tire size JEEP XJ 1995 Service And User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1320 of 2158

(5) Install the lower bearing insert in the bearing

cap. The lower insert must be dry. Place strip of Plas-

tigage across full width of the lower insert at the cen-

ter of bearing cap. Plastigage must not crumble in

use. If brittle, obtain fresh stock.

(6) Install bearing cap and connecting rod on the

journal and tighten nuts to 45 Nzm (33 ft. lbs.)

torque. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

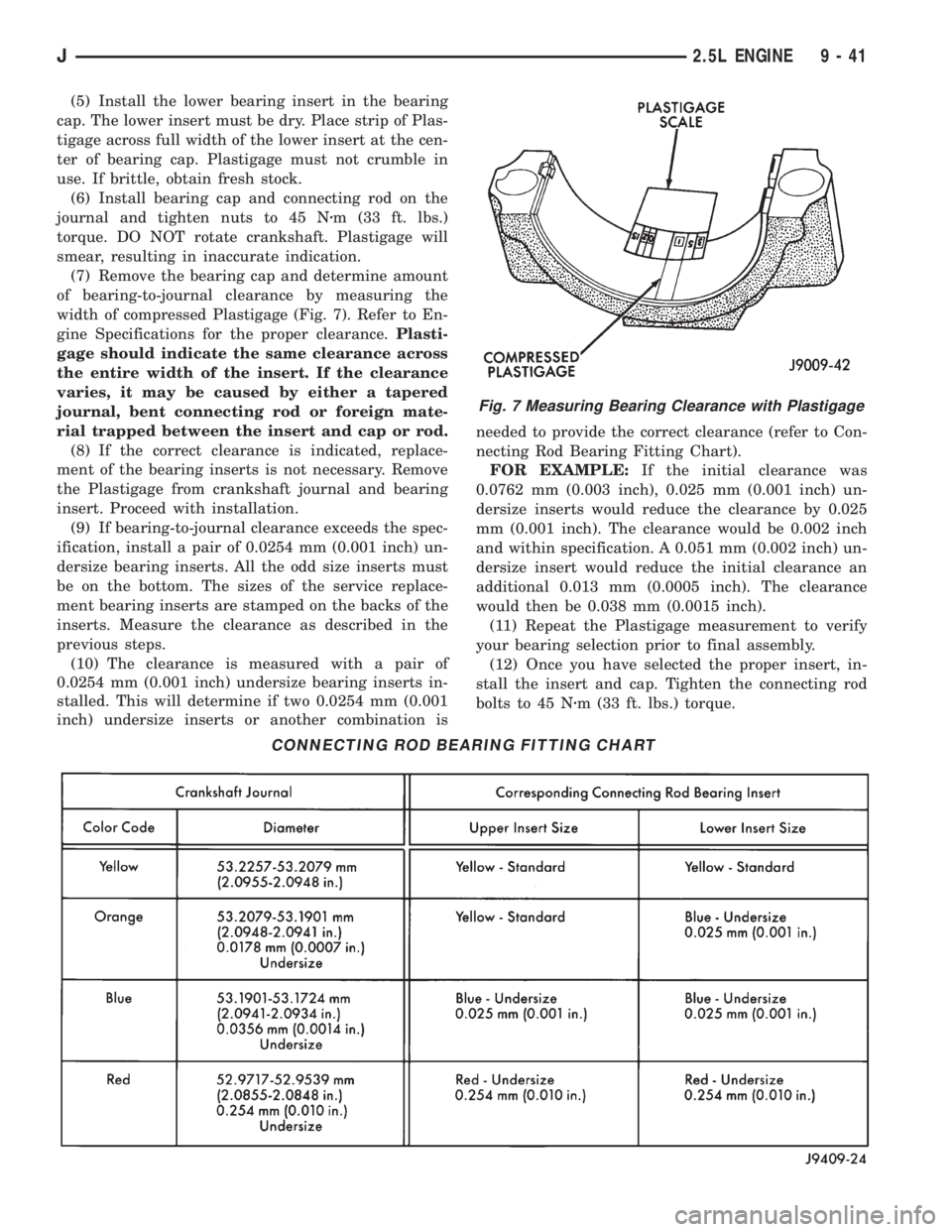

(7) Remove the bearing cap and determine amount

of bearing-to-journal clearance by measuring the

width of compressed Plastigage (Fig. 7). Refer to En-

gine Specifications for the proper clearance.Plasti-

gage should indicate the same clearance across

the entire width of the insert. If the clearance

varies, it may be caused by either a tapered

journal, bent connecting rod or foreign mate-

rial trapped between the insert and cap or rod.

(8) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(9) If bearing-to-journal clearance exceeds the spec-

ification, install a pair of 0.0254 mm (0.001 inch) un-

dersize bearing inserts. All the odd size inserts must

be on the bottom. The sizes of the service replace-

ment bearing inserts are stamped on the backs of the

inserts. Measure the clearance as described in the

previous steps.

(10) The clearance is measured with a pair of

0.0254 mm (0.001 inch) undersize bearing inserts in-

stalled. This will determine if two 0.0254 mm (0.001

inch) undersize inserts or another combination isneeded to provide the correct clearance (refer to Con-

necting Rod Bearing Fitting Chart).

FOR EXAMPLE:If the initial clearance was

0.0762 mm (0.003 inch), 0.025 mm (0.001 inch) un-

dersize inserts would reduce the clearance by 0.025

mm (0.001 inch). The clearance would be 0.002 inch

and within specification. A 0.051 mm (0.002 inch) un-

dersize insert would reduce the initial clearance an

additional 0.013 mm (0.0005 inch). The clearance

would then be 0.038 mm (0.0015 inch).

(11) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(12) Once you have selected the proper insert, in-

stall the insert and cap. Tighten the connecting rod

bolts to 45 Nzm (33 ft. lbs.) torque.

Fig. 7 Measuring Bearing Clearance with Plastigage

CONNECTING ROD BEARING FITTING CHART

J2.5L ENGINE 9 - 41

Page 1325 of 2158

FITTING (CRANKSHAFT INSTALLED)

The main bearing caps, numbered (front to rear)

from 1 through 5 have an arrow to indicate the for-

ward position. The upper main bearing inserts are

grooved to provide oil channels while the lower in-

serts are smooth.

Each bearing insert pair is selectively fitted to its

respective journal to obtain the specified operating

clearance. In production, the select fit is obtained by

using various-sized color-coded bearing insert pairs

as listed in the Main Bearing Fitting Chart. The

bearing color code appears on the edge of the insert.

The size is not stamped on bearing inserts used

for engine production.

The main bearing journal size (diameter) is identi-

fied by a color-coded paint mark on the adjacent

cheek. The rear main journal, is identified by a color-

coded paint mark on the crankshaft rear flange.

