seat adjustment JEEP XJ 1995 Service And Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1692 of 2158

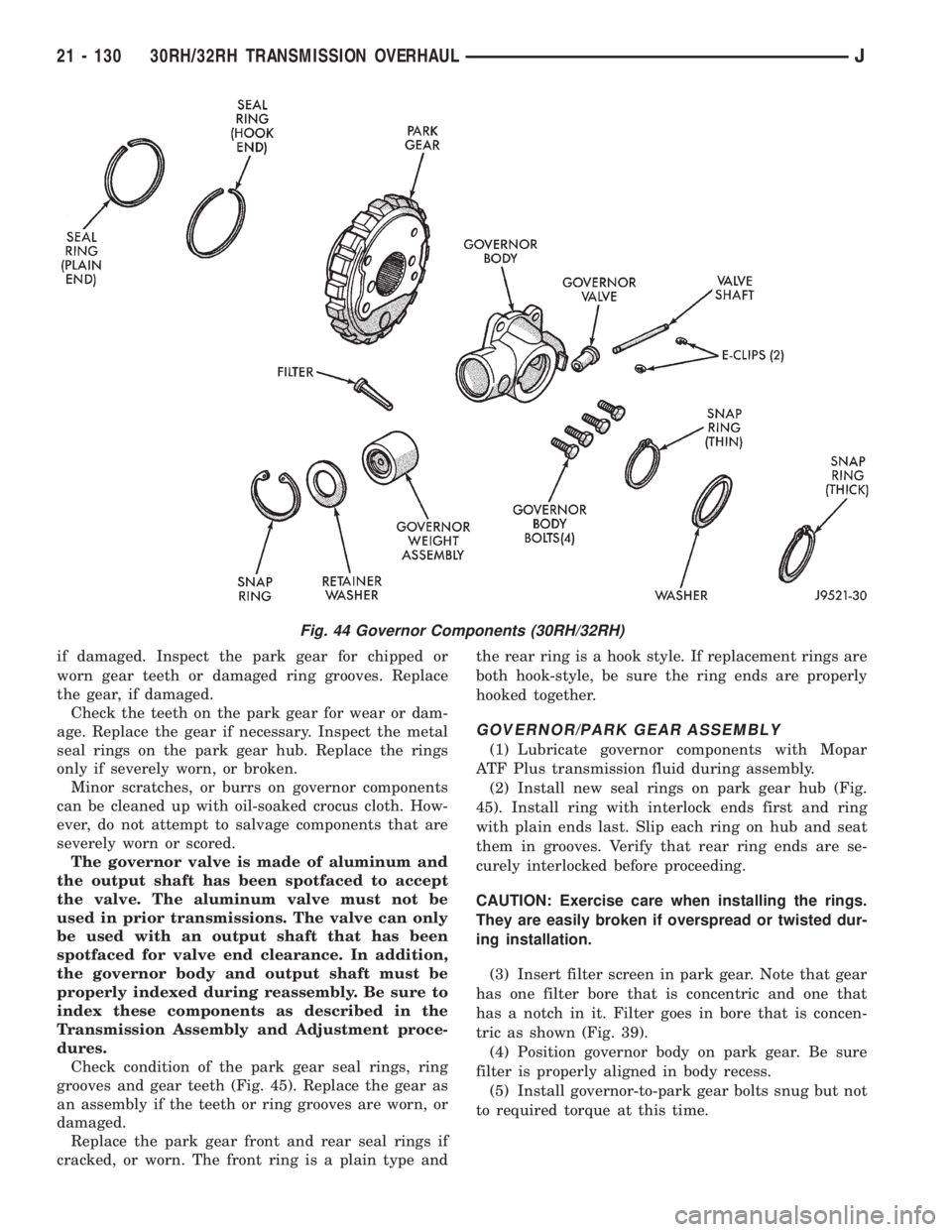

if damaged. Inspect the park gear for chipped or

worn gear teeth or damaged ring grooves. Replace

the gear, if damaged.

Check the teeth on the park gear for wear or dam-

age. Replace the gear if necessary. Inspect the metal

seal rings on the park gear hub. Replace the rings

only if severely worn, or broken.

Minor scratches, or burrs on governor components

can be cleaned up with oil-soaked crocus cloth. How-

ever, do not attempt to salvage components that are

severely worn or scored.

The governor valve is made of aluminum and

the output shaft has been spotfaced to accept

the valve. The aluminum valve must not be

used in prior transmissions. The valve can only

be used with an output shaft that has been

spotfaced for valve end clearance. In addition,

the governor body and output shaft must be

properly indexed during reassembly. Be sure to

index these components as described in the

Transmission Assembly and Adjustment proce-

dures.

Check condition of the park gear seal rings, ring

grooves and gear teeth (Fig. 45). Replace the gear as

an assembly if the teeth or ring grooves are worn, or

damaged.

Replace the park gear front and rear seal rings if

cracked, or worn. The front ring is a plain type andthe rear ring is a hook style. If replacement rings are

both hook-style, be sure the ring ends are properly

hooked together.

GOVERNOR/PARK GEAR ASSEMBLY

(1) Lubricate governor components with Mopar

ATF Plus transmission fluid during assembly.

(2) Install new seal rings on park gear hub (Fig.

45). Install ring with interlock ends first and ring

with plain ends last. Slip each ring on hub and seat

them in grooves. Verify that rear ring ends are se-

curely interlocked before proceeding.

CAUTION: Exercise care when installing the rings.

They are easily broken if overspread or twisted dur-

ing installation.

(3) Insert filter screen in park gear. Note that gear

has one filter bore that is concentric and one that

has a notch in it. Filter goes in bore that is concen-

tric as shown (Fig. 39).

(4) Position governor body on park gear. Be sure

filter is properly aligned in body recess.

(5) Install governor-to-park gear bolts snug but not

to required torque at this time.

Fig. 44 Governor Components (30RH/32RH)

21 - 130 30RH/32RH TRANSMISSION OVERHAULJ

Page 1715 of 2158

VALVE BODY ASSEMBLY AND ADJUSTMENT

CAUTION: Do not force valves or plugs into place

during reassembly. If the valve body bores, valves

and plugs are free of distortion or burrs, the valve

body components should all slide into place easily.

In addition, do not overtighten the transfer plate

and valve body screws during reassembly. Over-

tightening can distort the valve body resulting in

valve sticking, cross leakage and unsatisfactory op-

eration. Tighten valve body screws to recom-

mended torque only.

(1) Lubricate valve body bores, valves and plugs

with Mopar ATF Plus transmission fluid.

(2) Insert rear clutch and rear servo check balls in

transfer plate (Fig. 120).

(3) Install filter screen in separator plate (Fig.

120).

(4) Align and install separator plate on transfer

plate. Verify check ball position before installing sep-

arator plate on transfer plate.

(5) Install new O-ring on converter clutch solenoid

and insert solenoid in separator plate (Fig. 120).

