wheel JEEP PATRIOT 2015 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2015, Model line: PATRIOT, Model: JEEP PATRIOT 2015 1.GPages: 132, PDF Size: 19.28 MB

Page 79 of 132

FOUR-WHEEL DRIVE OPERATION

This vehicle has two full time, on-demand, four-wheel-drive (4WD) systems avail-

able, Freedom Drive I™ and Freedom-Drive II™. They provide for all-weather,

all-terrain capability for added driving security in less-than-ideal road conditions.

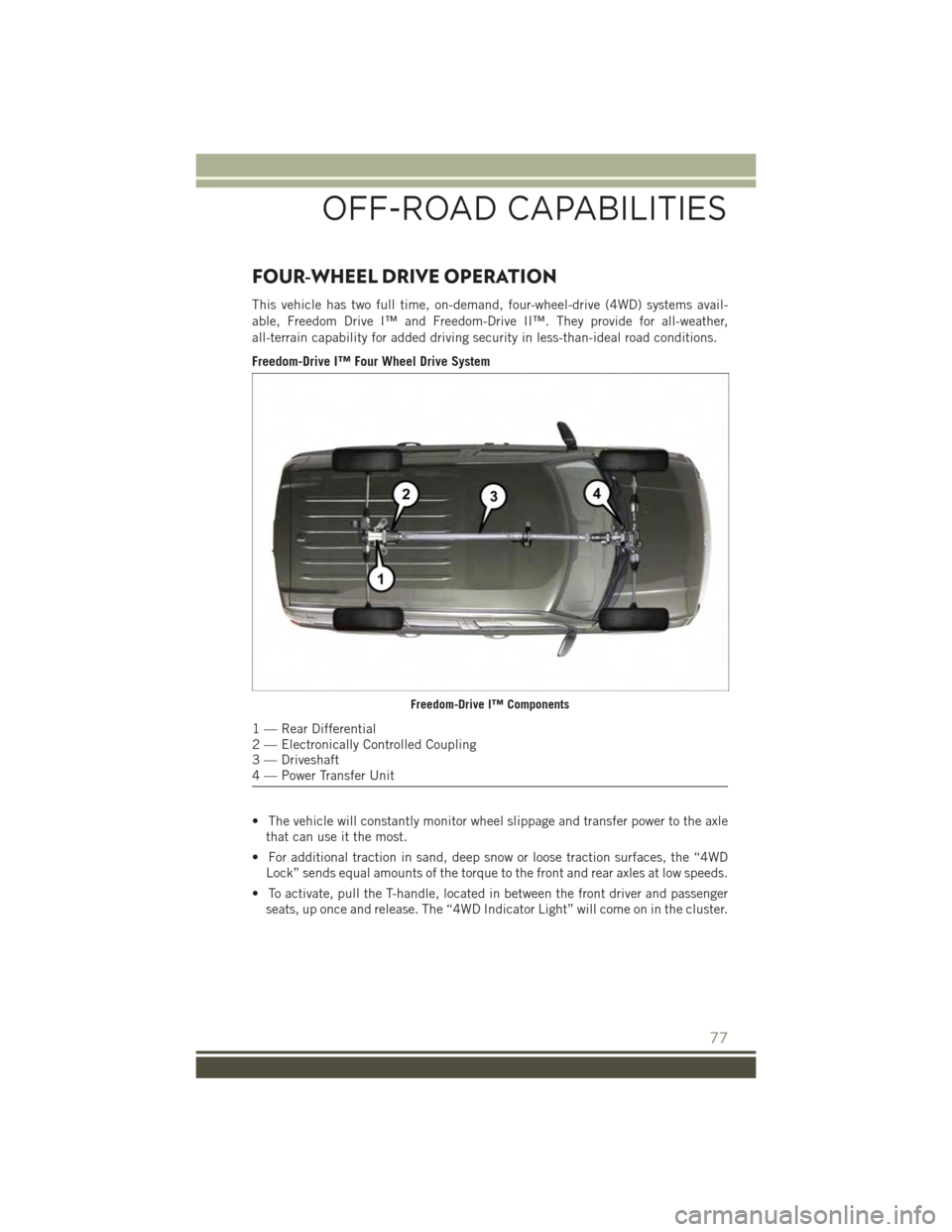

Freedom-Drive I™ Four Wheel Drive System

• The vehicle will constantly monitor wheel slippage and transfer power to the axle

that can use it the most.

• For additional traction in sand, deep snow or loose traction surfaces, the “4WD

Lock” sends equal amounts of the torque to the front and rear axles at low speeds.