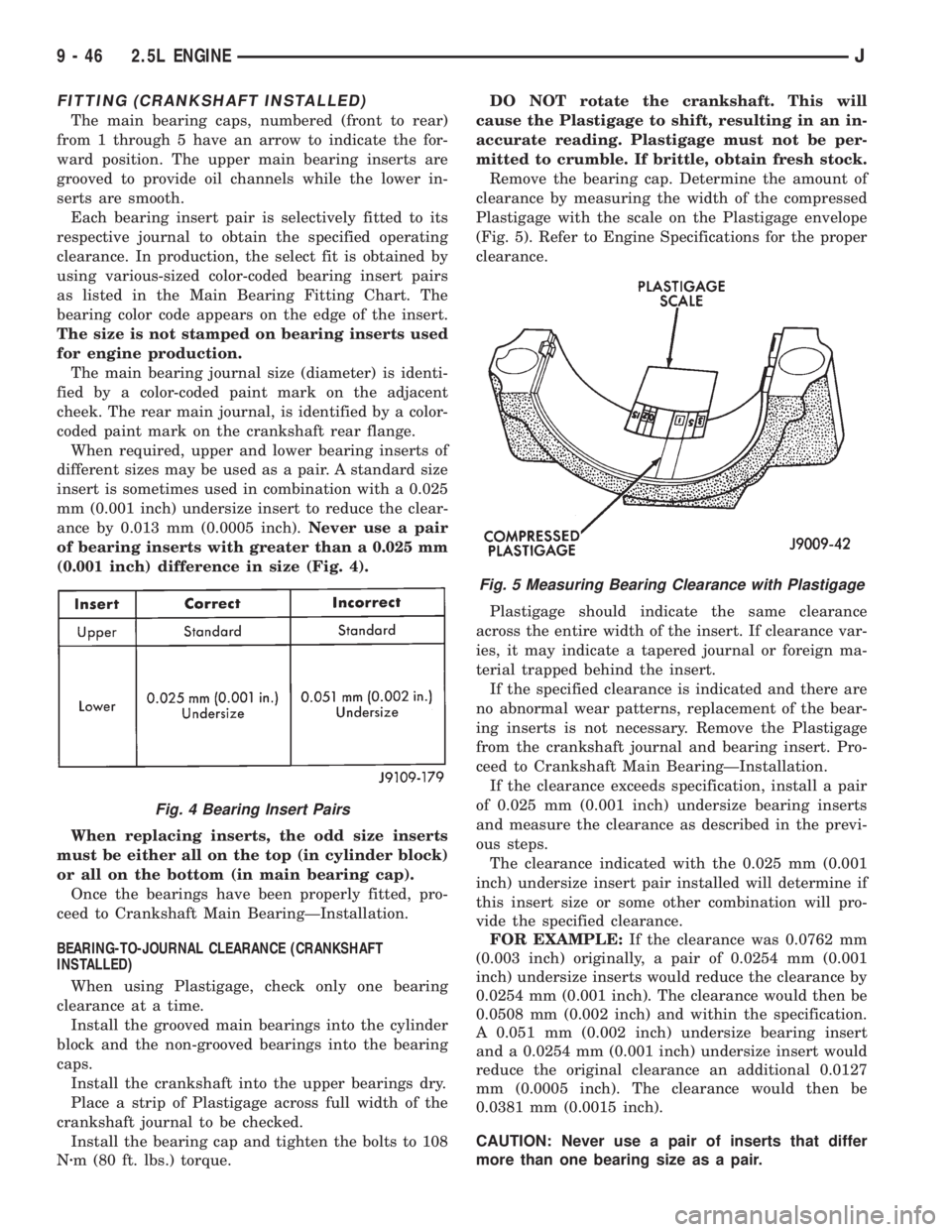

When required, upper and lower bearing inserts of

different sizes may be used as a pair. A standard size

insert is sometimes used in combination with a 0.025

mm (0.001 inch) undersize insert to reduce the clear-

ance by 0.013 mm (0.0005 inch).Never use a pair

of bearing inserts with greater than a 0.025 mm

(0.001 inch) difference in size (Fig. 4).

When replacing inserts, the odd size inserts

must be either all on the top (in cylinder block)

or all on the bottom (in main bearing cap).

Once the bearings have been properly fitted, pro-

ceed to Crankshaft Main BearingÐInstallation.

BEARING-TO-JOURNAL CLEARANCE (CRANKSHAFT

INSTALLED)

When using Plastigage, check only one bearing

clearance at a time.

Install the grooved main bearings into the cylinder

block and the non-grooved bearings into the bearing

caps.

Install the crankshaft into the upper bearings dry.

Place a strip of Plastigage across full width of the

crankshaft journal to be checked.

Install the bearing cap and tighten the bolts to 108

Nzm (80 ft. lbs.) torque.DO NOT rotate the crankshaft. This will

cause the Plastigage to shift, resulting in an in-

accurate reading. Plastigage must not be per-

mitted to crumble. If brittle, obtain fresh stock.

Remove the bearing cap. Determine the amount of

clearance by measuring the width of the compressed

Plastigage with the scale on the Plastigage envelope

(Fig. 5). Refer to Engine Specifications for the proper

clearance.

Plastigage should indicate the same clearance

across the entire width of the insert. If clearance var-

ies, it may indicate a tapered journal or foreign ma-

terial trapped behind the insert.

If the specified clearance is indicated and there are

no abnormal wear patterns, replacement of the bear-

ing inserts is not necessary. Remove the Plastigage

from the crankshaft journal and bearing insert. Pro-

ceed to Crankshaft Main BearingÐInstallation.

If the clearance exceeds specification, install a pair

of 0.025 mm (0.001 inch) undersize bearing inserts

and measure the clearance as described in the previ-

ous steps.

The clearance indicated with the 0.025 mm (0.001

inch) undersize insert pair installed will determine if

this insert size or some other combination will pro-

vide the specified clearance.

FOR EXAMPLE:If the clearance was 0.0762 mm

(0.003 inch) originally, a pair of 0.0254 mm (0.001

inch) undersize inserts would reduce the clearance by

0.0254 mm (0.001 inch). The clearance would then be

0.0508 mm (0.002 inch) and within the specification.

A 0.051 mm (0.002 inch) undersize bearing insert

and a 0.0254 mm (0.001 inch) undersize insert would

reduce the original clearance an additional 0.0127

mm (0.0005 inch). The clearance would then be

0.0381 mm (0.0015 inch).

CAUTION: Never use a pair of inserts that differ

more than one bearing size as a pair.

Fig. 4 Bearing Insert Pairs

Fig. 5 Measuring Bearing Clearance with Plastigage

9 - 46 2.5L ENGINEJ

Page 1362 of 2158

(5) Install the lower bearing insert in the bearing

cap. The lower insert must be dry. Place strip of Plas-

tigage across full width of the lower insert at the cen-

ter of bearing cap. Plastigage must not crumble in

use. If brittle, obtain fresh stock.

(6) Install bearing cap and connecting rod on the

journal and tighten nuts to 45 Nzm (33 ft. lbs.)

torque. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

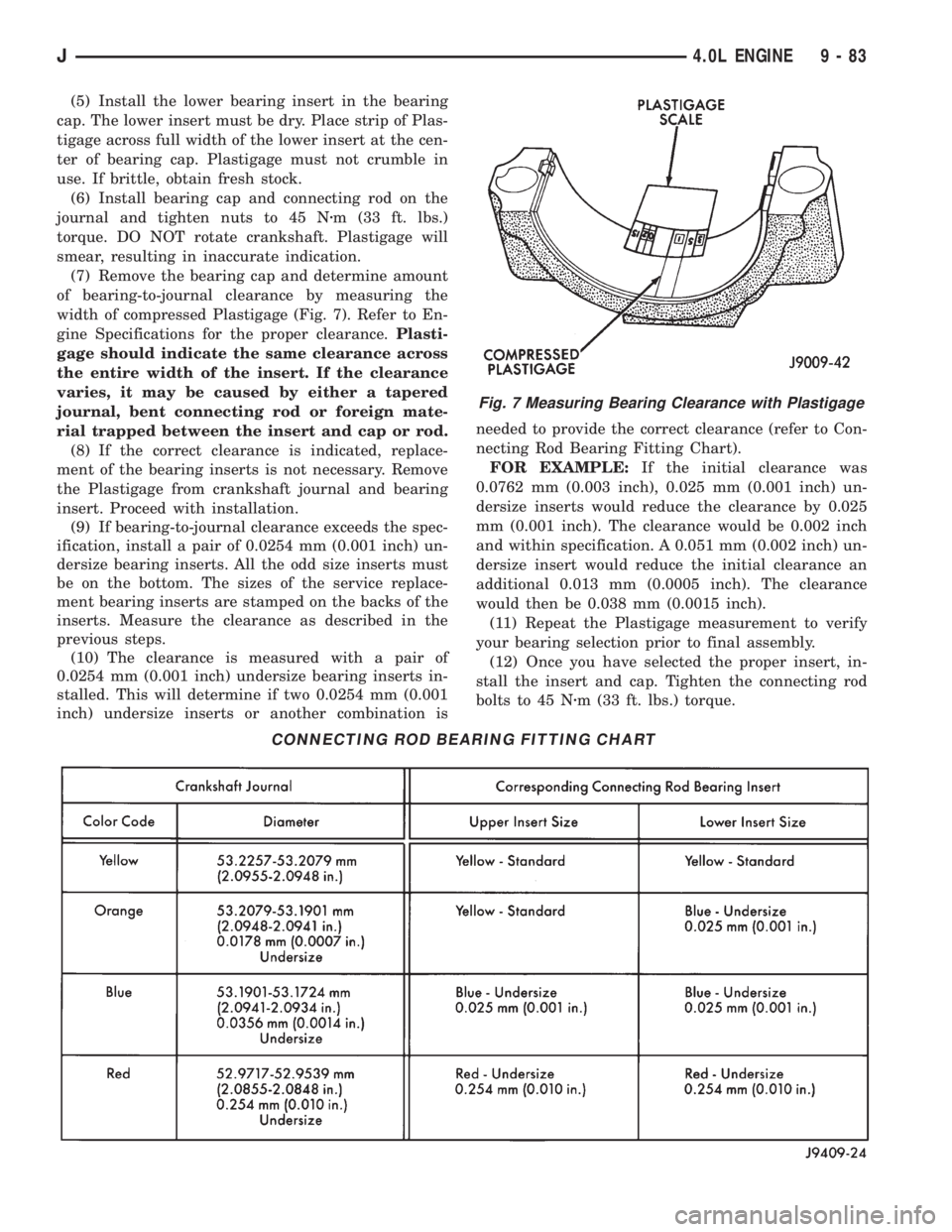

(7) Remove the bearing cap and determine amount

of bearing-to-journal clearance by measuring the

width of compressed Plastigage (Fig. 7). Refer to En-

gine Specifications for the proper clearance.Plasti-

gage should indicate the same clearance across

the entire width of the insert. If the clearance

varies, it may be caused by either a tapered

journal, bent connecting rod or foreign mate-

rial trapped between the insert and cap or rod.

