light JEEP PATRIOT 2017 1.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: PATRIOT, Model: JEEP PATRIOT 2017 1.GPages: 421, PDF Size: 3.4 MB

Page 245 of 421

HAZARD WARNING FLASHERS

The Hazard Warning flasher switch is located on the

instrument panel below the climate controls.Push the switch to turn on the Hazard Warning

flasher. When the switch is activated, all directional

turn signals will flash on and off to warn oncoming traffic

of an emergency. Push the switch a second time to turn off

the Hazard Warning flashers.

This is an emergency warning system and it should not be

used when the vehicle is in motion. Use it when your

vehicle is disabled and it is creating a safety hazard for

other motorists. When you must leave the vehicle to seek assistance, the

Hazard Warning flashers will continue to operate even

though the ignition is placed in the OFF position.

NOTE:

With extended use the Hazard Warning flashers

may wear down your battery.

BULB REPLACEMENT

Replacement Bulbs

All the inside bulbs are brass or glass wedge base. Alumi-

num base bulbs are not approved and should not be used

for replacement

Interior Bulbs

Bulb Number

Front Header Lamp T578

Center Dome Lamp T578

Rear Cargo Lamp/Flashlight 8–A35LF

7

IN CASE OF EMERGENCY 243

Page 247 of 421

Fog Lamps

1. Access lamp through the lower fascia cutout.

2. Remove electrical connector from bulb.

3. Remove bulb from housing.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

Rear Tail, Turn Signal And Backup Lamps

1. Raise the liftgate.

2. Remove the two push-pins from the taillamp housing.

3. Grasp the taillamp and pull firmly to disengage the lightfrom the aperture panel.

4. Twist and remove socket from the light.

5. Remove bulb from socket and replace.

License Lamps

1. Use a screw driver to gently pry against the side of the snap tab to remove the lamp from the liftgate.

2. Rotate the socket 1/4 turn counterclockwise.

3. Pull the bulb from the socket.

Center High-Mounted Stoplamp

This light is an LED assembly. See your authorized dealer

for replacement.

FUSES

WARNING!

• When replacing a blown fuse, always use an appro-

priate replacement fuse with the same amp rating as

the original fuse. Never replace a fuse with another

fuse of higher amp rating. Never replace a blown

fuse with metal wires or any other material. Failure

to use proper fuses may result in serious personal

injury, fire and/or property damage.

(Continued)

7

IN CASE OF EMERGENCY 245

Page 248 of 421

WARNING!(Continued)

•Before replacing a fuse, make sure that the ignition is

off and that all the other services are switched off

and/or disengaged.

• If the replaced fuse blows again, contact an autho-

rized dealer.

• If a general protection fuse for safety systems (air

bag system, braking system), power unit systems

(engine system, gearbox system) or steering system

blows, contact an authorized dealer.

