warning light JEEP PATRIOT 2017 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: PATRIOT, Model: JEEP PATRIOT 2017 1.GPages: 421, PDF Size: 3.4 MB

Page 248 of 421

WARNING!(Continued)

•Before replacing a fuse, make sure that the ignition is

off and that all the other services are switched off

and/or disengaged.

• If the replaced fuse blows again, contact an autho-

rized dealer.

• If a general protection fuse for safety systems (air

bag system, braking system), power unit systems

(engine system, gearbox system) or steering system

blows, contact an authorized dealer.

Integrated Power Module (IPM)

The Integrated Power Module is located in the engine

compartment near the air cleaner assembly. This center

contains cartridge fuses and mini-fuses. A label that iden-

tifies each component may be printed on the inside of the cover. Refer to “Engine Compartment” in “Maintaining

Your Vehicle” for further information.

Cavity

Cartridge Fuse Mini-FuseDescription

1 20 Amp Blue –Trailer Tow – If Equipped

2 –15 Amp Lt Blue AWD/4WD Control Module

– If Equipped

3 –10 Amp Red Rear Center Brake Light

Switch

4 –10 Amp Red Ignition Switch/Clock Spring

Integrated Power Module

246 IN CASE OF EMERGENCY

Page 256 of 421

Do not raise the vehicle until you are sure the jack is

securely engaged.

3. Turn the jack screw to the left until the jack can be placedunder the jacking location. Once the jack is positioned,

turn the jack screw to the right until the jack head is

properly engaged with the lift area closest to the wheel

to be changed.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

4. Using the swivel wrench raise the vehicle by turning the jack screw to the right. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.

5. Remove the wheel nuts and pull the wheel and wheel covers, where applicable, off the hub. Install the spare

wheel and wheel nuts with the cone shaped end of the

nuts toward the wheel. Lightly tighten the nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

Rear Jacking Location

254 IN CASE OF EMERGENCY

Page 258 of 421

9. Place the deflated (flat) tire in the cargo area,have the

tire repaired or replaced as soon as possible.

WARNING!

A loose tire thrown forward in a collision or hard stop

could injure the occupants in the vehicle. Have the

deflated (flat) tire repaired or replaced immediately.

10. Check the spare tire pressure as soon as possible. Correct the tire pressure as required.

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. Align the valve notch in the wheel cover with the valvestem on the wheel. Install the cover by hand. Do not use

a hammer or excessive force to install the cover. 3. Install the five wheel lug nuts with the cone shaped end

of the nut toward the wheel. Lightly tighten the lug

nuts.

