service schedule JEEP XJ 1995 Service And User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 52 of 2158

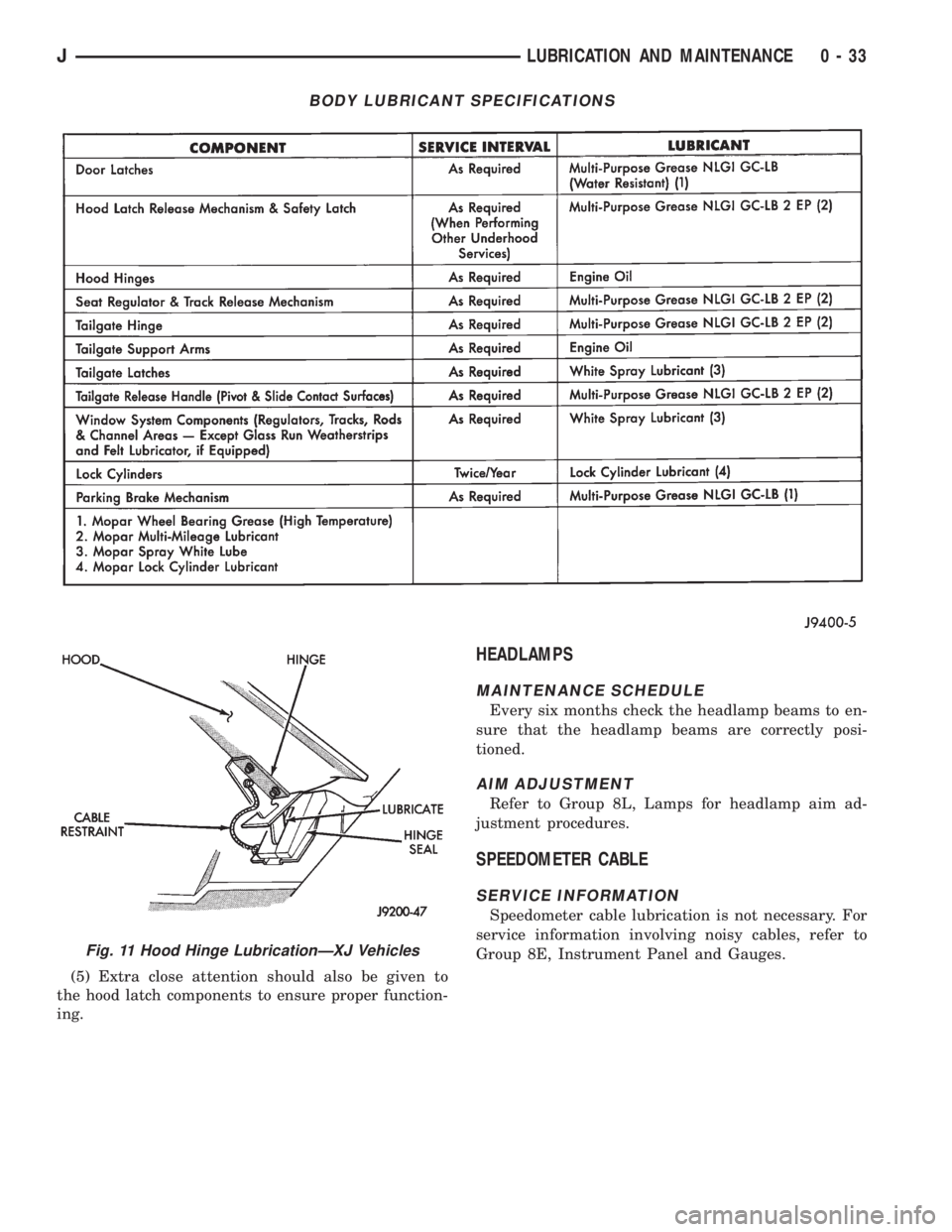

(5) Extra close attention should also be given to

the hood latch components to ensure proper function-

ing.

HEADLAMPS

MAINTENANCE SCHEDULE

Every six months check the headlamp beams to en-

sure that the headlamp beams are correctly posi-

tioned.

AIM ADJUSTMENT

Refer to Group 8L, Lamps for headlamp aim ad-

justment procedures.

SPEEDOMETER CABLE

SERVICE INFORMATION

Speedometer cable lubrication is not necessary. For

service information involving noisy cables, refer to

Group 8E, Instrument Panel and Gauges.

BODY LUBRICANT SPECIFICATIONS

Fig. 11 Hood Hinge LubricationÐXJ Vehicles

JLUBRICATION AND MAINTENANCE 0 - 33

Page 325 of 2158

IGNITION SYSTEMS

CONTENTS

page page

COMPONENT IDENTIFICATION/SYSTEM

OPERATION........................... 1

COMPONENT REMOVAL/INSTALLATION...... 17

DIAGNOSTICS/SERVICE PROCEDURES....... 6IGNITION SWITCHÐXJ MODELS........... 26

IGNITION SWITCHÐYJ MODELS........... 29

SPECIFICATIONS........................ 32

COMPONENT IDENTIFICATION/SYSTEM OPERATION

INDEX

page page

Automatic Shutdown (ASD) Relay.............. 1

Camshaft Position Sensor.................... 2

Crankshaft Position Sensor................... 3

Distributors............................... 4

Engine Coolant Temperature Sensor............ 5

General Information........................ 1Ignition Coil.............................. 4

Intake Manifold Air Temperature Sensor.......... 5

Manifold Absolute Pressure (MAP) Sensor........ 5

Oxygen (O2S) Sensor....................... 5

Powertrain Control Module (PCM).............. 5

Throttle Position Sensor..................... 5

GENERAL INFORMATION

Throughout this group, references are made to par-

ticular vehicle models by alphabetical designation

(XJ or YJ) or by the particular vehicle nameplate. A

chart showing a breakdown of alphabetical designa-

tions is included in the Introduction group at the be-

ginning of this manual.

This section of the group, Component Identifica-

tion/System Operation, will discuss ignition system

operation and will identify ignition system compo-

nents.

For diagnostic procedures and adjustments, refer to

the Diagnostics/Service Procedures section of this

group.

For removal and installation of ignition system

components, refer to the Component Removal/Instal-

lation section of this group.

For other useful information, refer to On-Board Di-

agnostics in the General Diagnosis sections of Group

14, Fuel System in this manual.

For operation of the DRB Scan Tool, refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice manual.

An Ignition specifications section is included at the

end of this group. A general Maintenance Schedule

(mileage intervals) for ignition related items can be

found in Group 0, Lubrication and Maintenance. This

schedule can also be found in the Owners Manual.

IGNITION SYSTEMS

A multi-port, fuel injected engine is used on all

models. The ignition system is controlled by the pow-

ertrain control module (PCM) on all engines. The

PCM was formerly referred to as the SBEC or engine

controller.

The ignition system consists of:

²Spark plugs

²Ignition coil

²Secondary ignition cables

²Distributor (contains rotor and camshaft position

sensor)

²Powertrain control module (PCM)

²Crankshaft position sensor

AUTOMATIC SHUTDOWN (ASD) RELAY

The automatic shutdown (ASD) relay is located in

the power distribution center (PDC) near the battery

(Fig. 1 or 2). As one of its functions, it will supply

battery voltage to the ignition coil.

The ground circuit for the ASD relay is controlled

by the powertrain control module (PCM). This is

done through pin/cavity number 51 of the PCM 60-

way connector. The PCM then regulates ASD relay

operation by switching this ground circuit on-and-off.

Also refer to Ignition Coil for additional informa-

tion.