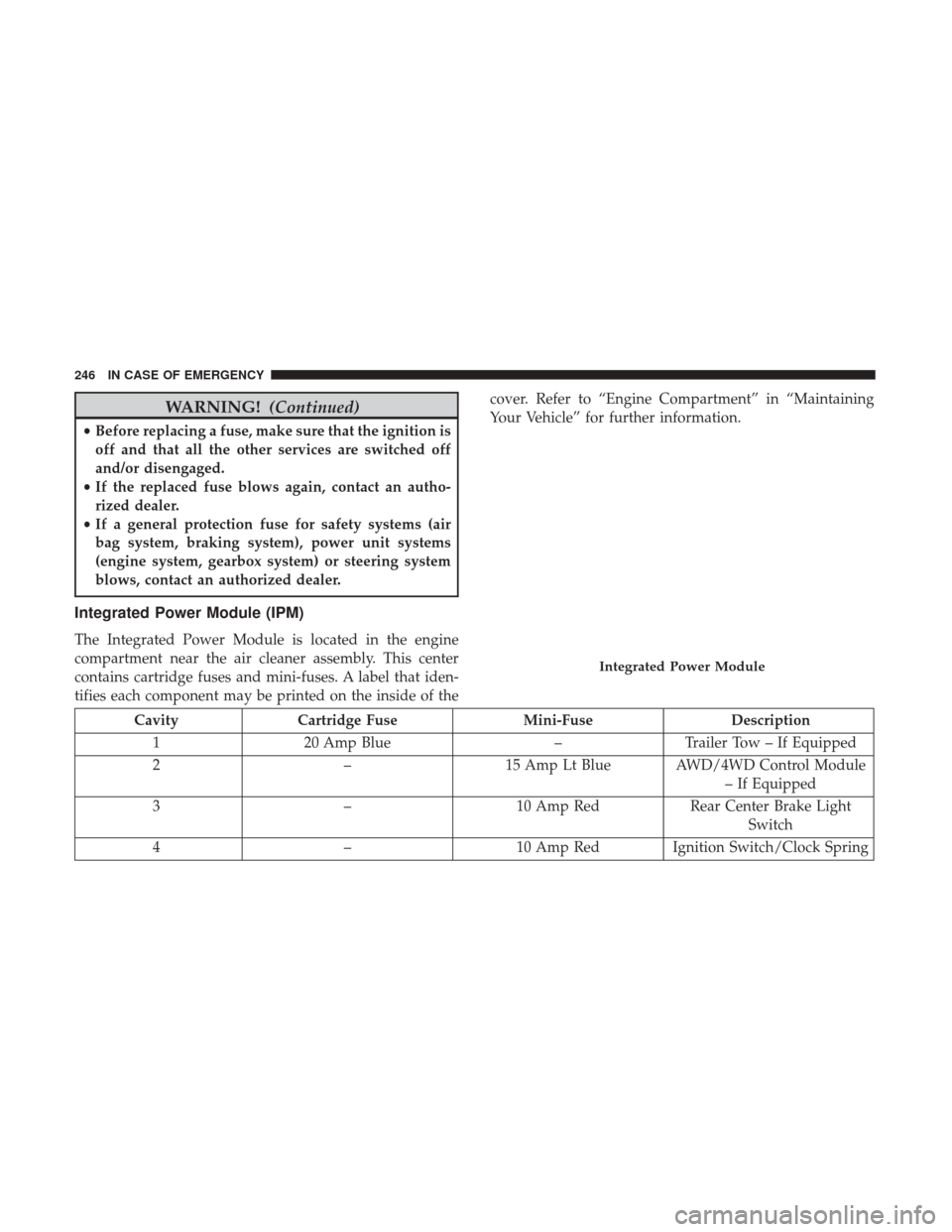

Integrated Power Module (IPM)

The Integrated Power Module is located in the engine

compartment near the air cleaner assembly. This center

contains cartridge fuses and mini-fuses. A label that iden-

tifies each component may be printed on the inside of the cover. Refer to “Engine Compartment” in “Maintaining

Your Vehicle” for further information.

