lock JEEP WRANGLER 1994 Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: WRANGLER, Model: JEEP WRANGLER 1994Pages: 1770, PDF Size: 75.27 MB

Page 693 of 1770

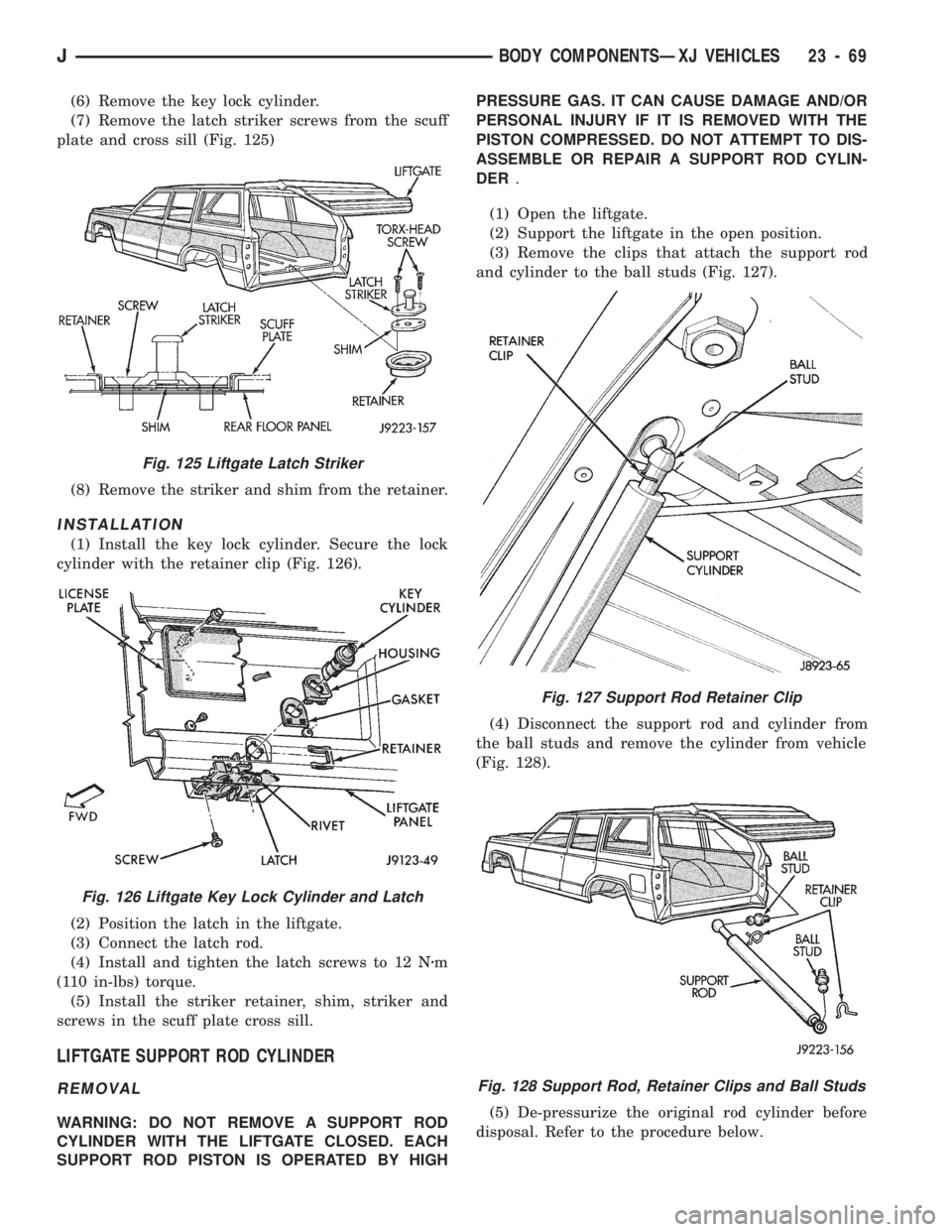

Fig. 128 Support Rod, Retainer Clips and Ball Studs

Fig. 125 Liftgate Latch Striker

Fig. 126 Liftgate Key Lock Cylinder and Latch

JBODY COMPONENTSÐXJ VEHICLES 23 - 69

Page 785 of 1770

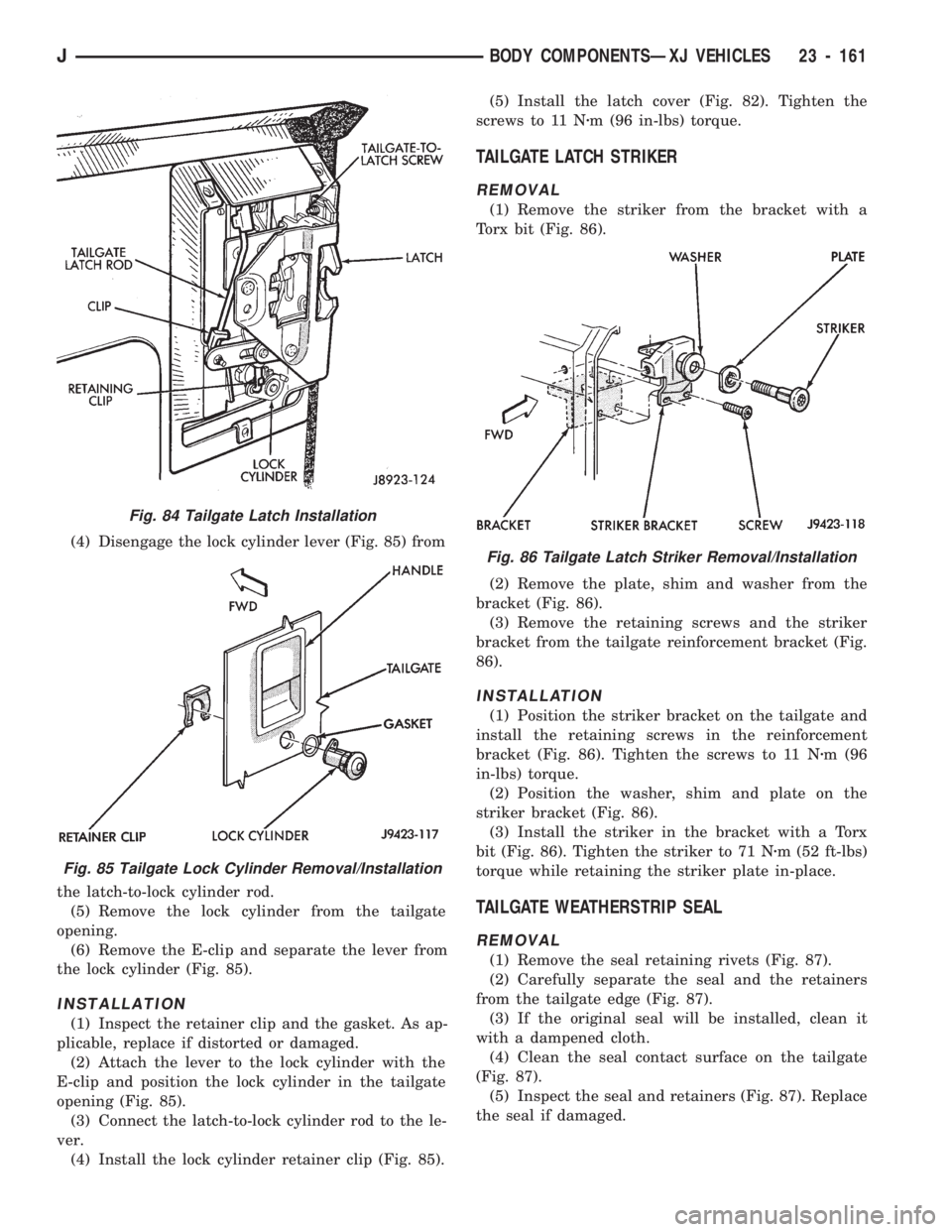

Fig. 85 Tailgate Lock Cylinder Removal/Installation

Fig. 86 Tailgate Latch Striker Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 161

