warning light JEEP XJ 1995 Service And Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 274 of 2158

(5) Be sure that the air conditioner (if equipped) is

turned off.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A DI-

RECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(6) Start the engine and operate at 2400 rpm.

Within ten minutes the air temperature (indicated on

the dial thermometer) should be up to 88É C (190É F).

Fan driveengagementshould have started to occur

at between 74É to 82É C (165É to 180É F). Engage-

ment is distinguishable by a definiteincreasein fan

flow noise (roaring). The timing light also will indi-

cate an increase in the speed of the fan.

(7) When the air temperature reaches 88É C (190É

F), remove the plastic sheet. Fan drivedisengage-

mentshould have started to occur at between 57É to

79É C (135É to 175É F). A definitedecreaseof fan

flow noise (roaring) should be noticed. If not, replace

the defective viscous fan drive unit.

VISCOUS FAN DRIVE REMOVAL/INSTALLATION

Refer to the previous section on Cooling System

Fan for removal and installation procedures of the

viscous drive unit.

Viscous Fan Drive Fluid Pump Out Require-

ment:After installing anewviscous fan drive, bring

the engine speed up to approximately 2000 rpm and

hold for approximately two minutes. This will ensure

proper fluid distribution within the drive.

AUXILIARY ELECTRIC COOLING FANÐXJ MODELS

WITH 4.0L 6-CYLINDER ENGINE

OPERATION

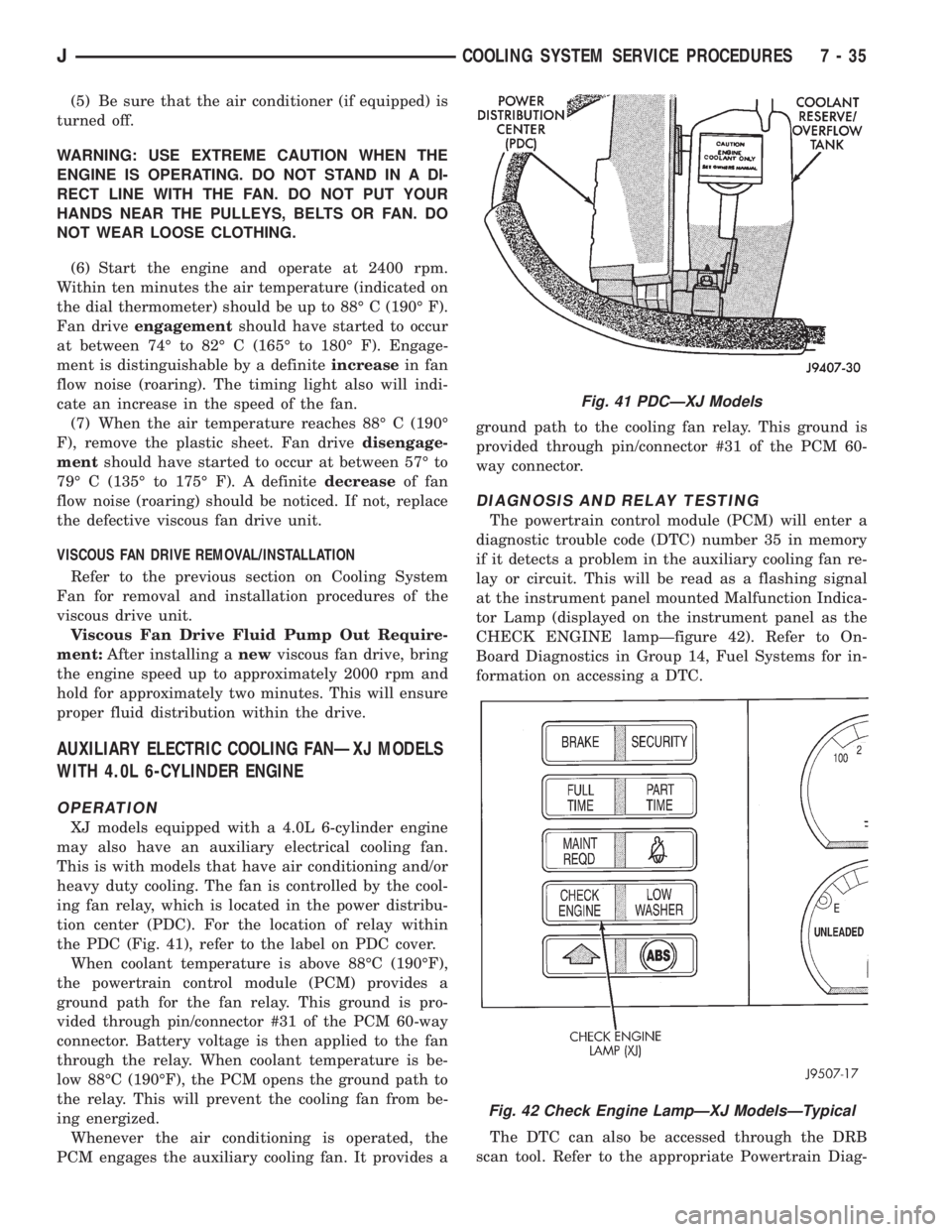

XJ models equipped with a 4.0L 6-cylinder engine

may also have an auxiliary electrical cooling fan.

This is with models that have air conditioning and/or

heavy duty cooling. The fan is controlled by the cool-

ing fan relay, which is located in the power distribu-

tion center (PDC). For the location of relay within

the PDC (Fig. 41), refer to the label on PDC cover.

When coolant temperature is above 88ÉC (190ÉF),

the powertrain control module (PCM) provides a

ground path for the fan relay. This ground is pro-

vided through pin/connector #31 of the PCM 60-way

connector. Battery voltage is then applied to the fan

through the relay. When coolant temperature is be-

low 88ÉC (190ÉF), the PCM opens the ground path to

the relay. This will prevent the cooling fan from be-

ing energized.

Whenever the air conditioning is operated, the

PCM engages the auxiliary cooling fan. It provides aground path to the cooling fan relay. This ground is

provided through pin/connector #31 of the PCM 60-

way connector.

