lug pattern JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 92 of 1803

(4) Remove the dial indicator.

(5) Install differential case in the housing. Ensure

differential bearing cups remain on the bearings and

preload shims are seated in the housing. Tap differ-

ential case to ensure bearings cups are seated in the

housing.

(6) Install bearing caps to their original locations

and loosely install cap bolts.

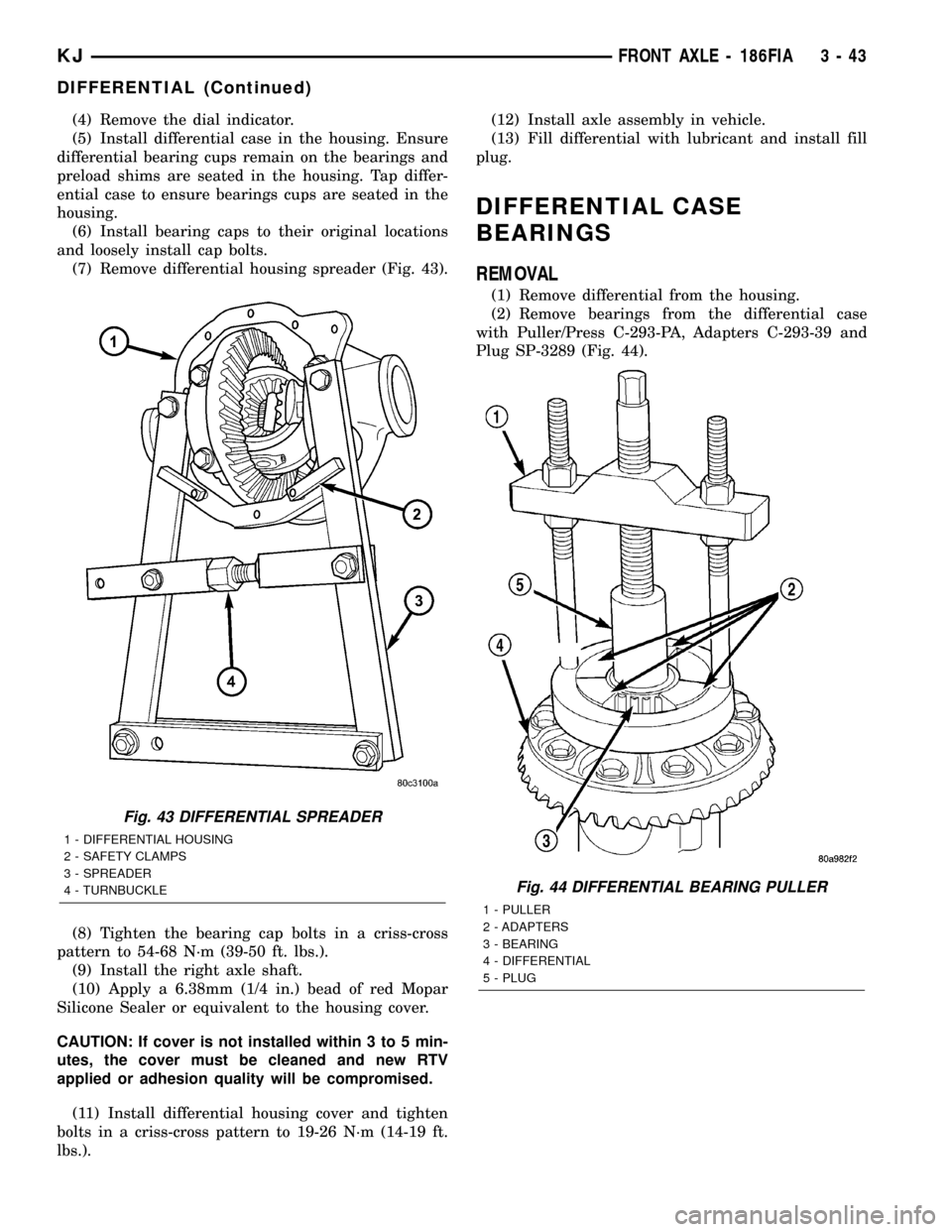

(7) Remove differential housing spreader (Fig. 43).

(8) Tighten the bearing cap bolts in a criss-cross

pattern to 54-68 N´m (39-50 ft. lbs.).

(9) Install the right axle shaft.

(10) Apply a 6.38mm (1/4 in.) bead of red Mopar

Silicone Sealer or equivalent to the housing cover.

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

(11) Install differential housing cover and tighten

bolts in a criss-cross pattern to 19-26 N´m (14-19 ft.

lbs.).(12) Install axle assembly in vehicle.

(13) Fill differential with lubricant and install fill

plug.

DIFFERENTIAL CASE

BEARINGS

REMOVAL

(1) Remove differential from the housing.

(2) Remove bearings from the differential case

with Puller/Press C-293-PA, Adapters C-293-39 and

Plug SP-3289 (Fig. 44).

Fig. 43 DIFFERENTIAL SPREADER

1 - DIFFERENTIAL HOUSING

2 - SAFETY CLAMPS

3 - SPREADER

4 - TURNBUCKLE

Fig. 44 DIFFERENTIAL BEARING PULLER

1 - PULLER

2 - ADAPTERS

3 - BEARING

4 - DIFFERENTIAL

5 - PLUG

KJFRONT AXLE - 186FIA 3 - 43

DIFFERENTIAL (Continued)

