steering wheel adjustment JEEP XJ 1995 Service And User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 203 of 2158

CALIPER INSTALLATION

(1) Install brakeshoes in caliper (Figs. 11, 12).

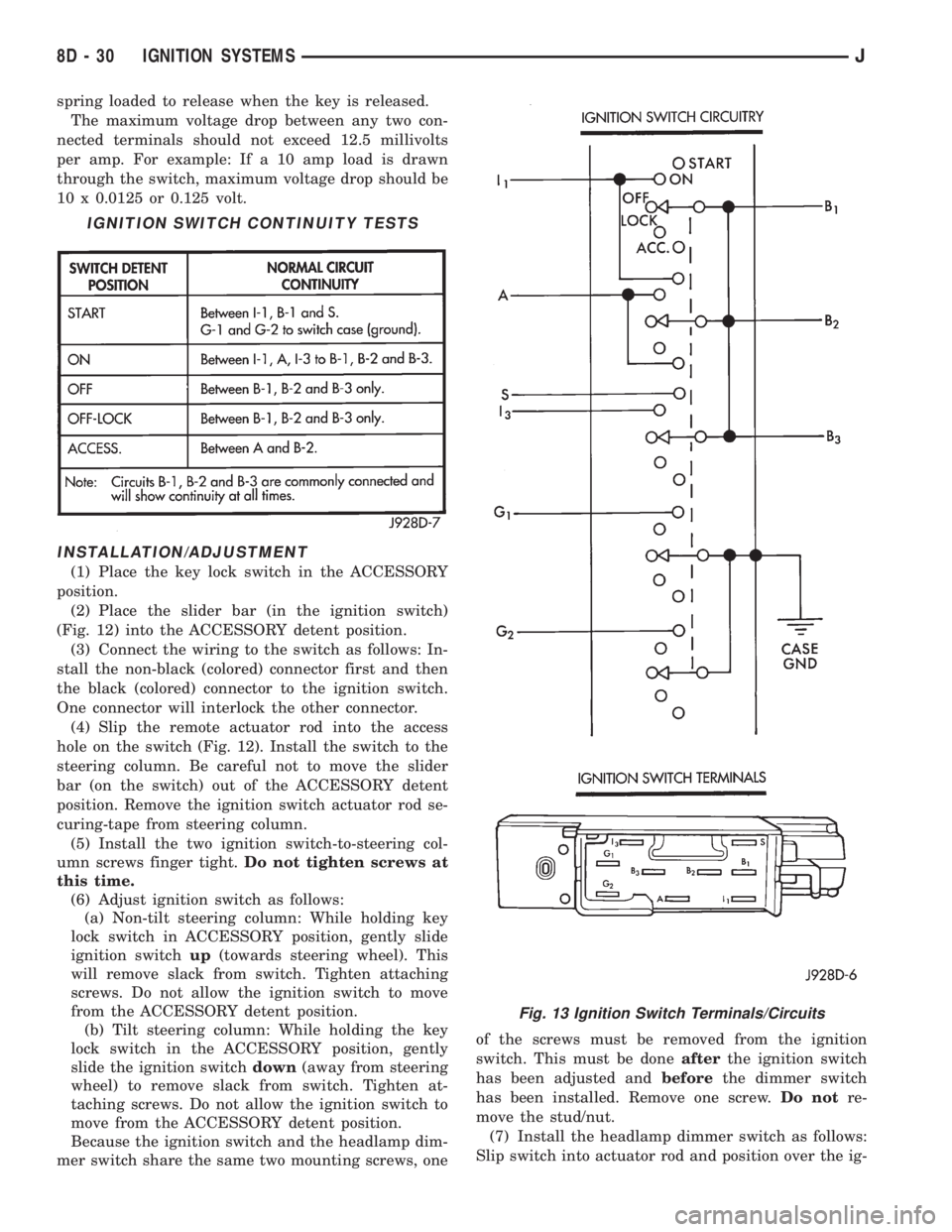

(2) Connect brake hose to caliper but do not

tighten fitting bolt completely at this time.Be sure

to use new gaskets on fitting bolt to avoid leaks

(Fig. 25).

(3) Install caliper. Position mounting notches at

lower end of brakeshoes on bottom mounting ledge

(Fig. 13). Then rotate caliper over rotor and seat

notches at upper end of shoes on mounting ledge

(Fig. 13).

(4) Coat caliper mounting bolts with GE 661 or

Dow 111 silicone grease. Then install and tighten

bolts to 10-20 Nzm (7-15 ft. lbs.) torque.CAUTION: If new caliper bolts are being installed,

or if the original reason for repair was a drag/pull

condition, check caliper bolt length before proceed-

ing. If the bolts have a shank length greater than

67.6 mm (2.66 in.), they may contact the inboard

brakeshoe causing a partial apply condition. Refer

to Figure 14 for the required caliper bolt length.

(5) Position front brake hose clear of all chassis

components and tighten caliper fitting bolt to 31 Nzm

(23 ft. lbs.) torque.

CAUTION: Be sure the brake hose is not twisted or

kinked at any point. Also be sure the hose is clear

of all steering and suspension components. Loosen

and reposition the hose if necessary.

(6) Install wheels. Tighten wheel lug nuts to 109-

150 Nzm (80-110 ft. lbs.) torque.

(7) Fill and bleed brake system. Refer to proce-

dures in Service Adjustments section.

ROTOR REMOVAL

(1) Raise vehicle and remove wheel.

(2) Remove caliper.

(3) Remove retainers securing rotor to hub studs

(Fig. 26).

(4) Remove rotor from hub (Fig. 26).

(5) If rotor shield requires service, remove front

hub and bearing assembly.

ROTOR INSTALLATION

(1) If new rotor is being installed, remove protec-

tive coating from rotor surfaces with Mopar carb

cleaner.It is not necessary to machine a rotor to

remove the coating. Mopar carb cleaner fol-

lowed by a rinse with brake cleaner will re-

move the coating.

(2) Install rotor on hub.

(3) Install caliper.

