check oil JEEP LIBERTY 2008 KK / 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2008, Model line: LIBERTY, Model: JEEP LIBERTY 2008 KK / 2.GPages: 493

Page 81 of 493

inspect the exhaust system each time the vehicle is raised

for lubrication or oil change. Replace as required.

WARNING!

²Exhaust gases can injure or kill. They contain

carbon monoxide (CO) which is colorless and

odorless. Breathing it can make you unconscious

and can eventually poison you. To avoid breathing

(CO) follow the safety tips below.

²If you are required to drive with the trunk open,

make sure that all windows are closed, and the

climate control blower switch is set at high speed.

DO NOT use the recirculation mode.

Safety Checks You Should Make Inside The

Vehicle

Seat Belts

Inspect the belt system periodically, checking for cuts,

frays, and loose parts. Damaged parts must be replaced

immediately. Do not disassemble or modify the system.

Front seat belt assemblies must be replaced after a

collision. Rear seat belt assemblies must be replaced after

a collision if they have been damaged (bent retractor, torn

webbing, etc. If there is any question regarding belt or

retractor condition, replace the belt.

Airbag Warning Light

The light should come on and remain on for 6 to 8

seconds as a bulb check when the ignition switch is first

turned ON. If the light is not lit during starting, see you

authorized dealer. If the light stays on, flickers, or comes

on while driving, have the system checked by an autho-

rized dealer.

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE 81

2

Page 82 of 493

Defroster

Check operation by selecting the defrost mode and place

the blower control on high speed. You should be able to

feel the air directed against the windshield. See your

authorized dealer for service if your defroster is inoper-

able.

Periodic Safety Checks You Should Make Outside

The Vehicle

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread. Inspect the tread and sidewall for

cuts and cracks. Check the wheel nuts for tightness.

Check the tires (including spare) for proper pressure.

Lights

Have someone observe the operation of exterior lights

while you work the controls. Check turn signal and high

beam indicator lights on the instrument panel.

Door Latches

Check for positive closing, latching, and locking.

Fluid Leaks

Check area under vehicle after overnight parking for fuel,

engine coolant, oil, or other fluid leaks. Also, if gasoline

fumes are detected or if fuel, power steering fluid, or

brake fluid leaks are suspected, the cause should be

located and corrected immediately.

82 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

Page 195 of 493

13. Oil Pressure Warning Light

This light shows low engine oil pressure. The light

will turn on and remain on when the ignition

switch is turned from the LOCK or ACC position to the

ON position. The light will turn off after the engine is

started. If the light does not turn on during starting, have

the system checked by an authorized dealer.

If the light turns on and remains on while driving, safely

bring the vehicle to a stop and shut off the engine. DO

NOT OPERATE THE VEHICLE UNTIL THE CAUSE IS

CORRECTED.

This light does not show the quantity of oil in the engine.

The engine oil level must be checked using the proper

procedure. (See page 403 for more information.)

14. Anti-Lock Brake Warning Light

This light monitors the Anti-Lock Brake Sys-

tem. This light will turn on when the ignition

switch is turned to the ON position and it may

stay on for approximately 3 seconds.If the light remains on or turns on during driving, it

indicates that the Anti-Lock portion of the brake system

is not functioning and that service is required. However,

the conventional brake system will continue to operate

normally, provided the BRAKE warning light is not on.

If the ABS light is on, the brake system should be serviced as

soon as possible to restore the benefit of Anti-Lock Brakes.

The ABS Warning light should be checked frequently to

assure that it is operating properly. Turn the ignition

switch to the ON position, but do not start the vehicle.

The light should turn on. If the light does not turn on,

have the system checked by an authorized dealer. (See

page 310 for more information.)

15. Tachometer

This gauge measures engine revolutions-per-minute

(rpm x 1000). Before the pointer reaches the red area, ease

up on the accelerator to prevent engine damage.

INSTRUMENT PANEL AND CONTROLS 195

4

Page 209 of 493

²Door(s) Ajar (with a single chime if vehicle is in

motion)

²Liftgate Ajar (with a single chime)

²Left Front Low Pressure (with a single chime). Refer to

ªTire Pressure Monitoring Systemº in Section 5 of this

manual.

²Left Rear Low Pressure (with a single chime). Refer to

ªTire Pressure Monitoring Systemº in Section 5 of this

manual.

²Right Front Low Pressure (with a single chime). Refer

to ªTire Pressure Monitoring Systemº in Section 5 of

this manual.

²Right Rear Low Pressure (with a single chime). Refer

to ªTire Pressure Monitoring Systemº in Section 5 of

this manual.

²Check TPM System (with a single chime). Refer to

ªTire Pressure Monitoring Systemº in Section 5 of this

manual.

