tire size JEEP LIBERTY 2004 KJ / 1.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2004, Model line: LIBERTY, Model: JEEP LIBERTY 2004 KJ / 1.GPages: 374, PDF Size: 5.71 MB

Page 223 of 374

CAUTION!

²Do not attempt to make a shift while only the

front or rear wheels are spinning. The Command-

Trac transfer case is not equipped with a synchro-

nizer and therefore the front and rear driveshaft

speeds must be equal for the shift to take place.

Shifting while only the front or rear wheels are

spinning can cause damage to the transfer case.

²When operating your vehicle in 4L, the engine

speed is approximately three times that of the 2H

or 4H positions at a given road speed. Take care

not to overspeed the engine and do not exceed 25

mph (40 km/h).

Proper operation of 4-wheel drive vehicles depends on

tires of equal size, type and circumference on each wheel.

Any difference will adversely affect shifting and can

cause damage to the transfer case.

STARTING AND OPERATING 223

5

Page 228 of 374

Proper operation of 4-wheel drive vehicles depends on

tires of equal size, type, and circumference on each

wheel. Any difference will adversely affect shifting and

can cause damage to the transfer case.WARNING!

²Because 4-wheel drive provides improved trac-

tion, there is a tendency to exceed safe turning and

stopping speeds. Do not go faster than road con-

ditions permit.

²You or others could be injured if you leave the

vehicle unattended with the transfer case in the

Neutral (N) position without first fully engaging

the parking brake. The transfer case Neutral (N)

position disengages both the front and rear drive-

shafts from the powertrain and will allow the

vehicle to move regardless of the transmission

position. The parking brake should always be

applied when the driver is not in the vehicle.

228 STARTING AND OPERATING

Page 234 of 374

ANTI-LOCK BRAKE SYSTEM Ð IF EQUIPPED

The Anti-Lock Brake System is designed to aid the driver

in maintaining vehicle control under adverse braking

conditions. The system operates with a separate com-

puter to modulate hydraulic pressure to prevent wheel

lock-up and help avoid skidding on slippery surfaces.

All vehicle wheels and tires must be the same size and

type and tires must be properly inflated to produce

accurate signals for the computer.

WARNING!

Significant over or under-inflation of tires, or mixing

sizes of tires or wheels on the vehicle can lead to loss

of braking effectiveness.

The Anti-Lock Brake System conducts a low speed self-

test at about 12 mph (20 km/h). If for any reason, your

foot is on the brake when the vehicle reaches 12 mph (20

km/h), this check will be delayed until 25 mph (40

km/h).

The Anti-Lock Brake System pump motor runs during

the self-test and during an ABS stop to provide the

regulated hydraulic pressure. The motor pump makes a

low humming noise during operation, this is normal.

During off-road use, loss of traction can temporarily

defeat the system and cause the warning light to illumi-

nate. Turn the ignition OFF and ON again to restore

Anti-Lock Brake System function.

234 STARTING AND OPERATING

Page 239 of 374

²After extended operation in mud, sand, water, or

similar dirty conditions, have brake rotors, wheels,

brake linings, and axle yokes inspected and cleaned as

soon as possible.

WARNING!

Abrasive material in any part of the brakes may

cause excessive wear or unpredictable braking. You

might not have full braking power when you need it

to prevent an accident. If you have been operating

your vehicle in dirty conditions, get your brakes

checked and cleaned as necessary.

²If you experience unusual vibration after driving in

mud, slush or similar conditions, check the wheels for

impacted material. Impacted material can cause a

wheel imbalance and freeing the wheels of it will

correct the situation.

