check engine JEEP RENEGADE 2014 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2014, Model line: RENEGADE, Model: JEEP RENEGADE 2014 1.GPages: 212, PDF Size: 17.48 MB

Page 145 of 212

FUEL CUT-OFF

SYSTEM

This intervenes in the case of an impact

causing:

❒the interruption of the fuel supply with

the engine consequently cutting out;

❒the automatic unlocking of the doors;

❒turning on of the lights inside the

vehicle;

❒deactivation of climate control system

ventilation;

❒switching on of the hazard warning

lights (to deactivate the lights press the

button on the dashboard).

On some versions, the intervention of

the system is indicated by a message

shown on the display. In the same way,

a dedicated message on the display

warns the driver if system operation is

compromised.

IMPORTANT Carefully check the vehicle

for fuel leaks, for instance in the engine

compartment, under the vehicle or

near the tank area. After a collision,

bring the ignition device to STOP to

prevent the battery from running down.

To restore correct operation of the

vehicle, carry out the following

procedure (this procedure must be

started and completed within less than

one minute):❒move the ignition device to MAR;

❒turn on the direction indicators on the

right, then on the left, then again on

the right and again on the left;

❒now deactivate the direction

indicators on the left;

❒bring the ignition device to STOP;

❒move the ignition device to MAR.

160)

WARNING

160)If, after an impact, you smell fuel or

notice leaks from the fuel system, do

not reactivate the system to avoid the risk

of fire.

AUTOMATIC

TRANSMISSION

GEAR LEVER

UNLOCKING

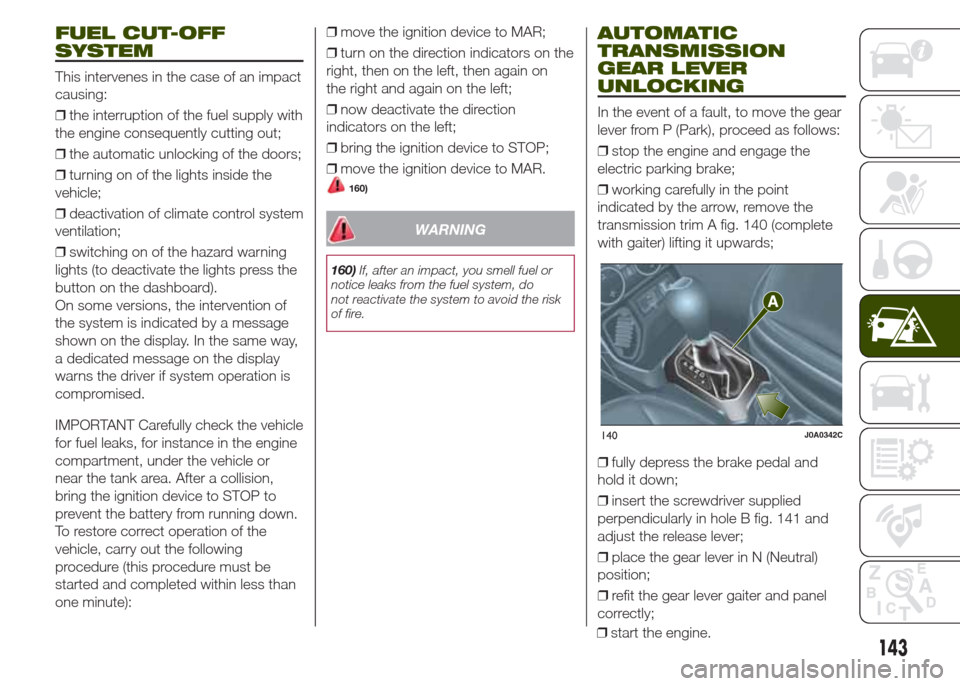

In the event of a fault, to move the gear

lever from P (Park), proceed as follows:

❒stop the engine and engage the

electric parking brake;

❒working carefully in the point

indicated by the arrow, remove the

transmission trim A fig. 140 (complete

with gaiter) lifting it upwards;

❒fully depress the brake pedal and

hold it down;

❒insert the screwdriver supplied

perpendicularly in hole B fig. 141 and

adjust the release lever;

❒place the gear lever in N (Neutral)

position;

❒refit the gear lever gaiter and panel

correctly;

140J0A0342C

143

❒start the engine.