²Check Gascap (refer to ªAdding Fuelº in Section 5 of

this manual for more details)

²Service Park Assist System (with a single chime)

²Oil Change Required (with a single chime)

Oil Change Required

Your vehicle is equipped with an engine oil change

indicator system. The ªOil Change Requiredº message

will flash in the EVIC display for approximately 10

seconds after a single chime has sounded to indicate the

next scheduled oil change interval. The engine oil change

indicator system is duty cycle based, which means the

engine oil change interval may fluctuate dependent upon

your personal driving style.

INSTRUMENT PANEL AND CONTROLS 209

4

Page 395 of 493

MAINTAINING YOUR VEHICLE

CONTENTS

m3.7L Engine Compartment................398

mOnboard Diagnostic System Ð OBD II........399

NLoose Fuel Filler Cap Message............400

mEmissions Inspection And Maintenance

Programs............................400

mReplacement Parts......................402

mDealer Service.........................402

mMaintenance Procedures..................402

NEngine Oil..........................403NEngine Oil Filter......................405

NDrive Belts Ð Check Condition And Tension . . 406

NSpark Plugs.........................406

NEngine Air Cleaner Filter................406

NFuel Filter..........................407

NCatalytic Converter....................407

NCrankcase Emission Control System........409

NMaintenance-Free Battery................409

NAir Conditioner Maintenance.............411

7

Page 403 of 493

These items should be inspected if a malfunction is

observed or suspected.

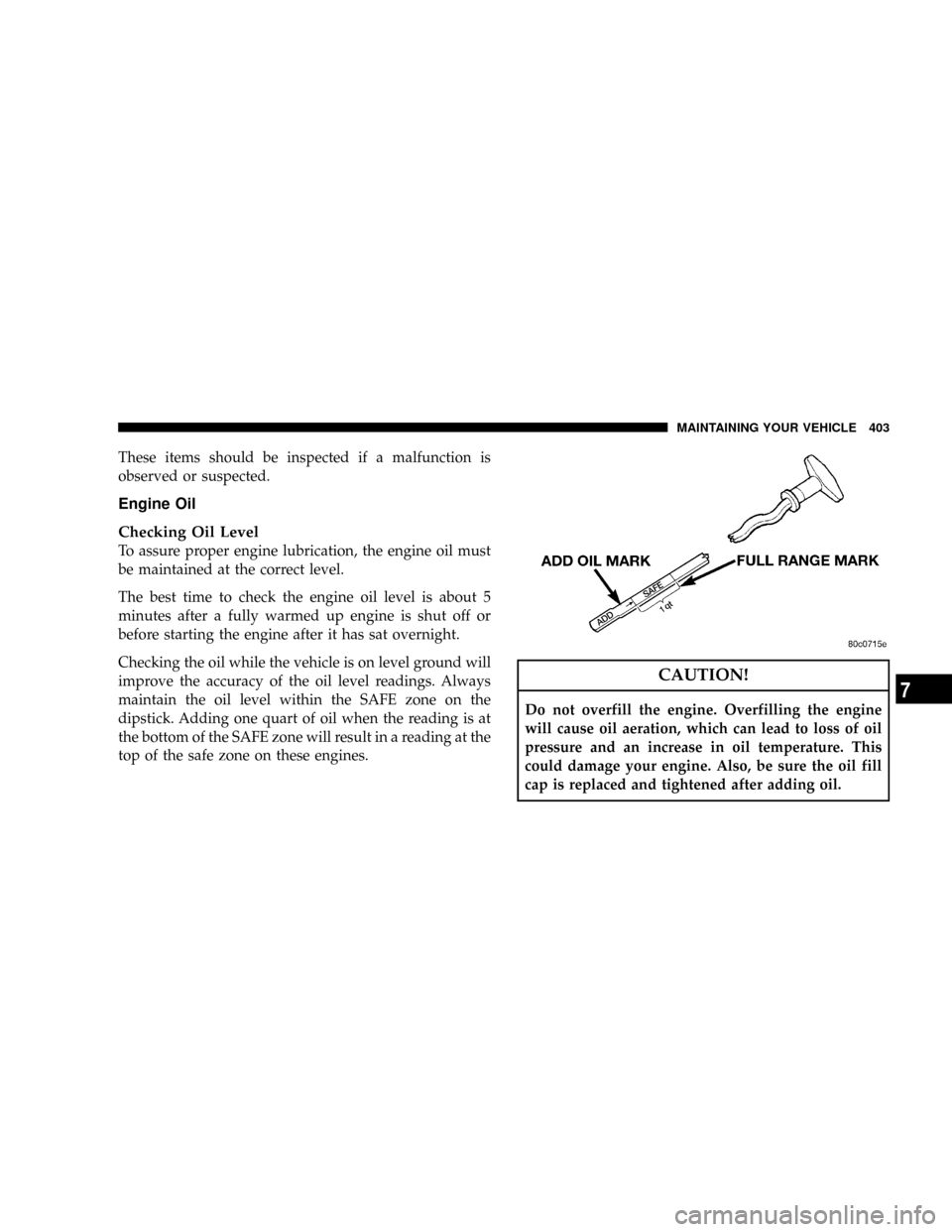

Engine Oil

Checking Oil Level

To assure proper engine lubrication, the engine oil must

be maintained at the correct level.