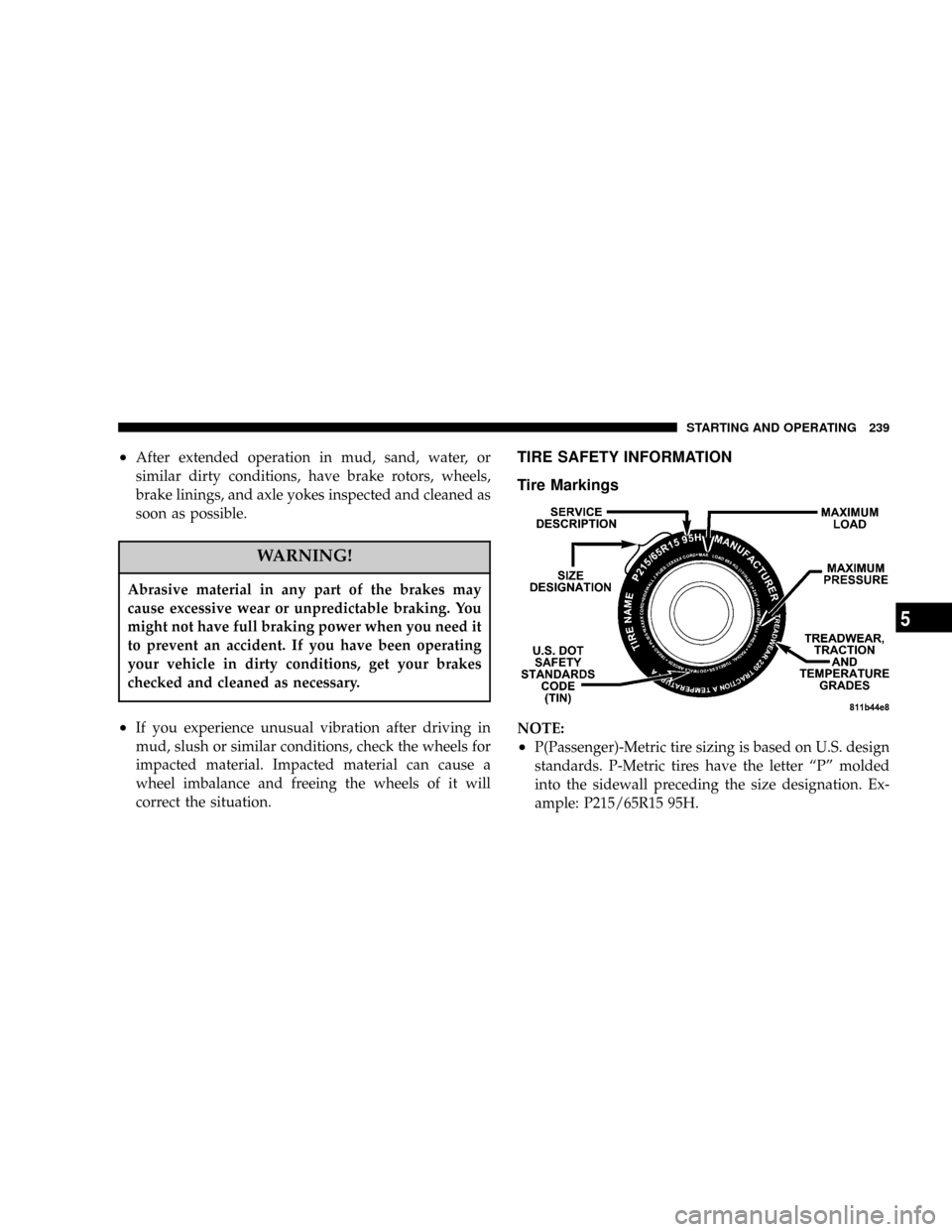

TIRE SAFETY INFORMATION

Tire Markings

NOTE:

²P(Passenger)-Metric tire sizing is based on U.S. design

standards. P-Metric tires have the letter ªPº molded

into the sidewall preceding the size designation. Ex-

ample: P215/65R15 95H.

STARTING AND OPERATING 239

5

Page 240 of 374

²European Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with

the section width. The letter9P9is absent from this tire

size designation. Example: 215/65R15 96H

²LT(Light Truck)-Metric tire sizing is based on U.S.

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters ªLTº that are molded into the sidewall preced-

ing the size designation. Example: LT235/85R16.

²Temporary Spare tires are high pressure compact

spares designed for temporary emergency use only.

Tires designed to this standard have the letter ªTº

molded into the sidewall preceding the size designa-

tion. Example: T145/80D18 103M.