Page 147 of 212

TOWING THE

VEHICLE

ATTACHING THE TOW

HOOK

161) 162) 163)

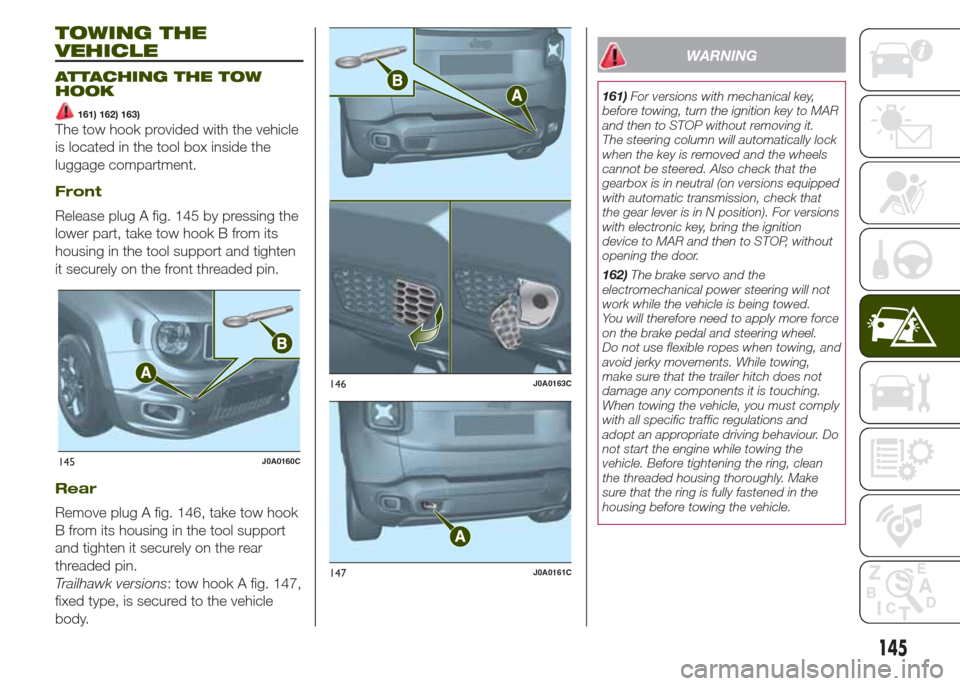

The tow hook provided with the vehicle

is located in the tool box inside the

luggage compartment.

Front

Release plug A fig. 145 by pressing the

lower part, take tow hook B from its

housing in the tool support and tighten

it securely on the front threaded pin.

Rear

Remove plug A fig. 146, take tow hook

B from its housing in the tool support

and tighten it securely on the rear

threaded pin.

Trailhawk versions: tow hook A fig. 147,

fixed type, is secured to the vehicle

body.

WARNING

161)For versions with mechanical key,

before towing, turn the ignition key to MAR

and then to STOP without removing it.

The steering column will automatically lock

when the key is removed and the wheels

cannot be steered. Also check that the

gearbox is in neutral (on versions equipped

with automatic transmission, check that

the gear lever is in N position). For versions

with electronic key, bring the ignition

device to MAR and then to STOP, without

opening the door.

162)The brake servo and the

electromechanical power steering will not

work while the vehicle is being towed.

You will therefore need to apply more force

on the brake pedal and steering wheel.

Do not use flexible ropes when towing, and

avoid jerky movements. While towing,

make sure that the trailer hitch does not

damage any components it is touching.

When towing the vehicle, you must comply

with all specific traffic regulations and

adopt an appropriate driving behaviour. Do

not start the engine while towing the

vehicle. Before tightening the ring, clean

the threaded housing thoroughly. Make

sure that the ring is fully fastened in the

housing before towing the vehicle.

