Brake fluid JEEP WRANGLER 2004 TJ / 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2004, Model line: WRANGLER, Model: JEEP WRANGLER 2004 TJ / 2.GPages: 299, PDF Size: 6.82 MB

Page 119 of 299

19. Trip Odometer Button

Press and release this button to toggle between the

odometer and trip odometer displays. This button is also

used to reset the trip odometer to 0. While the display is

showing the trip odometer, press and hold the button for

approximately 2 seconds and the display will reset to 0.

20. Odometer/Trip Odometer

The odometer shows the total distance the vehicle has

been driven.

The odometer will ªilluminateº when the driver's door

has been opened, and will remain on for 20 seconds after

exiting the vehicle.

U.S. federal regulations require that upon transfer of

vehicle ownership, the seller certify to the purchaser the

correct mileage that the vehicle has been driven. There-

fore, if the odometer reading is changed during repair or

replacement, be sure to keep a record of the reading

before and after the service so the correct mileage can be

determined.The trip odometer shows individual mileage up to 999.9

miles (1 600 km). To switch from odometer to trip

odometer, press the trip odometer button.

21. Anti-Lock (ABS) Warning Light

After ignition is turned on, illuminates to indi-

cate function check at vehicle start-up. If light

remains on after start-up or comes on and stays on at

road speeds, it may indicate that the ABS has detected

a malfunction or has become inoperative. The system

reverts to standard non-anti-lock brakes.

If both the red BRAKE warning light and the amber ABS

warning light are on, see your dealer immediately. Refer

to ªAnti-Lock Brake Systemº in Section 5 of this manual.

22. Brake Warning Light

After ignition is turned on, illuminates to in-

dicate function check at vehicle start-up. Indi-

cates parking brake is applied. If the light stays

on when the parking brake is off, it indicates a possible

brake system fluid leak or low pressure level,see your

authorized dealer immediately.

UNDERSTANDING YOUR INSTRUMENT PANEL 119

4

Page 203 of 299

²The weight of any other type of cargo or equipment

put in or on your vehicle.

Remember that everything put in or on the trailer adds to

the load on your vehicle.

Warranty Requirements

The manufacturer's warranty will apply to vehicles used

to tow trailers for noncommercial use, however the

following conditions must be met:

²The ªDº Overdrive range can be selected when tow-

ing. However, if frequent shifting occurs move the

shift lever to the next lower position to eliminate

excessive automatic transmission shifting. This action

will also reduce the possibility of transmission over-

heating and provide better engine braking. Refer to

ªTransmission Shiftingº in this section for additional

information.

²A load equalizing hitch is recommended for loaded

trailer weights above 1,000 lbs (454 kg).

CAUTION!

If the trailer weighs more than 1,000 lbs (454 kg)

loaded, it should have its own brakes and they

should be of adequate capacity. Failure to do this

could lead to accelerated brake lining wear, higher

brake pedal effort, and longer stopping distances.

WARNING!

Connecting trailer brakes to your vehicle's hydraulic

brake lines can overload your brake system and

cause it to fail. You might not have brakes when you

need them and could have an accident.

²Whenever you pull a trailer, regardless of the trailer

size, stop lights and turn signals on the trailer are

mandatory for motoring safety.

²Follow the maintenance intervals in schedule ªBº for

changing the automatic transmission fluid and filter, if

you REGULARLY tow a trailer for more than 45

minutes of continuous operation.

STARTING AND OPERATING 203

5

Page 205 of 299

NOTE:Refer to ªRecommended Fluids, Lubricants,

and Genuine Partsº in Section 7 for axle differential

lubrication specifications for towing.

SNOW PLOW

Snow plowsshould notbe added to the front end of your

vehicle.

RECREATIONAL TOWING (BEHIND

MOTORHOME, ETC.)

CAUTION!

Internal damage to the transfer case will occur if a

front or rear wheel lift is used when recreational

towing.

