brake JEEP WRANGLER 2016 JK / 3.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2016, Model line: WRANGLER, Model: JEEP WRANGLER 2016 JK / 3.GPages: 156, PDF Size: 8.82 MB

Page 111 of 156

Preparations For Jacking

1. Park on a firm, level surface. Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side of the vehicle close to moving traffic,

pull far enough off the road to avoid being hit when operating the jack or changing

the wheel.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Shift the automatic transmission into PARK, or a manual transmission into REVERSE.

5. Turn the ignition to LOCK.

6. Block both the front and rear of the wheel diagonally opposite of the jacking position. For example, if changing the right front tire, block the left rear wheel.

NOTE:

Passengers should not remain in the ve-

hicle when the vehicle is being jacked.

Wheel Blocked

WHAT TO DO IN EMERGENCIES

109

Page 112 of 156

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway aspossible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be raised.

• Set the parking brake firmly and set an automatic transmission in PARK; a

manual transmission in REVERSE.

• Never start or run the engine with the vehicle on a jack.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack. If you need to get under a

raised vehicle, take it to a service center where it can be raised on a lift.

• Only use the jack in the positions indicated and for lifting this vehicle during

a tire change.

• If working on or near a roadway, be extremely careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely stowed, spares must be

stowed with the valve stem facing the ground.

CAUTION!

Do not attempt to raise the vehicle by jacking on locations other than those

indicated in the Jacking Instructions for this vehicle.

1. Remove the spare tire, jack and tools from the stored location.

2. Loosen (but do not remove) the wheel lug nuts by turning them to the left one turn while the wheel is still on the ground.

3. Assemble the jack and jacking tools. Connect the jack handle driver to the extension, then to the lug wrench.

Warning Label

WHAT TO DO IN EMERGENCIES

110

Page 116 of 156

WARNING!

•Take care to avoid the radiator cooling fan whenever the hood is raised. It can start

anytime the ignition switch is ON. You can be injured by moving fan blades.

• Remove any metal jewelry such as rings, watch bands and bracelets that couldmake an inadvertent electrical contact. You could be seriously injured.

• Batteries contain sulfuric acid that can burn your skin or eyes and generate

hydrogen gas which is flammable and explosive. Keep open flames or sparks

away from the battery.

1. Set the parking brake, shift the automatic transmission into PARK (manual transmission in NEUTRAL) and turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary electrical accessories.

3. If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the parking brake and make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other as this could establish a ground

connection and personal injury could result.

Jump Starting Procedure

WARNING!

Failure to follow this jump-starting procedure could result in personal injury or

property damage due to battery explosion.

CAUTION!

Failure to follow these procedures could result in damage to the charging system

of the booster vehicle or the discharged vehicle.

Connecting The Jumper Cables

1. Connect the positive (+)end of the jumper cable to the positive (+)post of the

discharged vehicle.

2. Connect the opposite end of the positive (+)jumper cable to the positive (+)post

of the booster battery.

3. Connect the negative (-)end of the jumper cable to the negative (-)post of the

booster battery.

4. Connect the opposite end of the negative (-)jumper cable to a good engine ground

(exposed metal part of the discharged vehicle’s engine) away from the battery and

the fuel injection system.

WHAT TO DO IN EMERGENCIES

114

Page 118 of 156

CAUTION!

Tow hooks are for emergency use only, to rescue a vehicle stranded off road. Do not

use tow hooks for tow truck hookup or highway towing. You could damage your

vehicle. Tow straps are recommended when towing the vehicle, chains may cause

vehicle damage.