Page 795 of 1770

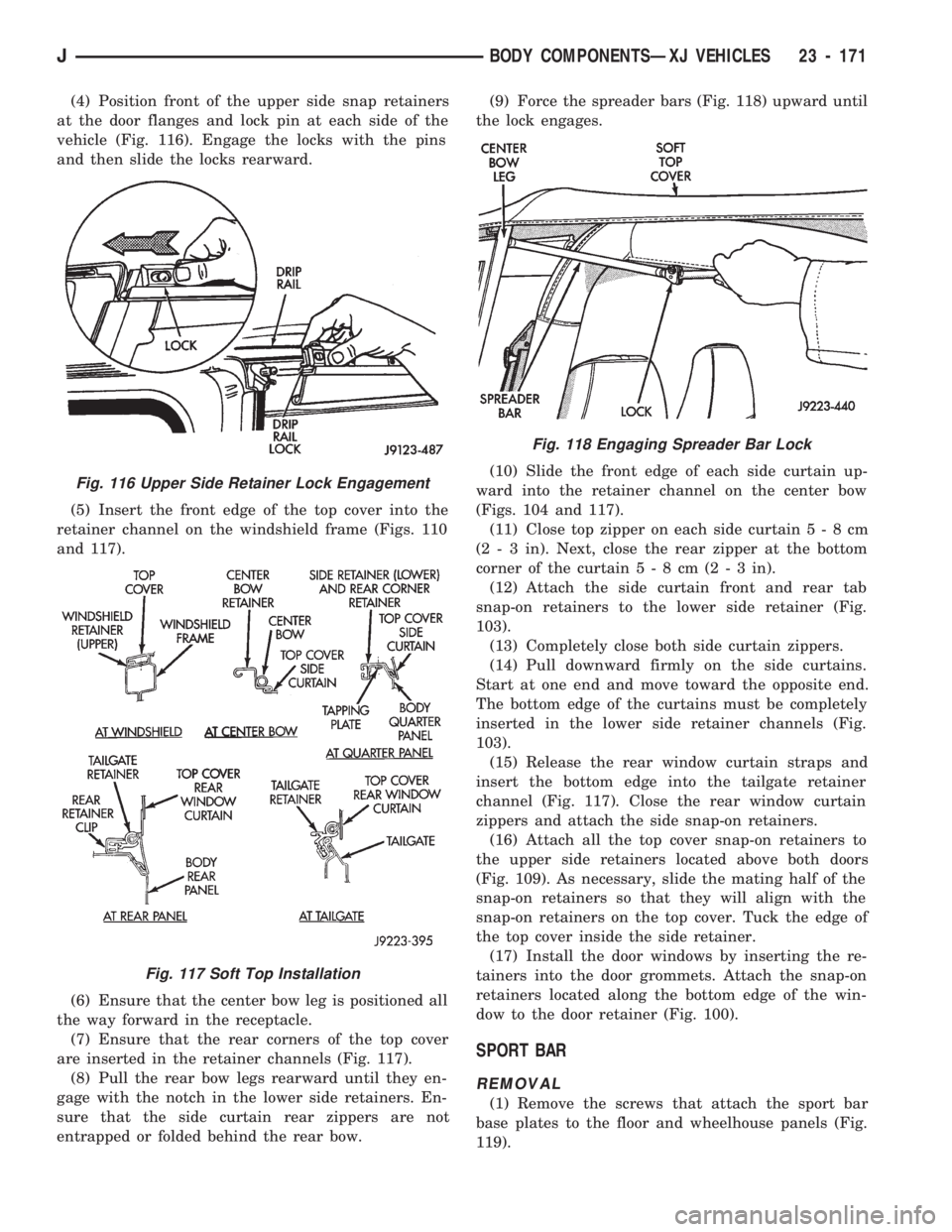

Fig. 117 Soft Top Installation

Fig. 118 Engaging Spreader Bar Lock

JBODY COMPONENTSÐXJ VEHICLES 23 - 171

Page 803 of 1770

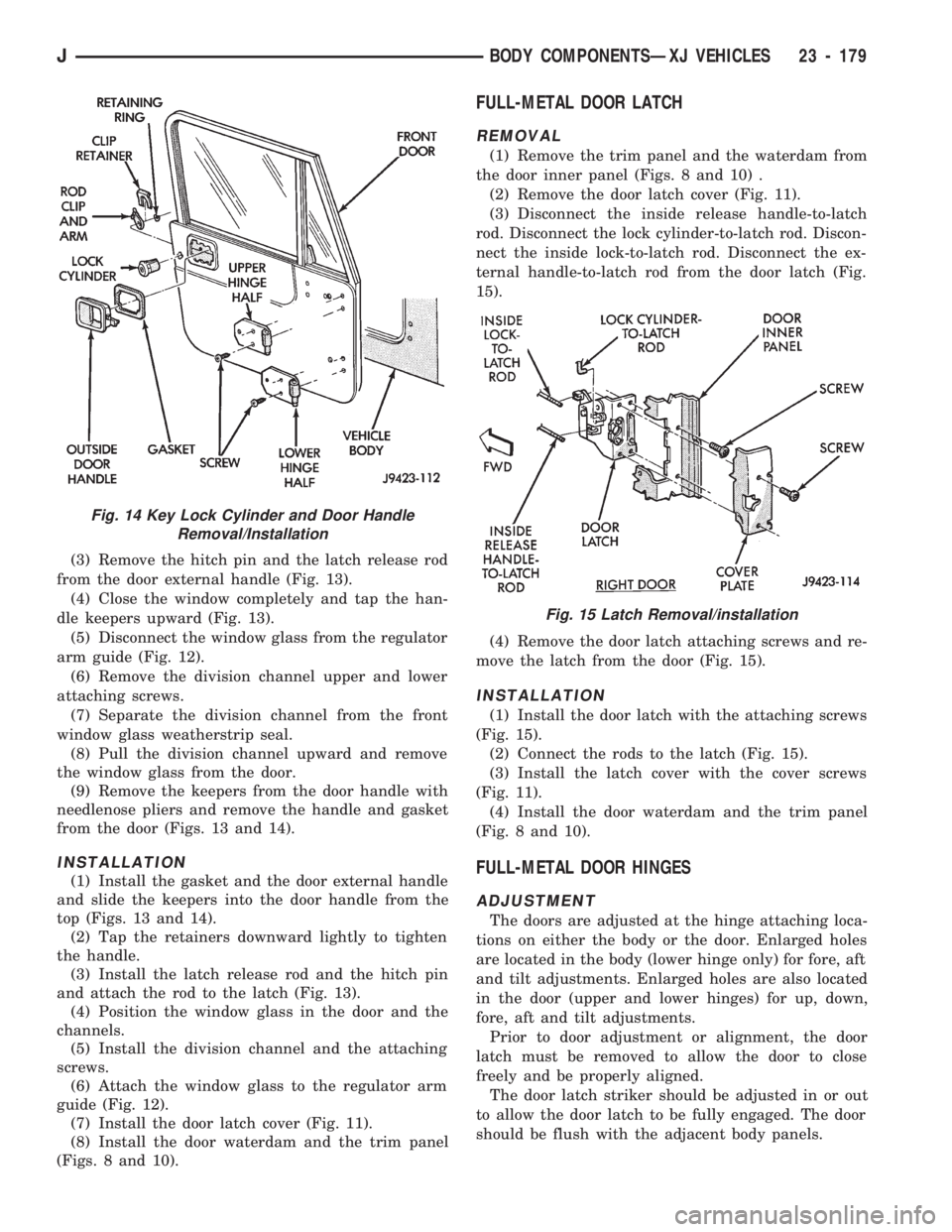

Fig. 14 Key Lock Cylinder and Door Handle

Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 179

Page 822 of 1770

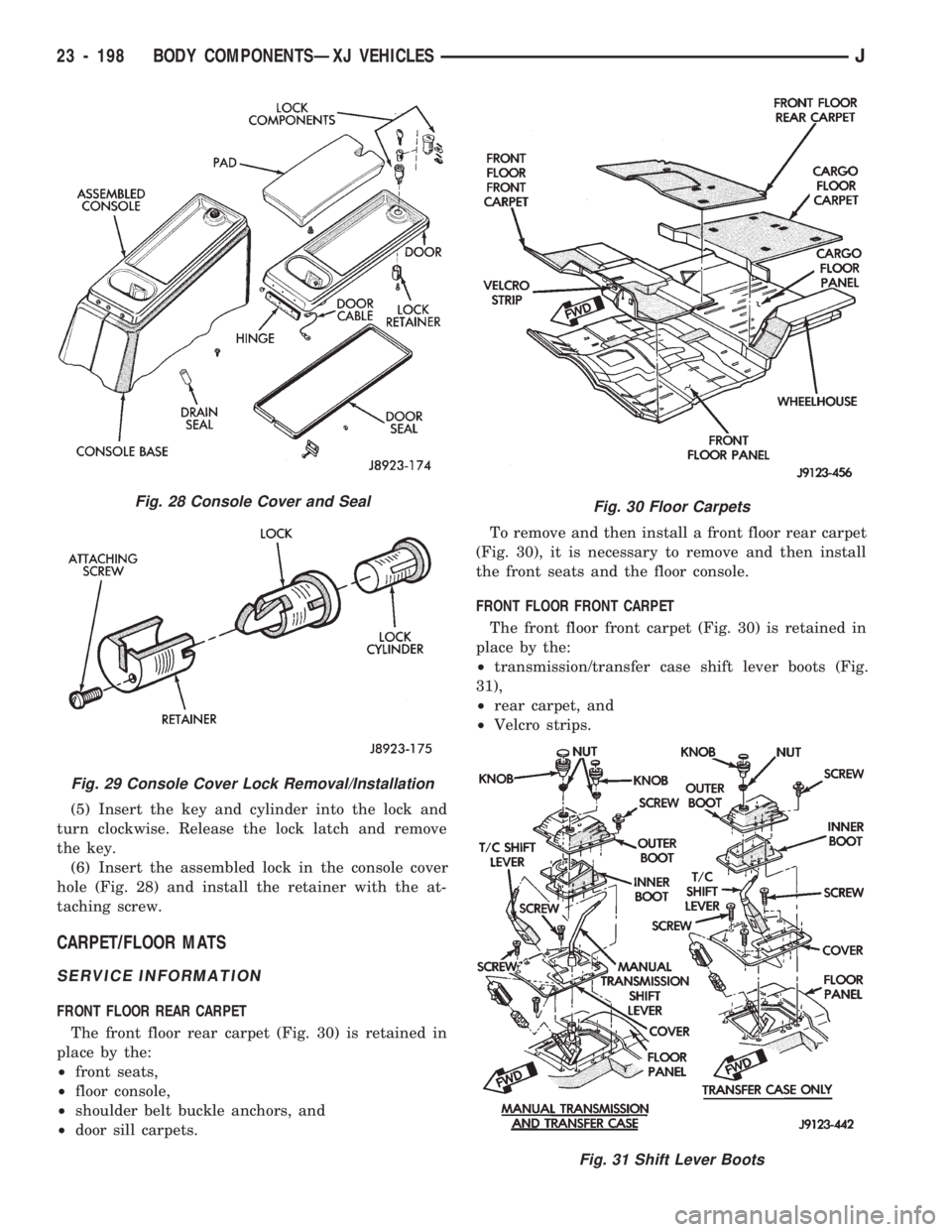

Fig. 29 Console Cover Lock Removal/Installation

Fig. 30 Floor Carpets

Fig. 31 Shift Lever Boots

23 - 198 BODY COMPONENTSÐXJ VEHICLESJ

Page 859 of 1770

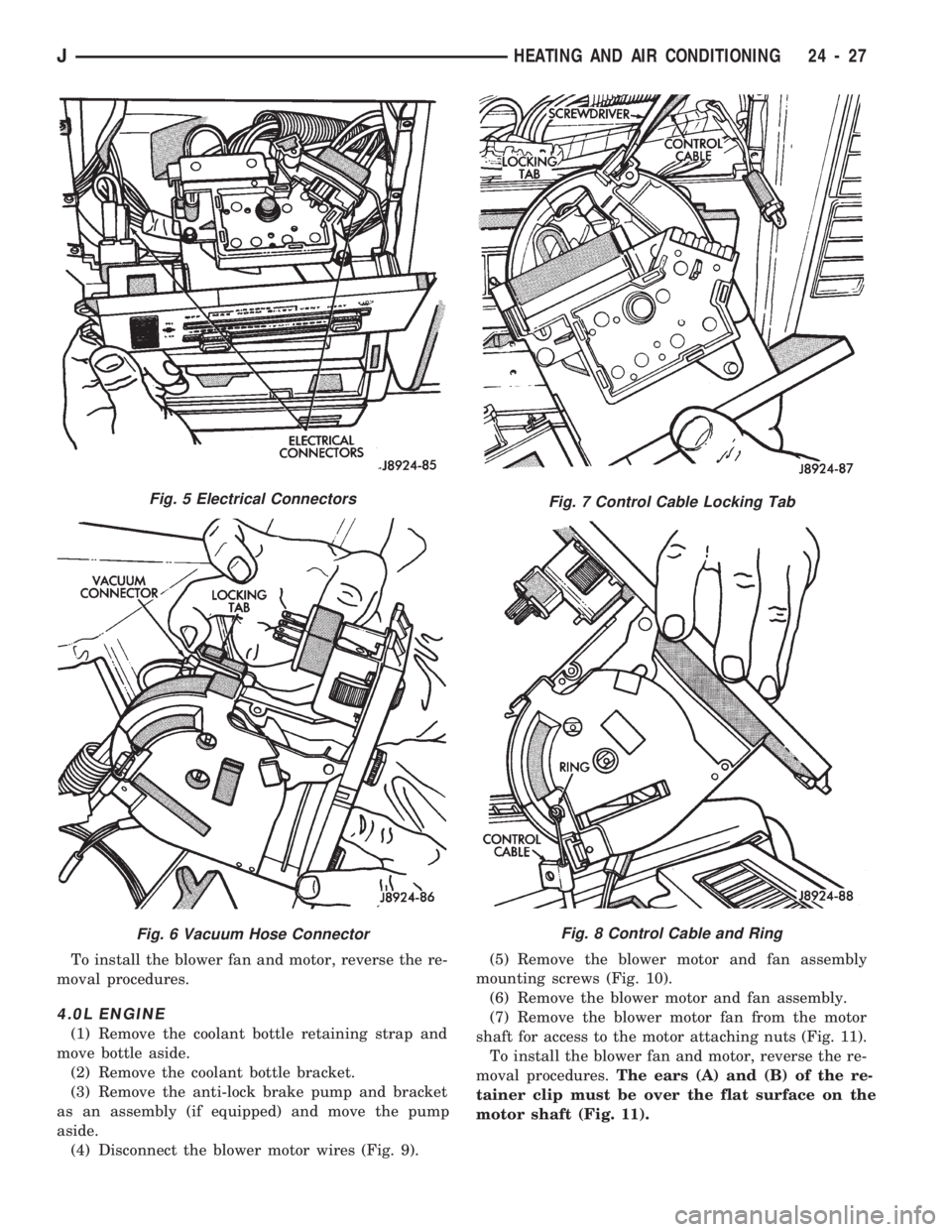

Fig. 6 Vacuum Hose Connector

