reset JEEP WRANGLER 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2020, Model line: WRANGLER, Model: JEEP WRANGLER 2020Pages: 276, PDF Size: 4.47 MB

Page 60 of 276

• Check Gascap (refer to “Refueling The Ve-

hicle” in “Starting And Operating” for fur-

ther information)

• Oil Change Required (with a single chime)

• ECO (Fuel Saver Indicator) — if equipped

Gear Shift Indicator (GSI) — If Equipped

The Gear Shift Indicator (GSI) system is en-

abled on vehicles with a manual transmis-

sion, or when a vehicle with an automatic

transmission is in manual shift mode. The

GSI provides the driver with a visual indica-

tion when the recommended gear shift point

has been reached. This indication notifies

the driver that changing gear will allow a

reduction in fuel consumption. When the up

shift indicator is shown on the display, the

GSI is advising the driver to engage a higher

gear. When the down shift indicator is shown

on the display, the GSI is advising the driver

to engage a lower gear.

The GSI indicator remains illuminated until

the driver changes gear, or the driving condi-

tions return to a situation where changing gear

is not required to improve fuel consumption.

Oil Change Required

Your vehicle is equipped with an engine oil

change indicator system. The “Oil Change

Required” message will display in the instru-

ment cluster display for approximately

10 seconds after a single chime has sounded

to indicate the next scheduled oil change

interval. The engine oil change indicator sys-

tem is duty cycle based, which means the

engine oil change interval may fluctuate de-

pendent upon your personal driving style.

Unless reset, this message will continue to

display each time you turn the ignition switch

to the ON position. To turn off the message

temporarily, push and release theMENUbut-

ton. To reset the oil change indicator system

(after performing the scheduled mainte-

nance), perform the following procedure:

WARNING LIGHTS AND

MESSAGES

The warning/indicator lights will illuminate in

the instrument panel together with a dedi-

cated message and/or acoustic signal when

applicable. These indications are indicativeand precautionary and as such must not be

considered as exhaustive and/or alternative

to the information contained in the Owner’s

Manual, which you are advised to read care-

fully in all cases. Always refer to the informa-

tion in this chapter in the event of a failure

indication. All active telltales will display first

if applicable. The system check menu may

appear different based upon equipment op-

tions and current vehicle status. Some tell-

tales are optional and may not appear.

Red Warning Lights

— Air Bag Warning Light

This light indicates a fault with the air bag,

and will turn on for four to eight seconds as a

bulb check when the ignition is placed in the

ON/RUN or ACC/ON/RUN position. This light

will illuminate with a single chime when a

fault with the air bag has been detected, it

will stay on until the fault is cleared. If the

light is either not on during startup, stays on,

or turns on while driving, have the system

inspected at an authorized dealer as soon as

possible.

GETTING TO KNOW YOUR INSTRUMENT PANEL

58

Page 67 of 276

If any of these systems require service, the

OBD II system will turn on the Malfunction

Indicator Light (MIL). It will also store diag-

nostic codes and other information to assist

your service technician in making repairs.

Although your vehicle will usually be drivable

and not need towing, see your authorized

dealer for service as soon as possible.

CAUTION!

• Prolonged driving with the MIL on could

cause further damage to the emission

control system. It could also affect fuel

economy and driveability. The vehicle

must be serviced before any emissions

tests can be performed.

• If the MIL is flashing while the vehicle is

running, severe catalytic converter dam-

age and power loss will soon occur. Im-

mediate service is required.

Onboard Diagnostic System (OBD II)

Cybersecurity

Your vehicle is required to have an Onboard

Diagnostic system (OBD II) and a connection

port to allow access to information related tothe performance of your emissions controls.

Authorized service technicians may need to

access this information to assist with the

diagnosis and service of your vehicle and

emissions system.

WARNING!

• ONLY an authorized service technician

should connect equipment to the OBD II

connection port in order to diagnose or

service your vehicle.