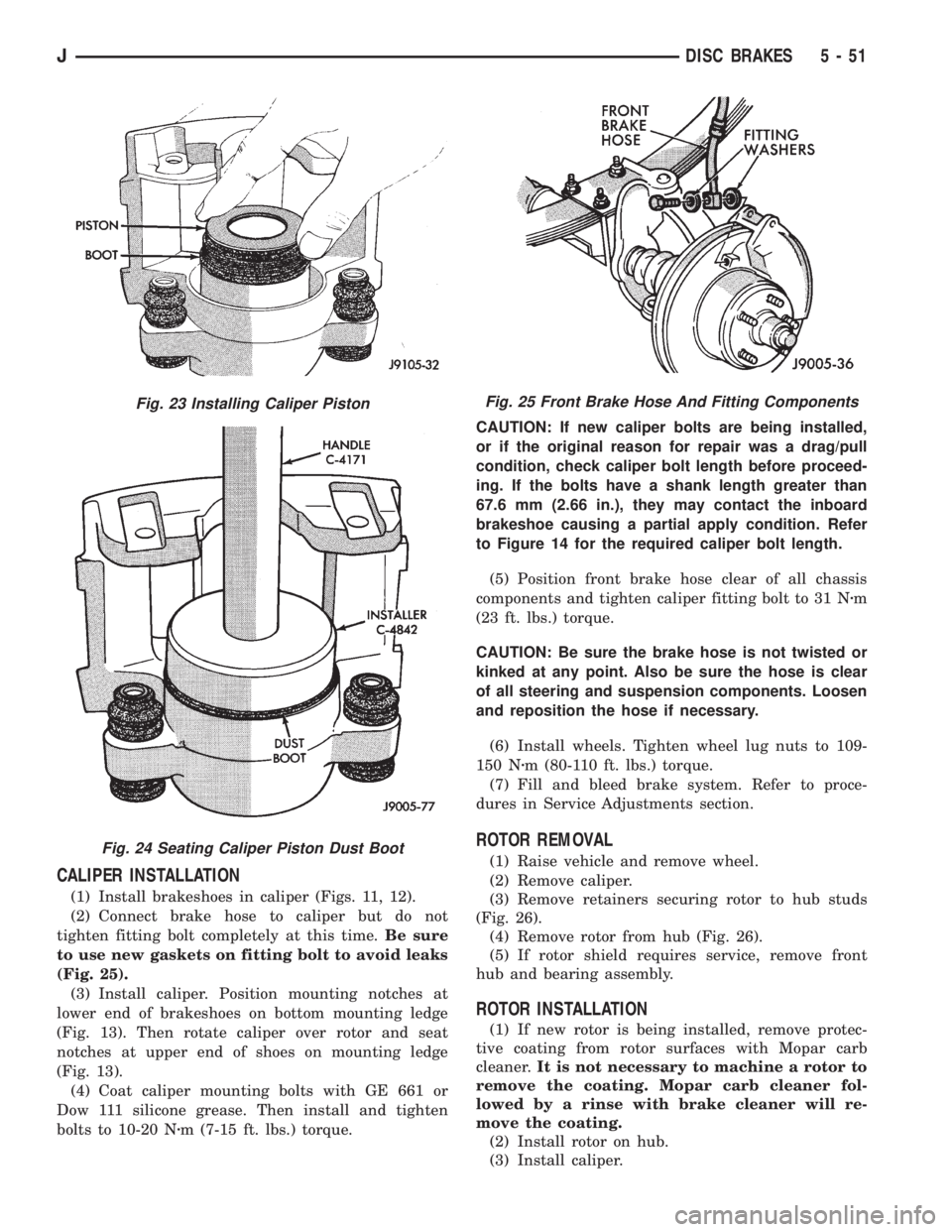

Fig. 23 Installing Caliper Piston

Fig. 24 Seating Caliper Piston Dust Boot

Fig. 25 Front Brake Hose And Fitting Components

JDISC BRAKES 5 - 51

Page 354 of 2158

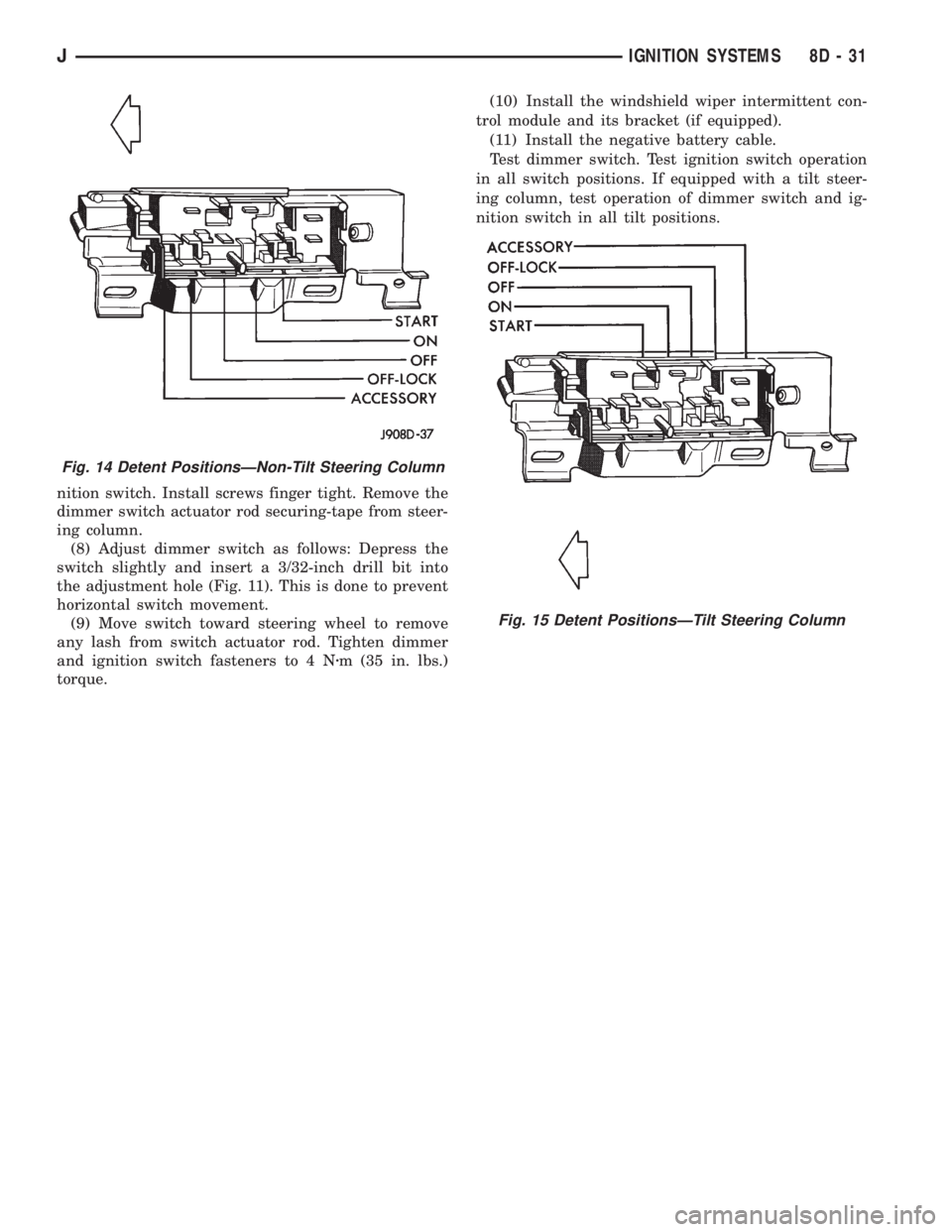

spring loaded to release when the key is released.

The maximum voltage drop between any two con-

nected terminals should not exceed 12.5 millivolts

per amp. For example: If a 10 amp load is drawn

through the switch, maximum voltage drop should be

10 x 0.0125 or 0.125 volt.

INSTALLATION/ADJUSTMENT

(1) Place the key lock switch in the ACCESSORY

position.

(2) Place the slider bar (in the ignition switch)

(Fig. 12) into the ACCESSORY detent position.

(3) Connect the wiring to the switch as follows: In-

stall the non-black (colored) connector first and then

the black (colored) connector to the ignition switch.

One connector will interlock the other connector.

(4) Slip the remote actuator rod into the access

hole on the switch (Fig. 12). Install the switch to the

steering column. Be careful not to move the slider

bar (on the switch) out of the ACCESSORY detent

position. Remove the ignition switch actuator rod se-

curing-tape from steering column.

