engine JEEP WRANGLER 2015 JK / 3.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2015, Model line: WRANGLER, Model: JEEP WRANGLER 2015 JK / 3.GPages: 695, PDF Size: 20.64 MB

Page 618 of 695

Disposal Of Used Engine Coolant

Used ethylene glycol-based engine coolant (antifreeze) is

a regulated substance requiring proper disposal. Check

with your local authorities to determine the disposal

rules for your community. To prevent ingestion by ani-

mals or children, do not store ethylene glycol-based

engine coolant in open containers or allow it to remain in

puddles on the ground. If ingested by a child or pet, seek

emergency assistance immediately. Clean up any ground

spills immediately.

Engine Coolant Level

The coolant bottle provides a quick visual method for

determining that the coolant level is adequate. With the

engine idling, and warm to normal operating tempera-

ture, the level of the engine coolant (antifreeze) in the

bottle should be between the ranges indicated on the

bottle.

The radiator normally remains completely full, so there is

no need to remove the radiator cap unless checking for

engine coolant (antifreeze) freeze point or replacing en-

gine coolant (antifreeze). Advise your service attendant

of this. As long as the engine operating temperature is

satisfactory, the coolant bottle need only be checked once

a month.

When additional engine coolant (antifreeze) is needed to

maintain the proper level, it should be added to the

coolant bottle. Do not overfill.

Points To Remember

NOTE:When the vehicle is stopped after a few miles/

kilometers of operation, you may observe vapor coming

from the front of the engine compartment. This is nor-

mally a result of moisture from rain, snow, or high

humidity accumulating on the radiator and being vapor-

ized when the thermostat opens, allowing hot engine

coolant (antifreeze) to enter the radiator.

616 MAINTAINING YOUR VEHICLE

Page 619 of 695

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

•Do not overfill the coolant expansion bottle.

•Check the coolant freeze point in the radiator and in

the coolant expansion bottle. If engine coolant (anti-

freeze) needs to be added, the contents of the coolant

expansion bottle must also be protected against freez-

ing.

•If frequent engine coolant (antifreeze) additions are

required, the cooling system should be pressure tested

for leaks.

•Maintain engine coolant (antifreeze) concentration

at a minimum of 50% OAT coolant (conforming to

MS-12106) and distilled water for proper corrosion

protection of your engine which contains aluminum

components.

•Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

•Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

•Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine coolant (antifreeze)

performance, poor gas mileage, and increased emis-

sions.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

7

MAINTAINING YOUR VEHICLE 617

Page 621 of 695

WARNING!(Continued)

•To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that has

been in a tightly closed container. Keep the master

cylinder reservoir cap secured at all times. Brake

fluid in a open container absorbs moisture from the

air resulting in a lower boiling point. This may

cause it to boil unexpectedly during hard or pro-

longed braking, resulting in sudden brake failure.

This could result in a collision.

•Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing

the brake fluid to catch fire. Brake fluid can also

damage painted and vinyl surfaces, care should be

taken to avoid its contact with these surfaces.

(Continued)

WARNING!(Continued)

•Do not allow petroleum based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

Automatic Transmission — If Equipped

Selection Of Lubricant

It is important to use the proper transmission fluid to

ensure optimum transmission performance and life. Use

only the manufacturer’s specified transmission fluid.

Refer to “Fluids, Lubricants, and Genuine Parts” in this

section for fluid specifications. It is important to maintain

the transmission fluid at the correct level using the

recommended fluid.

7

MAINTAINING YOUR VEHICLE 619

Page 622 of 695

NOTE:No chemical flushes should be used in any

transmission; only the approved lubricant should be

used.

CAUTION!

Using a transmission fluid other than the manufac-

turer’s recommended fluid may cause deterioration

in transmission shift quality and/or torque converter

shudder, and will require more frequent fluid and

filter changes. Refer to “Fluids, Lubricants, and

Genuine Parts” in this section for fluid specifica-

tions.

Special Additives

The manufacturer strongly recommends against using

any special additives in the transmission.

Automatic Transmission Fluid (ATF) is an engineered

product and its performance may be impaired by supple-

mental additives. Therefore, do not add any fluid addi-

tives to the transmission. The only exception to this

policy is the use of special dyes for diagnosing fluid

leaks. Avoid using transmission sealers as they may

adversely affect seals.

CAUTION!

