manual transmission JEEP XJ 1995 Service And Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1763 of 2158

AW-4 TRANSMISSION OVERHAUL

INDEX

page page

Cleaning and Inspection................... 214

Direct Clutch Overhaul.................... 228

First-Reverse Brake Piston and Transmission Case

Overhaul............................. 247

Forward Clutch Overhaul................... 232

Front Planetary Gear Overhaul.............. 237

Manual Valve Shaft Overhaul............... 215

Oil Pump Overhaul....................... 216

Overdrive Planetary Gear and Clutch Overhaul . . 218Overdrive Support Overhaul................ 226

Overhaul Service Tools.................... 201

Rear Planetary, No. 2 One-Way Clutch and Output

Shaft Overhaul......................... 244

Second Brake Overhaul................... 241

Sun Gear and No. 1 One-Way Clutch Overhaul . . 238

Transmission Assembly and Adjustment........ 265

Transmission Disassembly................. 201

Transmission Valve Body Overhaul........... 250

OVERHAUL SERVICE TOOLS

The special tools needed to overhaul the AW-4

transmission are provided in Tool Kit 6294. However,

Pressure Test Port Adapter 7554 is not included in

this kit and must be ordered separately. The over-

haul tool kit and test port adapter are available

through the parts division and dealer special tool

program.

TRANSMISSION DISASSEMBLY

(1) Remove torque converter.

(2) Remove lower half of filler tube if not previ-

ously removed.

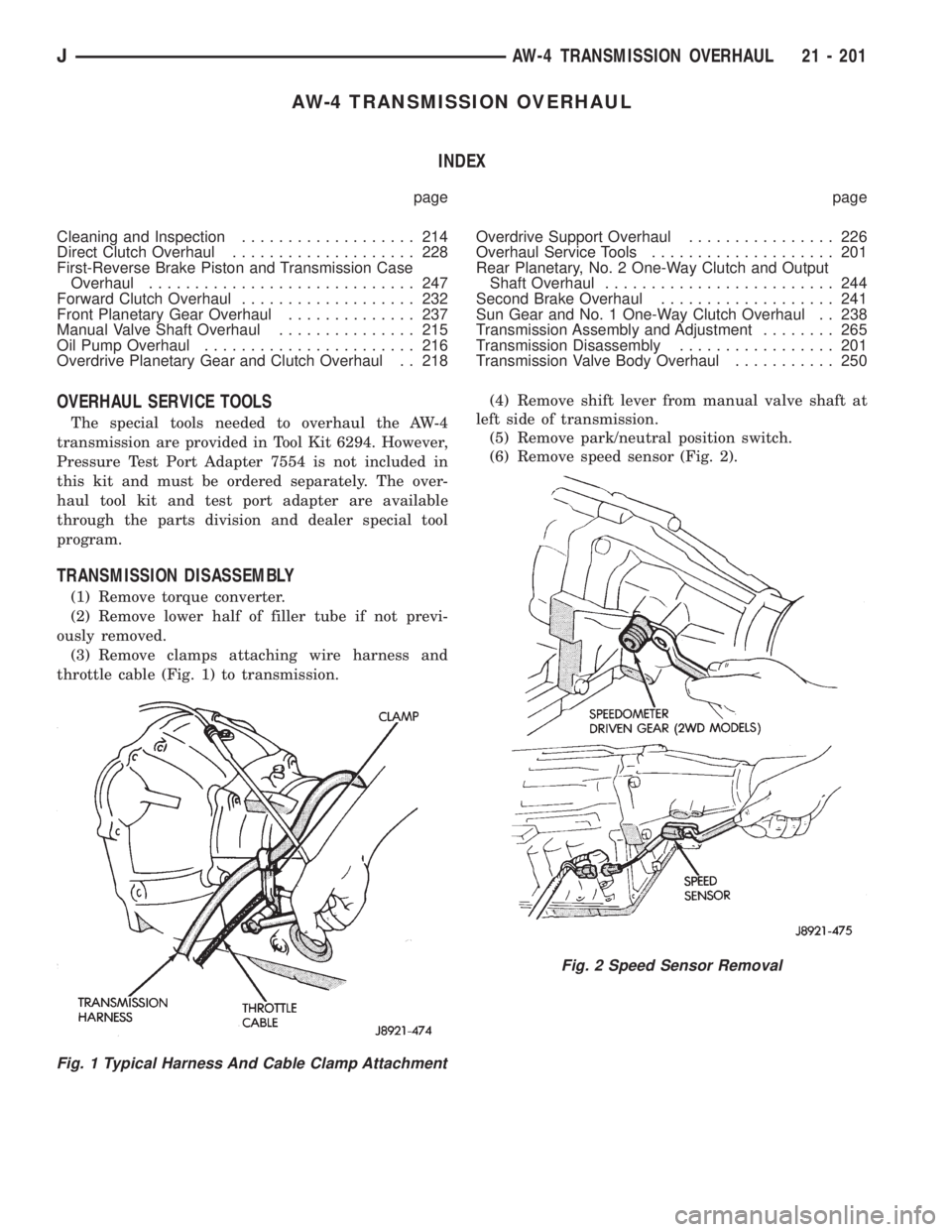

(3) Remove clamps attaching wire harness and

throttle cable (Fig. 1) to transmission.(4) Remove shift lever from manual valve shaft at

left side of transmission.

(5) Remove park/neutral position switch.

(6) Remove speed sensor (Fig. 2).