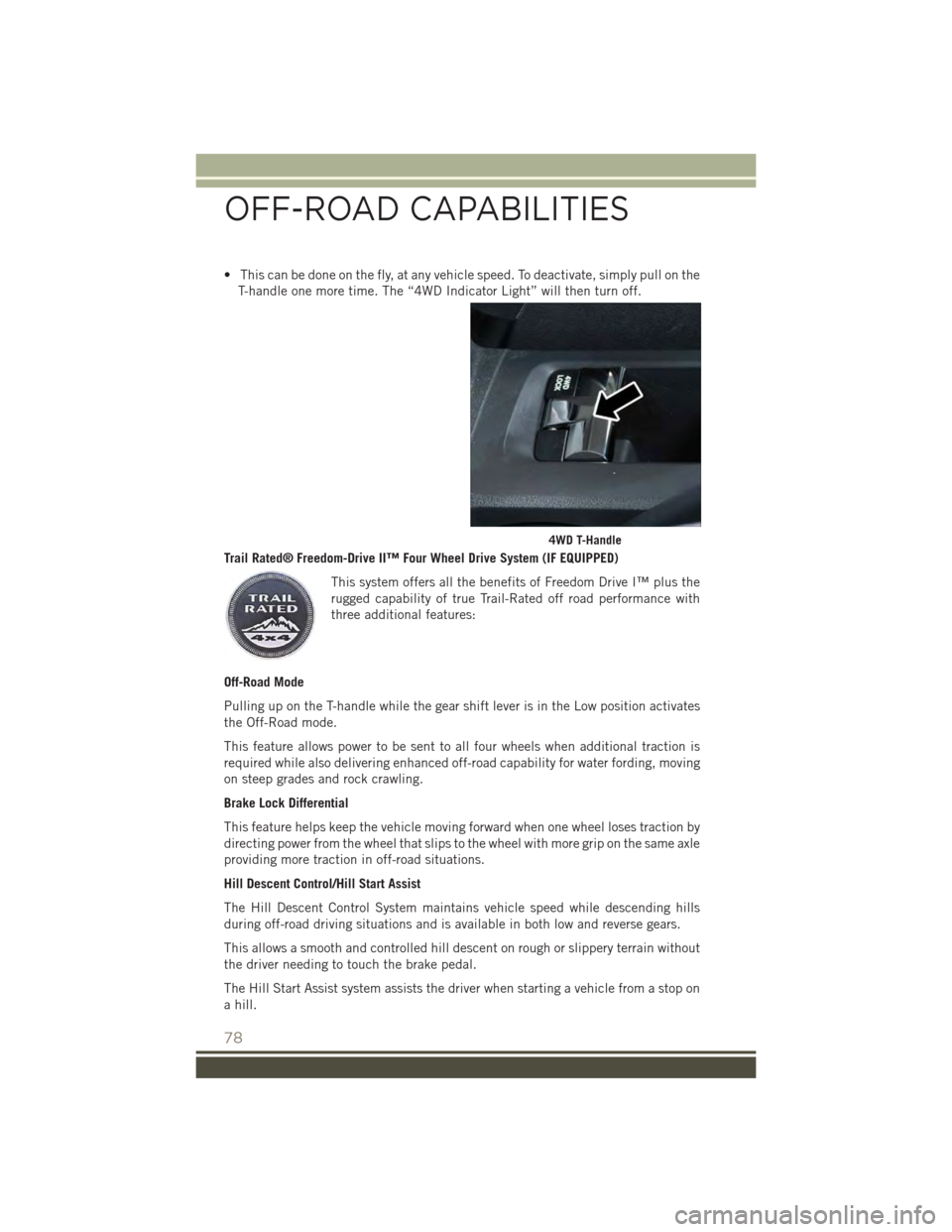

• To activate, pull the T-handle, located in between the front driver and passenger

seats, up once and release. The “4WD Indicator Light” will come on in the cluster.

Freedom-Drive I™ Components

1 — Rear Differential2 — Electronically Controlled Coupling3 — Driveshaft4 — Power Transfer Unit

OFF-ROAD CAPABILITIES

77

Page 80 of 132

• This can be done on the fly, at any vehicle speed. To deactivate, simply pull on the

T-handle one more time. The “4WD Indicator Light” will then turn off.

Trail Rated® Freedom-Drive II™ Four Wheel Drive System (IF EQUIPPED)

This system offers all the benefits of Freedom Drive I™ plus the

rugged capability of true Trail-Rated off road performance with

three additional features:

Off-Road Mode

Pulling up on the T-handle while the gear shift lever is in the Low position activates

the Off-Road mode.

This feature allows power to be sent to all four wheels when additional traction is

required while also delivering enhanced off-road capability for water fording, moving

on steep grades and rock crawling.

Brake Lock Differential

This feature helps keep the vehicle moving forward when one wheel loses traction by

directing power from the wheel that slips to the wheel with more grip on the same axle

providing more traction in off-road situations.

