain that the clockspring pig-

tail wires and steering wheel wire harness in the

steering wheel hub area are not pinched between the

driver airbag and the steering wheel armature.

(5) From the underside of the steering wheel,

install and tighten the two screws that secure the

driver airbag to the steering wheel armature.

Tighten the screws to 10 N´m (90 in. lbs.).

(6) Do not reconnect the battery negative cable at

this time. The airbag system verification test proce-

dure should be performed following service of any

supplemental restraint system component. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - VERIFICATION TEST).

8O - 20 RESTRAINTSKJ

DRIVER AIRBAG (Continued)

Page 675 of 1803

A ªtap downº feature is used to decelerate without

disengaging the speed control system. To decelerate

from an existing recorded target speed, momentarily

depress the COAST switch. For each switch activa-

tion, speed will be lowered approximately 1 mph.

OVERSHOOT/UNDERSHOOT

If the vehicle operator repeatedly presses and

releases the SET button with their foot off of the

accelerator (referred to as a ªlift foot setº), the vehicle

may accelerate and exceed the desired set speed by

up to 5 mph (8 km/h). It may also decelerate to less

than the desired set speed, before finally achieving

the desired set speed.

The Speed Control System has an adaptive strat-

egy that compensates for vehicle-to-vehicle variations

in speed control cable lengths. When the speed con-

trol is set with the vehicle operators foot off of the

accelerator pedal, the speed control thinks there is

excessive speed control cable slack and adapts

accordingly. If the ªlift foot setsº are continually used,

a speed control overshoot/undershoot condition will

develop.

To ªunlearnº the overshoot/undershoot condition,

the vehicle operator has to press and release the set

button while maintaining the desired set speed using

the accelerator pedal (not decelerating or accelerat-

ing), and then turning the cruise control switch to

the OFF position (or press the CANCEL button if

equipped) after waiting 10 seconds. This procedure

must be performed approximately 10±15 times to

completely unlearn the overshoot/undershoot condi-

tion.

DIAGNOSIS AND TESTING - ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road testshould include attention to the speedometer. Speed-

ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Group 8J,

Instrument Cluster for speedometer diagnosis.

If a road test verifies a system problem and the

speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose, damaged or corroded electrical connec-

tions at the servo. Corrosion should be removed from

electrical terminals and a light coating of Mopar

MultiPurpose Grease, or equivalent, applied.

²Leaking vacuum reservoir.

²Loose or leaking vacuum hoses or connections.

²Defective one-way vacuum check valve.

²Secure attachment of both ends of the speed con-

trol servo cable.

²Smooth operation of throttle linkage and throttle

body air valve.

²Failed speed control servo. Do the servo vacuum

test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

SPECIFICATIONS

TORQUE - SPEED CONTROL

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Servo Mounting Bracket-to-Servo Nuts 9 - 75

Servo Mounting Bracket-to-Body Bolts 12 - 105

Speed Control Switch Mounting Screws 1.5 - 14

Vacuum Reservoir Mounting Screws 3 - 20

8P - 2 SPEED CONTROLKJ

SPEED CONTROL (Continued)

Page 682 of 1803

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION..........................1

OPERATION............................3

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM....................6

STANDARD PROCEDURE

STANDARD PROCEDURE - SKIS

INITIALIZATION........................8

STANDARD PROCEDURE - SENTRY KEY

TRANSPONDER PROGRAMMING..........8

DOOR CYLINDER LOCK SWITCH

DESCRIPTION..........................9

OPERATION...........................10

DIAGNOSIS AND TESTING - DOOR

CYLINDER LOCK SWITCH..............10

REMOVAL.............................10

INSTALLATION.........................10

HOOD AJAR SWITCH

DESCRIPTION.........................11

OPERATION...........................12

DIAGNOSIS AND TESTING - HOOD AJAR

SWITCH............................12REMOVAL.............................12

INSTALLATION.........................12

HOOD AJAR SWITCH BRACKET

REMOVAL.............................13

INSTALLATION.........................13

HOOD AJAR SWITCH STRIKER

REMOVAL.............................13

INSTALLATION.........................14

INTRUSION TRANSCEIVER MODULE

DESCRIPTION.........................14

OPERATION...........................15

REMOVAL.............................15

INSTALLATION.........................16

SIREN

DESCRIPTION.........................16

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................17

TRANSPONDER KEY

DESCRIPTION.........................18

OPERATION...........................18

VEHICLE THEFT SECURITY

DESCRIPTION

The Vehicle Theft Security System (VTSS) is an

available factory-installed option on this model (Fig.