• If unauthorized equipment is connected

to the OBD II connection port, such as a

driver-behavior tracking device, it may:

• Be possible that vehicle systems,

including safety related systems,

could be impaired or a loss of ve-

hicle control could occur that may

result in an accident involving seri-

ous injury or death.

• Access, or allow others to access,

information stored in your vehicle

systems, including personal infor-

mation.For further information, refer to “Cybersecu-

rity” in “Multimedia” in your Owner's

Manual.

Loose Fuel Filler Cap Message

After fuel is added, the vehicle diagnostic

system can determine if the fuel filler cap is

possibly loose, improperly installed, or dam-

aged. A “gASCAP” message will be displayed

in the odometer. Tighten the gas cap until a

"clicking" sound is heard. This is an indica-

tion that the gas cap is properly tightened.

Push the odometer reset button to turn the

message off. If the problem persists, the

message will appear the next time the vehicle

is started. This might indicate a damaged

cap. If the problem is detected twice in a row,

the system will turn on the MIL. Resolving the

problem will turn the MIL off.

65

Page 90 of 276

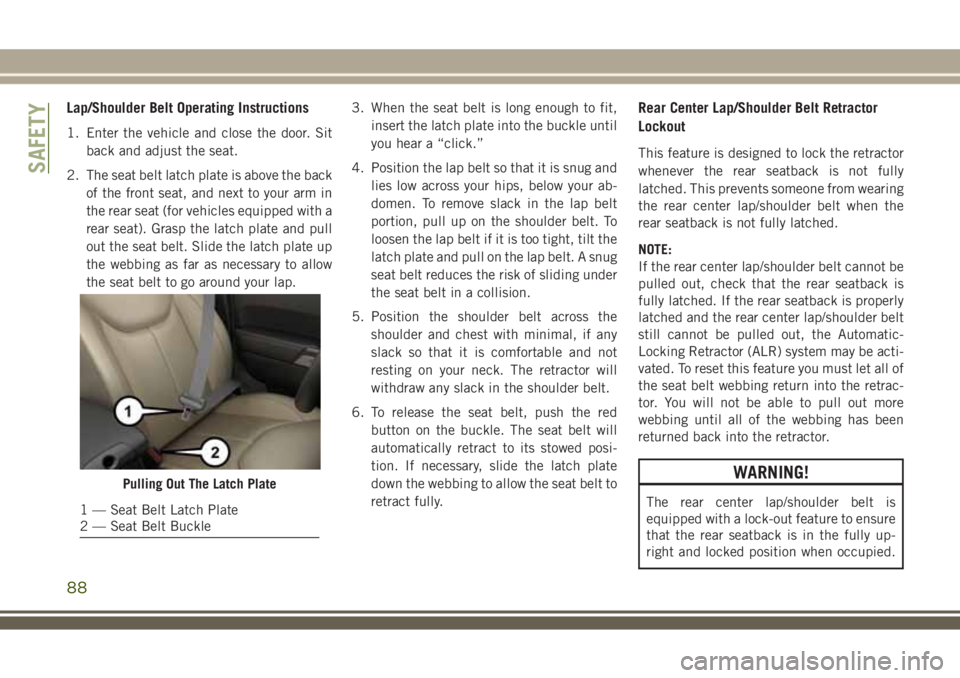

Lap/Shoulder Belt Operating Instructions

1. Enter the vehicle and close the door. Sit

back and adjust the seat.

2. The seat belt latch plate is above the back

of the front seat, and next to your arm in

the rear seat (for vehicles equipped with a

rear seat). Grasp the latch plate and pull

out the seat belt. Slide the latch plate up

the webbing as far as necessary to allow

the seat belt to go around your lap.3. When the seat belt is long enough to fit,

insert the latch plate into the buckle until

you hear a “click.”

4. Position the lap belt so that it is snug and

lies low across your hips, below your ab-

domen. To remove slack in the lap belt

portion, pull up on the shoulder belt. To

loosen the lap belt if it is too tight, tilt the

latch plate and pull on the lap belt. A snug

seat belt reduces the risk of sliding under

the seat belt in a collision.