Fig. 1 Typical Harness And Cable Clamp Attachment

Fig. 2 Speed Sensor Removal

JAW-4 TRANSMISSION OVERHAUL 21 - 201

Page 1774 of 2158

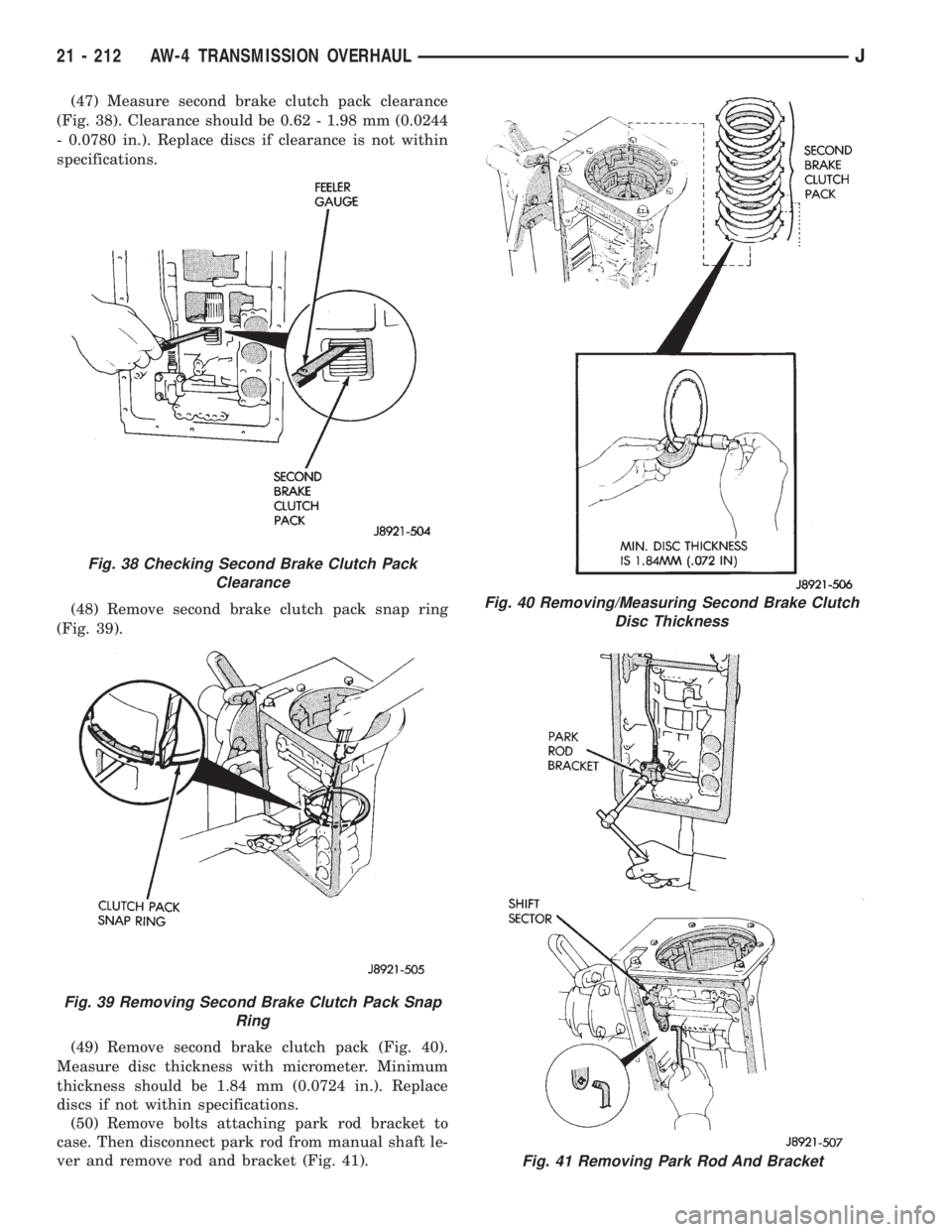

(47) Measure second brake clutch pack clearance

(Fig. 38). Clearance should be 0.62 - 1.98 mm (0.0244

- 0.0780 in.). Replace discs if clearance is not within

specifications.

(48) Remove second brake clutch pack snap ring

(Fig. 39).

(49) Remove second brake clutch pack (Fig. 40).

Measure disc thickness with micrometer. Minimum

thickness should be 1.84 mm (0.0724 in.). Replace

discs if not within specifications.

(50) Remove bolts attaching park rod bracket to

case. Then disconnect park rod from manual shaft le-

ver and remove rod and bracket (Fig. 41).