Fig. 7 Control Cable Locking Tab

Fig. 8 Control Cable and Ring

JHEATING AND AIR CONDITIONING 24 - 27

Page 900 of 1770

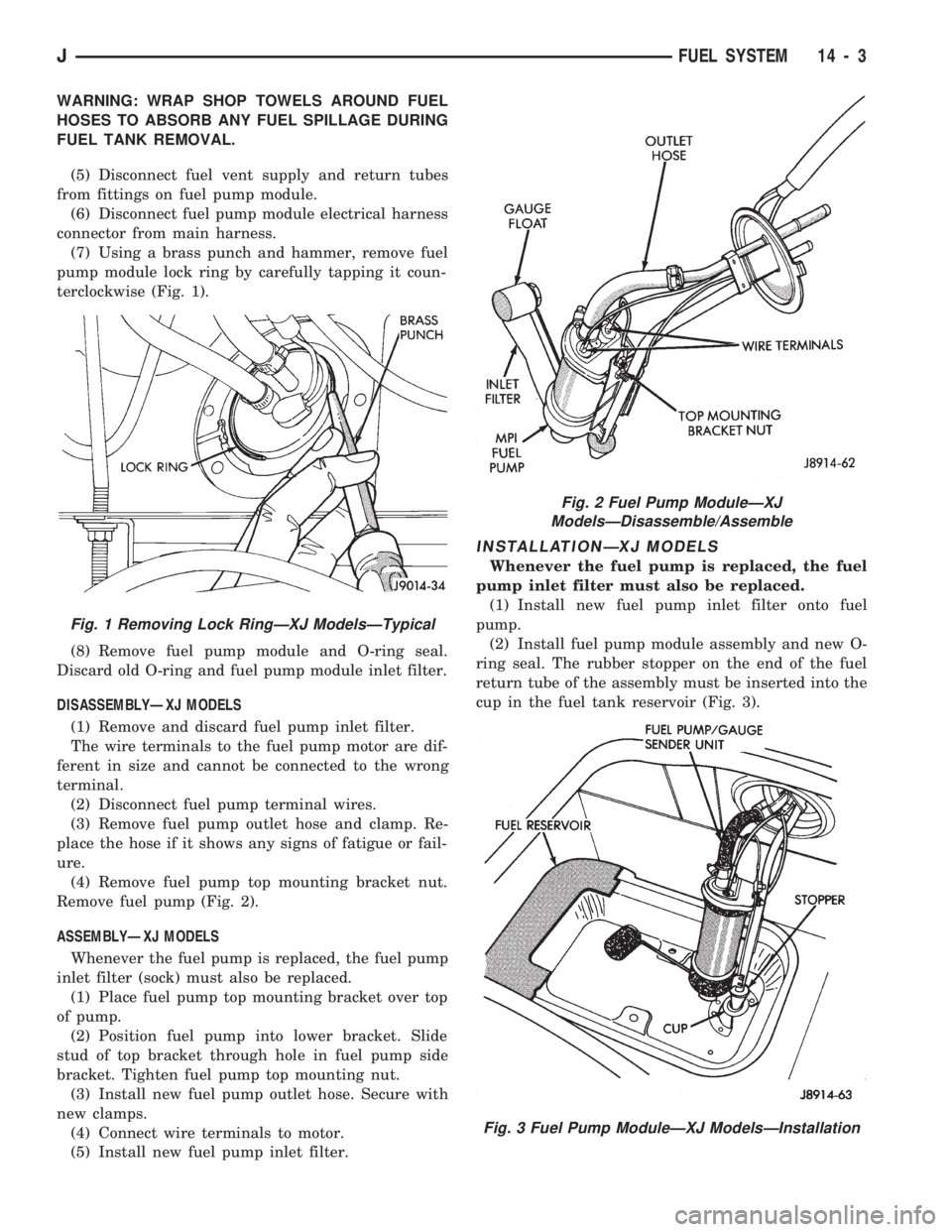

WARNING: WRAP SHOP TOWELS AROUND FUEL

HOSES TO ABSORB ANY FUEL SPILLAGE DURING

FUEL TANK REMOVAL.

(5) Disconnect fuel vent supply and return tubes

from fittings on fuel pump module.

(6) Disconnect fuel pump module electrical harness

connector from main harness.

(7) Using a brass punch and hammer, remove fuel

pump module lock ring by carefully tapping it coun-

terclockwise (Fig. 1).

(8) Remove fuel pump module and O-ring seal.

Discard old O-ring and fuel pump module inlet filter.