DIAGNOSIS AND RELAY TESTING

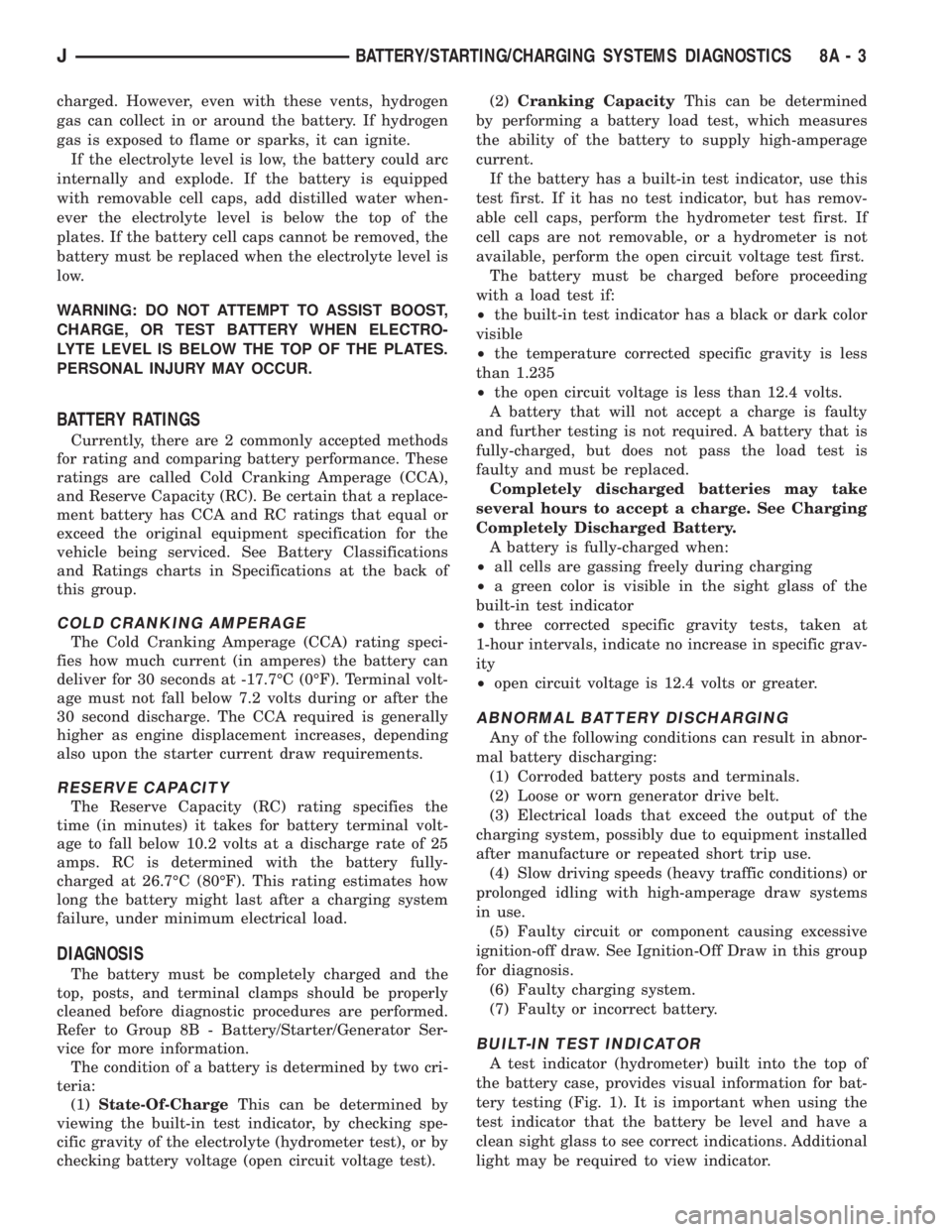

The powertrain control module (PCM) will enter a

diagnostic trouble code (DTC) number 35 in memory

if it detects a problem in the auxiliary cooling fan re-

lay or circuit. This will be read as a flashing signal

at the instrument panel mounted Malfunction Indica-

tor Lamp (displayed on the instrument panel as the

CHECK ENGINE lampÐfigure 42). Refer to On-

Board Diagnostics in Group 14, Fuel Systems for in-

formation on accessing a DTC.

The DTC can also be accessed through the DRB

scan tool. Refer to the appropriate Powertrain Diag-

Fig. 41 PDCÐXJ Models

Fig. 42 Check Engine LampÐXJ ModelsÐTypical

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 35

Page 288 of 2158

charged. However, even with these vents, hydrogen

gas can collect in or around the battery. If hydrogen

gas is exposed to flame or sparks, it can ignite.

If the electrolyte level is low, the battery could arc

internally and explode. If the battery is equipped

with removable cell caps, add distilled water when-

ever the electrolyte level is below the top of the

plates. If the battery cell caps cannot be removed, the

battery must be replaced when the electrolyte level is

low.

WARNING: DO NOT ATTEMPT TO ASSIST BOOST,

CHARGE, OR TEST BATTERY WHEN ELECTRO-

LYTE LEVEL IS BELOW THE TOP OF THE PLATES.

PERSONAL INJURY MAY OCCUR.

BATTERY RATINGS

Currently, there are 2 commonly accepted methods

for rating and comparing battery performance. These

ratings are called Cold Cranking Amperage (CCA),

and Reserve Capacity (RC). Be certain that a replace-

ment battery has CCA and RC ratings that equal or

exceed the original equipment specification for the

vehicle being serviced. See Battery Classifications

and Ratings charts in Specifications at the back of

this group.

COLD CRANKING AMPERAGE

The Cold Cranking Amperage (CCA) rating speci-

fies how much current (in amperes) the battery can

deliver for 30 seconds at -17.7ÉC (0ÉF). Terminal volt-

age must not fall below 7.2 volts during or after the

30 second discharge. The CCA required is generally

higher as engine displacement increases, depending

also upon the starter current draw requirements.

RESERVE CAPACITY

The Reserve Capacity (RC) rating specifies the

time (in minutes) it takes for battery terminal volt-

age to fall below 10.2 volts at a discharge rate of 25

amps. RC is determined with the battery fully-

charged at 26.7ÉC (80ÉF). This rating estimates how

long the battery might last after a charging system

failure, under minimum electrical load.

DIAGNOSIS

The battery must be completely charged and the

top, posts, and terminal clamps should be properly

cleaned before diagnostic procedures are performed.

Refer to Group 8B - Battery/Starter/Generator Ser-

vice for more information.

The condition of a battery is determined by two cri-

teria:

(1)State-Of-ChargeThis can be determined by

viewing the built-in test indicator, by checking spe-

cific gravity of the electrolyte (hydrometer test), or by

checking battery voltage (open circuit voltage test).(2)Cranking CapacityThis can be determined

by performing a battery load test, which measures

the ability of the battery to supply high-amperage

current.

If the battery has a built-in test indicator, use this

test first. If it has no test indicator, but has remov-

able cell caps, perform the hydrometer test first. If

cell caps are not removable, or a hydrometer is not

available, perform the open circuit voltage test first.

The battery must be charged before proceeding

with a load test if:

²the built-in test indicator has a black or dark color

visible

²the temperature corrected specific gravity is less

than 1.235

²the open circuit voltage is less than 12.4 volts.

A battery that will not accept a charge is faulty

and further testing is not required. A battery that is

fully-charged, but does not pass the load test is

faulty and must be replaced.

Completely discharged batteries may take

several hours to accept a charge. See Charging

Completely Discharged Battery.

A battery is fully-charged when:

²all cells are gassing freely during charging

²a green color is visible in the sight glass of the

built-in test indicator

²three corrected specific gravity tests, taken at

1-hour intervals, indicate no increase in specific grav-

ity

²open circuit voltage is 12.4 volts or greater.

ABNORMAL BATTERY DISCHARGING

Any of the following conditions can result in abnor-

mal battery discharging:

(1) Corroded battery posts and terminals.

(2) Loose or worn generator drive belt.

(3) Electrical loads that exceed the output of the

charging system, possibly due to equipment installed

after manufacture or repeated short trip use.

(4) Slow driving speeds (heavy traffic conditions) or

prolonged idling with high-amperage draw systems

in use.