5. Position the shoulder belt across the

shoulder and chest with minimal, if any

slack so that it is comfortable and not

resting on your neck. The retractor will

withdraw any slack in the shoulder belt.

6. To release the seat belt, push the red

button on the buckle. The seat belt will

automatically retract to its stowed posi-

tion. If necessary, slide the latch plate

down the webbing to allow the seat belt to

retract fully.

Rear Center Lap/Shoulder Belt Retractor

Lockout

This feature is designed to lock the retractor

whenever the rear seatback is not fully

latched. This prevents someone from wearing

the rear center lap/shoulder belt when the

rear seatback is not fully latched.

NOTE:

If the rear center lap/shoulder belt cannot be

pulled out, check that the rear seatback is

fully latched. If the rear seatback is properly

latched and the rear center lap/shoulder belt

still cannot be pulled out, the Automatic-

Locking Retractor (ALR) system may be acti-

vated. To reset this feature you must let all of

the seat belt webbing return into the retrac-

tor. You will not be able to pull out more

webbing until all of the webbing has been

returned back into the retractor.

WARNING!

The rear center lap/shoulder belt is

equipped with a lock-out feature to ensure

that the rear seatback is in the fully up-

right and locked position when occupied.

Pulling Out The Latch Plate

1 — Seat Belt Latch Plate

2 — Seat Belt Buckle

SAFETY

88

Page 100 of 276

NOTE:

• Air bag covers may not be obvious in the

interior trim, but they will open during air

bag deployment.

• After any collision, the vehicle should be

taken to an authorized dealer immediately.

Enhanced Accident Response System

In the event of an impact, if the communica-

tion network remains intact, and the power

remains intact, depending on the nature of

the event, the ORC will determine whether to

have the Enhanced Accident Response Sys-

tem perform the following functions:

• Cut off fuel to the engine.

• Flash hazard lights as long as the battery

has power or until the hazard light button is

pressed. The hazard lights can be deacti-

vated by pressing the hazard light button.

• Turn on the interior lights, which remain on

as long as the battery has power.

• Unlock the power door locks.

Enhanced Accident Response System Reset

Procedure

In order to reset the Enhanced Accident Re-

sponse System functions after an event, the

ignition switch must be changed from igni-

tion START or ON/RUN to ignition OFF. Care-

fully check the vehicle for fuel leaks in the

engine compartment and on the ground near

the engine compartment and fuel tank before

resetting the system and starting the engine.

Maintaining Your Air Bag System

WARNING!

• Modifications to any part of the air bag

system could cause it to fail when you

need it. You could be injured if the air

bag system is not there to protect you.

Do not modify the components or wiring,

including adding any kind of badges or

stickers to the steering wheel hub trim

cover or the upper right side of the

instrument panel. Do not modify the

front bumper, vehicle body structure, or

add aftermarket side steps or running

boards.

WARNING!

• It is dangerous to try to repair any part of

the air bag system yourself. Be sure to

tell anyone who works on your vehicle

that it has an air bag system.

• Do not attempt to modify any part of your

air bag system. The air bag may inflate

accidentally or may not function prop-

erly if modifications are made. Take your

vehicle to an authorized dealer for any

air bag system service. If your seat, in-

cluding your trim cover and cushion,

needs to be serviced in any way (includ-

ing removal or loosening/tightening of

seat attachment bolts), take the vehicle

to your authorized dealer. Only manufac-

turer approved seat accessories may be

used. If it is necessary to modify the air

bag system for persons with disabilities,

contact your authorized dealer.

