Vacuum hose diagram JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1661 of 1803

(5) Connect the test set hose or probe to the open

end of the leaking circuit. The test set gauge should

return to the 27 kPa (8 in. Hg.) setting shortly after

each connection is made. If OK, replace the faulty

disconnected component. If not OK, go to Step 6.

(6)

To locate a leak in a vacuum line, leave one end

of the line plugged and connect the test set hose or

probe to the other end of the line. Run your fingers

slowly along the line while watching the test set gauge.

The vacuum reading will fluctuate when your fingers

contact the source of the leak. To repair the vacuum

line, cut out the leaking section of the line. Then, insert

the loose ends of the line into a suitable length of 3 mil-

limeter (0.125 inch) inside diameter rubber hose.

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect the battery negative cable and iso-

late it.

(2) Locate the diode in the harness, and remove

the protective covering.

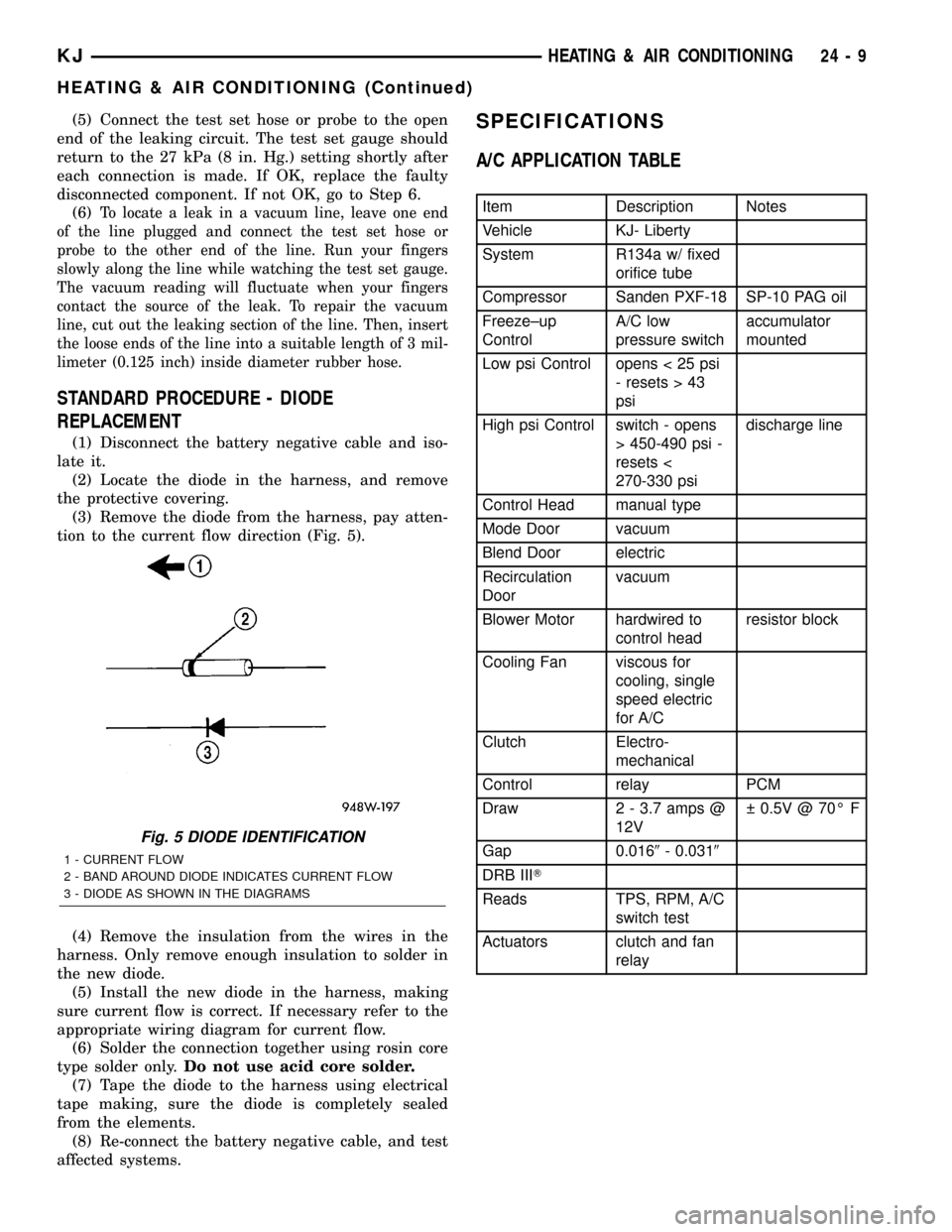

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 5).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8) Re-connect the battery negative cable, and test

affected systems.

SPECIFICATIONS

A/C APPLICATION TABLE

Item Description Notes

Vehicle KJ- Liberty

System R134a w/ fixed

orifice tube

Compressor Sanden PXF-18 SP-10 PAG oil

Freeze±up

ControlA/C low

pressure switchaccumulator

mounted

Low psi Control opens < 25 psi

- resets > 43

psi

High psi Control switch - opens

> 450-490 psi -

resets <

270-330 psidischarge line

Control Head manual type

Mode Door vacuum

Blend Door electric

Recirculation

Doorvacuum

Blower Motor hardwired to

control headresistor block

Cooling Fan viscous for

cooling, single

speed electric

for A/C

Clutch Electro-

mechanical

Control relay PCM

Draw 2 - 3.7 amps @

12V 0.5V @ 70É F

Gap 0.0169- 0.0319

DRB IIIT

Reads TPS, RPM, A/C

switch test

Actuators clutch and fan

relay

Fig. 5 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

KJHEATING & AIR CONDITIONING 24 - 9

HEATING & AIR CONDITIONING (Continued)