NOTE:The transfer case must be shifted into N (Neu-

tral) for recreational towing.

Shifting Into Neutral (N)

Use the following procedure to prepare your vehicle for

recreational towing.

CAUTION!

It is necessary to follow these steps to be certain that

the transfer case is fully in N (Neutral) before

recreational towing to prevent damage to internal

parts.

1. Depress brake pedal.

2. Shift automatic transmission into N (Neutral) or de-

press clutch pedal on manual transmission.

3. Shift transfer case lever into N (Neutral).

4. Start engine.

5. Shift automatic transmission into D (Drive) or manual

transmission into gear.

STARTING AND OPERATING 205

5

Page 216 of 299

²Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

²Apply the parking brake firmly before jacking.

²Always block the wheel diagonally opposite the wheel

being raised.

²Do not raise the vehicle higher than is necessary to

remove the tire.

²Never start the engine with the vehicle on a jack.

²Do not let passengers sit in the vehicle when it is on a

jack.

²Do not get under the vehicle when it is on a jack.

²Failure to follow the ªTire Changing Procedureº may

result in personal injury or damage to your vehicle.

²Only use the jack in the positions indicated.

JUMP STARTING

WARNING!

To prevent personal injury or damage to clothing, do

not allow battery fluid to contact eyes, skin, or

fabrics. Do not lean over a battery when connecting

jumper cables or allow cable clamps to touch each

other. Keep open flames or sparks away from battery

vent holes. Always wear eye protection when work-

ing with batteries. Do not use a booster battery or

any other booster source that has a greater than

12±volt system, i.e. do not use a 24±volt power

source.

Your vehicle is equipped with a 12±volt battery. If it

becomes necessary to use a booster battery, with jumper

cables, to start the vehicle's engine because it's battery is

discharged, the following procedure should be followed:

216 WHAT TO DO IN EMERGENCIES

Page 222 of 299

NWindshield Washers...................238

NExhaust System......................238

NCooling System.......................239

NHoses And Vacuum/Vapor Harnesses.......242

NBrake System........................243

NAutomatic Transmission................245

NHydraulic Clutch Fluid Ð

Manual Transmission..................246

NManual Transmission..................246

NTransfer Case........................247

NFront/Rear Axle Fluid..................248

NAppearance Care And Protection

From Corrosion......................248mFuse Panel...........................254

NInterior Fuses........................254

NUnderhood Fuses

(Power Distribution Center)..............256

mVehicle Storage........................256

mReplacement Bulbs Ð If Equipped.........257

mFluid Capacities.......................258

mRecommended Fluids, Lubricants And

Genuine Parts

.........................259

NEngine.............................259

NChassis............................260

222 MAINTAINING YOUR VEHICLE

Page 244 of 299

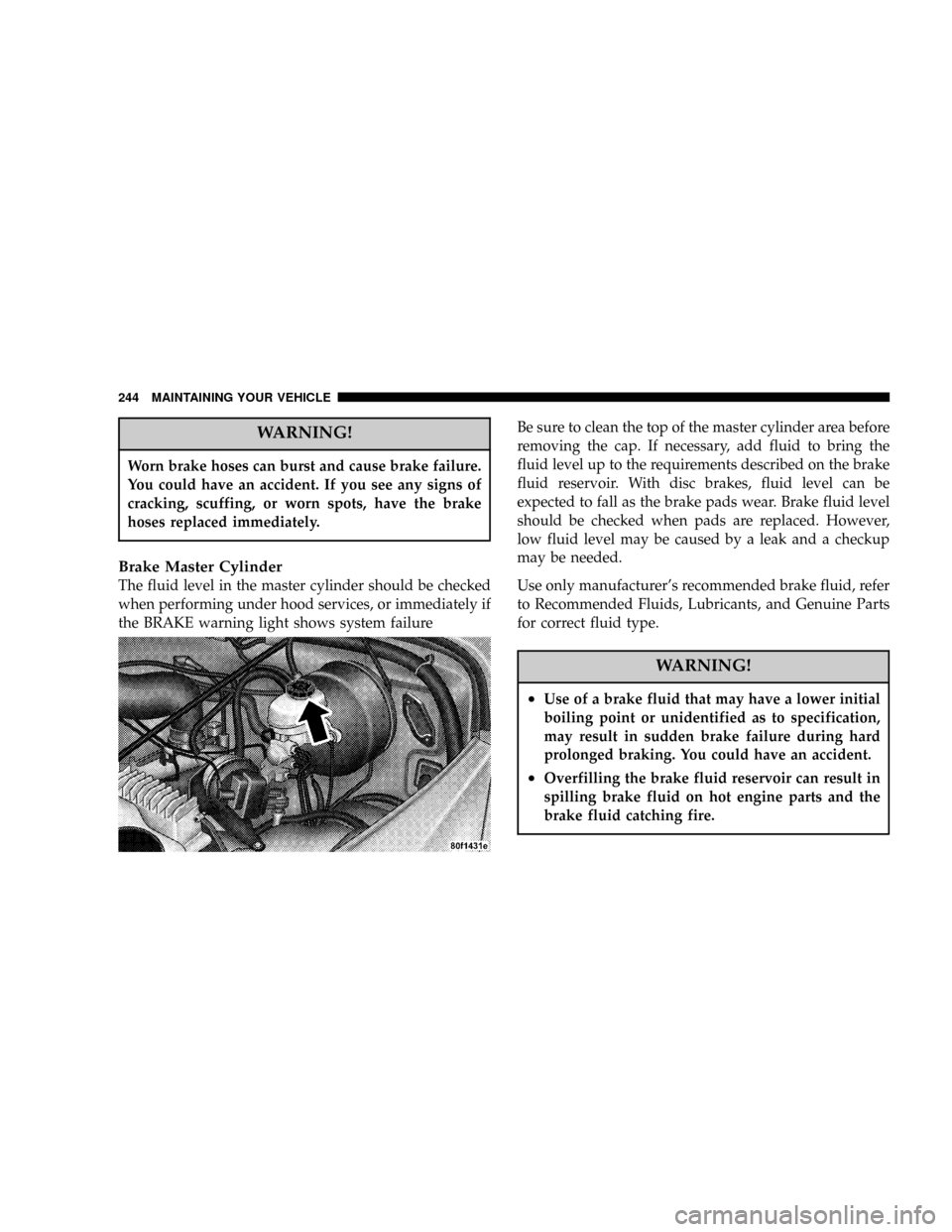

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the BRAKE warning light shows system failureBe sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brake

fluid reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear. Brake fluid level

should be checked when pads are replaced. However,

low fluid level may be caused by a leak and a checkup

may be needed.

Use only manufacturer's recommended brake fluid, refer

to Recommended Fluids, Lubricants, and Genuine Parts

for correct fluid type.

WARNING!

²Use of a brake fluid that may have a lower initial

boiling point or unidentified as to specification,

may result in sudden brake failure during hard

prolonged braking. You could have an accident.

²Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

244 MAINTAINING YOUR VEHICLE

Page 245 of 299

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter. Do

not allow petroleum base fluid to contaminate the brake

fluid as seal damage will result.

Automatic Transmission

Selection of Lubricant

It is important that the proper lubricant is used in the

transmission to assure optimum transmission perfor-

mance. Use only manufacturer's recommended transmis-

sion fluid, refer to Recommended Fluids, Lubricants, and

Genuine Parts for correct fluid type. It is important that

the transmission fluid be maintained at the prescribed

level using the recommended fluid.

CAUTION!

Using a transmission fluid other than the manufac-

turer's recommended fluid may cause deterioration

in transmission shift quality and/or torque converter

shudder. Using a transmission fluid other than the

manufacturer's recommended fluid will result in

more frequent fluid and filter changes. Refer to

Recommended Fluids, Lubricants, and Genuine

Parts for correct fluid type.