(5) Install the two ignition switch-to-steering col-

umn screws finger tight.Do not tighten screws at

this time.

(6) Adjust ignition switch as follows:

(a) Non-tilt steering column: While holding key

lock switch in ACCESSORY position, gently slide

ignition switchup(towards steering wheel). This

will remove slack from switch. Tighten attaching

screws. Do not allow the ignition switch to move

from the ACCESSORY detent position.

(b) Tilt steering column: While holding the key

lock switch in the ACCESSORY position, gently

slide the ignition switchdown(away from steering

wheel) to remove slack from switch. Tighten at-

taching screws. Do not allow the ignition switch to

move from the ACCESSORY detent position.

Because the ignition switch and the headlamp dim-

mer switch share the same two mounting screws, oneof the screws must be removed from the ignition

switch. This must be doneafterthe ignition switch

has been adjusted andbeforethe dimmer switch

has been installed. Remove one screw.Do notre-

move the stud/nut.

(7) Install the headlamp dimmer switch as follows:

Slip switch into actuator rod and position over the ig-

IGNITION SWITCH CONTINUITY TESTS

Fig. 13 Ignition Switch Terminals/Circuits

8D - 30 IGNITION SYSTEMSJ

Page 355 of 2158

nition switch. Install screws finger tight. Remove the

dimmer switch actuator rod securing-tape from steer-

ing column.

(8) Adjust dimmer switch as follows: Depress the

switch slightly and insert a 3/32-inch drill bit into

the adjustment hole (Fig. 11). This is done to prevent

horizontal switch movement.

(9) Move switch toward steering wheel to remove

any lash from switch actuator rod. Tighten dimmer

and ignition switch fasteners to 4 Nzm (35 in. lbs.)

torque.(10) Install the windshield wiper intermittent con-

trol module and its bracket (if equipped).

(11) Install the negative battery cable.

Test dimmer switch. Test ignition switch operation

in all switch positions. If equipped with a tilt steer-

ing column, test operation of dimmer switch and ig-

nition switch in all tilt positions.

Fig. 14 Detent PositionsÐNon-Tilt Steering Column

Fig. 15 Detent PositionsÐTilt Steering Column

JIGNITION SYSTEMS 8D - 31

Page 417 of 2158

VEHICLE SPEED CONTROL SYSTEM

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 9

GENERAL INFORMATION

The vehicle speed control system (Fig. 1) is an

available option on all XJ (Cherokee) models. The

system is electronically controlled and vacuum oper-

ated. Following are general descriptions of the major

components in the vehicle speed control system. Re-

fer to Group 8W - Wiring Diagrams for complete cir-

cuit descriptions and diagrams.

SPEED CONTROL SERVO

The speed control servo is mounted to a bracket on

the right side inner fender shield in the engine com-

partment. The servo unit consists of a solenoid valve

body, a vacuum servo and the mounting bracket. The

PCM controls the solenoid valve body. The solenoid

valve body controls the application and release of

vacuum to the diaphragm of the vacuum servo. The

servo unit cannot be repaired and is serviced only as

a complete assembly.

SPEED CONTROL SWITCH

The speed control switch module is mounted to the

center of the steering wheel below the driver's airbag

module. The PCM monitors the state of the speed

control switches. The individual switches are labeled:

OFF/ON, RESUME/ACCEL, SET/COAST. Refer to

the owner's manual for more information on speed

control switch functions and setting procedures. The

individual switches cannot be repaired. If one switch

fails, the entire switch module must be replaced.

STOP LAMP SWITCH

Vehicles with the speed control option use a dual

function stop lamp switch. The switch is mounted in

the same location as the conventional stop lamp

switch, on the brake pedal mounting bracket under

the instrument panel. The PCM monitors the state of

the dual function stop lamp switch. Refer to Group 5

- Brakes for more information on stop lamp switch

service and adjustment procedures.

SERVO CABLE

The speed control servo cable is connected betweenthe speed control vacuum servo diaphragm and the

throttle control linkage. This cable causes the throt-

tle control linkage to open or close the throttle valve

in response to movement of the vacuum servo dia-

phragm.

POWERTRAIN CONTROL MODULE

The speed control electronic control circuitry is in-

tegrated into the Powertrain Control Module (PCM).

The PCM is located in the engine compartment on

the left side inner fender shield. The PCM speed con-

trol functions are monitored by the On-Board Diag-

nostics (OBD). All OBD-sensed systems are

monitored by the PCM. Each monitored circuit is as-

signed a Diagnostic Trouble Code (DTC). The PCM

will store a DTC in electronic memory for any failure

it detects. See Using On-Board Diagnostic System in

this group for more information. The PCM cannot be

repaired and must be replaced if faulty.

VACUUM RESERVOIR

The vacuum reservoir is mounted behind the left

end of the front bumper bar. The reservoir contains a

one-way check valve to trap engine vacuum in the

reservoir. When engine vacuum drops, as in climbing

a grade while driving, the reservoir supplies the vac-

uum needed to maintain proper speed control opera-

tion. The vacuum reservoir cannot be repaired and

must be replaced if faulty.

VEHICLE SPEED SENSOR

The Vehicle Speed Sensor (VSS) is a pulse genera-

tor mounted to an adapter near the transmission

(two-wheel drive) or transfer case (four-wheel drive)

output shaft. The sensor is driven through the

adapter by a speedometer pinion gear. The VSS pulse

signal to the speedometer/odometer is monitored by

the PCM speed control circuitry to determine vehicle

speed and to maintain speed control set speed. Refer

to the appropriate Powertrain Diagnostic Procedures

manual for testing of this component. Refer to Group

14 - Fuel System for service of this component.

