oil plug JEEP PATRIOT 2017 1.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: PATRIOT, Model: JEEP PATRIOT 2017 1.GPages: 421, PDF Size: 3.4 MB

Page 199 of 421

WARNING!

Never pour fuel or other flammable liquid into the

throttle body air inlet opening in an attempt to start the

vehicle. This could result in flash fire causing serious

personal injury.

CAUTION!

To prevent damage to the starter, do not crank the

engine for more than 15 seconds at a time. Wait 10 to 15

seconds before trying again.

After Starting

The idle speed is controlled automatically, and it will

decrease as the engine warms up.

ENGINE BLOCK HEATER — IF EQUIPPED

The engine block heater warms the engine, and permits

quicker starts in cold weather. Connect the cord to a

standard 110-115 Volt AC electrical outlet with a grounded,

three-wire extension cord.

The engine block heater must be plugged in at least one

hour to have an adequate warming effect on the engine.

WARNING!

Remember to disconnect the engine block heater cord

before driving. Damage to the 110-115 Volt electrical

cord could cause electrocution.

ENGINE BREAK-IN RECOMMENDATIONS

A long break-in period is not required for the engine and

drivetrain (transmission and axle) in your vehicle.

Drive moderately during the first 300 miles (500 km). After

the initial 60 miles (100 km), speeds up to 50 or 55 mph (80

or 90 km/h) are desirable.

While cruising, brief full-throttle acceleration within the

limits of local traffic laws contributes to a good break-in.

Wide-open throttle acceleration in low gear can be detri-

mental and should be avoided.

The engine oil installed in the engine at the factory is a

high-quality energy conserving type lubricant. Oil changes

should be consistent with anticipated climate conditions

under which vehicle operations will occur. For the recom-

mended viscosity and quality grades, refer to “Dealer

Service” in “Servicing And Maintenance”.

6

STARTING AND OPERATING 197

Page 264 of 421

5. Uncoil the Power Plug (8) and insert the plug into thevehicle’s 12 Volt power outlet.

NOTE: Do not remove foreign objects (e.g., screws or nails)

from the tire.

(C) Injecting Tire Service Kit Sealant Into The

Deflated Tire:

• Always start the engine before turning on the Tire

Service Kit.

NOTE: Manual transmission vehicles must have the park-

ing brake engaged and the gear selector in NEUTRAL.

• After pushing the Power Button (4), the sealant (white

fluid) will flow from the Sealant Bottle (1) through the

Sealant Hose (6) and into the tire.

NOTE: Sealant may leak out through the puncture in the

tire.

If the sealant (white fluid) does not flow within0–10

seconds through the Sealant Hose (6):

1. Push the Power Button (4) to turn off the Tire Service Kit. Disconnect the Sealant Hose (6) from the valve stem.

Make sure the valve stem is free of debris. Reconnect the

Sealant Hose (6) to the valve stem. Check that the Mode Select Knob (5) is in the Sealant Mode position and not

Air Mode. Push the Power Button (4) to turn on the Tire

Service Kit.

2. Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or another vehicle, if available.

Make sure the engine is running before turning on the

Tire Service Kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE: If the Mode Select Knob (5) is on Air Mode and the

pump is operating, air will dispense from the Air Pump

Hose (7) only, not the Sealant Hose (6).

If the sealant (white fluid) does flow through the Sealant

Hose (6):

1. Continue to operate the pump until sealant is no longer flowing through hose (typically takes 30 - 70 seconds).

As the sealant flows through the Sealant Hose (6), the

Pressure Gauge (3) can read as high as 70 psi (4.8 Bar).

The Pressure Gauge (3) will decrease quickly from

approximately 70 psi (4.8 Bar) to the actual tire pressure

when the Sealant Bottle (1) is empty.

262 IN CASE OF EMERGENCY

Page 266 of 421

WARNING!(Continued)

Tire Service Kit. Do not exceed 55 mph (90 km/h) until

the tire is repaired or replaced. Failure to follow this

warning can result in injuries that are serious or fatal

to you, your passengers, and others around you.

(E) After Driving:

Pull over to a safe location. Refer to “Whenever You Stop to

Use Tire Service Kit” before continuing.

1. Push in the Mode Select Knob (5) and turn to the Air

Mode position.

2. Uncoil the power plug and insert the plug into the vehicle’s 12 Volt power outlet.

3. Uncoil the Air Pump Hose (7) (black in color) and screw the fitting at the end of hose (7) onto the valve stem.

4. Check the pressure in the tire by reading the Pressure Gauge (3).

If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to drive the

vehicle further. Call for assistance. If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button (4) to turn on Tire Service Kit

and inflate the tire to the pressure indicated on the tire

and loading information label on the driver-side door

opening.

NOTE: If the tire becomes over-inflated, push the Deflation

Button to reduce the tire pressure to the recommended

inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and unplug from 12

Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an authorized dealer or tire

service center.

5. Remove the Speed Limit sticker from the instrument panel after the tire has been repaired.

6. Replace the Sealant Bottle (1) and Sealant Hose (6) assembly at your authorized dealer as soon as possible.

Refer to (F) “Sealant Bottle and Hose Replacement”.

264 IN CASE OF EMERGENCY

Page 304 of 421

Fluid Level Check

Visually inspect the unit at each oil change for leakage. If

leakage is detected, check the fluid level by removing the

fill plug. The fluid level should be maintained between the

bottom of the fill hole to 1/8 inch (4 mm) below the fill

hole.

Add fluid, if necessary, to maintain the proper level.

Frequency Of Fluid Change

Refer to the “Maintenance Plan” for the proper mainte-

nance intervals.