²High Flotation tire sizing is based on U.S. design

standards and begins with the tire diameter molded

into the sidewall. Example: 31x10.5 R15 LT.

240 STARTING AND OPERATING

Page 241 of 374

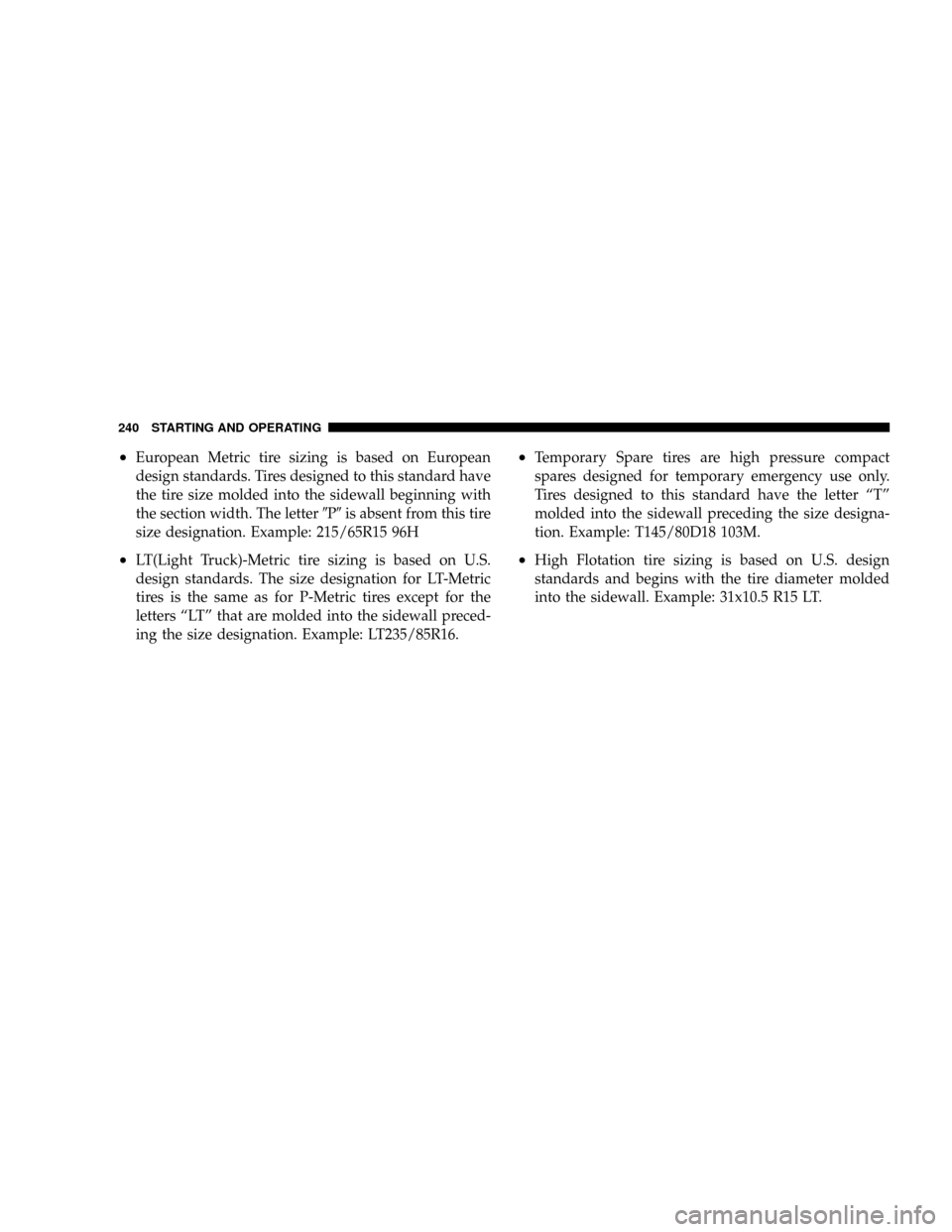

Tire Sizing Chart

EXAMPLE:

Size Designation:

P= Passenger car tire size based on U.S. design standards

(....blank....(= Passenger car tire based on European design standards

LT= Light Truck tire based on U.S. design standards

T= Temporary Spare tire

31= Overall Diameter in Inches (in)

215= Section Width in Milimeters (mm)

65= Aspect Ratio in Percent (%)

ÐRatio of section height to section width of tire.

