torque JEEP WRANGLER 1994 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: WRANGLER, Model: JEEP WRANGLER 1994Pages: 1770, PDF Size: 75.27 MB

Page 182 of 1770

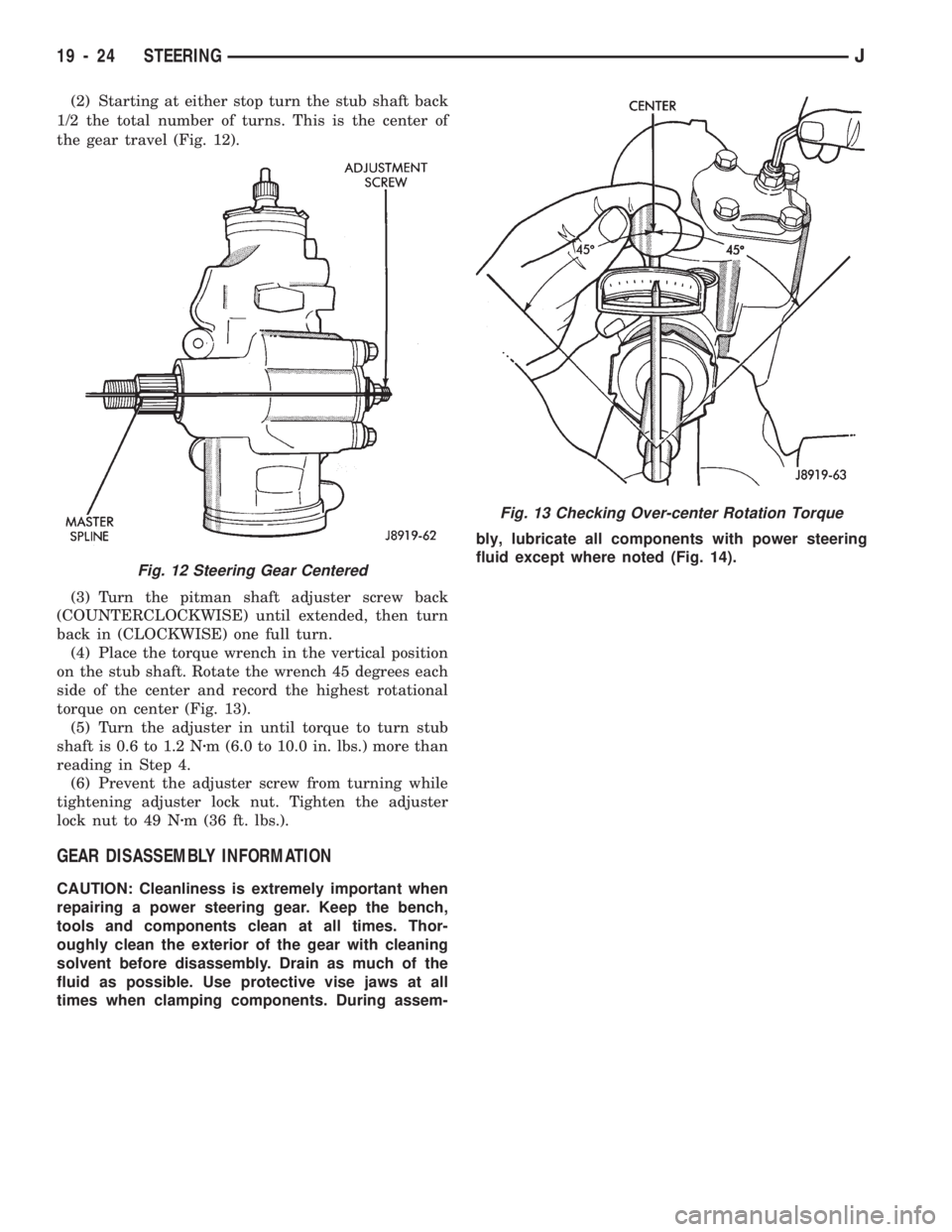

Fig. 13 Checking Over-center Rotation Torque

Fig. 12 Steering Gear Centered

19 - 24 STEERINGJ

Page 438 of 1770

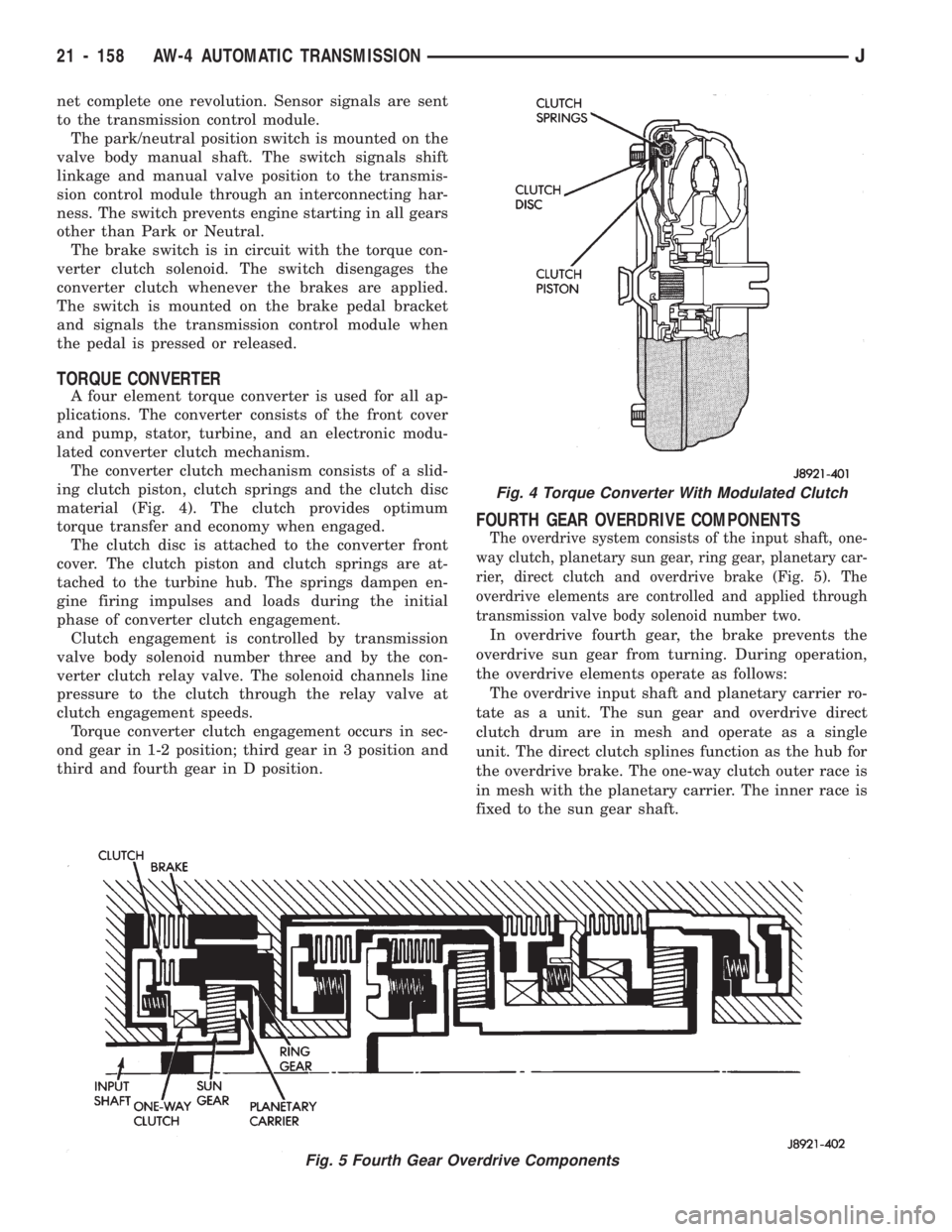

Fig. 4 Torque Converter With Modulated Clutch

21 - 158 AW-4 AUTOMATIC TRANSMISSIONJ

Page 603 of 1770

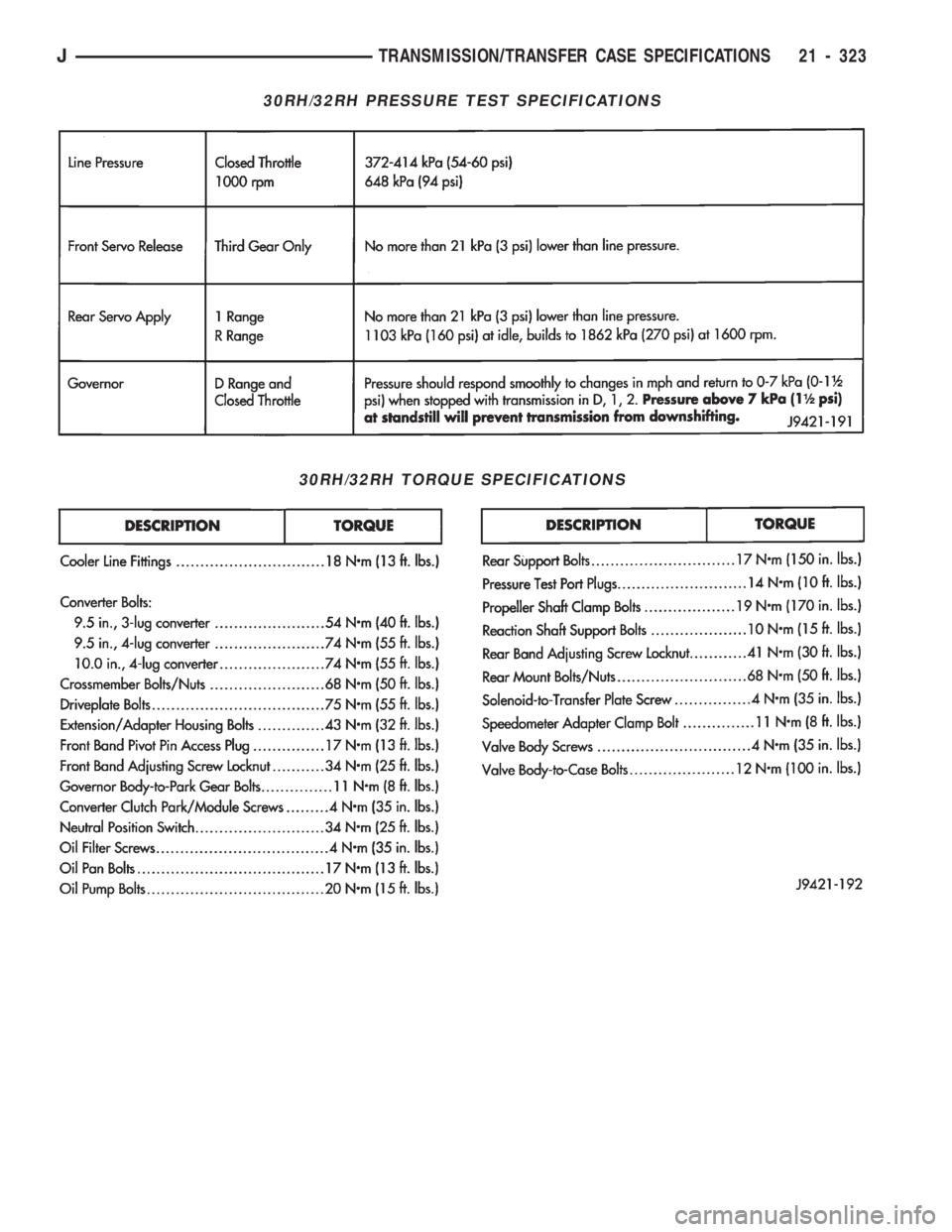

30RH/32RH TORQUE SPECIFICATIONS

JTRANSMISSION/TRANSFER CASE SPECIFICATIONS 21 - 323

Page 611 of 1770

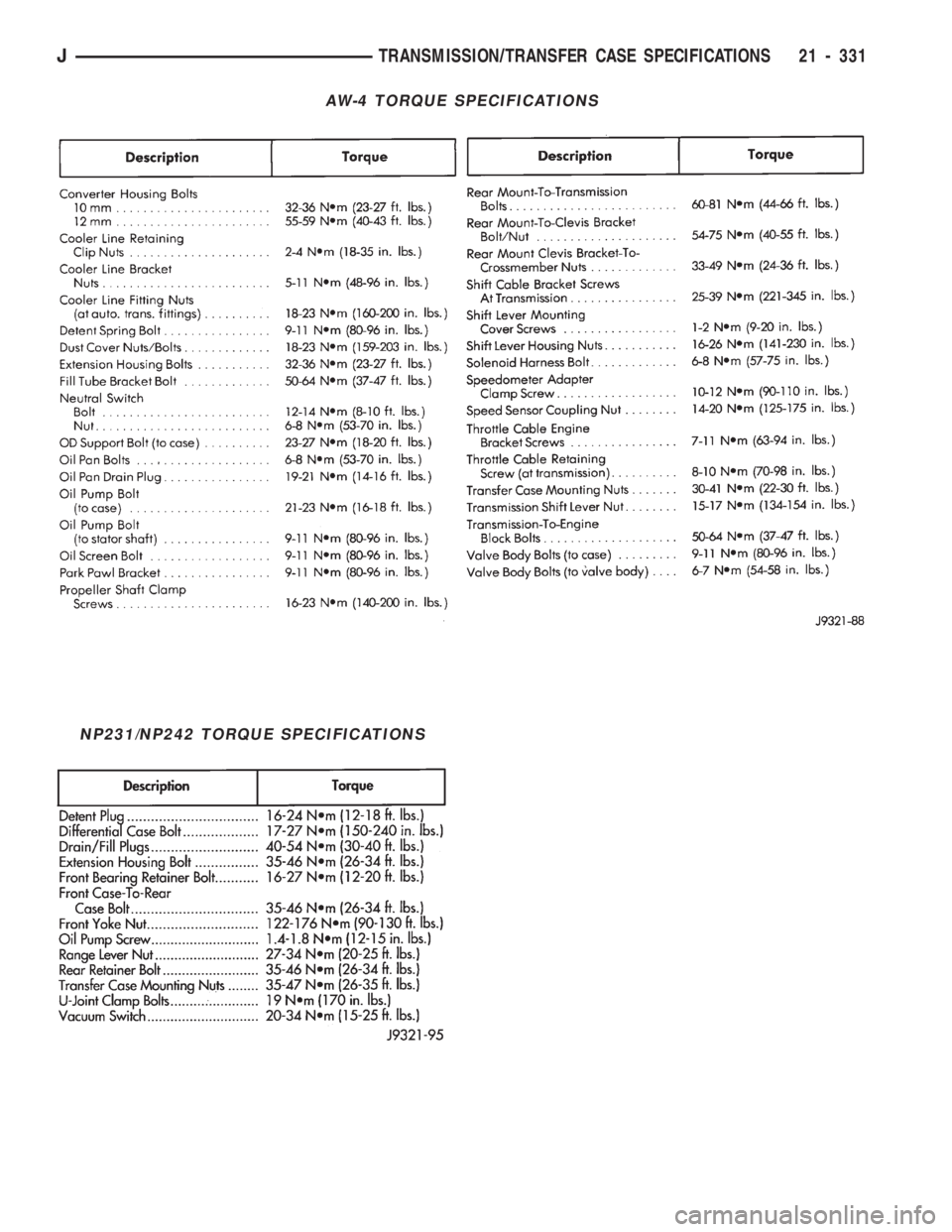

NP231/NP242 TORQUE SPECIFICATIONS

JTRANSMISSION/TRANSFER CASE SPECIFICATIONS 21 - 331

Page 902 of 1770

(3) Install new fuel pump outlet hose. Secure with