Hill Descent Control/Hill Start Assist

The Hill Descent Control System maintains vehicle speed while descending hills

during off-road driving situations and is available in both low and reverse gears.

This allows a smooth and controlled hill descent on rough or slippery terrain without

the driver needing to touch the brake pedal.

The Hill Start Assist system assists the driver when starting a vehicle from a stop on

a hill.

4WD T-Handle

OFF-ROAD CAPABILITIES

78

Page 82 of 132

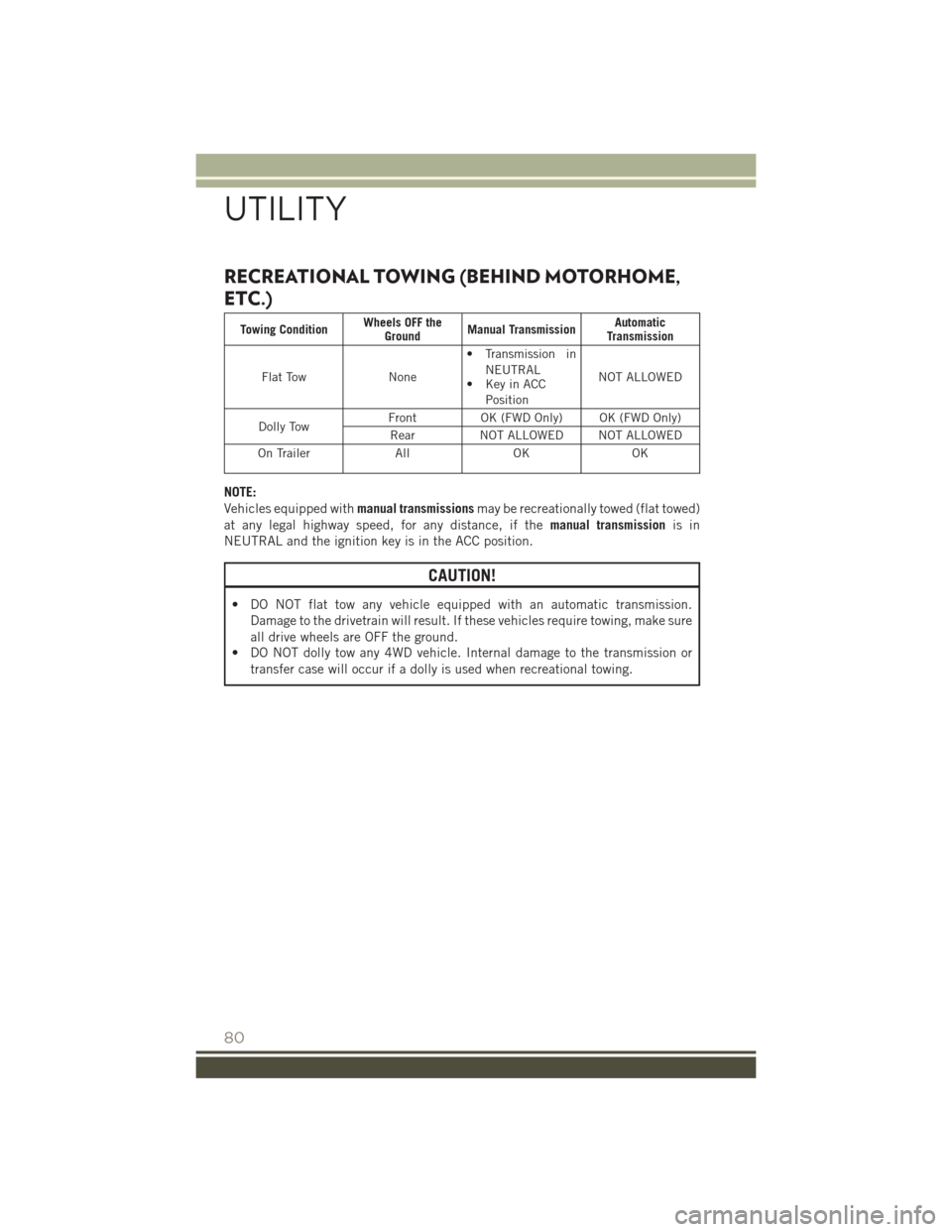

RECREATIONAL TOWING (BEHIND MOTORHOME,

ETC.)

Towing ConditionWheels OFF theGroundManual TransmissionAutomaticTransmission

Flat TowNone

• Transmission in

NEUTRAL• Key in ACCPosition

NOT ALLOWED

Dolly TowFrontOK (FWD Only) OK (FWD Only)

RearNOT ALLOWED NOT ALLOWED

On TrailerAllOKOK

NOTE:

Vehicles equipped withmanual transmissionsmay be recreationally towed (flat towed)

at any legal highway speed, for any distance, if themanual transmissionis in

NEUTRAL and the ignition key is in the ACC position.