Page 123 of 1803

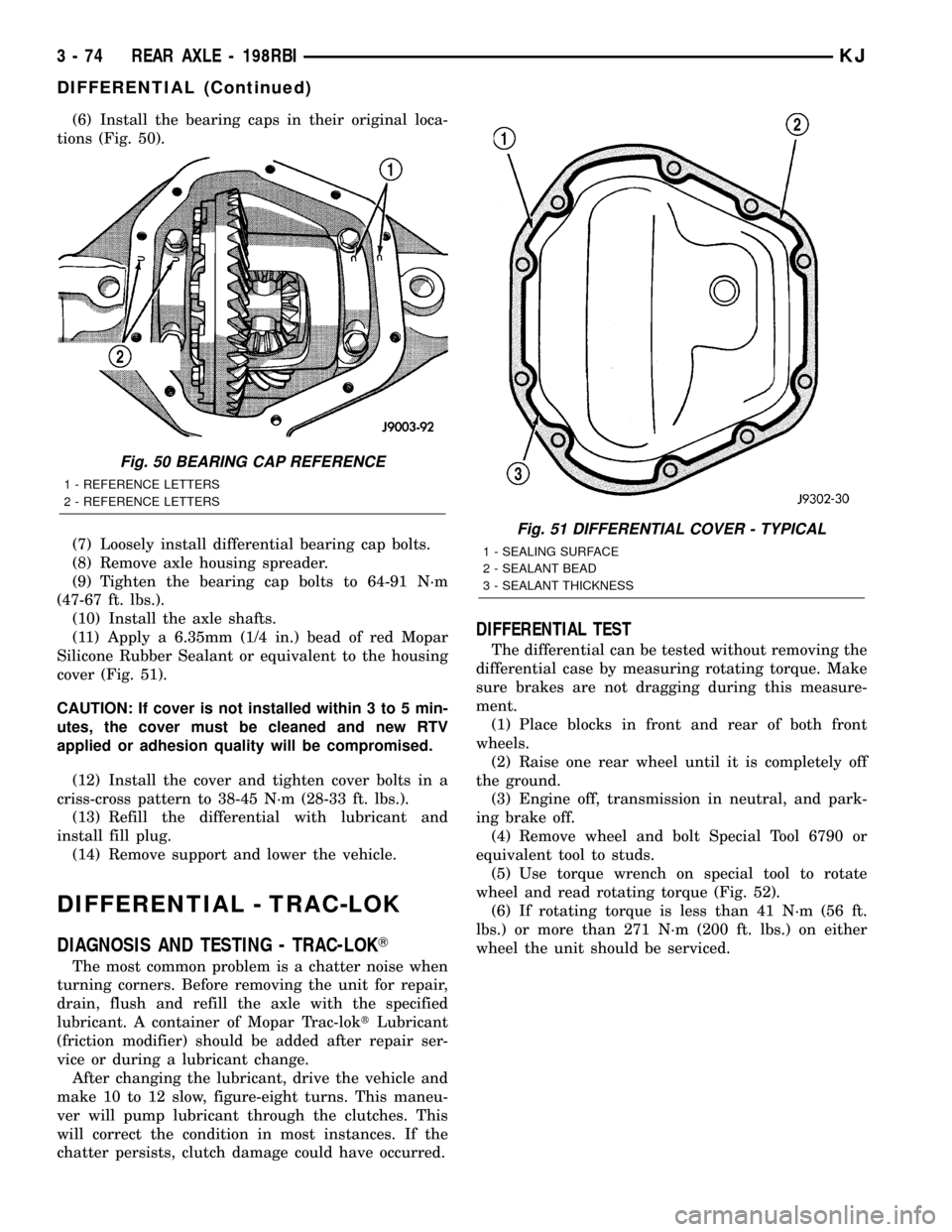

(6) Install the bearing caps in their original loca-

tions (Fig. 50).

(7) Loosely install differential bearing cap bolts.

(8) Remove axle housing spreader.

(9) Tighten the bearing cap bolts to 64-91 N´m

(47-67 ft. lbs.).

(10) Install the axle shafts.

(11) Apply a 6.35mm (1/4 in.) bead of red Mopar

Silicone Rubber Sealant or equivalent to the housing

cover (Fig. 51).

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

(12) Install the cover and tighten cover bolts in a

criss-cross pattern to 38-45 N´m (28-33 ft. lbs.).

(13) Refill the differential with lubricant and

install fill plug.

(14) Remove support and lower the vehicle.

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKT

The most common problem is a chatter noise when

turning corners. Before removing the unit for repair,

drain, flush and refill the axle with the specified

lubricant. A container of Mopar Trac-loktLubricant

(friction modifier) should be added after repair ser-

vice or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 52).

(6) If rotating torque is less than 41 N´m (56 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

Fig. 50 BEARING CAP REFERENCE

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 51 DIFFERENTIAL COVER - TYPICAL

1 - SEALING SURFACE

2 - SEALANT BEAD

3 - SEALANT THICKNESS

3 - 74 REAR AXLE - 198RBIKJ

DIFFERENTIAL (Continued)

Page 155 of 1803

(6) Install adjuster locks on the bearing caps.

(7) Install axle shafts.