new clamps.

(4) Connect wire terminals to motor.

(5) Install new fuel pump inlet filter.

INSTALLATIONÐYJ MODELS

(1) Install a new fuel pump inlet filter.

(2) Install fuel pump module assembly with a new

gasket between the assembly and tank. Tighten

mounting screws to 2 Nzm (18 in. lbs.) torque.

(3) Install fuel tank. Refer to Fuel Tank Installa-

tionÐYJ Models.

(4) Fill fuel tank. Install fuel tank cap.

(5) Install negative battery cable.

(6) Start vehicle and check for leaks.

FUEL PUMP ELECTRICAL CONTROL

For an electrical operational description of the fuel

pump, refer to the MFI SystemÐComponent Descrip-

tion/System Operation section of this group. See Au-

tomatic Shut Down (ASD) RelayÐPCM Output.

For the 1994 model year, the ballast resistor and

ballast resistor bypass relay are no longer used to

control the fuel pump circuit.

FUEL PRESSURE RELEASE PROCEDURE

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE (EVEN WITH THE ENGINE

OFF) OF APPROXIMATELY 131-269 KPA (19-39

PSI). THIS PRESSURE MUST BE RELEASED BE-

FORE SERVICING ANY FUEL SUPPLY OR FUEL RE-

TURN SYSTEM COMPONENT.

(1) Disconnect negative battery cable.

(2) Remove fuel tank filler neck cap to release fuel

tank pressure.

WARNING: DO NOT ALLOW FUEL TO SPILL ONTO

THE ENGINE INTAKE OR EXHAUST MANIFOLDS.

PLACE SHOP TOWELS UNDER AND AROUND THE

PRESSURE PORT TO ABSORB FUEL WHEN THE

PRESSURE IS RELEASED FROM THE FUEL RAIL.

WARNING: WEAR PROPER EYE PROTECTION

WHEN RELEASING FUEL SYSTEM PRESSURE.

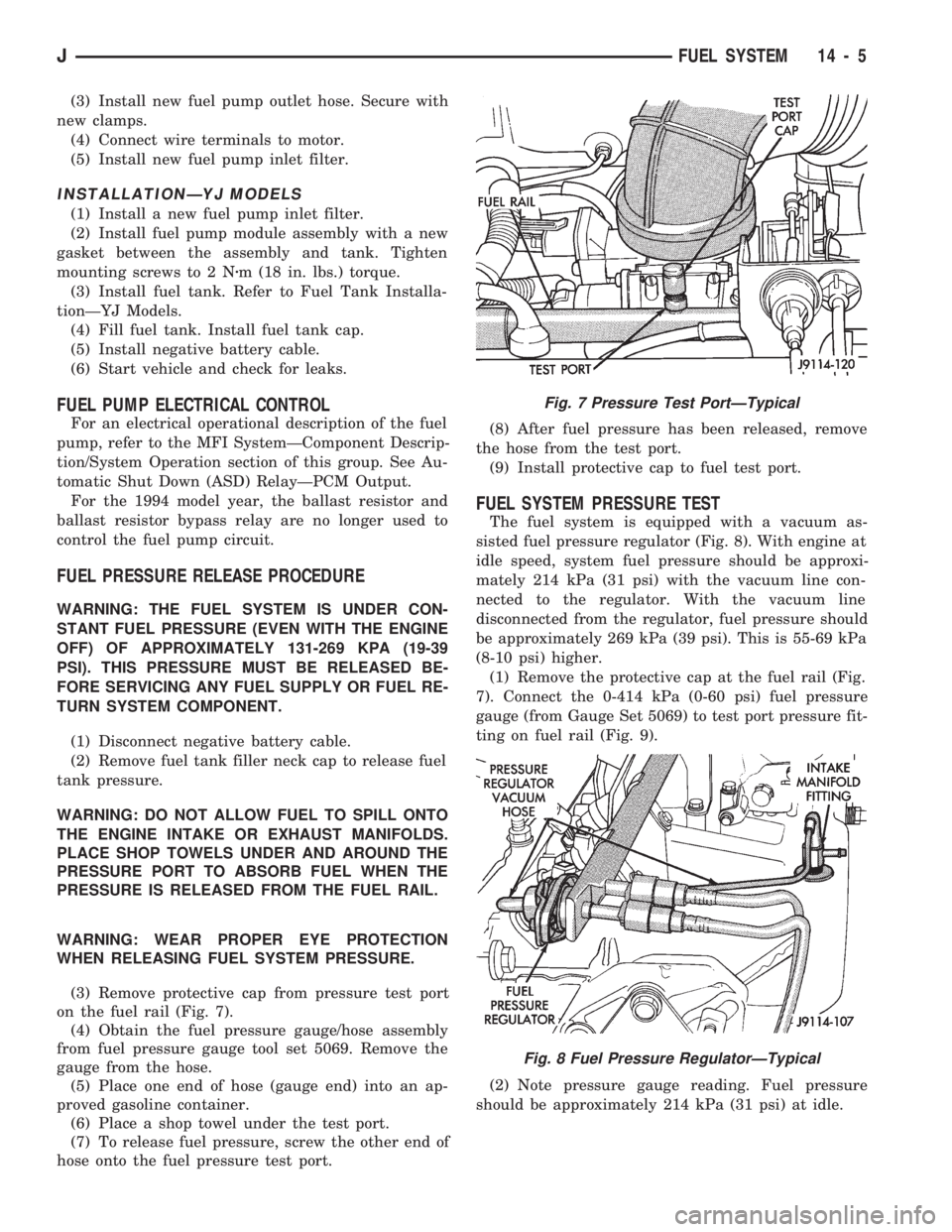

(3) Remove protective cap from pressure test port

on the fuel rail (Fig. 7).