Fig. 40 Removing/Measuring Second Brake Clutch

Disc Thickness

Fig. 41 Removing Park Rod And Bracket

Fig. 38 Checking Second Brake Clutch Pack

Clearance

Fig. 39 Removing Second Brake Clutch Pack Snap

Ring

21 - 212 AW-4 TRANSMISSION OVERHAULJ

Page 1777 of 2158

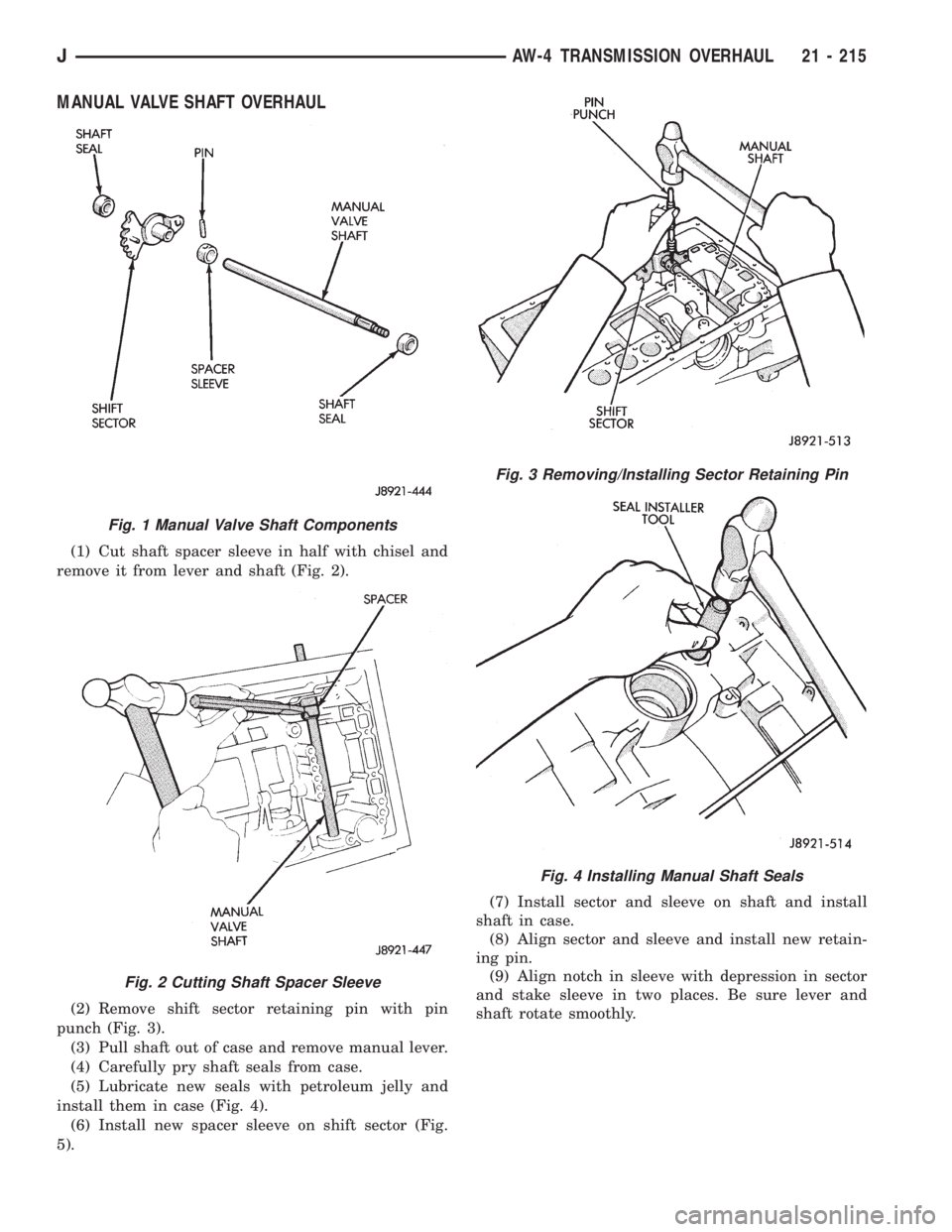

MANUAL VALVE SHAFT OVERHAUL

(1) Cut shaft spacer sleeve in half with chisel and

remove it from lever and shaft (Fig. 2).

(2) Remove shift sector retaining pin with pin

punch (Fig. 3).

(3) Pull shaft out of case and remove manual lever.

(4) Carefully pry shaft seals from case.

(5) Lubricate new seals with petroleum jelly and

install them in case (Fig. 4).

(6) Install new spacer sleeve on shift sector (Fig.

5).(7) Install sector and sleeve on shaft and install

shaft in case.

(8) Align sector and sleeve and install new retain-

ing pin.

(9) Align notch in sleeve with depression in sector

and stake sleeve in two places. Be sure lever and

shaft rotate smoothly.

Fig. 1 Manual Valve Shaft Components

Fig. 2 Cutting Shaft Spacer Sleeve

Fig. 3 Removing/Installing Sector Retaining Pin

Fig. 4 Installing Manual Shaft Seals

JAW-4 TRANSMISSION OVERHAUL 21 - 215

Page 1778 of 2158

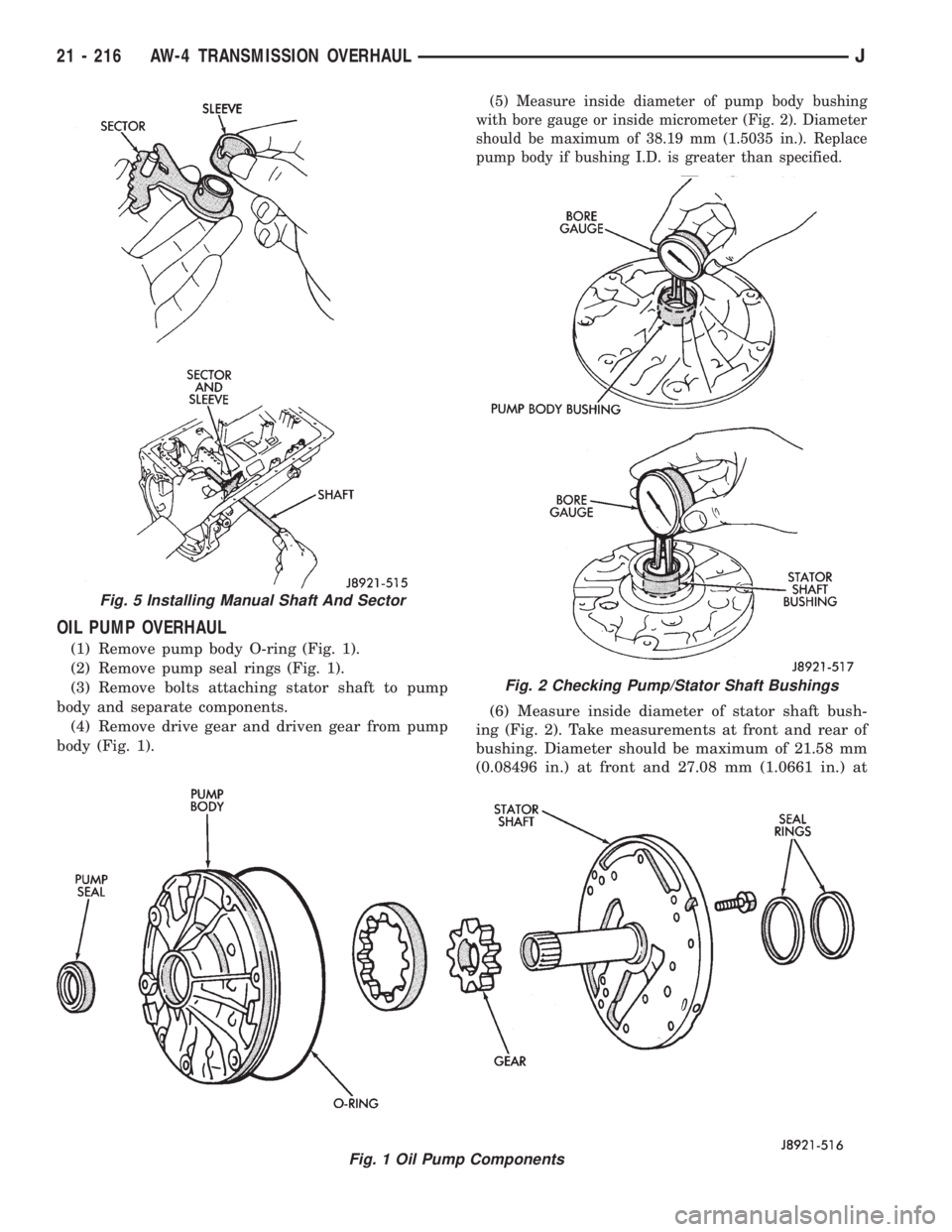

OIL PUMP OVERHAUL

(1) Remove pump body O-ring (Fig. 1).