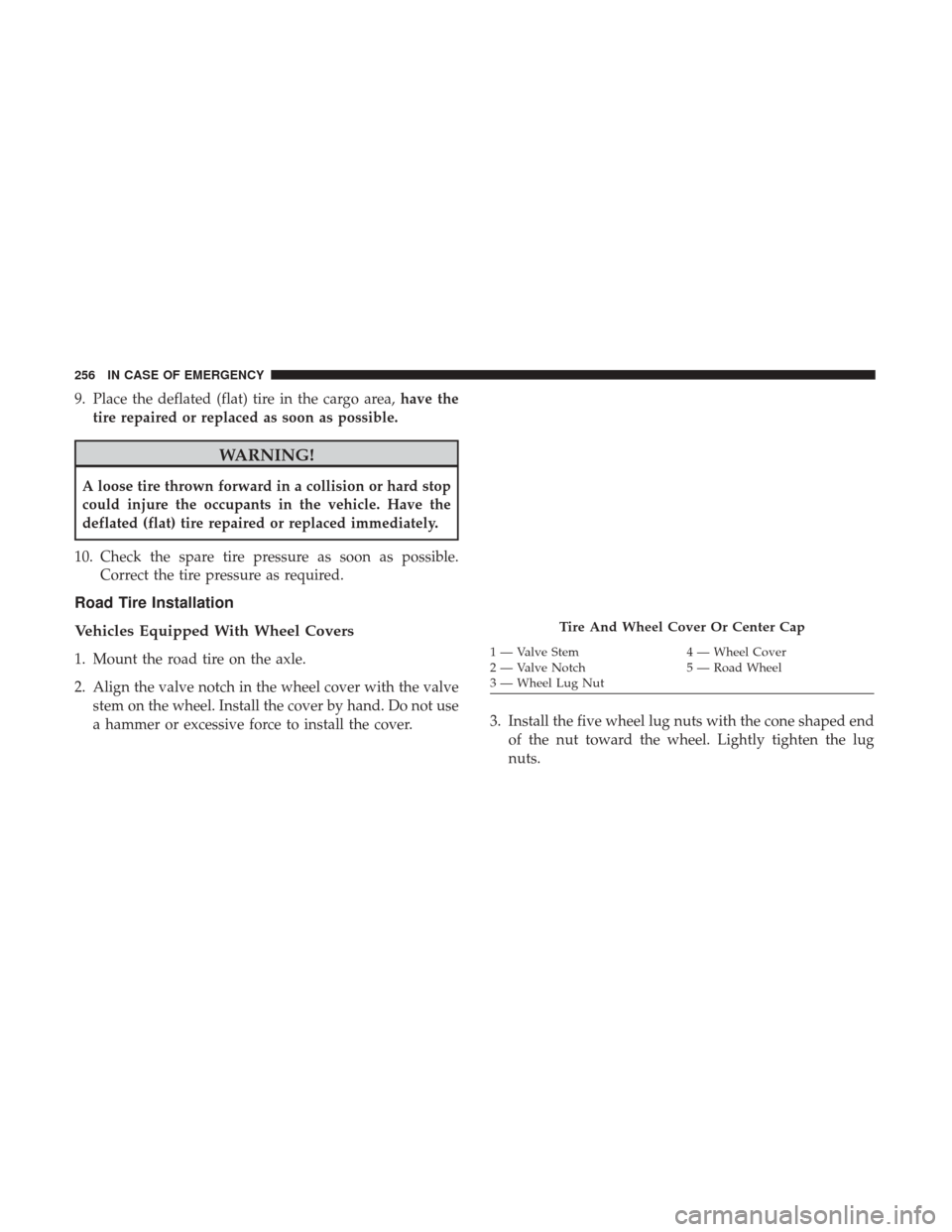

Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Road Wheel

3 — Wheel Lug Nut

256 IN CASE OF EMERGENCY

Page 259 of 421

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts fully until the vehicle has been

lowered. Failure to follow this warning may result in

serious injury.

4. Lower the vehicle to the ground by turning the jack handle counterclockwise.

5. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Refer to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.

6. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2.

Install the remaining lug nuts with the cone shaped end of

the nut toward the wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not fully tighten the lug nuts until the vehicle has been

lowered. Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Refer to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

7

IN CASE OF EMERGENCY 257

Page 279 of 421

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for your vehicle. Operating conditions such as

frequent short-trips, trailer tow, extremely hot or cold

ambient temperatures will influence when the “Change

Oil” or “Oil Change Required” message is displayed.

Severe Operating Conditions can cause the change oil

message to illuminate as early as 3,500 miles (5,600 km)

since last reset. Have your vehicle serviced as soon as

possible, within the next 500 miles (805 km).

On instrument cluster display equipped vehicles, “Oil

Change Required” will be displayed in the cluster and a

single chime will sound, indicating that an oil change is

necessary.

On non-instrument cluster display equipped vehicles,

“Change Oil” will flash in the odometer and a single chime

will sound, indicating that an oil change is necessary.Your authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If a

scheduled oil change is performed by someone other than

your authorized dealer, the message can be reset by

referring to the steps described under “Warning And

Indicator Lights” or “Instrument Cluster Display” in “Get-

ting To Know Your Instrument Panel” for further informa-

tion.