1). The VTSS is comprised of two primary sub-

systems: Vehicle Theft Alarm (VTA) and Sentry Key

Immobilizer System (SKIS). The VTA is an active

system that provides visual and audible responses as

deterrents to and warnings of unauthorized vehicle

tampering. The SKIS is a passive system that effec-

tively immobilizes the vehicle against unauthorized

operation. Following are paragraphs which describe

the various components that are included in each of

these subsystems of the VTSS.

Hard wired circuitry connects many of the VTSS

components to each other through the electrical sys-

tem of the vehicle. These hard wired circuits are

integral to several wire harnesses, which are routed

throughout the vehicle and retained by many differ-

ent methods. These circuits may be connected to each

other, to the vehicle electrical system and to the

VTSS components through the use of a combination

of soldered splices, splice block connectors, and many

different types of wire harness terminal connectorsand insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

VEHICLE THEFT ALARM The VTA is available in

two different configurations for this vehicle: One con-

figuration is designed for vehicles manufactured for

sale in North America; while, the other configuration

is designed for vehicles manufactured for sale in

markets outside of North America, also referred to as

Rest-Of-World or ROW. In addition, the VTA for

ROW is available in two versions: base and premium.

All vehicles equipped with VTA are also equipped

with the Remote Keyless Entry (RKE) system and

the Sentry Key Immobilizer System (SKIS), regard-

less of their market destination. The North American

and ROW base version of the VTA provides perimeter

vehicle protection by monitoring the vehicle doors,

the tailgate, the rear flip-up glass and, for vehicles

built for certain markets where it is required equip-

ment, the hood. If unauthorized vehicle use or tam-

pering is detected, these systems respond by pulsing

the horn and flashing certain exterior lamps. The

ROW premium version of the VTA is only available

KJVEHICLE THEFT SECURITY 8Q - 1

Page 687 of 1803

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM

The Vehicle Theft Security System (VTSS) is

divided into two basic subsystems: Vehicle Theft

Alarm (VTA) and Sentry Key Immobilizer System

(SKIS). Following are the recommended procedures

for diagnosis and testing of each of these two sub-

systems.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

VEHICLE THEFT ALARM

Models equipped with the Rest-Of-World (ROW)

premium version of the Vehicle Theft Alarm (VTA)

provide some preliminary diagnostic feedback by illu-minating the security indicator located in the Elec-

troMechanical Instrument Cluster (EMIC). If the

security indicator illuminates with the ignition

switch in the On position, it indicates that there is a

communication problem between the Intrusion

Transceiver Module (ITM) and the Body Control

Module (BCM), or between the ITM and the siren

module. The BCM will also turn on the security indi-

cator if it receives a message from the ITM indicating

that the ITM has stored a Diagnostic Trouble Code

(DTC) for a siren module fault.

The hard wired circuits and components of the

VTA may be diagnosed and tested using conventional

diagnostic tools and procedures. However, conven-

tional diagnostic methods may not prove conclusive

in the diagnosis of the Body Control Module (BCM),

the ElectroMechanical Instrument Cluster (EMIC),

the Intrusion Transceiver Module (ITM), or the Pro-

grammable Communications Interface (PCI) data bus

network. The most reliable, efficient, and accurate

means to diagnose the BCM, the EMIC, the ITM,

and the PCI data bus network inputs and outputs

related to the VTA requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

8Q - 6 VEHICLE THEFT SECURITYKJ

VEHICLE THEFT SECURITY (Continued)