Then secure solenoid in position with attaching

screw. Tighten screw to 4 Nzm 35 in. lbs.) torque.

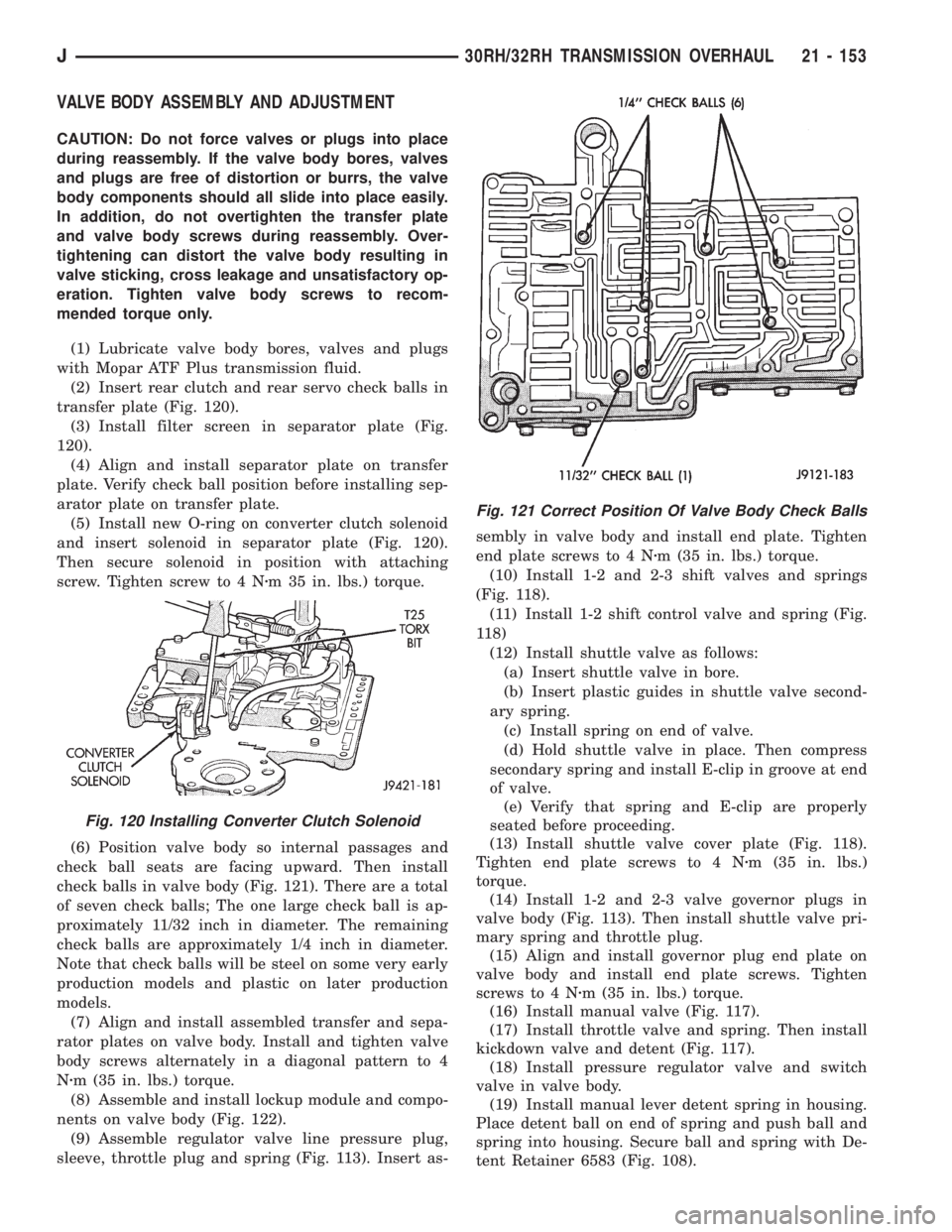

(6) Position valve body so internal passages and

check ball seats are facing upward. Then install

check balls in valve body (Fig. 121). There are a total

of seven check balls; The one large check ball is ap-

proximately 11/32 inch in diameter. The remaining

check balls are approximately 1/4 inch in diameter.

Note that check balls will be steel on some very early

production models and plastic on later production

models.

(7) Align and install assembled transfer and sepa-

rator plates on valve body. Install and tighten valve

body screws alternately in a diagonal pattern to 4

Nzm (35 in. lbs.) torque.