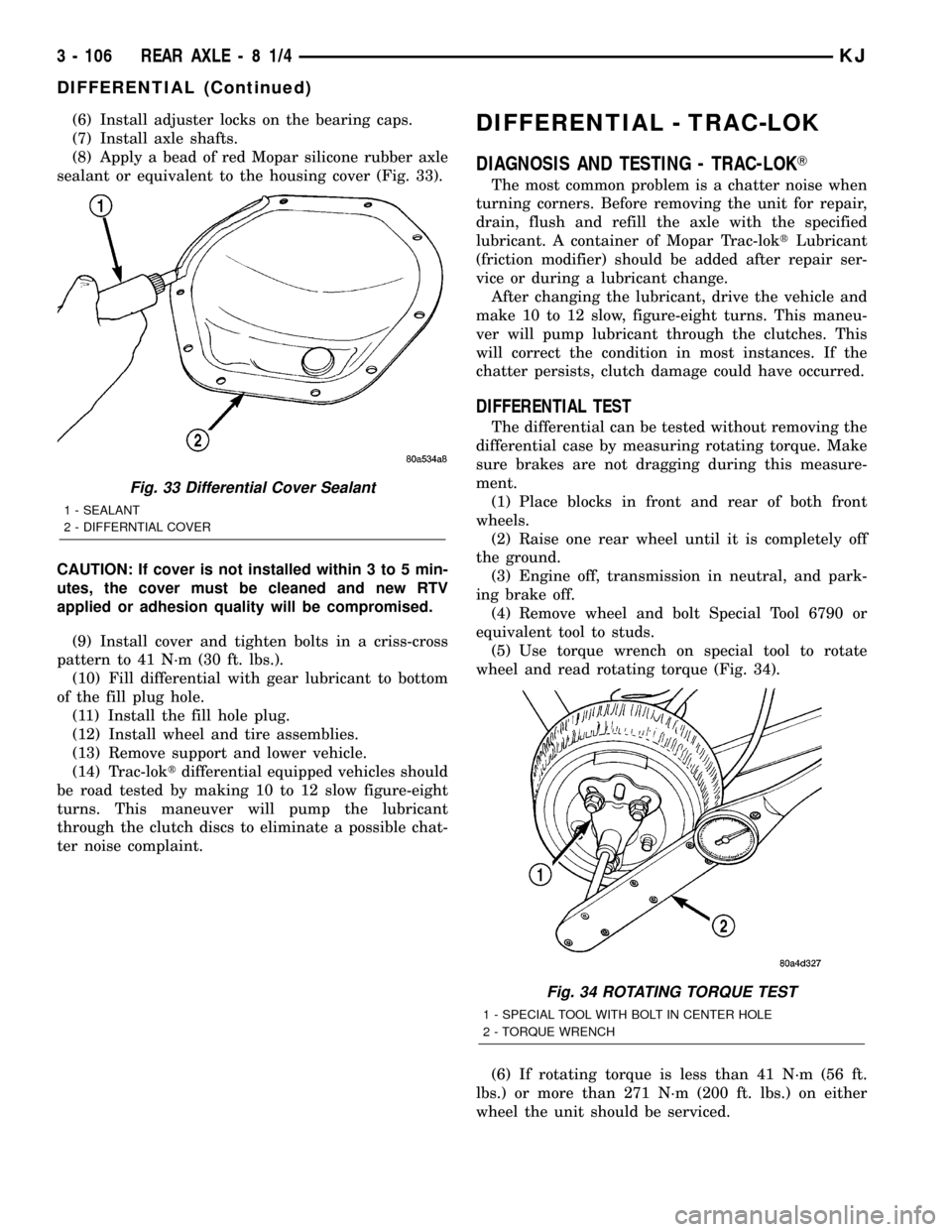

(8) Apply a bead of red Mopar silicone rubber axle

sealant or equivalent to the housing cover (Fig. 33).

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

(9) Install cover and tighten bolts in a criss-cross

pattern to 41 N´m (30 ft. lbs.).

(10) Fill differential with gear lubricant to bottom

of the fill plug hole.

(11) Install the fill hole plug.

(12) Install wheel and tire assemblies.

(13) Remove support and lower vehicle.

(14) Trac-loktdifferential equipped vehicles should

be road tested by making 10 to 12 slow figure-eight

turns. This maneuver will pump the lubricant

through the clutch discs to eliminate a possible chat-

ter noise complaint.DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKT

The most common problem is a chatter noise when

turning corners. Before removing the unit for repair,

drain, flush and refill the axle with the specified

lubricant. A container of Mopar Trac-loktLubricant

(friction modifier) should be added after repair ser-

vice or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 34).

(6) If rotating torque is less than 41 N´m (56 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

Fig. 33 Differential Cover Sealant

1 - SEALANT

2 - DIFFERNTIAL COVER

Fig. 34 ROTATING TORQUE TEST

1 - SPECIAL TOOL WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

3 - 106 REAR AXLE-81/4KJ

DIFFERENTIAL (Continued)

Page 485 of 1803

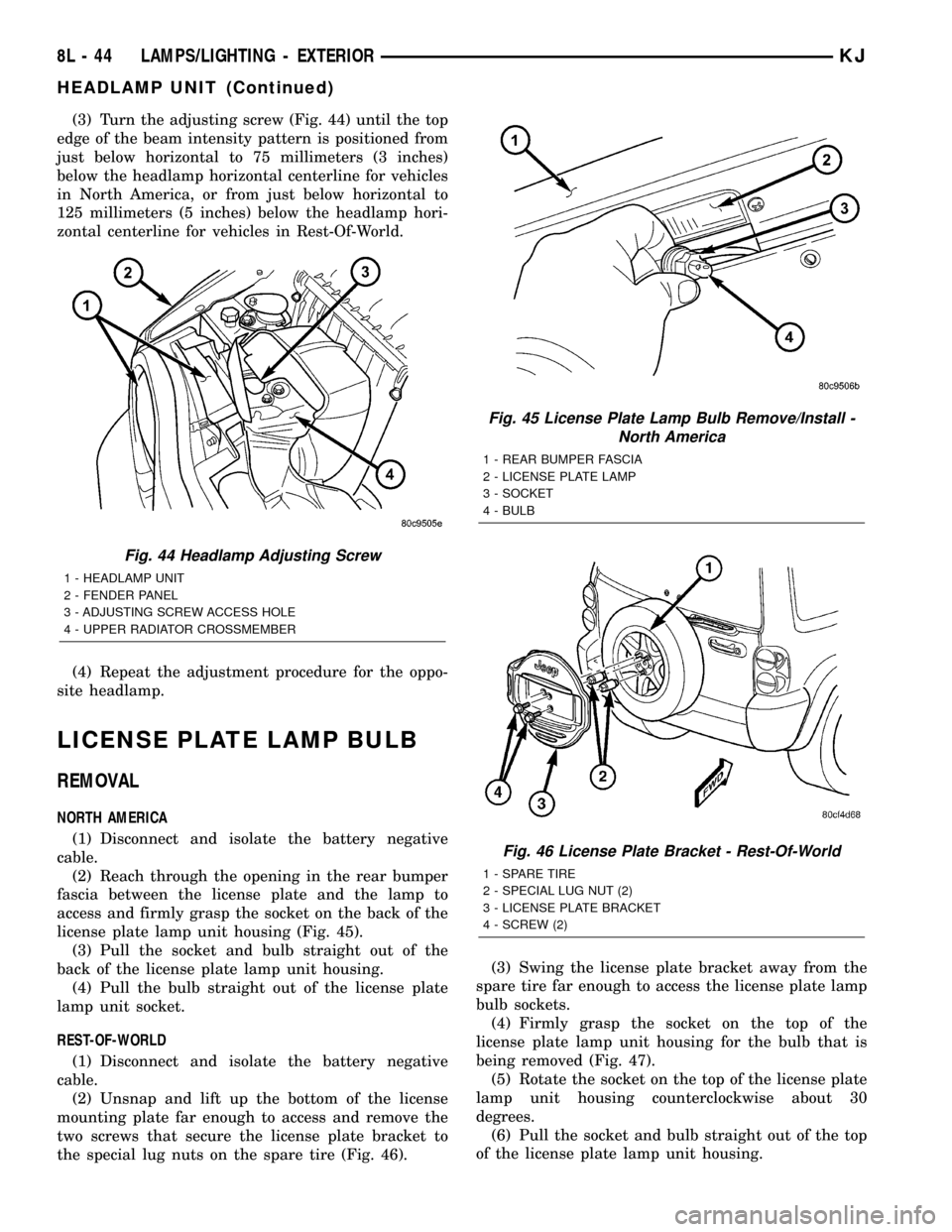

(3) Turn the adjusting screw (Fig. 44) until the top

edge of the beam intensity pattern is positioned from

just below horizontal to 75 millimeters (3 inches)

below the headlamp horizontal centerline for vehicles

in North America, or from just below horizontal to

125 millimeters (5 inches) below the headlamp hori-

zontal centerline for vehicles in Rest-Of-World.

(4) Repeat the adjustment procedure for the oppo-

site headlamp.

LICENSE PLATE LAMP BULB

REMOVAL

NORTH AMERICA

(1) Disconnect and isolate the battery negative

cable.