(8) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(9) If bearing-to-journal clearance exceeds the spec-

ification, install a pair of 0.0254 mm (0.001 inch) un-

dersize bearing inserts. All the odd size inserts must

be on the bottom. The sizes of the service replace-

ment bearing inserts are stamped on the backs of the

inserts. Measure the clearance as described in the

previous steps.

(10) The clearance is measured with a pair of

0.0254 mm (0.001 inch) undersize bearing inserts in-

stalled. This will determine if two 0.0254 mm (0.001

inch) undersize inserts or another combination isneeded to provide the correct clearance (refer to Con-

necting Rod Bearing Fitting Chart).

FOR EXAMPLE:If the initial clearance was

0.0762 mm (0.003 inch), 0.025 mm (0.001 inch) un-

dersize inserts would reduce the clearance by 0.025

mm (0.001 inch). The clearance would be 0.002 inch

and within specification. A 0.051 mm (0.002 inch) un-

dersize insert would reduce the initial clearance an

additional 0.013 mm (0.0005 inch). The clearance

would then be 0.038 mm (0.0015 inch).

(11) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(12) Once you have selected the proper insert, in-

stall the insert and cap. Tighten the connecting rod

bolts to 45 Nzm (33 ft. lbs.) torque.

Fig. 7 Measuring Bearing Clearance with Plastigage

CONNECTING ROD BEARING FITTING CHART

J4.0L ENGINE 9 - 83

Page 1367 of 2158

ward position. The upper main bearing inserts are

grooved to provide oil channels while the lower in-

serts are smooth.

Each bearing insert pair is selectively fitted to its

respective journal to obtain the specified operating

clearance. In production, the select fit is obtained by

using various-sized color-coded bearing insert pairs

as listed in the Main Bearing Fitting Chart. The

bearing color code appears on the edge of the insert.

The size is not stamped on bearing inserts used

for engine production.

The main bearing journal size (diameter) is identi-

fied by a color-coded paint mark on the adjacent

cheek. The rear main journal, is identified by a color-

coded paint mark on the crankshaft rear flange.

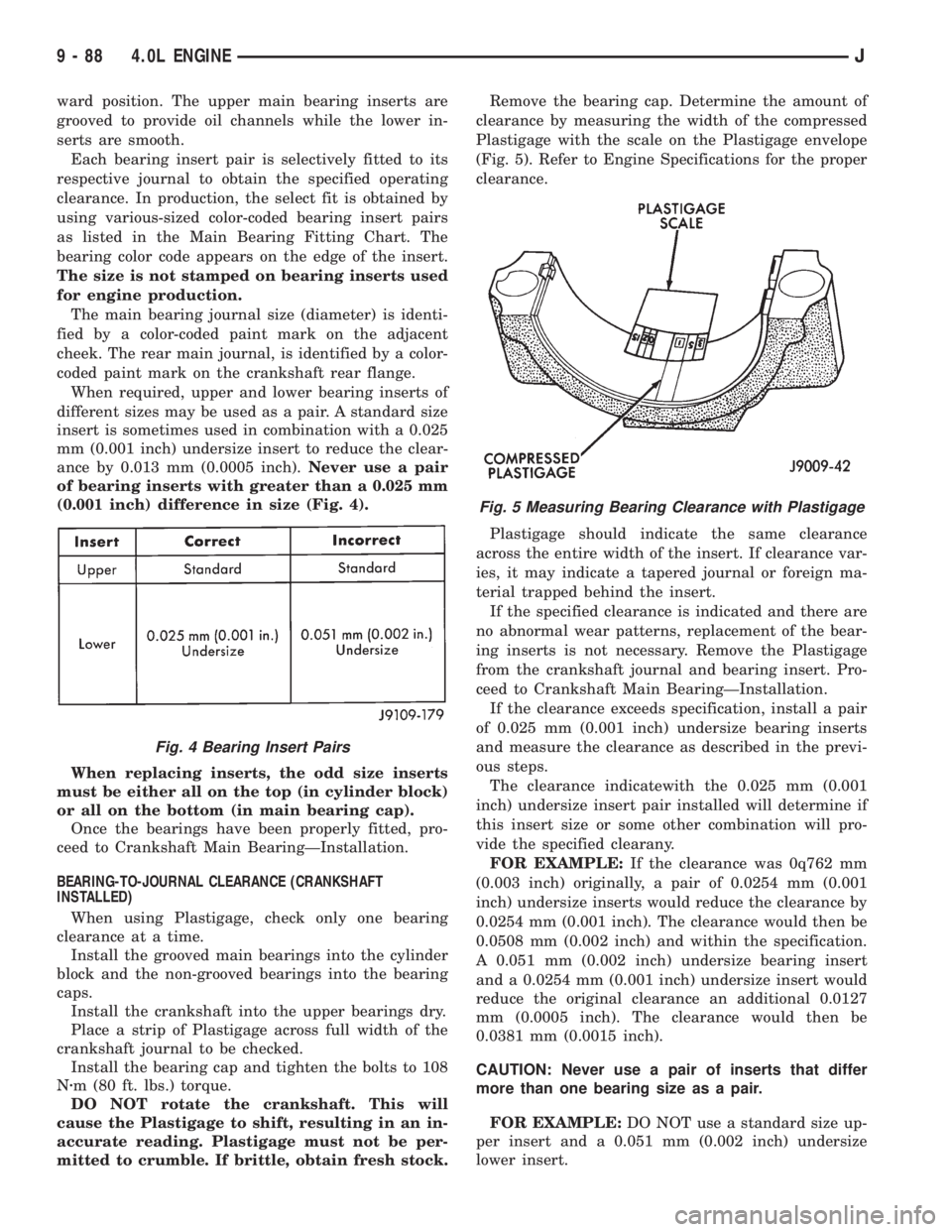

When required, upper and lower bearing inserts of

different sizes may be used as a pair. A standard size

insert is sometimes used in combination with a 0.025

mm (0.001 inch) undersize insert to reduce the clear-

ance by 0.013 mm (0.0005 inch).Never use a pair

of bearing inserts with greater than a 0.025 mm

(0.001 inch) difference in size (Fig. 4).

When replacing inserts, the odd size inserts

must be either all on the top (in cylinder block)

or all on the bottom (in main bearing cap).

Once the bearings have been properly fitted, pro-

ceed to Crankshaft Main BearingÐInstallation.

BEARING-TO-JOURNAL CLEARANCE (CRANKSHAFT

INSTALLED)

When using Plastigage, check only one bearing

clearance at a time.

Install the grooved main bearings into the cylinder

block and the non-grooved bearings into the bearing

caps.

Install the crankshaft into the upper bearings dry.

Place a strip of Plastigage across full width of the

crankshaft journal to be checked.

Install the bearing cap and tighten the bolts to 108

Nzm (80 ft. lbs.) torque.

DO NOT rotate the crankshaft. This will

cause the Plastigage to shift, resulting in an in-

accurate reading. Plastigage must not be per-

mitted to crumble. If brittle, obtain fresh stock.Remove the bearing cap. Determine the amount of

clearance by measuring the width of the compressed

Plastigage with the scale on the Plastigage envelope

(Fig. 5). Refer to Engine Specifications for the proper

clearance.

Plastigage should indicate the same clearance

across the entire width of the insert. If clearance var-

ies, it may indicate a tapered journal or foreign ma-

terial trapped behind the insert.

If the specified clearance is indicated and there are

no abnormal wear patterns, replacement of the bear-

ing inserts is not necessary. Remove the Plastigage

from the crankshaft journal and bearing insert. Pro-

ceed to Crankshaft Main BearingÐInstallation.

If the clearance exceeds specification, install a pair

of 0.025 mm (0.001 inch) undersize bearing inserts

and measure the clearance as described in the previ-

ous steps.

The clearance indicatewith the 0.025 mm (0.001

inch) undersize insert pair installed will determine if

this insert size or some other combination will pro-

vide the specified clearany.

FOR EXAMPLE:If the clearance was 0q762 mm

(0.003 inch) originally, a pair of 0.0254 mm (0.001

inch) undersize inserts would reduce the clearance by

0.0254 mm (0.001 inch). The clearance would then be

0.0508 mm (0.002 inch) and within the specification.