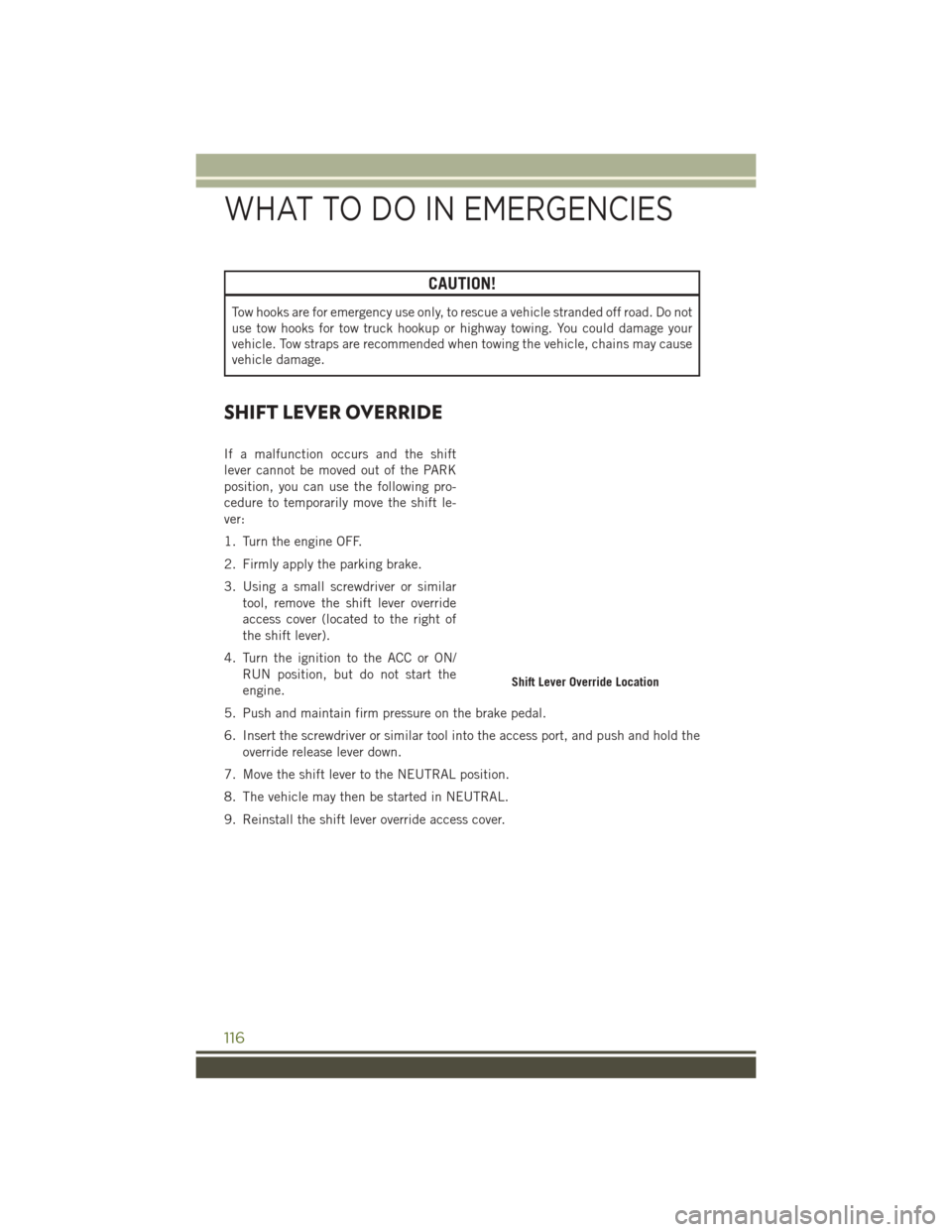

SHIFT LEVER OVERRIDE

If a malfunction occurs and the shift

lever cannot be moved out of the PARK

position, you can use the following pro-

cedure to temporarily move the shift le-

ver:

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Using a small screwdriver or similartool, remove the shift lever override

access cover (located to the right of

the shift lever).

4. Turn the ignition to the ACC or ON/ RUN position, but do not start the

engine.

