spare tire location JEEP WRANGLER 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2020, Model line: WRANGLER, Model: JEEP WRANGLER 2020Pages: 276, PDF Size: 4.47 MB

Page 81 of 276

• Driving on a significantly under-inflated tire

causes the tire to overheat and can lead to

tire failure. Under-inflation also reduces

fuel efficiency and tire tread life, and may

affect the vehicle’s handling and stopping

ability.

• The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s respon-

sibility to maintain correct tire pressure,

even if under-inflation has not reached the

level to trigger illumination of the “Tire

Pressure Monitoring Telltale Light.”

• Seasonal temperature changes will affect

tire pressure, and the TPMS will monitor

the actual tire pressure in the tire.

Base System

The Tire Pressure Monitor System (TPMS)

uses wireless technology with wheel rim-

mounted electronic sensors to monitor tire

pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire

pressure readings to the Receiver Module.NOTE:

It is particularly important for you to check

the tire pressure in all of your tires regularly

and to maintain the proper pressure.

The Tire Pressure Monitor System (TPMS)

consists of the following components:

• Receiver Module

• Four Tire Pressure Monitoring Sensors

• Tire Pressure Monitoring Telltale Light

A tire pressure monitoring sensor is located in

the spare wheel if the vehicle is equipped

with a matching full size spare wheel and tire

assembly. The matching full size spare tire

can be used in place of any of the four road

tires. A low spare tire will not cause the “Tire

Pressure Monitoring Telltale Light” to illumi-

nate or the chime to sound while stowed in

the spare location.

The “Tire Pressure Monitoring Tell-

tale Light” will illuminate in the in-

strument cluster, a “LOW TIRE

PRESSURE” message will display in the in-

strument cluster, and an audible chime will

be activated when one or more of the four

active road tire pressures are low. Should thisoccur, you should stop as soon as possible,

check the inflation pressure of each tire on

your vehicle, and inflate each tire to the

vehicle's recommended cold placard pres-

sure value. The system will automatically

update and the “Tire Pressure Monitoring

Telltale Light” will extinguish once the up-

dated tire pressures have been received. The

vehicle may need to be driven for up to

10 minutes above 15 mph (24 km/h) to

receive this information

The “Tire Pressure Monitoring Telltale Light”

will flash on and off for 75 seconds, and will

remain on solid when a system fault is de-

tected. The system fault will also sound a

chime. If the ignition key is cycled, this

sequence will repeat, providing the system

fault still exists. The “Tire Pressure Monitor-

ing Telltale Light” will turn off when the fault

condition no longer exists. A system fault can

occur by any of the following scenarios:

1. Jamming due to electronic devices or driv-

ing next to facilities emitting the same

Radio Frequencies as the TPM sensors.

79

Page 82 of 276

2. Installing some form of aftermarket win-

dow tinting that affects radio wave

signals.

3. Lots of snow or ice around the wheels or

wheel housings.

4. Using tire chains on the vehicle.

5. Using wheels/tires not equipped with

TPM sensors.

Vehicles not equipped with instrument clus-

ter display will inform the driver which tire(s)

are low but not provide actual tire pressure.

The low tire ISO telltale will illuminate along

with “LoTIrE” message displayed in the ODO

and then it will scroll to which tire location is

lower than the Placard Value.

Tire location will be displayed as follows:

LF =LeftFront

rF =rightFront

Lr =Leftrear

rr =rightrearNOTE:

• If your vehicle is equipped with a matching

full-size spare wheel and tire assembly, it

has a tire pressure monitoring sensor, and

can be monitored by the Tire Pressure

Monitoring System (TPMS) when swapped

with a low pressure road tire. In the event

that the matching full-size spare tire is

swapped with a low pressure road tire, the

next ignition key cycle will still show the

“Tire Pressure Monitoring Telltale Light” to

be ON, and a chime to sound. Driving the

vehicle for up to 10 minutes above 15 mph

(24 km/h) will turn OFF the “Tire Pressure

Monitoring Telltale Light” as long as none

of the road tires are below the low pressure

warning threshold.