JVEHICLE SPEED CONTROL SYSTEM 8H - 1

Page 422 of 2158

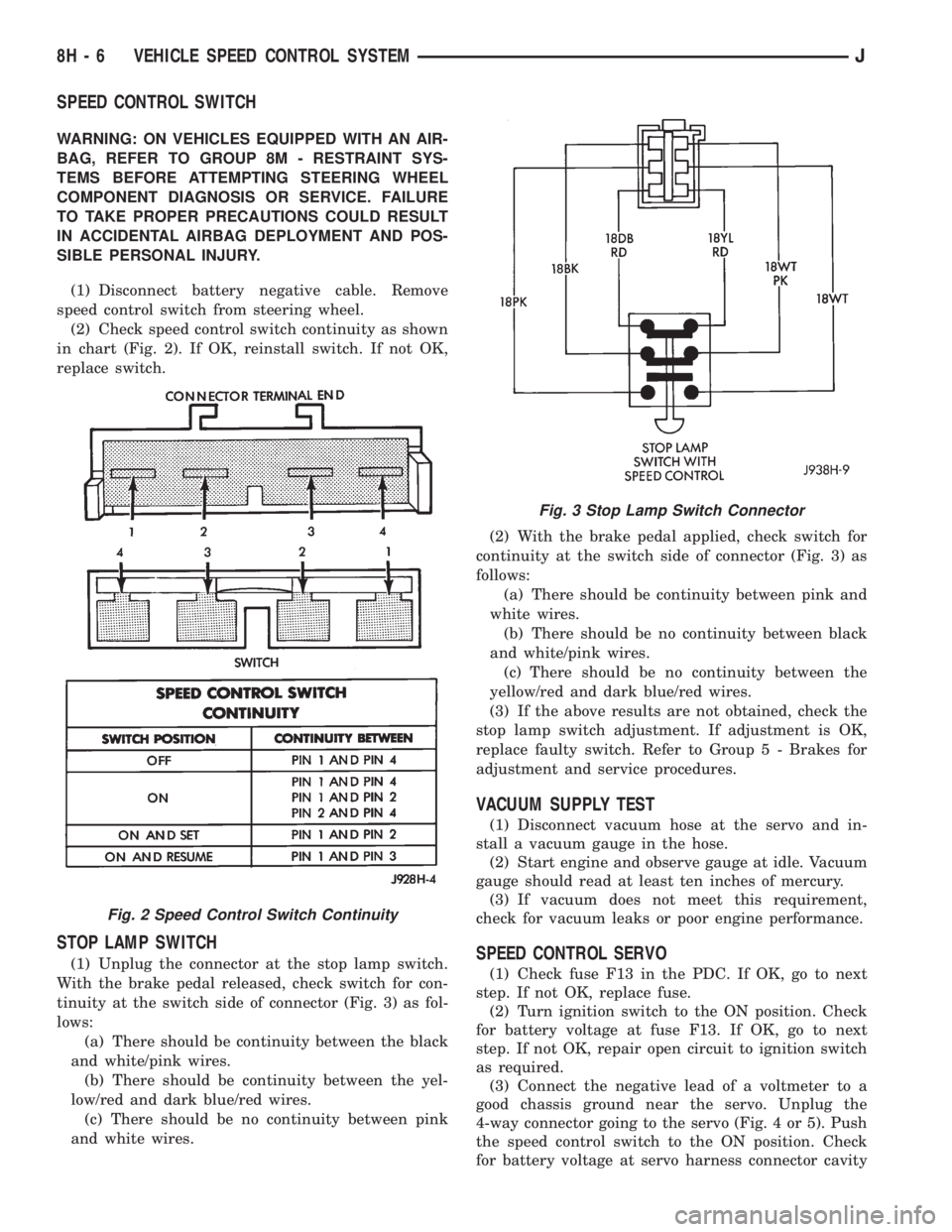

SPEED CONTROL SWITCH

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO GROUP 8M - RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POS-

SIBLE PERSONAL INJURY.

(1) Disconnect battery negative cable. Remove

speed control switch from steering wheel.

(2) Check speed control switch continuity as shown

in chart (Fig. 2). If OK, reinstall switch. If not OK,

replace switch.

STOP LAMP SWITCH

(1) Unplug the connector at the stop lamp switch.

With the brake pedal released, check switch for con-

tinuity at the switch side of connector (Fig. 3) as fol-

lows:

(a) There should be continuity between the black

and white/pink wires.

(b) There should be continuity between the yel-

low/red and dark blue/red wires.

(c) There should be no continuity between pink

and white wires.(2) With the brake pedal applied, check switch for

continuity at the switch side of connector (Fig. 3) as

follows:

(a) There should be continuity between pink and

white wires.

(b) There should be no continuity between black

and white/pink wires.

(c) There should be no continuity between the

yellow/red and dark blue/red wires.

(3) If the above results are not obtained, check the

stop lamp switch adjustment. If adjustment is OK,

replace faulty switch. Refer to Group 5 - Brakes for

adjustment and service procedures.

VACUUM SUPPLY TEST

(1) Disconnect vacuum hose at the servo and in-

stall a vacuum gauge in the hose.

(2) Start engine and observe gauge at idle. Vacuum

gauge should read at least ten inches of mercury.

(3) If vacuum does not meet this requirement,

check for vacuum leaks or poor engine performance.

SPEED CONTROL SERVO

(1) Check fuse F13 in the PDC. If OK, go to next

step. If not OK, replace fuse.

(2) Turn ignition switch to the ON position. Check

for battery voltage at fuse F13. If OK, go to next

step. If not OK, repair open circuit to ignition switch

as required.

(3) Connect the negative lead of a voltmeter to a

good chassis ground near the servo. Unplug the

4-way connector going to the servo (Fig. 4 or 5). Push

the speed control switch to the ON position. Check

for battery voltage at servo harness connector cavity

Fig. 2 Speed Control Switch Continuity

Fig. 3 Stop Lamp Switch Connector

8H - 6 VEHICLE SPEED CONTROL SYSTEMJ

Page 487 of 2158

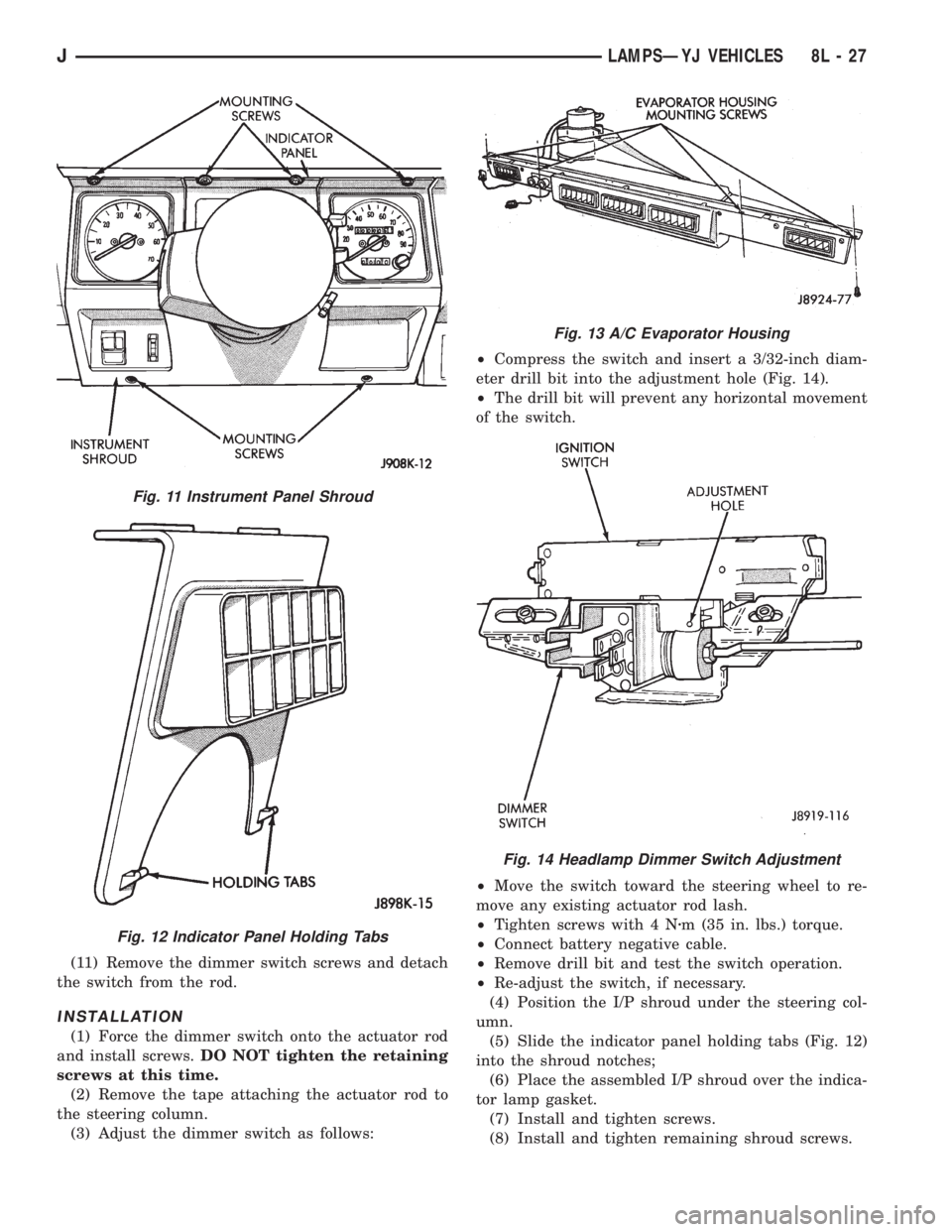

(11) Remove the dimmer switch screws and detach

the switch from the rod.