Page 1761 of 1803

RELAY - OPERATION, FRONT FOG LAMP . . 8L-22

RELAY - OPERATION, FUEL PUMP.......14-34

RELAY - OPERATION, HEADLAMP HIGH

BEAM..............................8L-33

RELAY - OPERATION, HEADLAMP LOW

BEAM..............................8L-39

RELAY - OPERATION, PARK LAMP.......8L-54

RELAY - OPERATION, REAR FOG LAMP . . . 8L-57

RELAY - OPERATION, REAR WINDOW

DEFOGGER..........................8G-6

RELAY - OPERATION, STARTER MOTOR . . . 8F-42

RELAY - OPERATION, TRAILER TOW.....8L-62

RELAY - OPERATION, TRANSMISSION

CONTROL.........................21-168

RELAY - OPERATION, WIPER HIGH/LOW . . 8R-23

RELAY - OPERATION, WIPER ON/OFF....8R-25

RELAY - REMOVAL................8W-97-14

RELAY - REMOVAL, A/C COMPRESSOR

CLUTCH............................24-16

RELAY - REMOVAL, AMPLIFIER CHOKE....8A-4

RELAY - REMOVAL, BLOWER MOTOR....24-21

RELAY - REMOVAL, CLUTCH SWITCH

OVERRIDE...........................6-10

RELAY - REMOVAL, DAYTIME RUNNING

LAMP..............................8L-21

RELAY - REMOVAL, DOOR LOCK.........8N-6

RELAY - REMOVAL, FRONT FOG LAMP . . . 8L-24

RELAY - REMOVAL, FUEL PUMP........14-34

RELAY - REMOVAL, HEADLAMP HIGH

BEAM..............................8L-34

RELAY - REMOVAL, HEADLAMP LOW

BEAM..............................8L-40

RELAY - REMOVAL, HORN..............8H-3

RELAY - REMOVAL, PARK LAMP........8L-55

RELAY - REMOVAL, REAR FOG LAMP....8L-58

RELAY - REMOVAL, REAR WINDOW

DEFOGGER..........................8G-7

RELAY - REMOVAL, STARTER MOTOR....8F-43

RELAY - REMOVAL, TRAILER TOW.......8L-63

RELAY - REMOVAL, WIPER HIGH/LOW . . . 8R-24

RELAY - REMOVAL, WIPER ON/OFF......8R-26

RELAYS - DIAGNOSIS AND TESTING,

ASD AND FUEL PUMP..................8I-4

RELEASE - STANDARD PROCEDURE,

FUEL SYSTEM PRESSURE..............14-4

RELEASE BEARING - INSTALLATION,

CLUTCH..............................6-6

RELEASE BEARING - REMOVAL, CLUTCH . . . 6-6

RELEASE CABLE - INSTALLATION, LATCH . 23-120

RELEASE CABLE - REMOVAL, LATCH....23-120

RELEASE HANDLE - INSTALLATION,

LATCH ............................23-120

RELEASE HANDLE - REMOVAL, LATCH . . 23-120

RELEASE SWITCH - DIAGNOSIS AND

TESTING, FLIP-UP GLASS..............8N-5

RELIEF VALVE - DESCRIPTION, HIGH

PRESSURE.........................24-42

RELIEF VALVE - OPERATION, HIGH

PRESSURE.........................24-42

REMOTE KEYLESS ENTRY MODULE -

DESCRIPTION........................8N-7

REMOTE KEYLESS ENTRY MODULE -

DIAGNOSIS AND TESTING..............8N-7

REMOTE KEYLESS ENTRY MODULE -

INSTALLATION.......................8N-7

REMOTE KEYLESS ENTRY MODULE -

OPERATION..........................8N-7

REMOTE KEYLESS ENTRY MODULE -

REMOVAL...........................8N-7

REMOTE KEYLESS ENTRY

TRANSMITTER - DIAGNOSIS AND

TESTING............................8N-8

REMOTE KEYLESS ENTRY

TRANSMITTER - SPECIFICATIONS........8N-9

REMOTE SWITCHES - DESCRIPTION.....8A-11