CAUTION!

• DO NOT flat tow any vehicle equipped with an automatic transmission.

Damage to the drivetrain will result. If these vehicles require towing, make sure

all drive wheels are OFF the ground.

• DO NOT dolly tow any 4WD vehicle. Internal damage to the transmission or

transfer case will occur if a dolly is used when recreational towing.

UTILITY

80

Page 85 of 132

When the system detects a malfunction, the telltale will flash for approximately one

minute and then remain continuously illuminated. This sequence will continue upon

subsequent vehicle start-ups as long as the malfunction exists. When the malfunction

indicator is illuminated, the system may not be able to detect or signal low tire pressure

as intended. TPMS malfunctions may occur for a variety of reasons, including the

installation of replacement or alternate tires or wheels on the vehicle that prevent the

TPMS from functioning properly. Always check the TPMS malfunction telltale after

replacing one or more tires or wheels on your vehicle to ensure that the replacement or

alternate tires and wheels allow the TPMS to continue to function properly.

NOTE:

Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C) of air

temperature change. Keep this in mind when checking tire pressure inside a garage,

especially in the Winter. Example: If garage temperature is 68°F (20°C), and the

outside temperature is 32°F (0°C), then the cold tire inflation pressure should be

increased by 3 psi (21 kPa), which equals 1 psi (7 kPa) for every 12°F (7°C) for this

outside temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels. TPMS

pressures and warning have been established for the tire size equipped on your

vehicle. Undesirable system operation or sensor damage may result when using

replacement equipment that is not of the same size, type, and/or style. Aftermar-

ket wheels can cause sensor damage. Do not use tire sealant from a can, or

balance beads if your vehicle is equipped with a TPMS, as damage to the sensors

may result.

- Brake Warning Light

This light monitors various brake functions, including brake fluid level and parking

brake application. If the brake light turns on, it may indicate that the parking brake

is applied, that the brake fluid level is low, or that there is a problem with the

anti-lock brake system reservoir.

If the light remains on when the parking brake has been disengaged, and the fluid

level is at the full mark on the master cylinder reservoir, it indicates a possible brake

hydraulic system malfunction or that a problem with the Brake Booster has been

detected by the Anti-Lock Brake System (ABS)/Electronic Stability Control (ESC)

system. In this case, the light will remain on until the condition has been corrected.

If the problem is related to the brake booster, the ABS pump will run when applying

the brake, and a brake pedal pulsation may be felt during each stop.

The dual brake system provides a reserve braking capacity in the event of a failure to

a portion of the hydraulic system. A leak in either half of the dual brake system is

indicated by the Brake Warning Light, which will turn on when the brake fluid level

in the master cylinder has dropped below a specified level. The light will remain on

until the cause is corrected.

WHAT TO DO IN EMERGENCIES

83

Page 88 of 132

INSTRUMENT CLUSTER INDICATOR LIGHTS

- Turn Signal Indicator

The arrows will flash with the exterior turn signals when the turn signal lever is

operated. A tone will chime, and a EVIC message will appear if either turn signal is

left on for more than 1 mile (1.6 km).

NOTE:

If either indicator flashes at a rapid rate, check for a defective outside light bulb.

- High Beam Indicator

Indicates that headlights are on high beam.

- Front Fog Light Indicator

This indicator will illuminate when the front fog lights are on.

- Vehicle Security Light

This light will flash rapidly for approximately 15 seconds when the vehicle security

alarm is arming. The light will flash at a slower speed continuously after the alarm is

set. The security light will also come on for about three seconds when the ignition is

first turned on.

– 4WD Indicator

This light indicates the vehicle is in 4-wheel drive (4WD) mode.

- Electronic Stability Control (ESC) OFF Indicator Light

This light indicates the Electronic Stability Control (ESC) is off.

— Cruise Indicator

This indicator shows that the Electronic Speed Control System is ON.

- Hill Descent Control Indicator — If Equipped

This indicator will illuminate when Hill Descent Control (HDC) has been selected

using the Hill Descent Control Switch.

Oil Change Indicator

Message

If an “oil change” message (shown as CHANgE OIL) appears and a single chime

sounds, it is time for your next required oil change.