(4) Obtain the fuel pressure gauge/hose assembly

from fuel pressure gauge tool set 5069. Remove the

gauge from the hose.

(5) Place one end of hose (gauge end) into an ap-

proved gasoline container.

(6) Place a shop towel under the test port.

(7) To release fuel pressure, screw the other end of

hose onto the fuel pressure test port.(8) After fuel pressure has been released, remove

the hose from the test port.

(9) Install protective cap to fuel test port.

FUEL SYSTEM PRESSURE TEST

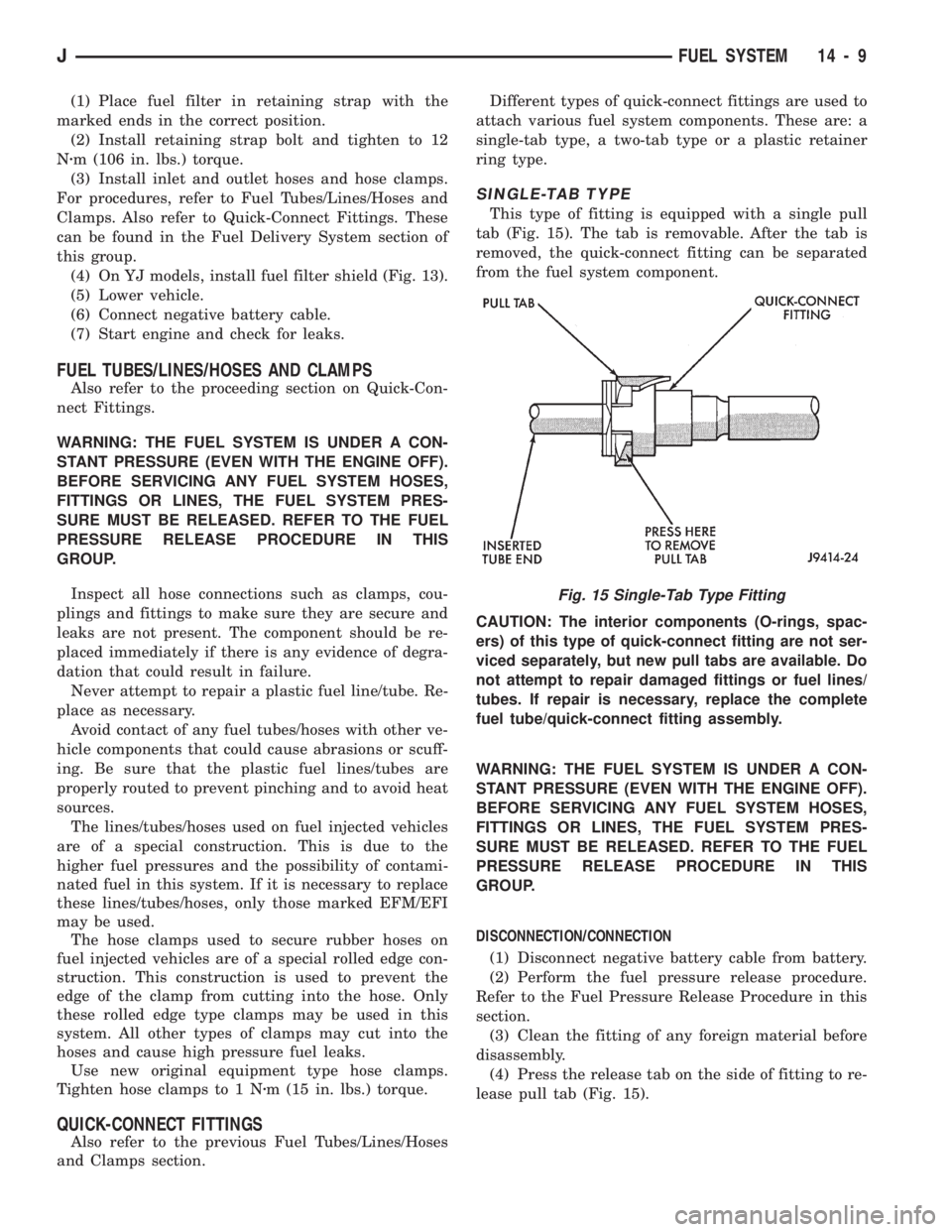

The fuel system is equipped with a vacuum as-

sisted fuel pressure regulator (Fig. 8). With engine at

idle speed, system fuel pressure should be approxi-

mately 214 kPa (31 psi) with the vacuum line con-

nected to the regulator. With the vacuum line

disconnected from the regulator, fuel pressure should

be approximately 269 kPa (39 psi). This is 55-69 kPa

(8-10 psi) higher.

(1) Remove the protective cap at the fuel rail (Fig.

7). Connect the 0-414 kPa (0-60 psi) fuel pressure

gauge (from Gauge Set 5069) to test port pressure fit-

ting on fuel rail (Fig. 9).

(2) Note pressure gauge reading. Fuel pressure

should be approximately 214 kPa (31 psi) at idle.

Fig. 7 Pressure Test PortÐTypical

Fig. 8 Fuel Pressure RegulatorÐTypical

JFUEL SYSTEM 14 - 5

Page 906 of 1770

(1) Place fuel filter in retaining strap with the

marked ends in the correct position.

(2) Install retaining strap bolt and tighten to 12

Nzm (106 in. lbs.) torque.

(3) Install inlet and outlet hoses and hose clamps.

For procedures, refer to Fuel Tubes/Lines/Hoses and

Clamps. Also refer to Quick-Connect Fittings. These

can be found in the Fuel Delivery System section of

this group.

(4) On YJ models, install fuel filter shield (Fig. 13).

(5) Lower vehicle.

(6) Connect negative battery cable.

(7) Start engine and check for leaks.

FUEL TUBES/LINES/HOSES AND CLAMPS

Also refer to the proceeding section on Quick-Con-

nect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE IN THIS

GROUP.

Inspect all hose connections such as clamps, cou-

plings and fittings to make sure they are secure and

leaks are not present. The component should be re-

placed immediately if there is any evidence of degra-

dation that could result in failure.

Never attempt to repair a plastic fuel line/tube. Re-

place as necessary.

Avoid contact of any fuel tubes/hoses with other ve-

hicle components that could cause abrasions or scuff-

ing. Be sure that the plastic fuel lines/tubes are

properly routed to prevent pinching and to avoid heat

sources.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

The hose clamps used to secure rubber hoses on

fuel injected vehicles are of a special rolled edge con-

struction. This construction is used to prevent the

edge of the clamp from cutting into the hose. Only

these rolled edge type clamps may be used in this

system. All other types of clamps may cut into the

hoses and cause high pressure fuel leaks.

Use new original equipment type hose clamps.

Tighten hose clamps to 1 Nzm (15 in. lbs.) torque.

QUICK-CONNECT FITTINGS

Also refer to the previous Fuel Tubes/Lines/Hoses

and Clamps section.Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type.