JIGNITION SYSTEMS 8D - 1

Page 1304 of 2158

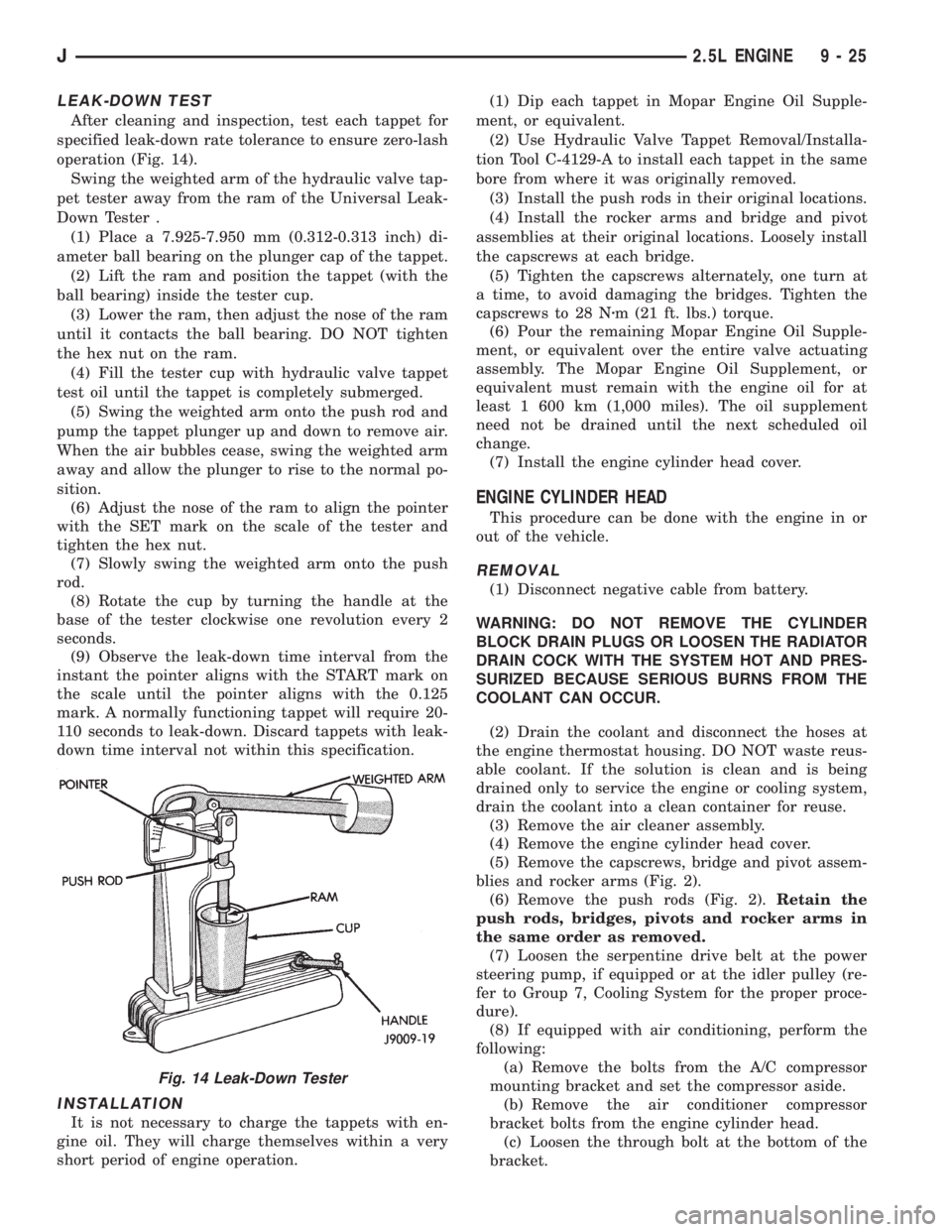

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 14).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester .

(1) Place a 7.925-7.950 mm (0.312-0.313 inch) di-

ameter ball bearing on the plunger cap of the tappet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal po-

sition.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require 20-

110 seconds to leak-down. Discard tappets with leak-

down time interval not within this specification.

INSTALLATION

It is not necessary to charge the tappets with en-

gine oil. They will charge themselves within a very

short period of engine operation.(1) Dip each tappet in Mopar Engine Oil Supple-

ment, or equivalent.

(2) Use Hydraulic Valve Tappet Removal/Installa-

tion Tool C-4129-A to install each tappet in the same

bore from where it was originally removed.

(3) Install the push rods in their original locations.

(4) Install the rocker arms and bridge and pivot

assemblies at their original locations. Loosely install

the capscrews at each bridge.

(5) Tighten the capscrews alternately, one turn at

a time, to avoid damaging the bridges. Tighten the

capscrews to 28 Nzm (21 ft. lbs.) torque.

(6) Pour the remaining Mopar Engine Oil Supple-

ment, or equivalent over the entire valve actuating

assembly. The Mopar Engine Oil Supplement, or

equivalent must remain with the engine oil for at

least 1 600 km (1,000 miles). The oil supplement

need not be drained until the next scheduled oil

change.

(7) Install the engine cylinder head cover.

ENGINE CYLINDER HEAD

This procedure can be done with the engine in or

out of the vehicle.

REMOVAL

(1) Disconnect negative cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.

(2) Drain the coolant and disconnect the hoses at

the engine thermostat housing. DO NOT waste reus-

able coolant. If the solution is clean and is being

drained only to service the engine or cooling system,

drain the coolant into a clean container for reuse.

(3) Remove the air cleaner assembly.

(4) Remove the engine cylinder head cover.

(5) Remove the capscrews, bridge and pivot assem-

blies and rocker arms (Fig. 2).

(6) Remove the push rods (Fig. 2).Retain the

push rods, bridges, pivots and rocker arms in

the same order as removed.

(7) Loosen the serpentine drive belt at the power

steering pump, if equipped or at the idler pulley (re-

fer to Group 7, Cooling System for the proper proce-

dure).

(8) If equipped with air conditioning, perform the

following:

(a) Remove the bolts from the A/C compressor

mounting bracket and set the compressor aside.

(b) Remove the air conditioner compressor

bracket bolts from the engine cylinder head.

(c) Loosen the through bolt at the bottom of the

bracket.