A 0.051 mm (0.002 inch) undersize bearing insert

and a 0.0254 mm (0.001 inch) undersize insert would

reduce the original clearance an additional 0.0127

mm (0.0005 inch). The clearance would then be

0.0381 mm (0.0015 inch).

CAUTION: Never use a pair of inserts that differ

more than one bearing size as a pair.

FOR EXAMPLE:DO NOT use a standard size up-

per insert and a 0.051 mm (0.002 inch) undersize

lower insert.

Fig. 4 Bearing Insert Pairs

Fig. 5 Measuring Bearing Clearance with Plastigage

9 - 88 4.0L ENGINEJ

Page 1671 of 2158

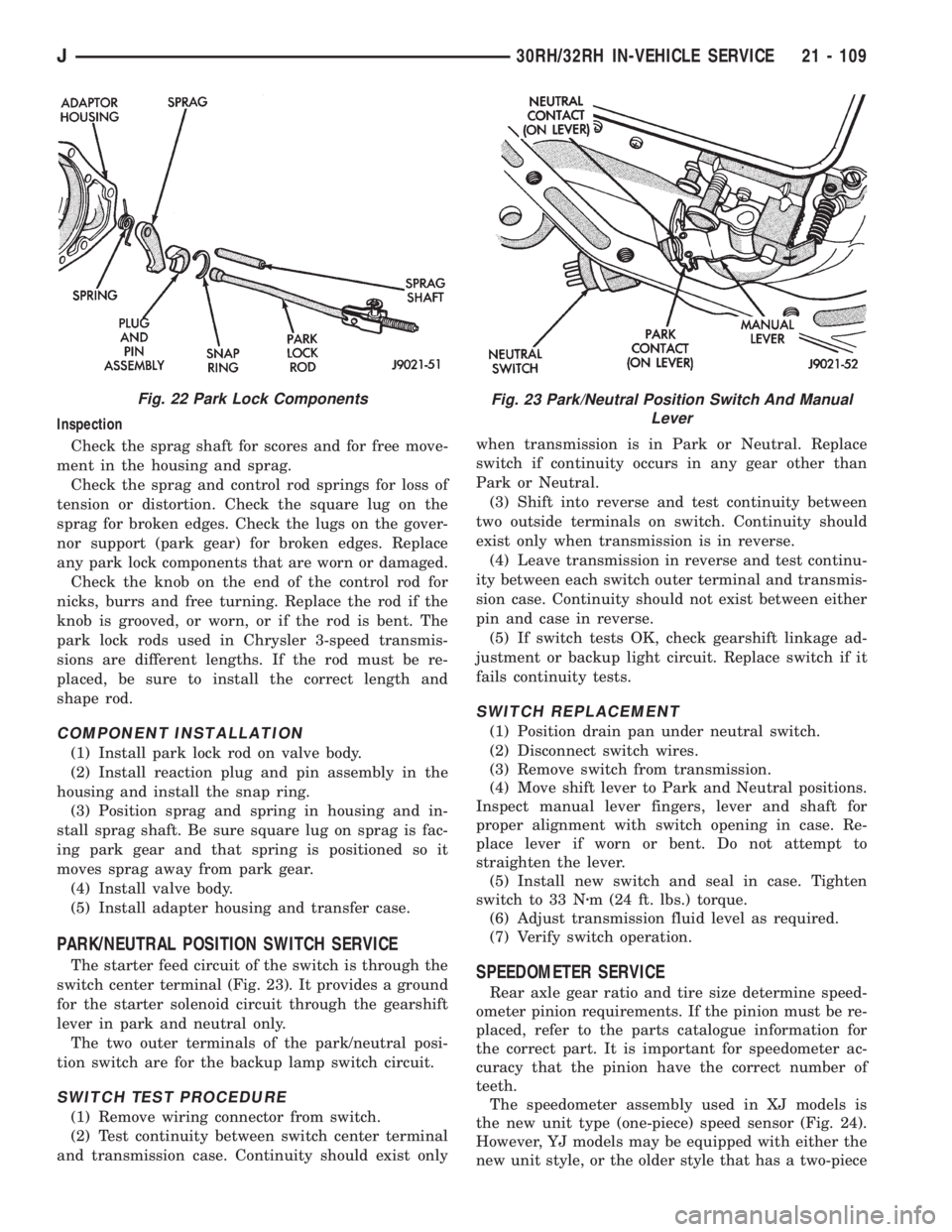

Inspection

Check the sprag shaft for scores and for free move-

ment in the housing and sprag.

Check the sprag and control rod springs for loss of

tension or distortion. Check the square lug on the

sprag for broken edges. Check the lugs on the gover-

nor support (park gear) for broken edges. Replace

any park lock components that are worn or damaged.

Check the knob on the end of the control rod for

nicks, burrs and free turning. Replace the rod if the

knob is grooved, or worn, or if the rod is bent. The

park lock rods used in Chrysler 3-speed transmis-

sions are different lengths. If the rod must be re-

placed, be sure to install the correct length and

shape rod.

COMPONENT INSTALLATION

(1) Install park lock rod on valve body.

(2) Install reaction plug and pin assembly in the

housing and install the snap ring.

(3) Position sprag and spring in housing and in-

stall sprag shaft. Be sure square lug on sprag is fac-

ing park gear and that spring is positioned so it

moves sprag away from park gear.

(4) Install valve body.

(5) Install adapter housing and transfer case.

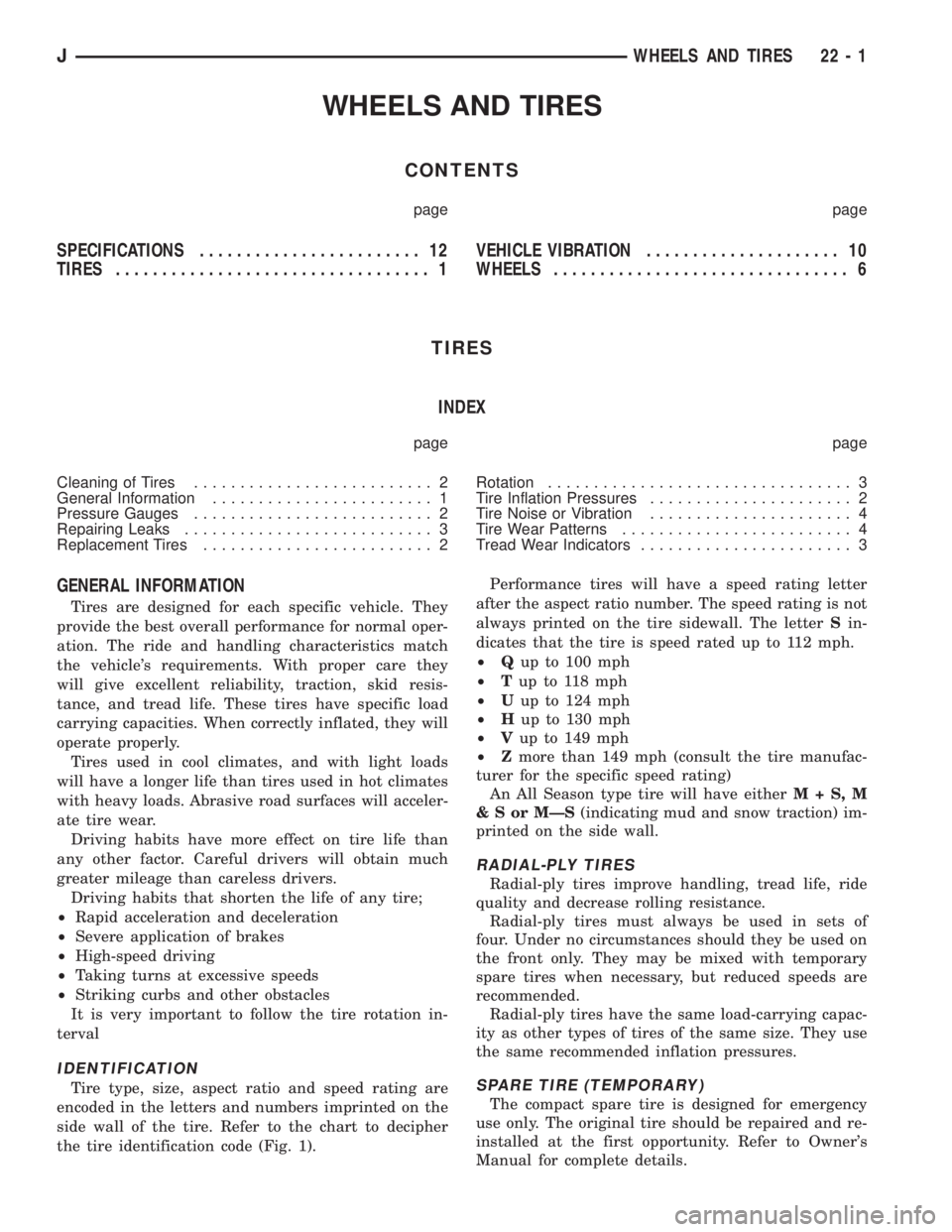

PARK/NEUTRAL POSITION SWITCH SERVICE

The starter feed circuit of the switch is through the

switch center terminal (Fig. 23). It provides a ground

for the starter solenoid circuit through the gearshift

lever in park and neutral only.