(2) Reach through the opening in the rear bumper

fascia between the license plate and the lamp to

access and firmly grasp the socket on the back of the

license plate lamp unit housing (Fig. 45).

(3) Pull the socket and bulb straight out of the

back of the license plate lamp unit housing.

(4) Pull the bulb straight out of the license plate

lamp unit socket.

REST-OF-WORLD

(1) Disconnect and isolate the battery negative

cable.

(2) Unsnap and lift up the bottom of the license

mounting plate far enough to access and remove the

two screws that secure the license plate bracket to

the special lug nuts on the spare tire (Fig. 46).(3) Swing the license plate bracket away from the

spare tire far enough to access the license plate lamp

bulb sockets.

(4) Firmly grasp the socket on the top of the

license plate lamp unit housing for the bulb that is

being removed (Fig. 47).

(5) Rotate the socket on the top of the license plate

lamp unit housing counterclockwise about 30

degrees.

(6) Pull the socket and bulb straight out of the top

of the license plate lamp unit housing.

Fig. 44 Headlamp Adjusting Screw

1 - HEADLAMP UNIT

2 - FENDER PANEL

3 - ADJUSTING SCREW ACCESS HOLE

4 - UPPER RADIATOR CROSSMEMBER

Fig. 45 License Plate Lamp Bulb Remove/Install -

North America

1 - REAR BUMPER FASCIA

2 - LICENSE PLATE LAMP

3 - SOCKET

4 - BULB

Fig. 46 License Plate Bracket - Rest-Of-World

1 - SPARE TIRE

2 - SPECIAL LUG NUT (2)

3 - LICENSE PLATE BRACKET

4 - SCREW (2)

8L - 44 LAMPS/LIGHTING - EXTERIORKJ

HEADLAMP UNIT (Continued)

Page 708 of 1803

ity of the headlamp and dash wire harness connector

for the washer pump/motor unit and a good ground.

There should be no continuity. If OK, go to Step 4. If

not OK, repair the shorted washer pump driver cir-

cuit between the washer pump/motor unit and the

multi-function switch as required.

(4) Check for continuity between the washer pump

driver circuit cavities of the headlamp and dash wire

harness connector for the washer pump/motor unit

and the instrument panel wire harness connector for

the multi-function switch (Connector C-2). There

should be continuity. If OK, go to Step 5. If not OK,

repair the open washer pump driver circuit between

the washer pump/motor unit and the multi-function

switch as required.

(5) Check for continuity between the washer pump

sense circuit cavity of the headlamp and dash wire

harness connector for the washer pump/motor unit

and a good ground. There should be no continuity. If

OK, go to Step 6. If not OK, repair the shorted

washer pump sense circuit between the washer

pump/motor unit and the multi-function switch as

required.

(6) Check for continuity between the washer pump

sense circuit cavities of the headlamp and dash wire

harness connector for the washer pump/motor unit

and the instrument panel wire harness connector for

the multi-function switch (Connector C-2). There

should be continuity. If OK, replace the faulty washer

pump/motor unit. If not OK, repair the open washer

pump sense circuit between the washer pump/motor

unit and the multi-function switch as required.

CLEANING - FRONT WIPER & WASHER

SYSTEM

FRONT WIPER SYSTEM

The squeegees of wiper blades exposed to the ele-

ments for a long time tend to lose their wiping effec-

tiveness. Periodic cleaning of the squeegees is

suggested to remove any deposits of salt or road film.

The wiper blades, arms, and windshield glass should

only be cleaned using a sponge or soft cloth and

windshield washer fluid, a mild detergent, or a non-

abrasive cleaner. If the wiper blades continue to

leave streaks, smears, hazing, or beading on the

glass after thorough cleaning of the squeegees and

the glass, the entire wiper blade assembly must be

replaced.

CAUTION: Protect the rubber squeegees of the

wiper blades from any petroleum-based cleaners,

solvents, or contaminants. These products can rap-

idly deteriorate the rubber squeegees.FRONT WASHER SYSTEM

If the washer system is contaminated with foreign

material, drain the washer reservoir by removing the

washer pump/motor from the reservoir. Clean foreign

material from the inside of the washer pump/motor

inlet filter screen and the washer reservoir using

clean washer fluid, a mild detergent, or a non-abra-

sive cleaner. Flush foreign material from the washer

system plumbing by first disconnecting the washer

hoses from the washer nozzles, then running the

washer pump/motor to run clean washer fluid or

water through the system. Plugged or restricted

washer nozzles should be carefully back-flushed

using compressed air. If the washer nozzle obstruc-

tion cannot be cleared, replace the washer nozzle.

CAUTION: Never introduce petroleum-based clean-

ers, solvents, or contaminants into the washer sys-

tem. These products can rapidly deteriorate the

rubber seals and hoses of the washer system, as

well as the rubber squeegees of the wiper blades.

CAUTION: Never use compressed air to flush the

washer system plumbing. Compressed air pres-

sures are too great for the washer system plumbing

components and will result in further system dam-

age. Never use sharp instruments to clear a

plugged washer nozzle or damage to the nozzle ori-

fice and improper nozzle spray patterns will result.

INSPECTION - FRONT WIPER & WASHER

SYSTEM

FRONT WIPER SYSTEM

The front wiper blades and wiper arms should be

inspected periodically, not just when wiper perfor-

mance problems are experienced. This inspection

should include the following points:

(1) Inspect the wiper arms for any indications of

damage, or contamination. If the wiper arms are con-

taminated with any foreign material, clean them as

required. (Refer to 8 - ELECTRICAL/FRONT WIP-

ERS/WASHERS - CLEANING). If a wiper arm is

damaged or corrosion is evident, replace the wiper

arm with a new unit. Do not attempt to repair a

wiper arm that is damaged or corroded.

(2) Carefully lift the wiper blade off of the glass.

Note the action of the wiper arm hinge. The wiper

arm should pivot freely at the hinge, but with no lat-

eral looseness evident. If there is any binding evident

in the wiper arm hinge, or there is evident lateral

play in the wiper arm hinge, replace the wiper arm.

KJFRONT WIPERS/WASHERS 8R - 7

FRONT WIPERS/WASHERS (Continued)

Page 734 of 1803

REAR WASHER SYSTEM

If the washer system is contaminated with foreign

material, drain the washer reservoir by removing the

washer pump/motor from the reservoir. Clean foreign

material from the inside of the washer pump/motor

inlet filter screen and the washer reservoir using

clean washer fluid, a mild detergent, or a non-abra-

sive cleaner. Flush foreign material from the washer

system plumbing by first disconnecting the washer

hose from the washer nozzle, then running the

washer pump/motor to run clean washer fluid or

water through the system. A plugged or restricted

washer nozzle should be carefully back-flushed using

compressed air. If the washer nozzle obstruction can-

not be cleared, replace the washer nozzle.