• If your vehicle is not equipped with a

matching full-size spare wheel and tire as-

sembly, it does not have a tire pressure

monitoring sensor in the spare tire. The

TPMS will not be able to monitor the tire

pressure. If you install the spare tire in

place of a road tire that has a pressure

below the low-pressure warning limit, upon

the next ignition key cycle, a chime will

sound and the “Tire Pressure MonitoringTelltale Light” will turn ON. After driving

the vehicle for up to 10 minutes above

15 mph (24 km/h), the “Tire Pressure

Monitoring Telltale Light” will flash on and

off for 75 seconds and then remain on

solid. For each subsequent ignition key

cycle, a chime will sound and the “Tire

Pressure Monitoring Telltale Light” will

flash on and off for 75 seconds and then

remain on solid. Once you repair or replace

the original road tire, and reinstall it on the

vehicle in place of the spare tire, the TPMS

will update automatically and the “Tire

Pressure Monitoring Telltale Light” will

turn OFF, as long as no tire pressure is

below the low-pressure warning limit in any

of the four active road tires. The vehicle

may need to be driven for up to 10 minutes

above 15 mph (24 km/h) in order for the

TPMS to receive this information.

Premium System — If Equipped

The Tire Pressure Monitor System (TPMS)

uses wireless technology with wheel rim-

mounted electronic sensors to monitor tire

pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire

pressure readings to the Receiver Module.

SAFETY

80

Page 151 of 276

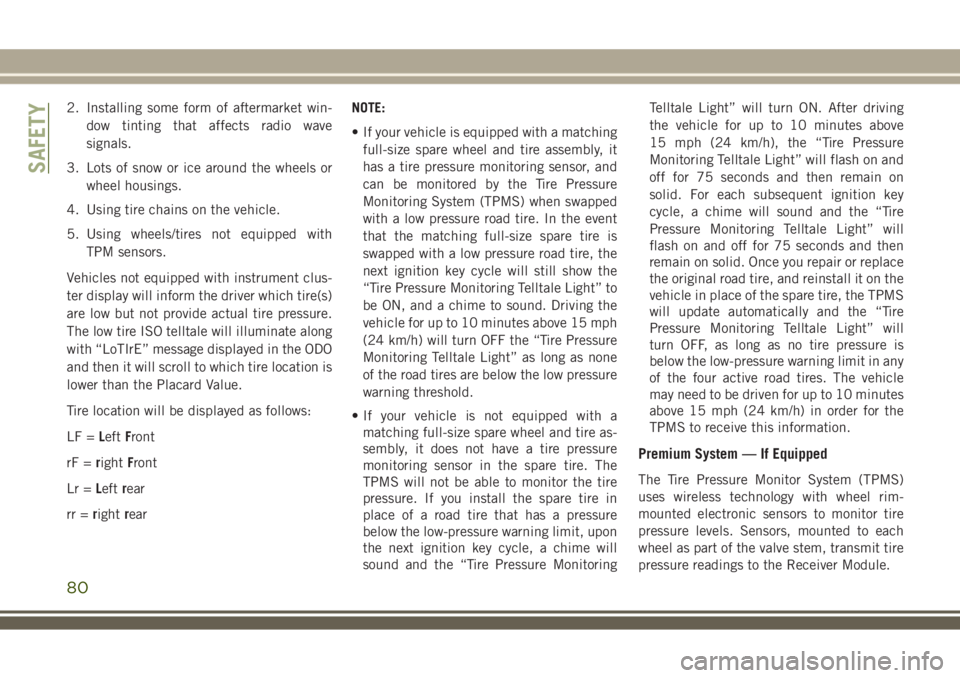

Rear Tail, Stop, Turn Signal, And Backup

Lamp

1. Remove the two inboard screws attaching

the tail light housing to the body.DO NOT

REMOVE THE OUTBOARD SCREWS AT ANY

TIME.

2. Separate the housing from the body by

pushing the lamp inboard while pulling

the lamp away from the body.3. Rotate the appropriate socket 1/4 turn

counterclockwise, then remove it from the

housing.

4. Pull the bulb straight from the socket to

replace.

Center High-Mounted Stop Lamp (CHMSL)

The stop lamp is mounted on a bracket that

extends upward from the tailgate behind the

spare tire. If service is needed, obtain the

LED/Cover Assembly from your local autho-

rized dealer.

1. Remove the spare tire.

2. Remove the four screws holding the lens/

cover in place on the spare tire carrier.

3. Disconnect the wire harness from the

back of the LED cover.

FUSES

WARNING!

• When replacing a blown fuse, always use

an appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Failure to use proper fuses may

result in serious personal injury, fire

and/or property damage.

• Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

• If a general protection fuse for safety

systems (air bag system, braking sys-

tem), power unit systems (engine sys-

tem, gearbox system) or steering system

blows, contact an authorized dealer.

Inboard Screw Location

149

Page 156 of 276

JACKING AND TIRE

CHANGING

WARNING!

• Do not attempt to change a tire on the

side of the vehicle close to moving traf-

fic. Pull far enough off the road to avoid

the danger of being hit when operating

the jack or changing the wheel.

