tires JEEP WRANGLER UNLIMITED 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: WRANGLER UNLIMITED, Model: JEEP WRANGLER UNLIMITED 2019Pages: 348, PDF Size: 6.5 MB

Page 100 of 348

ignition cycle, the TPMS Warning Light

will remain on and a chime will sound. In

addition, the graphic in the instrument

cluster will still display a different color

pressure value.

3. After driving the vehicle for up to 10 min-

utes above 15 mph (24 km/h), the TPMS

Warning Light will flash on and off for

75 seconds and then remain on solid. In

addition, the instrument cluster will dis-

play a “Service Tire Pressure System”

message for five seconds and then display

dashes (- -) in place of the pressure value.

4. For each subsequent ignition cycle, a

chime will sound, the TPMS Warning

Light will flash on and off for 75 seconds

and then remain on solid, and the instru-

ment cluster will display a “SERVICE

TIRE PRESSURE SYSTEM” message for

five seconds and then display dashes (- -)

in place of the pressure value.

5. Once you repair or replace the original

road tire and reinstall it on the vehicle in

place of the compact spare or non-

matching full size, the TPMS will update

automatically. In addition, the TPMSWarning Light will turn off and the graphic

in the instrument cluster will display a

new pressure value instead of dashes (- -),

as long as no tire pressure is below the

low-pressure warning limit in any of the

four active road tires. The vehicle may

need to be driven for up to 10 minutes

above 15 mph (24 km/h) in order for the

TPMS to receive this information.

Vehicles With a Full Size Matching Spare

1. If your vehicle is equipped with a match-

ing full-size spare wheel and tire assem-

bly, it has a tire pressure monitoring sen-

sor, and can be monitored by the Tire

Pressure Monitoring System (TPMS)

when swapped with a low pressure road

tire.

2. In the event that the matching full-size

spare tire is swapped with a low pressure

road tire, the next ignition switch cycle

will still show the TPMS Warning Light to

be on, a chime to sound, and the graphic

display will still show the low tire pressure

value in a different color.3. Driving the vehicle for up to 10 minutes

above 15 mph (24 km/h) will turn off the

TPMS Warning Light as long as none of

road tires are below the low pressure

warning threshold.

TPMS Deactivation — If Equipped

The TPMS can be deactivated if replacing all

four wheel and tire assemblies (road tires)

with wheel and tire assemblies that do not

have TPMS sensors, such as when installing

winter wheel and tire assemblies on your

vehicle.

To deactivate the TPMS, first replace all four

wheel and tire assemblies (road tires) with

tires not equipped with Tire Pressure Moni-

toring (TPM) Sensors. Then, drive the vehicle

for 10 minutes above 15 mph (24 km/h). The

TPMS will chime, the TPMS Warning Light

will flash on and off for 75 seconds and then

remain on. The instrument cluster will dis-

play the “SERVICE TIRE PRESSURE SYS-

TEM” message and then display dashes (--)

in place of the pressure values.

SAFETY

98

Page 101 of 348

Beginning with the next ignition cycle, the

TPMS will no longer chime or display the

“SERVICE TIRE PRESSURE SYSTEM” mes-

sage in the instrument cluster but dashes (--)

will remain in place of the pressure values.

To reactivate the TPMS, replace all four

wheel and tire assemblies (road tires) with

tires equipped with TPMS sensors. Then,

drive the vehicle for up to 10 minutes above

15 mph (24 km/h). The TPMS will chime, the

TPMS Warning Light will flash on and off for

75 seconds and then turn off. The instrument

cluster will display the “SERVICE TIRE

PRESSURE SYSTEM” message and then dis-

play pressure values in place of the dashes.

On the next ignition cycle the "SERVICE TIRE

PRESSURE SYSTEM" message will no longer

be displayed as long as no system fault exists.

OCCUPANT RESTRAINT

SYSTEMS

Some of the most important safety features in

your vehicle are the restraint systems:

Occupant Restraint Systems Features

• Seat Belt Systems

• Supplemental Restraint Systems (SRS) Air

Bags

• Child Restraints

Some of the safety features described in this

section may be standard equipment on some

models, or may be optional equipment on

others. If you are not sure, ask an authorized

dealer.