CAUTION: Never introduce petroleum-based clean-

ers, solvents, or contaminants into the washer sys-

tem. These products can rapidly deteriorate the

rubber seals and hoses of the washer system, as

well as the rubber squeegee of the wiper blade.

CAUTION: Never use compressed air to flush the

washer system plumbing. Compressed air pres-

sures are too great for the washer system plumbing

components and will result in further system dam-

age. Never use sharp instruments to clear a

plugged washer nozzle or damage to the nozzle ori-

fice and improper nozzle spray patterns will result.

INSPECTION - REAR WIPER & WASHER

SYSTEM

REAR WIPER SYSTEM

The rear wiper blade and wiper arm should be

inspected periodically, not just when wiper perfor-

mance problems are experienced. This inspection

should include the following points:

(1) Inspect the wiper arm for any indications of

damage, or contamination. If the wiper arm is con-

taminated with any foreign material, clean as

required. (Refer to 8 - ELECTRICAL/REAR WIPERS/

WASHERS - CLEANING). If a wiper arm is damaged

or corrosion is evident, replace the wiper arm with a

new unit. Do not attempt to repair a wiper arm that

is damaged or corroded.

(2) Carefully lift the wiper arm off of the park

ramp. Note the action of the wiper arm hinge. The

wiper arm should pivot freely at the hinge, but with

no lateral looseness evident. If there is any binding

evident in the wiper arm hinge, or there is evident

lateral play in the wiper arm hinge, replace the

wiper arm.CAUTION: Do not allow the wiper arm to spring

back against the glass without the wiper blade in

place or the glass may be damaged.

(3) Once proper hinge action of the wiper arm is

confirmed, check the hinge for proper spring tension.

The spring tension of the wiper arm should be suffi-

cient to cause the rubber squeegee to conform to the

curvature of the glass. Replace a wiper arm if it has

low or no spring tension.

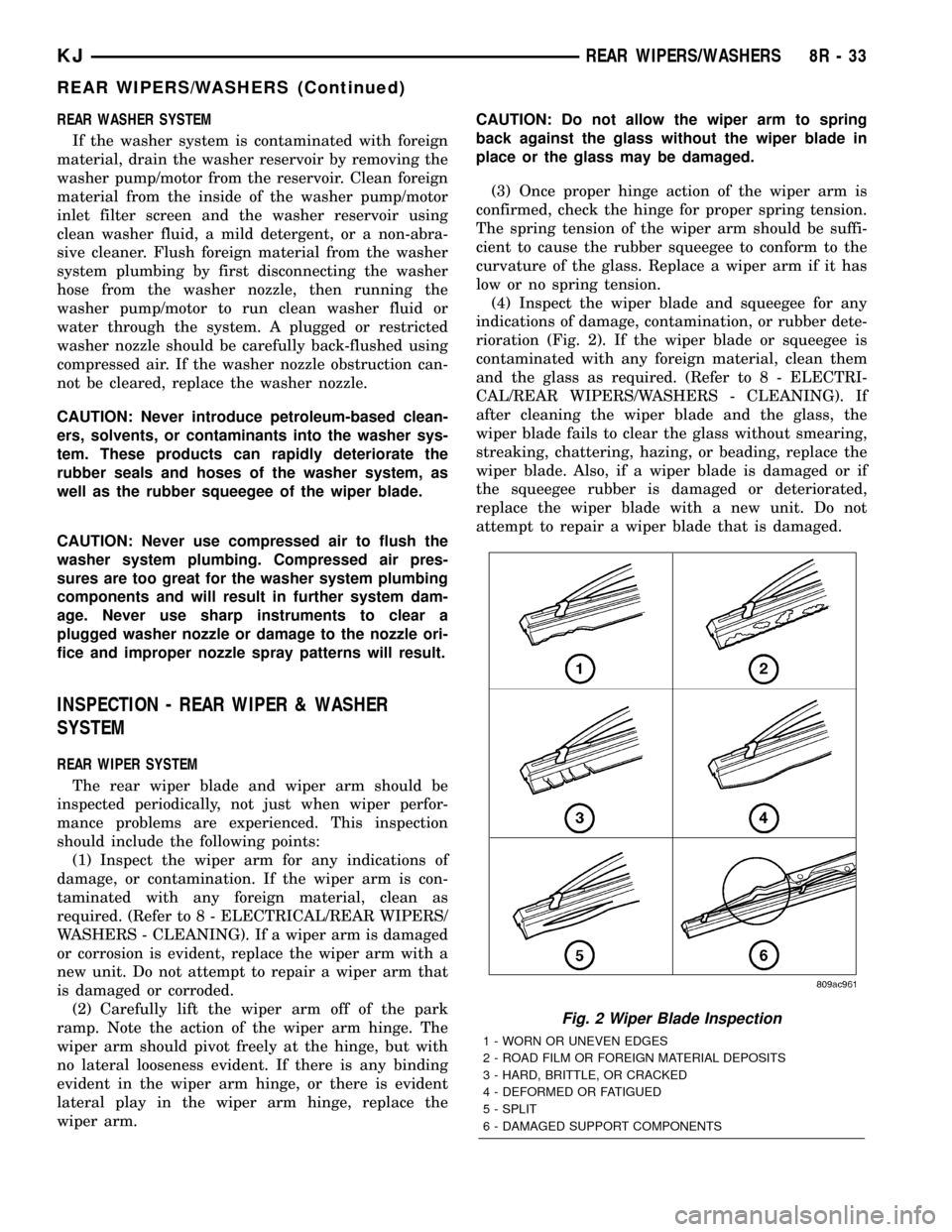

(4) Inspect the wiper blade and squeegee for any

indications of damage, contamination, or rubber dete-

rioration (Fig. 2). If the wiper blade or squeegee is

contaminated with any foreign material, clean them

and the glass as required. (Refer to 8 - ELECTRI-

CAL/REAR WIPERS/WASHERS - CLEANING). If

after cleaning the wiper blade and the glass, the

wiper blade fails to clear the glass without smearing,

streaking, chattering, hazing, or beading, replace the

wiper blade. Also, if a wiper blade is damaged or if

the squeegee rubber is damaged or deteriorated,

replace the wiper blade with a new unit. Do not

attempt to repair a wiper blade that is damaged.