5. Push and maintain firm pressure on the brake pedal.

6. Insert the screwdriver or similar tool into the access port, and push and hold the override release lever down.

7. Move the shift lever to the NEUTRAL position.

8. The vehicle may then be started in NEUTRAL.

9. Reinstall the shift lever override access cover.

Shift Lever Override Location

WHAT TO DO IN EMERGENCIES

116

Page 121 of 156

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or snow, it can often be moved using a

rocking motion. Turn the steering wheel right and left to clear the area around the

front wheels. Then shift back and forth between DRIVE and REVERSE (with

automatic transmission) or 2nd gear and REVERSE (with manual transmission),

while gently pressing the accelerator. Use the least amount of accelerator pedal

pressure that will maintain the rocking motion, without spinning the wheels, or racing

the engine.

CAUTION!

Racing the engine or spinning the wheels may lead to transmission overheating

and failure. Allow the engine to idle with the transmission in NEUTRAL for at least

one minute after every five rocking-motion cycles. This will minimize overheating

and reduce the risk of clutch or transmission failure during prolonged efforts to

free a stuck vehicle.

NOTE:

Push the "ESC Off" switch, to place the Electronic Stability Control (ESC) system in

"Partial Off" mode, before rocking the vehicle. Refer to “Electronic Brake Control” in

“Starting And Operating” in the Owner’s Manual on the DVD for further information.

Once the vehicle has been freed, push the "ESC Off" switch again to restore "ESC On"

mode.

CAUTION!

• When “rocking” a stuck vehicle by shifting between DRIVE/2nd gear and REVERSE, do not spin the wheels faster than 15 mph (24 km/h), or drivetrain

damage may result.

• Revving the engine or spinning the wheels too fast may lead to transmission

overheating and failure. It can also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear (no transmission shifting occurring).

WARNING!

Fast spinning tires can be dangerous. Forces generated by excessive wheel speeds

may cause damage, or even failure, of the axle and tires. A tire could explode and

injure someone. Do not spin your vehicle's wheels faster than 30 mph (48 km/h)

or for longer than 30 seconds continuously without stopping when you are stuck

and do not let anyone near a spinning wheel, no matter what the speed.

WHAT TO DO IN EMERGENCIES

119

Page 124 of 156

ENGINE COMPARTMENT — 3.6L

1. Battery

2. Integrated Power Module (Fuses)

3. Engine Oil Dipstick

4. Engine Oil Fill

5. Brake Fluid Reservoir

MAINTAINING YOUR VEHICLE

122

Page 127 of 156

CAUTION!

•Mixing of engine coolant (antifreeze) other than specified Organic Additive Tech-

nology (OAT) engine coolant (antifreeze), may result in engine damage and may

decrease corrosion protection. Organic Additive Technology (OAT) engine coolant is

different and should not be mixed with Hybrid Organic Additive Technology (HOAT)

engine coolant (antifreeze) or any “globally compatible” coolant (antifreeze). If a

non-OAT engine coolant (antifreeze) is introduced into the cooling system in an

emergency, the cooling system will need to be drained, flushed, and refilled with

fresh OAT coolant (conforming to MS.90032), by an authorized dealer as soon as

possible.

• Do not use water alone or alcohol-based engine coolant (antifreeze) products.Do not use additional rust inhibitors or antirust products, as they may not be

compatible with the radiator engine coolant and may plug the radiator.

• This vehicle has not been designed for use with propylene glycol-based engine

coolant (antifreeze). Use of propylene glycol-based engine coolant (antifreeze)

is not recommended.

Chassis

Component Fluid, Lubricant, or Genuine Part

Automatic Transmission – If Equipped

Use only ATF+4 Automatic Transmission

Fluid. Failure to use ATF+4 fluid may affect

the function or performance of your transmis-

sion. We recommend MOPAR ATF+4 fluid.

Manual Transmission – If EquippedWe recommend you use MOPAR Manual

Transmission Lubricant meeting the require-

ments of FCA US Material Standard MS-

9224.

Transfer Case We recommend you use MOPAR ATF+4

Automatic Transmission Fluid.

Axle Differential (Front) We recommend you use MOPAR Gear &

Axle Lubricant (SAE 80W-90) (API GL-5).