(2) Remove pump seal rings (Fig. 1).

(3) Remove bolts attaching stator shaft to pump

body and separate components.

(4) Remove drive gear and driven gear from pump

body (Fig. 1).

(5) Measure inside diameter of pump body bushing

with bore gauge or inside micrometer (Fig. 2). Diameter

should be maximum of 38.19 mm (1.5035 in.). Replace

pump body if bushing I.D. is greater than specified.

(6) Measure inside diameter of stator shaft bush-

ing (Fig. 2). Take measurements at front and rear of

bushing. Diameter should be maximum of 21.58 mm

(0.08496 in.) at front and 27.08 mm (1.0661 in.) at

Fig. 1 Oil Pump Components

Fig. 5 Installing Manual Shaft And Sector

Fig. 2 Checking Pump/Stator Shaft Bushings

21 - 216 AW-4 TRANSMISSION OVERHAULJ

Page 1814 of 2158

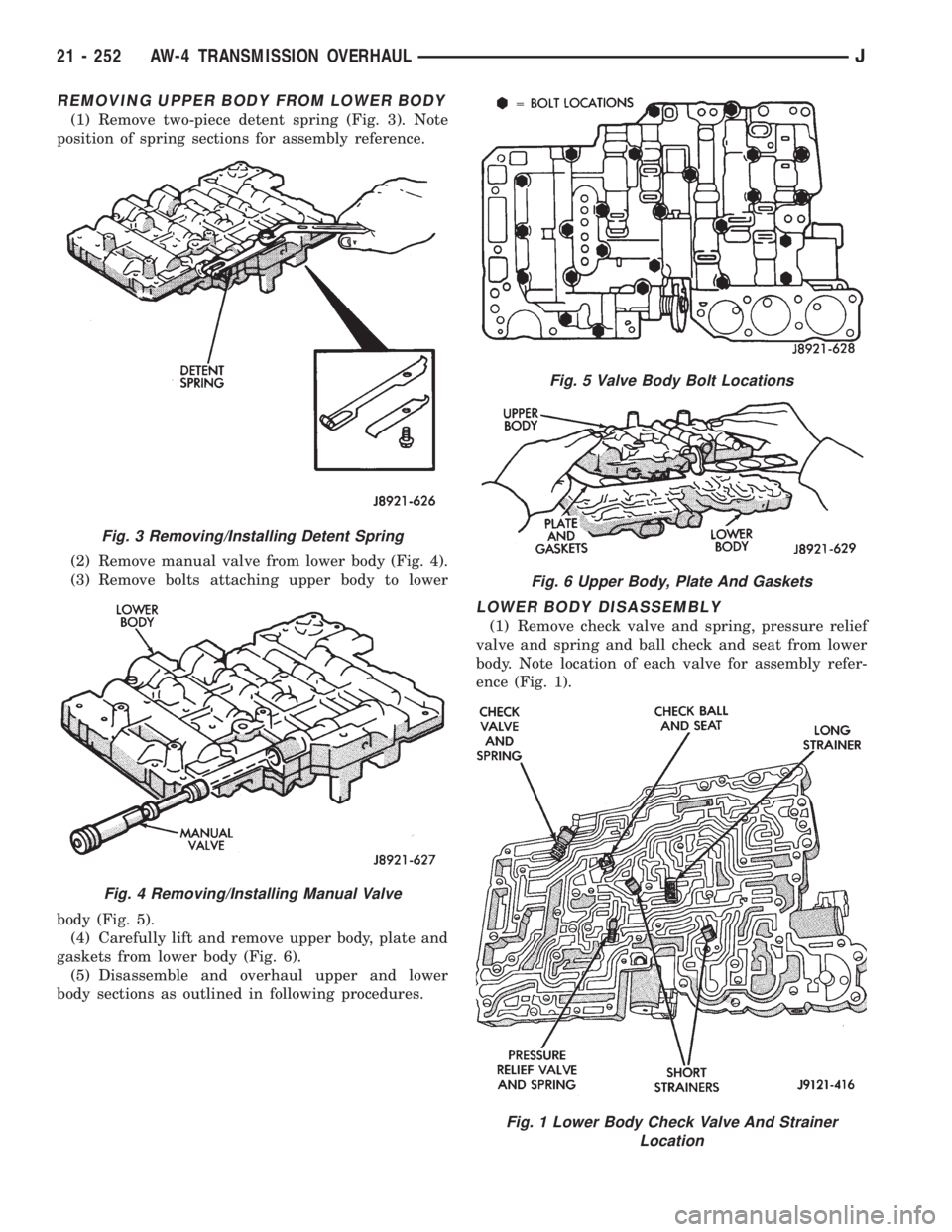

REMOVING UPPER BODY FROM LOWER BODY

(1) Remove two-piece detent spring (Fig. 3). Note

position of spring sections for assembly reference.

(2) Remove manual valve from lower body (Fig. 4).

(3) Remove bolts attaching upper body to lower

body (Fig. 5).

(4) Carefully lift and remove upper body, plate and

gaskets from lower body (Fig. 6).

(5) Disassemble and overhaul upper and lower

body sections as outlined in following procedures.

LOWER BODY DISASSEMBLY

(1) Remove check valve and spring, pressure relief

valve and spring and ball check and seat from lower

body. Note location of each valve for assembly refer-

ence (Fig. 1).