INSTALLATION

(1) Force the dimmer switch onto the actuator rod

and install screws.DO NOT tighten the retaining

screws at this time.

(2) Remove the tape attaching the actuator rod to

the steering column.

(3) Adjust the dimmer switch as follows:²Compress the switch and insert a 3/32-inch diam-

eter drill bit into the adjustment hole (Fig. 14).

²The drill bit will prevent any horizontal movement

of the switch.

²Move the switch toward the steering wheel to re-

move any existing actuator rod lash.

²Tighten screws with 4 Nzm (35 in. lbs.) torque.

²Connect battery negative cable.

²Remove drill bit and test the switch operation.

²Re-adjust the switch, if necessary.

(4) Position the I/P shroud under the steering col-

umn.

(5) Slide the indicator panel holding tabs (Fig. 12)

into the shroud notches;

(6) Place the assembled I/P shroud over the indica-

tor lamp gasket.

(7) Install and tighten screws.

(8) Install and tighten remaining shroud screws.

Fig. 11 Instrument Panel Shroud

Fig. 12 Indicator Panel Holding Tabs

Fig. 13 A/C Evaporator Housing

Fig. 14 Headlamp Dimmer Switch Adjustment

JLAMPSÐYJ VEHICLES 8L - 27

Page 1500 of 2158

STEERING LINKAGEÐXJ

INDEX

page page

Drag Link............................... 16

Pitman Arm.............................. 17

Service Information........................ 16Steering Damper.......................... 17

TieRod ................................ 16

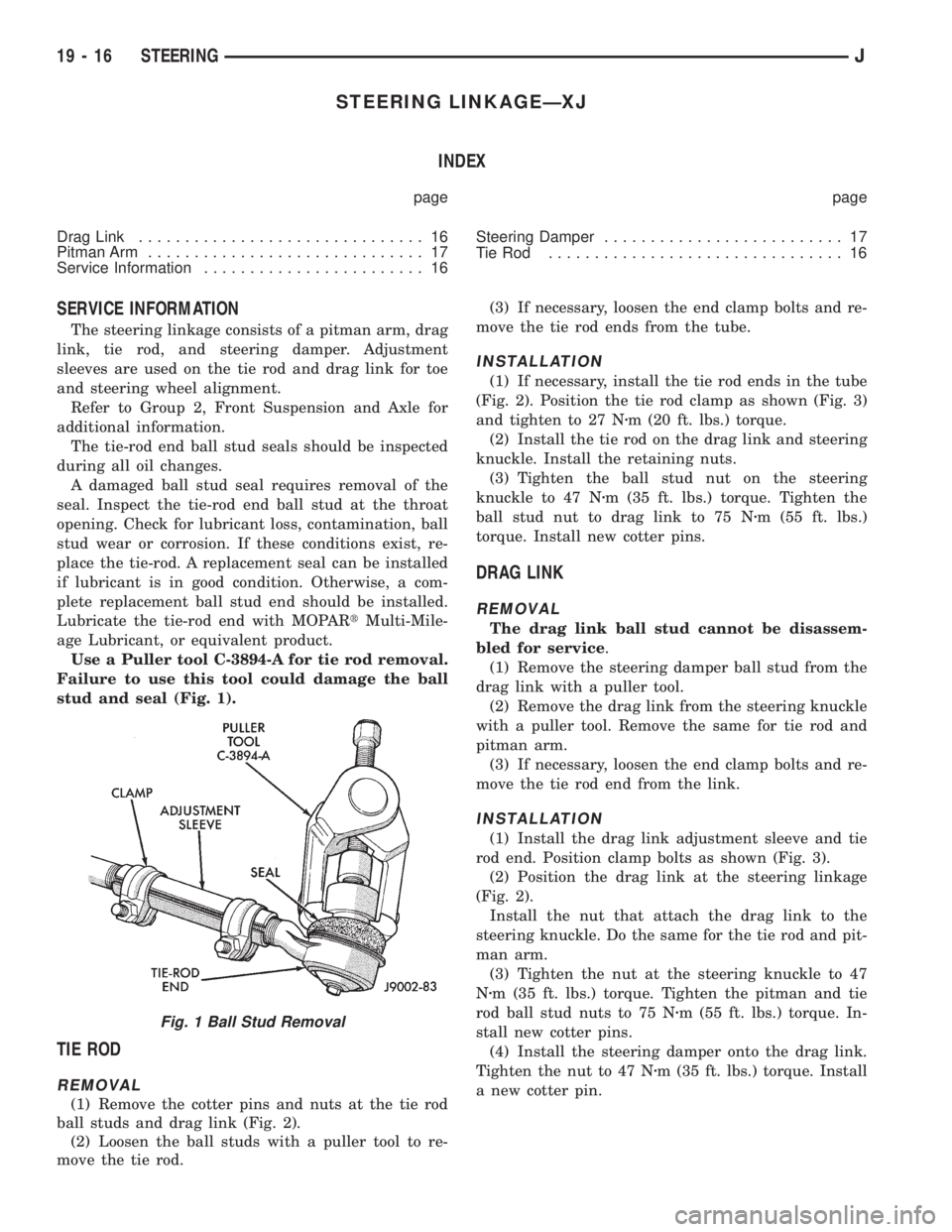

SERVICE INFORMATION

The steering linkage consists of a pitman arm, drag

link, tie rod, and steering damper. Adjustment

sleeves are used on the tie rod and drag link for toe

and steering wheel alignment.

Refer to Group 2, Front Suspension and Axle for

additional information.

The tie-rod end ball stud seals should be inspected

during all oil changes.

A damaged ball stud seal requires removal of the

seal. Inspect the tie-rod end ball stud at the throat

opening. Check for lubricant loss, contamination, ball

stud wear or corrosion. If these conditions exist, re-

place the tie-rod. A replacement seal can be installed

if lubricant is in good condition. Otherwise, a com-

plete replacement ball stud end should be installed.

Lubricate the tie-rod end with MOPARtMulti-Mile-

age Lubricant, or equivalent product.

Use a Puller tool C-3894-A for tie rod removal.

Failure to use this tool could damage the ball

stud and seal (Fig. 1).

TIE ROD

REMOVAL

(1) Remove the cotter pins and nuts at the tie rod

ball studs and drag link (Fig. 2).

(2) Loosen the ball studs with a puller tool to re-

move the tie rod.(3) If necessary, loosen the end clamp bolts and re-

move the tie rod ends from the tube.

