engine oil JEEP WRANGLER 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2020, Model line: WRANGLER, Model: JEEP WRANGLER 2020Pages: 276, PDF Size: 4.47 MB

Page 178 of 276

Diesel Models with Diesel Particulate Filter

(DPF)

The oil change indicator system will remind

you that it is time to take your vehicle in for

scheduled maintenance.A “CHANgE OIL” message will flash in the

instrument cluster odometer and a single

chime will sound, indicating that an oil

change is necessary.

Based on engine operation conditions, the oil

change indicator message will illuminate, thismeans that service is required for your vehicle.

Have your vehicle serviced as soon as possible,

within the next 500 miles (805 km).

Your dealer will reset the oil change indicator

message after completing the scheduled oil

change.

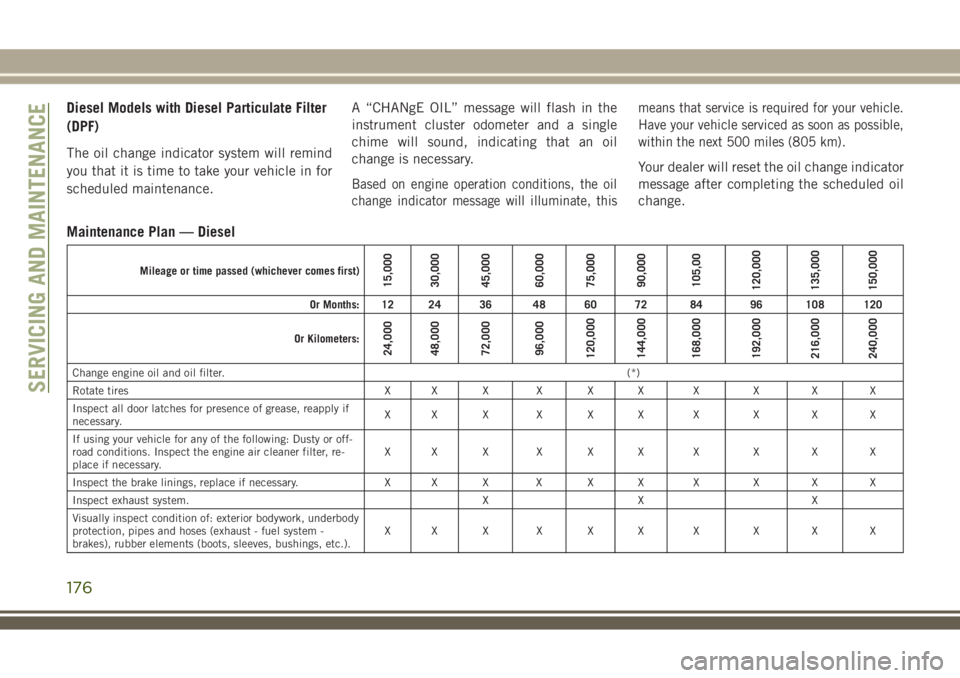

Maintenance Plan — Diesel

Mileage or time passed (whichever comes first)15,000

30,000

45,000

60,000

75,000

90,000

105,00

120,000

135,000

150,000

Or Months: 12 24 36 48 60 72 84 96 108 120

Or Kilometers:

24,000

48,000

72,000

96,000

120,000

144,000

168,000

192,000

216,000

240,000

Change engine oil and oil filter.(*)

Rotate tires X X X X X X X X X X

Inspect all door latches for presence of grease, reapply if

necessary.XX X X X X X X X X

If using your vehicle for any of the following: Dusty or off-

road conditions. Inspect the engine air cleaner filter, re-

place if necessary.XX X X X X X X X X

Inspect the brake linings, replace if necessary. X X X X X X X X X X

Inspect exhaust system. X X X

Visually inspect condition of: exterior bodywork, underbody

protection, pipes and hoses (exhaust - fuel system -

brakes), rubber elements (boots, sleeves, bushings, etc.).XX X X X X X X X X

SERVICING AND MAINTENANCE

176

Page 181 of 276

* The actual interval for changing engine oil

and replacing the engine oil filter depends on

the vehicle usage conditions and is signalled

by the warning light or message in the instru-

ment panel. In all cases, never exceed 1 year/

15,000 miles (24,000 km).

** DOT 4 brake fluid is time based only;

mileage intervals do not apply.

WARNING!

• You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge

and the right equipment. If you have any

doubt about your ability to perform a

service job, take your vehicle to a com-

petent mechanic.

• Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an

accident.

179

Page 182 of 276

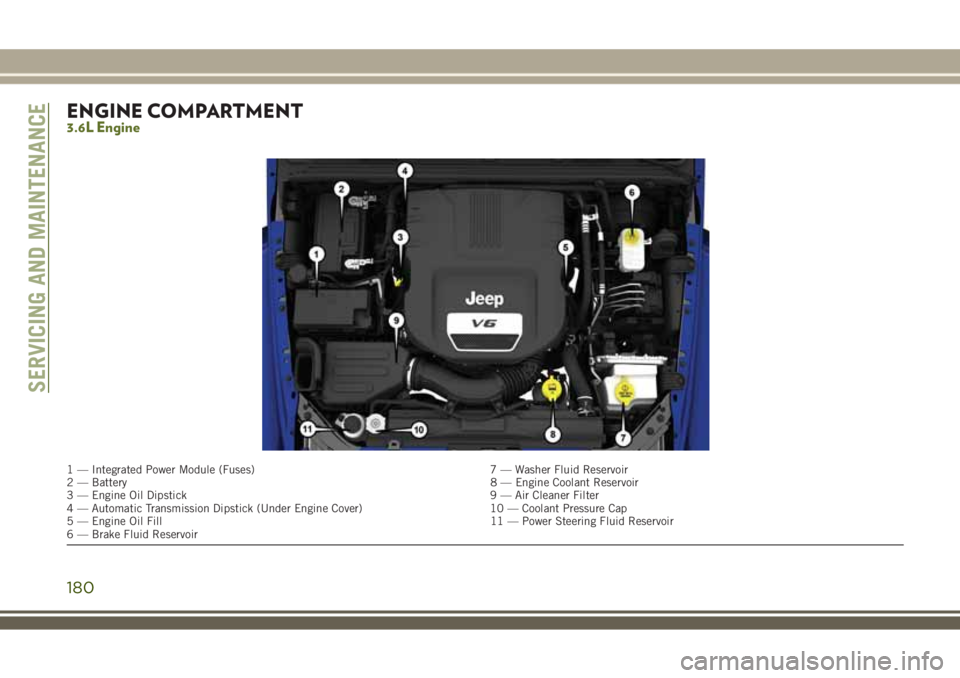

ENGINE COMPARTMENT3.6L Engine

1 — Integrated Power Module (Fuses) 7 — Washer Fluid Reservoir

2 — Battery8 — Engine Coolant Reservoir

3 — Engine Oil Dipstick 9 — Air Cleaner Filter

4 — Automatic Transmission Dipstick (Under Engine Cover) 10 — Coolant Pressure Cap