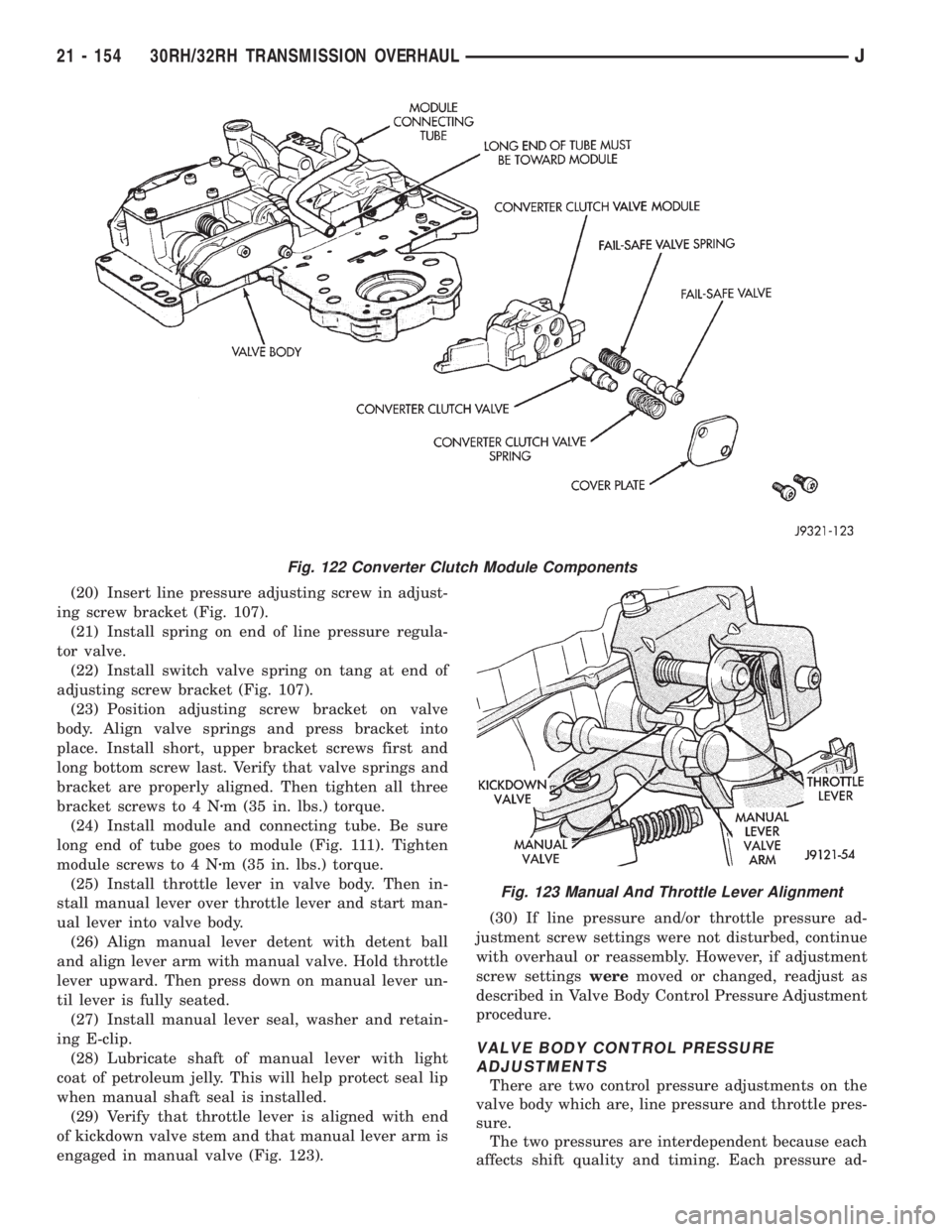

(8) Assemble and install lockup module and compo-

nents on valve body (Fig. 122).

(9) Assemble regulator valve line pressure plug,

sleeve, throttle plug and spring (Fig. 113). Insert as-sembly in valve body and install end plate. Tighten

end plate screws to 4 Nzm (35 in. lbs.) torque.

(10) Install 1-2 and 2-3 shift valves and springs

(Fig. 118).

(11) Install 1-2 shift control valve and spring (Fig.

118)

(12) Install shuttle valve as follows:

(a) Insert shuttle valve in bore.

(b) Insert plastic guides in shuttle valve second-

ary spring.

(c) Install spring on end of valve.

(d) Hold shuttle valve in place. Then compress

secondary spring and install E-clip in groove at end

of valve.

(e) Verify that spring and E-clip are properly

seated before proceeding.

(13) Install shuttle valve cover plate (Fig. 118).

Tighten end plate screws to 4 Nzm (35 in. lbs.)

torque.

(14) Install 1-2 and 2-3 valve governor plugs in

valve body (Fig. 113). Then install shuttle valve pri-

mary spring and throttle plug.

(15) Align and install governor plug end plate on

valve body and install end plate screws. Tighten

screws to 4 Nzm (35 in. lbs.) torque.

(16) Install manual valve (Fig. 117).

(17) Install throttle valve and spring. Then install

kickdown valve and detent (Fig. 117).

(18) Install pressure regulator valve and switch

valve in valve body.

(19) Install manual lever detent spring in housing.

Place detent ball on end of spring and push ball and

spring into housing. Secure ball and spring with De-

tent Retainer 6583 (Fig. 108).

Fig. 120 Installing Converter Clutch Solenoid

Fig. 121 Correct Position Of Valve Body Check Balls

J30RH/32RH TRANSMISSION OVERHAUL 21 - 153

Page 1716 of 2158

(20) Insert line pressure adjusting screw in adjust-

ing screw bracket (Fig. 107).

(21) Install spring on end of line pressure regula-

tor valve.

(22) Install switch valve spring on tang at end of

adjusting screw bracket (Fig. 107).

(23) Position adjusting screw bracket on valve

body. Align valve springs and press bracket into

place. Install short, upper bracket screws first and

long bottom screw last. Verify that valve springs and

bracket are properly aligned. Then tighten all three

bracket screws to 4 Nzm (35 in. lbs.) torque.

(24) Install module and connecting tube. Be sure

long end of tube goes to module (Fig. 111). Tighten

module screws to 4 Nzm (35 in. lbs.) torque.

(25) Install throttle lever in valve body. Then in-

stall manual lever over throttle lever and start man-

ual lever into valve body.

(26) Align manual lever detent with detent ball

and align lever arm with manual valve. Hold throttle

lever upward. Then press down on manual lever un-

til lever is fully seated.

(27) Install manual lever seal, washer and retain-

ing E-clip.

(28) Lubricate shaft of manual lever with light

coat of petroleum jelly. This will help protect seal lip

when manual shaft seal is installed.

(29) Verify that throttle lever is aligned with end

of kickdown valve stem and that manual lever arm is

engaged in manual valve (Fig. 123).(30) If line pressure and/or throttle pressure ad-

justment screw settings were not disturbed, continue

with overhaul or reassembly. However, if adjustment

screw settingsweremoved or changed, readjust as

described in Valve Body Control Pressure Adjustment

procedure.

VALVE BODY CONTROL PRESSURE

ADJUSTMENTS

There are two control pressure adjustments on the

valve body which are, line pressure and throttle pres-

sure.

The two pressures are interdependent because each

affects shift quality and timing. Each pressure ad-

Fig. 122 Converter Clutch Module Components

Fig. 123 Manual And Throttle Lever Alignment

21 - 154 30RH/32RH TRANSMISSION OVERHAULJ

Page 1740 of 2158

PRESSURE TEST ANALYSIS

If pressures in D and Reverse are higher than

specified in test, check for the following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, throttle cam, or pri-

mary regulator valve are sticking, worn or damaged

If pressures in D and Reverse are lower than spec-

ified in test, check for following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, or throttle cam

sticking, worn or damaged

²primary regulator valve sticking, worn, or dam-

aged

²oil pump gears or housing worn, or damaged

²overdrive clutch worn, or damaged

If pressures are low in D range only, check for fol-

lowing:

²forward clutch worn or damaged

²fluid leakage in D range circuit (component seal

and O-rings)

If pressures are low in Reverse only, check for fol-

lowing:

²shift cable and manual valve out of adjustment

²fluid leakage in reverse circuit (component seal

and O-rings)

²direct clutch worn or damaged

²first/reverse brake worn or damaged

TORQUE CONVERTER STALL TEST

Stall testing checks the holding ability of the trans-

mission clutches and brakes and of the torque con-

verter stator overrunning clutch.Stall speeds are

checked in both Drive and Reverse ranges with

the AW-4 transmission.

(1) Before starting test, be sure fluid level is cor-

rect and fluid is at normal operating temperature.

(2) Connect tachometer to engine. Position tachom-

eter so it can be viewed from drivers seat.

(3) Apply parking brakes and block wheels.

(4) Apply and hold service brakes.

(5) Shift transfer case into 2H position.

(6) Start engine.

WARNING: DO NOT ALLOW ANYONE TO STAND AT

THE FRONT OR REAR OF THE VEHICLE DURING

THE TEST.

(7) Shift transmission into D range.

(8) Open throttle completely and record maximum

engine rpm registered on tachometer. It takes any-

where from 4 to 10 seconds to reach maximum rpm.