145J0A0160C

146J0A0163C

147J0A0161C

145

Page 150 of 212

SCHEDULED

SERVICING

Correct servicing is crucial for

guaranteeing a long life for the vehicle

under the best conditions. For this

reason, Jeep has planned a series of

checks and services at fixed distance

intervals and, where provided, at fixed

time intervals, as described in the

Scheduled Servicing Plan.

Before each service, it is always

necessary to carefully follow the

instructions in the Scheduled Servicing

Plan (e.g. periodically check level of

fluids, tyre pressure, etc.).

Scheduled Servicing is offered by all

Jeep Dealerships according to a set

time schedule. If, during each

operation, in addition to the ones

scheduled, the need arises for further

replacements or repairs, these may

be carried out with your explicit

agreement only. If your vehicle is used

frequently for towing, the interval

between one service operation and the

next should be reduced.IMPORTANT Scheduled Servicing

Coupons are required by the

Manufacturer. Failure to have them

carried out may invalidate the warranty.

It is advisable to inform a Jeep

Dealership of any small operating

irregularities without waiting for the next

service.

PERIODIC CHECKS

Every1,000km or before long

journeys, check and if necessary, top

up: engine coolant level; brake fluid

level; screen washer fluid level; tyre

inflation pressure and condition; lighting

system operation (headlights, direction

indicators, hazard warning lights, etc.);

screen washer/wiper system operation

and positioning/wear of windscreen/

rear window wiper blades.

Every3,000km, check and top up if

required: engine oil level.

HEAVY-DUTY USE OF THE

VEHICLE

If the vehicle is used under one of the

following conditions: towing a trailer

or caravan; dusty roads; short (less

than 7-8 km), repeated journeys with

sub-zero outside temperatures; engine

often idling or driving long distances

at low speed or long periods of

inactivity, the following checks must be

carried out more often than indicated

in the Scheduled Servicing Plan:❒check front disc brake pad condition

and wear;

❒check cleanliness of bonnet and

luggage compartment locks,

cleanliness and lubrication of linkage;

❒visually inspect condition of: engine,

gearbox, transmission, pipes and hoses

(exhaust/fuel system/brakes) and

rubber elements (boots/sleeves/

bushes, etc.);

❒check battery charge and battery

fluid level (electrolyte);

❒visually inspect condition of the

accessory drive belts;

❒check and, if necessary, change

engine oil and replace oil filter;

❒check and, if necessary, replace

pollen filter;

❒check and, if necessary, replace air

cleaner.

On versions with automatic

transmission, change transmission oil

and replace oil filter every 60,000 km

(40,000) or every 4 years.