Important Safety Precautions

Please pay close attention to the information

in this section. It tells you how to use your

restraint system properly, to keep you and

your passengers as safe as possible.

Here are some simple steps you can take to

minimize the risk of harm from a deploying

air bag:

1. Children 12 years old and under should

always ride buckled up in the rear seat of

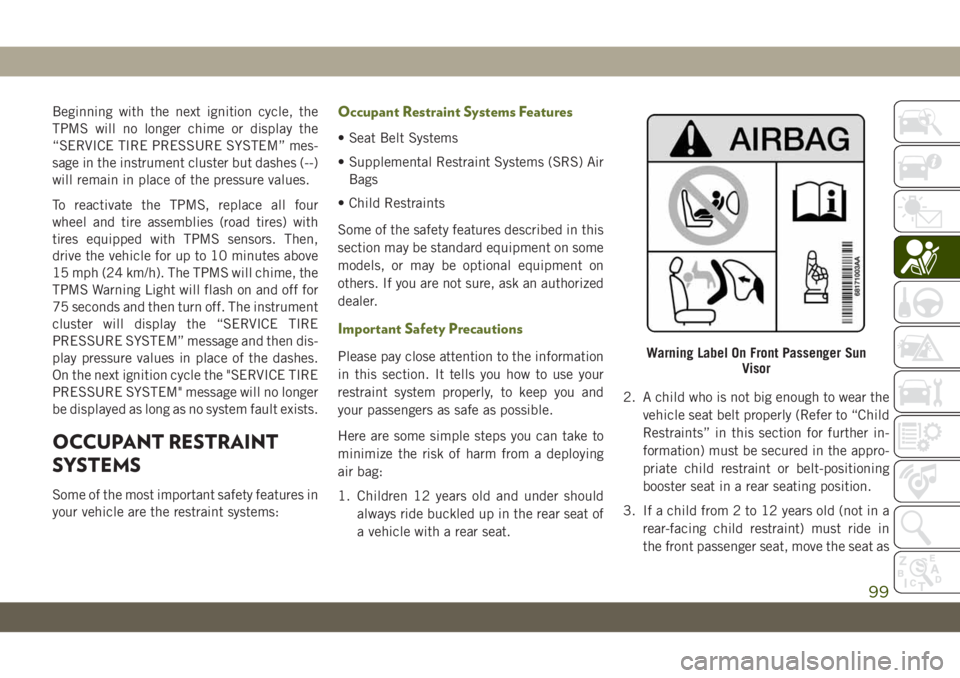

a vehicle with a rear seat.2. A child who is not big enough to wear the

vehicle seat belt properly (Refer to “Child

Restraints” in this section for further in-

formation) must be secured in the appro-

priate child restraint or belt-positioning

booster seat in a rear seating position.

3. If a child from 2 to 12 years old (not in a

rear-facing child restraint) must ride in

the front passenger seat, move the seat asWarning Label On Front Passenger Sun

Visor

99

Page 141 of 348

WARNING!

• NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These ob-

jects could change the position of the

floor mat and may cause interference

with the accelerator, brake, or clutch

pedals.

• If the vehicle carpet has been removed

and re-installed, always properly attach

carpet to the floor and check the floor

mat fasteners are secure to the vehicle

carpet. Fully depress each pedal to

check for interference with the accelera-

tor, brake, or clutch pedals then re-

install the floor mats.

• It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat

WARNING!

has been properly installed and is se-

cured to your vehicle using the floor mat

fasteners by lightly pulling mat.

Periodic Safety Checks You Should Make

Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones,

nails, glass, or other objects lodged in the

tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts,

cracks, and bulges. Check the wheel nuts for

tightness. Check the tires (including spare)

for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and lock-

ing.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid

leaks. Also, if gasoline fumes are detected or

if fuel, or brake fluid leaks are suspected. The

cause should be located and corrected imme-

diately.

139

Page 154 of 348

Proper operation of four-wheel drive vehicles

depends on tires of equal size, type, and

circumference on each wheel. Any difference

will adversely affect shifting and cause dam-

age to the transfer case.