Do not use chemical flushes in your transmission as

the chemicals can damage your transmission compo-

nents. Such damage is not covered by the New

Vehicle Limited Warranty.

Fluid Level Check

It is best to check the fluid level when the transmission

is at normal operating temperature (approximately

180° F/82° C). This occurs after at least 15 miles (25 km)

620 MAINTAINING YOUR VEHICLE

Page 623 of 695

of driving. At normal operating temperature, the fluid

cannot be held comfortably between the fingertips.

Use the following procedure to check the transmission

fluid level properly:

1. Park the vehicle on level ground.

2. Remove the engine cover by pulling it up off the

mounting studs (two in the front and two in the rear).

3. Run the engine at idle speed and normal operating

temperature.

4. Fully apply the parking brake, and press the brake

pedal.

5. Place the shift lever momentarily into each gear posi-

tion (allowing time for the transmission to fully en-

gage in each position), ending with the transmission in

PARK.

6. Remove the dipstick, wipe it clean and reinsert it until

seated.

7. Remove the dipstick again and note the fluid level on

both sides. The fluid level reading is only valid if there

is a solid coating of oil on both sides of the dipstick.

Note that the holes in the dipstick will be full of fluid

if the actual level is at or above the hole. The fluid level

should be between the HOT (upper) reference holes on

the dipstick at normal operating temperature. If the

fluid level is low, add fluid through the dipstick tube

to bring it to the proper level.Do not overfill.Use

ONLY the specified fluid (refer to#Fluids, Lubricants,

and Genuine Parts#for fluid specifications). After

adding any quantity of oil through the dipstick tube,

wait a minimum of two minutes for the oil to fully

drain into the transmission before rechecking the fluid

level.

7

MAINTAINING YOUR VEHICLE 621

Page 624 of 695

NOTE:

•The holes in the dipstick will be full of fluid if the

actual level is at or above the hole.

•If it is necessary to check the transmission below the

operating temperature, the fluid level should be

between the two COLD (lower) holes on the dipstick

with the fluid at approximately 80° F (27° C). If the

fluid level is correctly established at 80° F (27° C), it

should be between the HOT (upper) reference holes

when the transmission reaches 180° F (82° C). Re-

member it is best to check the level at the normal

operating temperature.

CAUTION!

If the fluid temperature is below 50°F (10°C) it may

not register on the dipstick. Do not add fluid until

(Continued)

CAUTION!(Continued)

the temperature is elevated enough to produce an

accurate reading. Run the engine at idle, in PARK, to

warm the fluid.

8. Reinstall the engine cover and snap it down securely

onto the four mounting studs.

9. Check for leaks. Release the parking brake.

NOTE:To prevent dirt and water from entering the

transmission after checking or replenishing fluid, make

sure that the dipstick cap is properly reseated. It is

normal for the dipstick cap to spring back slightly from

its fully seated position, as long as its seal remains

engaged in the dipstick tube.

Fluid And Filter Changes

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

622 MAINTAINING YOUR VEHICLE

Page 635 of 695

the MOPAR® Soft Top Zipper Cleaner and Lubricant or

equivalent into the zipper slide. Several applications

may be required before the zipper comes free.

6. Never paste stickers, gummed labels or any tape to the

windows. Adhesives are hard to remove and may

damage the windows.

FUSES

WARNING!

•When replacing a blown fuse, always use an appro-

priate replacement fuse with the same amp rating as

the original fuse. Never replace a fuse with another

fuse of higher amp rating. Never replace a blown

fuse with metal wires or any other material. Failure

to use proper fuses may result in serious personal

injury, fire and/or property damage.

(Continued)

WARNING!(Continued)

•Before replacing a fuse, make sure that the ignition

is off and that all the other services are switched off

and/or disengaged.

•If the replaced fuse blows again, contact an autho-

rized dealer.

•If a general protection fuse for safety systems (air

bag system, braking system), power unit systems

(engine system, gearbox system) or steering system

blows, contact an authorized dealer.