Event Data Recorder (EDR)

This vehicle is equipped with an event data

recorder (EDR). The main purpose of an EDR

is to record, in certain crash or near crash-

like situations, such as an air bag deployment

SAFETY

98

Page 138 of 276

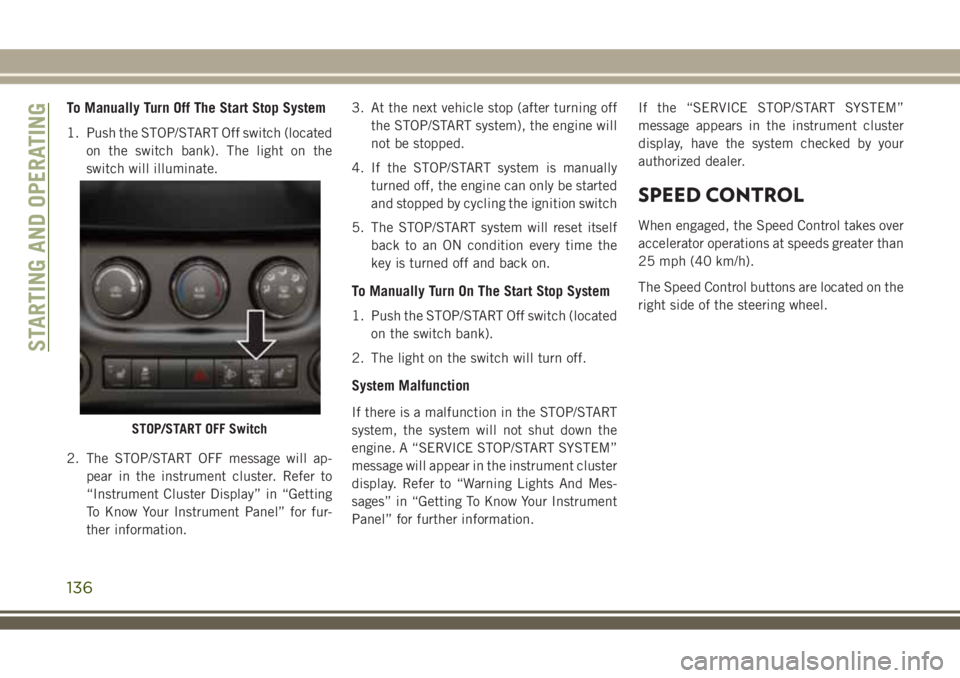

To Manually Turn Off The Start Stop System

1. Push the STOP/START Off switch (located

on the switch bank). The light on the

switch will illuminate.

2. The STOP/START OFF message will ap-

pear in the instrument cluster. Refer to

“Instrument Cluster Display” in “Getting

To Know Your Instrument Panel” for fur-

ther information.3. At the next vehicle stop (after turning off

the STOP/START system), the engine will

not be stopped.

4. If the STOP/START system is manually

turned off, the engine can only be started

and stopped by cycling the ignition switch

5. The STOP/START system will reset itself

back to an ON condition every time the

key is turned off and back on.

To Manually Turn On The Start Stop System

1. Push the STOP/START Off switch (located

on the switch bank).

2. The light on the switch will turn off.

System Malfunction

If there is a malfunction in the STOP/START

system, the system will not shut down the

engine. A “SERVICE STOP/START SYSTEM”

message will appear in the instrument cluster

display. Refer to “Warning Lights And Mes-

sages” in “Getting To Know Your Instrument

Panel” for further information.If the “SERVICE STOP/START SYSTEM”

message appears in the instrument cluster

display, have the system checked by your

authorized dealer.