Fig. 14 Leak-Down Tester

J2.5L ENGINE 9 - 25

Page 1346 of 2158

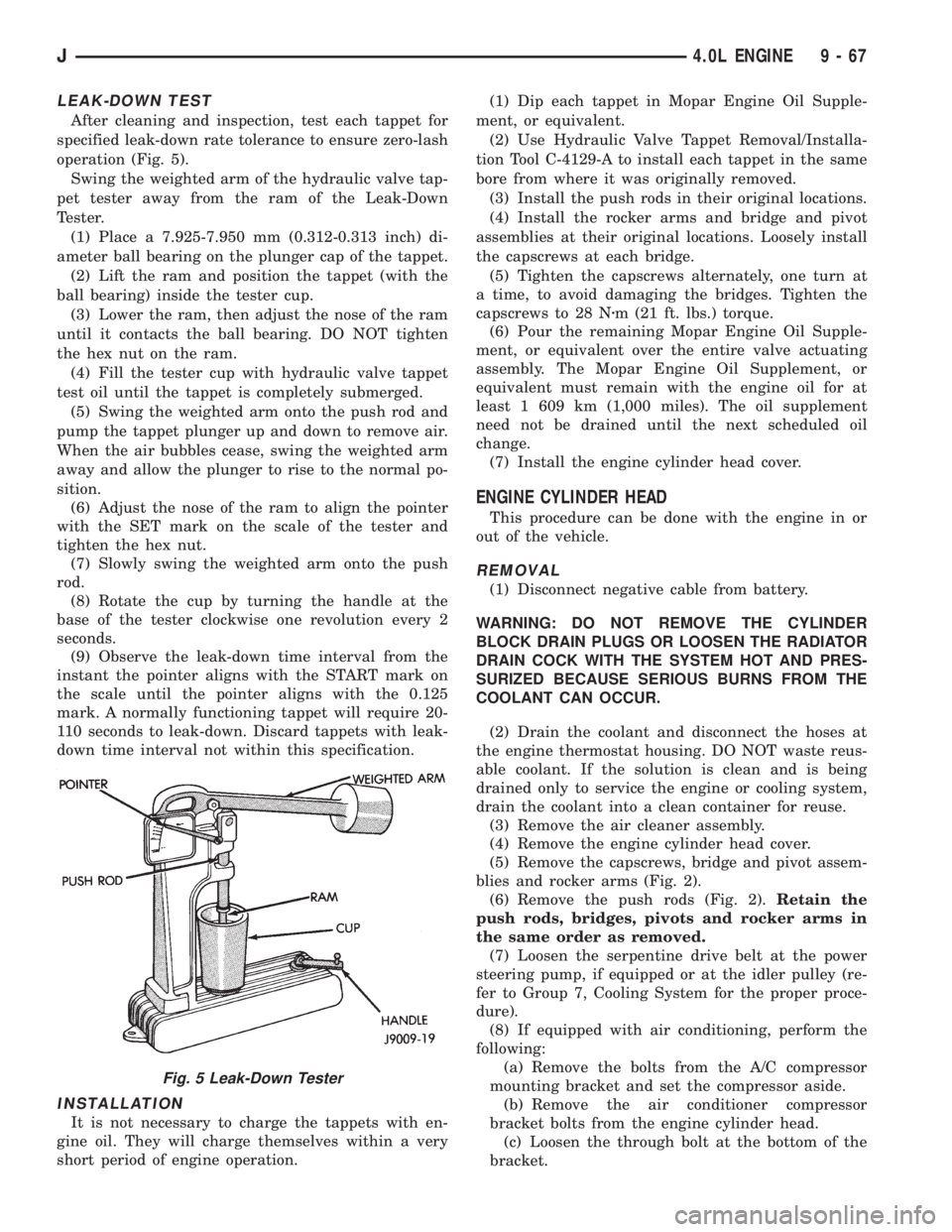

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 5).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Leak-Down

Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch) di-

ameter ball bearing on the plunger cap of the tappet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal po-

sition.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require 20-

110 seconds to leak-down. Discard tappets with leak-

down time interval not within this specification.

INSTALLATION

It is not necessary to charge the tappets with en-

gine oil. They will charge themselves within a very

short period of engine operation.(1) Dip each tappet in Mopar Engine Oil Supple-

ment, or equivalent.

(2) Use Hydraulic Valve Tappet Removal/Installa-

tion Tool C-4129-A to install each tappet in the same

bore from where it was originally removed.

(3) Install the push rods in their original locations.

(4) Install the rocker arms and bridge and pivot

assemblies at their original locations. Loosely install

the capscrews at each bridge.

(5) Tighten the capscrews alternately, one turn at

a time, to avoid damaging the bridges. Tighten the

capscrews to 28 Nzm (21 ft. lbs.) torque.

(6) Pour the remaining Mopar Engine Oil Supple-

ment, or equivalent over the entire valve actuating

assembly. The Mopar Engine Oil Supplement, or

equivalent must remain with the engine oil for at

least 1 609 km (1,000 miles). The oil supplement

need not be drained until the next scheduled oil

change.

(7) Install the engine cylinder head cover.

ENGINE CYLINDER HEAD

This procedure can be done with the engine in or

out of the vehicle.

REMOVAL

(1) Disconnect negative cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.

(2) Drain the coolant and disconnect the hoses at

the engine thermostat housing. DO NOT waste reus-

able coolant. If the solution is clean and is being

drained only to service the engine or cooling system,

drain the coolant into a clean container for reuse.

(3) Remove the air cleaner assembly.

(4) Remove the engine cylinder head cover.

(5) Remove the capscrews, bridge and pivot assem-

blies and rocker arms (Fig. 2).

(6) Remove the push rods (Fig. 2).Retain the

push rods, bridges, pivots and rocker arms in

the same order as removed.

(7) Loosen the serpentine drive belt at the power

steering pump, if equipped or at the idler pulley (re-

fer to Group 7, Cooling System for the proper proce-

dure).

(8) If equipped with air conditioning, perform the

following:

(a) Remove the bolts from the A/C compressor

mounting bracket and set the compressor aside.

(b) Remove the air conditioner compressor

bracket bolts from the engine cylinder head.

(c) Loosen the through bolt at the bottom of the

bracket.

Fig. 5 Leak-Down Tester

J4.0L ENGINE 9 - 67

Page 1354 of 2158

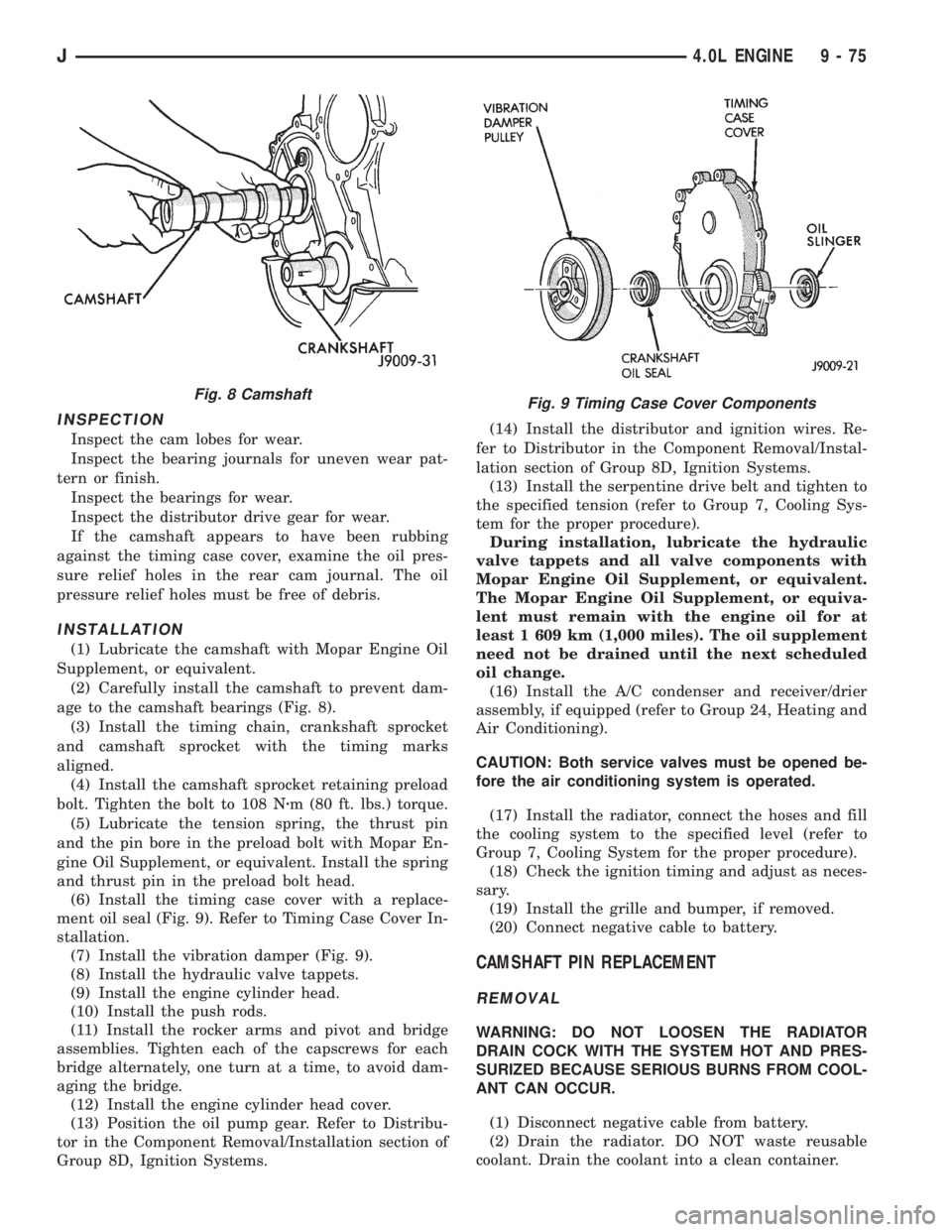

INSPECTION

Inspect the cam lobes for wear.

Inspect the bearing journals for uneven wear pat-

tern or finish.

Inspect the bearings for wear.

Inspect the distributor drive gear for wear.

If the camshaft appears to have been rubbing

against the timing case cover, examine the oil pres-

sure relief holes in the rear cam journal. The oil

pressure relief holes must be free of debris.

INSTALLATION

(1) Lubricate the camshaft with Mopar Engine Oil

Supplement, or equivalent.

