Cooling system JEEP WRANGLER 2014 JK / 3.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2014, Model line: WRANGLER, Model: JEEP WRANGLER 2014 JK / 3.GPages: 678, PDF Size: 4.97 MB

Page 599 of 678

To minimize the possibility of catalytic converter dam-

age:

•Do not shut off the engine or interrupt the ignition,

when the transmission is in gear and the vehicle is in

motion.

• Do not try to start the engine by pushing or towing the

vehicle.

• Do not idle the engine with any spark plug wires

disconnected or removed, such as when diagnostic

testing, or for prolonged periods during very rough

idle or malfunctioning operating conditions.Cooling System

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator. If

you see or hear steam coming from under the hood,

do not open the hood until the radiator has had time

to cool. Never try to open a cooling system pressure

cap when the radiator or coolant bottle is hot.

Engine Coolant Checks

Check the engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where

applicable). If the engine coolant (antifreeze) is dirty or

rusty in appearance, the system should be drained,

flushed and refilled with fresh engine coolant (anti-

freeze). Check the front of the A/C condenser (if

equipped) or radiator for any accumulation of bugs,

7

MAINTAINING YOUR VEHICLE 597

Page 600 of 678

leaves, etc. If dirty, clean by gently spraying water from a

garden hose vertically down the face of the A/C con-

denser (if equipped) or the back of the radiator core.

Check the engine cooling system hoses for brittle rubber,

cracking, tears, cuts, and tightness of the connection at

the coolant recovery bottle and radiator. Inspect the

entire system for leaks.

With the engine at normal operating temperature (but

not running), check the cooling system pressure cap for

proper vacuum sealing by draining a small amount of

engine coolant (antifreeze) from the radiator drain cock.

If the cap is sealing properly, the engine coolant (anti-

freeze) will begin to drain from the coolant recovery

bottle. DO NOT REMOVE THE COOLANT PRESSURE

CAP WHEN THE COOLING SYSTEM IS HOT.Cooling System — Drain, Flush And Refill

If the engine coolant (antifreeze) is dirty or contains

visible sediment, have an authorized dealer clean and

flush with OAT coolant (antifreeze) (conforming to

MS-12106).

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

NOTE:Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly could lead

to severe internal engine damage. If any coolant is

needed to be added to the system please contact your

local authorized dealer.

Selection Of Coolant

Refer to “Fluids, Lubricants, and Genuine Parts” in

“Maintaining Your Vehicle” for further information.

598 MAINTAINING YOUR VEHICLE

Page 601 of 678

CAUTION!

•Mixing of engine coolant (antifreeze) other than

specified Organic Additive Technology (OAT) en-

gine coolant (antifreeze), may result in engine

damage and may decrease corrosion protection.

Organic Additive Technology (OAT) engine cool-

ant is different and should not be mixed with

Hybrid Organic Additive Technology (HOAT) en-

gine coolant (antifreeze) or any “globally compat-

ible” coolant (antifreeze). If a non-OAT engine

coolant (antifreeze) is introduced into the cooling

system in an emergency, the cooling system will

need to be drained, flushed, and refilled with fresh

OAT coolant (conforming to MS-12106), by an

authorized dealer as soon as possible.

(Continued)

CAUTION! (Continued)

•Do not use water alone or alcohol-based engine

coolant (antifreeze) products. Do not use additional

rust inhibitors or antirust products, as they may not

be compatible with the radiator engine coolant and

may plug the radiator.

• This vehicle has not been designed for use with

propylene glycol-based engine coolant (antifreeze).

Use of propylene glycol-based engine coolant (an-

tifreeze) is not recommended.

Adding Coolant

Your vehicle has been built with an improved engine

coolant (OAT coolant conforming to MS-12106) that allows

extended maintenance intervals. This engine coolant (anti-

freeze) can be used up to ten years or 150,000 miles

(240,000 km) before replacement. To prevent reducing this

extended maintenance period, it is important that you use7

MAINTAINING YOUR VEHICLE 599

Page 602 of 678

the same engine coolant (OAT coolant conforming to

MS-12106) throughout the life of your vehicle.

Please review these recommendations for using Organic

Additive Technology (OAT) engine coolant (antifreeze)

that meets the requirements of Chrysler Material Stan-

dard MS-12106. When adding engine coolant (antifreeze):

•We recommend using MOPAR® Antifreeze/Coolant

10 Year/150,000 Mile Formula OAT (Organic Additive

Technology) that meets the requirements of Chrysler

Material Standard MS-12106.