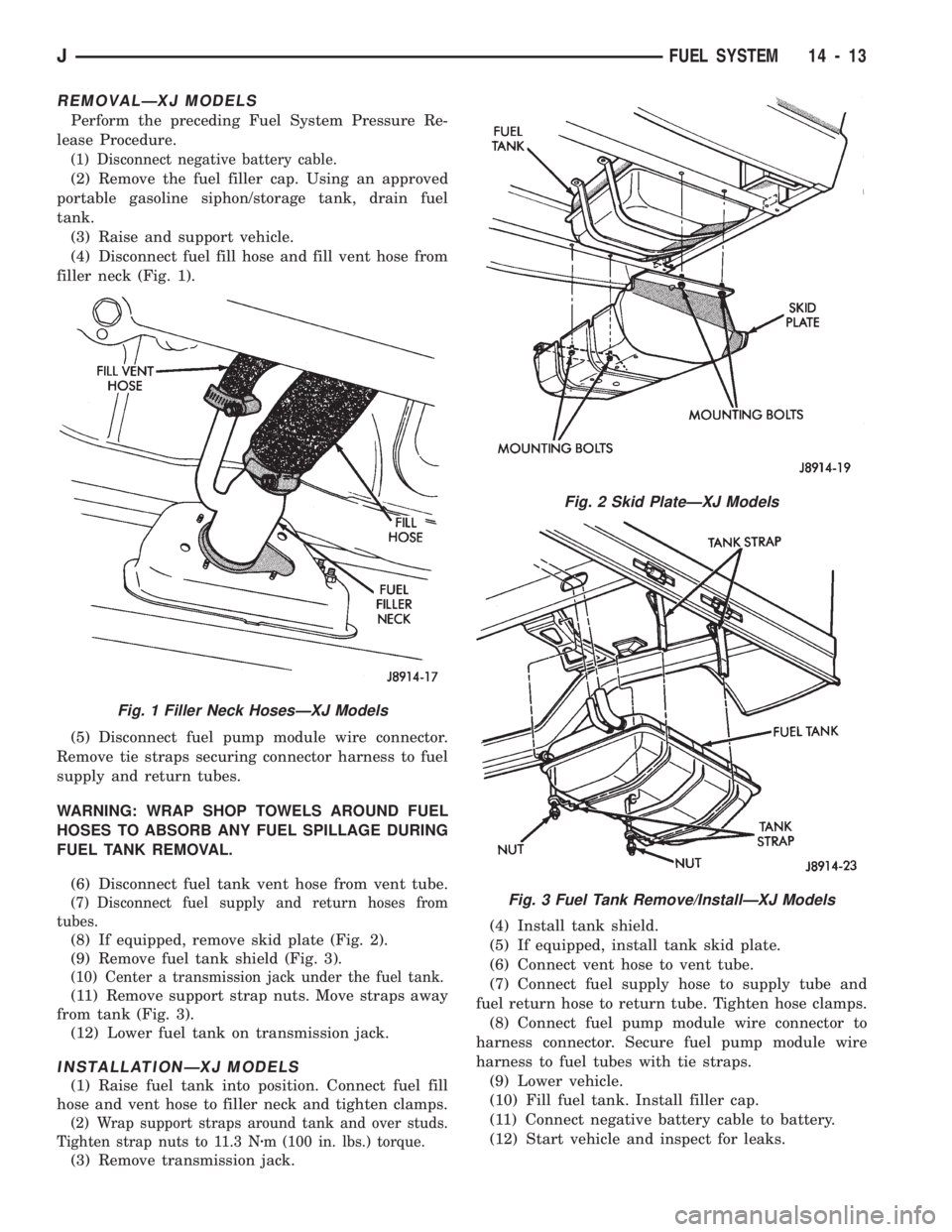

SINGLE-TAB TYPE

This type of fitting is equipped with a single pull

tab (Fig. 15). The tab is removable. After the tab is

removed, the quick-connect fitting can be separated

from the fuel system component.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new pull tabs are available. Do

not attempt to repair damaged fittings or fuel lines/

tubes. If repair is necessary, replace the complete

fuel tube/quick-connect fitting assembly.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE IN THIS

GROUP.

DISCONNECTION/CONNECTION

(1) Disconnect negative battery cable from battery.

(2) Perform the fuel pressure release procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Clean the fitting of any foreign material before

disassembly.

(4) Press the release tab on the side of fitting to re-

lease pull tab (Fig. 15).

Fig. 15 Single-Tab Type Fitting

JFUEL SYSTEM 14 - 9

Page 910 of 1770

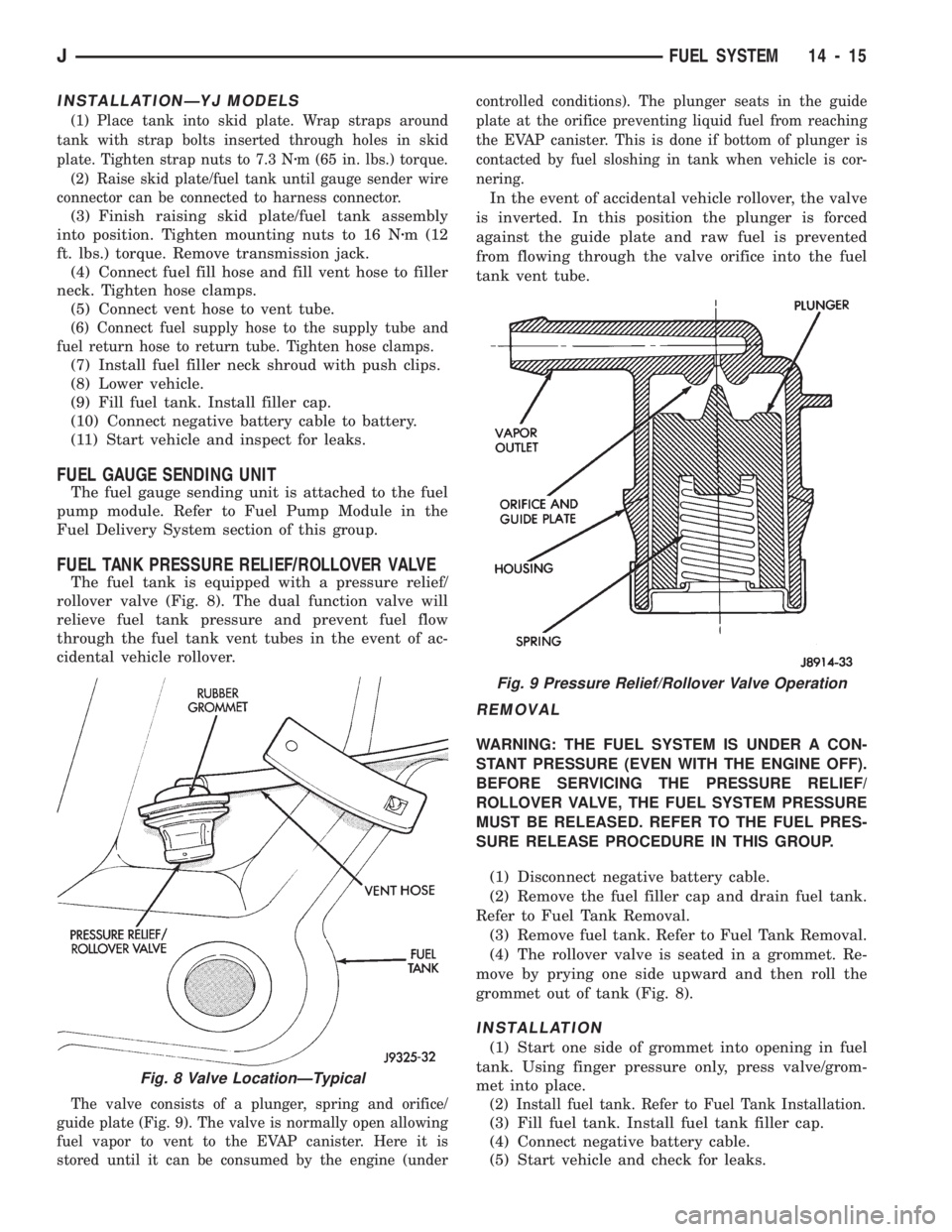

REMOVALÐXJ MODELS

Perform the preceding Fuel System Pressure Re-

lease Procedure.