The two outer terminals of the park/neutral posi-

tion switch are for the backup lamp switch circuit.

SWITCH TEST PROCEDURE

(1) Remove wiring connector from switch.

(2) Test continuity between switch center terminal

and transmission case. Continuity should exist onlywhen transmission is in Park or Neutral. Replace

switch if continuity occurs in any gear other than

Park or Neutral.

(3) Shift into reverse and test continuity between

two outside terminals on switch. Continuity should

exist only when transmission is in reverse.

(4) Leave transmission in reverse and test continu-

ity between each switch outer terminal and transmis-

sion case. Continuity should not exist between either

pin and case in reverse.

(5) If switch tests OK, check gearshift linkage ad-

justment or backup light circuit. Replace switch if it

fails continuity tests.

SWITCH REPLACEMENT

(1) Position drain pan under neutral switch.

(2) Disconnect switch wires.

(3) Remove switch from transmission.

(4) Move shift lever to Park and Neutral positions.

Inspect manual lever fingers, lever and shaft for

proper alignment with switch opening in case. Re-

place lever if worn or bent. Do not attempt to

straighten the lever.

(5) Install new switch and seal in case. Tighten

switch to 33 Nzm (24 ft. lbs.) torque.

(6) Adjust transmission fluid level as required.

(7) Verify switch operation.

SPEEDOMETER SERVICE

Rear axle gear ratio and tire size determine speed-

ometer pinion requirements. If the pinion must be re-

placed, refer to the parts catalogue information for

the correct part. It is important for speedometer ac-

curacy that the pinion have the correct number of

teeth.

The speedometer assembly used in XJ models is

the new unit type (one-piece) speed sensor (Fig. 24).

However, YJ models may be equipped with either the

new unit style, or the older style that has a two-piece

Fig. 22 Park Lock ComponentsFig. 23 Park/Neutral Position Switch And Manual

Lever

J30RH/32RH IN-VEHICLE SERVICE 21 - 109

Page 1907 of 2158

WHEELS AND TIRES

CONTENTS

page page

SPECIFICATIONS........................ 12

TIRES.................................. 1VEHICLE VIBRATION..................... 10

WHEELS................................ 6

TIRES

INDEX

page page

Cleaning of Tires.......................... 2

General Information........................ 1

Pressure Gauges.......................... 2

Repairing Leaks........................... 3

Replacement Tires......................... 2Rotation................................. 3

Tire Inflation Pressures...................... 2

Tire Noise or Vibration...................... 4

Tire Wear Patterns......................... 4

Tread Wear Indicators....................... 3

GENERAL INFORMATION

Tires are designed for each specific vehicle. They

provide the best overall performance for normal oper-

ation. The ride and handling characteristics match

the vehicle's requirements. With proper care they

will give excellent reliability, traction, skid resis-

tance, and tread life. These tires have specific load

carrying capacities. When correctly inflated, they will

operate properly.

Tires used in cool climates, and with light loads

will have a longer life than tires used in hot climates

with heavy loads. Abrasive road surfaces will acceler-

ate tire wear.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain much

greater mileage than careless drivers.

Driving habits that shorten the life of any tire;

²Rapid acceleration and deceleration

²Severe application of brakes

²High-speed driving

²Taking turns at excessive speeds

²Striking curbs and other obstacles

It is very important to follow the tire rotation in-

terval

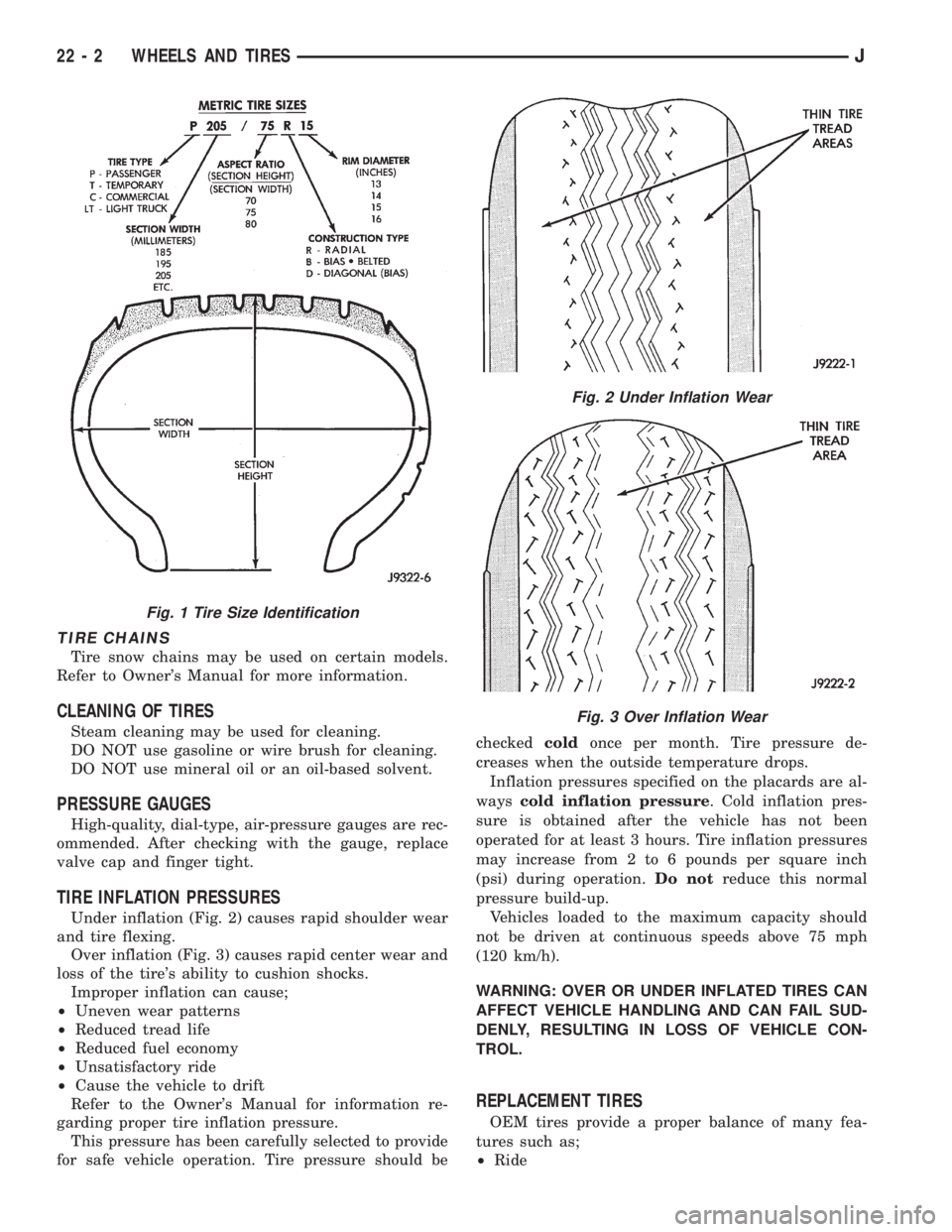

IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 1).Performance tires will have a speed rating letter

after the aspect ratio number. The speed rating is not

always printed on the tire sidewall. The letterSin-

dicates that the tire is speed rated up to 112 mph.

²Qup to 100 mph

²Tup to 118 mph

²Uup to 124 mph

²Hup to 130 mph

²Vup to 149 mph

²Zmore than 149 mph (consult the tire manufac-

turer for the specific speed rating)

An All Season type tire will have eitherM+S,M

&SorMÐS(indicating mud and snow traction) im-

printed on the side wall.

RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life, ride

quality and decrease rolling resistance.

Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary, but reduced speeds are

recommended.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They use

the same recommended inflation pressures.

SPARE TIRE (TEMPORARY)

The compact spare tire is designed for emergency

use only. The original tire should be repaired and re-

installed at the first opportunity. Refer to Owner's

Manual for complete details.

JWHEELS AND TIRES 22 - 1

Page 1908 of 2158

TIRE CHAINS

Tire snow chains may be used on certain models.

Refer to Owner's Manual for more information.

CLEANING OF TIRES

Steam cleaning may be used for cleaning.

DO NOT use gasoline or wire brush for cleaning.

DO NOT use mineral oil or an oil-based solvent.