DISASSEMBLYÐXJ MODELS

(1) Remove and discard fuel pump inlet filter.

The wire terminals to the fuel pump motor are dif-

ferent in size and cannot be connected to the wrong

terminal.

(2) Disconnect fuel pump terminal wires.

(3) Remove fuel pump outlet hose and clamp. Re-

place the hose if it shows any signs of fatigue or fail-

ure.

(4) Remove fuel pump top mounting bracket nut.

Remove fuel pump (Fig. 2).

ASSEMBLYÐXJ MODELS

Whenever the fuel pump is replaced, the fuel pump

inlet filter (sock) must also be replaced.

(1) Place fuel pump top mounting bracket over top

of pump.

(2) Position fuel pump into lower bracket. Slide

stud of top bracket through hole in fuel pump side

bracket. Tighten fuel pump top mounting nut.

(3) Install new fuel pump outlet hose. Secure with

new clamps.

(4) Connect wire terminals to motor.

(5) Install new fuel pump inlet filter.

INSTALLATIONÐXJ MODELS

Whenever the fuel pump is replaced, the fuel

pump inlet filter must also be replaced.

(1) Install new fuel pump inlet filter onto fuel

pump.

(2) Install fuel pump module assembly and new O-

ring seal. The rubber stopper on the end of the fuel

return tube of the assembly must be inserted into the

cup in the fuel tank reservoir (Fig. 3).