Because four-wheel drive provides improved

traction, there is a tendency to exceed safe

turning and stopping speeds. Do not go faster

than road conditions permit.

Shifting Procedures

2H To 4H Or 4H To 2H

Shifting between 2H and 4H can be made

with the vehicle stopped or in motion. The

preferred shifting speed would be 0 to

45 mph (72 km/h). With the vehicle in mo-

tion, the transfer case will engage/disengage

faster if you momentarily release the accel-

erator pedal after completing the shift. Do

not accelerate while shifting the transfer

case. Apply a constant force when shifting

the transfer case lever.NOTE:

• Do not attempt to make a shift while only

the front or rear wheels are spinning. The

front and rear driveshaft speeds must be

equal for the shift to take place. Shifting

while only the front or rear wheels are

spinning can cause damage to the transfer

case.

• Delayed shifts out of four-wheel drive may

be experienced due to uneven tire wear, low

or uneven tire pressures, excessive vehicle

loading, or cold temperatures.

• Shifting effort will increase with speed, this

is normal.

During cold weather, you may experience

increased effort in shifting until the transfer

case fluid warms up. This is normal.

4H To 4L Or 4L To 4H

With the vehicle rolling at 2 to 3 mph (3 to

5 km/h), shift the transmission into NEU-

TRAL (N). While the vehicle is coasting at

2 to 3 mph (3 to 5 km/h), shift the transfer

case lever firmly to the desired position. Donot pause with the transfer case in N (Neu-

tral). Once the shift is completed, place the

transmission into DRIVE.

NOTE:

Shifting into or out of 4L is possible with the

vehicle completely stopped; however, diffi-

culty may occur due to the mating teeth not

being properly aligned. Several attempts may

be required for clutch teeth alignment and

shift completion to occur. The preferred

method is with the vehicle rolling at 2 to

3 mph (3 to 5 km/h). Avoid attempting to

engage or disengage 4L with the vehicle

moving faster than 2 to 3 mph (3 to 5 km/h).

WARNING!

Failure to engage a transfer case position

completely can cause transfer case dam-

age or loss of power and vehicle control.

You could have a collision. Do not drive the

vehicle unless the transfer case is fully

engaged.

STARTING AND OPERATING

152

Page 156 of 348

speed. This range provides additional trac-

tion and maximum pulling power for loose,

slippery road surfaces only. Do not exceed

25 mph (40 km/h).

This transfer case is designed to be driven in

the two-wheel drive position (2WD) or four-

wheel drive position (4WD AUTO) for normal

street and highway conditions on dry hard

surfaced roads. Driving the vehicle in 2WD

will have greater fuel economy benefits as the

front axle is not engaged in 2WD.

For variable driving conditions, the 4WD

AUTO mode can be used. In this mode, the

front axle is engaged, but the vehicle's power

is sent to the rear wheels. Four-wheel drive

will be automatically engaged when the ve-

hicle senses a loss of traction. Because the

front axle is engaged, this mode will result in

lower fuel economy than the 2WD mode.

In the event that additional traction is re-

quired, the transfer case 4H and 4L positions

can be used to lock the front and rear drive-

shafts together, forcing the front and rear

wheels to rotate at the same speed. The 4H

and 4L positions are intended for loose, slip-

pery road surfaces only and not intended fornormal driving. Driving in the 4H and 4L

positions on hard-surfaced roads will cause

increased tire wear and damage to the drive-

line components. Refer to “Shifting Proce-

dures” in this section for further information

on shifting into 4H or 4L.

The instrument cluster alerts the driver that

the vehicle is in four-wheel drive, and the

front and rear driveshafts are locked together.

The light will illuminate when the transfer

case is shifted into the 4H position.

When operating your vehicle in 4L, the en-

gine speed will be approximately three times

(four times for Rubicon models) that of the

2H or 4H positions at a given road speed.

Take care not to overspeed the engine.

Proper operation of four-wheel drive vehicles

depends on tires of equal size, type, and

circumference on each wheel. Any difference

will adversely affect shifting and cause dam-

age to the transfer case.