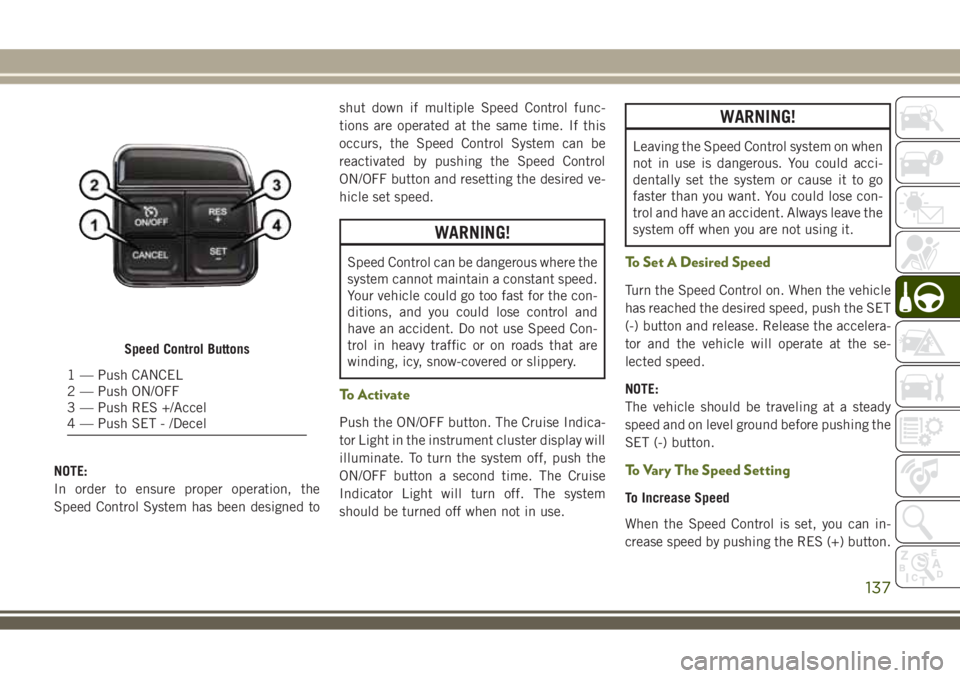

SPEED CONTROL

When engaged, the Speed Control takes over

accelerator operations at speeds greater than

25 mph (40 km/h).

The Speed Control buttons are located on the

right side of the steering wheel.

STOP/START OFF Switch

STARTING AND OPERATING

136

Page 139 of 276

NOTE:

In order to ensure proper operation, the

Speed Control System has been designed toshut down if multiple Speed Control func-

tions are operated at the same time. If this

occurs, the Speed Control System can be

reactivated by pushing the Speed Control

ON/OFF button and resetting the desired ve-

hicle set speed.

WARNING!

Speed Control can be dangerous where the

system cannot maintain a constant speed.

Your vehicle could go too fast for the con-

ditions, and you could lose control and

have an accident. Do not use Speed Con-

trol in heavy traffic or on roads that are

winding, icy, snow-covered or slippery.

To Activate

Push the ON/OFF button. The Cruise Indica-

tor Light in the instrument cluster display will

illuminate. To turn the system off, push the

ON/OFF button a second time. The Cruise

Indicator Light will turn off. The system

should be turned off when not in use.

WARNING!

Leaving the Speed Control system on when

not in use is dangerous. You could acci-

dentally set the system or cause it to go

faster than you want. You could lose con-

trol and have an accident. Always leave the

system off when you are not using it.

To Set A Desired Speed

Turn the Speed Control on. When the vehicle

has reached the desired speed, push the SET

(-) button and release. Release the accelera-

tor and the vehicle will operate at the se-

lected speed.

NOTE:

The vehicle should be traveling at a steady

speed and on level ground before pushing the

SET (-) button.

To Vary The Speed Setting

To Increase Speed

When the Speed Control is set, you can in-

crease speed by pushing the RES (+) button.

Speed Control Buttons

1 — Push CANCEL

2 — Push ON/OFF

3 — Push RES +/Accel

4 — Push SET - /Decel

137

Page 142 of 276

CAUTION!

• To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

NOTE:

• When the fuel nozzle “clicks” or shuts off,

the fuel tank is full.

• Tighten the fuel filler cap about 1/4 turn

until you hear one click. This is an indica-

tion that the cap is properly tightened.

• If the fuel filler cap is not tightened prop-

erly, the MIL will come on. Be sure the cap

is tightened every time the vehicle is

refueled.