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

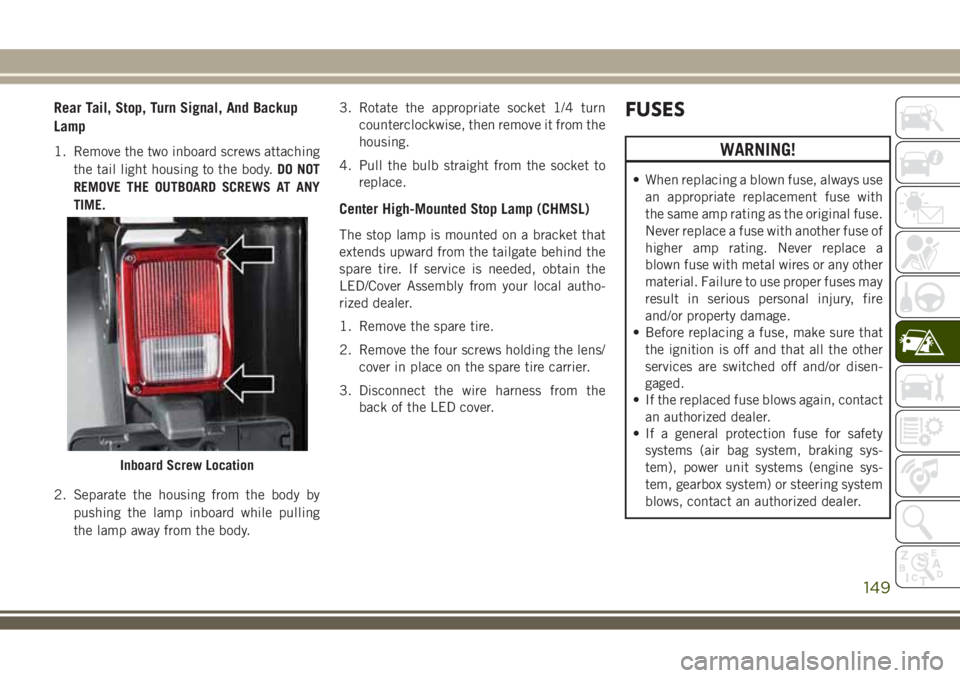

Jack/Spare Tire Stowage

The jack and lug wrench are located in the

rear storage compartment.

NOTE:

Turn the black plastic wing nut counterclock-

wise to loosen the jack from the storage bin.Spare Tire Removal

To remove the spare tire from the carrier,

remove the tire cover, if equipped, and re-

move the lug nuts with the lug wrench, turn-

ing them counterclockwise.

NOTE:

If you have added aftermarket accessories to

the spare tire mounted carrier, it cannot ex-

ceed a gross weight of 85 lbs (38.5 kg)

including the weight of the spare tire.

Preparations For Jacking

1. Park on a firm, level surface. Avoid ice or

slippery areas.

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic, pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

2. Turn on the Hazard Warning flasher.

3. Apply the parking brake.

Plastic Wing Nut Location

IN CASE OF EMERGENCY

154

Page 158 of 276

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated.

1. Remove the spare tire, jack and tools from

the stored location.

2. Loosen (but do not remove) the wheel lug

nuts by turning them to the left one turn

while the wheel is still on the ground.