• Mix a minimum solution of 50% OAT engine coolant

that meets the requirements of Chrysler Material Stan-

dard MS-12106 and distilled water. Use higher concen-

trations (not to exceed 70%) if temperatures below

�34° F (�37° C) are anticipated. •

Use only high purity water such as distilled or deion-

ized water when mixing the water/engine coolant

(antifreeze) solution. The use of lower quality water

will reduce the amount of corrosion protection in the

engine cooling system.

Please note that it is the owner’s responsibility to main-

tain the proper level of protection against freezing ac-

cording to the temperatures occurring in the area where

the vehicle is operated.

NOTE:

• Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly could

lead to severe internal engine damage. If any coolant is

needed to be added to the system please contact your

local authorized dealer.

600 MAINTAINING YOUR VEHICLE

Page 603 of 678

•Mixing engine coolant (antifreeze) types is not recom-

mended and can result in cooling system damage. If

HOAT and OAT coolant are mixed in an emergency,

have a authorized dealer drain, flush, and refill with

OAT coolant (conforming to MS-12106) as soon as

possible.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of engine

coolant (antifreeze), and to ensure that engine coolant

(antifreeze) will return to the radiator from the coolant

recovery tank.

The cap should be inspected and cleaned if there is any

accumulation of foreign material on the sealing surfaces.

WARNING!

• Do not open hot engine cooling system. Never add

engine coolant (antifreeze) when the engine is

overheated. Do not loosen or remove the cap to cool

an overheated engine. Heat causes pressure to

build up in the cooling system. To prevent scalding

or injury, do not remove the pressure cap while the

system is hot or under pressure.

• Do not use a pressure cap other than the one

specified for your vehicle. Personal injury or en-

gine damage may result.

Disposal Of Used Engine Coolant

Used ethylene glycol-based engine coolant (antifreeze) is

a regulated substance requiring proper disposal. Check

with your local authorities to determine the disposal

rules for your community. To prevent ingestion by ani-

mals or children, do not store ethylene glycol-based

7

MAINTAINING YOUR VEHICLE 601

Page 605 of 678

•Check the coolant freeze point in the radiator and in

the coolant expansion bottle. If engine coolant (anti-

freeze) needs to be added, the contents of the coolant

expansion bottle must also be protected against freez-

ing.

• If frequent engine coolant (antifreeze) additions are

required, the cooling system should be pressure tested

for leaks.

• Maintain engine coolant (antifreeze) concentration at a

minimum of 50% OAT coolant (conforming to

MS-12106) and distilled water for proper corrosion

protection of your engine which contains aluminum

components.

• Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

• Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean. •

Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine coolant (antifreeze)

performance, poor gas mileage, and increased emis-

sions.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting or

riding on the brake pedal can result in abnormally

(Continued)