7

MAINTAINING YOUR VEHICLE 633

Page 636 of 695

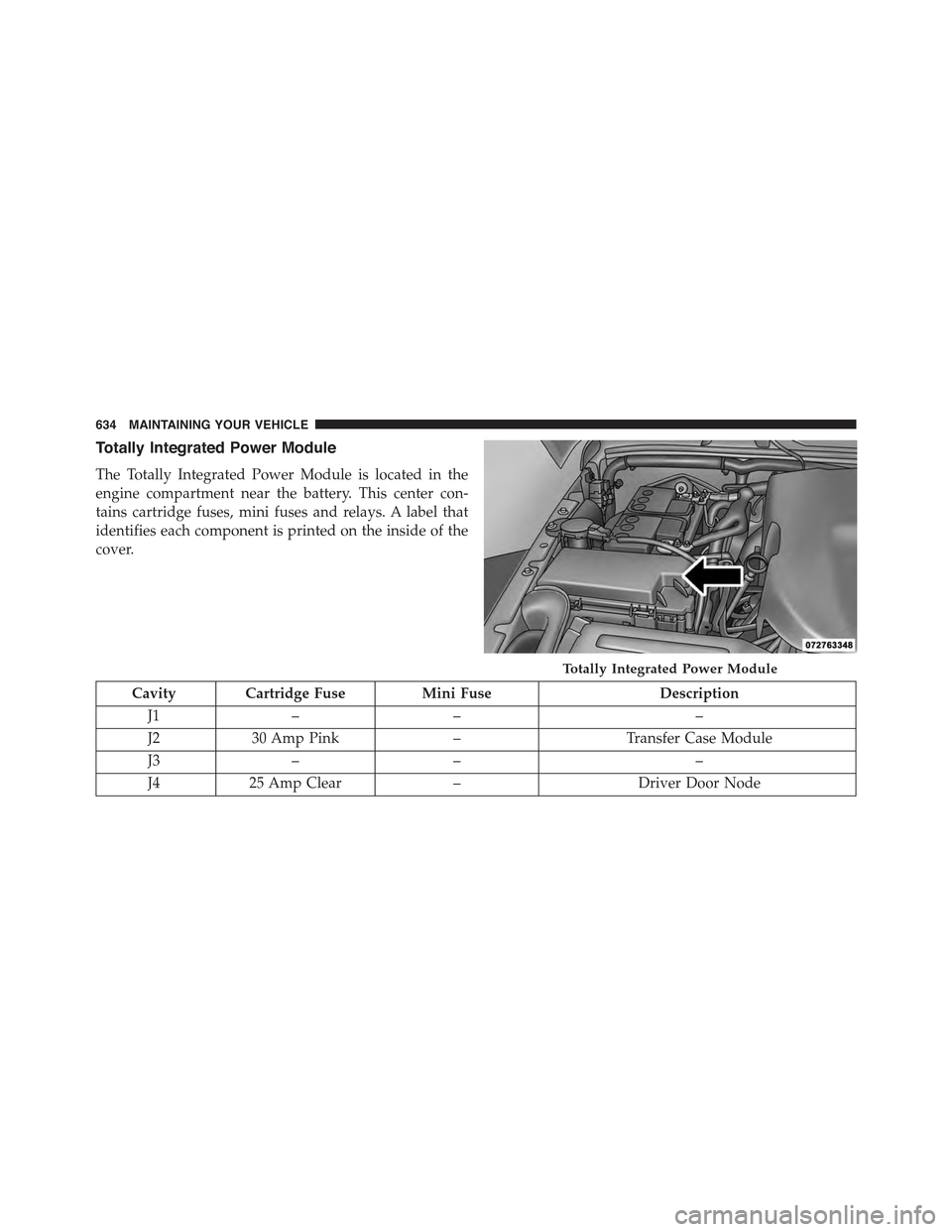

Totally Integrated Power Module

The Totally Integrated Power Module is located in the

engine compartment near the battery. This center con-

tains cartridge fuses, mini fuses and relays. A label that

identifies each component is printed on the inside of the

cover.