Fig. 1 Removing Lock RingÐXJ ModelsÐTypical

Fig. 2 Fuel Pump ModuleÐXJ

ModelsÐDisassemble/Assemble

Fig. 3 Fuel Pump ModuleÐXJ ModelsÐInstallation

JFUEL SYSTEM 14 - 3

Page 901 of 1770

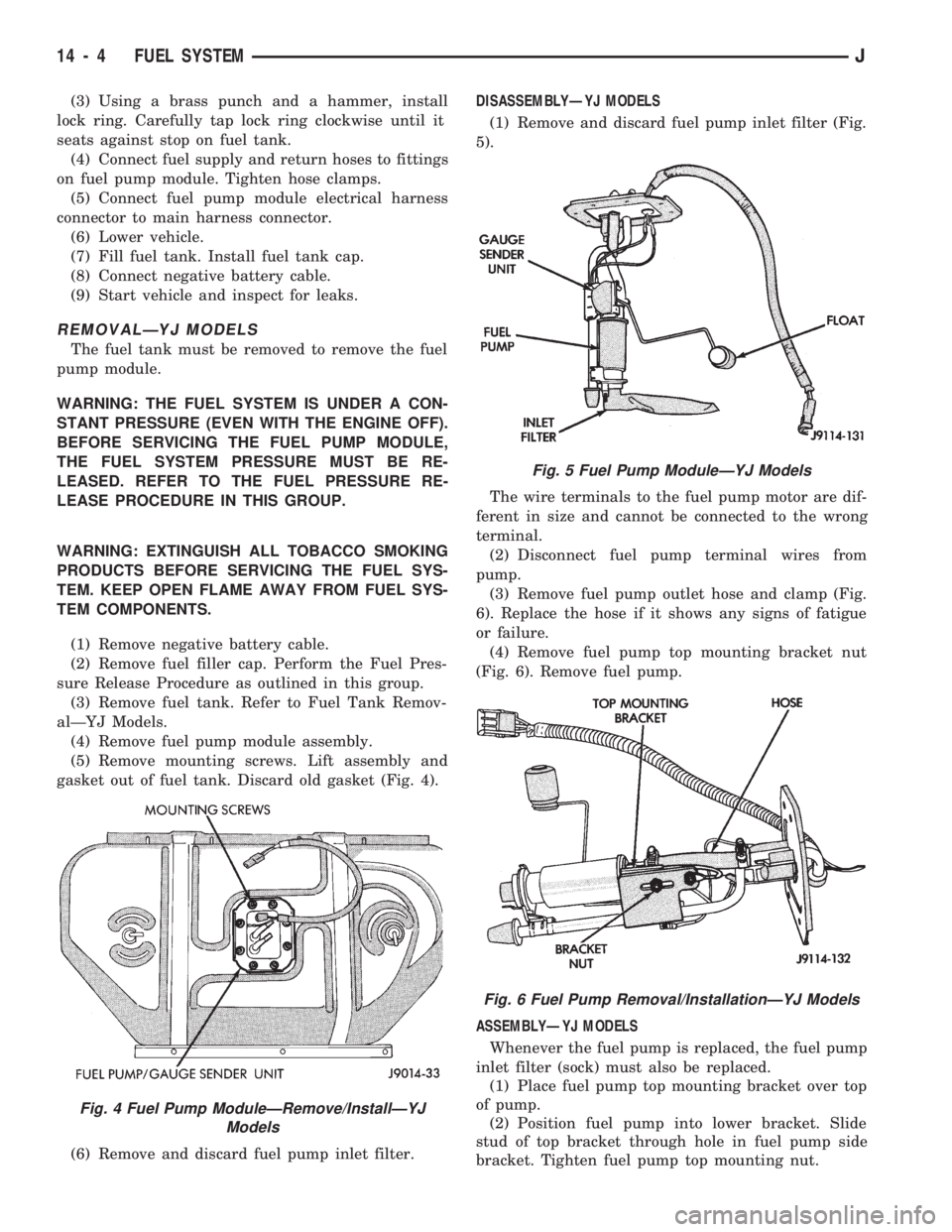

(3) Using a brass punch and a hammer, install

lock ring. Carefully tap lock ring clockwise until it

seats against stop on fuel tank.

(4) Connect fuel supply and return hoses to fittings

on fuel pump module. Tighten hose clamps.

(5) Connect fuel pump module electrical harness

connector to main harness connector.

(6) Lower vehicle.

(7) Fill fuel tank. Install fuel tank cap.

(8) Connect negative battery cable.

(9) Start vehicle and inspect for leaks.

REMOVALÐYJ MODELS

The fuel tank must be removed to remove the fuel

pump module.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING THE FUEL PUMP MODULE,

THE FUEL SYSTEM PRESSURE MUST BE RE-

LEASED. REFER TO THE FUEL PRESSURE RE-

LEASE PROCEDURE IN THIS GROUP.

WARNING: EXTINGUISH ALL TOBACCO SMOKING

PRODUCTS BEFORE SERVICING THE FUEL SYS-

TEM. KEEP OPEN FLAME AWAY FROM FUEL SYS-

TEM COMPONENTS.

(1) Remove negative battery cable.

(2) Remove fuel filler cap. Perform the Fuel Pres-

sure Release Procedure as outlined in this group.

(3) Remove fuel tank. Refer to Fuel Tank Remov-

alÐYJ Models.

(4) Remove fuel pump module assembly.

(5) Remove mounting screws. Lift assembly and

gasket out of fuel tank. Discard old gasket (Fig. 4).

(6) Remove and discard fuel pump inlet filter.DISASSEMBLYÐYJ MODELS

(1) Remove and discard fuel pump inlet filter (Fig.

5).

The wire terminals to the fuel pump motor are dif-

ferent in size and cannot be connected to the wrong

terminal.

(2) Disconnect fuel pump terminal wires from

pump.

(3) Remove fuel pump outlet hose and clamp (Fig.

6). Replace the hose if it shows any signs of fatigue

or failure.

(4) Remove fuel pump top mounting bracket nut

(Fig. 6). Remove fuel pump.

ASSEMBLYÐYJ MODELS

Whenever the fuel pump is replaced, the fuel pump

inlet filter (sock) must also be replaced.

(1) Place fuel pump top mounting bracket over top

of pump.

(2) Position fuel pump into lower bracket. Slide

stud of top bracket through hole in fuel pump side

bracket. Tighten fuel pump top mounting nut.