(2) Carefully install the camshaft to prevent dam-

age to the camshaft bearings (Fig. 8).

(3) Install the timing chain, crankshaft sprocket

and camshaft sprocket with the timing marks

aligned.

(4) Install the camshaft sprocket retaining preload

bolt. Tighten the bolt to 108 Nzm (80 ft. lbs.) torque.

(5) Lubricate the tension spring, the thrust pin

and the pin bore in the preload bolt with Mopar En-

gine Oil Supplement, or equivalent. Install the spring

and thrust pin in the preload bolt head.

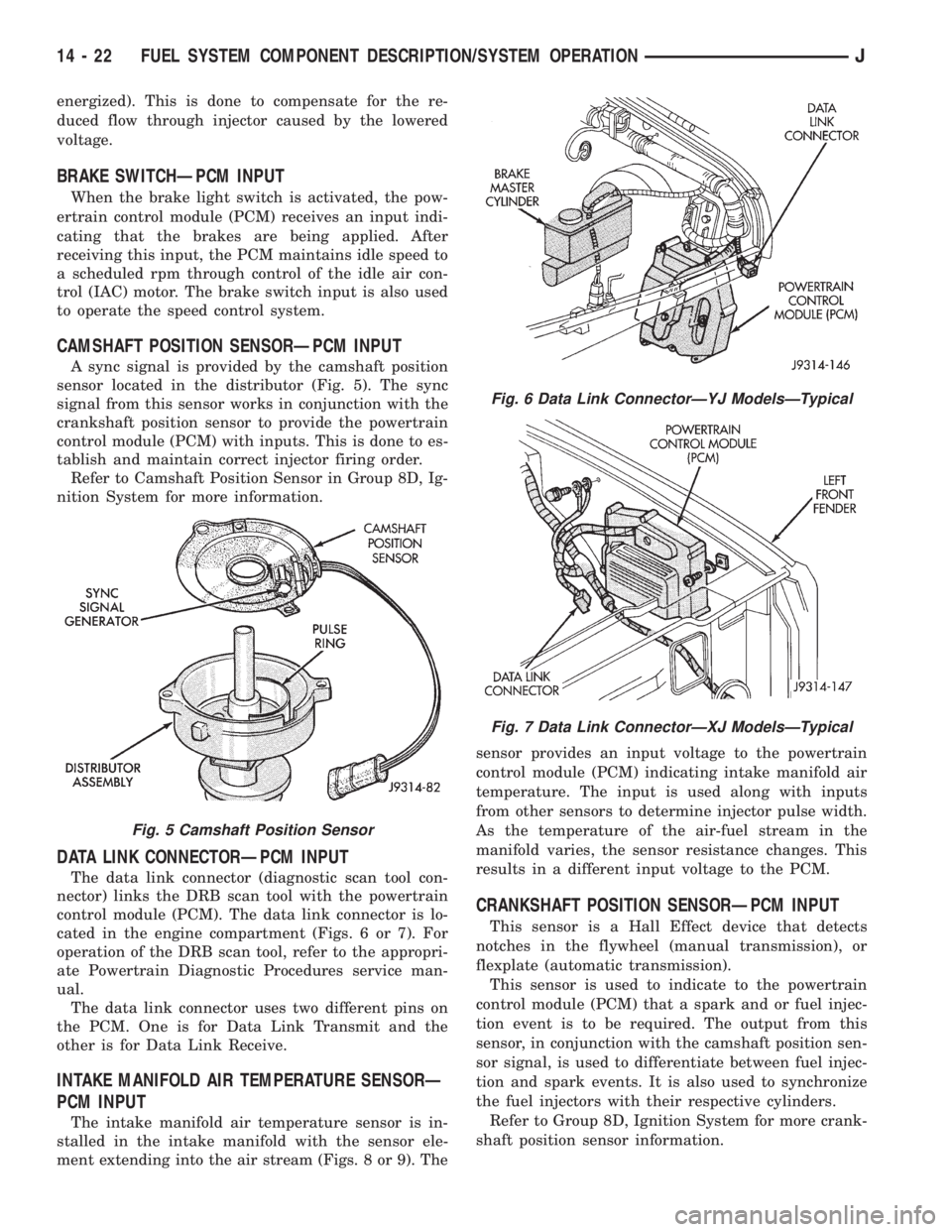

(6) Install the timing case cover with a replace-

ment oil seal (Fig. 9). Refer to Timing Case Cover In-

stallation.

(7) Install the vibration damper (Fig. 9).

(8) Install the hydraulic valve tappets.

(9) Install the engine cylinder head.

(10) Install the push rods.

(11) Install the rocker arms and pivot and bridge

assemblies. Tighten each of the capscrews for each

bridge alternately, one turn at a time, to avoid dam-

aging the bridge.

(12) Install the engine cylinder head cover.

(13) Position the oil pump gear. Refer to Distribu-

tor in the Component Removal/Installation section of

Group 8D, Ignition Systems.(14) Install the distributor and ignition wires. Re-

fer to Distributor in the Component Removal/Instal-

lation section of Group 8D, Ignition Systems.

(13) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tem for the proper procedure).

During installation, lubricate the hydraulic

valve tappets and all valve components with

Mopar Engine Oil Supplement, or equivalent.

The Mopar Engine Oil Supplement, or equiva-

lent must remain with the engine oil for at

least 1 609 km (1,000 miles). The oil supplement

need not be drained until the next scheduled

oil change.

(16) Install the A/C condenser and receiver/drier

assembly, if equipped (refer to Group 24, Heating and

Air Conditioning).

CAUTION: Both service valves must be opened be-

fore the air conditioning system is operated.

(17) Install the radiator, connect the hoses and fill

the cooling system to the specified level (refer to

Group 7, Cooling System for the proper procedure).

(18) Check the ignition timing and adjust as neces-

sary.

(19) Install the grille and bumper, if removed.

(20) Connect negative cable to battery.

CAMSHAFT PIN REPLACEMENT

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM COOL-

ANT CAN OCCUR.

(1) Disconnect negative cable from battery.

(2) Drain the radiator. DO NOT waste reusable

coolant. Drain the coolant into a clean container.

Fig. 9 Timing Case Cover ComponentsFig. 8 Camshaft

J4.0L ENGINE 9 - 75

Page 1424 of 2158

energized). This is done to compensate for the re-

duced flow through injector caused by the lowered

voltage.

BRAKE SWITCHÐPCM INPUT

When the brake light switch is activated, the pow-

ertrain control module (PCM) receives an input indi-

cating that the brakes are being applied. After

receiving this input, the PCM maintains idle speed to

a scheduled rpm through control of the idle air con-

trol (IAC) motor. The brake switch input is also used

to operate the speed control system.