Loose Fuel Filler Cap Message

After fuel has been added, the vehicle diag-

nostic system can determine if the fuel filler

cap is possibly loose, improperly installed, or

damaged. If the system detects a malfunc-

tion, the “gASCAP” message will display in

the odometer display. Tighten the gas cap

until a "clicking" sound is heard. This is an

indication that the gas cap is properly tight-

ened. Push the odometer reset button to turn

the message off. If the problem persists, the

message will appear the next time the vehicleis started. This might indicate a damaged

cap. If the problem is detected twice in a row,

the system will turn on the MIL. Resolving

the problem will turn the MIL off.

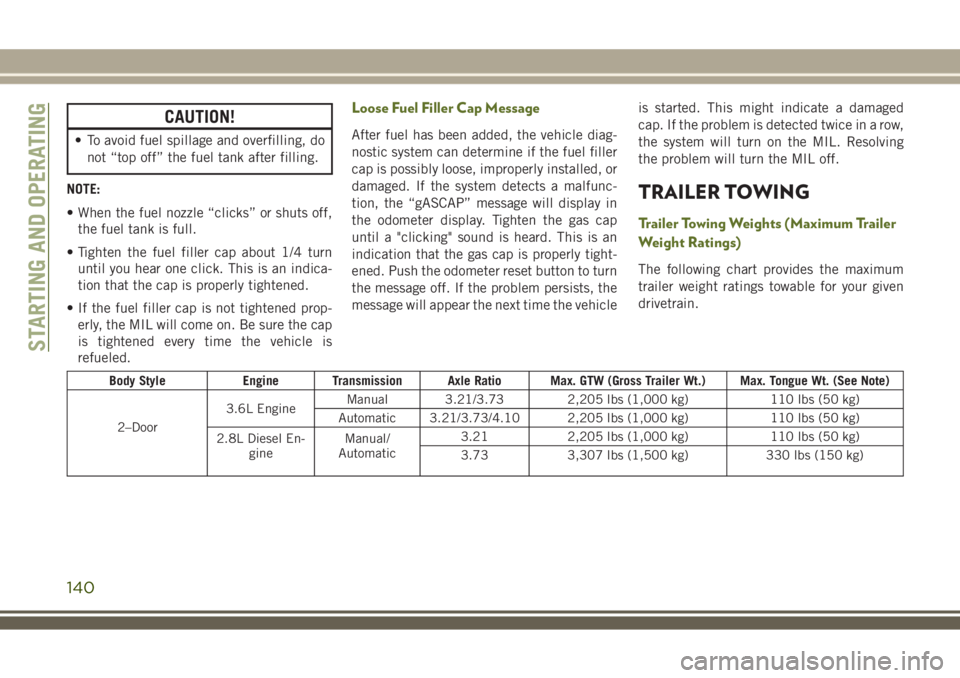

TRAILER TOWING

Trailer Towing Weights (Maximum Trailer

Weight Ratings)

The following chart provides the maximum

trailer weight ratings towable for your given

drivetrain.

Body Style Engine Transmission Axle Ratio Max. GTW (Gross Trailer Wt.) Max. Tongue Wt. (See Note)

2–Door3.6L EngineManual 3.21/3.73 2,205 lbs (1,000 kg) 110 lbs (50 kg)

Automatic 3.21/3.73/4.10 2,205 lbs (1,000 kg) 110 lbs (50 kg)

2.8L Diesel En-

gineManual/

Automatic3.21 2,205 lbs (1,000 kg) 110 lbs (50 kg)

3.73 3,307 lbs (1,500 kg) 330 lbs (150 kg)

STARTING AND OPERATING

140

Page 172 of 276

SCHEDULED SERVICING

Scheduled Servicing — Gasoline Engine

The scheduled services listed in this manual

must be done at the times or mileages speci-

fied to protect your vehicle warranty and

ensure the best vehicle performance and re-

liability. More frequent maintenance may be

needed for vehicles in severe operating con-

ditions, such as dusty areas and very short

trip driving. Inspection and service should

also be done anytime a malfunction is sus-

pected.

The oil change indicator system will remind

you that it is time to take your vehicle in for

scheduled maintenance.