INSTALLATION

(1) If necessary, install the tie rod ends in the tube

(Fig. 2). Position the tie rod clamp as shown (Fig. 3)

and tighten to 27 Nzm (20 ft. lbs.) torque.

(2) Install the tie rod on the drag link and steering

knuckle. Install the retaining nuts.

(3) Tighten the ball stud nut on the steering

knuckle to 47 Nzm (35 ft. lbs.) torque. Tighten the

ball stud nut to drag link to 75 Nzm (55 ft. lbs.)

torque. Install new cotter pins.

DRAG LINK

REMOVAL

The drag link ball stud cannot be disassem-

bled for service.

(1) Remove the steering damper ball stud from the

drag link with a puller tool.

(2) Remove the drag link from the steering knuckle

with a puller tool. Remove the same for tie rod and

pitman arm.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod end from the link.

INSTALLATION

(1) Install the drag link adjustment sleeve and tie

rod end. Position clamp bolts as shown (Fig. 3).

(2) Position the drag link at the steering linkage

(Fig. 2).

Install the nut that attach the drag link to the

steering knuckle. Do the same for the tie rod and pit-

man arm.

(3) Tighten the nut at the steering knuckle to 47

Nzm (35 ft. lbs.) torque. Tighten the pitman and tie

rod ball stud nuts to 75 Nzm (55 ft. lbs.) torque. In-

stall new cotter pins.

(4) Install the steering damper onto the drag link.

Tighten the nut to 47 Nzm (35 ft. lbs.) torque. Install

a new cotter pin.

Fig. 1 Ball Stud Removal

19 - 16 STEERINGJ

Page 1503 of 2158

STEERING LINKAGEÐYJ

INDEX

page page

Drag Link............................... 20

Pitman Arm.............................. 20

Service Information........................ 19Steering Damper.......................... 20

TieRod ................................ 19

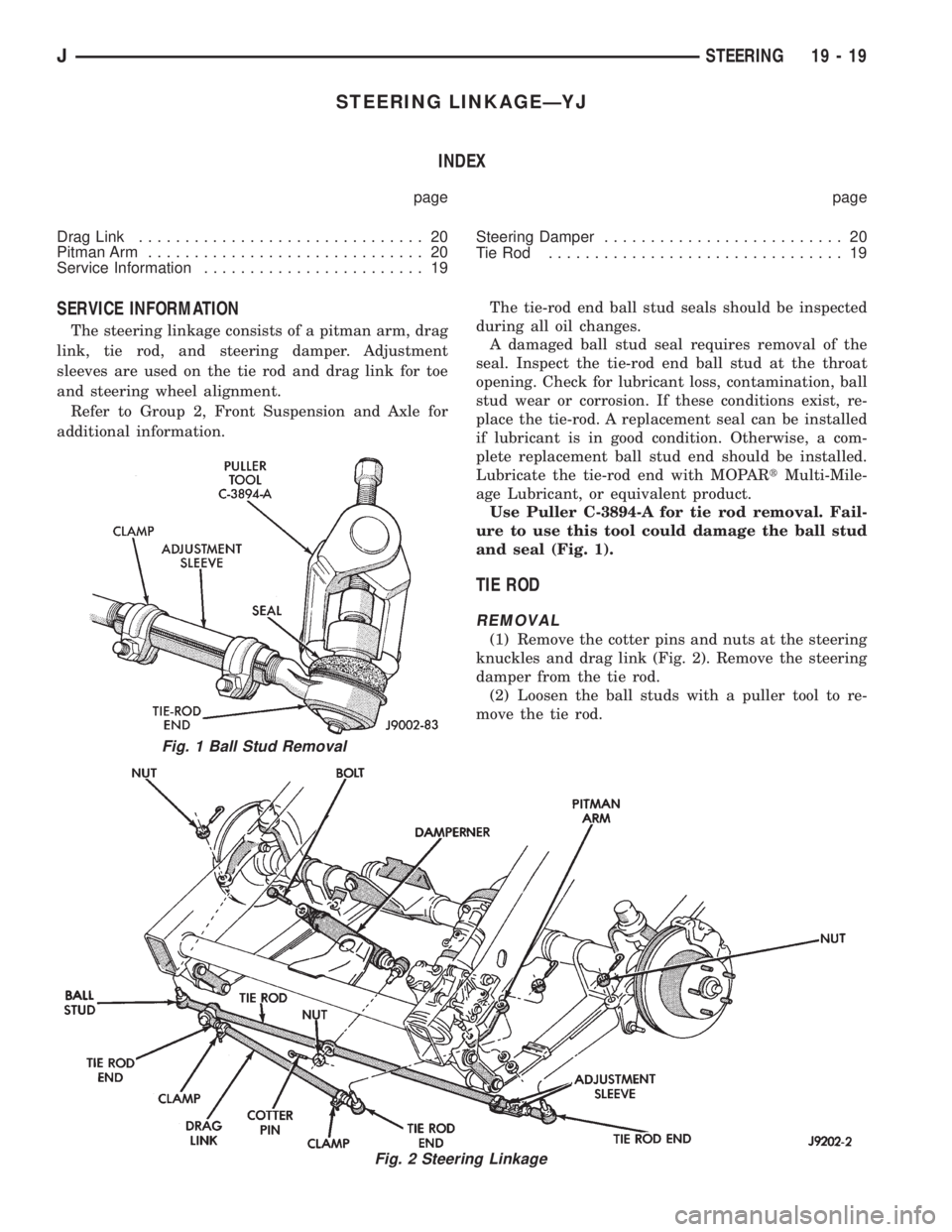

SERVICE INFORMATION

The steering linkage consists of a pitman arm, drag

link, tie rod, and steering damper. Adjustment

sleeves are used on the tie rod and drag link for toe

and steering wheel alignment.

Refer to Group 2, Front Suspension and Axle for

additional information.The tie-rod end ball stud seals should be inspected

during all oil changes.

A damaged ball stud seal requires removal of the

seal. Inspect the tie-rod end ball stud at the throat

opening. Check for lubricant loss, contamination, ball

stud wear or corrosion. If these conditions exist, re-

place the tie-rod. A replacement seal can be installed

if lubricant is in good condition. Otherwise, a com-

plete replacement ball stud end should be installed.

Lubricate the tie-rod end with MOPARtMulti-Mile-

age Lubricant, or equivalent product.

Use Puller C-3894-A for tie rod removal. Fail-

ure to use this tool could damage the ball stud

and seal (Fig. 1).

TIE ROD

REMOVAL

(1) Remove the cotter pins and nuts at the steering

knuckles and drag link (Fig. 2). Remove the steering

damper from the tie rod.

(2) Loosen the ball studs with a puller tool to re-

move the tie rod.

Fig. 1 Ball Stud Removal

Fig. 2 Steering Linkage

JSTEERING 19 - 19

Page 1504 of 2158

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod end from the tube.