Fig. 2 Wiper Blade Inspection

1 - WORN OR UNEVEN EDGES

2 - ROAD FILM OR FOREIGN MATERIAL DEPOSITS

3 - HARD, BRITTLE, OR CRACKED

4 - DEFORMED OR FATIGUED

5 - SPLIT

6 - DAMAGED SUPPORT COMPONENTS

KJREAR WIPERS/WASHERS 8R - 33

REAR WIPERS/WASHERS (Continued)

Page 1255 of 1803

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the plugs to 34 N´m (25 ft. lbs.) torque.

INSPECTION

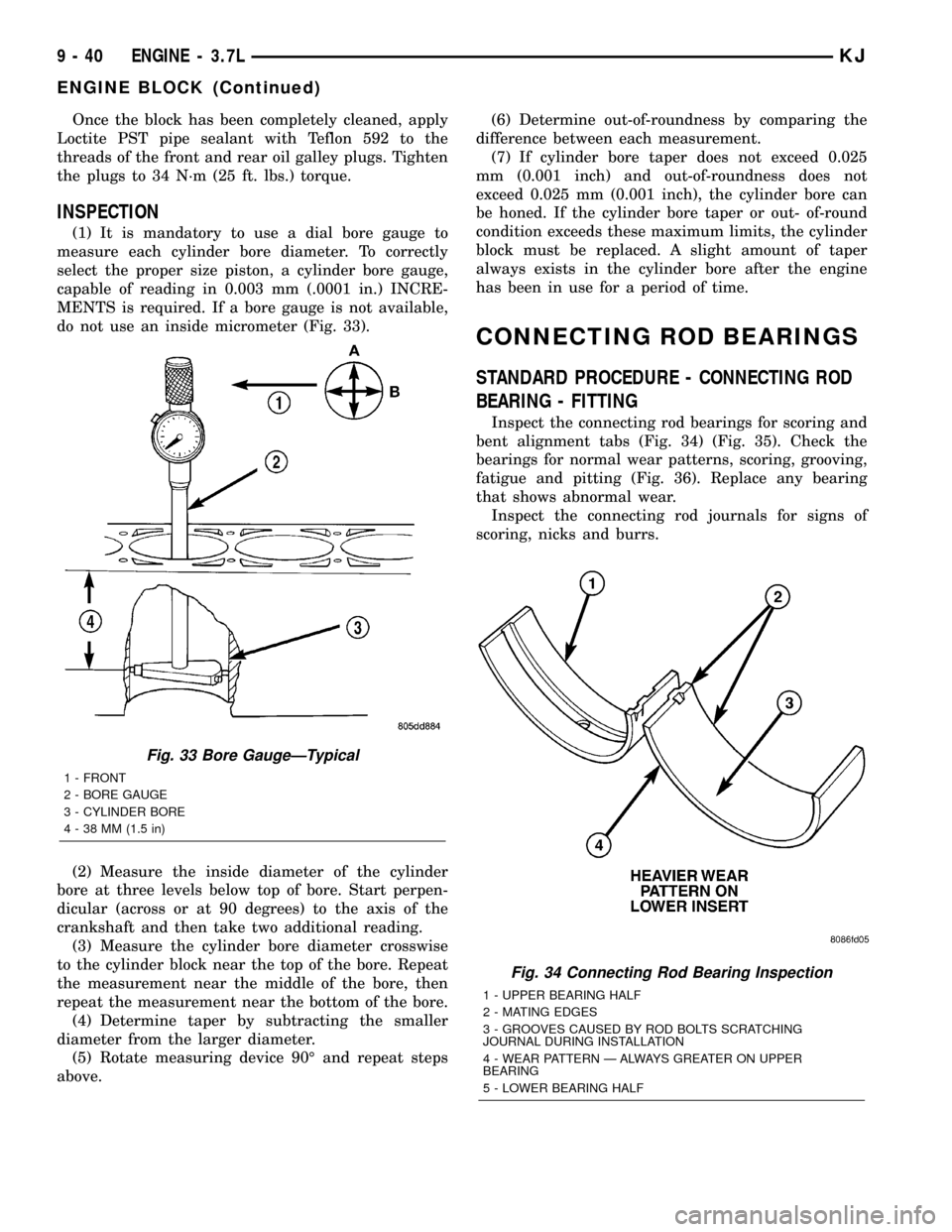

(1) It is mandatory to use a dial bore gauge to

measure each cylinder bore diameter. To correctly

select the proper size piston, a cylinder bore gauge,

capable of reading in 0.003 mm (.0001 in.) INCRE-

MENTS is required. If a bore gauge is not available,

do not use an inside micrometer (Fig. 33).

(2) Measure the inside diameter of the cylinder

bore at three levels below top of bore. Start perpen-

dicular (across or at 90 degrees) to the axis of the

crankshaft and then take two additional reading.

(3) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the bore.

(4) Determine taper by subtracting the smaller

diameter from the larger diameter.

(5) Rotate measuring device 90É and repeat steps

above.(6) Determine out-of-roundness by comparing the

difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025

mm (0.001 inch) and out-of-roundness does not

exceed 0.025 mm (0.001 inch), the cylinder bore can

be honed. If the cylinder bore taper or out- of-round

condition exceeds these maximum limits, the cylinder

block must be replaced. A slight amount of taper

always exists in the cylinder bore after the engine

has been in use for a period of time.