NOTE:

Under no circumstances should oil change inter-

vals exceed 10,000 miles (16,000 km), twelve months or 350

hours of engine run time, whichever comes first. The 350

hours of engine run or idle time is generally only a concern

for fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) if the vehicle

is operated in a dusty and off road environment or is

operated predominately at idle or only very low engine

RPM’s. This type of vehicle use is considered Severe Duty.

8

SERVICING AND MAINTENANCE 277

Page 299 of 421

•Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

• Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install ONLY

the correct type thermostat. Other designs may result in

unsatisfactory engine coolant (antifreeze) performance,

poor gas mileage, and increased emissions.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically. Refer

to the “Maintenance Plan” for the proper maintenance

intervals.

WARNING!

Riding the brakes can lead to brake failure and possi-

bly a collision. Driving with your foot resting or riding

on the brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible

brake damage. You would not have your full braking

capacity in an emergency.

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning light is on.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the fluid

level up to the requirements described on the brake fluid

reservoir. Fluid level can be expected to fall as the brake

pads wear. The brake fluid level should be checked when

the pads are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.

NOTE: If your vehicle is equipped with a manual trans-

mission, the brake fluid reservoir supplies fluid to both the

brake system and the clutch release system. The two

systems are separated in the reservoir, and a leak in one

system will not affect the other system. The manual

transmission clutch release system should not require fluid

replacement during the life of the vehicle. If the brake fluid

reservoir is low and the brake system does not indicate any

leaks or other problems, it may be a result of a leak in the

hydraulic clutch release system. See your local authorized

dealer for service.

8

SERVICING AND MAINTENANCE 297

Page 317 of 421

Keep dismounted tires in a cool, dry place with as little

exposure to light as possible. Protect tires from contact with

oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of many

characteristics. They should be inspected regularly for

wear and correct cold tire inflation pressures. The manu-

facturer strongly recommends that you use tires equivalent

to the originals in size, quality and performance when

replacement is needed. Refer to the paragraph on “Tread

Wear Indicator”. Refer to the Tire and Loading Information

placard or the Vehicle Certification Label for the size

designation of your tire. The Load Index and Speed

Symbol for your tire will be found on the original equip-

ment tire sidewall. See the Tire Sizing Chart example found

in the “Tire Safety Information” section of this manual for

more information relating to the Load Index and Speed

Symbol of a tire.

It is recommended to replace the two front tires or two rear

tires as a pair. Replacing just one tire can seriously affect

your vehicle’s handling. If you ever replace a wheel, make

sure that the wheel’s specifications match those of the

original wheels.It is recommended you contact your authorized tire dealer

or original equipment dealer with any questions you may

have on tire specifications or capability. Failure to use

equivalent replacement tires may adversely affect the

safety, handling, and ride of your vehicle.

WARNING!

•

Do not use a tire, wheel size, load rating, or speed

rating other than that specified for your vehicle.

Some combinations of unapproved tires and wheels

may change suspension dimensions and perfor-

mance characteristics, resulting in changes to steer-

ing, handling, and braking of your vehicle. This can

cause unpredictable handling and stress to steering

and suspension components. You could lose control

and have a collision resulting in serious injury or

death. Use only the tire and wheel sizes with load

ratings approved for your vehicle.

• Never use a tire with a smaller load index or capacity,

other than what was originally equipped on your

vehicle. Using a tire with a smaller load index could

result in tire overloading and failure. You could lose

control and have a collision.

(Continued)

8

SERVICING AND MAINTENANCE 315

Page 325 of 421

WARNING!

The temperature grade for this tire is established for a

tire that is properly inflated and not overloaded. Ex-

cessive speed, under-inflation, or excessive loading,

either separately or in combination, can cause heat

buildup and possible tire failure.

BODYWORK

Protection From Atmospheric Agents

Vehicle body care requirements vary according to geo-

graphic locations and usage. Chemicals that make roads

passable in snow and ice and those that are sprayed on

trees and road surfaces during other seasons are highly

corrosive to the metal in your vehicle. Outside parking,

which exposes your vehicle to airborne contaminants, road

surfaces on which the vehicle is operated, extreme hot or

cold weather and other extreme conditions will have an

adverse effect on paint, metal trim, and underbody protec-

tion.