Power Transfer Unit (PTU) — AWD/4WD Models

Only

Lubricant Selection

Use only the manufacturer’s recommended fluid. Refer to

“Fluids And Lubricants” in “Technical Specifications” for

further information.

Fluid Level Check

Visually inspect the unit at each oil change for leakage. If

leakage is detected, Check the fluid level by removing thefill plug. The fluid level should be maintained between the

bottom of the fill hole to 1/8 inch (4 mm) below the fill

hole.

Add fluid, if necessary, to maintain the proper level.

Frequency Of Fluid Change

Refer to the “Maintenance Plan” for the proper mainte-

nance intervals.

RAISING THE VEHICLE

In the case where it is necessary to raise the vehicle, go to

an authorized dealer or service station.

TIRES

Tire Safety Information

Tire safety information will cover aspects of the following

information: Tire Markings, Tire Identification Numbers,

Tire Terminology and Definitions, Tire Pressures and Tire

Loading.

302 SERVICING AND MAINTENANCE

Page 338 of 421

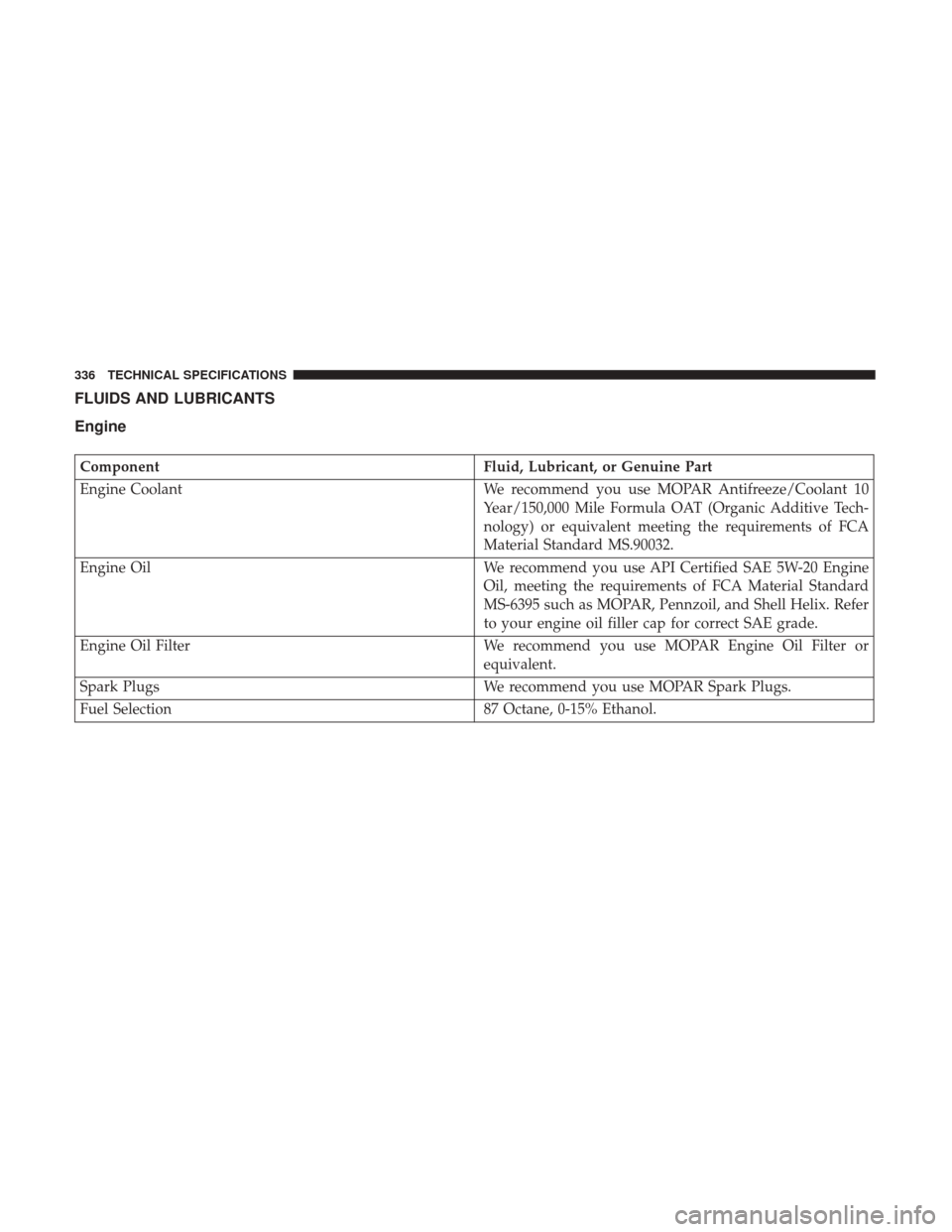

FLUIDS AND LUBRICANTS

Engine

ComponentFluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use MOPAR Antifreeze/Coolant 10

Year/150,000 Mile Formula OAT (Organic Additive Tech-

nology) or equivalent meeting the requirements of FCA

Material Standard MS.90032.

Engine Oil We recommend you use API Certified SAE 5W-20 Engine

Oil, meeting the requirements of FCA Material Standard

MS-6395 such as MOPAR, Pennzoil, and Shell Helix. Refer

to your engine oil filler cap for correct SAE grade.

Engine Oil Filter We recommend you use MOPAR Engine Oil Filter or

equivalent.

Spark Plugs We recommend you use MOPAR Spark Plugs.

Fuel Selection 87 Octane, 0-15% Ethanol.

336 TECHNICAL SPECIFICATIONS