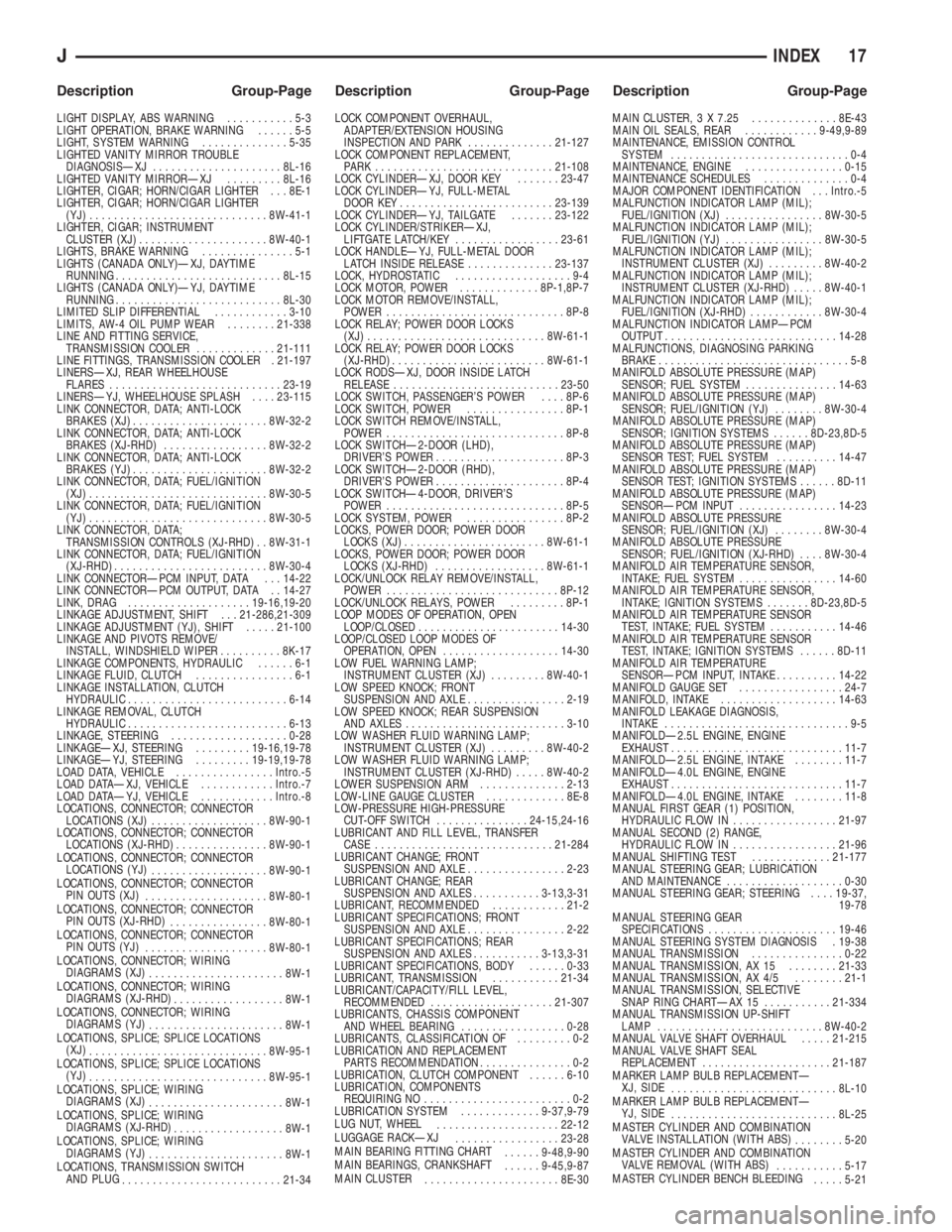

CAMSHAFT POSITION SENSORÐPCM INPUT

A sync signal is provided by the camshaft position

sensor located in the distributor (Fig. 5). The sync

signal from this sensor works in conjunction with the

crankshaft position sensor to provide the powertrain

control module (PCM) with inputs. This is done to es-

tablish and maintain correct injector firing order.

Refer to Camshaft Position Sensor in Group 8D, Ig-

nition System for more information.

DATA LINK CONNECTORÐPCM INPUT

The data link connector (diagnostic scan tool con-

nector) links the DRB scan tool with the powertrain

control module (PCM). The data link connector is lo-

cated in the engine compartment (Figs. 6 or 7). For

operation of the DRB scan tool, refer to the appropri-

ate Powertrain Diagnostic Procedures service man-

ual.

The data link connector uses two different pins on

the PCM. One is for Data Link Transmit and the

other is for Data Link Receive.

INTAKE MANIFOLD AIR TEMPERATURE SENSORÐ

PCM INPUT

The intake manifold air temperature sensor is in-

stalled in the intake manifold with the sensor ele-

ment extending into the air stream (Figs. 8 or 9). Thesensor provides an input voltage to the powertrain

control module (PCM) indicating intake manifold air

temperature. The input is used along with inputs

from other sensors to determine injector pulse width.

As the temperature of the air-fuel stream in the

manifold varies, the sensor resistance changes. This

results in a different input voltage to the PCM.

CRANKSHAFT POSITION SENSORÐPCM INPUT

This sensor is a Hall Effect device that detects

notches in the flywheel (manual transmission), or

flexplate (automatic transmission).

This sensor is used to indicate to the powertrain

control module (PCM) that a spark and or fuel injec-

tion event is to be required. The output from this

sensor, in conjunction with the camshaft position sen-

sor signal, is used to differentiate between fuel injec-

tion and spark events. It is also used to synchronize

the fuel injectors with their respective cylinders.

Refer to Group 8D, Ignition System for more crank-

shaft position sensor information.

Fig. 5 Camshaft Position Sensor

Fig. 6 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 7 Data Link ConnectorÐXJ ModelsÐTypical

14 - 22 FUEL SYSTEM COMPONENT DESCRIPTION/SYSTEM OPERATIONJ

Page 2141 of 2158

LIGHT DISPLAY, ABS WARNING...........5-3

LIGHT OPERATION, BRAKE WARNING......5-5

LIGHT, SYSTEM WARNING..............5-35

LIGHTED VANITY MIRROR TROUBLE

DIAGNOSISÐXJ.....................8L-16

LIGHTED VANITY MIRRORÐXJ.........8L-16

LIGHTER, CIGAR; HORN/CIGAR LIGHTER . . . 8E-1

LIGHTER, CIGAR; HORN/CIGAR LIGHTER

(YJ).............................8W-41-1

LIGHTER, CIGAR; INSTRUMENT

CLUSTER (XJ).....................8W-40-1

LIGHTS, BRAKE WARNING...............5-1

LIGHTS (CANADA ONLY)ÐXJ, DAYTIME

RUNNING...........................8L-15

LIGHTS (CANADA ONLY)ÐYJ, DAYTIME

RUNNING...........................8L-30

LIMITED SLIP DIFFERENTIAL............3-10

LIMITS, AW-4 OIL PUMP WEAR........21-338

LINE AND FITTING SERVICE,

TRANSMISSION COOLER.............21-111

LINE FITTINGS, TRANSMISSION COOLER . 21-197

LINERSÐXJ, REAR WHEELHOUSE

FLARES............................23-19

LINERSÐYJ, WHEELHOUSE SPLASH....23-115

LINK CONNECTOR, DATA; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

LINK CONNECTOR, DATA; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

LINK CONNECTOR, DATA; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

LINK CONNECTOR, DATA; FUEL/IGNITION

(XJ).............................8W-30-5

LINK CONNECTOR, DATA; FUEL/IGNITION

(YJ).............................8W-30-5

LINK CONNECTOR, DATA;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

LINK CONNECTOR, DATA; FUEL/IGNITION

(XJ-RHD).........................8W-30-4

LINK CONNECTORÐPCM INPUT, DATA . . . 14-22

LINK CONNECTORÐPCM OUTPUT, DATA . . 14-27

LINK, DRAG....................19-16,19-20

LINKAGE ADJUSTMENT, SHIFT . . . 21-286,21-309

LINKAGE ADJUSTMENT (YJ), SHIFT.....21-100

LINKAGE AND PIVOTS REMOVE/

INSTALL, WINDSHIELD WIPER..........8K-17

LINKAGE COMPONENTS, HYDRAULIC......6-1

LINKAGE FLUID, CLUTCH................6-1

LINKAGE INSTALLATION, CLUTCH

HYDRAULIC..........................6-14

LINKAGE REMOVAL, CLUTCH

HYDRAULIC..........................6-13

LINKAGE, STEERING...................0-28

LINKAGEÐXJ, STEERING.........19-16,19-78

LINKAGEÐYJ, STEERING.........19-19,19-78

LOAD DATA, VEHICLE................Intro.-5

LOAD DATAÐXJ, VEHICLE............Intro.-7

LOAD DATAÐYJ, VEHICLE............Intro.-8

LOCATIONS, CONNECTOR; CONNECTOR

LOCATIONS (XJ)...................8W-90-1

LOCATIONS, CONNECTOR; CONNECTOR

LOCATIONS (XJ-RHD)...............8W-90-1

LOCATIONS, CONNECTOR; CONNECTOR

LOCATIONS (YJ)

...................8W-90-1

LOCATIONS, CONNECTOR; CONNECTOR

PIN OUTS (XJ)

....................8W-80-1

LOCATIONS, CONNECTOR; CONNECTOR

PIN OUTS (XJ-RHD)