Axle Differential (Rear)

226 RBI (Model 44) – We recommend you use

MOPAR Gear & Axle Lubricant (SAE 80W-90)

(API GL-5) or equivalent. For trailer towing,

use MOPAR Synthetic Gear & Axle Lubricant

(SAE 75W-140). Models equipped with Trac-

Lok require an additive.

Brake Master Cylinder We recommend you use MOPAR DOT 3

Brake Fluid, SAE J1703. If DOT 3, SAE

J1703 brake fluid is not available, then

DOT 4 is acceptable.

Power Steering Reservoir We recommend you use MOPAR Power

Steering Fluid +4, MOPAR ATF+4 Auto-

matic Transmission Fluid.

MAINTAINING YOUR VEHICLE

125

Page 129 of 156

Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look for unusual wear or damage

• Check the fluid levels of the coolant reservoir, brake master cylinder, powersteering and automatic transmission, and fill as needed

• Check function of all interior and exterior lights

Required Maintenance Intervals

Refer to the maintenance schedules on the following page for the required mainte-

nance intervals.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

• Change oil and filter

• Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil

indicator system turns on.

• Inspect battery and clean and tighten terminals as required

• Inspect automatic transmission fluid if equipped with dipstick

• Inspect brake pads, shoes, rotors, drums, hoses and park brake

• Inspect engine cooling system protection and hoses

• Inspect exhaust system

• Inspect engine air cleaner if using in dusty or off-road conditions

• Inspect all door latches for presence of grease, reapply if necessary.