(5) Faulty circuit or component causing excessive

ignition-off draw. See Ignition-Off Draw in this group

for diagnosis.

(6) Faulty charging system.

(7) Faulty or incorrect battery.

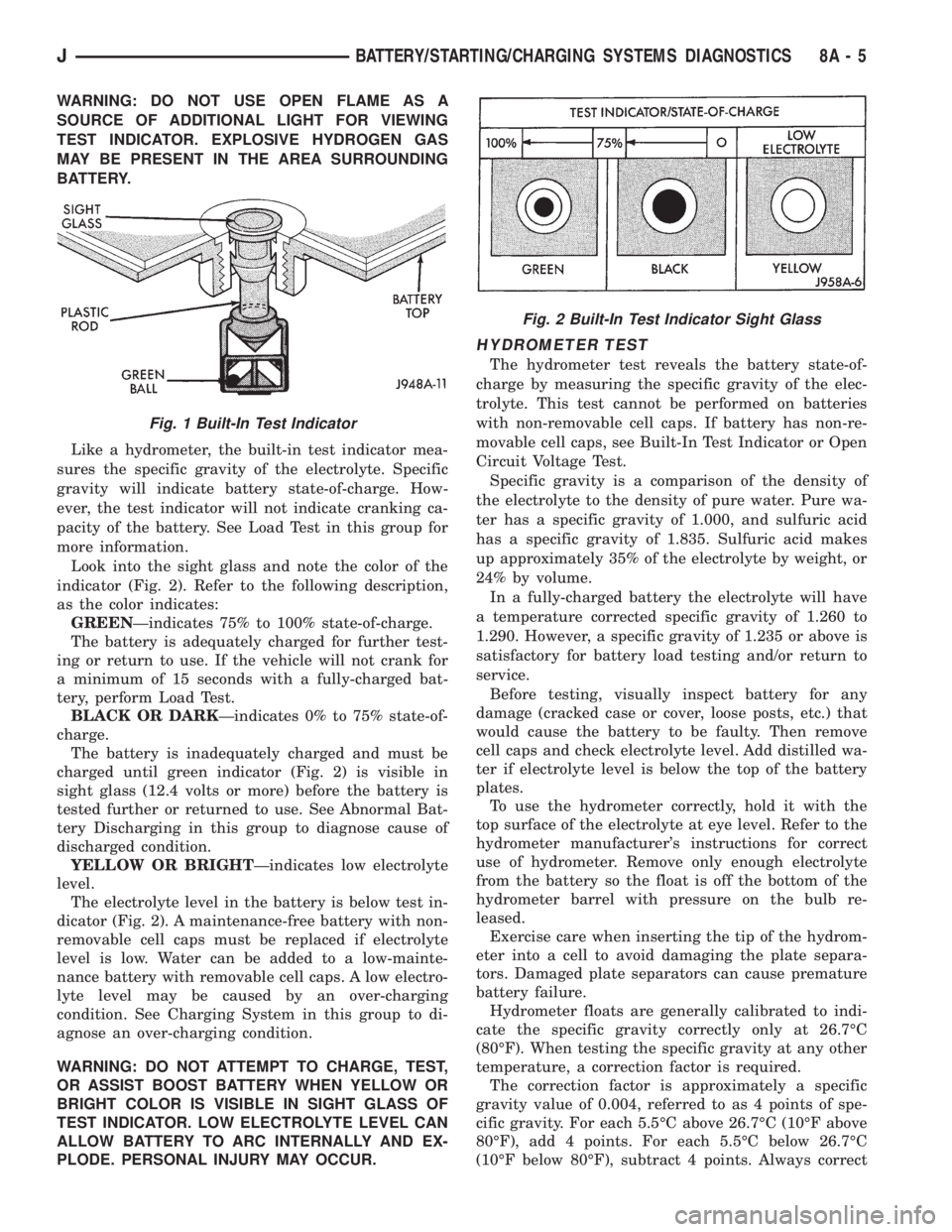

BUILT-IN TEST INDICATOR

A test indicator (hydrometer) built into the top of

the battery case, provides visual information for bat-

tery testing (Fig. 1). It is important when using the

test indicator that the battery be level and have a

clean sight glass to see correct indications. Additional

light may be required to view indicator.

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 3

Page 290 of 2158

WARNING: DO NOT USE OPEN FLAME AS A

SOURCE OF ADDITIONAL LIGHT FOR VIEWING

TEST INDICATOR. EXPLOSIVE HYDROGEN GAS

MAY BE PRESENT IN THE AREA SURROUNDING

BATTERY.

Like a hydrometer, the built-in test indicator mea-

sures the specific gravity of the electrolyte. Specific

gravity will indicate battery state-of-charge. How-

ever, the test indicator will not indicate cranking ca-

pacity of the battery. See Load Test in this group for

more information.

Look into the sight glass and note the color of the

indicator (Fig. 2). Refer to the following description,

as the color indicates:

GREENÐindicates 75% to 100% state-of-charge.

The battery is adequately charged for further test-

ing or return to use. If the vehicle will not crank for

a minimum of 15 seconds with a fully-charged bat-

tery, perform Load Test.

BLACK OR DARKÐindicates 0% to 75% state-of-

charge.

The battery is inadequately charged and must be

charged until green indicator (Fig. 2) is visible in

sight glass (12.4 volts or more) before the battery is

tested further or returned to use. See Abnormal Bat-

tery Discharging in this group to diagnose cause of

discharged condition.

YELLOW OR BRIGHTÐindicates low electrolyte

level.

The electrolyte level in the battery is below test in-

dicator (Fig. 2). A maintenance-free battery with non-

removable cell caps must be replaced if electrolyte

level is low. Water can be added to a low-mainte-

nance battery with removable cell caps. A low electro-

lyte level may be caused by an over-charging

condition. See Charging System in this group to di-

agnose an over-charging condition.

WARNING: DO NOT ATTEMPT TO CHARGE, TEST,

OR ASSIST BOOST BATTERY WHEN YELLOW OR

BRIGHT COLOR IS VISIBLE IN SIGHT GLASS OF

TEST INDICATOR. LOW ELECTROLYTE LEVEL CAN

ALLOW BATTERY TO ARC INTERNALLY AND EX-

PLODE. PERSONAL INJURY MAY OCCUR.

HYDROMETER TEST

The hydrometer test reveals the battery state-of-

charge by measuring the specific gravity of the elec-

trolyte. This test cannot be performed on batteries

with non-removable cell caps. If battery has non-re-

movable cell caps, see Built-In Test Indicator or Open

Circuit Voltage Test.

Specific gravity is a comparison of the density of

the electrolyte to the density of pure water. Pure wa-

ter has a specific gravity of 1.000, and sulfuric acid

has a specific gravity of 1.835. Sulfuric acid makes

up approximately 35% of the electrolyte by weight, or

24% by volume.

In a fully-charged battery the electrolyte will have

a temperature corrected specific gravity of 1.260 to

1.290. However, a specific gravity of 1.235 or above is

satisfactory for battery load testing and/or return to

service.

Before testing, visually inspect battery for any

damage (cracked case or cover, loose posts, etc.) that

would cause the battery to be faulty. Then remove

cell caps and check electrolyte level. Add distilled wa-

ter if electrolyte level is below the top of the battery

plates.