Cavity

Cartridge Fuse Mini-FuseDescription

1 20 Amp Blue –Trailer Tow – If Equipped

2 –15 Amp Lt Blue AWD/4WD Control Module

– If Equipped

3 –10 Amp Red Rear Center Brake Light

Switch

4 –10 Amp Red Ignition Switch/Clock Spring

Integrated Power Module

246 IN CASE OF EMERGENCY

Page 249 of 421

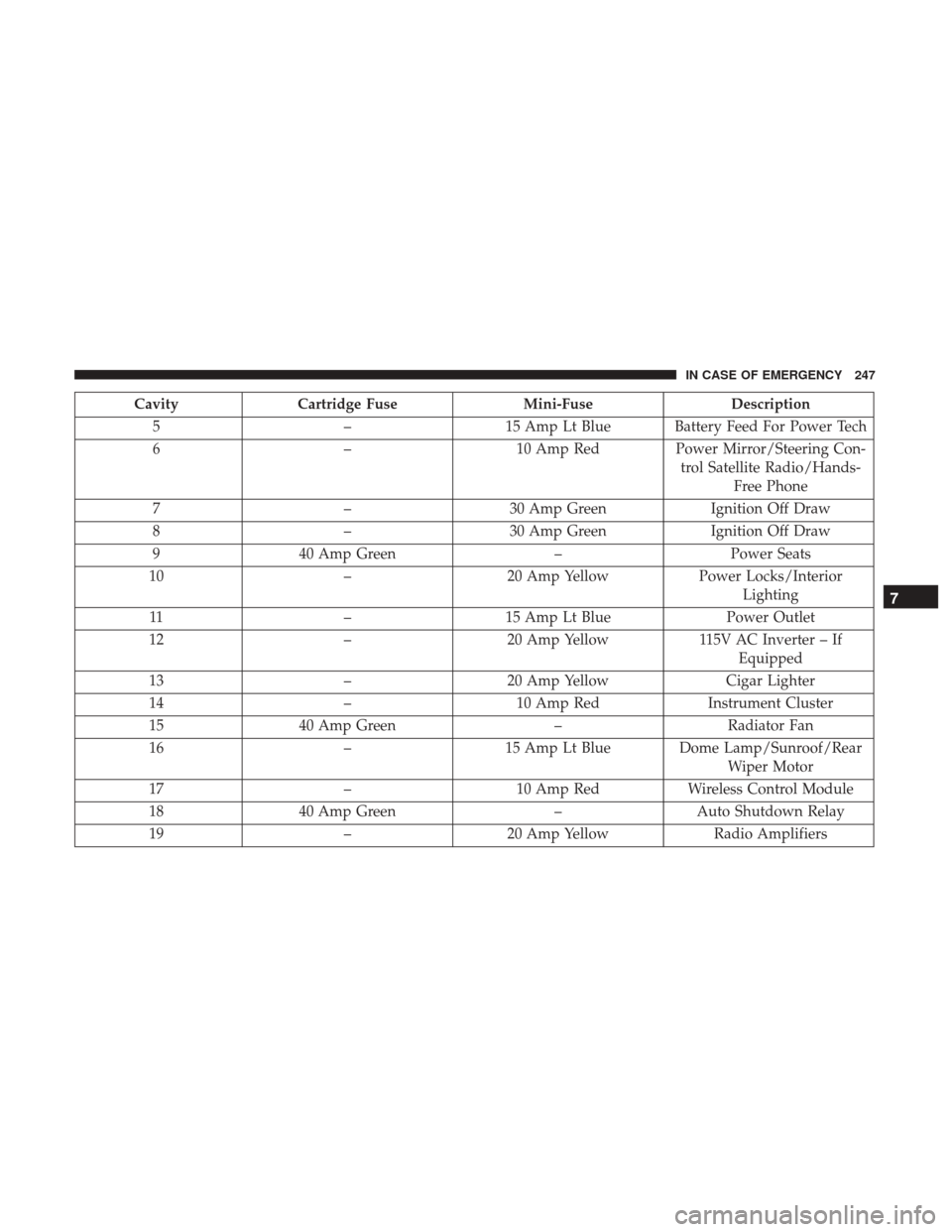

CavityCartridge Fuse Mini-FuseDescription

5 –15 Amp Lt Blue Battery Feed For Power Tech

6 –10 Amp RedPower Mirror/Steering Con-

trol Satellite Radio/Hands- Free Phone

7 –30 Amp Green Ignition Off Draw

8 –30 Amp Green Ignition Off Draw

9 40 Amp Green –Power Seats

10 –20 Amp Yellow Power Locks/Interior

Lighting

11 –15 Amp Lt Blue Power Outlet

12 –20 Amp Yellow 115V AC Inverter – If

Equipped

13 –20 Amp Yellow Cigar Lighter

14 –10 Amp Red Instrument Cluster

15 40 Amp Green –Radiator Fan

16 –15 Amp Lt Blue Dome Lamp/Sunroof/Rear

Wiper Motor

17 –10 Amp RedWireless Control Module

18 40 Amp Green –Auto Shutdown Relay

19 –20 Amp Yellow Radio Amplifiers

7

IN CASE OF EMERGENCY 247

Page 256 of 421

Do not raise the vehicle until you are sure the jack is

securely engaged.

3. Turn the jack screw to the left until the jack can be placedunder the jacking location. Once the jack is positioned,

turn the jack screw to the right until the jack head is

properly engaged with the lift area closest to the wheel

to be changed.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

4. Using the swivel wrench raise the vehicle by turning the jack screw to the right. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.

5. Remove the wheel nuts and pull the wheel and wheel covers, where applicable, off the hub. Install the spare

wheel and wheel nuts with the cone shaped end of the

nuts toward the wheel. Lightly tighten the nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

Rear Jacking Location

254 IN CASE OF EMERGENCY

Page 258 of 421

9. Place the deflated (flat) tire in the cargo area,have the

tire repaired or replaced as soon as possible.

WARNING!

A loose tire thrown forward in a collision or hard stop

could injure the occupants in the vehicle. Have the

deflated (flat) tire repaired or replaced immediately.