However, once maximum rpm has been achieved,do

not hold wide open throttle for more than 3-4

seconds.CAUTION: Stalling the converter causes a rapid in-

crease in fluid temperature. To avoid fluid overheat-

ing, hold wide open throttle for no more than 4

seconds after reaching peak rpm. In addition, if

more than one stall test is required, run the engine

at 1000 rpm with the transmission in Neutral for at

least 20 seconds to cool the fluid.

(9) Stall speed should be in 2100-2400 rpm range

in Drive.

(10) Release throttle, shift transmission into Neu-

tral, and run engine for 20-30 seconds to cool fluid.

(11) Shift transmission into Reverse.

(12) Repeat stall test described in step (8).

(13) Stall speed in Reverse should also be in 2100-

2400 rpm range.

(14) Release accelerator pedal, shift transmission

into Neutral, and run engine for 20-30 seconds to

cool fluid.

STALL SPEED TEST ANALYSIS

If engine rpm is lower than specified in D and Re-

verse, check for the following:

²engine output/performance insufficient

²stator overrunning clutch in torque converter not

holding if engine speed was 1500 rpm or less.

If stall speed in D range is higher than specified,

check for the following:

²line pressure low

²forward clutch slipping

²No. 2 one-way clutch not holding

²overdrive one-way clutch not holding

If stall speed in Reverse was higher than specified,

check for the following:

²line pressure low

²direct clutch slipping

²first/ reverse brake slipping

²overdrive one-way clutch not holding

If stall speeds were higher than specified in both D

and Reverse, check for the following:

²low fluid level

²line pressure low

²overdrive one-way clutch not holding

TIME LAG TEST

This test checks general condition of the overdrive

clutch, forward clutch, rear clutch and first/reverse

brake. Condition is indicated by the amount of time

required for clutch/brake engagement with the en-

gine at curb idle speed. Engagement time is mea-

sured for D and Reverse positions. A stop watch is

recommended for test accuracy.

TEST PROCEDURE

(1) Check and adjust transmission fluid level if

necessary.

(2) Bring transmission to normal operating tem-

perature.

21 - 178 AW-4 TRANSMISSION DIAGNOSISJ

Page 1744 of 2158

AW-4 IN-VEHICLE SERVICE

INDEX

page page

Accumulator Pistons and Springs............. 189

Adapter Housing Seal Replacement........... 191

Checking Fluid Level and Condition........... 182

Manual Valve Shaft Seal Replacement......... 187

Park Interlock Cable Adjustment............. 195

Park Rod and Pawl Service................. 190

Park/Neutral Position Switch................ 183

Refilling After Overhaul or Fluid/Filter Change . . . 182

Second Coast Brake Servo................. 190

Shift Cable Adjustment.................... 195

Speed Sensor........................... 192Speed Sensor RotorÐSpeedometer Drive Gear . . 193

Throttle Position Sensor (TPS) Service........ 193

Transmission Control Module (TCM) Service.... 183

Transmission Cooler Line Fittings............ 197

Transmission Cooler Service................ 196

Transmission Throttle Cable Adjustment........ 194

Transmission Throttle Cable Replacement...... 193

Transmission Valve Body Installation.......... 187

Transmission Valve Body Removal........... 186

Transmission Valve Body Solenoids........... 184

CHECKING FLUID LEVEL AND CONDITION

Recommended fluid for AW-4 transmissions is Mo-

par Dexron IIE/Mercon.

Mopar Dexron II can also be used but only when

Mercon fluid is not available.

CHECKING FLUID LEVEL

(1) Be sure transmission fluid is at normal operat-

ing temperature. Normal operating temperature is

reached after approximately 15 miles (25 km) of op-

eration.

(2) Position vehicle on level surface. This is impor-

tant for an accurate fluid level check.

(3) Shift transmission through all gear ranges and

back to Park.

(4) Apply parking brakes.

(5) Verify that transmission is in Park.

(6) Wipe off dipstick handle to prevent dirt from

entering fill tube. Then remove dipstick and check

fluid level and condition.

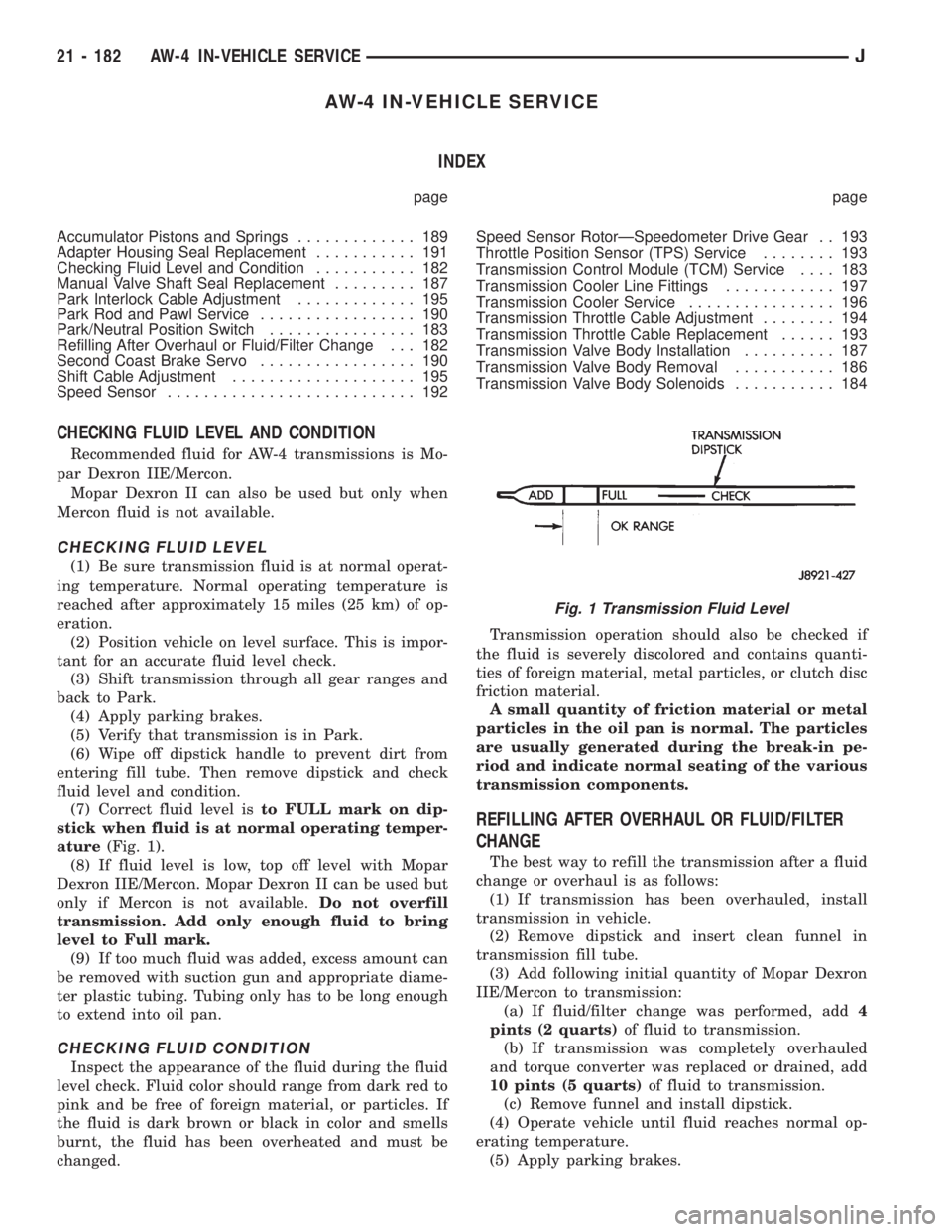

(7) Correct fluid level isto FULL mark on dip-

stick when fluid is at normal operating temper-

ature(Fig. 1).