................8W-80-1

LOCATIONS, CONNECTOR; CONNECTOR

PIN OUTS (YJ)

....................8W-80-1

LOCATIONS, CONNECTOR; WIRING

DIAGRAMS (XJ)

......................8W-1

LOCATIONS, CONNECTOR; WIRING

DIAGRAMS (XJ-RHD)

..................8W-1

LOCATIONS, CONNECTOR; WIRING

DIAGRAMS (YJ)

......................8W-1

LOCATIONS, SPLICE; SPLICE LOCATIONS

(XJ)

.............................8W-95-1

LOCATIONS, SPLICE; SPLICE LOCATIONS

(YJ)

.............................8W-95-1

LOCATIONS, SPLICE; WIRING

DIAGRAMS (XJ)

......................8W-1

LOCATIONS, SPLICE; WIRING

DIAGRAMS (XJ-RHD)

..................8W-1

LOCATIONS, SPLICE; WIRING

DIAGRAMS (YJ)

......................8W-1

LOCATIONS, TRANSMISSION SWITCH

AND PLUG

..........................21-34LOCK COMPONENT OVERHAUL,

ADAPTER/EXTENSION HOUSING

INSPECTION AND PARK..............21-127

LOCK COMPONENT REPLACEMENT,

PARK .............................21-108

LOCK CYLINDERÐXJ, DOOR KEY.......23-47

LOCK CYLINDERÐYJ, FULL-METAL

DOOR KEY.........................23-139

LOCK CYLINDERÐYJ, TAILGATE.......23-122

LOCK CYLINDER/STRIKERÐXJ,

LIFTGATE LATCH/KEY.................23-61

LOCK HANDLEÐYJ, FULL-METAL DOOR

LATCH INSIDE RELEASE..............23-137

LOCK, HYDROSTATIC...................9-4

LOCK MOTOR, POWER.............8P-1,8P-7

LOCK MOTOR REMOVE/INSTALL,

POWER.............................8P-8

LOCK RELAY; POWER DOOR LOCKS

(XJ).............................8W-61-1

LOCK RELAY; POWER DOOR LOCKS

(XJ-RHD).........................8W-61-1

LOCK RODSÐXJ, DOOR INSIDE LATCH

RELEASE...........................23-50

LOCK SWITCH, PASSENGER'S POWER....8P-6

LOCK SWITCH, POWER................8P-1

LOCK SWITCH REMOVE/INSTALL,

POWER.............................8P-8

LOCK SWITCHÐ2-DOOR (LHD),

DRIVER'S POWER.....................8P-3

LOCK SWITCHÐ2-DOOR (RHD),

DRIVER'S POWER.....................8P-4

LOCK SWITCHÐ4-DOOR, DRIVER'S

POWER.............................8P-5

LOCK SYSTEM, POWER................8P-2

LOCKS, POWER DOOR; POWER DOOR

LOCKS (XJ).......................8W-61-1

LOCKS, POWER DOOR; POWER DOOR

LOCKS (XJ-RHD)..................8W-61-1

LOCK/UNLOCK RELAY REMOVE/INSTALL,

POWER............................8P-12

LOCK/UNLOCK RELAYS, POWER.........8P-1

LOOP MODES OF OPERATION, OPEN

LOOP/CLOSED.......................14-30

LOOP/CLOSED LOOP MODES OF

OPERATION, OPEN...................14-30

LOW FUEL WARNING LAMP;

INSTRUMENT CLUSTER (XJ).........8W-40-1

LOW SPEED KNOCK; FRONT

SUSPENSION AND AXLE................2-19

LOW SPEED KNOCK; REAR SUSPENSION

AND AXLES..........................3-10

LOW WASHER FLUID WARNING LAMP;

INSTRUMENT CLUSTER (XJ).........8W-40-2

LOW WASHER FLUID WARNING LAMP;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

LOWER SUSPENSION ARM..............2-13

LOW-LINE GAUGE CLUSTER.............8E-8

LOW-PRESSURE HIGH-PRESSURE

CUT-OFF SWITCH...............24-15,24-16

LUBRICANT AND FILL LEVEL, TRANSFER

CASE.............................21-284

LUBRICANT CHANGE; FRONT

SUSPENSION AND AXLE................2-23

LUBRICANT CHANGE; REAR

SUSPENSION AND AXLES...........3-13,3-31

LUBRICANT, RECOMMENDED............21-2

LUBRICANT SPECIFICATIONS; FRONT

SUSPENSION AND AXLE................2-22

LUBRICANT SPECIFICATIONS; REAR

SUSPENSION AND AXLES...........3-13,3-31

LUBRICANT SPECIFICATIONS, BODY......0-33

LUBRICANT, TRANSMISSION...........21-34

LUBRICANT/CAPACITY/FILL LEVEL,

RECOMMENDED....................21-307

LUBRICANTS, CHASSIS COMPONENT

AND WHEEL BEARING.................0-28

LUBRICANTS, CLASSIFICATION OF.........0-2

LUBRICATION AND REPLACEMENT

PARTS RECOMMENDATION...............0-2

LUBRICATION, CLUTCH COMPONENT......6-10

LUBRICATION, COMPONENTS

REQUIRING NO........................0-2

LUBRICATION SYSTEM.............9-37,9-79

LUG NUT, WHEEL

....................22-12

LUGGAGE RACKÐXJ

.................23-28

MAIN BEARING FITTING CHART

......9-48,9-90

MAIN BEARINGS, CRANKSHAFT

......9-45,9-87

MAIN CLUSTER

......................8E-30MAIN CLUSTER, 3 X 7.25..............8E-43

MAIN OIL SEALS, REAR............9-49,9-89

MAINTENANCE, EMISSION CONTROL

SYSTEM.............................0-4

MAINTENANCE, ENGINE................0-15

MAINTENANCE SCHEDULES..............0-4

MAJOR COMPONENT IDENTIFICATION . . . Intro.-5

MALFUNCTION INDICATOR LAMP (MIL);

FUEL/IGNITION (XJ)................8W-30-5

MALFUNCTION INDICATOR LAMP (MIL);

FUEL/IGNITION (YJ)................8W-30-5

MALFUNCTION INDICATOR LAMP (MIL);

INSTRUMENT CLUSTER (XJ).........8W-40-2

MALFUNCTION INDICATOR LAMP (MIL);

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-1

MALFUNCTION INDICATOR LAMP (MIL);

FUEL/IGNITION (XJ-RHD)............8W-30-4

MALFUNCTION INDICATOR LAMPÐPCM

OUTPUT............................14-28

MALFUNCTIONS, DIAGNOSING PARKING

BRAKE...............................5-8

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR; FUEL SYSTEM...............14-63

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR; FUEL/IGNITION (YJ)........8W-30-4

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR; IGNITION SYSTEMS......8D-23,8D-5

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR TEST; FUEL SYSTEM..........14-47

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR TEST; IGNITION SYSTEMS......8D-11