Fluid Level Check Ð 42RLE

This fluid level should be checked when the engine is

fully warmed up and the fluid in the transmission is

heated to its normal operating temperature. Operation of

the transmission with an improper fluid level will greatly

reduce the life of the transmission and of the fluid.

To check the automatic transmission fluid level properly,

the following procedure must be used:

1. The vehicle must be on level ground.

MAINTAINING YOUR VEHICLE 245

7

Page 246 of 299

2. The engine should be running at curb idle speed for a

minimum of 60 seconds.

3. Fully apply parking brake.

4. Apply the brakes and shift the transmission into P

(Park).

5. The fluidMUSTbe checked with the transmission in

P (Park) to be sure that the fluid level is accurate.

6. Wipe the dipstick clean and reinsert until seated.

Remove dipstick and note reading.

At normal operating temperature (approximately 180É F

(82É C), the fluid level is correct if it is in the HOT region

(cross-hatched area) on the oil level indicator. The fluid

level indicator should be in the COLD region at 70É F (21É

C) fluid temperature.

If the fluid level is low, add sufficient fluid to bring to the

proper level. Refer to Recommended Fluids, Lubricants

and Genuine Parts for correct fluid type.

Fluid is added through the dipstick tube.NOTE:To prevent dirt and water from entering the

transmission after checking or replenishing fluid, make

certain that the dipstick cap is properly reseated.

Special Additives

The manufacturer strongly recommends against the ad-

dition of any additives to the transmission. The only

exception to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided as they may adversely affect seals.

Hydraulic Clutch Fluid Ð Manual Transmission

The clutch hydraulic system is a sealed maintenance free

system. In the event of leakage or other malfunction, the

system must be replaced.

Manual Transmission

Selection of Lubricant

Use only manufacturer's recommended manual trans-

mission fluid, refer to Recommended Fluids, Lubricants,

and Genuine Parts for correct fluid type.