Page 688 of 1803

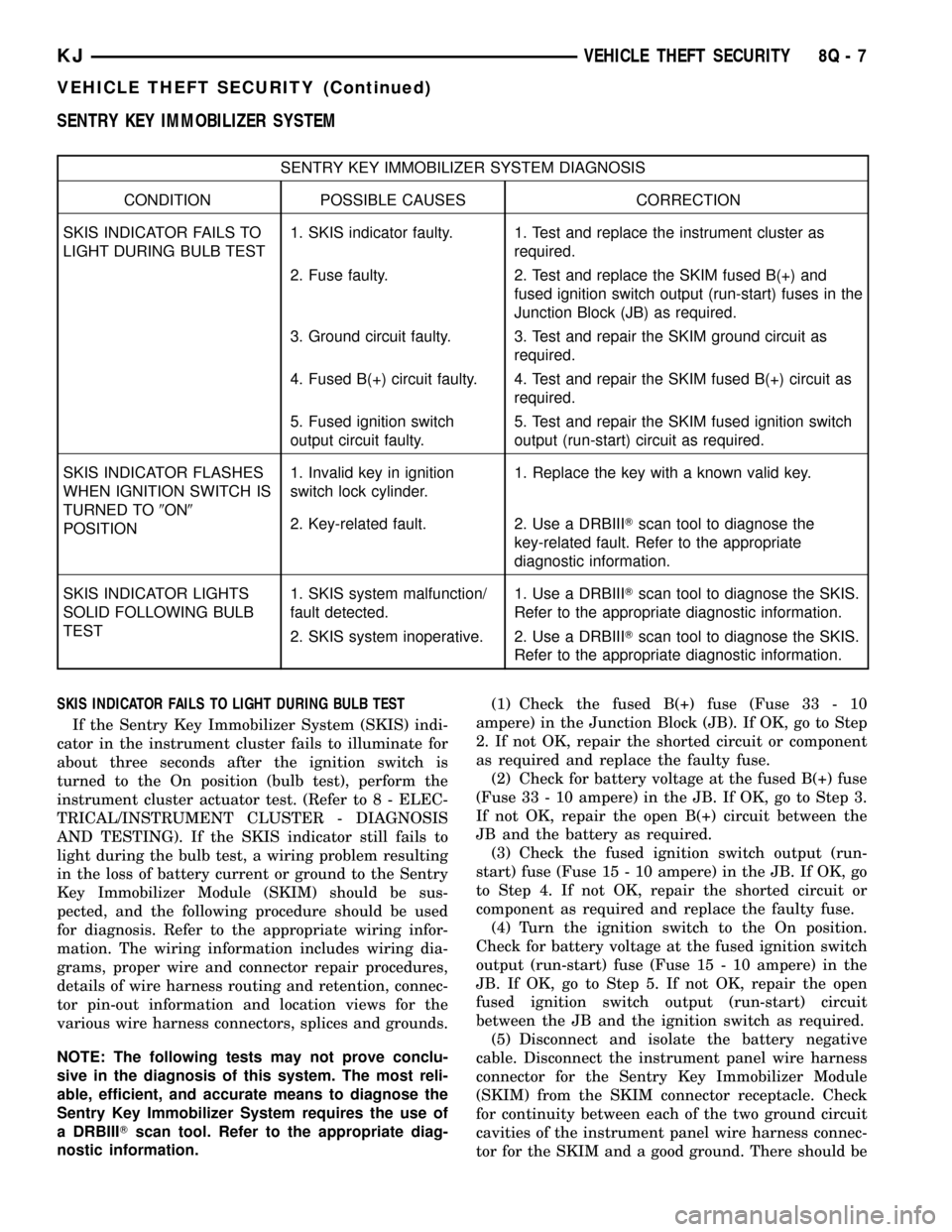

SENTRY KEY IMMOBILIZER SYSTEM

SENTRY KEY IMMOBILIZER SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

SKIS INDICATOR FAILS TO

LIGHT DURING BULB TEST1. SKIS indicator faulty. 1. Test and replace the instrument cluster as

required.

2. Fuse faulty. 2. Test and replace the SKIM fused B(+) and

fused ignition switch output (run-start) fuses in the

Junction Block (JB) as required.

3. Ground circuit faulty. 3. Test and repair the SKIM ground circuit as

required.

4. Fused B(+) circuit faulty. 4. Test and repair the SKIM fused B(+) circuit as

required.

5. Fused ignition switch

output circuit faulty.5. Test and repair the SKIM fused ignition switch

output (run-start) circuit as required.

SKIS INDICATOR FLASHES

WHEN IGNITION SWITCH IS

TURNED TO9ON9

POSITION1. Invalid key in ignition

switch lock cylinder.1. Replace the key with a known valid key.

2. Key-related fault. 2. Use a DRBIIITscan tool to diagnose the

key-related fault. Refer to the appropriate

diagnostic information.

