wheel torque JEEP WRANGLER UNLIMITED 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: WRANGLER UNLIMITED, Model: JEEP WRANGLER UNLIMITED 2019Pages: 348, PDF Size: 6.5 MB

Page 76 of 348

Yellow Indicator Lights

/— 4WD Indicator Light — If

Equipped

This light alerts the driver that the vehicle is

in the four-wheel drive mode, and the front

and rear driveshafts are mechanically locked

together forcing the front and rear wheels to

rotate at the same speed.

4L/4WD

LOW— 4WD Low Indicator Light — If

Equipped

This light alerts the driver that the vehicle is

in the four-wheel drive LOW mode. The front

and rear driveshafts are mechanically locked

together forcing the front and rear wheels to

rotate at the same speed. Low range provides

a greater gear reduction ratio to provide in-

creased torque at the wheels.

4HPART

TIME/4WD

PART

TIME—4WD Part Time Indicator Light —

If Equipped

This light alerts the driver that the vehicle is

in the four-wheel drive part time mode, and

the front and rear driveshafts are mechani-

cally locked together forcing the front and

rear wheels to rotate at the same speed.

— Active Speed Limiter Fault Indica-

tor Light — If Equipped

This warning light will illuminate to signal

when there is a fault detected with the Active

Speed Limiter.

— Axle Locker Fault Indicator Light

This light indicates when the front and/or rear

axle locker fault has been detected.

— Front And Rear Axle Lock Indicator

Light

This light indicates when the front, rear, or

both axles have been locked. The telltale will

display the lock icon on the front and rear

axles to indicate the current lock status.

N/NEUTRAL— Neutral Indicator Light

— If Equipped

This light alerts the driver that the vehicle is

in the neutral mode.

— Rear Axle Lock Indicator Light

This light indicates when the rear axle lock

has been activated.

— Rear Fog Indicator — If Equipped

This indicator light will illuminate when the

rear fog lights are on.

— Sway Bar Indicator Light — If

Equipped

This indicator light will illuminate when the

front sway bar is disconnected.

— Wait To Start Light — If Equipped

This indicator light will illuminate for ap-

proximately two seconds when the ignition is

turned to the RUN position. Its duration may

be longer based on colder operating condi-

tions. Vehicle will not initiate start until tell-

tale is no longer displayed.

Refer to “Starting The Engine” in “Starting

And Operating” for further information.

NOTE:

The “Wait To Start” telltale may not illumi-

nate if the intake manifold temperature is

warm enough.

GETTING TO KNOW YOUR INSTRUMENT PANEL

74

Page 85 of 348

required. However, the conventional brake

system will continue to operate normally if

the “Anti-Lock Brake Warning Light” is on.

If the “Anti-Lock Brake Warning Light” is on,

the brake system should be serviced as soon

as possible to restore the benefits of anti-lock

brakes. If the “Anti-Lock Brake Warning

Light” does not come on when the ignition is

turned to the ON/RUN mode, have the light

repaired as soon as possible.

Electronic Brake Control System

Your vehicle is equipped with an advanced

Electronic Brake Control system (EBC). This

system includes Electronic Brake Force Dis-

tribution (EBD), Anti-Lock Brake System

(ABS), Brake Assist System (BAS), Hill Start

Assist (HSA), Traction Control System (TCS),

Electronic Stability Control (ESC), and Elec-

tronic Roll Mitigation (ERM). These systems

work together to enhance both vehicle stabil-

ity and control in various driving conditions.Your vehicle may also be equipped with

Trailer Sway Control (TSC), Ready Alert Brak-

ing (RAB), Rain Brake Support (RBS), Dy-

namic Steering Torque (DST), and Hill De-

scent Control (HDC).

Electronic Brake Force Distribution (EBD)

This function manages the distribution of the

braking torque between the front and rear

axles by limiting braking pressure to the rear

axle. This is done to prevent overslip of the

rear wheels to avoid vehicle instability, and to

prevent the rear axle from entering ABS be-

fore the front axle.