148

SERVICING AND MAINTENANCE

Page 151 of 212

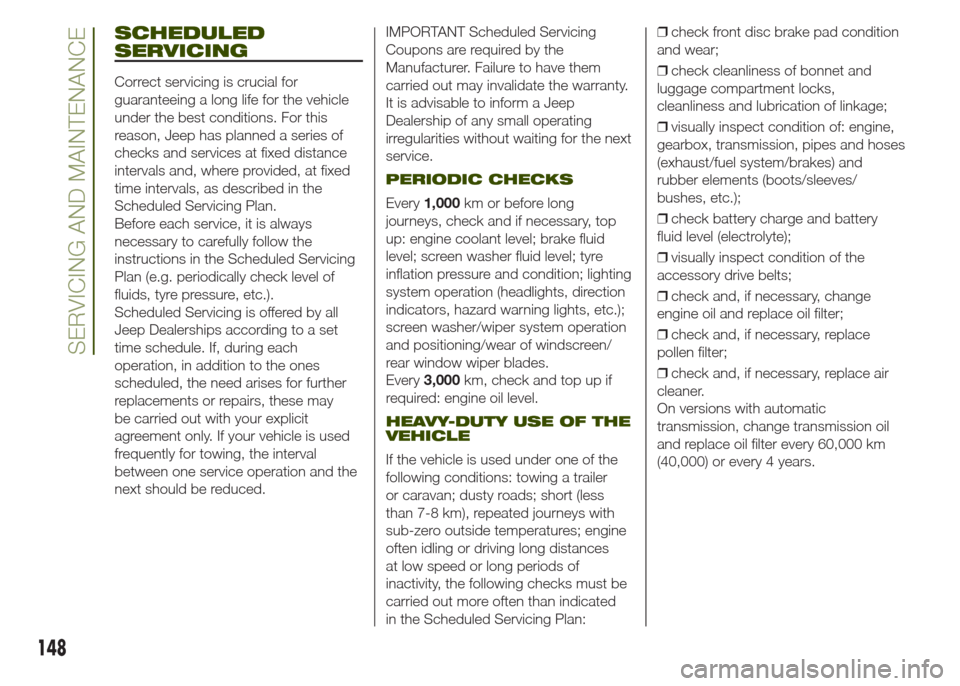

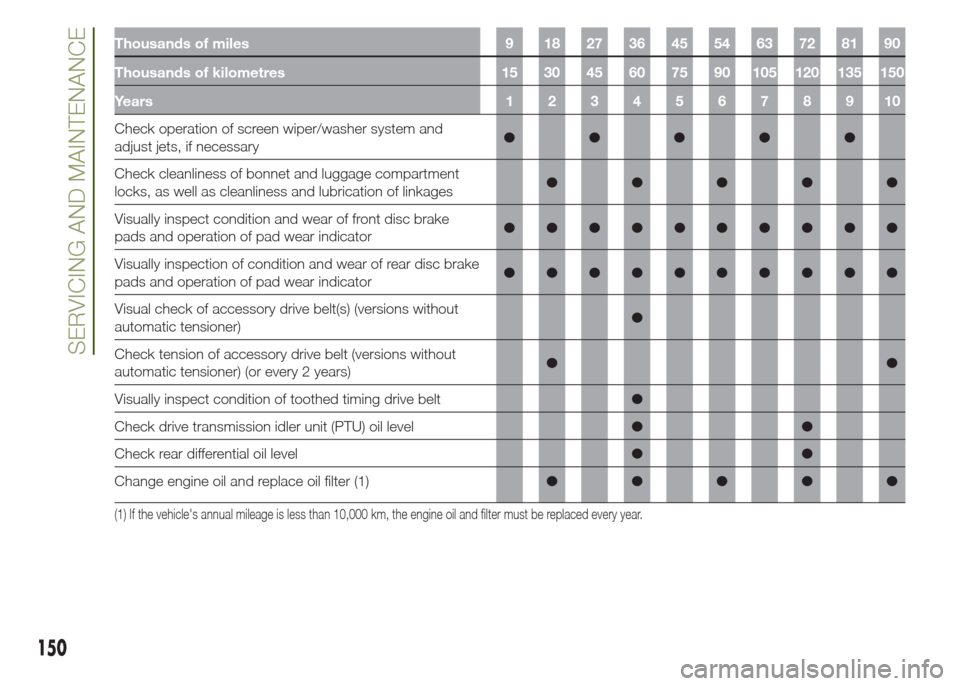

SCHEDULED SERVICING PLAN (petrol versions)

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/8 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of miles 9 18 27 36 45 54 63 72 81 90

Thousands of kilometres 15 30 45 60 75 90 105 120 135 150

Years12345678910

Check tyre condition/wear and adjust pressure, if

necessary. Check TireKit recharge (where provided) expiry

date●●●●●●●●●●

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, luggage compartment,

passenger compartment, glove compartment, instrument

panel warning lights, etc.)●●●●●●●●●●

Check and, if necessary, top up fluid levels (engine

coolant, hydraulic clutch/brakes, screen washer, battery,

etc.)●●●●●●●●●●

Check exhaust emissions/smokiness●●●●●●●●●●

Use the diagnosis socket to check supply/engine

management system operation, emissions and, where

provided, engine oil degradation●●●●●●●●●●

Visually inspect condition of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (gaiters, sleeves,