(8) If fluid level is low, top off level with Mopar

Dexron IIE/Mercon. Mopar Dexron II can be used but

only if Mercon is not available.Do not overfill

transmission. Add only enough fluid to bring

level to Full mark.

(9) If too much fluid was added, excess amount can

be removed with suction gun and appropriate diame-

ter plastic tubing. Tubing only has to be long enough

to extend into oil pan.

CHECKING FLUID CONDITION

Inspect the appearance of the fluid during the fluid

level check. Fluid color should range from dark red to

pink and be free of foreign material, or particles. If

the fluid is dark brown or black in color and smells

burnt, the fluid has been overheated and must be

changed.Transmission operation should also be checked if

the fluid is severely discolored and contains quanti-

ties of foreign material, metal particles, or clutch disc

friction material.

A small quantity of friction material or metal

particles in the oil pan is normal. The particles

are usually generated during the break-in pe-

riod and indicate normal seating of the various

transmission components.

REFILLING AFTER OVERHAUL OR FLUID/FILTER

CHANGE

The best way to refill the transmission after a fluid

change or overhaul is as follows:

(1) If transmission has been overhauled, install

transmission in vehicle.

(2) Remove dipstick and insert clean funnel in

transmission fill tube.

(3) Add following initial quantity of Mopar Dexron

IIE/Mercon to transmission:

(a) If fluid/filter change was performed, add4

pints (2 quarts)of fluid to transmission.

(b) If transmission was completely overhauled

and torque converter was replaced or drained, add

10 pints (5 quarts)of fluid to transmission.

(c) Remove funnel and install dipstick.

(4) Operate vehicle until fluid reaches normal op-

erating temperature.

(5) Apply parking brakes.

Fig. 1 Transmission Fluid Level

21 - 182 AW-4 IN-VEHICLE SERVICEJ

Page 1745 of 2158

(6) Let engine run at normal curb idle speed, apply

service brakes. Then shift transmission through all

gear ranges and back to PARK (leave engine run-

ning).

(7) Remove dipstick and check fluid level. Add only

enough fluid to bring level to Full mark on dipstick.

Do not overfill.If too much fluid is added, excess

amount can be removed with suction gun and

plastic tubing. Tubing only has to be long

enough to extend into oil pan.

(8) When fluid level is correct, shut engine off, re-

lease park brake, remove funnel, and reseat dipstick

in fill tube.

TRANSMISSION CONTROL MODULE (TCM)

SERVICE

Use the DRB scan tool to diagnose transmission

control module function whenever a fault is sus-

pected. Replace the module only when the scan tool

indicates the module is actually faulty.

TRANSMISSION CONTROL MODULE

REPLACEMENT

The transmission control module is mounted under

the instrument panel. On left hand drive models, it is

at the driver side of the lower finish panel (Fig. 2).

On right hand drive models, it is at the passenger

side of the lower finish panel (Fig. 3).

To remove the module, disconnect the wire harness,

remove the mounting screws and remove the module

from the finish panel. Tighten the module mounting

screws securely after installation. Also be sure the

wire harness is not twisted, kinked or touching any

body panels.

PARK/NEUTRAL POSITION SWITCH

SWITCH TESTING

Test switch continuity with an ohmmeter. Discon-

nect the switch and check continuity at the connector

terminal positions and in the gear ranges indicated

in Figure 3. Switch continuity should be as follows:

²Continuity should exist between terminals B and

C with the transmission in Park and Neutral only

(Fig. 4).²Continuity should exist between terminals A and E

with the transmission in Reverse (Fig. 4).

²Continuity should exist between terminals A and

G with the transmission in third gear (Fig. 4).

²Continuity should exist between terminals A and

H with the transmission in first and/or second gear

(Fig. 4).

²Continuity should not exist in D position.

PARK/NEUTRAL POSITION SWITCH REMOVAL

(1) Raise vehicle.

(2) Disconnect switch wire harness connector.

(3) Pry washer lock tabs upward and remove

switch attaching nut and tabbed washer (Fig. 5).

(4) Remove switch adjusting bolt (Fig. 5).

(5) Slide switch off manual valve shaft.

PARK/NEUTRAL POSITION SWITCH

INSTALLATION AND ADJUSTMENT

(1) Disconnect shift linkage rod from shift lever on

left side of transmission.

Fig. 2 TCM Location (Left Hand Drive)

Fig. 3 TCM Location (Right Hand Drive)

Fig. 4 Park/Neutral Position Switch Terminals And

Testing

JAW-4 IN-VEHICLE SERVICE 21 - 183

Page 1869 of 2158

NP242 TRANSFER CASE

INDEX

page page

General Information....................... 307

Operating Ranges........................ 307

Overhaul Cleaning and Inspection............ 318

Recommended Lubricant/Capacity/Fill Level..... 307

Shift Lever Installation (XJ)................. 309

Shift Lever Removal (XJ)................... 309

Shift Linkage Adjustment................... 309

Shift Mechanism......................... 307Speedometer Service..................... 309