(1) Disconnect negative battery cable.

(2) Remove the fuel filler cap. Using an approved

portable gasoline siphon/storage tank, drain fuel

tank.

(3) Raise and support vehicle.

(4) Disconnect fuel fill hose and fill vent hose from

filler neck (Fig. 1).

(5) Disconnect fuel pump module wire connector.

Remove tie straps securing connector harness to fuel

supply and return tubes.

WARNING: WRAP SHOP TOWELS AROUND FUEL

HOSES TO ABSORB ANY FUEL SPILLAGE DURING

FUEL TANK REMOVAL.

(6) Disconnect fuel tank vent hose from vent tube.

(7) Disconnect fuel supply and return hoses from

tubes.

(8) If equipped, remove skid plate (Fig. 2).

(9) Remove fuel tank shield (Fig. 3).

(10) Center a transmission jack under the fuel tank.

(11) Remove support strap nuts. Move straps away

from tank (Fig. 3).

(12) Lower fuel tank on transmission jack.

INSTALLATIONÐXJ MODELS

(1) Raise fuel tank into position. Connect fuel fill

hose and vent hose to filler neck and tighten clamps.

(2) Wrap support straps around tank and over studs.

Tighten strap nuts to 11.3 Nzm (100 in. lbs.) torque.

(3) Remove transmission jack.(4) Install tank shield.

(5) If equipped, install tank skid plate.

(6) Connect vent hose to vent tube.

(7) Connect fuel supply hose to supply tube and

fuel return hose to return tube. Tighten hose clamps.

(8) Connect fuel pump module wire connector to

harness connector. Secure fuel pump module wire

harness to fuel tubes with tie straps.

(9) Lower vehicle.

(10) Fill fuel tank. Install filler cap.

(11) Connect negative battery cable to battery.

(12) Start vehicle and inspect for leaks.

Fig. 1 Filler Neck HosesÐXJ Models

Fig. 2 Skid PlateÐXJ Models

Fig. 3 Fuel Tank Remove/InstallÐXJ Models

JFUEL SYSTEM 14 - 13

Page 912 of 1770

INSTALLATIONÐYJ MODELS

(1) Place tank into skid plate. Wrap straps around

tank with strap bolts inserted through holes in skid

plate. Tighten strap nuts to 7.3 Nzm (65 in. lbs.) torque.

(2) Raise skid plate/fuel tank until gauge sender wire

connector can be connected to harness connector.

(3) Finish raising skid plate/fuel tank assembly

into position. Tighten mounting nuts to 16 Nzm (12

ft. lbs.) torque. Remove transmission jack.

(4) Connect fuel fill hose and fill vent hose to filler

neck. Tighten hose clamps.

(5) Connect vent hose to vent tube.

(6) Connect fuel supply hose to the supply tube and

fuel return hose to return tube. Tighten hose clamps.

(7) Install fuel filler neck shroud with push clips.

(8) Lower vehicle.

(9) Fill fuel tank. Install filler cap.

(10) Connect negative battery cable to battery.

(11) Start vehicle and inspect for leaks.

FUEL GAUGE SENDING UNIT

The fuel gauge sending unit is attached to the fuel

pump module. Refer to Fuel Pump Module in the

Fuel Delivery System section of this group.

FUEL TANK PRESSURE RELIEF/ROLLOVER VALVE

The fuel tank is equipped with a pressure relief/

rollover valve (Fig. 8). The dual function valve will

relieve fuel tank pressure and prevent fuel flow

through the fuel tank vent tubes in the event of ac-

cidental vehicle rollover.

The valve consists of a plunger, spring and orifice/

guide plate (Fig. 9). The valve is normally open allowing

fuel vapor to vent to the EVAP canister. Here it is

stored until it can be consumed by the engine (undercontrolled conditions). The plunger seats in the guide

plate at the orifice preventing liquid fuel from reaching

the EVAP canister. This is done if bottom of plunger is

contacted by fuel sloshing in tank when vehicle is cor-

nering.

In the event of accidental vehicle rollover, the valve

is inverted. In this position the plunger is forced

against the guide plate and raw fuel is prevented

from flowing through the valve orifice into the fuel

tank vent tube.

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING THE PRESSURE RELIEF/

ROLLOVER VALVE, THE FUEL SYSTEM PRESSURE

MUST BE RELEASED. REFER TO THE FUEL PRES-

SURE RELEASE PROCEDURE IN THIS GROUP.

(1) Disconnect negative battery cable.

(2) Remove the fuel filler cap and drain fuel tank.

Refer to Fuel Tank Removal.

(3) Remove fuel tank. Refer to Fuel Tank Removal.

(4) The rollover valve is seated in a grommet. Re-

move by prying one side upward and then roll the

grommet out of tank (Fig. 8).

INSTALLATION

(1) Start one side of grommet into opening in fuel

tank. Using finger pressure only, press valve/grom-

met into place.

(2) Install fuel tank. Refer to Fuel Tank Installation.

(3) Fill fuel tank. Install fuel tank filler cap.

(4) Connect negative battery cable.

(5) Start vehicle and check for leaks.