REMOTE SWITCHES - DIAGNOSIS AND

TESTING...........................8A-12

REMOTE SWITCHES - INSTALLATION.....8A-13

REMOTE SWITCHES - OPERATION.......8A-12

REMOTE SWITCHES - REMOVAL

........8A-13

REPAIR - DESCRIPTION, THREADED

HOLE

.............................Intro.-4

REPAIR - STANDARD PROCEDURE,

ALUMINUM THREAD

..................21-81

REPAIR - STANDARD PROCEDURE,

REAR GLASS HEATING GRID

............8G-4

REPAIR DAMAGED OR WORN THREADS

- STANDARD PROCEDURE

...............9-9REPAIRING LEAKS - STANDARD

PROCEDURE.........................22-8

REPEATER LAMP BULB - INSTALLATION . . 8L-60

REPEATER LAMP BULB - REMOVAL......8L-60

REPEATER LAMP UNIT - INSTALLATION . . 8L-61

REPEATER LAMP UNIT - REMOVAL......8L-60

REQUIREMENTS - DESCRIPTION,

COOLING SYSTEM....................24-1

RESERVOIR - DESCRIPTION, VACUUM....8P-7

RESERVOIR - DESCRIPTION, WASHER . . . 8R-21

RESERVOIR - DIAGNOSIS AND TESTING,

VACUUM............................8P-7

RESERVOIR - INSTALLATION, FLUID......5-26

RESERVOIR - INSTALLATION, VACUUM....8P-8

RESERVOIR - INSTALLATION, WASHER . . . 8R-22

RESERVOIR - OPERATION, VACUUM......8P-7

RESERVOIR - OPERATION, WASHER.....8R-21

RESERVOIR - REMOVAL, FLUID..........5-26

RESERVOIR - REMOVAL, VACUUM........8P-7

RESERVOIR - REMOVAL, WASHER......8R-21

RESISTANCE, 2.4L - IGNITION COIL.......8I-2

RESISTANCE, 2.4L - SPARK PLUG CABLE . . . 8I-3

RESISTANCE, 3.7L V-6 - IGNITION COIL....8I-3

RESISTOR - DESCRIPTION, BLOWER

MOTOR............................24-22

RESISTOR - DIAGNOSIS AND TESTING,

BLOWER MOTOR....................24-22

RESISTOR - INSTALLATION, BLOWER

MOTOR............................24-22

RESISTOR - OPERATION, BLOWER

MOTOR............................24-22

RESISTOR - REMOVAL, BLOWER

MOTOR............................24-22

RESTRAINT DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL......................8O-6

RESTRAINT SYSTEM - DIAGNOSIS AND

TESTING, SUPPLEMENTAL..............8O-6

RESTRAINT SYSTEM - WARNING........8O-5

RESTRAINTS - DESCRIPTION............8O-2

RESTRAINTS - OPERATION.............8O-4

RESTRAINTS - STANDARD PROCEDURE,

HANDLING NON-DEPLOYED

SUPPLEMENTAL......................8O-6

RETAINER/BULKHEAD - ASSEMBLY, 4C . . 21-123

RETAINER/BULKHEAD - DISASSEMBLY,

4C ...............................21-122

RETRACTOR - INSTALLATION, FRONT

SEAT BELT .........................8O-24

RETRACTOR - INSTALLATION, REAR

CENTER SEAT BELT..................8O-33

RETRACTOR - INSTALLATION, REAR

OUTBOARD SEAT BELT................8O-34

RETRACTOR - REMOVAL, FRONT SEAT

BELT ..............................8O-23

RETRACTOR - REMOVAL, REAR CENTER

SEAT BELT .........................8O-32

RETRACTOR - REMOVAL, REAR

OUTBOARD SEAT BELT................8O-33

RETURN - DESCRIPTION, SENSOR.......8E-14

RETURN HOSE (GEAR TO THE COOLER)

- INSTALLATION.....................19-22

RETURN HOSE (GEAR TO THE COOLER)