5 — Engine Oil Fill 11 — Power Steering Fluid Reservoir

6 — Brake Fluid Reservoir

SERVICING AND MAINTENANCE

180

Page 183 of 276

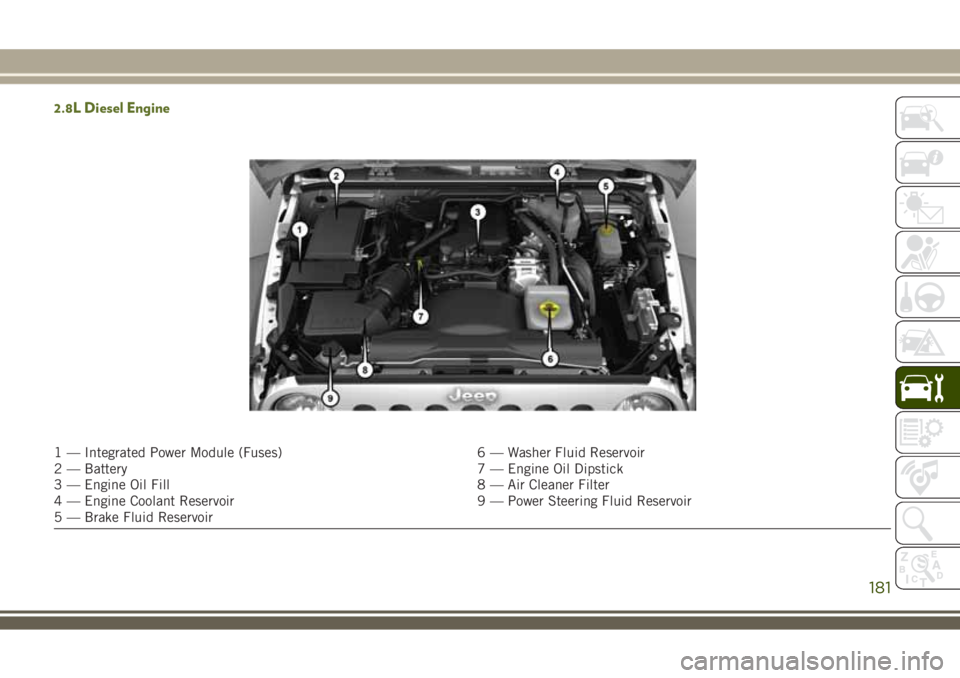

2.8L Diesel Engine

1 — Integrated Power Module (Fuses) 6 — Washer Fluid Reservoir

2 — Battery 7 — Engine Oil Dipstick

3 — Engine Oil Fill 8 — Air Cleaner Filter

4 — Engine Coolant Reservoir 9 — Power Steering Fluid Reservoir

5 — Brake Fluid Reservoir

181

Page 184 of 276

Checking Oil Level — Gasoline Engine

To ensure proper lubrication of your vehicle's

engine, the engine oil must be maintained at

the correct level. The engine oil level should

be checked five minutes after a warmed up

engine has been shut off.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil

level readings. Always maintain the oil level

within the SAFE zone on the dipstick. Adding

1 quart (0.95 liters) of oil when the reading is

at the bottom of the crosshatch zone will

result in a reading at the top of the cross-

hatch zone on these engines.

CAUTION!

Overfilling or underfilling the crankcase

will cause aeration or loss of oil pressure.

This could damage your engine.

Checking Oil Level — Diesel Engine

To assure proper engine lubrication, the en-

gine oil must be maintained at the correct

level. Check the oil level at regular intervals,

such as every fuel stop.For vehicles equipped with a Diesel Particu-

late Filter (DPF), it is acceptable to have an

oil level up to 3/8 inch (10 mm) above the

MAX line. Beyond 3/8 inch (10 mm) it is

recommended to change the oil.

The best time to check the engine oil level is

about five minutes after a fully warmed en-

gine is shut off.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil

level readings. Maintain the oil level between

the MIN and MAX markings on the dipstick.

Adding 1 U.S. Quart (0.95 L) of oil when the

reading is at the MIN mark will result in a

MAX reading on these engines.

Cooling System

WARNING!

• You or others can be badly burned by hot

engine coolant (antifreeze) or steam

from your radiator. If you see or hear

steam coming from under the hood, do

not open the hood until the radiator has

had time to cool. Never open a cooling

WARNING!

system pressure cap when the radiator

or coolant bottle is hot.

• Keep hands, tools, clothing, and jewelry

away from the radiator cooling fan when

the hood is raised. The fan starts auto-

matically and may start at any time,

whether the engine is running or not.

• When working near the radiator cooling

fan, disconnect the fan motor lead or

turn the ignition to the OFF mode. The

fan is temperature controlled and can

start at any time the ignition is in the ON

mode.

Engine Coolant Checks

Check the engine coolant (antifreeze) protec-

tion every 12 months (before the onset of

freezing weather, where applicable). If the

engine coolant (antifreeze) is dirty or rusty in

appearance, the system should be drained,

flushed and refilled with fresh engine coolant

(antifreeze). Check the front of the A/C con-

denser (if equipped) or radiator for any accu-

mulation of bugs, leaves, etc. If dirty, clean

SERVICING AND MAINTENANCE

182

Page 186 of 276

WARNING!

• Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri-

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its per-

formance. The proper type of brake fluid

for your vehicle is also identified on the

original factory installed hydraulic mas-

ter cylinder reservoir.

• To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master cylin-

der reservoir cap secured at all times.

Brake fluid in a open container absorbs

moisture from the air resulting in a lower

boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake fail-

ure. This could result in a collision.

• Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot en-

gine parts, causing the brake fluid to

WARNING!

catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should

be taken to avoid its contact with these

surfaces.

• Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This

could result in a collision.

Manual Transmission

Fluid Level Check

Check the fluid level by removing the fill

plug. The fluid level should be between the

bottom of the fill hole and a point not more

than 3/16 of an inch (4.76 mm) below the

bottom of the hole.

Add fluid, if necessary, to maintain the

proper level.

Automatic Transmission

Fluid Level Check — Gasoline Engine

It is best to check the fluid level when the

transmission is at normal operating tempera-

ture (approximately 180°F/82°C). This oc-

curs after at least 15 miles (25 km) of driv-

ing. At normal operating temperature, the

fluid cannot be held comfortably between the

fingertips.