WHAT TO DO IN EMERGENCIES

86

Page 91 of 132

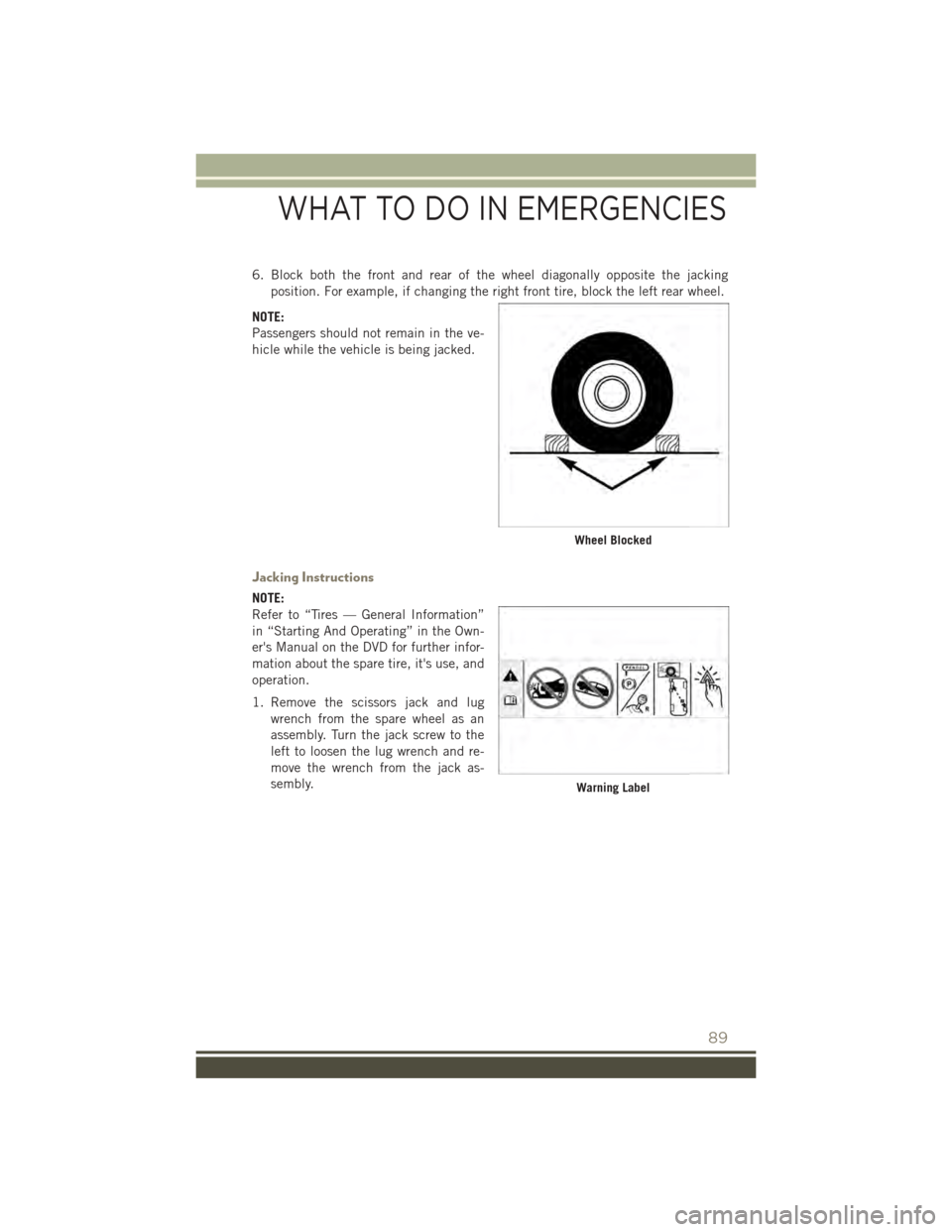

6. Block both the front and rear of the wheel diagonally opposite the jacking

position. For example, if changing the right front tire, block the left rear wheel.

NOTE:

Passengers should not remain in the ve-

hicle while the vehicle is being jacked.

Jacking Instructions

NOTE:

Refer to “Tires — General Information”

in “Starting And Operating” in the Own-

er's Manual on the DVD for further infor-

mation about the spare tire, it's use, and

operation.

1. Remove the scissors jack and lug

wrench from the spare wheel as an

assembly. Turn the jack screw to the

left to loosen the lug wrench and re-

move the wrench from the jack as-

sembly.