To use the hydrometer correctly, hold it with the

top surface of the electrolyte at eye level. Refer to the

hydrometer manufacturer's instructions for correct

use of hydrometer. Remove only enough electrolyte

from the battery so the float is off the bottom of the

hydrometer barrel with pressure on the bulb re-

leased.

Exercise care when inserting the tip of the hydrom-

eter into a cell to avoid damaging the plate separa-

tors. Damaged plate separators can cause premature

battery failure.

Hydrometer floats are generally calibrated to indi-

cate the specific gravity correctly only at 26.7ÉC

(80ÉF). When testing the specific gravity at any other

temperature, a correction factor is required.

The correction factor is approximately a specific

gravity value of 0.004, referred to as 4 points of spe-

cific gravity. For each 5.5ÉC above 26.7ÉC (10ÉF above

80ÉF), add 4 points. For each 5.5ÉC below 26.7ÉC

(10ÉF below 80ÉF), subtract 4 points. Always correct

Fig. 1 Built-In Test Indicator

Fig. 2 Built-In Test Indicator Sight Glass

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 5

Page 302 of 2158

CHARGING SYSTEM

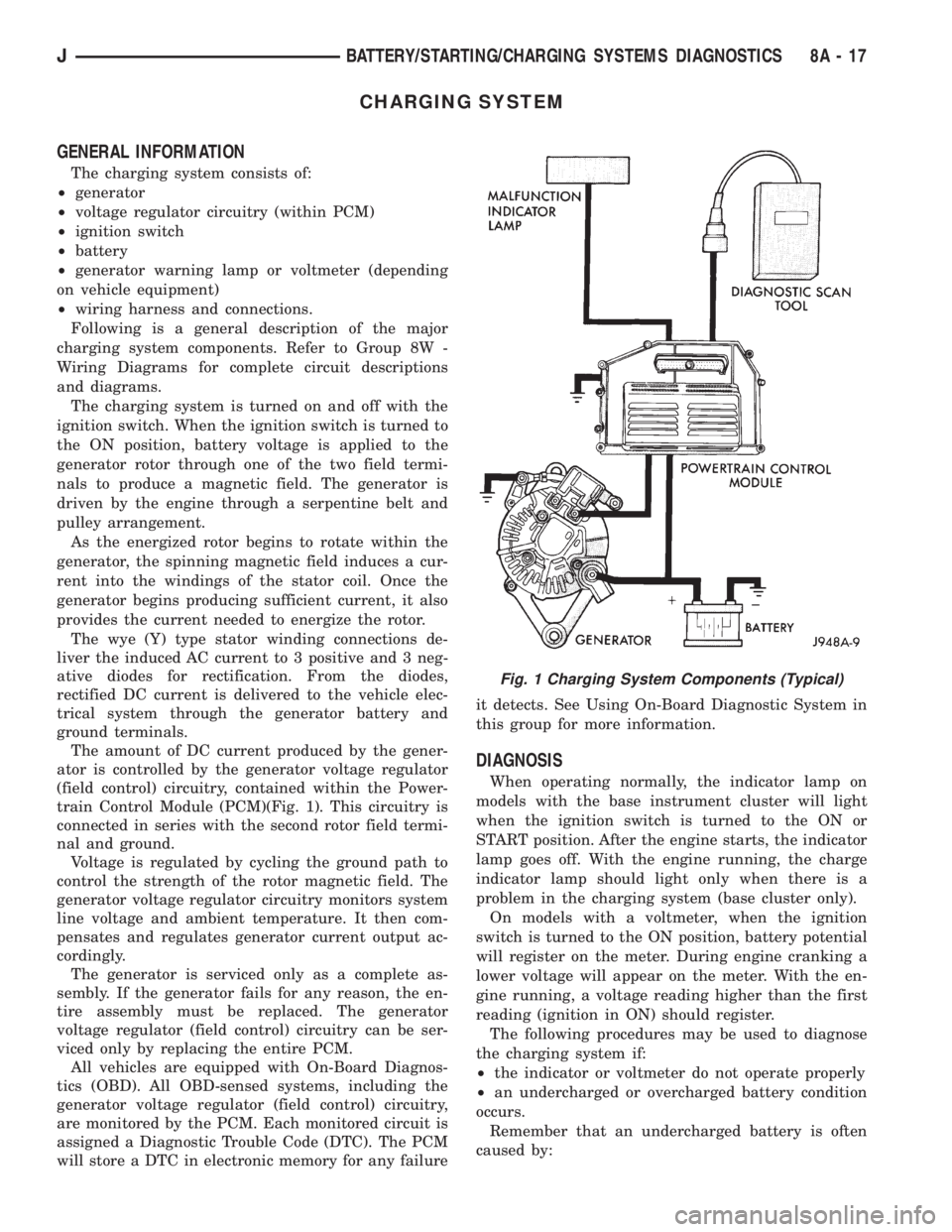

GENERAL INFORMATION

The charging system consists of:

²generator

²voltage regulator circuitry (within PCM)

²ignition switch

²battery

²generator warning lamp or voltmeter (depending

on vehicle equipment)

²wiring harness and connections.

Following is a general description of the major

charging system components. Refer to Group 8W -

Wiring Diagrams for complete circuit descriptions

and diagrams.

The charging system is turned on and off with the

ignition switch. When the ignition switch is turned to

the ON position, battery voltage is applied to the

generator rotor through one of the two field termi-

nals to produce a magnetic field. The generator is

driven by the engine through a serpentine belt and

pulley arrangement.

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The wye (Y) type stator winding connections de-

liver the induced AC current to 3 positive and 3 neg-

ative diodes for rectification. From the diodes,

rectified DC current is delivered to the vehicle elec-

trical system through the generator battery and

ground terminals.

The amount of DC current produced by the gener-

ator is controlled by the generator voltage regulator

(field control) circuitry, contained within the Power-

train Control Module (PCM)(Fig. 1). This circuitry is

connected in series with the second rotor field termi-

nal and ground.

Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. The

generator voltage regulator circuitry monitors system

line voltage and ambient temperature. It then com-

pensates and regulates generator current output ac-

cordingly.

The generator is serviced only as a complete as-

sembly. If the generator fails for any reason, the en-

tire assembly must be replaced. The generator

voltage regulator (field control) circuitry can be ser-

viced only by replacing the entire PCM.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including the

generator voltage regulator (field control) circuitry,

are monitored by the PCM. Each monitored circuit is

assigned a Diagnostic Trouble Code (DTC). The PCM

will store a DTC in electronic memory for any failureit detects. See Using On-Board Diagnostic System in

this group for more information.

DIAGNOSIS

When operating normally, the indicator lamp on

models with the base instrument cluster will light

when the ignition switch is turned to the ON or

START position. After the engine starts, the indicator

lamp goes off. With the engine running, the charge

indicator lamp should light only when there is a

problem in the charging system (base cluster only).

On models with a voltmeter, when the ignition

switch is turned to the ON position, battery potential

will register on the meter. During engine cranking a

lower voltage will appear on the meter. With the en-

gine running, a voltage reading higher than the first

reading (ignition in ON) should register.