bushes, etc.)●●●●●

Check windscreen/rear window wiper blade position/wear●●●●●

149

Page 152 of 212

Thousands of miles 9 18 27 36 45 54 63 72 81 90

Thousands of kilometres 15 30 45 60 75 90 105 120 135 150

Years12345678910

Check operation of screen wiper/washer system and

adjust jets, if necessary●●●●●

Check cleanliness of bonnet and luggage compartment

locks, as well as cleanliness and lubrication of linkages●●●●●

Visually inspect condition and wear of front disc brake

pads and operation of pad wear indicator●●●●●●●●●●

Visually inspection of condition and wear of rear disc brake

pads and operation of pad wear indicator●●●●●●●●●●

Visual check of accessory drive belt(s) (versions without

automatic tensioner)●

Check tension of accessory drive belt (versions without

automatic tensioner) (or every 2 years)●●

Visually inspect condition of toothed timing drive belt●

Check drive transmission idler unit (PTU) oil level●●

Check rear differential oil level●●

Change engine oil and replace oil filter (1)●●●●●

(1) If the vehicle's annual mileage is less than 10,000 km, the engine oil and filter must be replaced every year.

150

SERVICING AND MAINTENANCE

Page 154 of 212

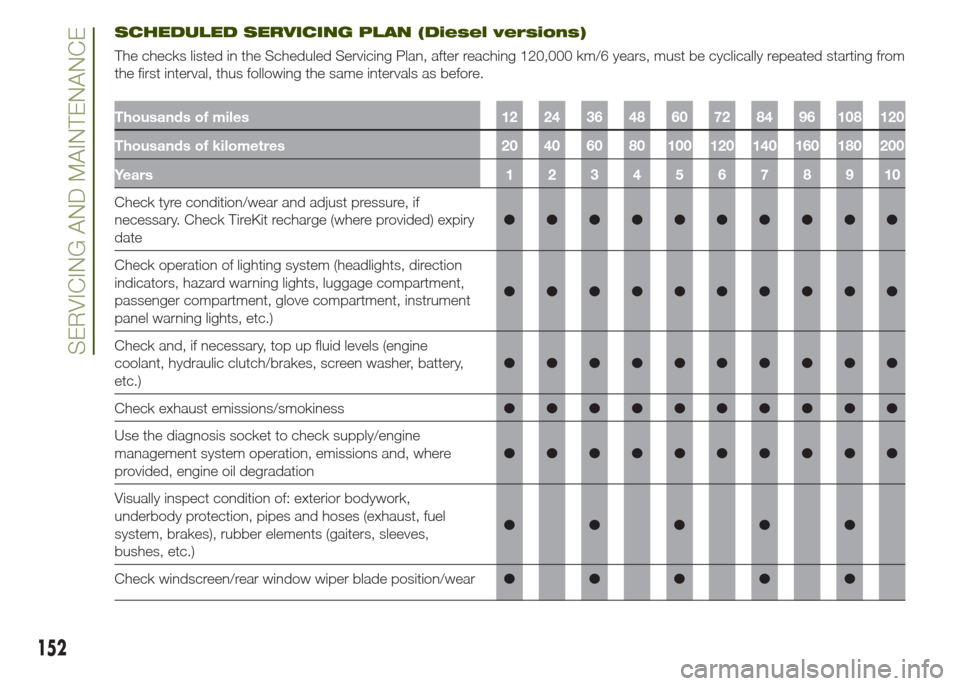

SCHEDULED SERVICING PLAN (Diesel versions)

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/6 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of miles 12 24 36 48 60 72 84 96 108 120

Thousands of kilometres 20 40 60 80 100 120 140 160 180 200

Years12345678910

Check tyre condition/wear and adjust pressure, if

necessary. Check TireKit recharge (where provided) expiry

date●●●●●●●●●●

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, luggage compartment,

passenger compartment, glove compartment, instrument

panel warning lights, etc.)●●●●●●●●●●

Check and, if necessary, top up fluid levels (engine

coolant, hydraulic clutch/brakes, screen washer, battery,

etc.)●●●●●●●●●●

Check exhaust emissions/smokiness●●●●●●●●●●

Use the diagnosis socket to check supply/engine

management system operation, emissions and, where

provided, engine oil degradation●●●●●●●●●●

Visually inspect condition of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (gaiters, sleeves,