Wheel Blocked

Warning Label

WHAT TO DO IN EMERGENCIES

89

Page 92 of 132

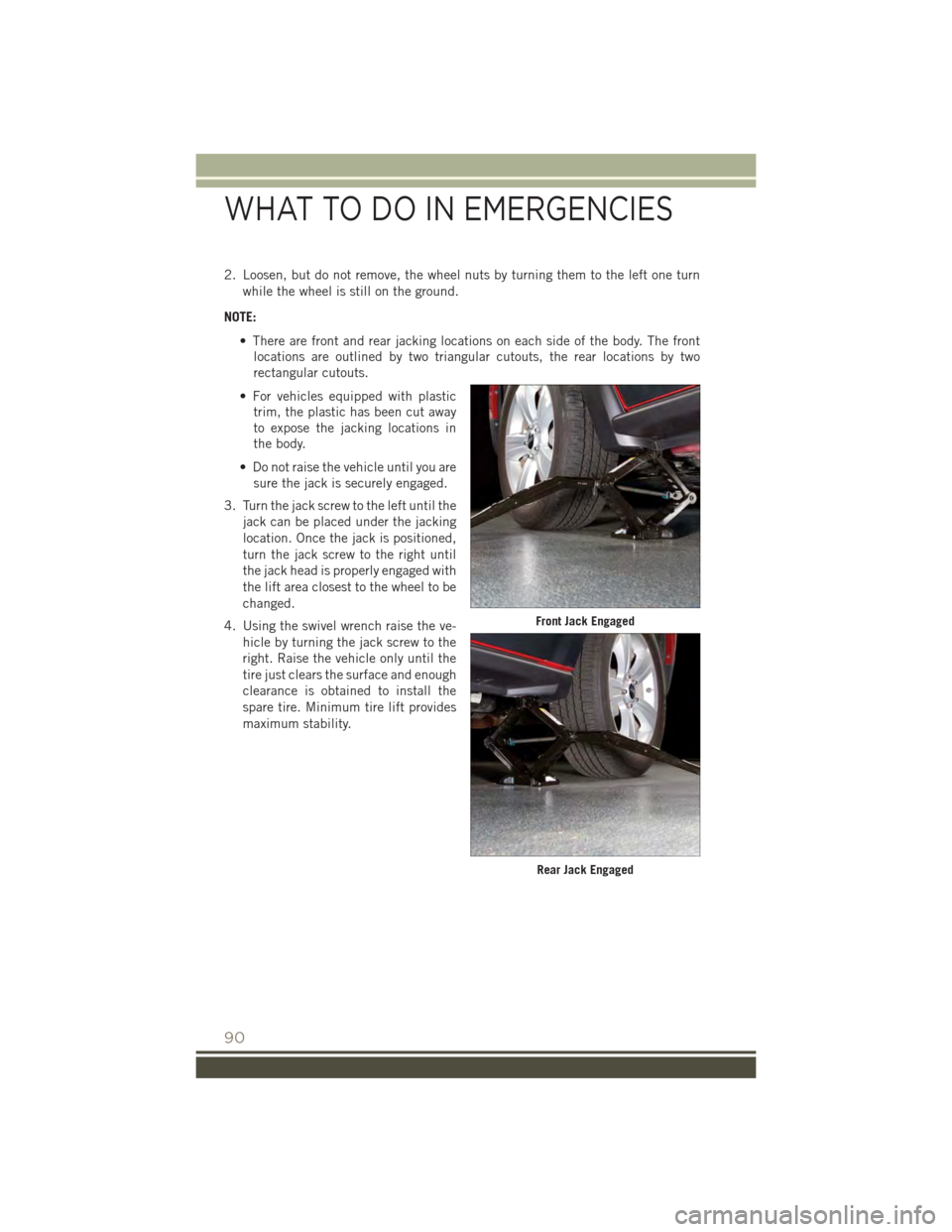

2. Loosen, but do not remove, the wheel nuts by turning them to the left one turn

while the wheel is still on the ground.

NOTE:

• There are front and rear jacking locations on each side of the body. The front

locations are outlined by two triangular cutouts, the rear locations by two

rectangular cutouts.

• For vehicles equipped with plastic

trim, the plastic has been cut away

to expose the jacking locations in

the body.

• Do not raise the vehicle until you are

sure the jack is securely engaged.

3. Turn the jack screw to the left until the

jack can be placed under the jacking

location. Once the jack is positioned,

turn the jack screw to the right until

the jack head is properly engaged with

the lift area closest to the wheel to be

changed.

4. Using the swivel wrench raise the ve-

hicle by turning the jack screw to the

right. Raise the vehicle only until the

tire just clears the surface and enough

clearance is obtained to install the

spare tire. Minimum tire lift provides

maximum stability.