- REMOVAL.........................19-21

RETURN HOSE (RESERVOIR TO THE

COOLER) - INSTALLATION.............19-22

RETURN HOSE (RESERVOIR TO THE

COOLER) - REMOVAL

.................19-21

REVERSE FLUSHING - STANDARD

PROCEDURE, COOLING SYSTEM

.........7-12

RFE TRANSMISSION, SPECIAL TOOLS

. . . 21-120

RHD - INSTALLATION

...............8W-97-6

RHD - REMOVAL

...................8W-97-5

RIGHT POWER SEAT SWITCH -

DESCRIPTION

.......................8N-19

RIGHT POWER SEAT SWITCH -

DIAGNOSIS AND TESTING

.............8N-19

RIGHT POWER SEAT SWITCH -

INSTALLATION

......................8N-20

RIGHT POWER SEAT SWITCH -

OPERATION

.........................8N-19

RIGHT POWER SEAT SWITCH -

REMOVAL

..........................8N-20

RIGHT SIDE - INSTALLATION

........2-12,2-15

RIGHT SIDE - REMOVAL

............2-11,2-14

RING - INSTALLATION, PINION

GEAR/RING GEAR/TONE

...........3-112,3-82RING - REMOVAL, PINION GEAR/RING

GEAR/TONE.....................3-110,3-79

RING FITTING - STANDARD

PROCEDURE, PISTON..................9-52

RISER - INSTALLATION, MANUAL SEAT . . 23-168

RISER - REMOVAL, MANUAL SEAT......23-167

RKE TRANSMITTER BATTERIES -

STANDARD PROCEDURE...............8N-8

RKE TRANSMITTER CUSTOMER

PREFERENCES - STANDARD

PROCEDURE.........................8N-8

RKE TRANSMITTER PROGRAMING -

STANDARD PROCEDURE...............8N-9

ROAD TEST - DIAGNOSIS AND TESTING . . . 8P-2

ROAD TESTING - DIAGNOSIS AND

TESTING...........................21-78

ROCKER ARM - DESCRIPTION.......9-29,9-37

ROCKER ARM - INSTALLATION..........9-37

ROCKER ARM - REMOVAL..............9-37

ROD - DESCRIPTION, PISTON &

CONNECTING.........................9-49

ROD BEARING - FITTING - STANDARD

PROCEDURE, CONNECTING.............9-40

ROD BEARING, FITTING - CONNECTING....9-49

ROD END - INSTALLATION, TIE.........19-16

ROD END - REMOVAL, TIE.............19-16

ROD END REMOVAL TOOL, SPECIAL

TOOLS - OUTER TIE..................19-15

ROTATION - STANDARD PROCEDURE,

TIRE................................22-2

ROTOR - DIAGNOSIS AND TESTING,

DISC BRAKE.........................5-18

ROTOR - STANDARD PROCEDURE, DISC

BRAKE..............................5-19

ROTORS - INSTALLATION...............5-19

ROTORS - REMOVAL..................5-19

ROUTING 3.7L ENGINE - DESCRIPTION,

COOLING SYSTEM.....................7-2

RUN CHANNEL - INSTALLATION, GLASS . 23-123,

23-130

RUN CHANNEL - REMOVAL, GLASS....23-123,

23-130

RUNNING LAMP RELAY - DESCRIPTION,

DAYTIME...........................8L-20

RUNNING LAMP RELAY - INSTALLATION,

DAYTIME...........................8L-21

RUNNING LAMP RELAY - OPERATION,

DAYTIME...........................8L-20

RUNNING LAMP RELAY - REMOVAL,

DAYTIME...........................8L-21

RUNOUT - DIAGNOSIS AND TESTING,

TIRES AND WHEEL....................22-1

SAFETY CERTIFICATION LABEL -

DESCRIPTION, VEHICLE..............Intro.-9

SAFETY PRECAUTIONS AND WARNINGS,

WARNING...........................23-1

SAFETY PRECAUTIONS, WARNING -

WINDSHIELD.......................23-173

SANDING/BUFFING & POLISHING -

DESCRIPTION, FINESSE..............23-163

SCHEDULES - DESCRIPTION,

MAINTENANCE........................0-4

SCHEMATICS AND DIAGRAMS -

HYDRAULIC SCHEMATICS.............21-100

SCHEMATICS, SCHEMATICS AND

DIAGRAMS - HYDRAULIC.............21-100

SCUFF PLATE - INSTALLATION, DOOR

SILL..............................23-157

SCUFF PLATE - INSTALLATION, REAR

DOOR............................23-160

SCUFF PLATE - REMOVAL, DOOR SILL . . . 23-157

SCUFF PLATE - REMOVAL, REAR DOOR . . 23-160

SEAL - FRONT - INSTALLATION,

CRANKSHAFT OIL.....................9-47

SEAL - FRONT - REMOVAL,

CRANKSHAFT OIL.....................9-46

SEAL - INSTALLATION, ADAPTER

HOUSING..........................21-124

SEAL - INSTALLATION, A-PILLAR.......23-185

SEAL - INSTALLATION, COWL/PLENUM . . 23-187

SEAL - INSTALLATION, COWL/PLENUM

WINDOW BAFFLE

...................23-187

SEAL - INSTALLATION, FRONT OUTPUT

SHAFT

......................21-208,21-246

SEAL - INSTALLATION, GLASS PANEL

. . . 23-178

SEAL - INSTALLATION, OIL PUMP

FRONT

............................21-152

SEAL - INSTALLATION, PINION

. . 3-103,3-39,3-68

22 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page