The following procedures may be used to diagnose

the charging system if:

²the indicator or voltmeter do not operate properly

²an undercharged or overcharged battery condition

occurs.

Remember that an undercharged battery is often

caused by:

Fig. 1 Charging System Components (Typical)

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 17

Page 334 of 2158

IGNITION SECONDARY CIRCUIT DIAGNOSIS

CHECKING FOR SPARK

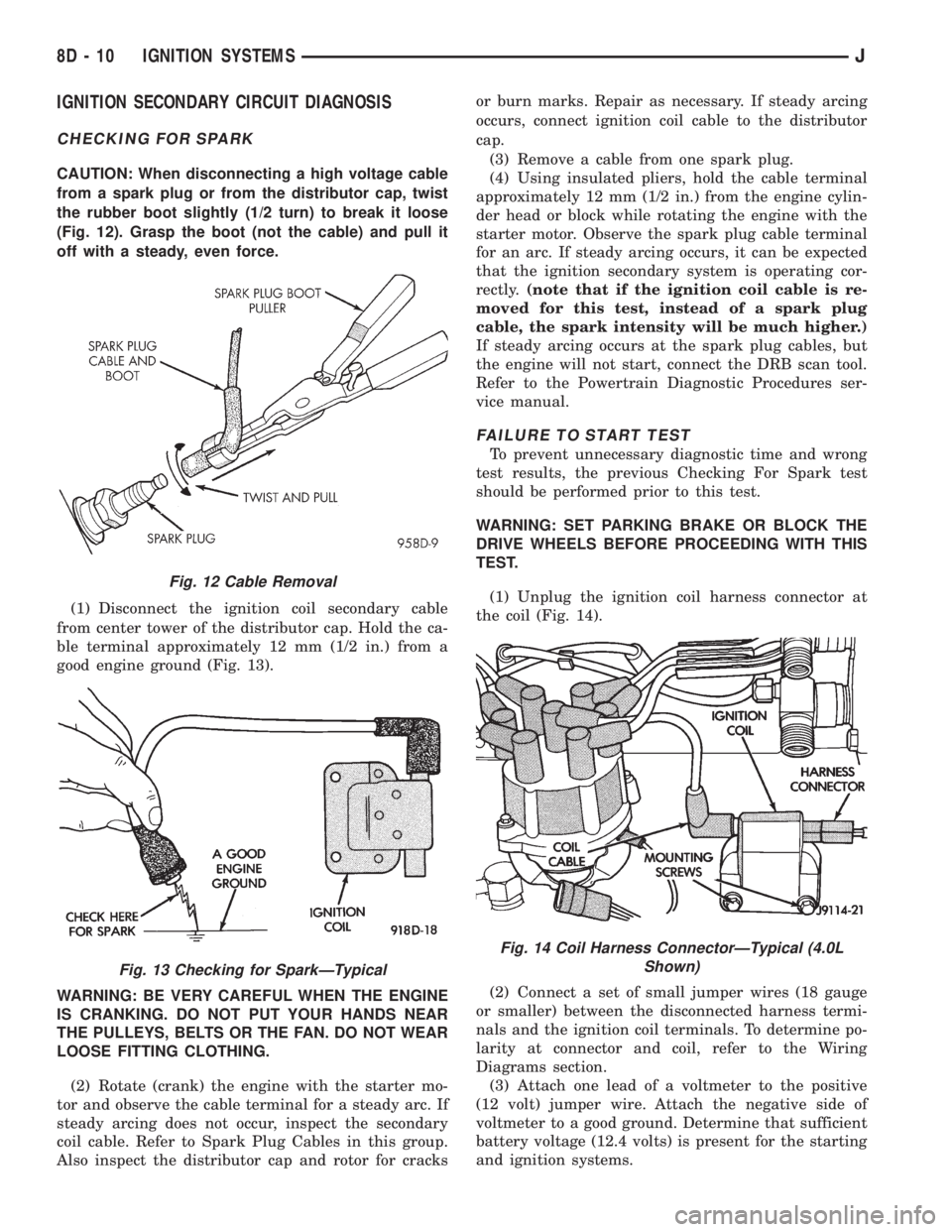

CAUTION: When disconnecting a high voltage cable

from a spark plug or from the distributor cap, twist

the rubber boot slightly (1/2 turn) to break it loose

(Fig. 12). Grasp the boot (not the cable) and pull it

off with a steady, even force.

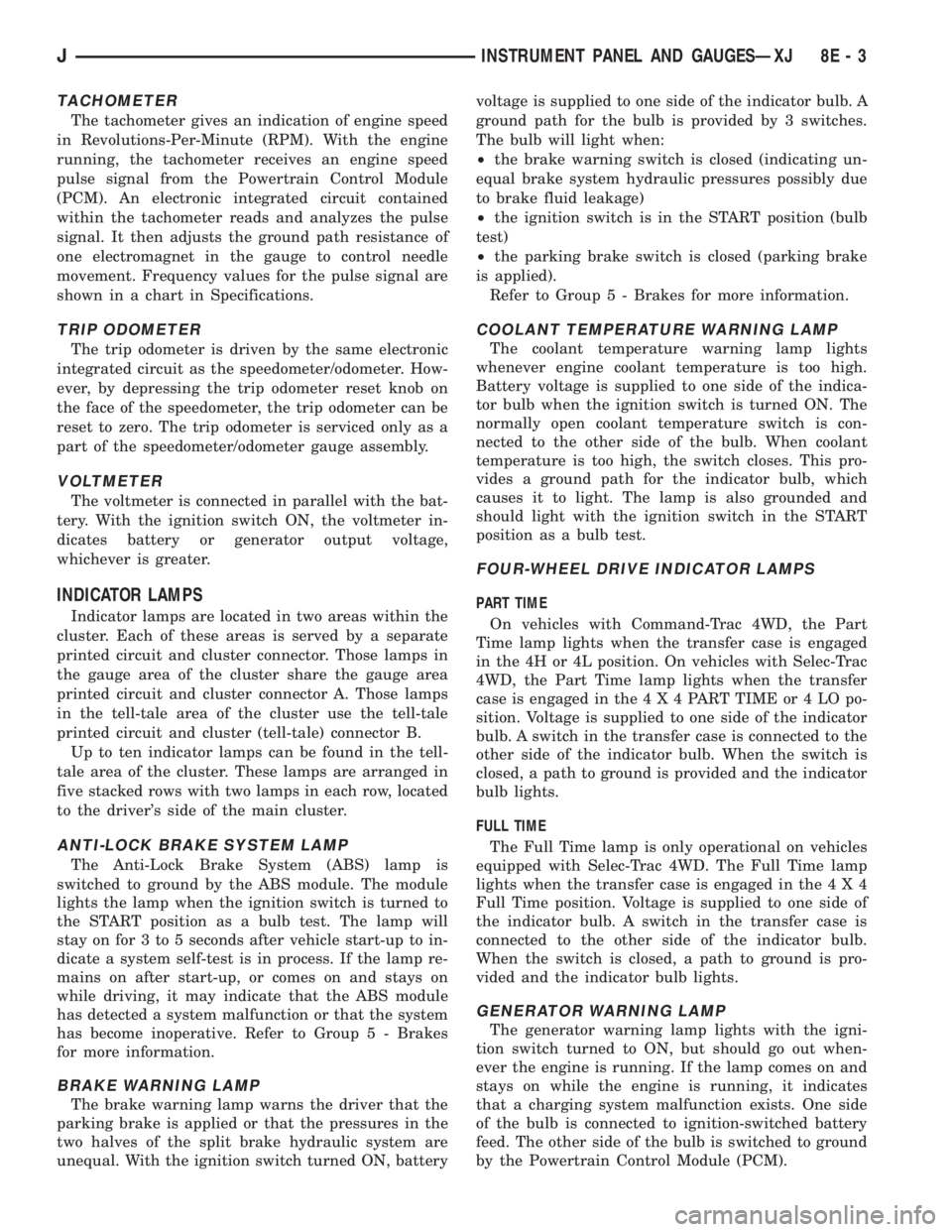

(1) Disconnect the ignition coil secondary cable

from center tower of the distributor cap. Hold the ca-

ble terminal approximately 12 mm (1/2 in.) from a

good engine ground (Fig. 13).