Brake System Warning Light

The red “Brake System Warning Light” will

turn on when the ignition is turned to the

ON/RUN mode and may stay on for as long as

four seconds.

If the “Brake System Warning Light” remains

on or comes on while driving, it indicates that

the brake system is not functioning properly

and that immediate service is required. If the“Brake System Warning Light” does not

come on when the ignition is turned to the

ON/RUN mode, have the light repaired as

soon as possible.

Brake Assist System (BAS)

The BAS is designed to optimize the vehicle’s

braking capability during emergency braking

maneuvers. The system detects an emer-

gency braking situation by sensing the rate

and amount of brake application and then

applies optimum pressure to the brakes. This

can help reduce braking distances. The BAS

complements the anti-lock brake system

(ABS). Applying the brakes very quickly re-

sults in the best BAS assistance. To receive

the benefit of the system, you must apply

continuous braking pressure during the stop-

ping sequence, (do not “pump” the brakes).

Do not reduce brake pedal pressure unless

braking is no longer desired. Once the brake

pedal is released, the BAS is deactivated.

WARNING!

The Brake Assist System (BAS) cannot

prevent the natural laws of physics from

83

Page 87 of 348

Towing With HSA

HSA will also provide assistance to mitigate

roll back while towing a trailer.

WARNING!

• If you use a trailer brake controller with

your trailer, the trailer brakes may be

activated and deactivated with the brake

switch. If so, there may not be enough

brake pressure to hold both the vehicle

and the trailer on a hill when the brake

pedal is released. In order to avoid roll-

ing down an incline while resuming ac-

celeration, manually activate the trailer

brake or apply more vehicle brake pres-

sure prior to releasing the brake pedal.

• HSA is not a parking brake. Always apply

the parking brake fully when exiting your

vehicle. Also, be certain to place the

transmission in PARK.

• Failure to follow these warnings can re-

sult in a collision or serious personal

injury.

Traction Control System (TCS)

This system monitors the amount of wheel

spin of each of the driven wheels. If wheel

spin is detected, the TCS may apply brake

pressure to the spinning wheel(s) and/or re-

duce engine power to provide enhanced ac-

celeration and stability. A feature of the TCS,

Brake Limited Differential (BLD), functions

similar to a limited slip differential and con-

trols the wheel spin across a driven axle. If

one wheel on a driven axle is spinning faster

than the other, the system will apply the

brake of the spinning wheel. This will allow

more engine torque to be applied to the wheel

that is not spinning. BLD may remain en-

abled even if TCS and ESC are in a reduced

mode.

Electronic Stability Control (ESC)

This system enhances directional control and

stability of the vehicle under various driving

conditions. ESC corrects for oversteering or

understeering of the vehicle by applying the

brake of the appropriate wheel(s) to assist in

counteracting the oversteer or understeer

condition. Engine power may also be reduced

to help the vehicle maintain the desired path.ESC uses sensors in the vehicle to determine

the vehicle path intended by the driver and

compares it to the actual path of the vehicle.

When the actual path does not match the

intended path, ESC applies the brake of the

appropriate wheel to assist in counteracting

the oversteer or understeer condition.

• Oversteer — when the vehicle is turning

more than appropriate for the steering

wheel position.

• Understeer — when the vehicle is turning

less than appropriate for the steering wheel

position.

The “ESC Activation/Malfunction Indicator

Light” located in the instrument cluster will

start to flash as soon as the ESC system

becomes active. The “ESC Activation/

Malfunction Indicator Light” also flashes

when the TCS is active. If the “ESC

Activation/Malfunction Indicator Light” be-

gins to flash during acceleration, ease up on

the accelerator and apply as little throttle as

possible. Be sure to adapt your speed and

driving to the prevailing road conditions.

85

Page 153 of 348

For additional information on the appropriate

use of each transfer case mode position, see

the information below:

2H

Rear Wheel Drive High Range — This range is

for normal street and highway driving on dry,

hard surfaced roads.