Front Jack Engaged

Rear Jack Engaged

WHAT TO DO IN EMERGENCIES

90

Page 93 of 132

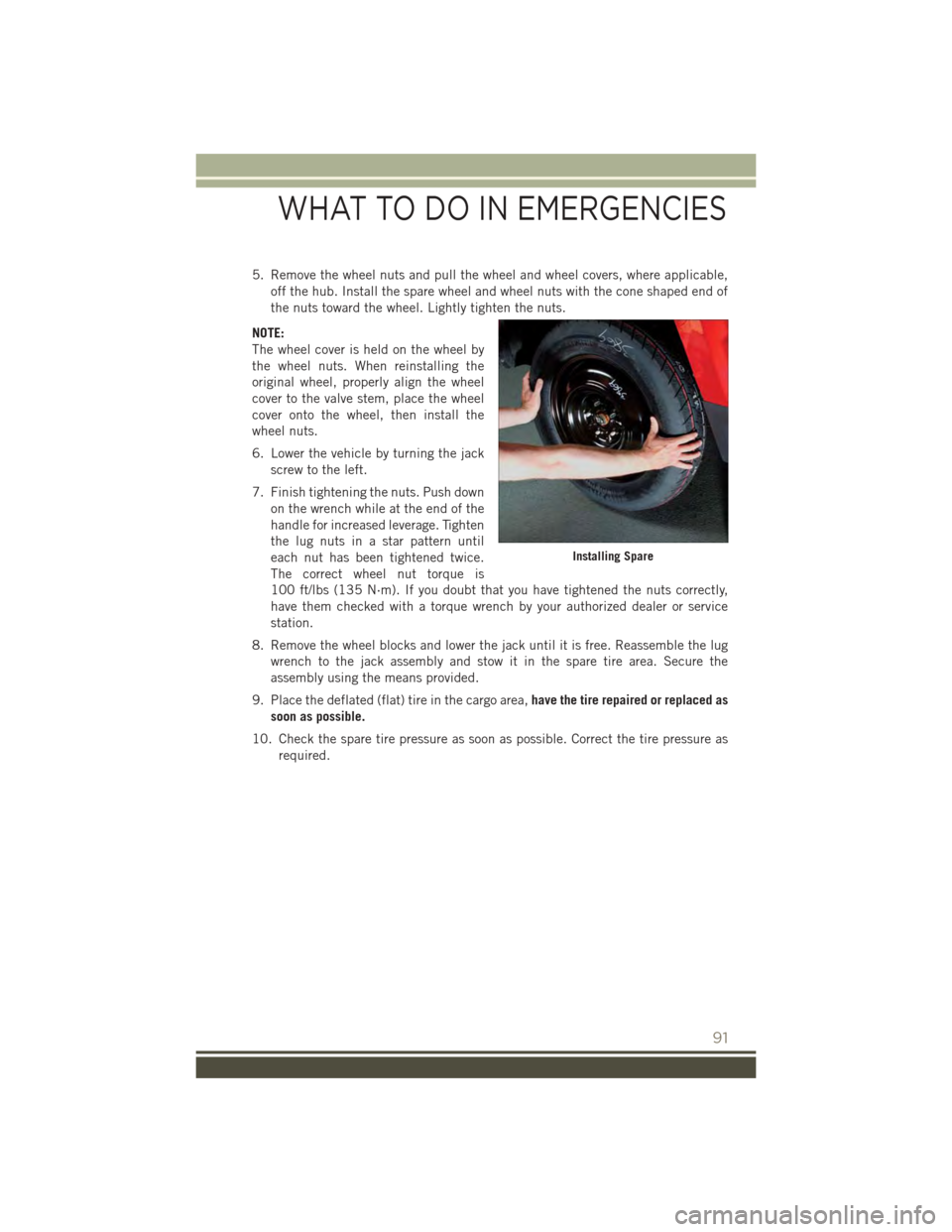

5. Remove the wheel nuts and pull the wheel and wheel covers, where applicable,

off the hub. Install the spare wheel and wheel nuts with the cone shaped end of

the nuts toward the wheel. Lightly tighten the nuts.

NOTE:

The wheel cover is held on the wheel by

the wheel nuts. When reinstalling the

original wheel, properly align the wheel

cover to the valve stem, place the wheel

cover onto the wheel, then install the

wheel nuts.

6. Lower the vehicle by turning the jack

screw to the left.

7. Finish tightening the nuts. Push down

on the wrench while at the end of the

handle for increased leverage. Tighten

the lug nuts in a star pattern until

each nut has been tightened twice.

The correct wheel nut torque is

100 ft/lbs (135 N·m). If you doubt that you have tightened the nuts correctly,

have them checked with a torque wrench by your authorized dealer or service

station.

8. Remove the wheel blocks and lower the jack until it is free. Reassemble the lug

wrench to the jack assembly and stow it in the spare tire area. Secure the

assembly using the means provided.

9. Place the deflated (flat) tire in the cargo area,have the tire repaired or replaced as

soon as possible.

10. Check the spare tire pressure as soon as possible. Correct the tire pressure as

required.