Use the following procedure to check the

transmission fluid level properly:

1. Park the vehicle on level ground.

2. Remove the engine cover by pulling it up

off the mounting studs (two in the front

and two in the rear).

3. Run the engine at normal idle speed for at

least 60 seconds, and leave the engine

running for the rest of this procedure.

4. Fully apply the parking brake, and press

the brake pedal.

SERVICING AND MAINTENANCE

184

Page 187 of 276

5. Place the gear selector momentarily into

each gear position (allowing time for the

transmission to fully engage in each posi-

tion), ending with the transmission in

PARK.

6. Remove the dipstick, wipe it clean and

reinsert it until seated.

7. Remove the dipstick again and note the

fluid level on both sides. The fluid level

reading is only valid if there is a solid

coating of oil on both sides of the dipstick.

Note that the holes in the dipstick will be

full of fluid if the actual level is at or above

the hole. The fluid level should be be-

tween the HOT (upper) reference holes on

the dipstick at normal operating tempera-

ture. If the fluid level is low, add fluid

through the dipstick tube to bring it to the

proper level.Do not overfill.Use ONLY the

specified fluid (refer to "Fluids And Lubri-

cants" under “Technical Specifications”

for fluid specifications). After adding any

quantity of oil through the dipstick tube,

wait a minimum of two minutes for the oil

to fully drain into the transmission before

rechecking the fluid level.NOTE:

• The holes in the dipstick will be full of

fluid if the actual level is at or above the

hole.

• If it is necessary to check the transmis-

sion below the operating temperature,

the fluid level should be between the

two COLD (lower) holes on the dipstick

with the fluid at approximately 80°F

(27°C). If the fluid level is correctly

established at 80° F (27°C), it should

be between the HOT (upper) reference

holes when the transmission reaches

180° F (82°C). Remember it is best to

check the level at the normal operating

temperature.

CAUTION!

If the fluid temperature is below 50°F

(10°C) it may not register on the dipstick.

Do not add fluid until the temperature is

elevated enough to produce an accurate

reading. Run the engine at idle, in PARK,

to warm the fluid.8. Reinstall the engine cover and snap it

down securely onto the four mounting

studs.

9. Check for leaks. Release the parking

brake.

NOTE:

To prevent dirt and water from entering the

transmission after checking or replenishing

fluid, make sure that the dipstick cap is

properly reseated. It is normal for the dipstick

cap to spring back slightly from its fully

seated position, as long as its seal remains

engaged in the dipstick tube.

Fluid Level Check — 2.8L Turbo Diesel

Engine

The fluid level is preset at the factory and

does not require adjustment under normal

operating conditions. Routine fluid level

checks are not required, therefore the trans-

mission filler tube is capped and no dipstick

is provided. An authorized dealer can check

your transmission fluid level using a special

service dipstick.

185

Page 191 of 276

CAUTION!

The cabin air filter is identified with an

arrow to indicate airflow direction through

the filter. Failure to properly install the

filter will result in the need to replace it

more often.

8. Close A/C Air Filter access doors and se-

cure retaining tabs.

9. Rotate the glove compartment door back

into position.

Refer to the “Maintenance Plan” for the

proper maintenance intervals.

DEALER SERVICE

An authorized dealer has the qualified service

personnel, special tools, and equipment to

perform all service operations in an expert

manner. Service Manuals are available which

include detailed service information for your

vehicle. Refer to these Service Manuals be-

fore attempting any procedure yourself.NOTE:

Intentional tampering with emissions control

systems may void your warranty and could

result in civil penalties being assessed

against you.

WARNING!

You can be badly injured working on or

around a motor vehicle. Only do service

work for which you have the knowledge

and the proper equipment. If you have any

doubt about your ability to perform a ser-

vice job, take your vehicle to a competent

mechanic.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades

and the windshield periodically with a sponge

or soft cloth and a mild nonabrasive cleaner.

This will remove accumulations of salt or road

film.Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using

the wipers to remove salt or dirt from a dry

windshield.

Avoid using the wiper blades to remove frost

or ice from the windshield. Keep the blade

rubber out of contact with petroleum prod-

ucts such as engine oil, gasoline, etc.

NOTE:

Life expectancy of wiper blades varies de-

pending on geographical area and frequency

of use. Poor performance of blades may be

present with chattering, marks, water lines or

wet spots. If any of these conditions are

present, clean the wiper blades or replace as

necessary.