On non-instrument cluster display equipped

vehicles, “CHANgE OIL” will flash in the

instrument cluster odometer and a single

chime will sound, indicating that an oil

change is necessary.The oil change indicator message will illumi-

nate approximately 7,000 miles

(11,200 km) after the most recent oil change

was performed. Have your vehicle serviced as

soon as possible, within 500 miles (800 km).

However, an earlier oil change at 4,500 miles

(7,500 km) may be required if the vehicle is

operated under “Severe Duty Conditions”

later in this section.

NOTE:

• The oil change indicator message will not

monitor the time since the last oil change.

Change your vehicle's oil if it has been

6 months since your last oil change even if

the oil change indicator message is NOT

illuminated.

• Change your engine oil more often if you

drive your vehicle off-road for an extended

period of time.

• Under no circumstances should oil change

intervals exceed 7,500 miles (12,000 km)

or 6 months, whichever comes first.

Your authorized dealer will reset the oil

change indicator message after completing

the scheduled oil change.Once A Month Or Before A Long Trip

• Check the engine oil level about five min-

utes after a fully warmed engine is shut off.

Checking the oil level while the vehicle is

on level ground will improve the accuracy of

the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

• Check the windshield washer solvent and

add if required.

• Check tire pressure and look for unusual

wear or damage. Rotate tires at the first

sign of irregular wear, even if it occurs

before the oil indicator system turns on.

• Inspect the battery and clean and tighten

the terminals as required.

• Check the fluid levels of coolant reservoir,

automatic transmission, brake master cyl-

inder and power steering and fill as needed.

• Check all lights and other electrical items

for correct operation.

SERVICING AND MAINTENANCE

170

Page 178 of 276

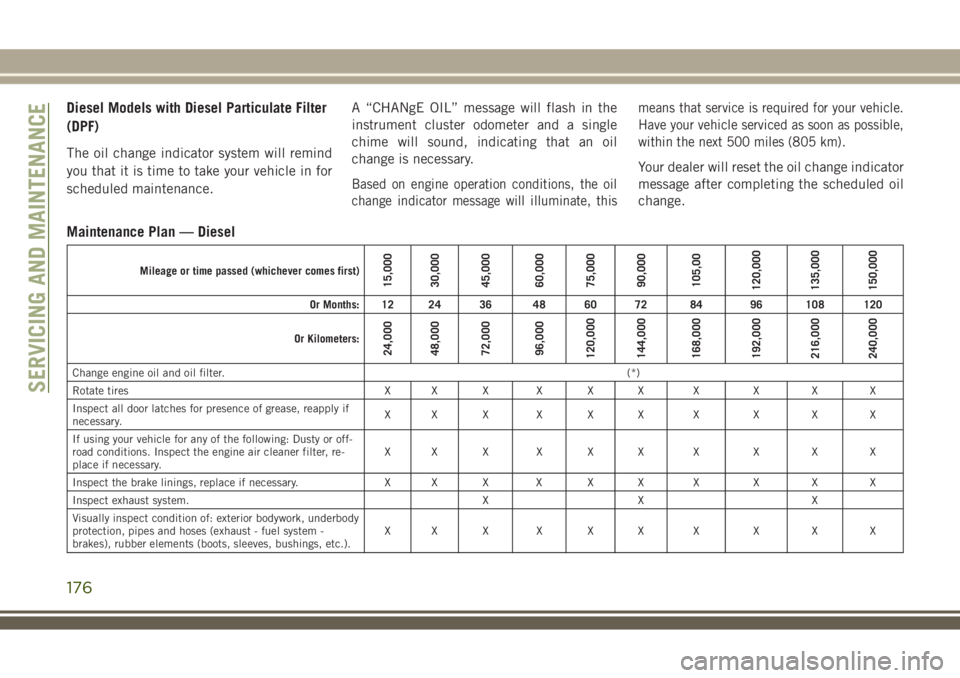

Diesel Models with Diesel Particulate Filter

(DPF)

The oil change indicator system will remind

you that it is time to take your vehicle in for

scheduled maintenance.A “CHANgE OIL” message will flash in the

instrument cluster odometer and a single

chime will sound, indicating that an oil

change is necessary.