Transfer Case Assembly................... 319

Transfer Case Changes.................... 307

Transfer Case Disassembly and Overhaul...... 310

Transfer Case Identification................. 307

Transfer Case Installation.................. 309

Transfer Case Removal.................... 309

GENERAL INFORMATION

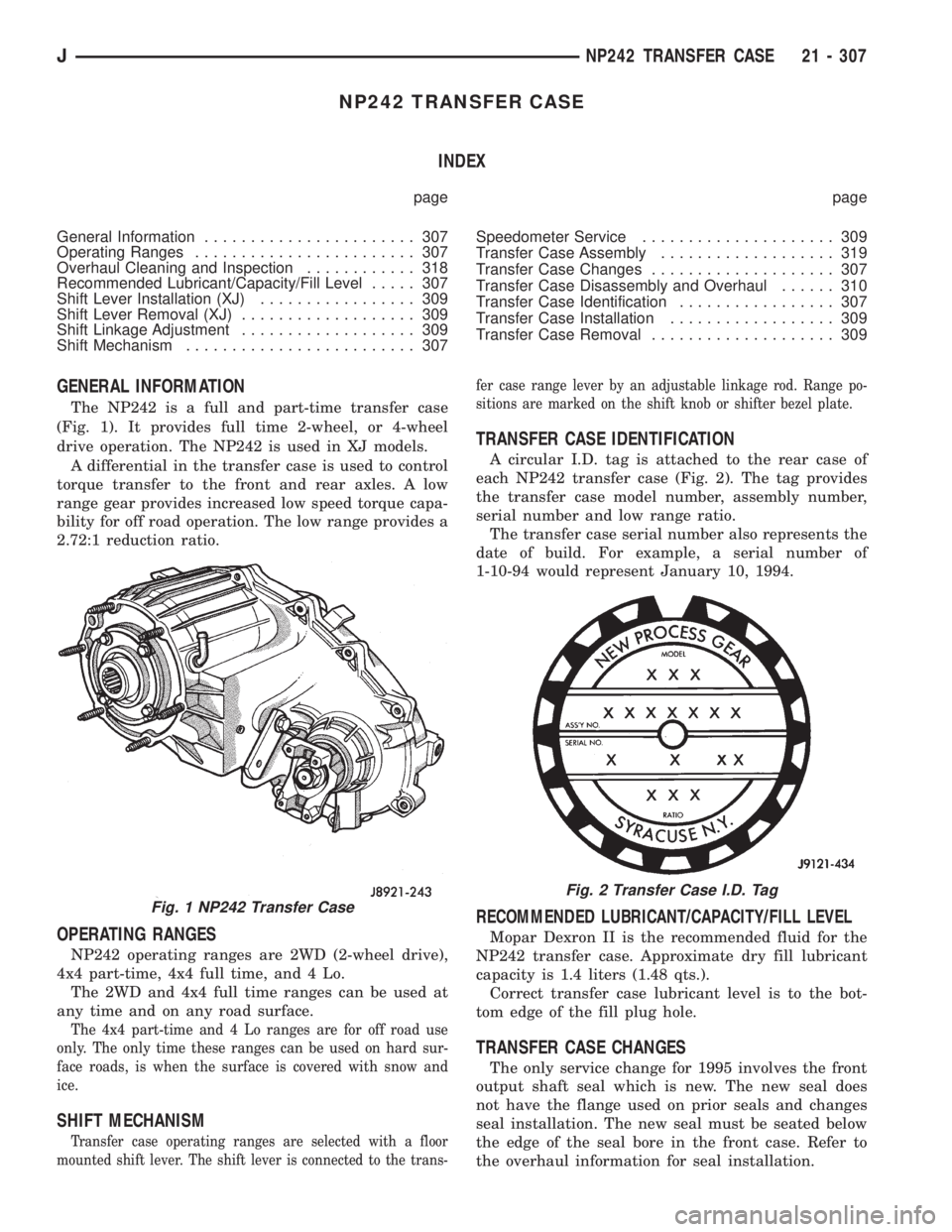

The NP242 is a full and part-time transfer case

(Fig. 1). It provides full time 2-wheel, or 4-wheel

drive operation. The NP242 is used in XJ models.

A differential in the transfer case is used to control

torque transfer to the front and rear axles. A low

range gear provides increased low speed torque capa-

bility for off road operation. The low range provides a

2.72:1 reduction ratio.

OPERATING RANGES

NP242 operating ranges are 2WD (2-wheel drive),

4x4 part-time, 4x4 full time, and 4 Lo.

The 2WD and 4x4 full time ranges can be used at

any time and on any road surface.

The 4x4 part-time and 4 Lo ranges are for off road use

only. The only time these ranges can be used on hard sur-

face roads, is when the surface is covered with snow and

ice.

SHIFT MECHANISM

Transfer case operating ranges are selected with a floor

mounted shift lever. The shift lever is connected to the trans-fer case range lever by an adjustable linkage rod. Range po-

sitions are marked on the shift knob or shifter bezel plate.

TRANSFER CASE IDENTIFICATION

A circular I.D. tag is attached to the rear case of

each NP242 transfer case (Fig. 2). The tag provides

the transfer case model number, assembly number,

serial number and low range ratio.

The transfer case serial number also represents the

date of build. For example, a serial number of

1-10-94 would represent January 10, 1994.

RECOMMENDED LUBRICANT/CAPACITY/FILL LEVEL

Mopar Dexron II is the recommended fluid for the

NP242 transfer case. Approximate dry fill lubricant

capacity is 1.4 liters (1.48 qts.).

Correct transfer case lubricant level is to the bot-

tom edge of the fill plug hole.

TRANSFER CASE CHANGES

The only service change for 1995 involves the front

output shaft seal which is new. The new seal does

not have the flange used on prior seals and changes

seal installation. The new seal must be seated below

the edge of the seal bore in the front case. Refer to

the overhaul information for seal installation.

Fig. 1 NP242 Transfer Case

Fig. 2 Transfer Case I.D. Tag

JNP242 TRANSFER CASE 21 - 307

Page 1916 of 2158

VEHICLE VIBRATION

Vehicle vibration can be caused by:

²Tire/wheel unbalance or excessive runout

²Defective tires with extreme tread wear

²Nylon overlay flat spots (performance tires only)

²Incorrect wheel bearing adjustment (if applicable)

²Loose or worn suspension/steering components

²Certain tire tread patterns

²Incorrect drive shaft angles or excessive drive

shaft/yoke runout

²Defective or worn U-joints

²Excessive brake rotor or drum runout

²Loose engine or transmission supports/mounts

²And by engine operated accessories

Refer to the appropriate Groups in this man-

ual for additional information.

VIBRATION TYPES

There are two types of vehicle vibration:

²Mechanical

²Audible.

Mechanical vehicle vibration can be felt through

the seats, floor pan and/or steering wheel.

Audible vehicle vibration is heard above normal

background noise. The sound can be a droning or

drumming noise.

Vibrations are sensitive to change in engine torque,

vehicle speed or engine speed.

ENGINE TORQUE SENSITIVE VIBRATION

This vibration can be increased or decreased by:

²Accelerating

²Decelerating

²Coasting

²Maintaining a constant vehicle speed

VEHICLE SPEED SENSITIVE VIBRATION

This vibration condition always occurs at the same

vehicle speed regardless of the engine torque or en-

gine speed.

ENGINE SPEED (RPM) SENSITIVE VIBRATION

This vibration occurs at varying engine speeds. It

can be isolated by increasing or decreasing the en-

gine speed with the transmission in NEUTRAL posi-

tion.

VIBRATION DIAGNOSIS

A vibration diagnosis should always begin with a

10 mile (16 km) trip (to warm the vehicle and tires).

Then a road test to identify the vibration. Corrective

action should not be attempted until the vibration

type has been identified via a road test.