Because four-wheel drive provides improved

traction, there is a tendency to exceed safe

turning and stopping speeds. Do not go faster

than road conditions permit.Shifting Procedures

2H To 4H Auto Or 4H Auto To 2H

Shifting between 2H and 4H Auto can be

made with the vehicle stopped or in motion.

The preferred shifting speed would be 0 to

45 mph (72 km/h). With the vehicle in mo-

tion, the transfer case will engage/disengage

faster if you momentarily release the accel-

erator pedal after completing the shift. Do

not accelerate while shifting the transfer

case. Apply a constant force when shifting

the transfer case lever.

2H/4H Auto To 4H Part Time Or 4H Part Time

To 2H/4H Auto

Shifting between 2H/4H AUTO to 4H PART

TIME can be made with the vehicle stopped

or in motion. The preferred shifting speed

would be 0 to 45 mph (72 km/h). With the

vehicle in motion, the transfer case will

engage/disengage faster if you momentarily

release the accelerator pedal after complet-

ing the shift. Do not accelerate while shifting

the transfer case. Apply a constant force

when shifting the transfer case lever.

STARTING AND OPERATING

154

Page 192 of 348

WARNING!

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

Jack Location

The jack and lug wrench are located in the

rear cargo area. To remove jack and tools

proceed as follows:

1. Lift the load floor in the cargo area.NOTE:

The load floor can be removed for easier

access by pulling the load floor directly

rearward.

2. Remove the hardware storage cover by

pinching the latch on the left side and

pulling upward.

3. Turn the black plastic wing nut counter-

clockwise to loosen the jack from the

storage bin.

4. Remove tool kit and assemble tools.

Spare Tire Removal

1. To remove the spare tire from the carrier,

remove the tire cover, if equipped.

NOTE:

The spare wheel is mounted on the out-

side of the tailgate, protected by a plastic

cover with fasteners. Under traffic regula-

tions, the cover must not be removed or

insecurely fixed during use of the vehicle

on the public highway. Reference should

be made to local laws and regulations. Ifthe spare wheel is used, before continuing

your journey check that the damaged

wheel is securely mounted and the cover

is correctly fixed in place. Also take care

not to obstruct the rear camera.

2. Remove the Rear Camera Cover by turning

the lock bolt to the left with the #T40 Torx

head driver and ratchet from the supplied

tool kit.

3. Remove the lug nuts with the lug wrench

turning them counterclockwise. If

equipped, remove the locking lug nut with

the lock key (located in the glove box)

turning it counterclockwise.

Stowing The Replaced Spare Tire

1. Mount the spare tire onto the carrier.

Torque down lug nuts and locking lug nut.

2. Return the lock bolt to the lock position

on the camera cover by turning the lock to

the right using the provided #T40 Torx

head driver and ratchet. Then, reinstall

the camera cover by slipping it over the

camera/tire carrier until it snaps into

place.

IN CASE OF EMERGENCY

190

Page 194 of 348

WARNING!

• If working on or near a roadway, be

extremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated.

1. Remove the spare tire, jack and tools from

the stored location.

2. Loosen (but do not remove) the wheel lug

nuts by turning them to the left one turn

while the wheel is still on the ground.

3. Assemble the jack and jacking tools. Con-

nect the jack handle driver to the exten-

sion, then to the lug wrench.

4. Operate the jack from the front or the rear

of the vehicle. Place the jack under the

axle tube, as shown.Do not raise the ve-

hicle until you are sure the jack is fully

engaged.

Warning Label

Front Jack Engagement Location

IN CASE OF EMERGENCY

192

Page 203 of 348

To Reset The Manual Park Release:

1. Pull upward on the tether strap, releasing

it from the “locked” position.

2. Lower the Manual Park Release lever

downward and to the right, into its original

position.

3. Tuck the tether strap into the base of the

console, and reinstall the cover.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left

to clear the area around the front wheels. For

vehicles with automatic transmission, push

and hold the lock button on the gear selector.