Based on engine operation conditions, the oil

change indicator message will illuminate, thismeans that service is required for your vehicle.

Have your vehicle serviced as soon as possible,

within the next 500 miles (805 km).

Your dealer will reset the oil change indicator

message after completing the scheduled oil

change.

Maintenance Plan — Diesel

Mileage or time passed (whichever comes first)15,000

30,000

45,000

60,000

75,000

90,000

105,00

120,000

135,000

150,000

Or Months: 12 24 36 48 60 72 84 96 108 120

Or Kilometers:

24,000

48,000

72,000

96,000

120,000

144,000

168,000

192,000

216,000

240,000

Change engine oil and oil filter.(*)

Rotate tires X X X X X X X X X X

Inspect all door latches for presence of grease, reapply if

necessary.XX X X X X X X X X

If using your vehicle for any of the following: Dusty or off-

road conditions. Inspect the engine air cleaner filter, re-

place if necessary.XX X X X X X X X X

Inspect the brake linings, replace if necessary. X X X X X X X X X X

Inspect exhaust system. X X X

Visually inspect condition of: exterior bodywork, underbody

protection, pipes and hoses (exhaust - fuel system -

brakes), rubber elements (boots, sleeves, bushings, etc.).XX X X X X X X X X

SERVICING AND MAINTENANCE

176

Page 187 of 276

5. Place the gear selector momentarily into

each gear position (allowing time for the

transmission to fully engage in each posi-

tion), ending with the transmission in

PARK.

6. Remove the dipstick, wipe it clean and

reinsert it until seated.

7. Remove the dipstick again and note the

fluid level on both sides. The fluid level

reading is only valid if there is a solid

coating of oil on both sides of the dipstick.

Note that the holes in the dipstick will be

full of fluid if the actual level is at or above

the hole. The fluid level should be be-

tween the HOT (upper) reference holes on

the dipstick at normal operating tempera-

ture. If the fluid level is low, add fluid

through the dipstick tube to bring it to the

proper level.Do not overfill.Use ONLY the

specified fluid (refer to "Fluids And Lubri-

cants" under “Technical Specifications”

for fluid specifications). After adding any

quantity of oil through the dipstick tube,

wait a minimum of two minutes for the oil

to fully drain into the transmission before

rechecking the fluid level.NOTE:

• The holes in the dipstick will be full of

fluid if the actual level is at or above the

hole.

• If it is necessary to check the transmis-

sion below the operating temperature,

the fluid level should be between the

two COLD (lower) holes on the dipstick

with the fluid at approximately 80°F

(27°C). If the fluid level is correctly

established at 80° F (27°C), it should

be between the HOT (upper) reference

holes when the transmission reaches

180° F (82°C). Remember it is best to

check the level at the normal operating

temperature.

CAUTION!

If the fluid temperature is below 50°F

(10°C) it may not register on the dipstick.

Do not add fluid until the temperature is

elevated enough to produce an accurate

reading. Run the engine at idle, in PARK,

to warm the fluid.8. Reinstall the engine cover and snap it

down securely onto the four mounting

studs.

9. Check for leaks. Release the parking

brake.

NOTE:

To prevent dirt and water from entering the

transmission after checking or replenishing

fluid, make sure that the dipstick cap is

properly reseated. It is normal for the dipstick

cap to spring back slightly from its fully

seated position, as long as its seal remains

engaged in the dipstick tube.

Fluid Level Check — 2.8L Turbo Diesel

Engine

The fluid level is preset at the factory and

does not require adjustment under normal

operating conditions. Routine fluid level

checks are not required, therefore the trans-

mission filler tube is capped and no dipstick

is provided. An authorized dealer can check

your transmission fluid level using a special

service dipstick.

185