The following maintenance recommendations will enable

you to obtain maximum benefit from the corrosion resis-

tance built into your vehicle.

What Causes Corrosion?

Corrosion is the result of deterioration or removal of paint

and protective coatings from your vehicle.

The most common causes are:

•Road salt, dirt and moisture accumulation.

• Stone and gravel impact.

• Insects, tree sap and tar.

• Salt in the air near seacoast localities.

• Atmospheric fallout/industrial pollutants.

Body And Underbody Maintenance

Cleaning Headlights

Your vehicle is equipped with plastic headlights and fog

lights that are lighter and less susceptible to stone breakage

than glass headlights.

Plastic is not as scratch resistant as glass and therefore

different lens cleaning procedures must be followed.

To minimize the possibility of scratching the lenses and

reducing light output, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild soap solution followed

by rinsing.

8

SERVICING AND MAINTENANCE 323

Page 331 of 421

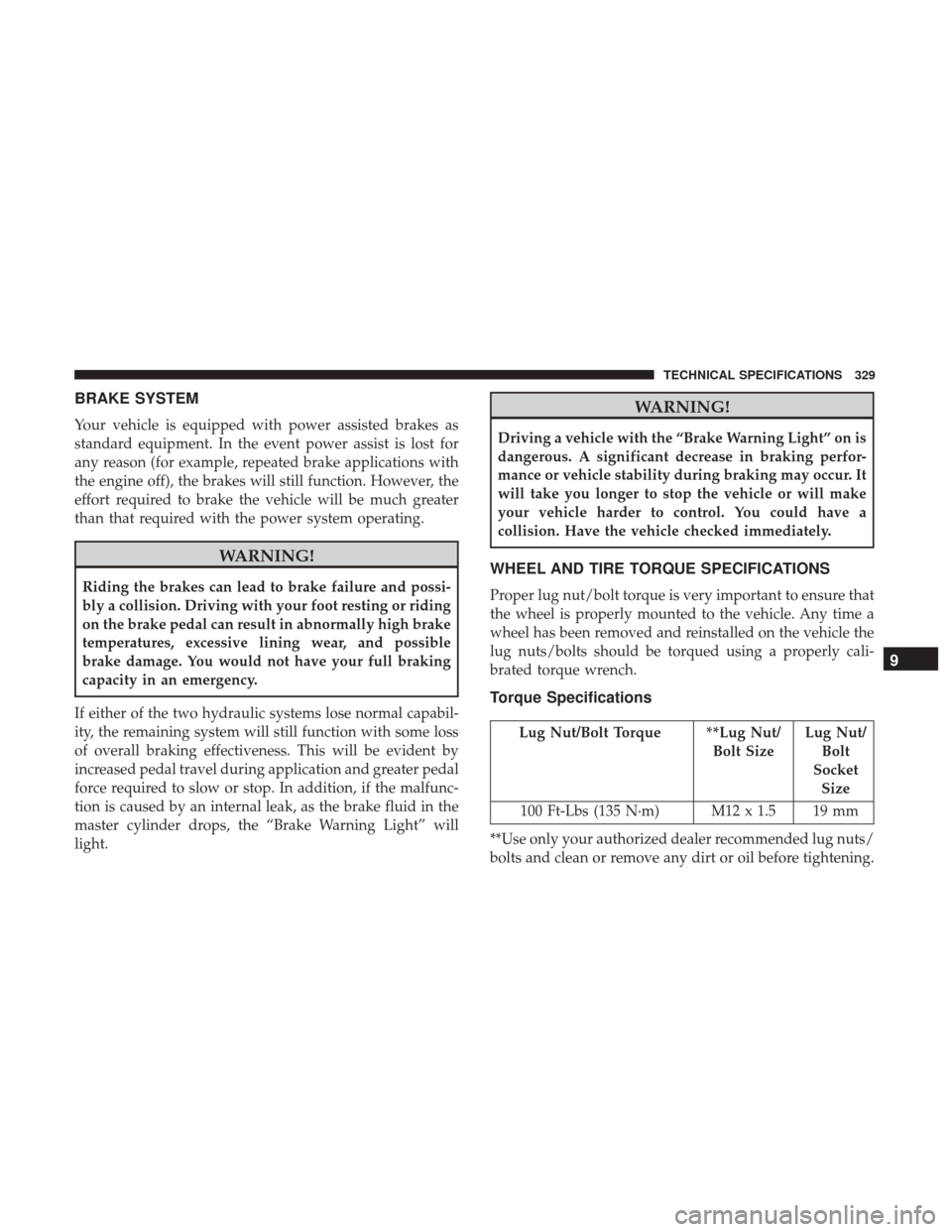

BRAKE SYSTEM

Your vehicle is equipped with power assisted brakes as

standard equipment. In the event power assist is lost for

any reason (for example, repeated brake applications with

the engine off), the brakes will still function. However, the

effort required to brake the vehicle will be much greater

than that required with the power system operating.

WARNING!

Riding the brakes can lead to brake failure and possi-

bly a collision. Driving with your foot resting or riding

on the brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible

brake damage. You would not have your full braking

capacity in an emergency.

If either of the two hydraulic systems lose normal capabil-

ity, the remaining system will still function with some loss

of overall braking effectiveness. This will be evident by

increased pedal travel during application and greater pedal

force required to slow or stop. In addition, if the malfunc-

tion is caused by an internal leak, as the brake fluid in the

master cylinder drops, the “Brake Warning Light” will

light.

WARNING!

Driving a vehicle with the “Brake Warning Light” on is

dangerous. A significant decrease in braking perfor-

mance or vehicle stability during braking may occur. It

will take you longer to stop the vehicle or will make