7

MAINTAINING YOUR VEHICLE 603

Page 634 of 678

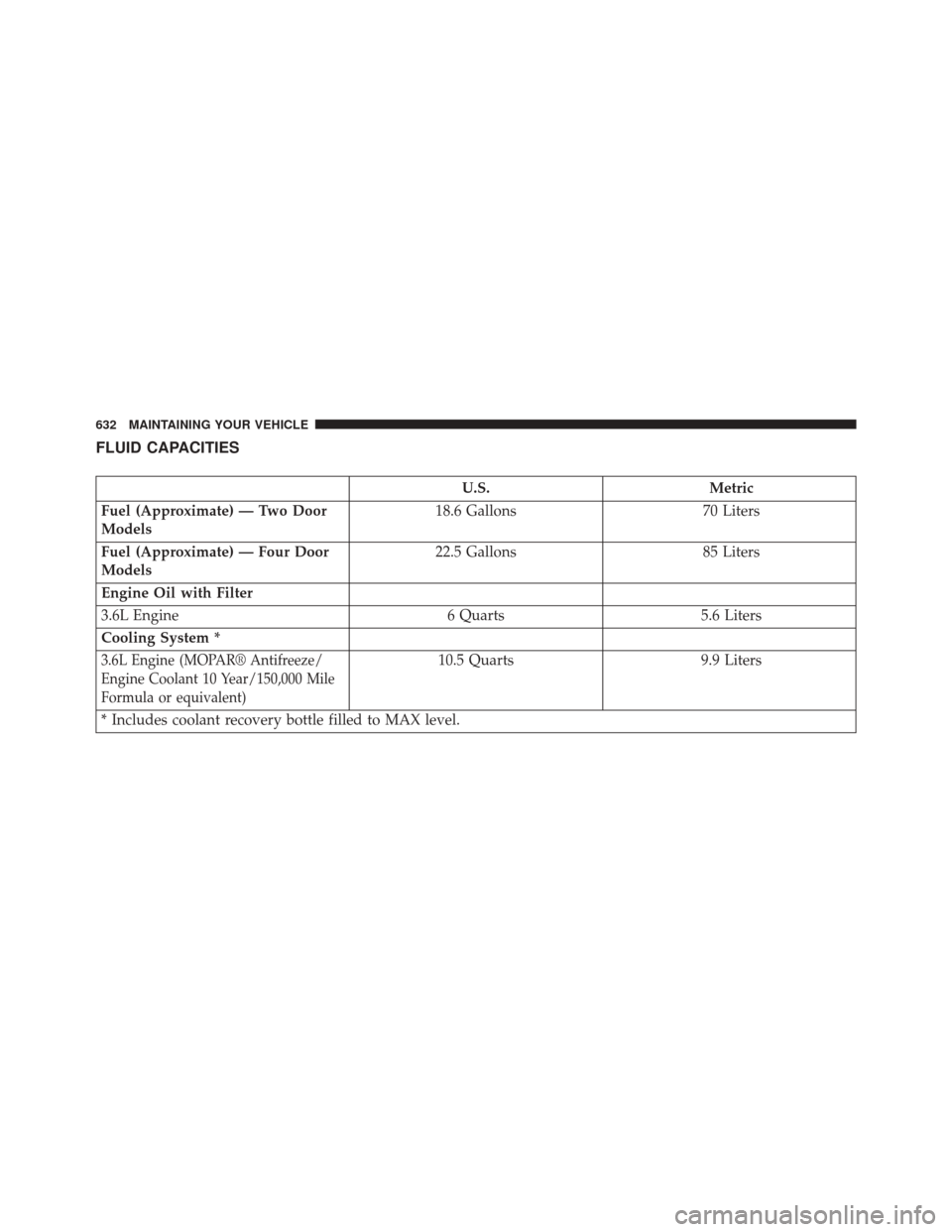

FLUID CAPACITIES

U.S.Metric

Fuel (Approximate) — Two Door

Models 18.6 Gallons

70 Liters

Fuel (Approximate) — Four Door

Models 22.5 Gallons

85 Liters

Engine Oil with Filter

3.6L Engine 6 Quarts5.6 Liters

Cooling System *

3.6L Engine (MOPAR® Antifreeze/

Engine Coolant 10 Year/150,000 Mile

Formula or equivalent)10.5 Quarts 9.9 Liters

* Includes coolant recovery bottle filled to MAX level.