Installing Spare

WHAT TO DO IN EMERGENCIES

91

Page 94 of 132

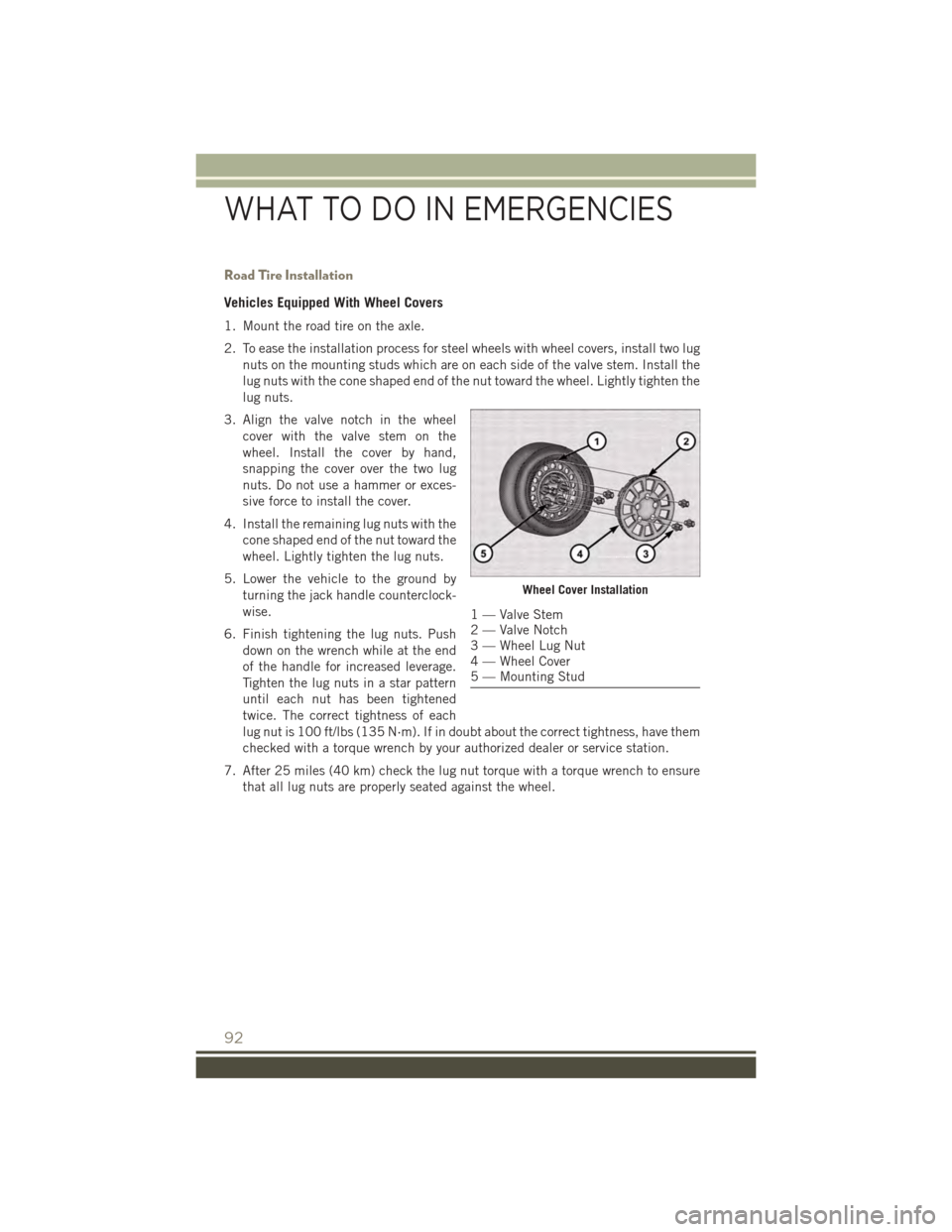

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug

nuts on the mounting studs which are on each side of the valve stem. Install the

lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the

lug nuts.

3. Align the valve notch in the wheel

cover with the valve stem on the

wheel. Install the cover by hand,

snapping the cover over the two lug

nuts. Do not use a hammer or exces-

sive force to install the cover.

4. Install the remaining lug nuts with the

cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

5. Lower the vehicle to the ground by

turning the jack handle counterclock-

wise.

6. Finish tightening the lug nuts. Push

down on the wrench while at the end

of the handle for increased leverage.

Tighten the lug nuts in a star pattern

until each nut has been tightened

twice. The correct tightness of each

lug nut is 100 ft/lbs (135 N·m). If in doubt about the correct tightness, have them

checked with a torque wrench by your authorized dealer or service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure

that all lug nuts are properly seated against the wheel.

Wheel Cover Installation

1 — Valve Stem2 — Valve Notch3 — Wheel Lug Nut4 — Wheel Cover5 — Mounting Stud

WHAT TO DO IN EMERGENCIES

92

Page 95 of 132

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the

handle for increased leverage. Tighten the lug nuts in a star pattern until each nut

has been tightened twice. The correct tightness of each lug nut is 100 ft/lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a

torque wrench by your authorized dealer or service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure

that all lug nuts are properly seated against the wheel.

CAUTION!

• Do not attempt to raise the vehicle by jacking on locations other than those

indicated in the Jacking Instructions for this vehicle.

• Be sure to mount the spare tire with the valve stem facing outward. The vehicle

could be damaged if the spare tire is mounted incorrectly.

WHAT TO DO IN EMERGENCIES

93