3. Assemble the jack and jacking tools. Con-

nect the jack handle driver to the exten-

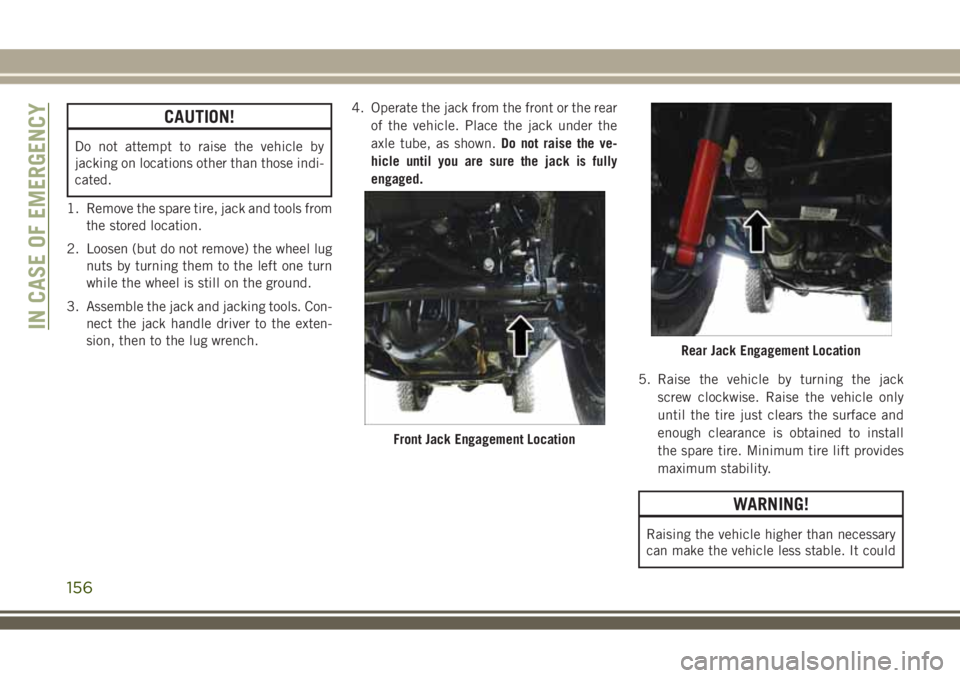

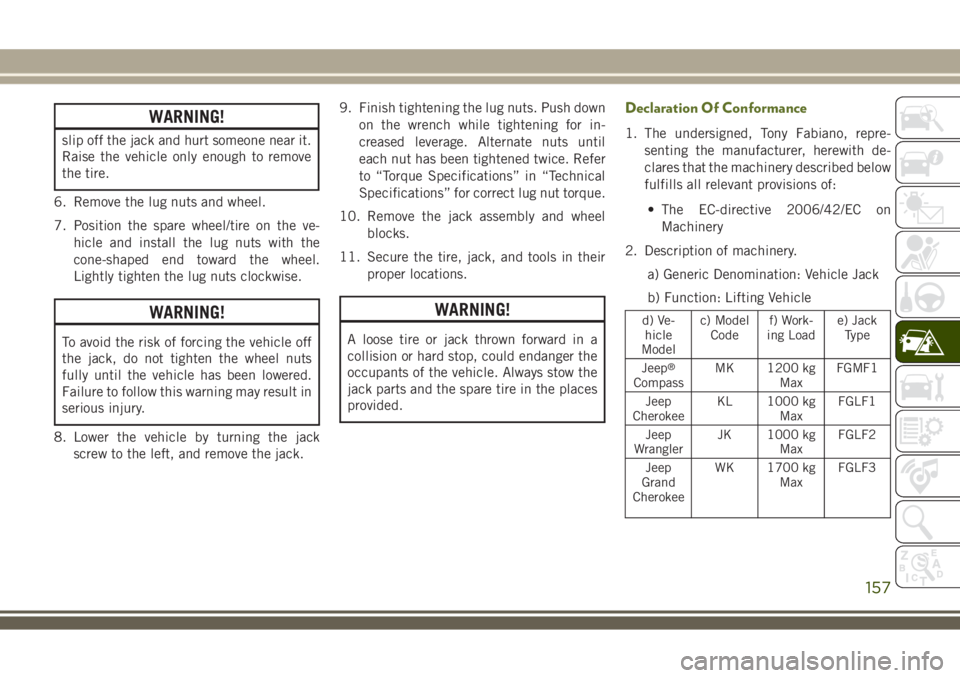

sion, then to the lug wrench.4. Operate the jack from the front or the rear

of the vehicle. Place the jack under the

axle tube, as shown.Do not raise the ve-

hicle until you are sure the jack is fully

engaged.

5. Raise the vehicle by turning the jack

screw clockwise. Raise the vehicle only

until the tire just clears the surface and

enough clearance is obtained to install

the spare tire. Minimum tire lift provides

maximum stability.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

Front Jack Engagement Location

Rear Jack Engagement Location

IN CASE OF EMERGENCY

156

Page 159 of 276

WARNING!

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the lug nuts and wheel.

7. Position the spare wheel/tire on the ve-

hicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the lug nuts clockwise.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

8. Lower the vehicle by turning the jack

screw to the left, and remove the jack.9. Finish tightening the lug nuts. Push down

on the wrench while tightening for in-

creased leverage. Alternate nuts until

each nut has been tightened twice. Refer

to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.

10. Remove the jack assembly and wheel

blocks.

11. Secure the tire, jack, and tools in their

proper locations.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

Declaration Of Conformance

1. The undersigned, Tony Fabiano, repre-

senting the manufacturer, herewith de-

clares that the machinery described below

fulfills all relevant provisions of:

• The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d) Ve-

hicle

Modelc) Model

Codef) Work-

ing Loade) Jack

Type

Jeep

®

CompassMK 1200 kg

MaxFGMF1

Jeep

CherokeeKL 1000 kg

MaxFGLF1

Jeep

WranglerJK 1000 kg

MaxFGLF2

Jeep

Grand

CherokeeWK 1700 kg

MaxFGLF3

157