4H

Four-Wheel Drive High Range — This range

maximizes torque to the front driveshaft,

forcing the front and rear wheels to rotate at

the same speed. This range provides addi-

tional traction for loose, slippery road sur-

faces only.

NEUTRAL (N)

WARNING!

You or others could be injured or killed if

you leave the vehicle unattended with the

transfer case in the NEUTRAL (N) position

without first fully engaging the parking

brake. The transfer case NEUTRAL (N)

position disengages both the front and rear

driveshafts from the powertrain, and will

WARNING!

allow the vehicle to roll, even if the auto-

matic transmission is in PARK. The park-

ing brake should always be applied when

the driver is not in the vehicle.

Neutral — This range disengages both the

front and rear driveshafts from the pow-

ertrain. To be used for flat towing behind

another vehicle.

Refer to “Recreational Towing” in “Starting

And Operating” for further information.

4L

Four-Wheel Drive Low Range — This range

provides low speed four-wheel drive. It maxi-

mizes torque to the front driveshaft, forcing

the front and rear wheels to rotate at the same

speed. This range provides additional trac-

tion and maximum pulling power for loose,

slippery road surfaces only. Do not exceed

25 mph (40 km/h).

The transfer case is intended to be driven in

the 2H position for normal street and highway

conditions, such as hard-surfaced roads.In the event that additional traction is re-

quired, the transfer case 4H and 4L positions

can be used to lock the front and rear drive-

shafts together, forcing the front and rear

wheels to rotate at the same speed. The 4H

and 4L positions are intended for loose, slip-

pery road surfaces only and not intended for

normal driving. Driving in the 4H and 4L

positions on hard-surfaced roads will cause

increased tire wear and damage to the drive-

line components. Refer to “Shifting Proce-

dures” in this section for further information

on shifting into 4H or 4L.

The instrument cluster alerts the driver that

the vehicle is in four-wheel drive, and the

front and rear driveshafts are locked together.

The light will illuminate when the transfer

case is shifted into the 4H position.

When operating your vehicle in 4L, the en-

gine speed will be approximately three times

(four times for Rubicon models) that of the

2H or 4H positions at a given road speed.

Take care not to overspeed the engine.

151

Page 155 of 348

Five-Position Transfer Case

The transfer case provides five mode posi-

tions:

• 2H (Two-Wheel Drive High Range)

•

4H Auto (Four-Wheel Drive Auto High Range)

• 4H PT (Four-Wheel Drive Part Time High

Range)

• N (Neutral)

• 4L (Four-Wheel Drive Low Range)For additional information on the appropriate

use of each transfer case mode position, see

the information below:

2H

Rear Wheel Drive High Range — This range is

for normal street and highway driving on dry,

hard surfaced roads.

4H AUTO

Four-Wheel Drive Auto High Range — This

range sends power to the front wheels. The

four-wheel drive system will be automatically

engaged when the vehicle senses a loss of

traction. Additional traction for varying road

conditions.

4H P-T

Four-Wheel Drive Part Time High Range —

This range maximizes torque to the front

driveshaft, forcing the front and rear wheels

to rotate at the same speed. This range pro-

vides additional traction for loose, slippery

road surfaces only.NEUTRAL (N)

WARNING!

You or others could be injured or killed if

you leave the vehicle unattended with the

transfer case in the NEUTRAL (N) position

without first fully engaging the parking

brake. The transfer case NEUTRAL (N)

position disengages both the front and rear

driveshafts from the powertrain, and will

allow the vehicle to roll, even if the auto-

matic transmission is in PARK. The park-

ing brake should always be applied when

the driver is not in the vehicle.

Neutral — This range disengages both the

front and rear driveshafts from the pow-

ertrain. To be used for flat towing behind

another vehicle.

Refer to “Recreational Towing” in “Starting

And Operating” for further information.