PRESSURE GAUGES

High-quality, dial-type, air-pressure gauges are rec-

ommended. After checking with the gauge, replace

valve cap and finger tight.

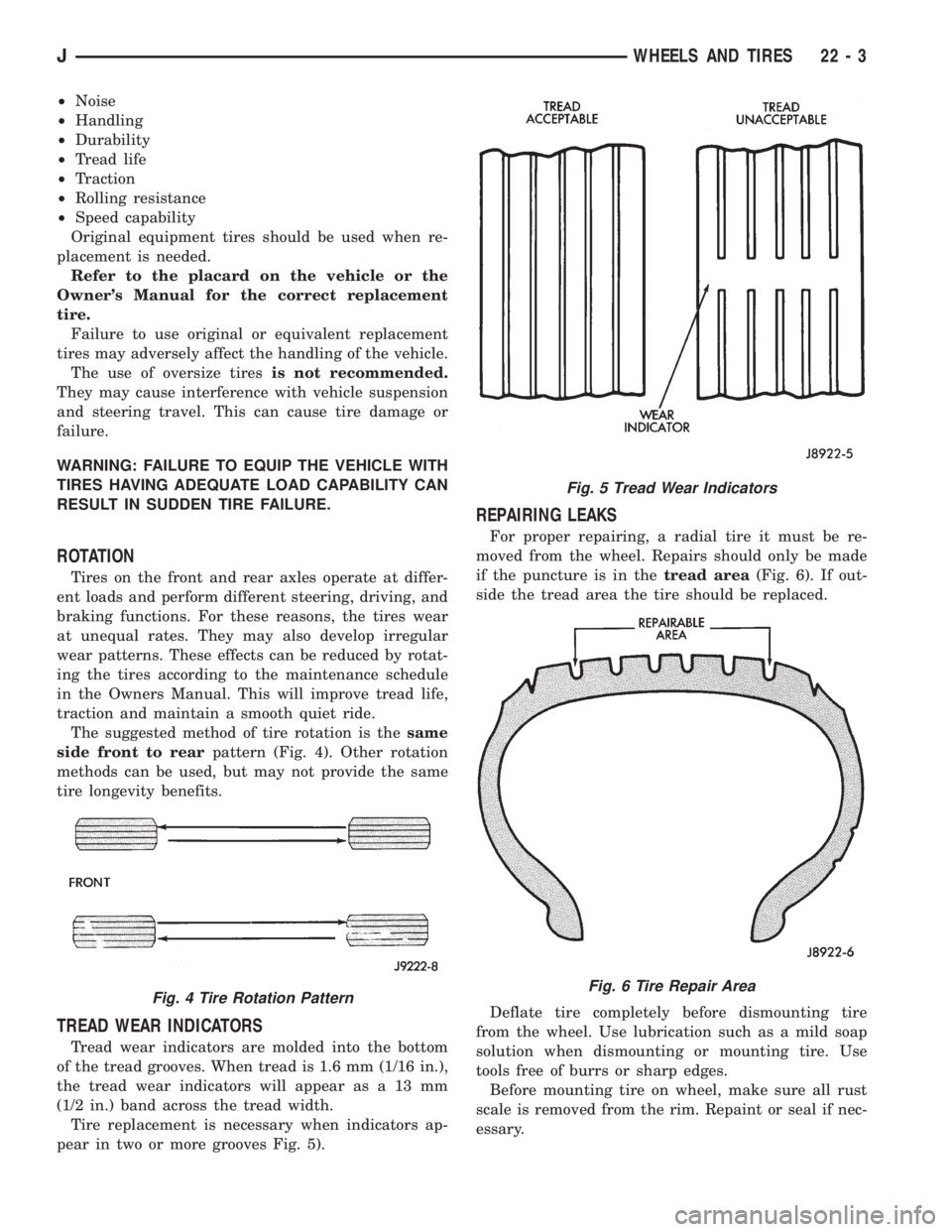

TIRE INFLATION PRESSURES

Under inflation (Fig. 2) causes rapid shoulder wear

and tire flexing.

Over inflation (Fig. 3) causes rapid center wear and

loss of the tire's ability to cushion shocks.

Improper inflation can cause;

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²Cause the vehicle to drift

Refer to the Owner's Manual for information re-

garding proper tire inflation pressure.

This pressure has been carefully selected to provide

for safe vehicle operation. Tire pressure should becheckedcoldonce per month. Tire pressure de-

creases when the outside temperature drops.

Inflation pressures specified on the placards are al-

wayscold inflation pressure. Cold inflation pres-

sure is obtained after the vehicle has not been

operated for at least 3 hours. Tire inflation pressures

may increase from 2 to 6 pounds per square inch

(psi) during operation.Do notreduce this normal

pressure build-up.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph

(120 km/h).

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING AND CAN FAIL SUD-

DENLY, RESULTING IN LOSS OF VEHICLE CON-

TROL.

REPLACEMENT TIRES

OEM tires provide a proper balance of many fea-

tures such as;

²Ride

Fig. 1 Tire Size Identification

Fig. 2 Under Inflation Wear

Fig. 3 Over Inflation Wear

22 - 2 WHEELS AND TIRESJ

Page 1909 of 2158

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capability

Original equipment tires should be used when re-

placement is needed.

Refer to the placard on the vehicle or the

Owner's Manual for the correct replacement

tire.

Failure to use original or equivalent replacement

tires may adversely affect the handling of the vehicle.

The use of oversize tiresis not recommended.

They may cause interference with vehicle suspension

and steering travel. This can cause tire damage or

failure.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE LOAD CAPABILITY CAN

RESULT IN SUDDEN TIRE FAILURE.

ROTATION

Tires on the front and rear axles operate at differ-

ent loads and perform different steering, driving, and

braking functions. For these reasons, the tires wear

at unequal rates. They may also develop irregular

wear patterns. These effects can be reduced by rotat-

ing the tires according to the maintenance schedule

in the Owners Manual. This will improve tread life,

traction and maintain a smooth quiet ride.

The suggested method of tire rotation is thesame

side front to rearpattern (Fig. 4). Other rotation

methods can be used, but may not provide the same

tire longevity benefits.

TREAD WEAR INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread is 1.6 mm (1/16 in.),

the tread wear indicators will appear as a 13 mm

(1/2 in.) band across the tread width.

Tire replacement is necessary when indicators ap-

pear in two or more grooves Fig. 5).

REPAIRING LEAKS

For proper repairing, a radial tire it must be re-

moved from the wheel. Repairs should only be made

if the puncture is in thetread area(Fig. 6). If out-

side the tread area the tire should be replaced.

Deflate tire completely before dismounting tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges.

Before mounting tire on wheel, make sure all rust

scale is removed from the rim. Repaint or seal if nec-

essary.

Fig. 4 Tire Rotation Pattern

Fig. 5 Tread Wear Indicators

Fig. 6 Tire Repair Area

JWHEELS AND TIRES 22 - 3

Page 1995 of 2158

TRAILER HITCH

TRAILER HITCHÐXJ

CLASS III HITCH

A class III weight-distributing/equalizer type hitch

can be used to tow a trailer:

²Having a maximum gross weight of 5,000 lbs/2250

kg.

²Having a maximum tongue weight of 750 lbs/332

kg).

The following vehicle basic equipment is required

for class III trailer towing:

²P205/75R15 or larger tires.

²Full size spare tire.

²Trailer sway control.

²Trailer tow wire harness and connector.

²Heavy duty turn signal flasher element.

²Heavy duty axle (with synthetic lubricant).

²Heavy duty cooling system.

²Heavy duty generator/battery.

²Auxiliary automatic transmission fluid cooler.

²I-6, 4.0L engine.

Wide-angle type door mirrors are recommended but

not required.