SKIS INDICATOR LIGHTS

SOLID FOLLOWING BULB

TEST1. SKIS system malfunction/

fault detected.1. Use a DRBIIITscan tool to diagnose the SKIS.

Refer to the appropriate diagnostic information.

2. SKIS system inoperative. 2. Use a DRBIIITscan tool to diagnose the SKIS.

Refer to the appropriate diagnostic information.

SKIS INDICATOR FAILS TO LIGHT DURING BULB TEST

If the Sentry Key Immobilizer System (SKIS) indi-

cator in the instrument cluster fails to illuminate for

about three seconds after the ignition switch is

turned to the On position (bulb test), perform the

instrument cluster actuator test. (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). If the SKIS indicator still fails to

light during the bulb test, a wiring problem resulting

in the loss of battery current or ground to the Sentry

Key Immobilizer Module (SKIM) should be sus-

pected, and the following procedure should be used

for diagnosis. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Sentry Key Immobilizer System requires the use of

a DRBIIITscan tool. Refer to the appropriate diag-

nostic information.(1) Check the fused B(+) fuse (Fuse 33 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 33 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open B(+) circuit between the

JB and the battery as required.

(3) Check the fused ignition switch output (run-

start) fuse (Fuse 15 - 10 ampere) in the JB. If OK, go

to Step 4. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run-start) fuse (Fuse 15 - 10 ampere) in the

JB. If OK, go to Step 5. If not OK, repair the open

fused ignition switch output (run-start) circuit

between the JB and the ignition switch as required.

(5) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector for the Sentry Key Immobilizer Module

(SKIM) from the SKIM connector receptacle. Check

for continuity between each of the two ground circuit

cavities of the instrument panel wire harness connec-

tor for the SKIM and a good ground. There should be

KJVEHICLE THEFT SECURITY 8Q - 7

VEHICLE THEFT SECURITY (Continued)