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT................14-23

MANIFOLD ABSOLUTE PRESSURE

SENSOR; FUEL/IGNITION (XJ)........8W-30-4

MANIFOLD ABSOLUTE PRESSURE

SENSOR; FUEL/IGNITION (XJ-RHD)....8W-30-4

MANIFOLD AIR TEMPERATURE SENSOR,

INTAKE; FUEL SYSTEM................14-60

MANIFOLD AIR TEMPERATURE SENSOR,

INTAKE; IGNITION SYSTEMS.......8D-23,8D-5

MANIFOLD AIR TEMPERATURE SENSOR

TEST, INTAKE; FUEL SYSTEM...........14-46

MANIFOLD AIR TEMPERATURE SENSOR

TEST, INTAKE; IGNITION SYSTEMS......8D-11

MANIFOLD AIR TEMPERATURE

SENSORÐPCM INPUT, INTAKE..........14-22

MANIFOLD GAUGE SET.................24-7

MANIFOLD, INTAKE...................14-63

MANIFOLD LEAKAGE DIAGNOSIS,

INTAKE ..............................9-5

MANIFOLDÐ2.5L ENGINE, ENGINE

EXHAUST............................11-7

MANIFOLDÐ2.5L ENGINE, INTAKE........11-7

MANIFOLDÐ4.0L ENGINE, ENGINE

EXHAUST............................11-7

MANIFOLDÐ4.0L ENGINE, INTAKE........11-8

MANUAL FIRST GEAR (1) POSITION,

HYDRAULIC FLOW IN.................21-97

MANUAL SECOND (2) RANGE,

HYDRAULIC FLOW IN.................21-96

MANUAL SHIFTING TEST.............21-177

MANUAL STEERING GEAR; LUBRICATION

AND MAINTENANCE...................0-30

MANUAL STEERING GEAR; STEERING....19-37,

19-78

MANUAL STEERING GEAR

SPECIFICATIONS.....................19-46

MANUAL STEERING SYSTEM DIAGNOSIS . 19-38

MANUAL TRANSMISSION...............0-22

MANUAL TRANSMISSION, AX 15........21-33

MANUAL TRANSMISSION, AX 4/5........21-1

MANUAL TRANSMISSION, SELECTIVE

SNAP RING CHARTÐAX 15...........21-334

MANUAL TRANSMISSION UP-SHIFT

LAMP...........................8W-40-2

MANUAL VALVE SHAFT OVERHAUL.....21-215

MANUAL VALVE SHAFT SEAL

REPLACEMENT.....................21-187

MARKER LAMP BULB REPLACEMENTÐ

XJ, SIDE

...........................8L-10

MARKER LAMP BULB REPLACEMENTÐ

YJ, SIDE

...........................8L-25

MASTER CYLINDER AND COMBINATION

VALVE INSTALLATION (WITH ABS)

........5-20

MASTER CYLINDER AND COMBINATION

VALVE REMOVAL (WITH ABS)