MAINTAINING YOUR VEHICLE

127

Page 130 of 156

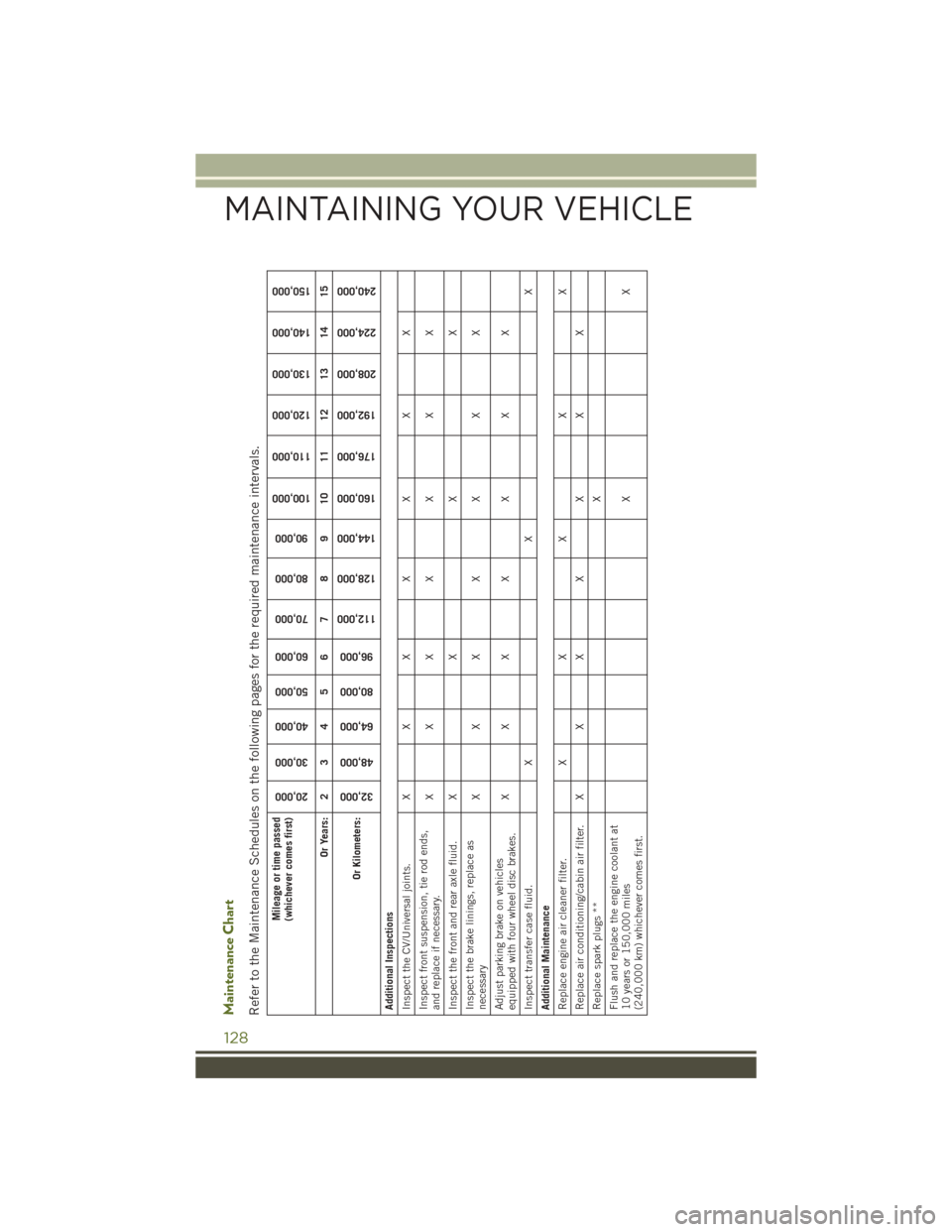

Maintenance ChartRefer to the Maintenance Schedules on the following pages for the required maintenance intervals.