During the road test, drive the vehicle on a smooth

surface. If vibration exists, note and record the fol-

lowing information:²Identify the vehicle speed range when the vibra-

tion occurs

²Identify the type of vibration

²Identify the vibration sensitivity

²Determine if the vibration is affected by changes

in vehicle speed, engine speed and engine torque.

When the vibration has been identified, refer to the

Vibration Diagnosis chart for causes. Consider cor-

recting only those causes coded in the chart that are

related to the vibration condition.

Refer to the following cause codes and descriptions

for explanations when referring to the chart.

TRRÐTire and Wheel Radial Runout:Vehicle

speed sensitive, mechanical vibration. The runout

will not cause vibration below 20 mph (32 km/h).

WHÐWheel Hop:Vehicle speed sensitive, me-

chanical vibration. The wheel hop generates rapid

up-down movement in the steering wheel. The vibra-

tion is most noticeable in the 20 - 40 mph (32 - 64

km/h) range. The wheel hop will not cause vibration

below 20 mph (32 km/h). Wheel hop is caused by a

tire/wheel that has a radial runout of more than

0.045 of-an-inch (1.14 mm). If wheel runout is accept-

able and combined runout cannot be reduced by re-

positioning the tire on wheel, replace tire.

TBÐTire/Wheel Balance:Vehicle speed sensitive,

mechanical vibration. Static tire/wheel unbalance

will not cause vibration below 30 mph (46 km/h). Dy-

namic tire/wheel unbalance will not cause vibration

below 40 mph (64 km/h).

TLRÐTire/Wheel Lateral runout:Vehicle speed

sensitive, mechanical vibration. The runout will not

cause vibration below 50 - 55 mph (80 - 88 km/h). Ex-

cessive lateral runout will also cause front-end

shimmy.

TWÐTire Wear:Vehicle speed sensitive, audible

vibration. Abnormal tire wear causes small vibration

in the 30 - 55 mph (88 km/h) range. This will pro-

duce a whine noise at high speed. The whine will

change to a growl noise when the speed is reduced.

WÐTire Waddle:Vehicle speed sensitive, mechan-

ical vibration. Irregular tire uniformity can cause

side-to-side motion during speeds up to 15 mph (24

km/h). If the motion is excessive, identify the defec-

tive tire and replace it.

UAJÐUniversal Joint (Drive Shaft) Angles:

Torque/vehicle speed sensitive, mechanical/audible vi-

bration. Incorrect drive shaft angles cause mechani-

cal vibration below 20 mph (32 km/h) and in the 70

mph (112 km/h) range. The incorrect angles can also

produce an audible vibration in the 20 - 50 mph (32 -

80 km/h) range. Caster adjustment could be required

to correct the angles.

UJÐUniversal Joints:Engine torque/vehicle

speed sensitive, mechanical/audible vibration. If the

22 - 10 WHEELS AND TIRESJ

Page 1955 of 2158

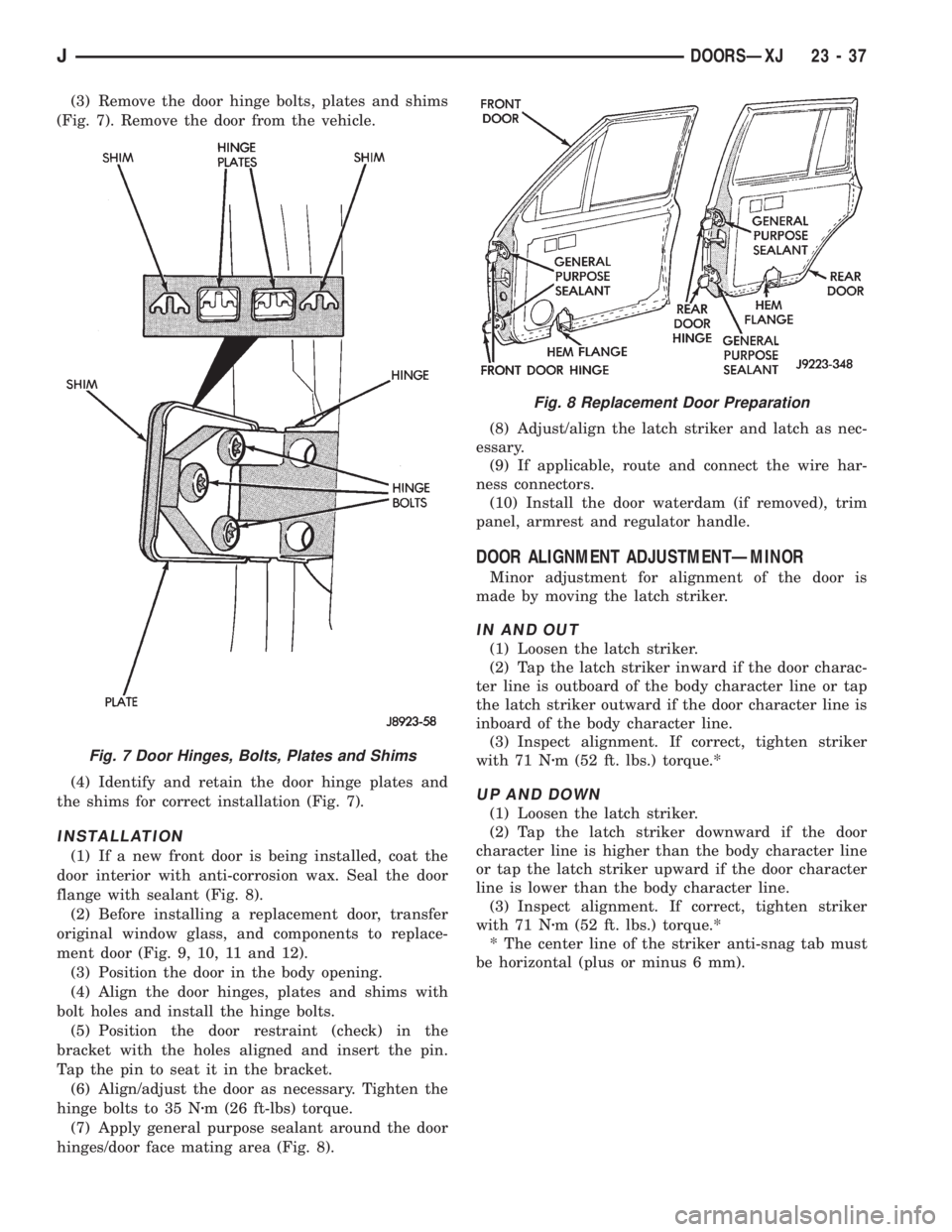

(3) Remove the door hinge bolts, plates and shims

(Fig. 7). Remove the door from the vehicle.

(4) Identify and retain the door hinge plates and

the shims for correct installation (Fig. 7).