The wiper blades and wiper arms should be

inspected periodically, not just when wiper

performance problems are experienced. This

inspection should include the following

points:

• Wear Or Uneven Edges

• Foreign Material

189

Page 210 of 276

VEHICLE IDENTIFICATION

NUMBER

The Vehicle Identification Number (VIN) is

found on the left front corner of the instru-

ment panel pad, visible from outside of the

vehicle through the windshield. This number

also appears underbody, on the right side of

the frame rail near the center of the vehicle,

as well as on the Automobile Information

Disclosure Label affixed to a window on your

vehicle. Save this label for a convenient re-

cord of your vehicle identification number

and optional equipment.

The VIN is also stamped on either right or left

hand side of the engine block.NOTE:

It is illegal to remove or alter the VIN plate.

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle, the lugnuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Lug Nut/Bolt

Torque**Lug Nut/Bolt

SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs

(135 N·m)1/2” x 20 19 mm

**Use only your authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it halfway).

Vehicle Identification NumberTECHNICAL SPECIFICATIONS

208

Page 212 of 276

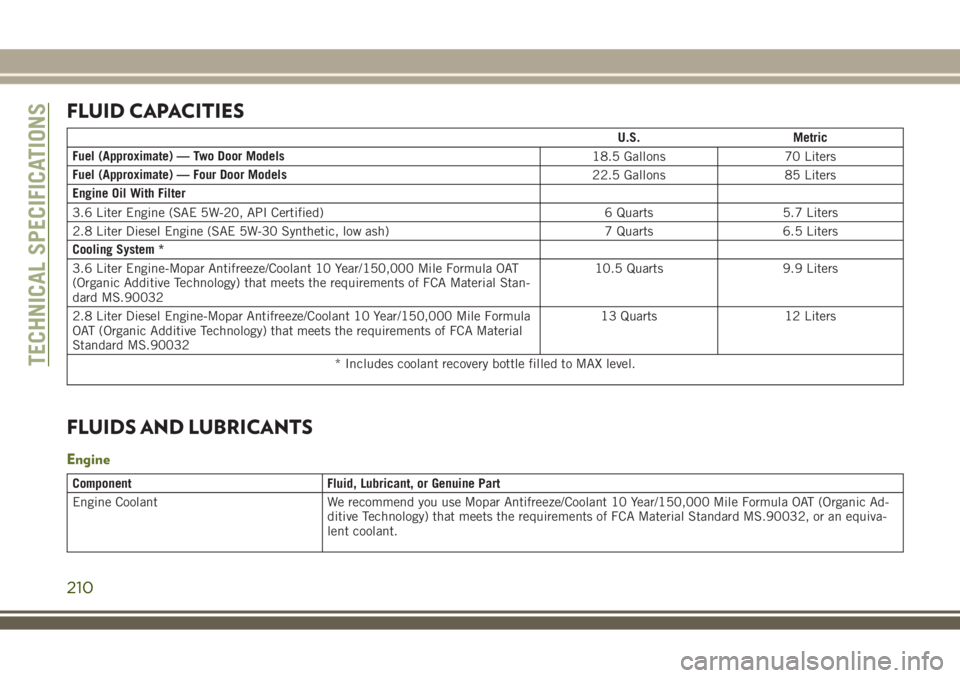

FLUID CAPACITIES

U.S. Metric

Fuel (Approximate) — Two Door Models

18.5 Gallons 70 Liters

Fuel (Approximate) — Four Door Models

22.5 Gallons 85 Liters

Engine Oil With Filter

3.6 Liter Engine (SAE 5W-20, API Certified) 6 Quarts 5.7 Liters

2.8 Liter Diesel Engine (SAE 5W-30 Synthetic, low ash) 7 Quarts 6.5 Liters

Cooling System *

3.6 Liter Engine-Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula OAT

(Organic Additive Technology) that meets the requirements of FCA Material Stan-

dard MS.9003210.5 Quarts 9.9 Liters

2.8 Liter Diesel Engine-Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula

OAT (Organic Additive Technology) that meets the requirements of FCA Material

Standard MS.9003213 Quarts 12 Liters

* Includes coolant recovery bottle filled to MAX level.

FLUIDS AND LUBRICANTS

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula OAT (Organic Ad-

ditive Technology) that meets the requirements of FCA Material Standard MS.90032, or an equiva-

lent coolant.

TECHNICAL SPECIFICATIONS

210