WARNING: BE VERY CAREFUL WHEN THE ENGINE

IS CRANKING. DO NOT PUT YOUR HANDS NEAR

THE PULLEYS, BELTS OR THE FAN. DO NOT WEAR

LOOSE FITTING CLOTHING.

(2) Rotate (crank) the engine with the starter mo-

tor and observe the cable terminal for a steady arc. If

steady arcing does not occur, inspect the secondary

coil cable. Refer to Spark Plug Cables in this group.

Also inspect the distributor cap and rotor for cracksor burn marks. Repair as necessary. If steady arcing

occurs, connect ignition coil cable to the distributor

cap.

(3) Remove a cable from one spark plug.

(4) Using insulated pliers, hold the cable terminal

approximately 12 mm (1/2 in.) from the engine cylin-

der head or block while rotating the engine with the

starter motor. Observe the spark plug cable terminal

for an arc. If steady arcing occurs, it can be expected

that the ignition secondary system is operating cor-

rectly.(note that if the ignition coil cable is re-

moved for this test, instead of a spark plug

cable, the spark intensity will be much higher.)

If steady arcing occurs at the spark plug cables, but

the engine will not start, connect the DRB scan tool.

Refer to the Powertrain Diagnostic Procedures ser-

vice manual.

FAILURE TO START TEST

To prevent unnecessary diagnostic time and wrong

test results, the previous Checking For Spark test

should be performed prior to this test.

WARNING: SET PARKING BRAKE OR BLOCK THE

DRIVE WHEELS BEFORE PROCEEDING WITH THIS

TEST.

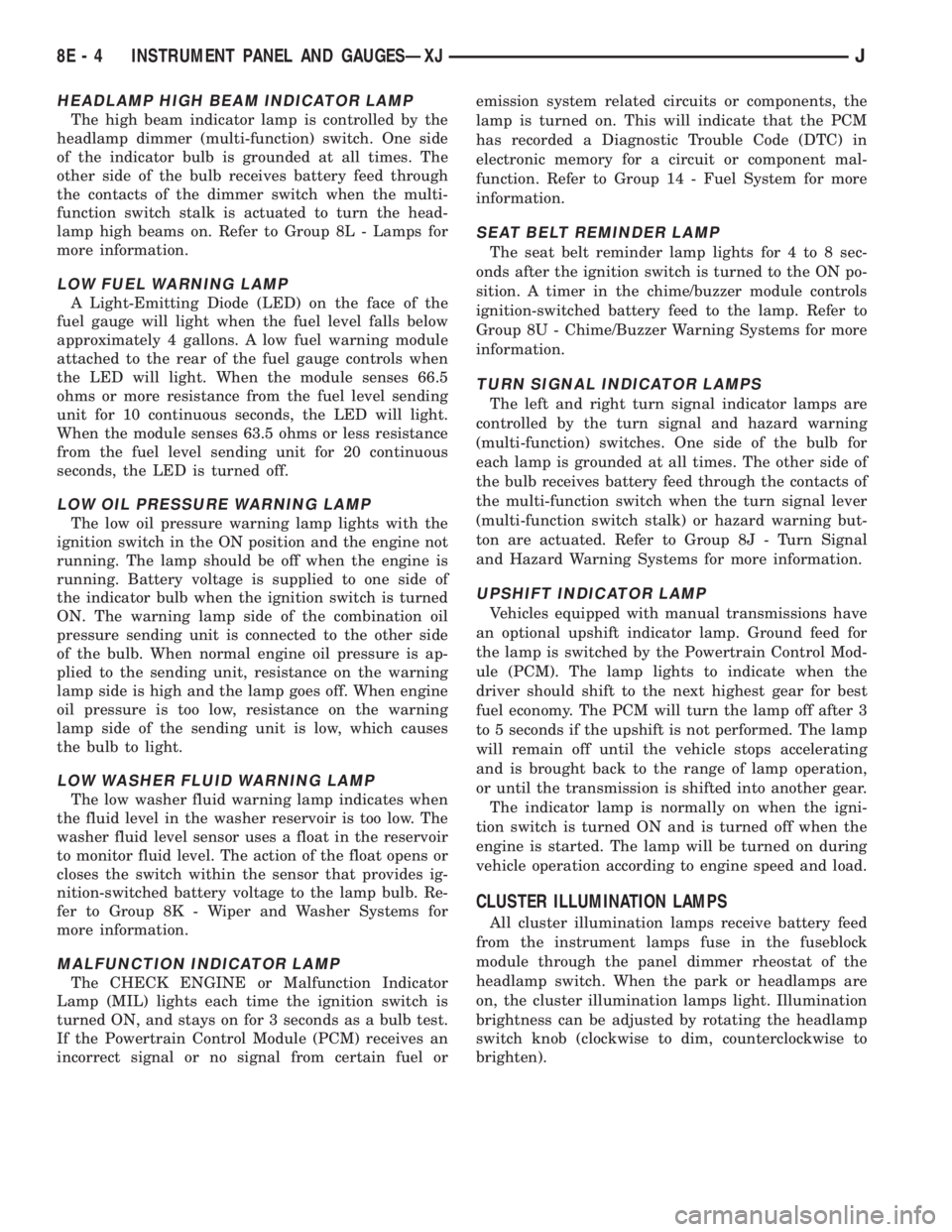

(1) Unplug the ignition coil harness connector at

the coil (Fig. 14).

(2) Connect a set of small jumper wires (18 gauge

or smaller) between the disconnected harness termi-

nals and the ignition coil terminals. To determine po-

larity at connector and coil, refer to the Wiring

Diagrams section.

(3) Attach one lead of a voltmeter to the positive

(12 volt) jumper wire. Attach the negative side of

voltmeter to a good ground. Determine that sufficient

battery voltage (12.4 volts) is present for the starting

and ignition systems.