INSTALLATION

(1) If necessary, install the tie rod end in the tube

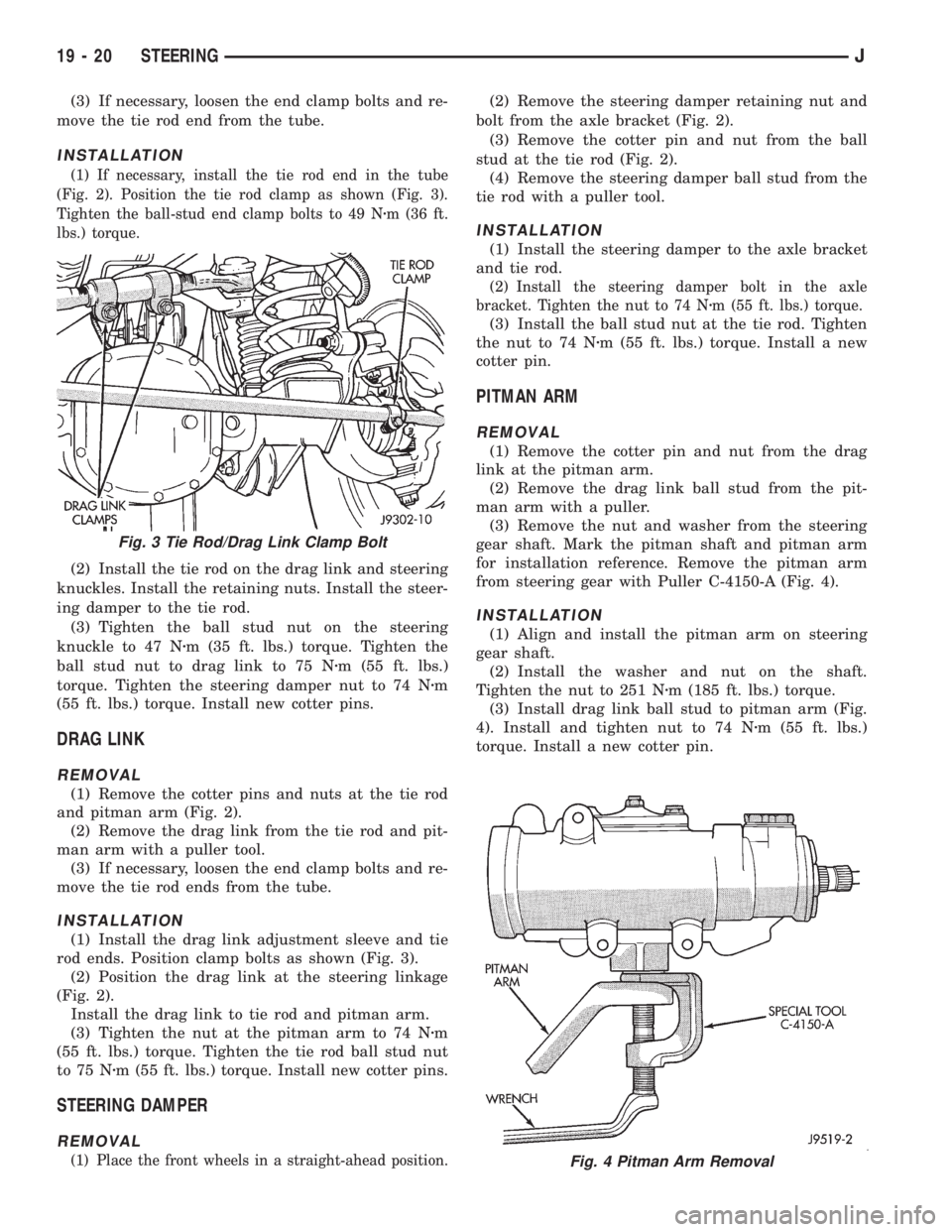

(Fig. 2). Position the tie rod clamp as shown (Fig. 3).

Tighten the ball-stud end clamp bolts to 49 Nzm (36 ft.

lbs.) torque.

(2) Install the tie rod on the drag link and steering

knuckles. Install the retaining nuts. Install the steer-

ing damper to the tie rod.

(3) Tighten the ball stud nut on the steering

knuckle to 47 Nzm (35 ft. lbs.) torque. Tighten the

ball stud nut to drag link to 75 Nzm (55 ft. lbs.)

torque. Tighten the steering damper nut to 74 Nzm

(55 ft. lbs.) torque. Install new cotter pins.

DRAG LINK

REMOVAL

(1) Remove the cotter pins and nuts at the tie rod

and pitman arm (Fig. 2).

(2) Remove the drag link from the tie rod and pit-

man arm with a puller tool.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod ends from the tube.

INSTALLATION

(1) Install the drag link adjustment sleeve and tie

rod ends. Position clamp bolts as shown (Fig. 3).

(2) Position the drag link at the steering linkage

(Fig. 2).

Install the drag link to tie rod and pitman arm.

(3) Tighten the nut at the pitman arm to 74 Nzm

(55 ft. lbs.) torque. Tighten the tie rod ball stud nut

to 75 Nzm (55 ft. lbs.) torque. Install new cotter pins.

STEERING DAMPER

REMOVAL

(1) Place the front wheels in a straight-ahead position.

(2) Remove the steering damper retaining nut and

bolt from the axle bracket (Fig. 2).

(3) Remove the cotter pin and nut from the ball

stud at the tie rod (Fig. 2).

(4) Remove the steering damper ball stud from the

tie rod with a puller tool.

INSTALLATION

(1) Install the steering damper to the axle bracket

and tie rod.

(2) Install the steering damper bolt in the axle

bracket. Tighten the nut to 74 Nzm (55 ft. lbs.) torque.

(3) Install the ball stud nut at the tie rod. Tighten

the nut to 74 Nzm (55 ft. lbs.) torque. Install a new

cotter pin.