bushes, etc.)●●●●●

Check windscreen/rear window wiper blade position/wear●●●●●

152

SERVICING AND MAINTENANCE

Page 155 of 212

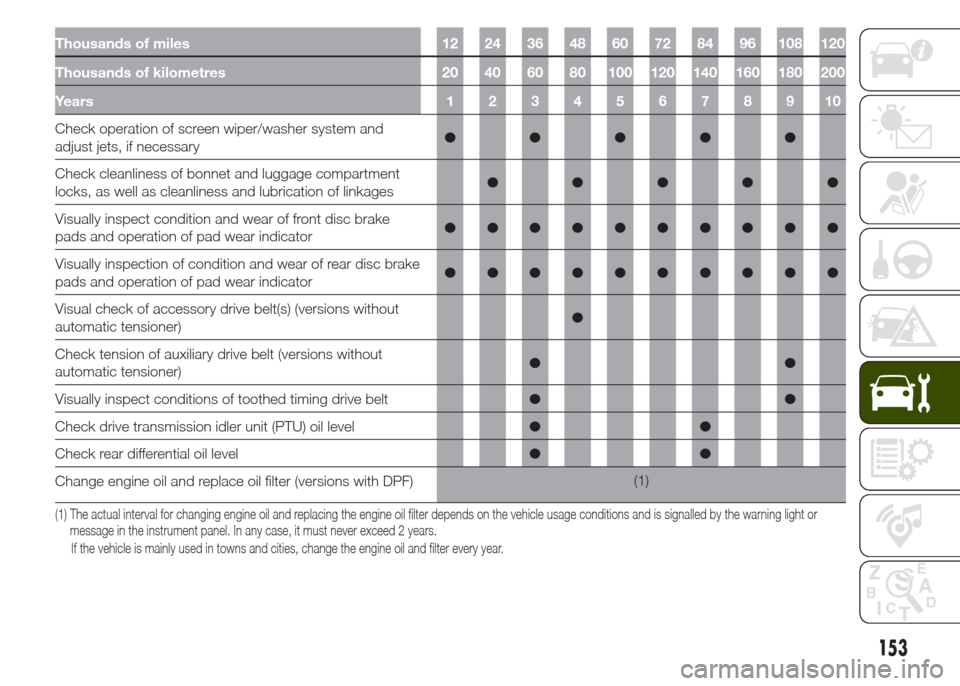

Thousands of miles 12 24 36 48 60 72 84 96 108 120

Thousands of kilometres 20 40 60 80 100 120 140 160 180 200

Years12345678910

Check operation of screen wiper/washer system and

adjust jets, if necessary●●●●●

Check cleanliness of bonnet and luggage compartment

locks, as well as cleanliness and lubrication of linkages●●●●●

Visually inspect condition and wear of front disc brake

pads and operation of pad wear indicator●●●●●●●●●●

Visually inspection of condition and wear of rear disc brake

pads and operation of pad wear indicator●●●●●●●●●●

Visual check of accessory drive belt(s) (versions without

automatic tensioner)●

Check tension of auxiliary drive belt (versions without

automatic tensioner)●●

Visually inspect conditions of toothed timing drive belt●●

Check drive transmission idler unit (PTU) oil level●●

Check rear differential oil level●●

Change engine oil and replace oil filter (versions with DPF)(1)

(1) The actual interval for changing engine oil and replacing the engine oil filter depends on the vehicle usage conditions and is signalled by the warning light or

message in the instrument panel. In any case, it must never exceed 2 years.

If the vehicle is mainly used in towns and cities, change the engine oil and filter every year.