The best time to check the engine oil level is about 5

minutes after a fully warmed up engine is shut off or

before starting the engine after it has sat overnight.

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings. Always

maintain the oil level within the SAFE zone on the

dipstick. Adding one quart of oil when the reading is at

the bottom of the SAFE zone will result in a reading at the

top of the safe zone on these engines.

CAUTION!

Do not overfill the engine. Overfilling the engine

will cause oil aeration, which can lead to loss of oil

pressure and an increase in oil temperature. This

could damage your engine. Also, be sure the oil fill

cap is replaced and tightened after adding oil.

MAINTAINING YOUR VEHICLE 403

7

Page 409 of 493

To minimize the possibility of catalytic converter dam-

age:

²Do not shut off the engine or interrupt the ignition

when the transmission is in gear and the vehicle is in

motion.

²Do not try to start the engine by pushing or towing the

vehicle.

²Do not idle the engine with any ignition coil connec-

tors disconnected for prolonged periods.

²Do not idle the engine for prolonged periods during

very rough idle or malfunctioning operating condi-

tions.

²Do not allow vehicle to run out of fuel.

Crankcase Emission Control System

Proper operation of this system depends on freedom

from sticking or plugging due to deposits. As vehicle

mileage builds up, the PCV valve and passages may

accumulate deposits. If a valve is not working properly,

replace it with a new valve. DO NOT ATTEMPT TO

CLEAN THE OLD PCV VALVE!

Check ventilation hose for indication of damage or

plugging deposits. Replace if necessary.

Maintenance-Free Battery

Your vehicle is equipped with a maintenance-free battery.

You will never have to add water, nor is periodic main-

tenance required.

MAINTAINING YOUR VEHICLE 409

7

Page 412 of 493

Refrigerant Recovery and Recycling

R-134a Air Conditioning Refrigerant is a hydrofluorocar-

bon (HFC) that is endorsed by the Environmental Pro-

tection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by dealers or other service facilities

using recovery and recycling equipment.

NOTE:Use only manufacturer approved A/C System

Sealers, Stop Leak Products, Seal Conditioners, Compres-

sor Oil, and Refrigerants.

A/C Air Filter Ð If Equipped

Refer to the ªMaintenance Scheduleº in Section 8 of this

manual for A/C Air Filter service intervals.

WARNING!

Do not remove the A/C Air Filter while the blower is

operating or personal injury may result.

Power Steering Ð Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to insure accurate fluid level reading. Do

not overfill. Use only manufacturer's recommended

power steering fluid.

412 MAINTAINING YOUR VEHICLE

Page 414 of 493

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Make sure that they are not frozen to the

glass before turning them on to avoid damaging the

blade.

Keep the blade rubber out of contact with petroleum

products such as engine oil, gasoline, etc.

NOTE:Always refer to the wiper blade packaging for

specific installation instructions. Many wiper blade re-

placements fit multiple vehicles.Windshield & Rear Window Washers

The windshield and rear window washers share the same

fluid reservoir. The fluid reservoir is located in the front

of the engine compartment. Be sure to check the fluid

level in the reservoir at regular intervals. Fill the reservoir

with windshield washer solvent (not radiator antifreeze)

and operate the system for a few seconds to flush out the

residual water.

When refilling the washer fluid reservoir, take some

washer fluid and apply it to a cloth or towel and wipe

clean the wiper blades, this will help blade performance.

To prevent freeze-up of your windshield washer system

in cold weather, select a solution or mixture that meets or

exceeds the temperature range of your climate. This

rating information can be found on most washer fluid

containers.

414 MAINTAINING YOUR VEHICLE

Page 423 of 493

²Inspect the brake hoses whenever the brake system is

serviced and at every engine oil change. Inspect hy-

draulic brake hoses for surface cracking, scuffing, or

worn spots. If there is any evidence of cracking,

scuffing, or worn spots, the hose should be replaced

immediately! Eventual deterioration of the hose can

take place resulting in a possibility of a burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Master Cylinder - Brake Fluid Level Check

Check the fluid level in the master cylinder immediately

if the brake system warning light indicates system fail-

ure.Check the fluid level in the master cylinder when per-

forming underhood services.

Clean the top of the master cylinder area before removing

the cap. If necessary, add fluid to bring the fluid level up

to the requirements described on the brake fluid reser-

voir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Fluid level can be expected to fall as the brake pads wear.

Brake fluid level should be checked when pads are

replaced. However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only manufacturer's recommended brake fluid. Re-

fer to ªFluids, Lubricants, and Genuine Partsº in this

section for the correct fluid type.

MAINTAINING YOUR VEHICLE 423

7