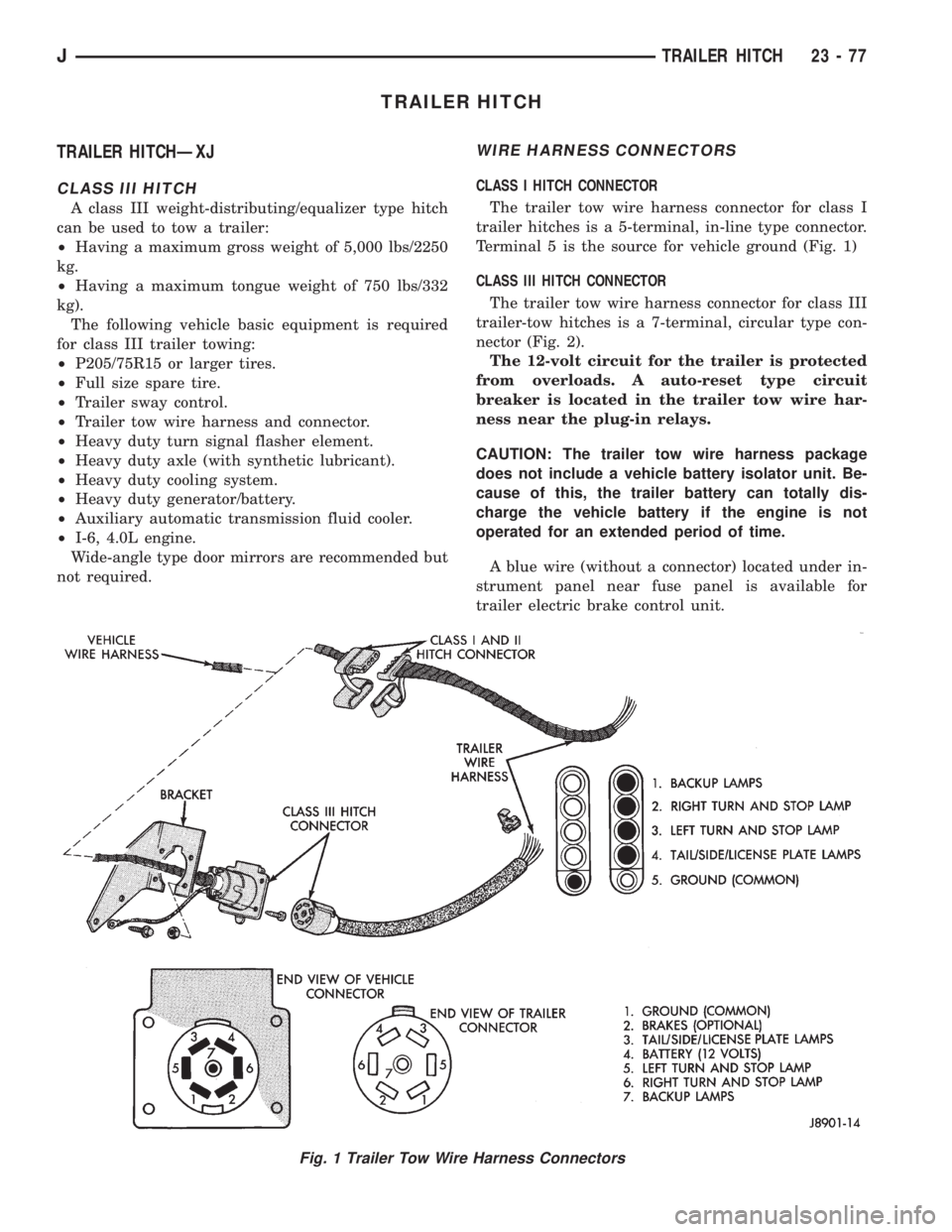

WIRE HARNESS CONNECTORS

CLASS I HITCH CONNECTOR

The trailer tow wire harness connector for class I

trailer hitches is a 5-terminal, in-line type connector.

Terminal 5 is the source for vehicle ground (Fig. 1)

CLASS III HITCH CONNECTOR

The trailer tow wire harness connector for class III

trailer-tow hitches is a 7-terminal, circular type con-

nector (Fig. 2).

The 12-volt circuit for the trailer is protected

from overloads. A auto-reset type circuit

breaker is located in the trailer tow wire har-

ness near the plug-in relays.

CAUTION: The trailer tow wire harness package

does not include a vehicle battery isolator unit. Be-

cause of this, the trailer battery can totally dis-

charge the vehicle battery if the engine is not

operated for an extended period of time.

A blue wire (without a connector) located under in-

strument panel near fuse panel is available for

trailer electric brake control unit.

Fig. 1 Trailer Tow Wire Harness Connectors

JTRAILER HITCH 23 - 77

Page 2138 of 2158

INDEX, DIAGRAM; FRONT LIGHTING

(XJ).............................8W-50-2

INDEX, DIAGRAM; FRONT LIGHTING

(XJ-RHD).........................8W-50-3

INDEX, DIAGRAM; FRONT LIGHTING

(YJ).............................8W-50-2

INDEX, DIAGRAM; FUEL/IGNITION (YJ) . 8W-30-5

INDEX, DIAGRAM; FUSE/FUSE BLOCK

(XJ).............................8W-10-1

INDEX, DIAGRAM; FUSE/FUSE BLOCK

(XJ-RHD).........................8W-10-1

INDEX, DIAGRAM; FUSE/FUSE BLOCK

(YJ).............................8W-10-1

INDEX, DIAGRAM; GROUND

DISTRIBUTION (XJ)................8W-15-1

INDEX, DIAGRAM; GROUND

DISTRIBUTION (XJ-RHD)............8W-15-1

INDEX, DIAGRAM; GROUND

DISTRIBUTION (YJ)................8W-15-1

INDEX, DIAGRAM; HEATED REAR

WINDOW (XJ).....................8W-48-1

INDEX, DIAGRAM; HEATED REAR

WINDOW (XJ-RHD).................8W-48-1

INDEX, DIAGRAM; HEATED REAR

WINDOW (YJ).....................8W-48-1

INDEX, DIAGRAM; HORN/CIGAR

LIGHTER............................8E-1

INDEX, DIAGRAM; HORN/CIGAR

LIGHTER (YJ).....................8W-41-1

INDEX, DIAGRAM; INSTRUMENT

CLUSTER (XJ).............8W-40-1,8W-40-3

INDEX, DIAGRAM; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-3

INDEX, DIAGRAM; INSTRUMENT

CLUSTER (YJ).....................8W-40-2

INDEX, DIAGRAM; INTERIOR LIGHTING

(XJ).............................8W-44-2

INDEX, DIAGRAM; INTERIOR LIGHTING

(XJ-RHD).........................8W-44-2

INDEX, DIAGRAM; INTERIOR LIGHTING

(YJ).............................8W-44-2

INDEX, DIAGRAM; OVERHEAD CONSOLE

(XJ).............................8W-49-1

INDEX, DIAGRAM; OVERHEAD CONSOLE

(XJ-RHD).........................8W-49-1

INDEX, DIAGRAM; POWER

DISTRIBUTION (XJ)................8W-11-1

INDEX, DIAGRAM; POWER

DISTRIBUTION (XJ-RHD)............8W-11-1

INDEX, DIAGRAM; POWER

DISTRIBUTION (YJ)................8W-11-1

INDEX, DIAGRAM; POWER DOOR LOCKS

(XJ).............................8W-61-1

INDEX, DIAGRAM; POWER DOOR LOCKS

(XJ-RHD).........................8W-61-1

INDEX, DIAGRAM; POWER MIRRORS

(XJ).............................8W-62-1

INDEX, DIAGRAM; POWER MIRRORS

(XJ-RHD).........................8W-62-1

INDEX, DIAGRAM; POWER SEAT (XJ) . . 8W-63-1

INDEX, DIAGRAM; POWER SEAT

(XJ-RHD).........................8W-63-1

INDEX, DIAGRAM; POWER WINDOWS

(XJ).............................8W-60-2

INDEX, DIAGRAM; POWER WINDOWS

(XJ-RHD).........................8W-60-2

INDEX, DIAGRAM; REAR LIGHTING

(XJ).............................8W-51-1

INDEX, DIAGRAM; REAR LIGHTING

(XJ-RHD).........................8W-51-1

INDEX, DIAGRAM; REAR LIGHTING

(YJ).............................8W-51-1

INDEX, DIAGRAM; STARTING SYSTEM

(XJ).............................8W-21-1

INDEX, DIAGRAM; STARTING SYSTEM

(XJ-RHD).........................8W-21-1

INDEX, DIAGRAM; STARTING SYSTEM

(YJ).............................8W-21-1

INDEX, DIAGRAM; TRAILER TOW (XJ) . . 8W-54-1

INDEX, DIAGRAM; TRAILER TOW

(XJ-RHD)

.........................8W-54-1

INDEX, DIAGRAM; TRANSMISSION

CONTROLS (XJ)

...................8W-31-1

INDEX, DIAGRAM; TRANSMISSION

CONTROLS (XJ-RHD)

...............8W-31-1

INDEX, DIAGRAM; TRANSMISSION

CONTROLS (YJ)

...................8W-31-1

INDEX, DIAGRAM; TURN SIGNALS (XJ)