4L

Four-Wheel Drive Low Range — This range

provides low speed four-wheel drive. It maxi-

mizes torque to the front driveshaft, forcing

the front and rear wheels to rotate at the same

Four-Wheel Drive Gear Selector

153

Page 157 of 348

NOTE:

• Do not attempt to make a shift while only

the front or rear wheels are spinning. The

front and rear driveshaft speeds must be

equal for the shift to take place. Shifting

while only the front or rear wheels are

spinning can cause damage to the transfer

case.

• Delayed shifts out of four-wheel drive may

be experienced due to uneven tire wear, low

or uneven tire pressures, excessive vehicle

loading, or cold temperatures.

• Shifting effort will increase with speed, this

is normal.

During cold weather, you may experience

increased effort in shifting until the transfer

case fluid warms up. This is normal.

4H Part Time/4H Auto To 4L Or 4L To 4H Part

Time/4H Auto

With the vehicle rolling at 2 to 3 mph (3 to

5 km/h), shift the transmission into NEU-

TRAL (N). While the vehicle is coasting at

2 to 3 mph (3 to 5 km/h), shift the transfer

case lever firmly to the desired position. Donot pause with the transfer case in N (Neu-

tral). Once the shift is completed, place the

transmission into DRIVE.

NOTE:

Shifting into or out of 4L is possible with the

vehicle completely stopped; however, diffi-

culty may occur due to the mating teeth not

being properly aligned. Several attempts may

be required for clutch teeth alignment and

shift completion to occur. The preferred

method is with the vehicle rolling at 2 to

3 mph (3 to 5 km/h). Avoid attempting to

engage or disengage 4L with the vehicle mov-

ing faster than 2 to 3 mph (3 to 5 km/h).

WARNING!

Failure to engage a transfer case position

completely can cause transfer case dam-

age or loss of power and vehicle control.

You could have a collision. Do not drive the

vehicle unless the transfer case is fully

engaged.

Trac-Lok Rear Axle — If Equipped

The Trac-Lok rear axle provides a constant

driving force to both rear wheels and reduces

wheel spin caused by the loss of traction at

one driving wheel. If traction differs between

the two rear wheels, the differential auto-

matically proportions the usable torque by

providing more torque to the wheel that has

traction.

Trac-Lok is especially helpful during slippery

driving conditions. With both rear wheels on a

slippery surface, a slight application of the

accelerator will supply maximum traction.

WARNING!

On vehicles equipped with a limited-slip

differential, never run the engine with one

rear wheel off the ground. The vehicle may

drive through the rear wheel remaining on

the ground and cause you to lose control of

your vehicle.

155

Page 159 of 348

Push the SWAY BAR switch to activate the

system. Push the switch again to deactivate

the system. The “Sway Bar Indicator Light”

(located in the instrument cluster) will illumi-

nate when the bar is disconnected. The

“Sway Bar Indicator Light” will flash during

activation transition, or when activation con-

ditions are not met. The stabilizer/sway bar

should remain in on-road mode during nor-

mal driving conditions.

WARNING!

Ensure the stabilizer/sway bar is recon-

nected before driving on hard surfaced

roads or at speeds above 18 mph

(29 km/h); a disconnected stabilizer/sway

bar may contribute to the loss of vehicle

control, which could result in serious in-

jury. Under certain circumstances, the

front stabilizer/sway bar enhances vehicle

stability and assists with vehicle control.

The system monitors vehicle speed and

will attempt to reconnect the stabilizer/

sway bar at speeds over 18 mph

(29 km/h). This is indicated by a flashing

or solid “Sway Bar Indicator Light.” Once

WARNING!

vehicle speed is reduced below 14 mph

(22 km/h), the system will once again

attempt to return to off-road mode.

To disconnect the stabilizer/sway bar, shift to

either 4H or 4L and push the SWAY BAR

switch to obtain the off-road position. Refer

to “Four-Wheel Drive Operation” in this sec-

tion for further information. The “Sway Bar

Indicator Light” will flash until the stabilizer/

sway bar has been fully disconnected.