Fig. 4 Fuel Pump ModuleÐRemove/InstallÐYJ

Models

Fig. 5 Fuel Pump ModuleÐYJ Models

Fig. 6 Fuel Pump Removal/InstallationÐYJ Models

14 - 4 FUEL SYSTEMJ

Page 903 of 1770

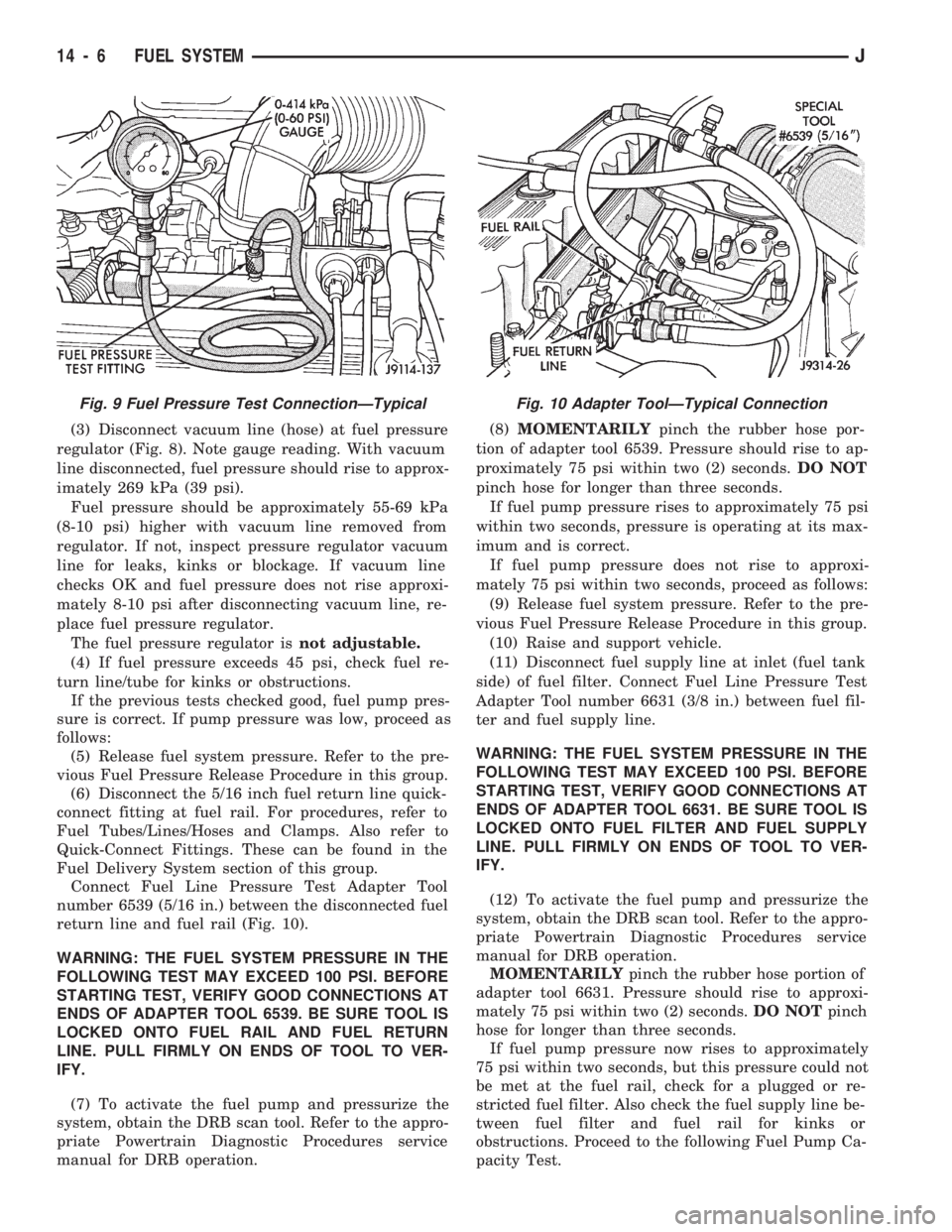

(3) Disconnect vacuum line (hose) at fuel pressure

regulator (Fig. 8). Note gauge reading. With vacuum

line disconnected, fuel pressure should rise to approx-

imately 269 kPa (39 psi).

Fuel pressure should be approximately 55-69 kPa

(8-10 psi) higher with vacuum line removed from

regulator. If not, inspect pressure regulator vacuum

line for leaks, kinks or blockage. If vacuum line

checks OK and fuel pressure does not rise approxi-

mately 8-10 psi after disconnecting vacuum line, re-

place fuel pressure regulator.

The fuel pressure regulator isnot adjustable.

(4) If fuel pressure exceeds 45 psi, check fuel re-

turn line/tube for kinks or obstructions.

If the previous tests checked good, fuel pump pres-

sure is correct. If pump pressure was low, proceed as

follows:

(5) Release fuel system pressure. Refer to the pre-

vious Fuel Pressure Release Procedure in this group.

(6) Disconnect the 5/16 inch fuel return line quick-

connect fitting at fuel rail. For procedures, refer to

Fuel Tubes/Lines/Hoses and Clamps. Also refer to

Quick-Connect Fittings. These can be found in the

Fuel Delivery System section of this group.

Connect Fuel Line Pressure Test Adapter Tool

number 6539 (5/16 in.) between the disconnected fuel

return line and fuel rail (Fig. 10).

WARNING: THE FUEL SYSTEM PRESSURE IN THE

FOLLOWING TEST MAY EXCEED 100 PSI. BEFORE

STARTING TEST, VERIFY GOOD CONNECTIONS AT

ENDS OF ADAPTER TOOL 6539. BE SURE TOOL IS

LOCKED ONTO FUEL RAIL AND FUEL RETURN

LINE. PULL FIRMLY ON ENDS OF TOOL TO VER-

IFY.

(7) To activate the fuel pump and pressurize the

system, obtain the DRB scan tool. Refer to the appro-

priate Powertrain Diagnostic Procedures service

manual for DRB operation.(8)MOMENTARILYpinch the rubber hose por-

tion of adapter tool 6539. Pressure should rise to ap-

proximately 75 psi within two (2) seconds.DO NOT

pinch hose for longer than three seconds.

If fuel pump pressure rises to approximately 75 psi

within two seconds, pressure is operating at its max-

imum and is correct.

If fuel pump pressure does not rise to approxi-

mately 75 psi within two seconds, proceed as follows:

(9) Release fuel system pressure. Refer to the pre-

vious Fuel Pressure Release Procedure in this group.

(10) Raise and support vehicle.

(11) Disconnect fuel supply line at inlet (fuel tank

side) of fuel filter. Connect Fuel Line Pressure Test

Adapter Tool number 6631 (3/8 in.) between fuel fil-

ter and fuel supply line.

WARNING: THE FUEL SYSTEM PRESSURE IN THE

FOLLOWING TEST MAY EXCEED 100 PSI. BEFORE

STARTING TEST, VERIFY GOOD CONNECTIONS AT

ENDS OF ADAPTER TOOL 6631. BE SURE TOOL IS

LOCKED ONTO FUEL FILTER AND FUEL SUPPLY

LINE. PULL FIRMLY ON ENDS OF TOOL TO VER-

IFY.