10. Check the spare tire pressure as soon as possible. Correct the tire pressure as required.

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. Align the valve notch in the wheel cover with the valvestem on the wheel. Install the cover by hand. Do not use

a hammer or excessive force to install the cover. 3. Install the five wheel lug nuts with the cone shaped end

of the nut toward the wheel. Lightly tighten the lug

nuts.

Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Road Wheel

3 — Wheel Lug Nut

256 IN CASE OF EMERGENCY

Page 259 of 421

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts fully until the vehicle has been

lowered. Failure to follow this warning may result in

serious injury.

4. Lower the vehicle to the ground by turning the jack handle counterclockwise.

5. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Refer to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.

6. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2.

Install the remaining lug nuts with the cone shaped end of

the nut toward the wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not fully tighten the lug nuts until the vehicle has been

lowered. Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Refer to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

7

IN CASE OF EMERGENCY 257

Page 279 of 421

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for your vehicle. Operating conditions such as

frequent short-trips, trailer tow, extremely hot or cold

ambient temperatures will influence when the “Change

Oil” or “Oil Change Required” message is displayed.

Severe Operating Conditions can cause the change oil

message to illuminate as early as 3,500 miles (5,600 km)

since last reset. Have your vehicle serviced as soon as

possible, within the next 500 miles (805 km).

On instrument cluster display equipped vehicles, “Oil

Change Required” will be displayed in the cluster and a

single chime will sound, indicating that an oil change is

necessary.

On non-instrument cluster display equipped vehicles,

“Change Oil” will flash in the odometer and a single chime

will sound, indicating that an oil change is necessary.Your authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If a

scheduled oil change is performed by someone other than

your authorized dealer, the message can be reset by

referring to the steps described under “Warning And

Indicator Lights” or “Instrument Cluster Display” in “Get-

ting To Know Your Instrument Panel” for further informa-

tion.

NOTE:

Under no circumstances should oil change inter-

vals exceed 10,000 miles (16,000 km), twelve months or 350

hours of engine run time, whichever comes first. The 350

hours of engine run or idle time is generally only a concern

for fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) if the vehicle

is operated in a dusty and off road environment or is

operated predominately at idle or only very low engine

RPM’s. This type of vehicle use is considered Severe Duty.

8

SERVICING AND MAINTENANCE 277

Page 280 of 421

Once A Month Or Before A Long Trip:

•Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look for unusual

wear or damage

• Check the fluid levels of the coolant reservoir, brake

master cylinder, power steering and fill as needed

• Check function of all interior and exterior lights

Maintenance Plan

Required Maintenance Intervals.

Refer to the “Maintenance Plan” on the following pages for

the required maintenance intervals.

At Every Oil Change Interval As Indicated By Oil

Change Indicator System:

•Change oil and filter.

• Rotate the tires. Rotate at the first sign of irregular

wear, even if it occurs before the oil indicator

system turns on.

• Inspect battery and clean and tighten terminals as

required.

• Inspect brake pads, shoes, rotors, drums, hoses and

park brake.

• Inspect engine cooling system protection and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or

off-road conditions.

278 SERVICING AND MAINTENANCE

Page 299 of 421

•Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

• Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install ONLY

the correct type thermostat. Other designs may result in

unsatisfactory engine coolant (antifreeze) performance,

poor gas mileage, and increased emissions.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically. Refer

to the “Maintenance Plan” for the proper maintenance

intervals.

WARNING!

Riding the brakes can lead to brake failure and possi-

bly a collision. Driving with your foot resting or riding

on the brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible

brake damage. You would not have your full braking

capacity in an emergency.

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning light is on.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the fluid

level up to the requirements described on the brake fluid

reservoir. Fluid level can be expected to fall as the brake

pads wear. The brake fluid level should be checked when

the pads are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.

NOTE: If your vehicle is equipped with a manual trans-

mission, the brake fluid reservoir supplies fluid to both the

brake system and the clutch release system. The two

systems are separated in the reservoir, and a leak in one

system will not affect the other system. The manual

transmission clutch release system should not require fluid

replacement during the life of the vehicle. If the brake fluid

reservoir is low and the brake system does not indicate any

leaks or other problems, it may be a result of a leak in the

hydraulic clutch release system. See your local authorized

dealer for service.

8

SERVICING AND MAINTENANCE 297