NOTE:

The stabilizer/sway bar may be torque locked

due to left and right suspension height differ-

ences. This condition is due to driving sur-

face differences or vehicle loading. In order

for the stabilizer/sway bar to disconnect/

reconnect, the right and left halves of the bar

must be aligned. This alignment may require

that the vehicle be driven onto level ground or

rocked from side to side.

To return to on-road mode, push the SWAY

BAR switch again.

WARNING!

If the stabilizer/sway bar will not return to

on-road mode, the “Sway Bar Indicator

Light” will flash in the instrument cluster

and vehicle stability may be reduced. Do

not attempt to drive the vehicle over

18 mph (29 km/h). Driving faster than

18 mph (29 km/h) with a disconnected

stabilizer/sway bar may contribute to the

loss of vehicle control, which could result

in serious injury.

STOP/START SYSTEM —

AUTOMATIC

TRANSMISSION (IF

EQUIPPED)

The Stop/Start function is developed to re-

duce fuel consumption. The system will stop

the engine automatically during a vehicle

stop if the required conditions are met. Re-

leasing the brake pedal or pressing the accel-

erator pedal will automatically re-start the

engine.

157

Page 192 of 348

WARNING!

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

Jack Location

The jack and lug wrench are located in the

rear cargo area. To remove jack and tools

proceed as follows:

1. Lift the load floor in the cargo area.NOTE:

The load floor can be removed for easier

access by pulling the load floor directly

rearward.

2. Remove the hardware storage cover by

pinching the latch on the left side and

pulling upward.

3. Turn the black plastic wing nut counter-

clockwise to loosen the jack from the

storage bin.

4. Remove tool kit and assemble tools.

Spare Tire Removal

1. To remove the spare tire from the carrier,

remove the tire cover, if equipped.

NOTE:

The spare wheel is mounted on the out-

side of the tailgate, protected by a plastic

cover with fasteners. Under traffic regula-

tions, the cover must not be removed or

insecurely fixed during use of the vehicle

on the public highway. Reference should

be made to local laws and regulations. Ifthe spare wheel is used, before continuing

your journey check that the damaged

wheel is securely mounted and the cover

is correctly fixed in place. Also take care

not to obstruct the rear camera.

2. Remove the Rear Camera Cover by turning

the lock bolt to the left with the #T40 Torx

head driver and ratchet from the supplied

tool kit.

3. Remove the lug nuts with the lug wrench

turning them counterclockwise. If

equipped, remove the locking lug nut with

the lock key (located in the glove box)

turning it counterclockwise.

Stowing The Replaced Spare Tire

1. Mount the spare tire onto the carrier.

Torque down lug nuts and locking lug nut.

2. Return the lock bolt to the lock position

on the camera cover by turning the lock to

the right using the provided #T40 Torx

head driver and ratchet. Then, reinstall

the camera cover by slipping it over the

camera/tire carrier until it snaps into

place.