INSTALLATION

(1) If a new front door is being installed, coat the

door interior with anti-corrosion wax. Seal the door

flange with sealant (Fig. 8).

(2) Before installing a replacement door, transfer

original window glass, and components to replace-

ment door (Fig. 9, 10, 11 and 12).

(3) Position the door in the body opening.

(4) Align the door hinges, plates and shims with

bolt holes and install the hinge bolts.

(5) Position the door restraint (check) in the

bracket with the holes aligned and insert the pin.

Tap the pin to seat it in the bracket.

(6) Align/adjust the door as necessary. Tighten the

hinge bolts to 35 Nzm (26 ft-lbs) torque.

(7) Apply general purpose sealant around the door

hinges/door face mating area (Fig. 8).(8) Adjust/align the latch striker and latch as nec-

essary.

(9) If applicable, route and connect the wire har-

ness connectors.

(10) Install the door waterdam (if removed), trim

panel, armrest and regulator handle.

DOOR ALIGNMENT ADJUSTMENTÐMINOR

Minor adjustment for alignment of the door is

made by moving the latch striker.

IN AND OUT

(1) Loosen the latch striker.

(2) Tap the latch striker inward if the door charac-

ter line is outboard of the body character line or tap

the latch striker outward if the door character line is

inboard of the body character line.

(3) Inspect alignment. If correct, tighten striker

with 71 Nzm (52 ft. lbs.) torque.*

UP AND DOWN

(1) Loosen the latch striker.

(2) Tap the latch striker downward if the door

character line is higher than the body character line

or tap the latch striker upward if the door character

line is lower than the body character line.

(3) Inspect alignment. If correct, tighten striker

with 71 Nzm (52 ft. lbs.) torque.*

* The center line of the striker anti-snag tab must

be horizontal (plus or minus 6 mm).

Fig. 7 Door Hinges, Bolts, Plates and Shims

Fig. 8 Replacement Door Preparation

JDOORSÐXJ 23 - 37

Page 1982 of 2158

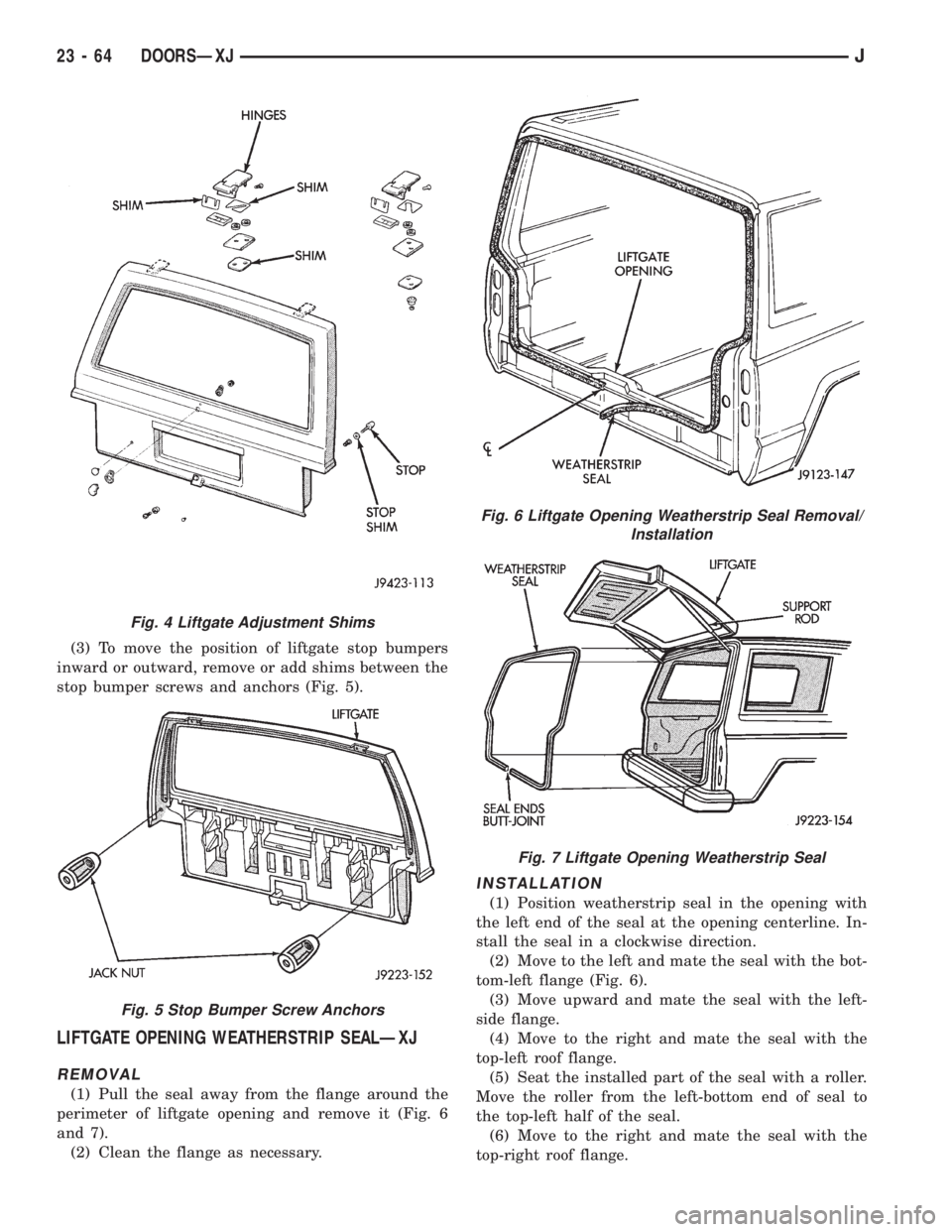

(3) To move the position of liftgate stop bumpers

inward or outward, remove or add shims between the

stop bumper screws and anchors (Fig. 5).

LIFTGATE OPENING WEATHERSTRIP SEALÐXJ

REMOVAL

(1) Pull the seal away from the flange around the

perimeter of liftgate opening and remove it (Fig. 6

and 7).

(2) Clean the flange as necessary.

INSTALLATION

(1) Position weatherstrip seal in the opening with

the left end of the seal at the opening centerline. In-

stall the seal in a clockwise direction.

(2) Move to the left and mate the seal with the bot-

tom-left flange (Fig. 6).

(3) Move upward and mate the seal with the left-

side flange.

(4) Move to the right and mate the seal with the

top-left roof flange.

(5) Seat the installed part of the seal with a roller.

Move the roller from the left-bottom end of seal to

the top-left half of the seal.

(6) Move to the right and mate the seal with the

top-right roof flange.

Fig. 4 Liftgate Adjustment Shims

Fig. 5 Stop Bumper Screw Anchors

Fig. 6 Liftgate Opening Weatherstrip Seal Removal/

Installation

Fig. 7 Liftgate Opening Weatherstrip Seal

23 - 64 DOORSÐXJJ