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING ROD

BEARING - FITTING

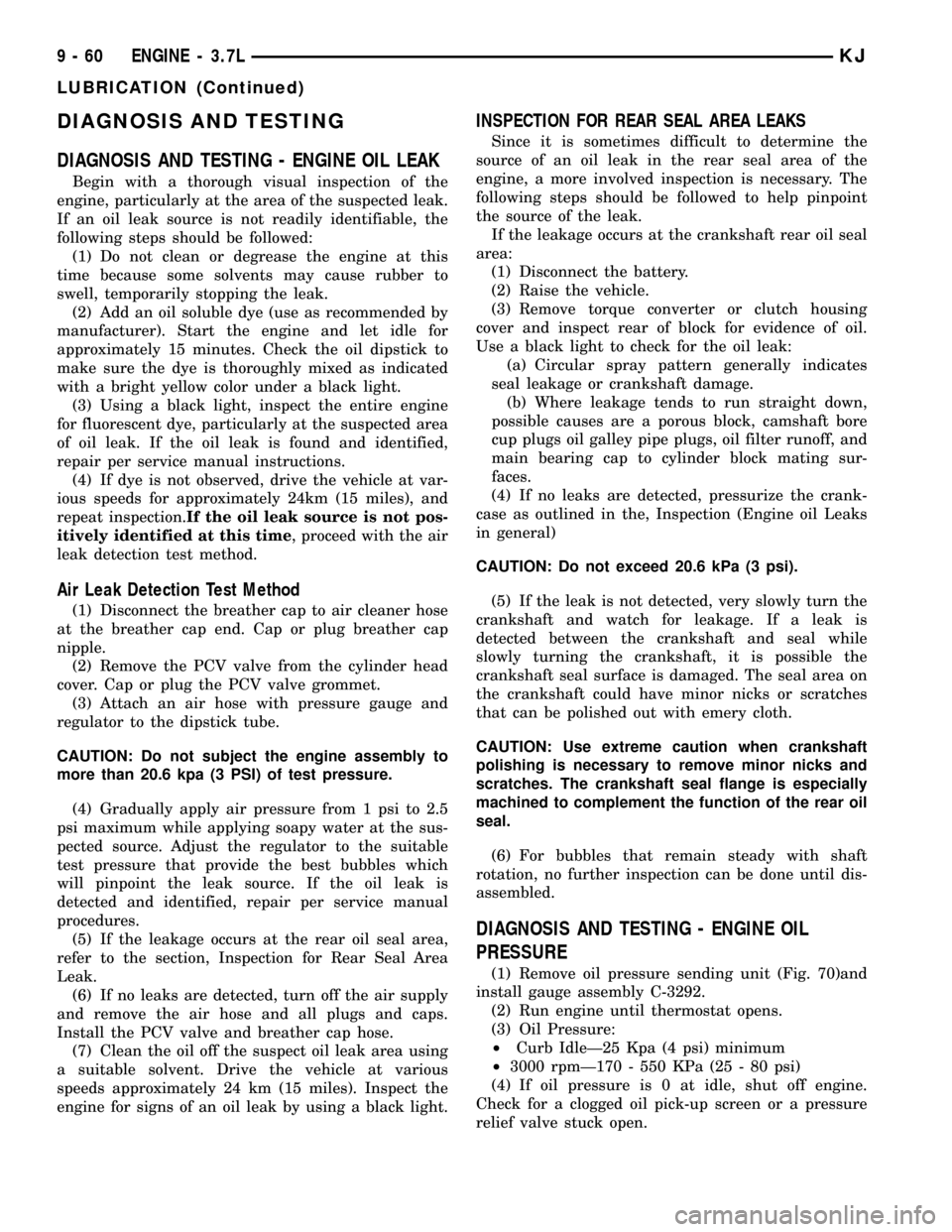

Inspect the connecting rod bearings for scoring and

bent alignment tabs (Fig. 34) (Fig. 35). Check the

bearings for normal wear patterns, scoring, grooving,

fatigue and pitting (Fig. 36). Replace any bearing

that shows abnormal wear.

Inspect the connecting rod journals for signs of

scoring, nicks and burrs.

Fig. 33 Bore GaugeÐTypical

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 38 MM (1.5 in)

Fig. 34 Connecting Rod Bearing Inspection

1 - UPPER BEARING HALF

2 - MATING EDGES

3 - GROOVES CAUSED BY ROD BOLTS SCRATCHING

JOURNAL DURING INSTALLATION

4 - WEAR PATTERN Ð ALWAYS GREATER ON UPPER

BEARING

5 - LOWER BEARING HALF

9 - 40 ENGINE - 3.7LKJ

ENGINE BLOCK (Continued)

Page 1275 of 1803

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat inspection.If the oil leak source is not pos-

itively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, camshaft bore

cup plugs oil galley pipe plugs, oil filter runoff, and

main bearing cap to cylinder block mating sur-

faces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE

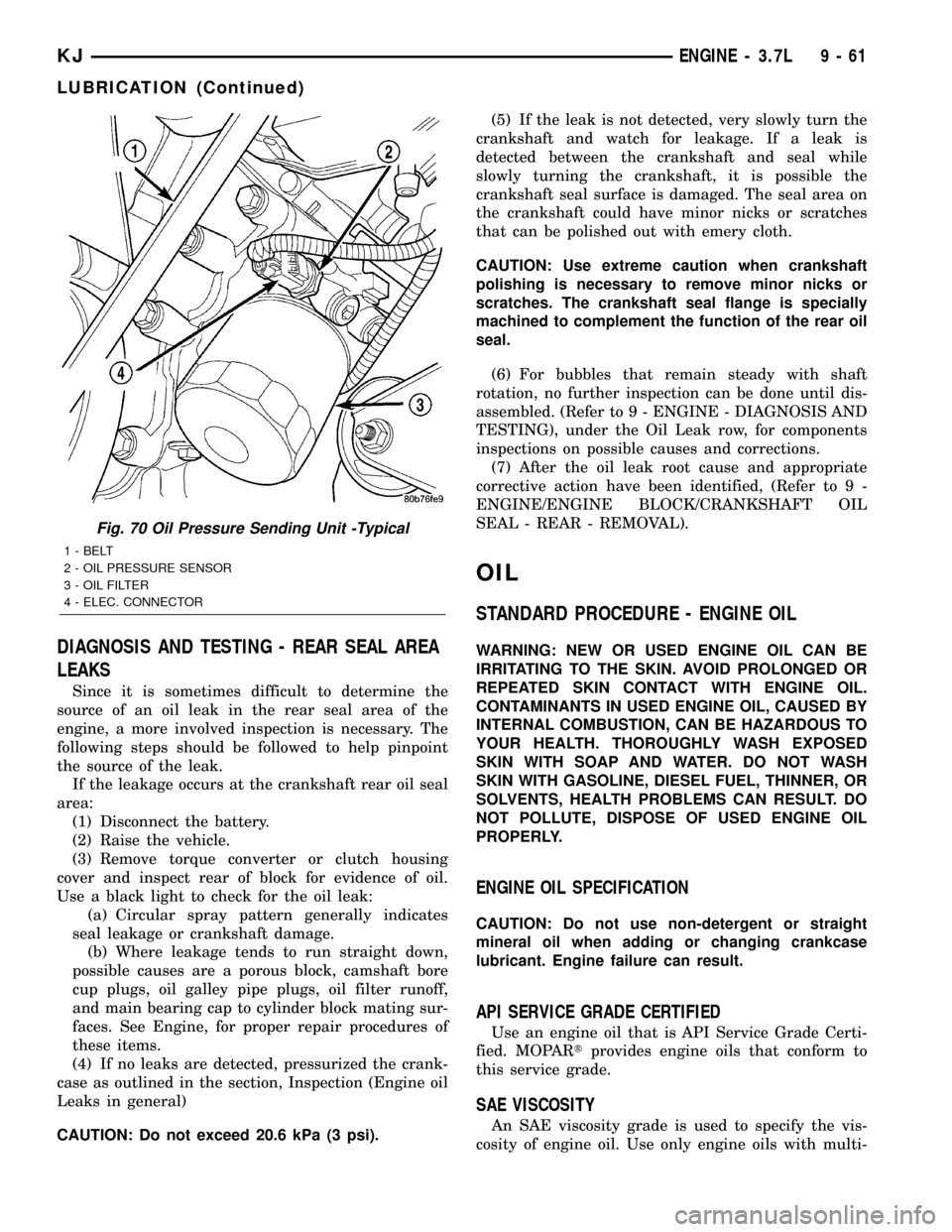

(1) Remove oil pressure sending unit (Fig. 70)and

install gauge assembly C-3292.