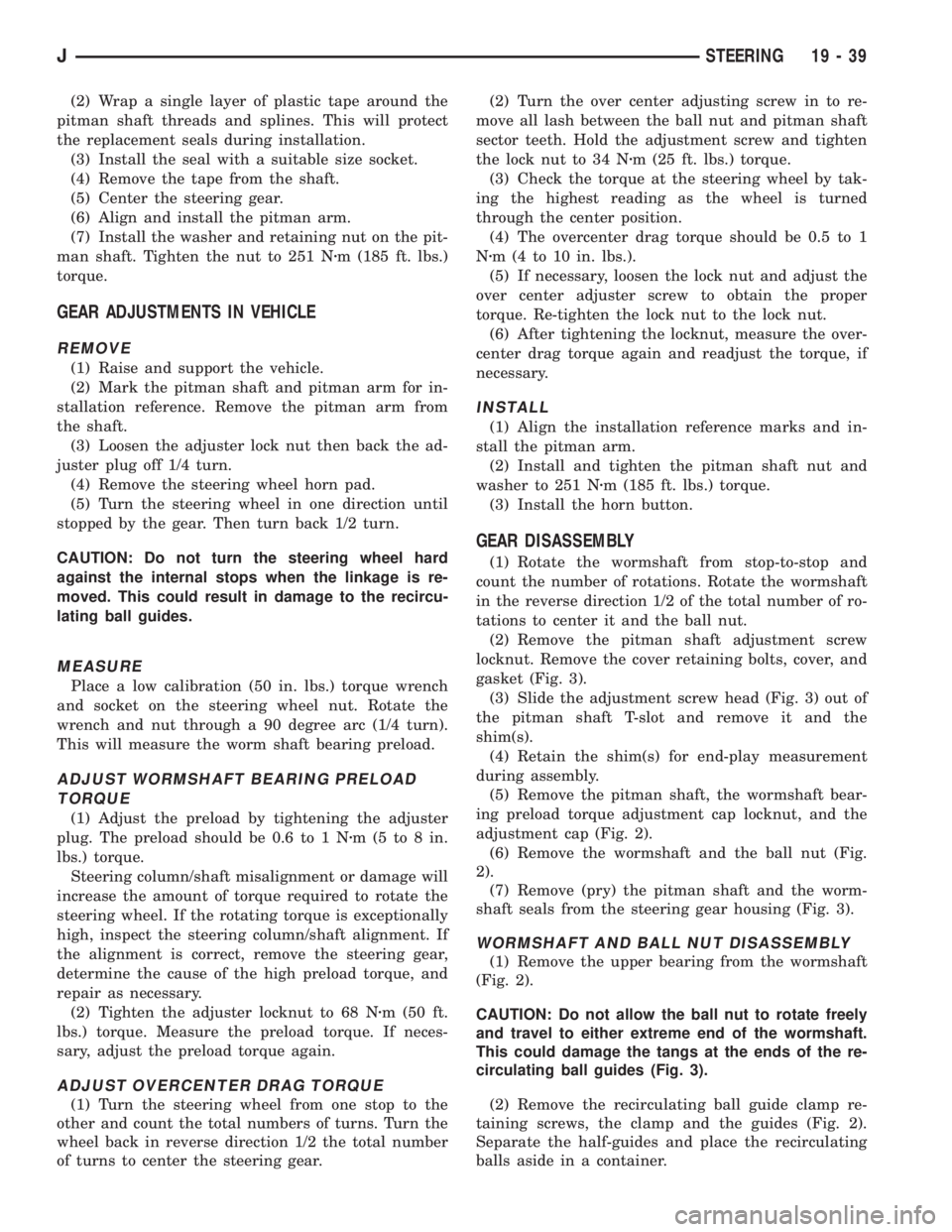

PITMAN ARM

REMOVAL

(1) Remove the cotter pin and nut from the drag

link at the pitman arm.

(2) Remove the drag link ball stud from the pit-

man arm with a puller.

(3) Remove the nut and washer from the steering

gear shaft. Mark the pitman shaft and pitman arm

for installation reference. Remove the pitman arm

from steering gear with Puller C-4150-A (Fig. 4).

INSTALLATION

(1) Align and install the pitman arm on steering

gear shaft.

(2) Install the washer and nut on the shaft.

Tighten the nut to 251 Nzm (185 ft. lbs.) torque.

(3) Install drag link ball stud to pitman arm (Fig.

4). Install and tighten nut to 74 Nzm (55 ft. lbs.)

torque. Install a new cotter pin.

Fig. 4 Pitman Arm Removal

Fig. 3 Tie Rod/Drag Link Clamp Bolt

19 - 20 STEERINGJ

Page 1523 of 2158

(2) Wrap a single layer of plastic tape around the

pitman shaft threads and splines. This will protect

the replacement seals during installation.

(3) Install the seal with a suitable size socket.

(4) Remove the tape from the shaft.

(5) Center the steering gear.

(6) Align and install the pitman arm.

(7) Install the washer and retaining nut on the pit-

man shaft. Tighten the nut to 251 Nzm (185 ft. lbs.)

torque.

GEAR ADJUSTMENTS IN VEHICLE

REMOVE

(1) Raise and support the vehicle.

(2) Mark the pitman shaft and pitman arm for in-

stallation reference. Remove the pitman arm from

the shaft.

(3) Loosen the adjuster lock nut then back the ad-

juster plug off 1/4 turn.

(4) Remove the steering wheel horn pad.

(5) Turn the steering wheel in one direction until

stopped by the gear. Then turn back 1/2 turn.

CAUTION: Do not turn the steering wheel hard

against the internal stops when the linkage is re-

moved. This could result in damage to the recircu-

lating ball guides.

MEASURE

Place a low calibration (50 in. lbs.) torque wrench

and socket on the steering wheel nut. Rotate the

wrench and nut through a 90 degree arc (1/4 turn).

This will measure the worm shaft bearing preload.

ADJUST WORMSHAFT BEARING PRELOAD

TORQUE

(1) Adjust the preload by tightening the adjuster

plug. The preload should be 0.6 to 1 Nzm(5to8in.

lbs.) torque.

Steering column/shaft misalignment or damage will

increase the amount of torque required to rotate the

steering wheel. If the rotating torque is exceptionally

high, inspect the steering column/shaft alignment. If

the alignment is correct, remove the steering gear,

determine the cause of the high preload torque, and

repair as necessary.

(2) Tighten the adjuster locknut to 68 Nzm (50 ft.

lbs.) torque. Measure the preload torque. If neces-

sary, adjust the preload torque again.

ADJUST OVERCENTER DRAG TORQUE

(1) Turn the steering wheel from one stop to the

other and count the total numbers of turns. Turn the

wheel back in reverse direction 1/2 the total number

of turns to center the steering gear.(2) Turn the over center adjusting screw in to re-

move all lash between the ball nut and pitman shaft

sector teeth. Hold the adjustment screw and tighten

the lock nut to 34 Nzm (25 ft. lbs.) torque.

(3) Check the torque at the steering wheel by tak-

ing the highest reading as the wheel is turned

through the center position.

(4) The overcenter drag torque should be 0.5 to 1

Nzm (4 to 10 in. lbs.).

(5) If necessary, loosen the lock nut and adjust the

over center adjuster screw to obtain the proper

torque. Re-tighten the lock nut to the lock nut.

(6) After tightening the locknut, measure the over-

center drag torque again and readjust the torque, if

necessary.

INSTALL

(1) Align the installation reference marks and in-

stall the pitman arm.

(2) Install and tighten the pitman shaft nut and

washer to 251 Nzm (185 ft. lbs.) torque.

(3) Install the horn button.

GEAR DISASSEMBLY

(1) Rotate the wormshaft from stop-to-stop and

count the number of rotations. Rotate the wormshaft

in the reverse direction 1/2 of the total number of ro-

tations to center it and the ball nut.

(2) Remove the pitman shaft adjustment screw

locknut. Remove the cover retaining bolts, cover, and

gasket (Fig. 3).

(3) Slide the adjustment screw head (Fig. 3) out of

the pitman shaft T-slot and remove it and the

shim(s).

(4) Retain the shim(s) for end-play measurement

during assembly.

(5) Remove the pitman shaft, the wormshaft bear-

ing preload torque adjustment cap locknut, and the

adjustment cap (Fig. 2).

(6) Remove the wormshaft and the ball nut (Fig.

2).

(7) Remove (pry) the pitman shaft and the worm-

shaft seals from the steering gear housing (Fig. 3).

WORMSHAFT AND BALL NUT DISASSEMBLY

(1) Remove the upper bearing from the wormshaft

(Fig. 2).

CAUTION: Do not allow the ball nut to rotate freely

and travel to either extreme end of the wormshaft.

This could damage the tangs at the ends of the re-

circulating ball guides (Fig. 3).

(2) Remove the recirculating ball guide clamp re-

taining screws, the clamp and the guides (Fig. 2).

Separate the half-guides and place the recirculating

balls aside in a container.

JSTEERING 19 - 39