IN CASE OF EMERGENCY

190

Page 195 of 348

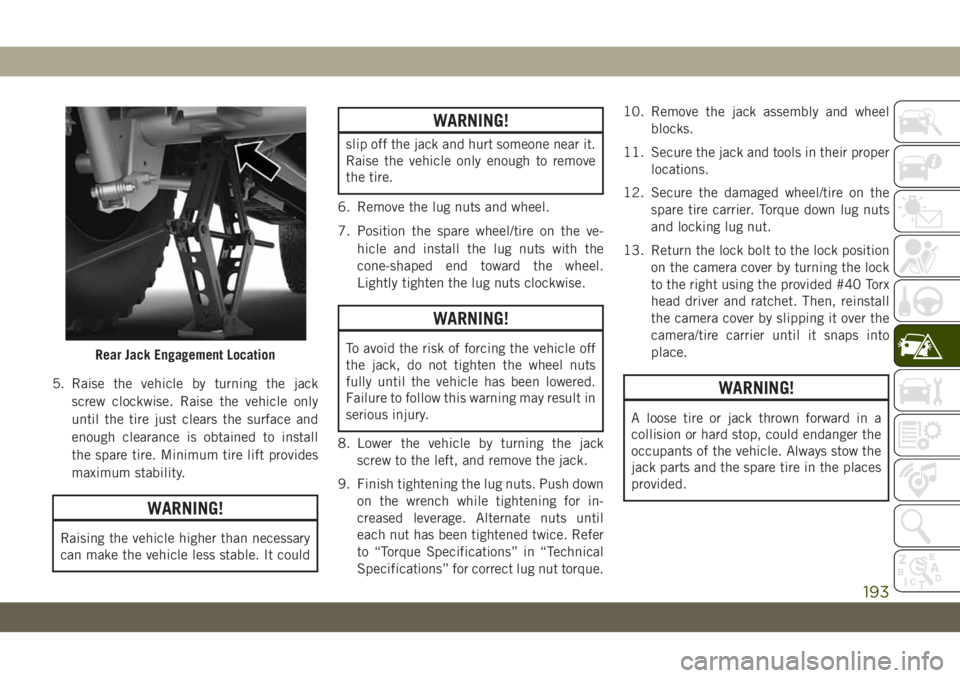

5. Raise the vehicle by turning the jack

screw clockwise. Raise the vehicle only

until the tire just clears the surface and

enough clearance is obtained to install

the spare tire. Minimum tire lift provides

maximum stability.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

WARNING!

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the lug nuts and wheel.

7. Position the spare wheel/tire on the ve-

hicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the lug nuts clockwise.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

8. Lower the vehicle by turning the jack

screw to the left, and remove the jack.

9. Finish tightening the lug nuts. Push down

on the wrench while tightening for in-

creased leverage. Alternate nuts until

each nut has been tightened twice. Refer

to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.10. Remove the jack assembly and wheel

blocks.

11. Secure the jack and tools in their proper

locations.

12. Secure the damaged wheel/tire on the

spare tire carrier. Torque down lug nuts

and locking lug nut.

13. Return the lock bolt to the lock position

on the camera cover by turning the lock

to the right using the provided #40 Torx

head driver and ratchet. Then, reinstall

the camera cover by slipping it over the

camera/tire carrier until it snaps into

place.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

Rear Jack Engagement Location

193

Page 196 of 348

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the

cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down

on the wrench while at the end of the

handle for increased leverage. Tighten the

lug nuts in a star pattern until each nut

has been tightened twice. For the correct

lug nut torque refer to “Torque Specifica-

tions” in “Technical Specifications”. If in

doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.5. After 25 miles (40 km), check the lug nut

torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

Declaration Of Conformance

1. The undersigned, FlexNGate, represent-

ing the manufacturer, herewith declares

that the machinery described below ful-

fills all relevant provisions of:

•The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d) Ve-

hicle

Modelc) Model

Codef) Work-

ing Loade) Jack

Type

Jeep

WranglerJL 1000 kg

MaxFGLF2

3. Manufacturers (1):

FlexNGate Seeburn, a division of Ventra

Group Co

P.O. Box 1170, 65 Industrial Road, Totten-

ham, ON CANADA L0G 1W04. Manufacturers (2):

FlexNGate Querétaro Ventramex, S.A. de

C.V

Av. Manantiales No. 3

Parque Industrial Bernardo Quintana, El

Marqués Querétaro C.P. 76249 – Mexico

5. Legal Person authorized to compile the

technical file:

FlexNGate – Barcelona

Avda de la Riera, 7-9

Sant Just Desvern, Barcelona, SPAIN 08960

6. References to harmonized standards:

PF-90065

7. Done at: Bradford, ON CANADA

8. Date: 10/02/2017FlexNGate Representative

IN CASE OF EMERGENCY

194