Fig. 12 Cable Removal

Fig. 13 Checking for SparkÐTypical

Fig. 14 Coil Harness ConnectorÐTypical (4.0L

Shown)

8D - 10 IGNITION SYSTEMSJ

Page 359 of 2158

TACHOMETER

The tachometer gives an indication of engine speed

in Revolutions-Per-Minute (RPM). With the engine

running, the tachometer receives an engine speed

pulse signal from the Powertrain Control Module

(PCM). An electronic integrated circuit contained

within the tachometer reads and analyzes the pulse

signal. It then adjusts the ground path resistance of

one electromagnet in the gauge to control needle

movement. Frequency values for the pulse signal are

shown in a chart in Specifications.

TRIP ODOMETER

The trip odometer is driven by the same electronic

integrated circuit as the speedometer/odometer. How-

ever, by depressing the trip odometer reset knob on

the face of the speedometer, the trip odometer can be

reset to zero. The trip odometer is serviced only as a

part of the speedometer/odometer gauge assembly.

VOLTMETER

The voltmeter is connected in parallel with the bat-

tery. With the ignition switch ON, the voltmeter in-

dicates battery or generator output voltage,

whichever is greater.

INDICATOR LAMPS

Indicator lamps are located in two areas within the

cluster. Each of these areas is served by a separate

printed circuit and cluster connector. Those lamps in

the gauge area of the cluster share the gauge area

printed circuit and cluster connector A. Those lamps

in the tell-tale area of the cluster use the tell-tale

printed circuit and cluster (tell-tale) connector B.

Up to ten indicator lamps can be found in the tell-

tale area of the cluster. These lamps are arranged in

five stacked rows with two lamps in each row, located

to the driver's side of the main cluster.

ANTI-LOCK BRAKE SYSTEM LAMP

The Anti-Lock Brake System (ABS) lamp is

switched to ground by the ABS module. The module

lights the lamp when the ignition switch is turned to

the START position as a bulb test. The lamp will

stay on for 3 to 5 seconds after vehicle start-up to in-

dicate a system self-test is in process. If the lamp re-

mains on after start-up, or comes on and stays on

while driving, it may indicate that the ABS module

has detected a system malfunction or that the system

has become inoperative. Refer to Group 5 - Brakes

for more information.

BRAKE WARNING LAMP

The brake warning lamp warns the driver that the

parking brake is applied or that the pressures in the

two halves of the split brake hydraulic system are

unequal. With the ignition switch turned ON, batteryvoltage is supplied to one side of the indicator bulb. A

ground path for the bulb is provided by 3 switches.

The bulb will light when:

²the brake warning switch is closed (indicating un-

equal brake system hydraulic pressures possibly due

to brake fluid leakage)

²the ignition switch is in the START position (bulb

test)

²the parking brake switch is closed (parking brake

is applied).

Refer to Group 5 - Brakes for more information.

COOLANT TEMPERATURE WARNING LAMP

The coolant temperature warning lamp lights

whenever engine coolant temperature is too high.

Battery voltage is supplied to one side of the indica-

tor bulb when the ignition switch is turned ON. The

normally open coolant temperature switch is con-

nected to the other side of the bulb. When coolant

temperature is too high, the switch closes. This pro-

vides a ground path for the indicator bulb, which

causes it to light. The lamp is also grounded and

should light with the ignition switch in the START

position as a bulb test.

FOUR-WHEEL DRIVE INDICATOR LAMPS

PART TIME

On vehicles with Command-Trac 4WD, the Part

Time lamp lights when the transfer case is engaged

in the 4H or 4L position. On vehicles with Selec-Trac

4WD, the Part Time lamp lights when the transfer

case is engaged in the4X4PARTTIME or 4 LO po-

sition. Voltage is supplied to one side of the indicator

bulb. A switch in the transfer case is connected to the

other side of the indicator bulb. When the switch is

closed, a path to ground is provided and the indicator

bulb lights.

FULL TIME

The Full Time lamp is only operational on vehicles

equipped with Selec-Trac 4WD. The Full Time lamp

lights when the transfer case is engaged in the4X4

Full Time position. Voltage is supplied to one side of

the indicator bulb. A switch in the transfer case is

connected to the other side of the indicator bulb.

When the switch is closed, a path to ground is pro-

vided and the indicator bulb lights.

GENERATOR WARNING LAMP

The generator warning lamp lights with the igni-

tion switch turned to ON, but should go out when-

ever the engine is running. If the lamp comes on and

stays on while the engine is running, it indicates

that a charging system malfunction exists. One side

of the bulb is connected to ignition-switched battery

feed. The other side of the bulb is switched to ground

by the Powertrain Control Module (PCM).

JINSTRUMENT PANEL AND GAUGESÐXJ 8E - 3

Page 360 of 2158

HEADLAMP HIGH BEAM INDICATOR LAMP

The high beam indicator lamp is controlled by the

headlamp dimmer (multi-function) switch. One side

of the indicator bulb is grounded at all times. The

other side of the bulb receives battery feed through

the contacts of the dimmer switch when the multi-

function switch stalk is actuated to turn the head-

lamp high beams on. Refer to Group 8L - Lamps for

more information.

LOW FUEL WARNING LAMP

A Light-Emitting Diode (LED) on the face of the

fuel gauge will light when the fuel level falls below

approximately 4 gallons. A low fuel warning module

attached to the rear of the fuel gauge controls when

the LED will light. When the module senses 66.5

ohms or more resistance from the fuel level sending

unit for 10 continuous seconds, the LED will light.

When the module senses 63.5 ohms or less resistance

from the fuel level sending unit for 20 continuous

seconds, the LED is turned off.

LOW OIL PRESSURE WARNING LAMP

The low oil pressure warning lamp lights with the

ignition switch in the ON position and the engine not

running. The lamp should be off when the engine is

running. Battery voltage is supplied to one side of

the indicator bulb when the ignition switch is turned

ON. The warning lamp side of the combination oil

pressure sending unit is connected to the other side

of the bulb. When normal engine oil pressure is ap-

plied to the sending unit, resistance on the warning

lamp side is high and the lamp goes off. When engine

oil pressure is too low, resistance on the warning

lamp side of the sending unit is low, which causes

the bulb to light.

LOW WASHER FLUID WARNING LAMP

The low washer fluid warning lamp indicates when

the fluid level in the washer reservoir is too low. The

washer fluid level sensor uses a float in the reservoir

to monitor fluid level. The action of the float opens or

closes the switch within the sensor that provides ig-

nition-switched battery voltage to the lamp bulb. Re-

fer to Group 8K - Wiper and Washer Systems for

more information.

MALFUNCTION INDICATOR LAMP

The CHECK ENGINE or Malfunction Indicator

Lamp (MIL) lights each time the ignition switch is

turned ON, and stays on for 3 seconds as a bulb test.

If the Powertrain Control Module (PCM) receives an

incorrect signal or no signal from certain fuel oremission system related circuits or components, the

lamp is turned on. This will indicate that the PCM

has recorded a Diagnostic Trouble Code (DTC) in

electronic memory for a circuit or component mal-

function. Refer to Group 14 - Fuel System for more

information.

SEAT BELT REMINDER LAMP

The seat belt reminder lamp lights for 4 to 8 sec-

onds after the ignition switch is turned to the ON po-

sition. A timer in the chime/buzzer module controls

ignition-switched battery feed to the lamp. Refer to

Group 8U - Chime/Buzzer Warning Systems for more

information.