Fig. 8 Valve LocationÐTypical

Fig. 9 Pressure Relief/Rollover Valve Operation

JFUEL SYSTEM 14 - 15

Page 913 of 1770

ACCELERATOR PEDAL AND THROTTLE CABLE

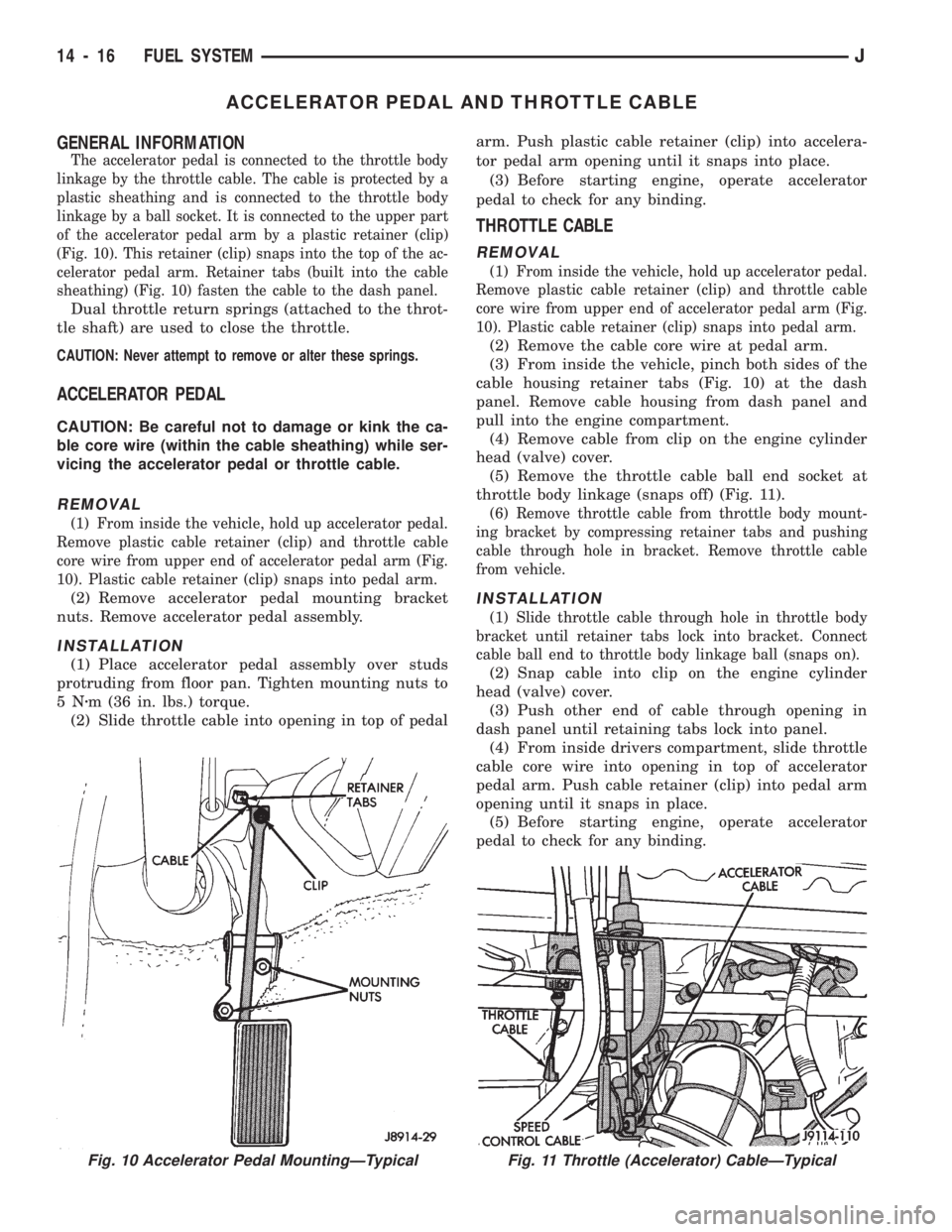

GENERAL INFORMATION

The accelerator pedal is connected to the throttle body

linkage by the throttle cable. The cable is protected by a

plastic sheathing and is connected to the throttle body

linkage by a ball socket. It is connected to the upper part

of the accelerator pedal arm by a plastic retainer (clip)

(Fig. 10). This retainer (clip) snaps into the top of the ac-

celerator pedal arm. Retainer tabs (built into the cable

sheathing) (Fig. 10) fasten the cable to the dash panel.

Dual throttle return springs (attached to the throt-

tle shaft) are used to close the throttle.

CAUTION: Never attempt to remove or alter these springs.

ACCELERATOR PEDAL

CAUTION: Be careful not to damage or kink the ca-

ble core wire (within the cable sheathing) while ser-

vicing the accelerator pedal or throttle cable.

REMOVAL

(1) From inside the vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle cable

core wire from upper end of accelerator pedal arm (Fig.

10). Plastic cable retainer (clip) snaps into pedal arm.

(2) Remove accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.

INSTALLATION

(1) Place accelerator pedal assembly over studs

protruding from floor pan. Tighten mounting nuts to

5Nzm (36 in. lbs.) torque.

(2) Slide throttle cable into opening in top of pedalarm. Push plastic cable retainer (clip) into accelera-

tor pedal arm opening until it snaps into place.

(3) Before starting engine, operate accelerator

pedal to check for any binding.

THROTTLE CABLE

REMOVAL

(1) From inside the vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle cable

core wire from upper end of accelerator pedal arm (Fig.

10). Plastic cable retainer (clip) snaps into pedal arm.

(2) Remove the cable core wire at pedal arm.

(3) From inside the vehicle, pinch both sides of the

cable housing retainer tabs (Fig. 10) at the dash

panel. Remove cable housing from dash panel and

pull into the engine compartment.

(4) Remove cable from clip on the engine cylinder

head (valve) cover.