Page 691 of 1803

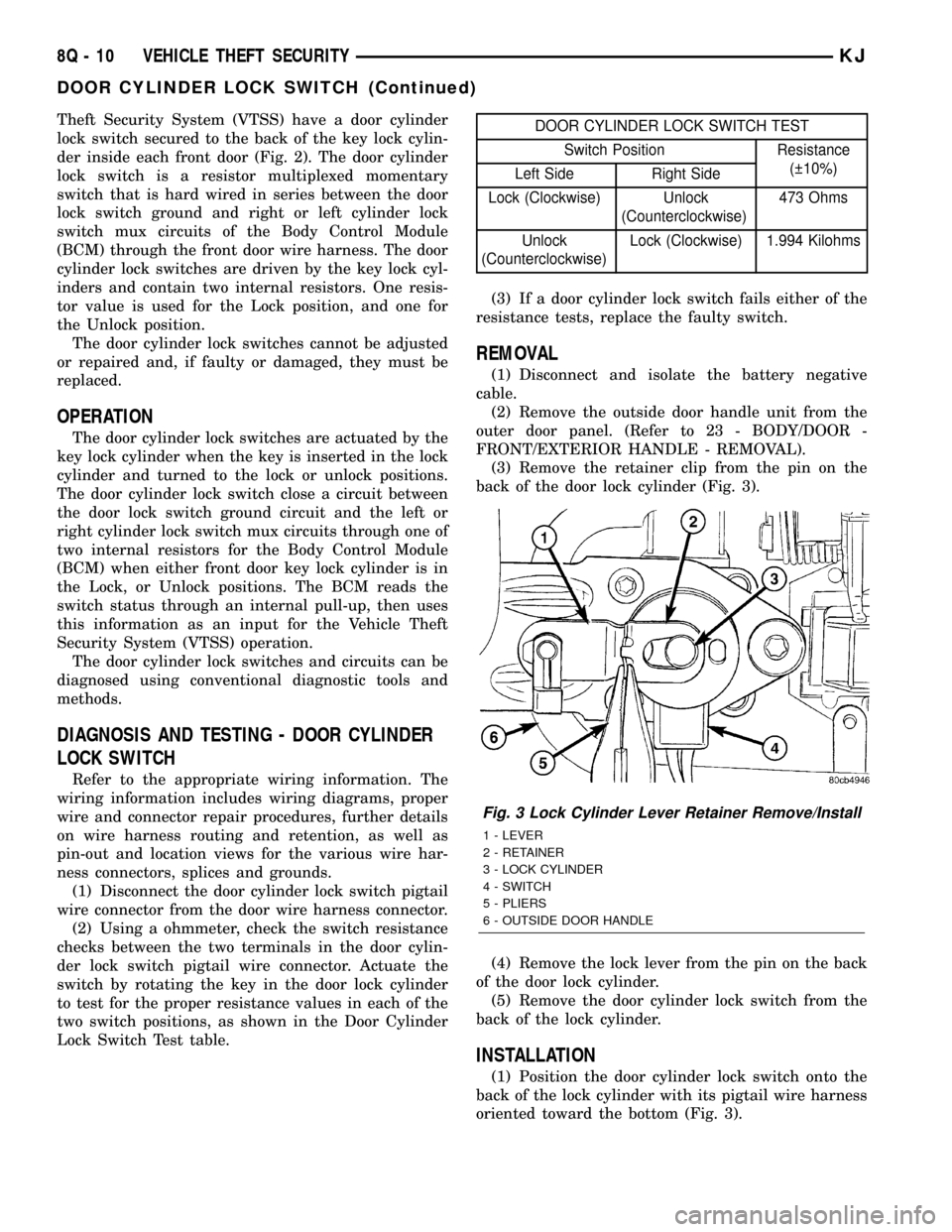

Theft Security System (VTSS) have a door cylinder

lock switch secured to the back of the key lock cylin-

der inside each front door (Fig. 2). The door cylinder

lock switch is a resistor multiplexed momentary

switch that is hard wired in series between the door

lock switch ground and right or left cylinder lock

switch mux circuits of the Body Control Module

(BCM) through the front door wire harness. The door

cylinder lock switches are driven by the key lock cyl-

inders and contain two internal resistors. One resis-

tor value is used for the Lock position, and one for

the Unlock position.

The door cylinder lock switches cannot be adjusted

or repaired and, if faulty or damaged, they must be

replaced.

OPERATION

The door cylinder lock switches are actuated by the

key lock cylinder when the key is inserted in the lock

cylinder and turned to the lock or unlock positions.

The door cylinder lock switch close a circuit between

the door lock switch ground circuit and the left or

right cylinder lock switch mux circuits through one of

two internal resistors for the Body Control Module

(BCM) when either front door key lock cylinder is in

the Lock, or Unlock positions. The BCM reads the

switch status through an internal pull-up, then uses

this information as an input for the Vehicle Theft

Security System (VTSS) operation.

The door cylinder lock switches and circuits can be

diagnosed using conventional diagnostic tools and

methods.

DIAGNOSIS AND TESTING - DOOR CYLINDER

LOCK SWITCH

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

(1) Disconnect the door cylinder lock switch pigtail

wire connector from the door wire harness connector.

(2) Using a ohmmeter, check the switch resistance

checks between the two terminals in the door cylin-

der lock switch pigtail wire connector. Actuate the

switch by rotating the key in the door lock cylinder

to test for the proper resistance values in each of the

two switch positions, as shown in the Door Cylinder

Lock Switch Test table.

DOOR CYLINDER LOCK SWITCH TEST

Switch Position Resistance

( 10%)

Left Side Right Side

Lock (Clockwise) Unlock

(Counterclockwise)473 Ohms

Unlock

(Counterclockwise)Lock (Clockwise) 1.994 Kilohms

(3) If a door cylinder lock switch fails either of the

resistance tests, replace the faulty switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the outside door handle unit from the

outer door panel. (Refer to 23 - BODY/DOOR -

FRONT/EXTERIOR HANDLE - REMOVAL).

(3) Remove the retainer clip from the pin on the

back of the door lock cylinder (Fig. 3).

(4) Remove the lock lever from the pin on the back

of the door lock cylinder.

(5) Remove the door cylinder lock switch from the

back of the lock cylinder.

INSTALLATION

(1) Position the door cylinder lock switch onto the

back of the lock cylinder with its pigtail wire harness

oriented toward the bottom (Fig. 3).

Fig. 3 Lock Cylinder Lever Retainer Remove/Install

1 - LEVER

2 - RETAINER

3 - LOCK CYLINDER

4 - SWITCH

5 - PLIERS

6 - OUTSIDE DOOR HANDLE

8Q - 10 VEHICLE THEFT SECURITYKJ

DOOR CYLINDER LOCK SWITCH (Continued)