Then, shift back and forth between DRIVE

and REVERSE, while gently pressing the ac-

celerator. Use the least amount of accelerator

pedal pressure that will maintain the rocking

motion, without spinning the wheels or racing

the engine.NOTE:

• For vehicles with automatic transmission:

Shifts between DRIVE and REVERSE can

only be achieved at wheel speeds of 5 mph

(8 km/h) or less. Whenever the transmis-

sion remains in NEUTRAL for more than

2 seconds, you must press the brake pedal

to engage DRIVE or REVERSE.

• Push the "ESC Off" switch, to place the

Electronic Stability Control (ESC) system in

"Partial Off" mode, before rocking the ve-

hicle. Refer to “Electronic Brake Control

System” in “Safety” in your Owner’s

Manual for further details. Once the vehicle

has been freed, push the "ESC Off" switch

again to restore "ESC On" mode.

WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause damage, or even failure,

of the axle and tires. A tire could explode

and injure someone. Do not spin your ve-

hicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping when you

WARNING!

are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

CAUTION!

• Racing the engine or spinning the

wheels may lead to transmission over-

heating and failure. Allow the engine to

idle with the transmission in NEUTRAL

for at least one minute after every five

rocking-motion cycles. This will mini-

mize overheating and reduce the risk of

clutch or transmission failure during

prolonged efforts to free a stuck vehicle.

• When “rocking” a stuck vehicle by shift-

ing between DRIVE/SECOND GEAR and

REVERSE, do not spin the wheels faster

than 15 mph (24 km/h), or drivetrain

damage may result.

• Revving the engine or spinning the

wheels too fast may lead to transmission

overheating and failure. It can also dam-

age the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear

(no transmission shifting occurring).

201

Page 209 of 348

SERVICING AND MAINTENANCE

SCHEDULED SERVICING......208

Scheduled Servicing — Gasoline Engine.208

Scheduled Servicing — Diesel Engine .213

ENGINE COMPARTMENT......217

2.0L Gasoline Engine............217

3.6L Gasoline Engine............218

2.2L Diesel Engine.............219

Checking Oil Level — Gasoline Engine .220

Adding Washer Fluid............220

Maintenance-Free Battery........221

DEALER SERVICE...........221

Windshield Wiper Blades.........222

Cooling System...............224

Brake System................224

Automatic Transmission..........225

RAISING THE VEHICLE.......226

TIRES....................226

Tire Safety Information..........226

Tires — General Information.......230

Tire Types...................234

Spare Tires — If Equipped........235

Wheel And Wheel Trim Care.......236Tire Chains (Traction Devices).......237

Tire Rotation Recommendations.....238

STORING THE VEHICLE......239

BODYWORK...............239

Body And Underbody Maintenance . . .239

Preserving The Bodywork.........239

INTERIORS................242

Seats And Fabric Parts...........242

Plastic And Coated Parts..........243

Leather Parts.................243

Glass Surfaces...............243

SERVICING AND MAINTENANCE

207

Page 211 of 348

Your authorized dealer will reset the oil

change indicator message after completing

the scheduled oil change.

Once A Month Or Before A Long Trip

• Check the engine oil level about five min-

utes after a fully warmed engine is shut off.

Checking the oil level while the vehicle is

on level ground will improve the accuracy of

the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

• Check the windshield washer solvent and

add if required.

• Check tire pressure and look for unusual

wear or damage. Rotate tires at the first

sign of irregular wear, even if it occurs

before the oil indicator system turns on.• Inspect the battery and clean and tighten

the terminals as required.

• Check the fluid levels of coolant reservoir,

brake master cylinder and power steering

and fill as needed.

• Check all lights and other electrical items

for correct operation.

At Each Oil Change

• Change the engine oil filter.

• Inspect the brake hoses and lines.

CAUTION!

Failure to perform the required mainte-

nance items may result in damage to the

vehicle.Required Maintenance Intervals

Refer to the Maintenance Plan on the follow-

ing pages for the required maintenance inter-

vals.

Maintenance Plan

NOTE:

Once you have carried out the last interven-

tion in the table, continue with the scheduled

servicing, maintaining the frequency indi-

cated in the plan by marking each operation

with a dot or dedicated note. Simply restart-

ing the maintenance from the start of the

plan may cause the allowed interval to be

exceeded for some operations.

209