246 MAINTAINING YOUR VEHICLE

Page 260 of 299

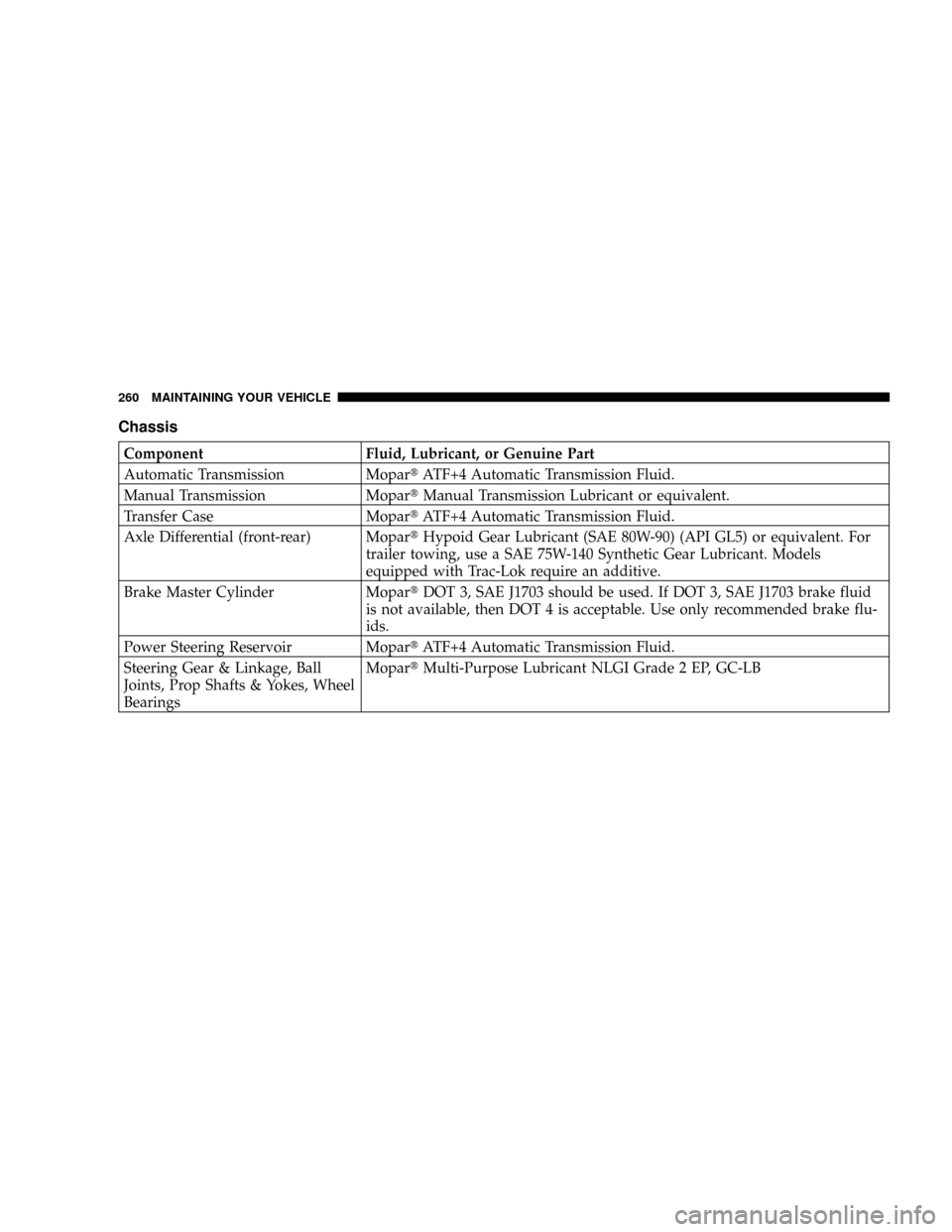

Chassis

Component Fluid, Lubricant, or Genuine Part

Automatic Transmission MopartATF+4 Automatic Transmission Fluid.

Manual Transmission MopartManual Transmission Lubricant or equivalent.

Transfer Case MopartATF+4 Automatic Transmission Fluid.

Axle Differential (front-rear) MopartHypoid Gear Lubricant (SAE 80W-90) (API GL5) or equivalent. For

trailer towing, use a SAE 75W-140 Synthetic Gear Lubricant. Models

equipped with Trac-Lok require an additive.

Brake Master Cylinder MopartDOT 3, SAE J1703 should be used. If DOT 3, SAE J1703 brake fluid

is not available, then DOT 4 is acceptable. Use only recommended brake flu-

ids.

Power Steering Reservoir MopartATF+4 Automatic Transmission Fluid.

Steering Gear & Linkage, Ball

Joints, Prop Shafts & Yokes, Wheel

BearingsMopartMulti-Purpose Lubricant NLGI Grade 2 EP, GC-LB

260 MAINTAINING YOUR VEHICLE

Page 263 of 299

NOTE:Most vehicles are operated under the conditions

listed for Schedule ªB.º

Second is ScheduleªAº. It is for vehicles that are not

operated under any of the conditions listed under Sched-

ule ªB.º

Use the schedule that best describes your driving condi-

tions. Where time and mileage are listed, follow the

interval that occurs first.

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

At Each Stop for Fuel

²

Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent, add as required.

Once a Month

²

Check the tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of the coolant reservoir, brake

master cylinder, and transmission, and add as needed.

²Check all lights and all other electrical items for correct

operation.

At Each Oil Change

²

Change the engine oil filter.

²Inspect the exhaust system.

²Inspect brake hoses.

²Check the coolant level, hoses, and clamps.

²Inspect manual transmission fluid level Ð if

equipped.

MAINTENANCE SCHEDULES 263

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S