Fig. 3 Removing/Installing Detent Spring

Fig. 4 Removing/Installing Manual Valve

Fig. 5 Valve Body Bolt Locations

Fig. 6 Upper Body, Plate And Gaskets

Fig. 1 Lower Body Check Valve And Strainer

Location

21 - 252 AW-4 TRANSMISSION OVERHAULJ

Page 1825 of 2158

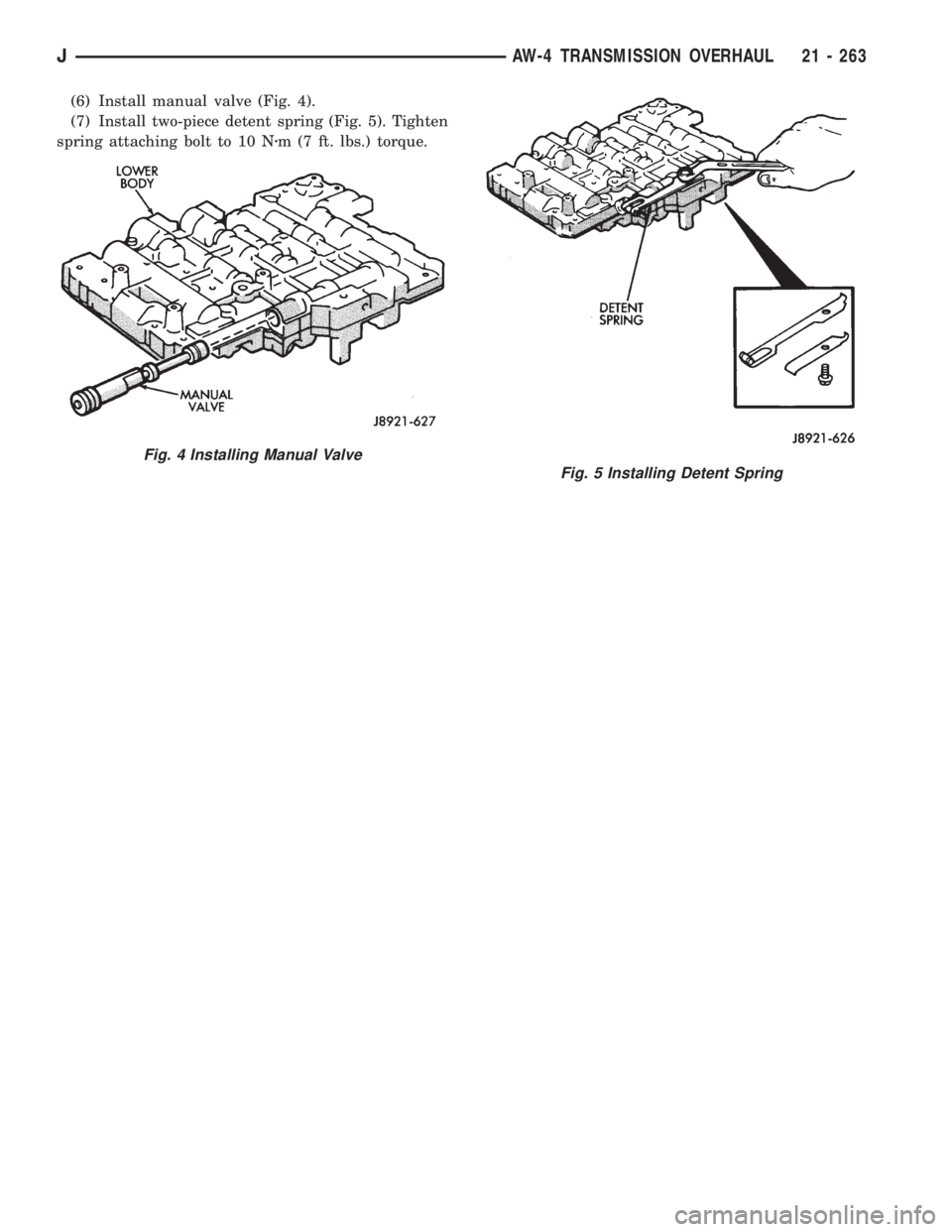

(6) Install manual valve (Fig. 4).

(7) Install two-piece detent spring (Fig. 5). Tighten

spring attaching bolt to 10 Nzm (7 ft. lbs.) torque.