Cavity Cartridge FuseMini FuseDescription

J1–––

J230 Amp Pink–Transfer Case Module

J3–––

J425 Amp Clear–Driver Door Node

Totally Integrated Power Module

634 MAINTAINING YOUR VEHICLE

Page 648 of 695

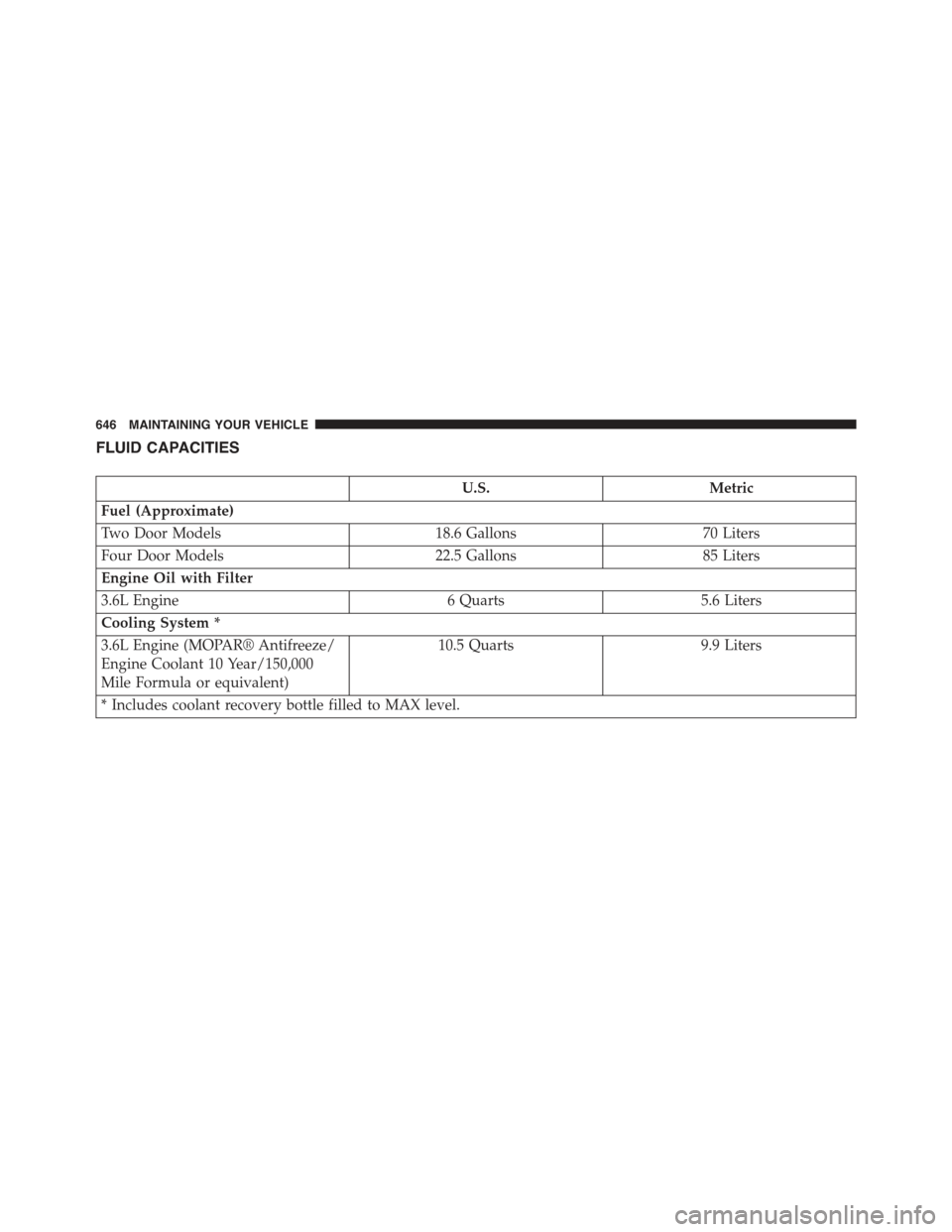

FLUID CAPACITIES

U.S.Metric

Fuel (Approximate)

Two Door Models18.6 Gallons70 Liters

Four Door Models22.5 Gallons85 Liters

Engine Oil with Filter

3.6L Engine6 Quarts5.6 Liters

Cooling System *

3.6L Engine (MOPAR® Antifreeze/

Engine Coolant 10 Year/150,000

Mile Formula or equivalent)

10.5 Quarts9.9 Liters

* Includes coolant recovery bottle filled to MAX level.