10.5= Section Width in Inches (in)

R= Construction Code

Ð9R9means Radial Construction.

Ð9D9means Diagonal or Bias Construction.

15= Rim Diameter in Inches (in)

STARTING AND OPERATING 241

5

Page 243 of 374

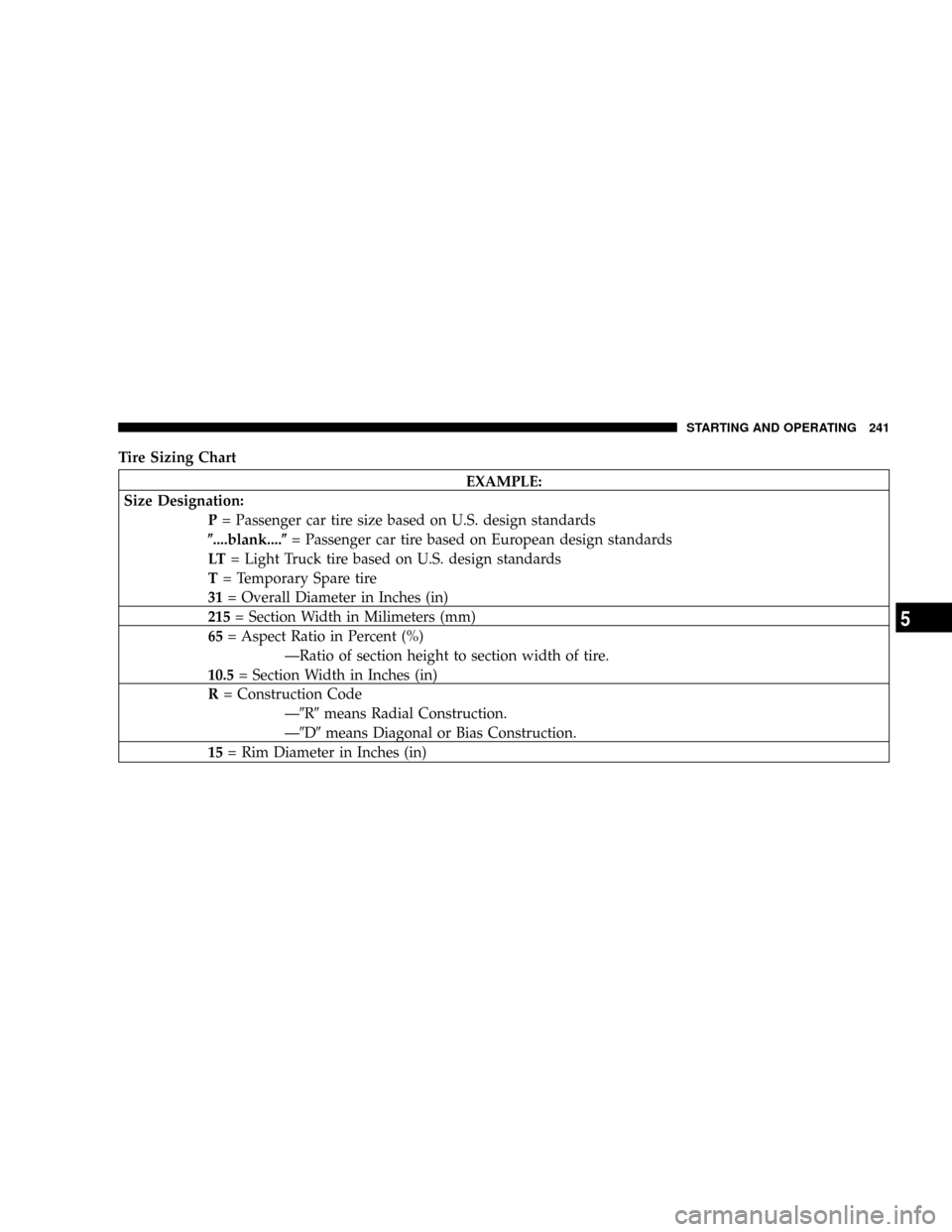

Tire Identification Number (TIN)

The TIN may be found on one or both sides of the tire

however the date code may only be on one side. Tires

with white sidewalls will have the full TIN including

date code located on the white sidewall side of the tire.Look for the TIN on the outboard side of black sidewall

tires as mounted on the vehicle. If the TIN is not found on

the outboard side then you will find it on the inboard side

of the tire.