Mileage or time passed

(whichever comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X X X

Inspect front suspension, tie rod ends,

and replace if necessary. XXX X X X X

Inspect the front and rear axle fluid. X X X X

Inspect the brake linings, replace as

necessary XXX X X X X

Adjust parking brake on vehicles

equipped with four wheel disc brakes. XXX X X X X

Inspect transfer case fluid. X X X

Additional Maintenance

Replace engine air cleaner filter. X X X X X

Replace air conditioning/cabin air filter. X X X X X X X

Replace spark plugs ** X

Flush and replace the engine coolant at

10 years or 150,000 miles

(240,000 km) whichever comes first. XX

MAINTAINING YOUR VEHICLE

128

Page 134 of 156

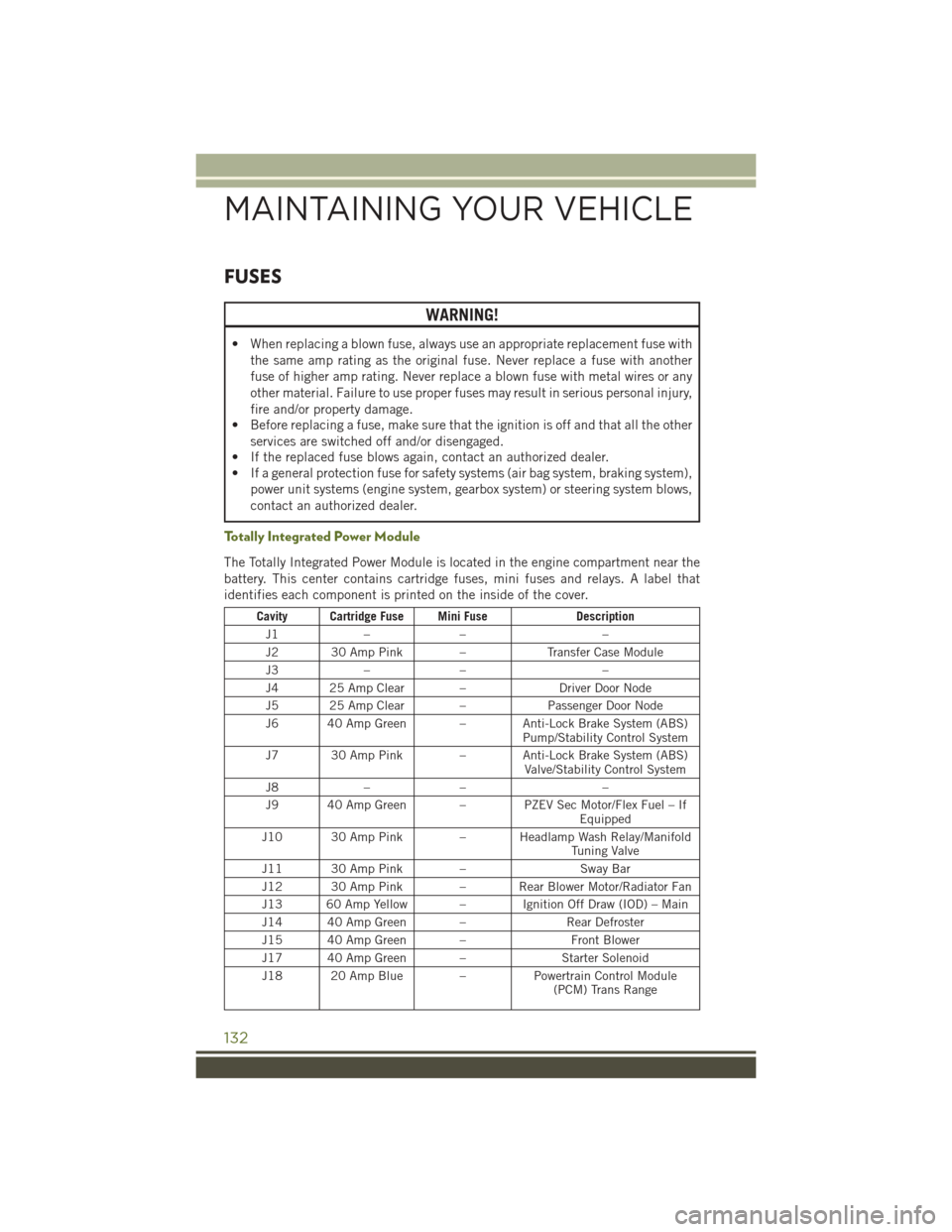

FUSES

WARNING!

• When replacing a blown fuse, always use an appropriate replacement fuse withthe same amp rating as the original fuse. Never replace a fuse with another

fuse of higher amp rating. Never replace a blown fuse with metal wires or any

other material. Failure to use proper fuses may result in serious personal injury,

fire and/or property damage.

• Before replacing a fuse, make sure that the ignition is off and that all the other

services are switched off and/or disengaged.

• If the replaced fuse blows again, contact an authorized dealer.

• If a general protection fuse for safety systems (air bag system, braking system),

power unit systems (engine system, gearbox system) or steering system blows,

contact an authorized dealer.

Totally Integrated Power Module

The Totally Integrated Power Module is located in the engine compartment near the

battery. This center contains cartridge fuses, mini fuses and relays. A label that

identifies each component is printed on the inside of the cover.

Cavity Cartridge Fuse Mini Fuse Description

J1 –– –

J2 30 Amp Pink – Transfer Case Module

J3 –– –

J4 25 Amp Clear – Driver Door Node

J5 25 Amp Clear – Passenger Door Node

J6 40 Amp Green – Anti-Lock Brake System (ABS) Pump/Stability Control System

J7 30 Amp Pink – Anti-Lock Brake System (ABS) Valve/Stability Control System

J8 –– –

J9 40 Amp Green – PZEV Sec Motor/Flex Fuel – If Equipped

J10 30 Amp Pink – Headlamp Wash Relay/Manifold Tuning Valve

J11 30 Amp Pink – Sway Bar

J12 30 Amp Pink – Rear Blower Motor/Radiator Fan

J13 60 Amp Yellow – Ignition Off Draw (IOD) – Main

J14 40 Amp Green – Rear Defroster

J15 40 Amp Green – Front Blower

J17 40 Amp Green – Starter Solenoid

J18 20 Amp Blue – Powertrain Control Module

(PCM) Trans Range

MAINTAINING YOUR VEHICLE

132