646 MAINTAINING YOUR VEHICLE

Page 649 of 695

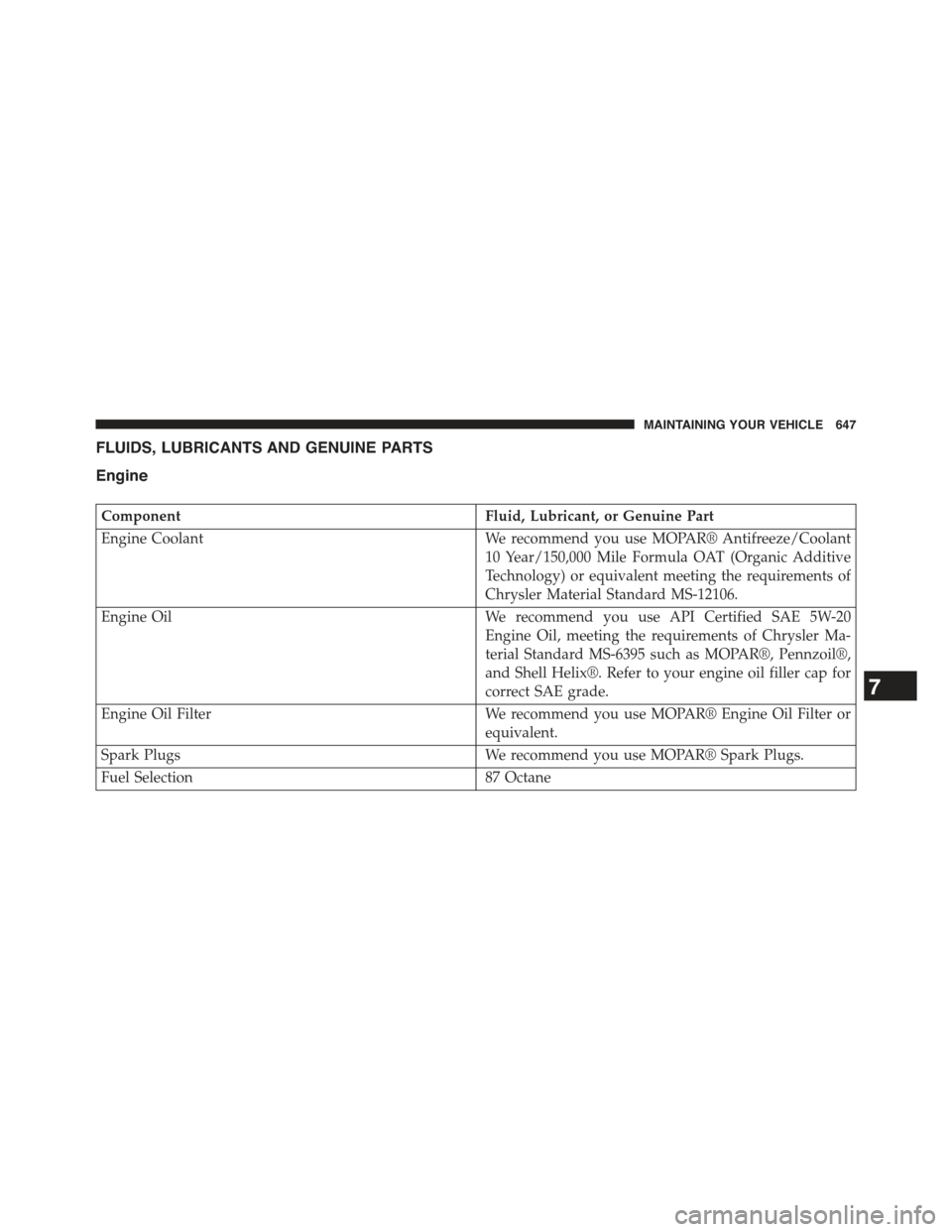

FLUIDS, LUBRICANTS AND GENUINE PARTS

Engine

ComponentFluid, Lubricant, or Genuine Part

Engine CoolantWe recommend you use MOPAR® Antifreeze/Coolant

10 Year/150,000 Mile Formula OAT (Organic Additive

Technology) or equivalent meeting the requirements of

Chrysler Material Standard MS-12106.

Engine OilWe recommend you use API Certified SAE 5W-20

Engine Oil, meeting the requirements of Chrysler Ma-

terial Standard MS-6395 such as MOPAR®, Pennzoil®,

and Shell Helix®. Refer to your engine oil filler cap for

correct SAE grade.

Engine Oil FilterWe recommend you use MOPAR® Engine Oil Filter or

equivalent.

Spark PlugsWe recommend you use MOPAR® Spark Plugs.

Fuel Selection87 Octane

7

MAINTAINING YOUR VEHICLE 647