(12) To activate the fuel pump and pressurize the

system, obtain the DRB scan tool. Refer to the appro-

priate Powertrain Diagnostic Procedures service

manual for DRB operation.

MOMENTARILYpinch the rubber hose portion of

adapter tool 6631. Pressure should rise to approxi-

mately 75 psi within two (2) seconds.DO NOTpinch

hose for longer than three seconds.

If fuel pump pressure now rises to approximately

75 psi within two seconds, but this pressure could not

be met at the fuel rail, check for a plugged or re-

stricted fuel filter. Also check the fuel supply line be-

tween fuel filter and fuel rail for kinks or

obstructions. Proceed to the following Fuel Pump Ca-

pacity Test.

Fig. 9 Fuel Pressure Test ConnectionÐTypicalFig. 10 Adapter ToolÐTypical Connection

14 - 6 FUEL SYSTEMJ

Page 907 of 1770

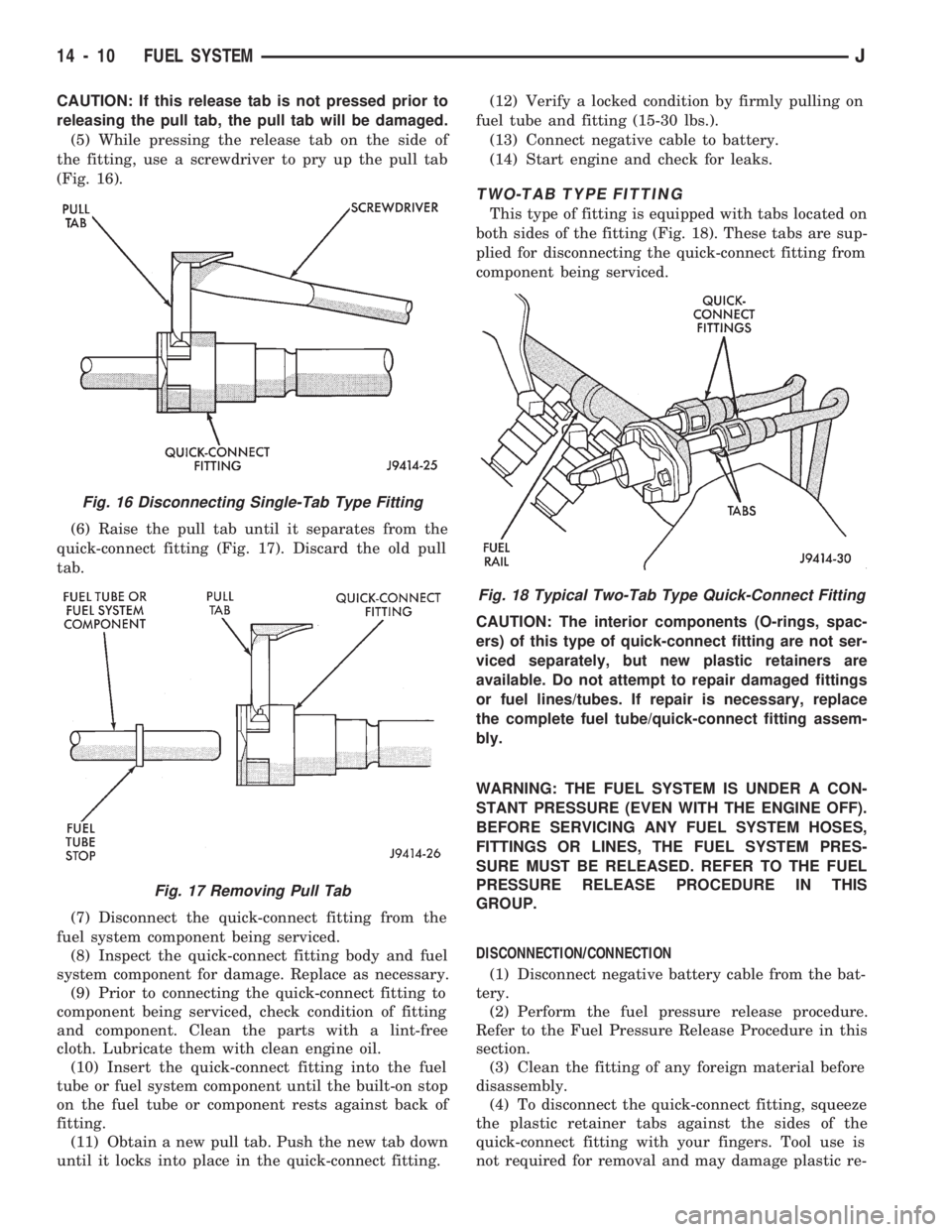

CAUTION: If this release tab is not pressed prior to

releasing the pull tab, the pull tab will be damaged.

(5) While pressing the release tab on the side of

the fitting, use a screwdriver to pry up the pull tab

(Fig. 16).

(6) Raise the pull tab until it separates from the

quick-connect fitting (Fig. 17). Discard the old pull

tab.

(7) Disconnect the quick-connect fitting from the

fuel system component being serviced.

(8) Inspect the quick-connect fitting body and fuel

system component for damage. Replace as necessary.

(9) Prior to connecting the quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean the parts with a lint-free

cloth. Lubricate them with clean engine oil.

(10) Insert the quick-connect fitting into the fuel

tube or fuel system component until the built-on stop

on the fuel tube or component rests against back of

fitting.

(11) Obtain a new pull tab. Push the new tab down

until it locks into place in the quick-connect fitting.(12) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(13) Connect negative cable to battery.

(14) Start engine and check for leaks.

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 18). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube/quick-connect fitting assem-

bly.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE IN THIS

GROUP.

DISCONNECTION/CONNECTION

(1) Disconnect negative battery cable from the bat-

tery.

(2) Perform the fuel pressure release procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Clean the fitting of any foreign material before

disassembly.

(4) To disconnect the quick-connect fitting, squeeze

the plastic retainer tabs against the sides of the

quick-connect fitting with your fingers. Tool use is

not required for removal and may damage plastic re-

Fig. 16 Disconnecting Single-Tab Type Fitting

Fig. 17 Removing Pull Tab

Fig. 18 Typical Two-Tab Type Quick-Connect Fitting

14 - 10 FUEL SYSTEMJ