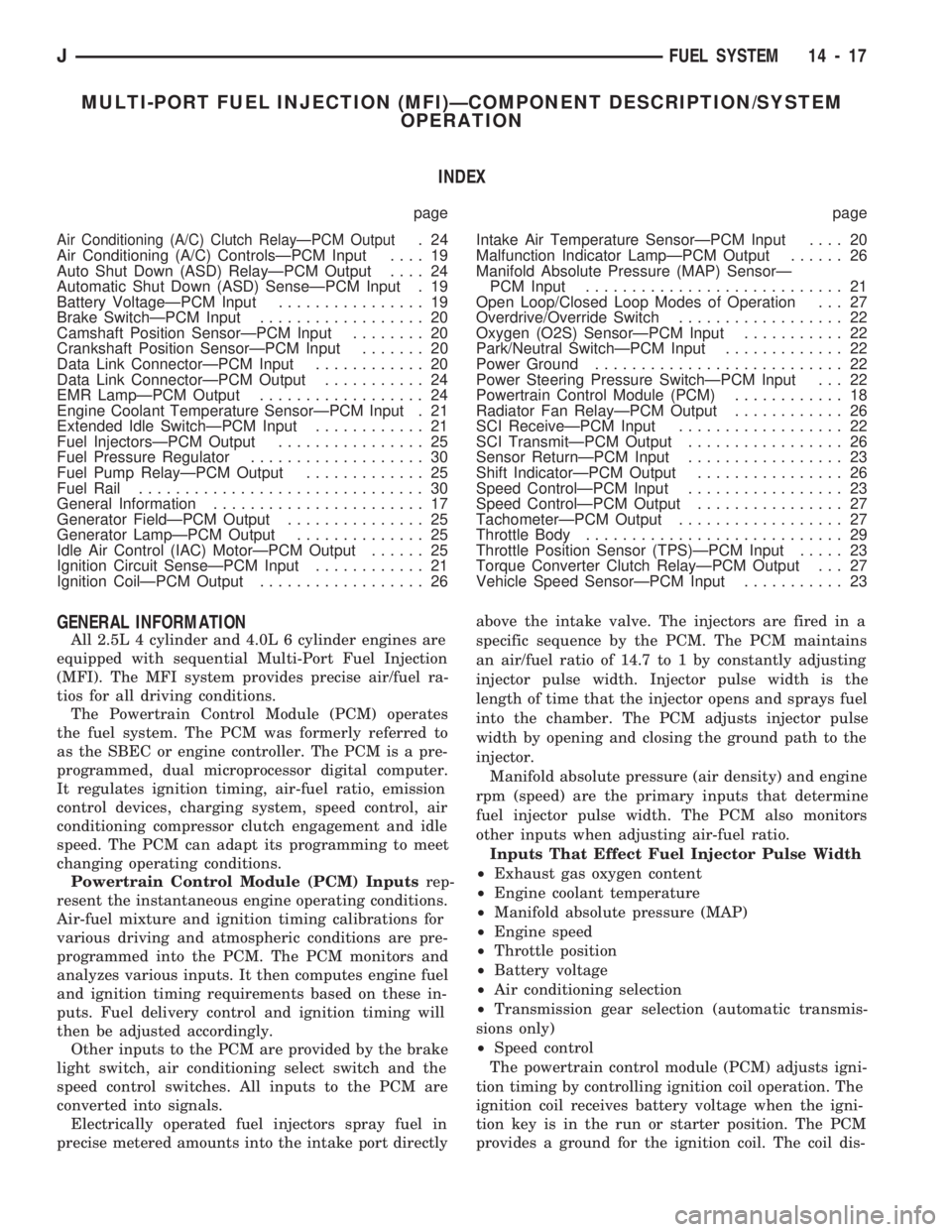

(5) Remove the throttle cable ball end socket at

throttle body linkage (snaps off) (Fig. 11).

(6) Remove throttle cable from throttle body mount-

ing bracket by compressing retainer tabs and pushing

cable through hole in bracket. Remove throttle cable

from vehicle.

INSTALLATION

(1) Slide throttle cable through hole in throttle body

bracket until retainer tabs lock into bracket. Connect

cable ball end to throttle body linkage ball (snaps on).

(2) Snap cable into clip on the engine cylinder

head (valve) cover.

(3) Push other end of cable through opening in

dash panel until retaining tabs lock into panel.

(4) From inside drivers compartment, slide throttle

cable core wire into opening in top of accelerator

pedal arm. Push cable retainer (clip) into pedal arm

opening until it snaps in place.

(5) Before starting engine, operate accelerator

pedal to check for any binding.

Fig. 10 Accelerator Pedal MountingÐTypicalFig. 11 Throttle (Accelerator) CableÐTypical

14 - 16 FUEL SYSTEMJ

Page 914 of 1770

MULTI-PORT FUEL INJECTION (MFI)ÐCOMPONENT DESCRIPTION/SYSTEM

OPERATION

INDEX

page page

Air Conditioning (A/C) Clutch RelayÐPCM Output.24

Air Conditioning (A/C) ControlsÐPCM Input.... 19

Auto Shut Down (ASD) RelayÐPCM Output.... 24

Automatic Shut Down (ASD) SenseÐPCM Input . 19

Battery VoltageÐPCM Input................ 19

Brake SwitchÐPCM Input.................. 20

Camshaft Position SensorÐPCM Input........ 20

Crankshaft Position SensorÐPCM Input....... 20

Data Link ConnectorÐPCM Input............ 20

Data Link ConnectorÐPCM Output........... 24

EMR LampÐPCM Output.................. 24

Engine Coolant Temperature SensorÐPCM Input . 21

Extended Idle SwitchÐPCM Input............ 21

Fuel InjectorsÐPCM Output................ 25

Fuel Pressure Regulator................... 30

Fuel Pump RelayÐPCM Output............. 25

Fuel Rail............................... 30

General Information....................... 17

Generator FieldÐPCM Output............... 25

Generator LampÐPCM Output.............. 25

Idle Air Control (IAC) MotorÐPCM Output...... 25

Ignition Circuit SenseÐPCM Input............ 21

Ignition CoilÐPCM Output.................. 26Intake Air Temperature SensorÐPCM Input.... 20

Malfunction Indicator LampÐPCM Output...... 26

Manifold Absolute Pressure (MAP) SensorÐ

PCM Input............................ 21

Open Loop/Closed Loop Modes of Operation . . . 27

Overdrive/Override Switch.................. 22

Oxygen (O2S) SensorÐPCM Input........... 22

Park/Neutral SwitchÐPCM Input............. 22

Power Ground........................... 22

Power Steering Pressure SwitchÐPCM Input . . . 22

Powertrain Control Module (PCM)............ 18

Radiator Fan RelayÐPCM Output............ 26

SCI ReceiveÐPCM Input.................. 22

SCI TransmitÐPCM Output................. 26

Sensor ReturnÐPCM Input................. 23

Shift IndicatorÐPCM Output................ 26

Speed ControlÐPCM Input................. 23

Speed ControlÐPCM Output................ 27

TachometerÐPCM Output.................. 27

Throttle Body............................ 29

Throttle Position Sensor (TPS)ÐPCM Input..... 23

Torque Converter Clutch RelayÐPCM Output . . . 27

Vehicle Speed SensorÐPCM Input........... 23

GENERAL INFORMATION

All 2.5L 4 cylinder and 4.0L 6 cylinder engines are

equipped with sequential Multi-Port Fuel Injection

(MFI). The MFI system provides precise air/fuel ra-

tios for all driving conditions.

The Powertrain Control Module (PCM) operates

the fuel system. The PCM was formerly referred to

as the SBEC or engine controller. The PCM is a pre-

programmed, dual microprocessor digital computer.

It regulates ignition timing, air-fuel ratio, emission

control devices, charging system, speed control, air

conditioning compressor clutch engagement and idle

speed. The PCM can adapt its programming to meet

changing operating conditions.

Powertrain Control Module (PCM) Inputsrep-

resent the instantaneous engine operating conditions.

Air-fuel mixture and ignition timing calibrations for

various driving and atmospheric conditions are pre-

programmed into the PCM. The PCM monitors and

analyzes various inputs. It then computes engine fuel

and ignition timing requirements based on these in-

puts. Fuel delivery control and ignition timing will

then be adjusted accordingly.

Other inputs to the PCM are provided by the brake

light switch, air conditioning select switch and the

speed control switches. All inputs to the PCM are

converted into signals.

Electrically operated fuel injectors spray fuel in

precise metered amounts into the intake port directlyabove the intake valve. The injectors are fired in a

specific sequence by the PCM. The PCM maintains

an air/fuel ratio of 14.7 to 1 by constantly adjusting

injector pulse width. Injector pulse width is the

length of time that the injector opens and sprays fuel

into the chamber. The PCM adjusts injector pulse

width by opening and closing the ground path to the

injector.

Manifold absolute pressure (air density) and engine

rpm (speed) are the primary inputs that determine

fuel injector pulse width. The PCM also monitors

other inputs when adjusting air-fuel ratio.

Inputs That Effect Fuel Injector Pulse Width

²Exhaust gas oxygen content

²Engine coolant temperature

²Manifold absolute pressure (MAP)

²Engine speed

²Throttle position

²Battery voltage

²Air conditioning selection

²Transmission gear selection (automatic transmis-

sions only)

²Speed control

The powertrain control module (PCM) adjusts igni-

tion timing by controlling ignition coil operation. The

ignition coil receives battery voltage when the igni-

tion key is in the run or starter position. The PCM

provides a ground for the ignition coil. The coil dis-

JFUEL SYSTEM 14 - 17