632 MAINTAINING YOUR VEHICLE

Page 640 of 678

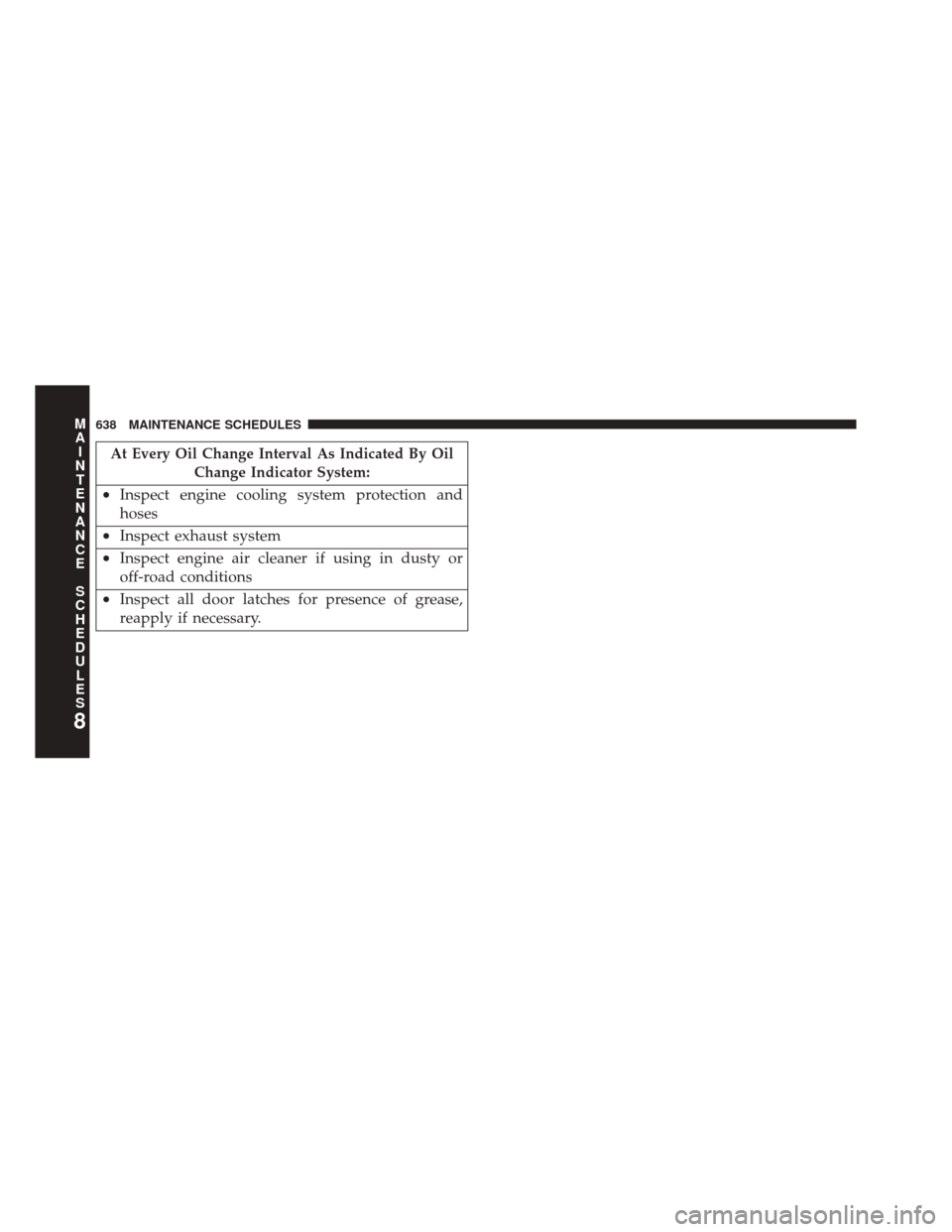

At Every Oil Change Interval As Indicated By OilChange Indicator System:

•Inspect engine cooling system protection and

hoses

• Inspect exhaust system

• Inspect engine air cleaner if using in dusty or

off-road conditions

• Inspect all door latches for presence of grease,

reapply if necessary.

8

M

A I

N T

E

N

A

N

C E

S

C

H E

D

U L

E

S638 MAINTENANCE SCHEDULES

Page 660 of 678

Chains, Tire............................ .506

Changing A Flat Tire ...................... .559

Chart, Tire Sizing ........................ .485

Check Engine Light (Malfunction Indicator Light) . .319

Checking Your Vehicle For Safety ..............103

Checks, Safety .......................... .103

Child Restraint ............................79

Child Restraints Child Seat Installation .....................99

Install A LATCH-compatible Child Restraint .....94

Installing Child Restraints Using The Vehicle Seat

Belt ..................................96

Lower Anchors And Tethers For Children .......87

Child Safety Locks .........................44

Clean Air Gasoline ....................... .522

Cleaning Wheels .............................. .614

Climate Control ......................... .399

Clock ................................. .345Cold Weather Operation

....................419

Compact Disc (CD) Maintenance ..............398

Compact Spare Tire ....................... .501

Compass .............................. .323

Compass Calibration ...................... .326

Compass Variance ........................ .325

Computer, Trip/Travel ..................... .322

Connector UCI................................ .390

Universal Consumer Interface (UCI) ..........390

Console ............................... .192

Console, Floor .......................... .192

Contract, Service ......................... .649

Coolant Pressure Cap (Radiator Cap) ...........601

Cooling System .......................... .597

Adding Coolant (Antifreeze) ...............599

Coolant Capacity ...................... .632

Coolant Level ......................... .602

Disposal of Used Coolant .................601

658 INDEX

Page 662 of 678

Electrical Outlet, Auxiliary (Power Outlet)........185

Electrical Power Outlets .....................185

Electric Remote Mirrors .....................117

Electronic Brake Control System ...............467

Brake Assist System .....................468

Electronic Roll Mitigation .................473

Traction Control System ...................468

Electronic Roll Mitigation (ERM) ..............473

Electronic Speed Control (Cruise Control) ........181

Electronic Stability Control (ESC) ..............474

Electronic Throttle Control Warning Light ........322

Electronic Vehicle Information Center (EVIC) ......322

Emergency Brake ........................ .462

Emergency, In Case of Jacking .............................. .559

Jump Starting ......................... .566

Tow Hooks ........................... .571

Emission Control System Maintenance ..........581Engine

Air Cleaner .......................... .587

Block Heater ......................... .422

Break-In Recommendations ................102

Compartment ......................... .579

Compartment Identification ................579

Cooling ............................. .597

Exhaust Gas Caution .....................104

Fails to Start .......................... .420

Flooded, Starting ...................... .420

Fuel Requirements ..................... .521

Jump Starting ......................... .566

Oil................................. .584

Oil Change Interval ..................... .332

Oil Selection .......................... .585

Oil Synthetic ......................... .586

Overheating .......................... .556

Starting ............................. .418

T

emperature Gauge ..................... .313

660 INDEX