EXAMPLE:

DOT MA L9 ABCD 0301

DOT= Department of Transportation

ÐThis symbol certifies that the tire is in compliance with the U.S. Department of Transportation tire

safety standards, and is approved for highway use.

MA= Code representing the tire manufacturing location.(2 digits)

L9= Code representing the tire size.(2 digits)

ABCD= Code used by tire manufacturer.(1 to 4 digits)

03= Number representing the week in which the tire was manufactured.(2 digits)

Ð03 means the 3rd week.

01= Number representing the year in which the tire was manufactured.(2 digits)

Ð01 means the year 2001.

ÐPrior to July 2000, tire manufacturers were only required to have 1 number to represent the year in

which the tire was manufactured. Example: 031 could represent the 3rd week of 1981 or 1991.

STARTING AND OPERATING 243

5

Page 244 of 374

Tire Loading and Tire Pressure

Tire Placard Location

NOTE:Some vehicles have a ªTire and Loading Infor-

mationº placard located on the driver's side ªBº pillar.

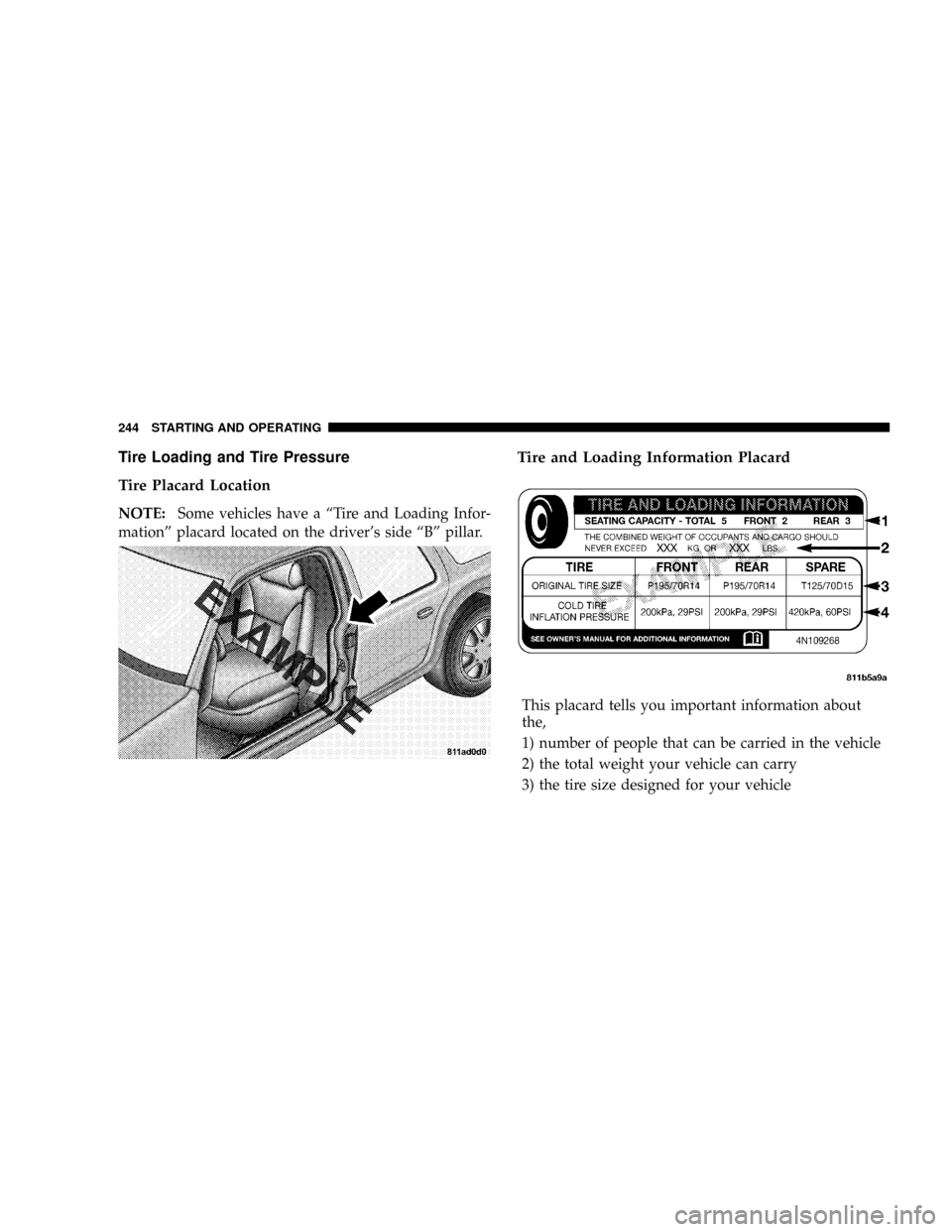

Tire and Loading Information Placard

This placard tells you important information about

the,

1) number of people that can be carried in the vehicle

2) the total weight your vehicle can carry

3) the tire size designed for your vehicle

244 STARTING AND OPERATING

Page 245 of 374

4) the cold tire inflation pressures for the front, rear

and spare tires.

Loading

The vehicle maximum load on the tire must not exceed

the load carrying capacity of the tire on your vehicle. You

will not exceed the tire's load carrying capacity if you

adhere to the loading conditions, tire size and cold tire

inflation pressures specified on the Tire and Loading

Information placard and the Vehicle Loading section of

this manual.

NOTE:Under a maximum loaded vehicle condition,

gross axle weight ratings (GAWR's) for the front and rear

axles must not be exceeded. For further information on

GAWR's, vehicle loading and trailer towing, see the

Vehicle Loading section of this manual.To determine the maximum loading conditions of your

vehicle, locate the statement ªThe combined weight of