Fig. 4 Installing Manual Valve

Fig. 5 Installing Detent Spring

JAW-4 TRANSMISSION OVERHAUL 21 - 263

Page 1829 of 2158

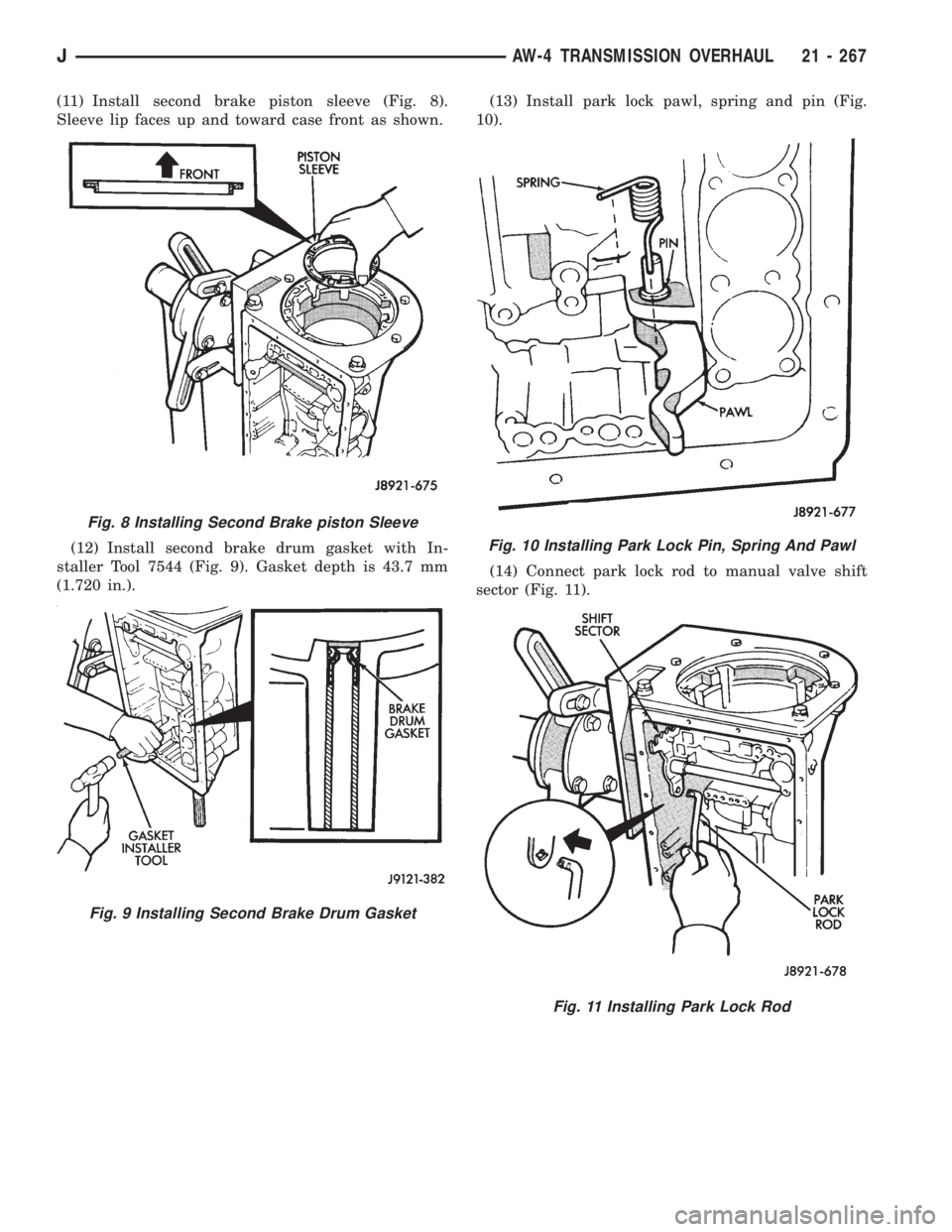

(11) Install second brake piston sleeve (Fig. 8).

Sleeve lip faces up and toward case front as shown.

(12) Install second brake drum gasket with In-

staller Tool 7544 (Fig. 9). Gasket depth is 43.7 mm

(1.720 in.).(13) Install park lock pawl, spring and pin (Fig.

10).

(14) Connect park lock rod to manual valve shift

sector (Fig. 11).

Fig. 8 Installing Second Brake piston Sleeve

Fig. 9 Installing Second Brake Drum Gasket

Fig. 10 Installing Park Lock Pin, Spring And Pawl

Fig. 11 Installing Park Lock Rod

JAW-4 TRANSMISSION OVERHAUL 21 - 267

Page 1841 of 2158

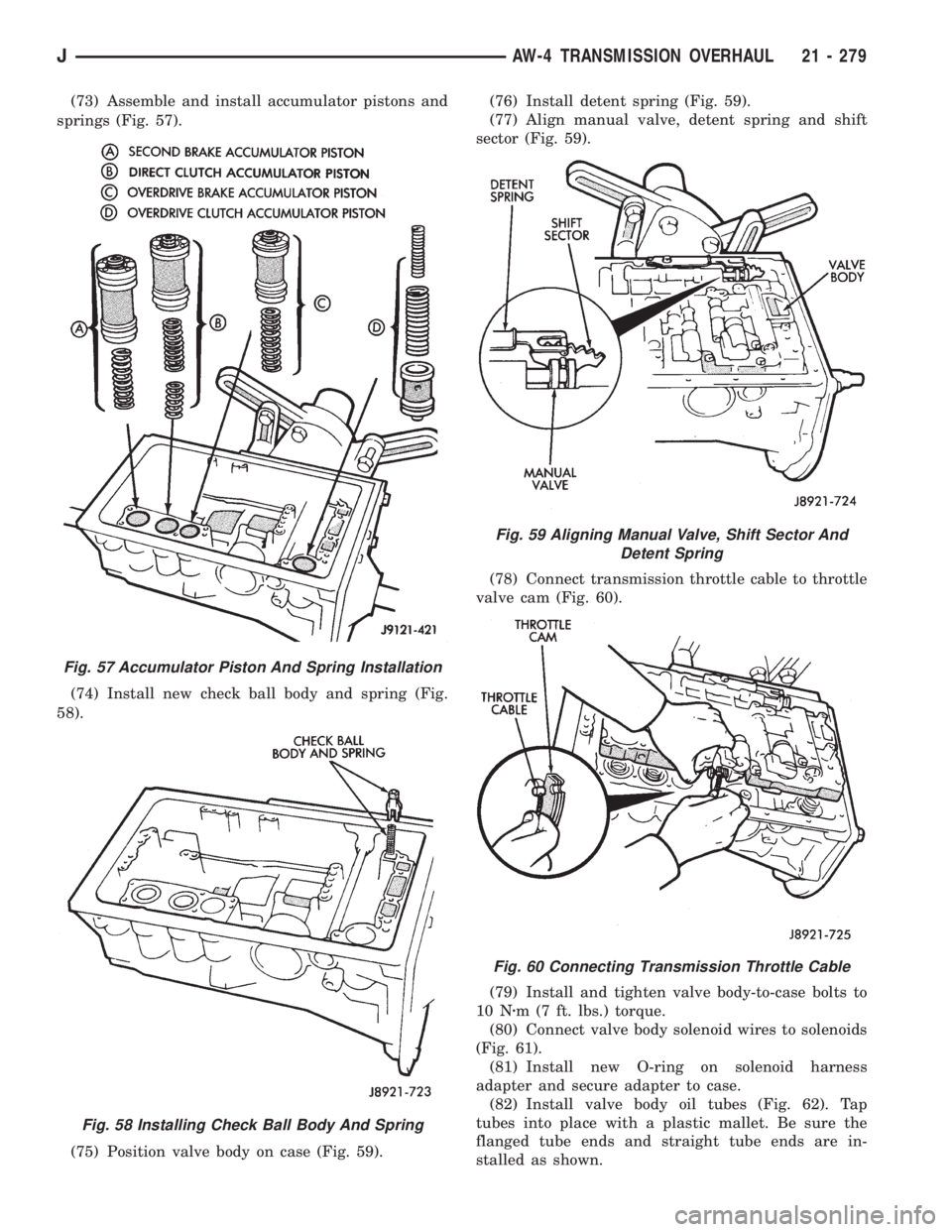

(73) Assemble and install accumulator pistons and

springs (Fig. 57).