. 8W-52-1INDEX, DIAGRAM; TURN SIGNALS

(XJ-RHD).........................8W-52-1

INDEX, DIAGRAM; TURN SIGNALS (YJ) . 8W-52-1

INDEX, DIAGRAM; VEHICLE SPEED

CONTROL (XJ)....................8W-33-1

INDEX, DIAGRAM; VEHICLE SPEED

CONTROL (XJ-RHD)................8W-33-1

INDEX, DIAGRAM; WIPERS (XJ).......8W-53-2

INDEX, DIAGRAM; WIPERS (XJ-RHD) . . 8W-53-2

INDEX, DIAGRAM; WIPERS (YJ).......8W-53-2

INDEX, DIAGRAM; FUEL/IGNITION

(XJ-RHD).........................8W-30-5

INDEX, GROUP; COOLING SYSTEM.......8E-1

INDEX, GROUP; INSTRUMENT PANEL

AND GAUGES........................8E-1

INDEX, SPLICE; SPLICE INFORMATION

(XJ).............................8W-70-1

INDEX, SPLICE; SPLICE INFORMATION

(XJ-RHD).........................8W-70-1

INDEX, SPLICE; SPLICE INFORMATION

(YJ).............................8W-70-1

INDEXÐ2.5L ENGINE, DIAGRAM......8W-30-6

INDEXÐ4.0L ENGINE, DIAGRAM......8W-30-6

INDICATOR LAMP, CHARGING SYSTEM . 8W-40-3

INDICATOR LAMP, HIGH-BEAM;

INSTRUMENT CLUSTER (XJ).........8W-40-2

INDICATOR LAMP, HIGH-BEAM;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

INDICATOR LAMP (MIL), MALFUNCTION;

FUEL/IGNITION (XJ)................8W-30-5

INDICATOR LAMP (MIL), MALFUNCTION;

FUEL/IGNITION (YJ)................8W-30-5

INDICATOR LAMP (MIL), MALFUNCTION;

INSTRUMENT CLUSTER (XJ).........8W-40-2

INDICATOR LAMP (MIL), MALFUNCTION;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-1

INDICATOR LAMP (MIL), MALFUNCTION;

FUEL/IGNITION (XJ-RHD)............8W-30-4

INDICATOR LAMPÐPCM OUTPUT,

MALFUNCTION......................14-28

INDICATOR LAMPS.....8E-12,8E-25,8E-32,8E-3

INDICATOR LAMPS, TURN SIGNAL;

INSTRUMENT CLUSTER (XJ).........8W-40-2

INDICATOR LAMPS, TURN SIGNAL;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

INDICATOR (SRI) LAMP, SERVICE

REMINDER..........................25-1

INDICATOR WARNING LAMP, SEAT BELT;

INSTRUMENT CLUSTER (XJ).........8W-40-2

INDICATOR WARNING LAMP, SEAT BELT;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

INDICATORÐPCM OUTPUT, SHIFT.......14-29

INDICATORS, TREAD WEAR.............22-3

INFLATION PRESSURES, TIRE...........22-2

INFORMATIONÐXJ, DOME/COURTESY

LAMP SERVICE......................8L-16

INFORMATIONÐXJ, UNDERHOOD LAMP

SERVICE...........................8L-12

INFORMATIONÐYJ, DOME/COURTESY

LAMP SERVICE......................8L-31

INFORMATIONÐYJ, SOFT TOP SERVICE . 23-127

INFORMATIONÐYJ, UNDERHOOD LAMP

SERVICE...........................8L-28

INITIALIZATION, ABS SYSTEM

POWER-UP..........................5-35

INJECTION (MFI)ÐCOMPONENT

DESCRIPTION/SYSTEM OPERATION,

MULTI-PORT FUEL...................14-19

INJECTION (MFI)ÐCOMPONENT

REMOVAL/INSTALLATION, MULTI-PORT

FUEL..............................14-58

INJECTION (MFI)ÐGENERAL

DIAGNOSIS, MULTI-PORT FUEL.........14-35

INJECTOR DIAGNOSISÐVEHICLE RUNS

ROUGH AND/OR HAS A MISS...........14-52

INJECTOR, FUEL.....................14-60

INJECTOR TEST, FUEL.................14-51

INJECTORS, FUEL; FUEL/IGNITION (XJ) . 8W-30-1

INJECTORS, FUEL; FUEL/IGNITION (YJ) . 8W-30-2

INJECTORS, FUEL; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

INJECTORSÐPCM OUTPUT, FUEL

.......14-27

IN-LINE FUSE

........................8F-1

INNER AXLE SHAFT OIL SEAL

REPLACEMENT

.......................2-35

INNER SCUFF PLATE/COWL SIDE TRIM

PANELÐXJ, FRONT

...................23-86

INNER SPLASH SHIELDSÐYJ, FENDER

. . 23-116INPUT, AIR CONDITIONING (A/C)

CONTROLSÐPCM....................14-21

INPUT, AUTOMATIC SHUTDOWN (ASD)

SENSEÐPCM.......................14-21

INPUT, BATTERY VOLTAGEÐPCM........14-21

INPUT, BRAKE SWITCH; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

INPUT, BRAKE SWITCH; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

INPUT, BRAKE SWITCH; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

INPUT, BRAKE SWITCH; FUEL/IGNITION

(XJ).............................8W-30-5

INPUT, BRAKE SWITCH; FUEL/IGNITION

(YJ).............................8W-30-5

INPUT, BRAKE SWITCH; FUEL/IGNITION

(XJ-RHD).........................8W-30-5

INPUT, BRAKE SWITCHÐPCM..........14-22

INPUT, CAMSHAFT POSITION SENSORÐ

PCM...............................14-22

INPUT, CRANKSHAFT POSITION

SENSORÐPCM......................14-22

INPUT, DATA LINK CONNECTORÐPCM . . . 14-22

INPUT, ENGINE COOLANT

TEMPERATURE SENSORÐPCM.........14-23

INPUT, EXTENDED IDLE SWITCHÐPCM . . . 14-23

INPUT, IGNITION CIRCUIT SENSEÐPCM . . 14-23

INPUT, INTAKE MANIFOLD AIR

TEMPERATURE SENSORÐPCM.........14-22

INPUT, MANIFOLD ABSOLUTE

PRESSURE (MAP) SENSORÐPCM.......14-23

INPUT, OXYGEN (O2S) SENSORÐPCM.....14-24

INPUT, PARK/NEUTRAL SWITCHÐPCM . . . 14-24

INPUT, POWER STEERING PRESSURE

SWITCHÐPCM......................14-24

INPUT, SCI RECEIVEÐPCM............14-24

INPUT, SENSOR RETURNÐPCM.........14-25

INPUT SIGNALS, WHEEL/TIRE SIZE........5-3

INPUT, SPEED CONTROLÐPCM.........14-25

INPUT, THROTTLE POSITION SENSOR

(TPS)ÐPCM........................14-25

INPUT, VEHICLE SPEED SENSORÐPCM . . 14-25

INSERTÐXJ, REAR QUARTER WINDOW

GLASS/REAR QUARTER PLASTIC........23-73

INSIDE LATCH RELEASE AND LOCK

RODSÐXJ, DOOR....................23-50

INSIDE RELEASE AND LOCK HANDLEÐ

YJ, FULL-METAL DOOR LATCH.........23-137

INSPECTION AND ADJUSTMENT,

PRELIMINARY......................21-176

INSPECTION AND DIAGNOSIS CHARTS.....6-4

INSPECTION AND PARK LOCK

COMPONENT OVERHAUL, ADAPTER/

EXTENSION HOUSING................21-127

INSPECTION, CALIPER CLEANING........5-50

INSPECTION (ENGINE OIL LEAKS IN

GENERAL)............................9-6

INSPECTION, GEAR CLEANING..........19-42

INSPECTION, OVERHAUL CLEANING....21-294,

21-318

INSPECTION, PRE-ALIGNMENT............2-6

INSPECTION, RUBBER AND PLASTIC

COMPONENT.........................0-20

INSPECTION, TORQUE CONVERTER

STATOR CLUTCH....................21-199

INSPECTION, TRANSMISSION CASE

CLEANING.........................21-125

INSPECTION, VALVE BODY

DISASSEMBLY......................21-147

INSTALLATION, 30RH/32RH

TRANSMISSION REMOVAL............21-115

INSTALLATION, ACCELERATION SWITCH . . . 5-39

INSTALLATION AND ADJUSTMENT, REAR

WHEEL SENSOR......................5-38

INSTALLATION, AW-4 TRANSMISSION

REMOVAL.........................21-198

INSTALLATION, BRAKE PEDAL...........5-31

INSTALLATION, BRAKELIGHT SWITCH.....5-32

INSTALLATION, CALIPER................5-51

INSTALLATION, CLUTCH COVER AND

DISC...............................6-10

INSTALLATION, CLUTCH HYDRAULIC

LINKAGE

............................6-14

INSTALLATION, CLUTCH PEDAL

..........6-15

INSTALLATION, DIFFERENTIAL

...........2-44

INSTALLATION, DIFFERENTIAL

MEASUREMENT

.......................3-25

INSTALLATION, DISC BRAKESHOE

........5-47

14 INDEXJ

Description Group-Page Description Group-Page Description Group-Page