occupants and cargo should never exceed XXX kg or XXX

lbs.º on the Tire and Loading Information placard. The

combined weight of occupants, cargo/luggage and

trailer tongue weight (if applicable) should never exceed

the weight referenced here.

Steps for Determining Correct Load Limit

1. Locate the statement ªThe combined weight of occu-

pants and cargo should never exceed XXX poundsº on

your vehicle's placard.

2. Determine the combined weight of the driver and

passengers that will be riding in your vehicle.

STARTING AND OPERATING 245

5

Page 253 of 374

WARNING!

²Do not use a tire, wheel size or rating other than that

specified for your vehicle. Some combinations of unap-

proved tires and wheels may change suspension dimen-

sions and performance characteristics, resulting in

changes to steering, handling, and braking of your

vehicle. This can cause unpredictable handling and

stress to steering and suspension components. You

could lose control and have an accident resulting in

serious injury or death. Use only the tire and wheel

sizes with load ratings approved for your vehicle.

²Never use a tire smaller than the minimum tire size

listed on your vehicle's tire label. Using a smaller tire

could result in tire overloading and failure. You could

lose control and have an accident.

²Failure to equip your vehicle with tires having adequate

speed capability can result in sudden tire failure and

loss of vehicle control.

²Overloading your tires is dangerous. Overloading can

cause tire failure. Use tires of the recommended load

capacity for your vehicle - never overload them.

CAUTION!

Replacing original tires with tires of a different size

may result in false speedometer and odometer read-

ings. Check with your dealer before replacing tires

with a different size.

Alignment and Balance

The suspension components of your vehicle should be

inspected and aligned when needed, to obtain maximum

tire tread life.

Poor suspension alignment may result in:

²reduced tread life;

²uneven tire wear, such as feathering and one-sided

wear;

²vehicle pull to the right or to the left.

STARTING AND OPERATING 253

5