(74) Install new check ball body and spring (Fig.

58).

(75) Position valve body on case (Fig. 59).(76) Install detent spring (Fig. 59).

(77) Align manual valve, detent spring and shift

sector (Fig. 59).

(78) Connect transmission throttle cable to throttle

valve cam (Fig. 60).

(79) Install and tighten valve body-to-case bolts to

10 Nzm (7 ft. lbs.) torque.

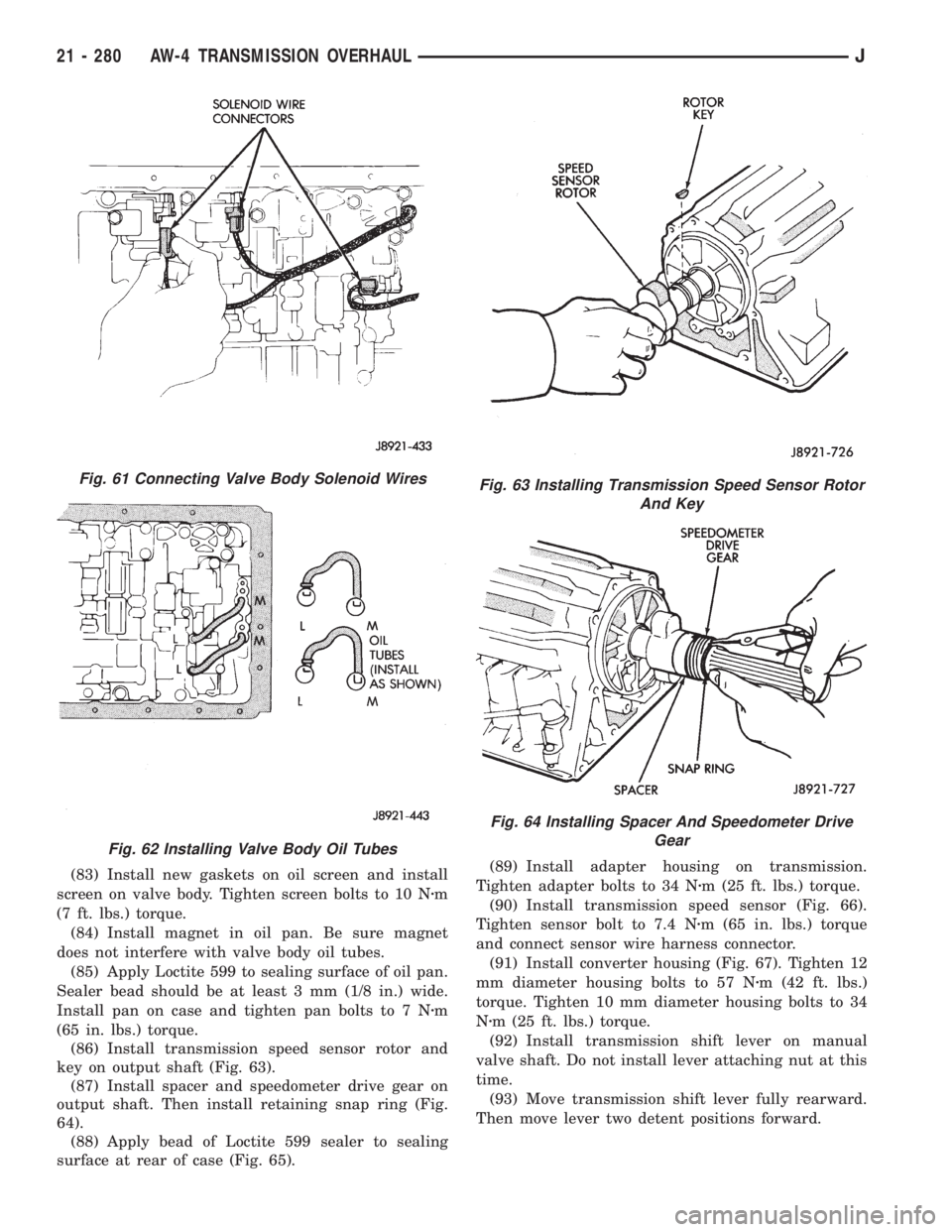

(80) Connect valve body solenoid wires to solenoids

(Fig. 61).

(81) Install new O-ring on solenoid harness

adapter and secure adapter to case.

(82) Install valve body oil tubes (Fig. 62). Tap

tubes into place with a plastic mallet. Be sure the

flanged tube ends and straight tube ends are in-

stalled as shown.

Fig. 57 Accumulator Piston And Spring Installation

Fig. 58 Installing Check Ball Body And Spring

Fig. 59 Aligning Manual Valve, Shift Sector And

Detent Spring

Fig. 60 Connecting Transmission Throttle Cable

JAW-4 TRANSMISSION OVERHAUL 21 - 279

Page 1842 of 2158

(83) Install new gaskets on oil screen and install

screen on valve body. Tighten screen bolts to 10 Nzm

(7 ft. lbs.) torque.

(84) Install magnet in oil pan. Be sure magnet

does not interfere with valve body oil tubes.

(85) Apply Loctite 599 to sealing surface of oil pan.

Sealer bead should be at least 3 mm (1/8 in.) wide.

Install pan on case and tighten pan bolts to 7 Nzm

(65 in. lbs.) torque.

(86) Install transmission speed sensor rotor and

key on output shaft (Fig. 63).