153

Page 157 of 212

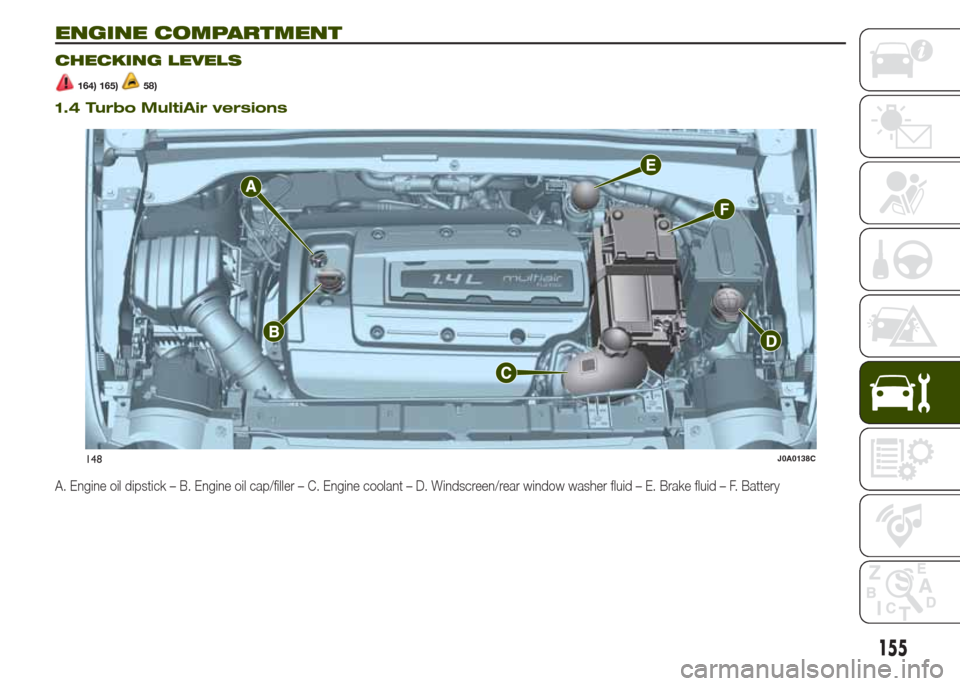

ENGINE COMPARTMENT.

CHECKING LEVELS

164) 165)58)

1.4 Turbo MultiAir versions

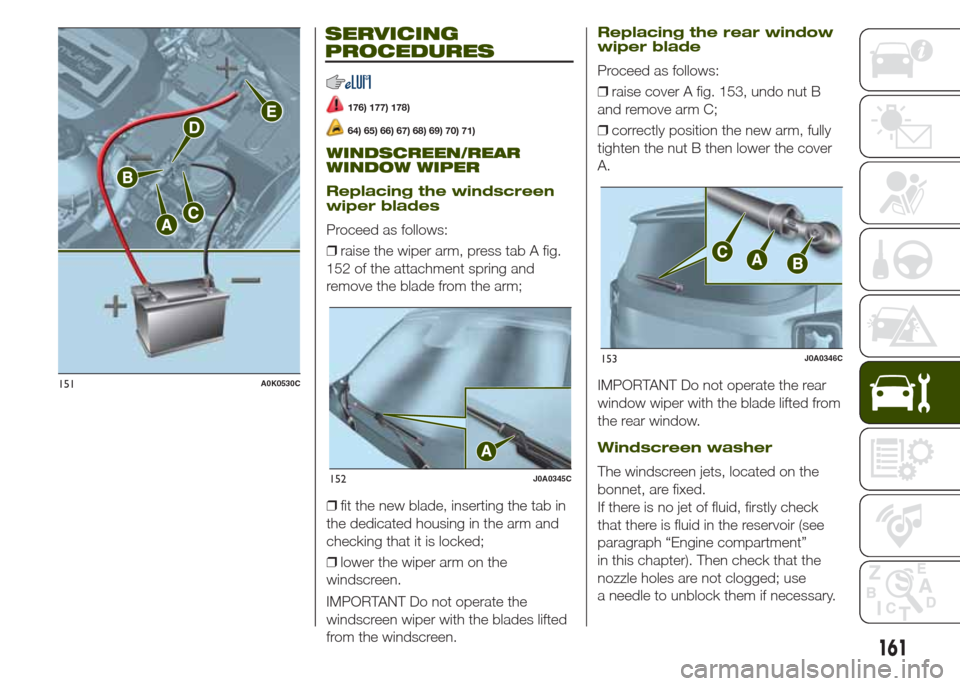

A. Engine oil dipstick – B. Engine oil cap/filler – C. Engine coolant – D. Windscreen/rear window washer fluid – E. Brake fluid – F. Battery

148J0A0138C

155

Page 160 of 212

ENGINE OIL

Check that the oil level is between the

MIN and MAX references on the

dipstick A. If the oil level is near or even

under the MIN line, add oil using the

filler B to reach the MAX line.