(2) Run engine until thermostat opens.

(3) Oil Pressure:

²Curb IdleÐ25 Kpa (4 psi) minimum

²3000 rpmÐ170 - 550 KPa (25 - 80 psi)

(4) If oil pressure is 0 at idle, shut off engine.

Check for a clogged oil pick-up screen or a pressure

relief valve stuck open.

9 - 60 ENGINE - 3.7LKJ

LUBRICATION (Continued)

Page 1276 of 1803

DIAGNOSIS AND TESTING - REAR SEAL AREA

LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, camshaft bore

cup plugs, oil galley pipe plugs, oil filter runoff,

and main bearing cap to cylinder block mating sur-

faces. See Engine, for proper repair procedures of

these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the section, Inspection (Engine oil

Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. (Refer to 9 - ENGINE - DIAGNOSIS AND

TESTING), under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

OIL

STANDARD PROCEDURE - ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conform to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

Fig. 70 Oil Pressure Sending Unit -Typical

1 - BELT

2 - OIL PRESSURE SENSOR

3 - OIL FILTER

4 - ELEC. CONNECTOR

KJENGINE - 3.7L 9 - 61

LUBRICATION (Continued)

Page 1301 of 1803

(7) Crank engine until maximum pressure is

reached on gage. Record this pressure as #1 cylinder

pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

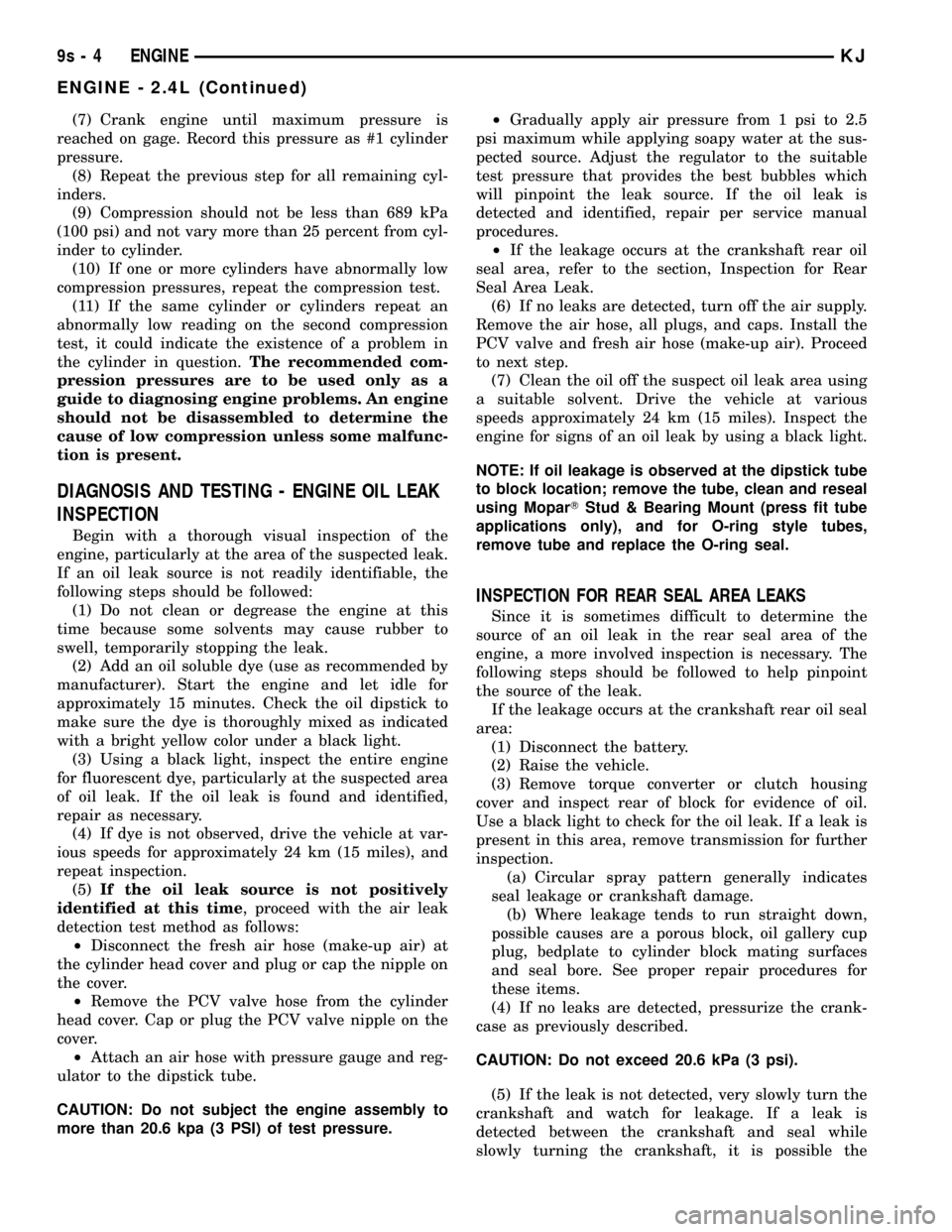

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair as necessary.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

²Disconnect the fresh air hose (make-up air) at

the cylinder head cover and plug or cap the nipple on

the cover.

²Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve nipple on the

cover.

²Attach an air hose with pressure gauge and reg-

ulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.²Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provides the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

²If the leakage occurs at the crankshaft rear oil

seal area, refer to the section, Inspection for Rear

Seal Area Leak.

(6) If no leaks are detected, turn off the air supply.

Remove the air hose, all plugs, and caps. Install the

PCV valve and fresh air hose (make-up air). Proceed

to next step.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

NOTE: If oil leakage is observed at the dipstick tube

to block location; remove the tube, clean and reseal

using MoparTStud & Bearing Mount (press fit tube

applications only), and for O-ring style tubes,

remove tube and replace the O-ring seal.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

9s - 4 ENGINEKJ

ENGINE - 2.4L (Continued)