(87) Install spacer and speedometer drive gear on

output shaft. Then install retaining snap ring (Fig.

64).

(88) Apply bead of Loctite 599 sealer to sealing

surface at rear of case (Fig. 65).(89) Install adapter housing on transmission.

Tighten adapter bolts to 34 Nzm (25 ft. lbs.) torque.

(90) Install transmission speed sensor (Fig. 66).

Tighten sensor bolt to 7.4 Nzm (65 in. lbs.) torque

and connect sensor wire harness connector.

(91) Install converter housing (Fig. 67). Tighten 12

mm diameter housing bolts to 57 Nzm (42 ft. lbs.)

torque. Tighten 10 mm diameter housing bolts to 34

Nzm (25 ft. lbs.) torque.

(92) Install transmission shift lever on manual

valve shaft. Do not install lever attaching nut at this

time.

(93) Move transmission shift lever fully rearward.

Then move lever two detent positions forward.

Fig. 61 Connecting Valve Body Solenoid Wires

Fig. 62 Installing Valve Body Oil Tubes

Fig. 63 Installing Transmission Speed Sensor Rotor

And Key

Fig. 64 Installing Spacer And Speedometer Drive

Gear

21 - 280 AW-4 TRANSMISSION OVERHAULJ

Page 1843 of 2158

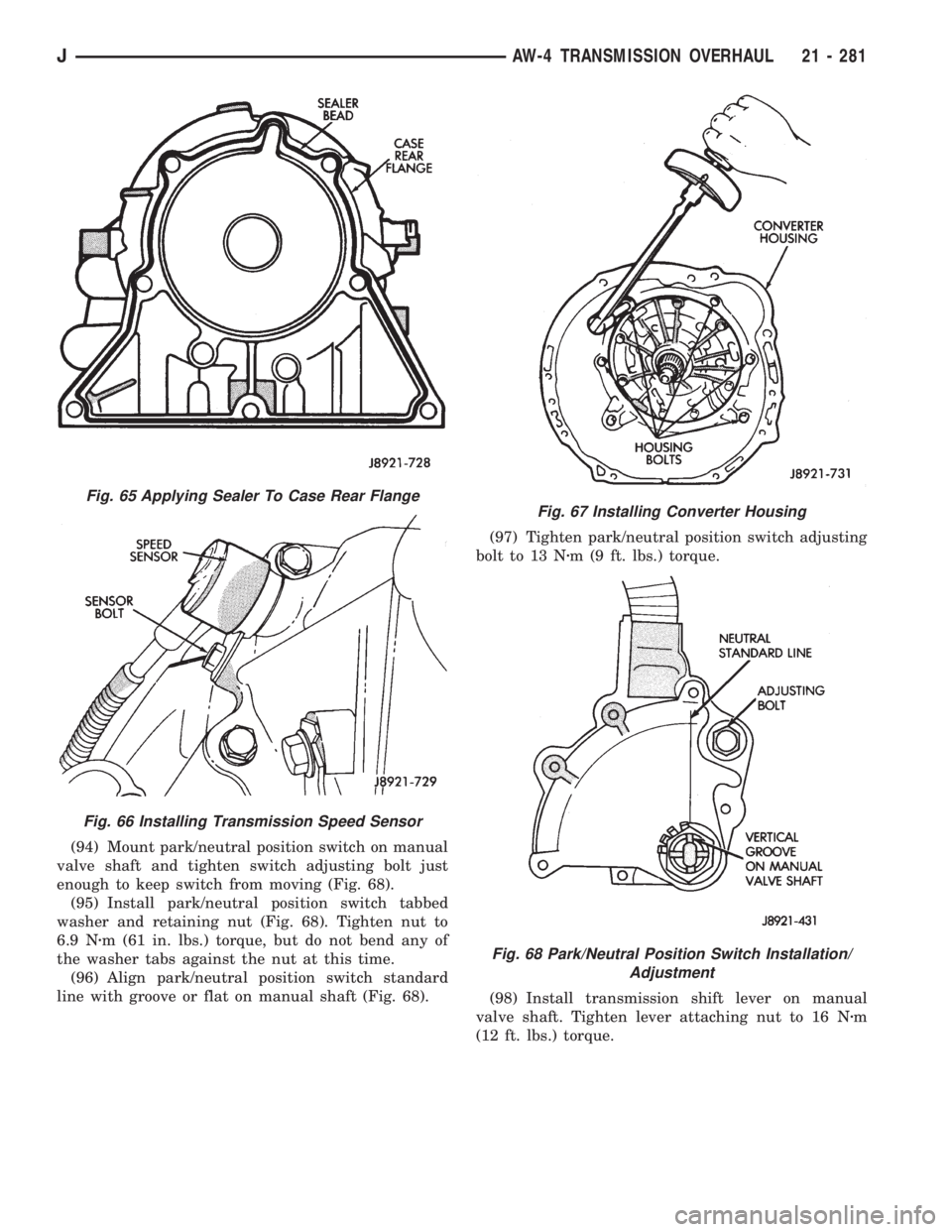

(94) Mount park/neutral position switch on manual

valve shaft and tighten switch adjusting bolt just

enough to keep switch from moving (Fig. 68).

(95) Install park/neutral position switch tabbed

washer and retaining nut (Fig. 68). Tighten nut to

6.9 Nzm (61 in. lbs.) torque, but do not bend any of

the washer tabs against the nut at this time.

(96) Align park/neutral position switch standard

line with groove or flat on manual shaft (Fig. 68).(97) Tighten park/neutral position switch adjusting

bolt to 13 Nzm (9 ft. lbs.) torque.

(98) Install transmission shift lever on manual

valve shaft. Tighten lever attaching nut to 16 Nzm

(12 ft. lbs.) torque.

Fig. 65 Applying Sealer To Case Rear Flange

Fig. 66 Installing Transmission Speed Sensor

Fig. 67 Installing Converter Housing

Fig. 68 Park/Neutral Position Switch Installation/

Adjustment

JAW-4 TRANSMISSION OVERHAUL 21 - 281