166)59)

Take out the engine oil dipstick A, clean

it with a lint-free cloth and reinsert it.

Extract it again and check that the level

is between the MIN and MAX marks

on the dipstick.

Engine oil consumption

60)4)

The maximum engine oil consumption

is usually 400 grams every 1,000 km.

During the initial period of use the

engine oil consumption conditions

should be considered as having

stabilised after the first 5000 - 6000

km.

ENGINE COOLANT

If the level is too low, unscrew the cap

of reservoir C and add the fluid

described in the "Technical

Specifications" section.

167)61)

WINDSCREEN/REAR

WINDOW WASHER FLUID

If the level is too low, lift reservoir cap D

and add the fluid described in the

chapter "Technical Specifications".

168) 169)

IMPORTANT The headlight washer

system will not operate when the fluid

level is low, even though the

windscreen/rear window washer

continues to operate. On some

versions there is a reference notch on

the dipstick: ONLY the windscreen/rear

window washer operates with the

level below this reference.

BRAKE FLUID

Check that the fluid is at the max. level.

If the fluid level in the reservoir is too

low, undo reservoir cap E and add the

fluid described in the chapter "Technical

Specifications".

170) 171)62)

AUTOMATIC

TRANSMISSION

ACTIVATION SYSTEM OIL

The transmission control oil level should

only be checked at a Jeep Dealership.

5)

BATTERY

172) 173) 174) 175)6)

The battery does not require the

electrolyte to be topped up with distilled

water. A periodic check carried out at

a Jeep Dealership is, however,

necessary to check efficiency.

IMPORTANT After the battery is

disconnected, the steering must be

initialised. The

warning light on the

instrument panel switches on to

indicate this. To carry out this

procedure turn the steering wheel all

the way from one end to the other

or drive in a straight line for about a

hundred metres.

IMPORTANT If the charge level remains

under 50% for a long time, the battery

is damaged by sulphation, reducing

its capacity and efficiency at start-up.

CLIMATE CONTROL

SYSTEM MAINTENANCE

In winter, the climate control system

must be turned on at least once a

month for about 10 minutes. Have the

system inspected at a Jeep Dealership

before the summer.

158

SERVICING AND MAINTENANCE

Page 163 of 212

SERVICING

PROCEDURES

176) 177) 178)

64) 65) 66) 67) 68) 69) 70) 71)

WINDSCREEN/REAR

WINDOW WIPER

Replacing the windscreen

wiper blades

Proceed as follows:

❒raise the wiper arm, press tab A fig.

152 of the attachment spring and

remove the blade from the arm;

❒fit the new blade, inserting the tab in

the dedicated housing in the arm and

checking that it is locked;

❒lower the wiper arm on the

windscreen.

IMPORTANT Do not operate the

windscreen wiper with the blades lifted

from the windscreen.

Replacing the rear window

wiper blade

Proceed as follows:

❒raise cover A fig. 153, undo nut B

and remove arm C;

❒correctly position the new arm, fully

tighten the nut B then lower the cover

A.

IMPORTANT Do not operate the rear

window wiper with the blade lifted from

the rear window.

Windscreen washer

The windscreen jets, located on the

bonnet, are fixed.

If there is no jet of fluid, firstly check

that there is fluid in the reservoir (see

paragraph “Engine compartment”

in this chapter). Then check that the

nozzle holes are not clogged; use

a needle to unblock them if necessary.

151A0K0530C

152J0A0345C

153J0A0346C

161