your vehicle harder to control. You could have a

collision. Have the vehicle checked immediately.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle the

lug nuts/bolts should be torqued using a properly cali-

brated torque wrench.

Torque Specifications

Lug Nut/Bolt Torque **Lug Nut/ Bolt SizeLug Nut/

Bolt

Socket Size

100 Ft-Lbs (135 N·m) M12 x 1.5 19 mm

**Use only your authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

9

TECHNICAL SPECIFICATIONS 329

Page 380 of 421

•The Uconnect Phone does slightly lower your chances of

successfully making a phone call as to that for the

mobile phone directly.

WARNING!

To use your Uconnect Phone System in an emergency,

your mobile phone must be:

• Turned on.

• Paired to the Uconnect System.

• Have network coverage.

Roadside Assistance/Towing Assistance

If you need roadside assistance:

• Push the Phone

button to begin.

•After the “Ready” prompt and the following beep, say

“Towing Assistance.”

NOTE: You should program the desired Towing Assistance

phone number using the Voice Command system. To do

this, push the Phone

button and say “Setup,” fol-

lowed by “Towing Assistance.” When prompted say

1-800-521-2779 for U.S./Canada, say 55-14-3454 for

Mexico City and 1-800-712-3040 for outside Mexico City

in Mexico. Paging

To learn how to page, refer to “Working with Automated

Systems.” Paging works properly except for pagers of

certain companies, which time out a little too soon to work

properly with the Uconnect Phone.

Voice Mail Calling

To learn how to access your voice mail, refer to “Working

with Automated Systems.”

Working with Automated Systems

This method is used in instances where one generally has

to press numbers on the mobile phone keypad while

navigating through an automated telephone system.

You can use your Uconnect Phone to access a voice mail

system or an automated service, such as a paging service or

automated customer service line. Some services require

immediate response selection. In some instances, that may

be too quick for use of the Uconnect Phone.

When calling a number with your Uconnect Phone that

normally requires you to enter in a touch-tone sequence on

your mobile phone keypad, you can push the Voice Com-

mand

button and say the sequence you wish to enter,

followed by the word “Send.” For example, if required

378 MULTIMEDIA