...........5-17

MASTER CYLINDER BENCH BLEEDING

.....5-21

JINDEX 17

Description Group-Page Description Group-Page Description Group-Page

Page 2148 of 2158

REPLACEMENTÐXJ VEHICLES, DRIVE

AXLE ASSEMBLY; REAR SUSPENSION

AND AXLES......................3-14,3-31

REPLACEMENTÐXJ, WINDSHIELD

GLASS.............................23-69

REPLACEMENTÐYJ, BACK-UP/REAR

TURN SIGNAL/TAIL LAMP BULB.........8L-28

REPLACEMENTÐYJ, DOOR FRAME

GLASS CHANNEL...................23-142

REPLACEMENTÐYJ, DOOR

WEATHERSTRIP SEAL................23-142

REPLACEMENTÐYJ, DRL MODULE......8L-30

REPLACEMENTÐYJ, FOG LAMP.........8L-25

REPLACEMENTÐYJ, FOG LAMP SWITCH . 8L-26

REPLACEMENTÐYJ, FRONT PARK/TURN

SIGNAL LAMP BULB..................8L-25

REPLACEMENTÐYJ, HEADLAMP BULB . . . 8L-23

REPLACEMENTÐYJ, HEADLAMP

DIMMER SWITCH....................8L-26

REPLACEMENTÐYJ, LIFTGATE GLASS

WEATHERSTRIP SEAL................23-125

REPLACEMENTÐYJ, SIDE MARKER

LAMP BULB.........................8L-25

REPLACEMENTÐYJ, UNDERHOOD LAMP . 8L-29

REPLACEMENTÐYJ, UNDERHOOD LAMP

BULB..............................8L-29

REPLACEMENTÐYJ VEHICLES, DRIVE

AXLE ASSEMBLY; FRONT SUSPENSION

AND AXLE...........................2-24

REPLACEMENTÐYJ VEHICLES, DRIVE

AXLE ASSEMBLY; REAR SUSPENSION

AND AXLES..........................3-14

REPLACEMENTÐYJ VEHICLES,

HARDTOP DOME/CARGO LAMP BULB....8L-31

REQUIREMENTS, FUEL..................0-1

REQUIRING NO LUBRICATION,

COMPONENTS.........................0-2

RESERVE/OVERFLOW SYSTEM,

COOLANT............................7-24

RESERVOIR REPLACEMENT (2-PIECE

MASTER CYLINDER)...................5-19

RESERVOIR, VACUUM.................8H-1

RESISTANCE, IGNITION COIL............8D-9

RESISTANCE (OHMS)ÐCOOLANT

TEMPERATURE SENSOR/MANIFOLD

AIR TEMPERATURE, SENSOR...........14-46

RESISTANCE, SPARK PLUG CABLE......8D-14

RESISTORS REPLACEMENT, BLOWER

MOTOR............................24-31

RESTRAINT REPLACEMENTÐXJ, DOOR . . . 23-41

RETAINER AND PISTON

SPECIFICATIONS, AW-4...............21-340

RETAINING BRACKETÐYJ, REARVIEW

MIRROR..........................23-144

RETURNÐPCM INPUT, SENSOR.........14-25

REVEAL MOLDINGÐXJ, WINDSHIELD....23-66

REVEAL MOLDINGÐYJ, WINDSHIELD . . . 23-144

RHD, STEERING.....................19-74

RIGHT HAND DRIVE, AUTOMATIC BELT

TENSIONERÐXJ MODELS WITH.........7-42

RIGHT HAND DRIVE, BELT SERVICEÐ

EXCEPT.............................7-40

RIGHT HAND DRIVE, BELT SERVICEÐXJ

MODELS WITH.......................7-42

RIGHT HAND DRIVE (RHD), BELT

TENSIONÐEXCEPT....................7-38

RIGHT HAND DRIVE (RHD) MODELS,

BELT TENSIONÐEXCEPT...............7-45

RIGHT HAND DRIVE VEHICLES...........23-1

RIGHT TURN RELAY; TRAILER TOW

(XJ).............................8W-54-1

RIGHT TURN RELAY; TRAILER TOW

(XJ-RHD).........................8W-54-1

RING CHARTÐAX 15 MANUAL

TRANSMISSION, SELECTIVE SNAP......21-334

RING/THRUST WASHER/THRUST PLATE

SPECIFICATIONS, 30RH/32RH SNAP.....21-335

ROCKER ARMS AND PUSH RODS....9-23,9-65

ROD AND PAWL SERVICE, PARK.......21-190

ROD BALL STUD REPLACEMENTÐXJ,

LIFTGATE SUPPORT

..................23-63

ROD BEARING FITTING CHART,

CONNECTING

.....................9-41,9-83

ROD CYLINDER DISPOSALÐXJ,

LIFTGATE SUPPORT

..................23-63

ROD CYLINDERÐXJ, LIFTGATE

SUPPORT

..........................23-62

ROD, TIE

......................19-16,19-19RODS, PISTONS AND CONNECTING . . . 9-39,9-81

RODS, ROCKER ARMS AND PUSH....9-23,9-65

RODSÐXJ, DOOR INSIDE LATCH

RELEASE AND LOCK..................23-50

ROOF VENTÐYJ, HARD TOP..........23-127

ROTOR, DISTRIBUTOR.................8D-8

ROTOR, IGNITION CABLES,

DISTRIBUTOR CAP....................0-20

ROTOR INSTALLATION.................5-51

ROTOR REFINISHING, DISC BRAKE.......5-53

ROTOR REMOVAL.....................5-51

ROTOR RUNOUT, DISC BRAKE...........5-52

ROTOR THICKNESS, DISC BRAKE........5-52

ROTORÐSPEEDOMETER DRIVE GEAR,

SPEED SENSOR.....................21-193

ROUGH AND/OR HAS A MISS, INJECTOR

DIAGNOSISÐVEHICLE RUNS...........14-52

ROUTING SCHEMATICÐ2.5L 4

CYLINDER ENGINE, VACUUM............25-3

ROUTING SCHEMATICÐ4.0L 6

CYLINDER ENGINE, VACUUM............25-3

ROUTING SCHEMATICS, VACUUM HOSE . . . 25-2

ROUTING, SYSTEM COOLANT.............7-1

RUBBER AND PLASTIC COMPONENT

INSPECTION.........................0-20

RUBBER AND PLASTIC HOSES/TUBING....0-26

RUNNING LAMP (DRL) MODULE,

DAYTIME.........................8W-50-2

RUNNING LAMP (DRL) MODULEÐ

CANADIAN VEHICLES ONLY, DAYTIME. . . 8W-50-2

RUNNING LIGHTS (CANADA ONLY)ÐXJ,

DAYTIME...........................8L-15

RUNNING LIGHTS (CANADA ONLY)ÐYJ,

DAYTIME...........................8L-30

RUNOUT............................16-4

RUNOUT, CLUTCH COVER AND DISC.......6-3

RUNOUT, DISC BRAKE ROTOR...........5-52

RUNOUT, FLYWHEEL....................6-3

RUNOUT SPECIFICATIONS..............16-4

RUNOUT, TIRE AND WHEEL.............22-8

RUNS ROUGH AND/OR HAS A MISS,

INJECTOR DIAGNOSISÐVEHICLE........14-52

SAFETY CERTIFICATION LABEL, VEHICLE . Intro.-4

SAFETY LATCH STRIKER

REPLACEMENTÐXJ..................23-11

SAFETY LATCHÐYJ, HOOD............23-109

SAFETY PRECAUTIONS AND WARNINGS . . 13-10

SAFETY PRECAUTIONS, BRAKE...........5-2

SAFETY PRECAUTIONS, CLUTCH.........6-10

SANDING,BUFFING AND POLISHING,

WET..............................23-158

SCAN TOOL, DRB; BRAKES...............5-3

SCAN TOOL, DRB; COOLING SYSTEM......7-5

SCAN TOOL, DRB; EMISSION CONTROL

SYSTEMS...........................25-2

SCAN TOOL, DRB; FUEL SYSTEM........14-54

SCAN TOOL, DRB; IGNITION SYSTEMS....8D-8

SCHEDULES, MAINTENANCE.............0-4

SCHEMATIC - YJ, BUZZER MODULE......8U-4

SCHEMATICÐ2.5L 4 CYLINDER ENGINE,

VACUUM ROUTING....................25-3

SCHEMATICÐ4.0L 6 CYLINDER ENGINE,

VACUUM ROUTING....................25-3

SCHEMATICÐXJ, AIR CONDITIONING.....24-5

SCHEMATICÐXJ, HEATING..............24-2

SCHEMATICS, BELT....................7-38

SCHEMATICS, PCM SYSTEM............14-41

SCHEMATICS, VACUUM HOSE ROUTING . . . 25-2

SCI RECEIVEÐPCM INPUT.............14-24

SCI TRANSMITÐPCM OUTPUT.........14-29

SCREENÐXJ, COWL GRILLE...........23-12

SCREENÐXJ, HEADLAMP/FOG LAMP

ADJUSTMENT USING ALIGNMENT........8L-7

SCREENÐYJ, COWL GRILLE..........23-109

SCREENÐYJ, HEADLAMP/FOG LAMP

ADJUSTMENT USING ALIGNMENT.......8L-23

SCREW ANCHOR AND BUMPERÐXJ,

LIFTGATE LICENSE PLATE..............23-65

SCUFF PLATE/COWL SIDE TRIM

PANELÐXJ, FRONT INNER.............23-86

SCUFF PLATESÐXJ, INTERIOR TRIM

PANELS

............................23-84

SCUFF PLATESÐXJ, OUTER

............23-89

SEAL AND BEARING, AXLE SHAFT

........3-17

SEAL AND BEARING SERVICE, AXLE

SHAFT

..............................3-32

SEAL AND SPRING REPLACEMENT,

VALVE STEM

.........................9-65SEAL REPLACEMENT, INNER AXLE

SHAFT OIL...........................2-35

SEAL REPLACEMENT, MANUAL VALVE

SHAFT............................21-187

SEAL REPLACEMENT, OIL PUMP.......21-199

SEAL REPLACEMENT, PINION; FRONT

SUSPENSION AND AXLE................2-25

SEAL REPLACEMENT, PINION; REAR

SUSPENSION AND AXLES...............3-33

SEAL REPLACEMENT, PINION SHAFT......3-15

SEAL REPLACEMENT, PITMAN SHAFT....19-37

SEAL REPLACEMENT, TIMING CASE

COVER OIL......................9-30,9-73

SEAL REPLACEMENTÐYJ, DOOR

WEATHERSTRIP....................23-142

SEAL REPLACEMENTÐYJ, LIFTGATE

GLASS WEATHERSTRIP..............23-125

SEAL/CROSSMEMBER AIR

DEFLECTORÐXJ, COWL

WEATHERSTRIP.....................23-11

SEALÐDRIVE PLATE SERVICE,

CONVERTERÐPUMP.................21-116

SEALÐXJ, LIFTGATE OPENING

WEATHERSTRIP.....................23-64

SEALÐYJ, BELTLINE.................23-142

SEALÐYJ, COWL WEATHERSTRIP......23-109

SEALÐYJ, TAILGATE WEATHERSTRIP . . . 23-123

SEALÐYJ, WINDSHIELD FRAME

WEATHERSTRIP....................23-146

SEALS AND BEARING REPLACEMENT,

PITMAN SHAFT......................19-34

SEALS, REAR MAIN OIL..............9-49,9-89

SEALS, VALVE SPRINGS AND OIL........9-23

SEALSÐIN CAR REPLACEMENT, PITMAN

SHAFT.............................19-23

SEALSÐXJ, DOOR WINDOW GLASS

AND DOOR OPENING WEATHERSTRIP....23-55

SEALSÐYJ, FULL-METAL DOOR

WEATHERSTRIP....................23-141

SEAT ADJUSTER/MOTORS, POWER . . . 8R-1,8R-2

SEAT ADJUSTER/MOTORS REMOVE/

INSTALL, POWER.....................8R-3

SEAT BELT INDICATOR WARNING LAMP;

INSTRUMENT CLUSTER (XJ).........8W-40-2

SEAT BELT INDICATOR WARNING LAMP;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

SEAT BELT SWITCH, DRIVER'S......8U-1,8U-3

SEAT CUSHION AND COVERÐXJ,

BUCKET............................23-81

SEAT CUSHION COVERÐXJ, REAR......23-82

SEAT CUSHIONÐXJ, REAR.............23-82

SEAT PLATFORMÐXJ, BUCKET.........23-82

SEAT, POWER; POWER SEAT (XJ).....8W-63-1

SEAT, POWER; POWER SEAT (XJ-RHD) . 8W-63-1

SEAT SWITCH CONTINUITY, POWER......8R-2

SEAT SWITCH, POWER............8R-1,8R-2

SEAT SWITCH REMOVE/INSTALL,

POWER.............................8R-3

SEATBACK COVER AND FRAMEÐXJ,

BUCKET............................23-81

SEATBACK COVERÐXJ, REAR..........23-84

SEATBACK LATCH STRIKER AND

BUMPERÐXJ, REAR..................23-84

SEATBACKÐXJ, REAR................23-83

SEATÐYJ, REAR BENCH..............23-153

SEATSÐXJ, FRONT BUCKET............23-81

SEATSÐYJ........................23-153

SEATSÐYJ, BUCKET.................23-153

SECOND (2) RANGE, HYDRAULIC FLOW

IN MANUAL.........................21-96

SECOND BRAKE OVERHAUL...........21-241

SECONDARY CABLES, SPARK PLUG.....8D-14,

8D-24

SECONDARY CIRCUIT DIAGNOSIS,

IGNITION...........................8D-10

SECTION IDENTIFICATION; WIRING

DIAGRAMS (XJ)......................8W-1

SECTION IDENTIFICATION; WIRING

DIAGRAMS (XJ-RHD)..................8W-1

SECTION IDENTIFICATION; WIRING

DIAGRAMS (YJ)

......................8W-1

SELECTIVE SNAP RING CHARTÐAX 15

MANUAL TRANSMISSION

.............21-334

SELF-DIAGNOSTIC TEST, COMPASS/

DISPLAY

............................8C-2

SENDING UNIT, FUEL GAUGE

...........14-16

SENSEÐPCM INPUT, AUTOMATIC

SHUTDOWN (ASD)

...................14-21

24 INDEXJ

Description Group-Page Description Group-Page Description Group-Page