TURN SIGNAL INDICATOR LAMPS

The left and right turn signal indicator lamps are

controlled by the turn signal and hazard warning

(multi-function) switches. One side of the bulb for

each lamp is grounded at all times. The other side of

the bulb receives battery feed through the contacts of

the multi-function switch when the turn signal lever

(multi-function switch stalk) or hazard warning but-

ton are actuated. Refer to Group 8J - Turn Signal

and Hazard Warning Systems for more information.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have

an optional upshift indicator lamp. Ground feed for

the lamp is switched by the Powertrain Control Mod-

ule (PCM). The lamp lights to indicate when the

driver should shift to the next highest gear for best

fuel economy. The PCM will turn the lamp off after 3

to 5 seconds if the upshift is not performed. The lamp

will remain off until the vehicle stops accelerating

and is brought back to the range of lamp operation,

or until the transmission is shifted into another gear.

The indicator lamp is normally on when the igni-

tion switch is turned ON and is turned off when the

engine is started. The lamp will be turned on during

vehicle operation according to engine speed and load.

CLUSTER ILLUMINATION LAMPS

All cluster illumination lamps receive battery feed

from the instrument lamps fuse in the fuseblock

module through the panel dimmer rheostat of the

headlamp switch. When the park or headlamps are

on, the cluster illumination lamps light. Illumination

brightness can be adjusted by rotating the headlamp

switch knob (clockwise to dim, counterclockwise to

brighten).

8E - 4 INSTRUMENT PANEL AND GAUGESÐXJJ

Page 368 of 2158

INDICATOR LAMPS

If an individual indicator lamp is inoperative, see

the diagnostic procedure under the heading for that

lamp. If more than one indicator lamp or a combina-

tion of lamps and gauges in the gauge area of the in-

strument cluster is inoperative, see Gauges in this

section for diagnosis.

If more than one indicator lamp in the tell-tale

area of the cluster is inoperative, perform the follow-

ing:

(1) Check fuse 17 (fuse 26 - RHD) in the fuseblock

module. If OK, go to next step. If not OK, replace

fuse.

(2) Check for battery voltage at fuse 17 (fuse 26 -

RHD) with ignition switch in ON position. If OK, go

to next step. If not OK, repair circuit to ignition

switch and/or refer to Group 8D - Ignition Systems

for testing of ignition switch.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove instrument cluster bezel and

cluster assembly. Unplug cluster (tell-tale) connector

B.

(4) Connect battery negative cable. Turn ignition

switch to ON. Check for battery voltage at cavities 3,

4, and 14 (cavities 3 and 14 - RHD) of cluster connec-

tor B. If OK, go to next step. If not OK, repair open

circuit to fuse 17 (fuse 26 - RHD) as required.

(5) Turn ignition switch to OFF. Disconnect battery

negative cable. Probe cavity 16 (cavity 1 - RHD) of

cluster connector B. Check for continuity to a good

ground. There should be continuity. If OK, replace

cluster tell-tale printed circuit. If not OK, repair open

circuit to ground as required.

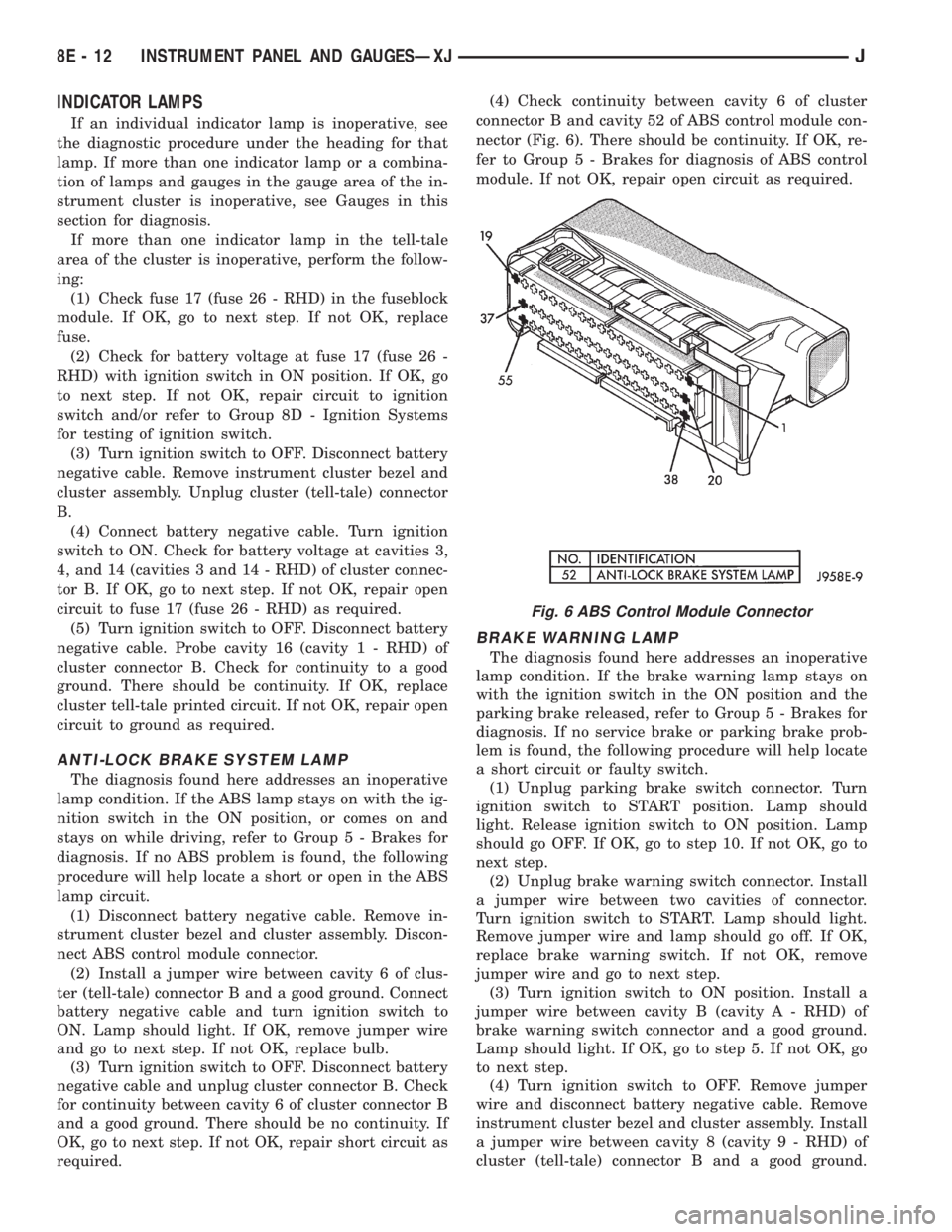

ANTI-LOCK BRAKE SYSTEM LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the ABS lamp stays on with the ig-

nition switch in the ON position, or comes on and

stays on while driving, refer to Group 5 - Brakes for

diagnosis. If no ABS problem is found, the following

procedure will help locate a short or open in the ABS

lamp circuit.

(1) Disconnect battery negative cable. Remove in-

strument cluster bezel and cluster assembly. Discon-

nect ABS control module connector.

(2) Install a jumper wire between cavity 6 of clus-

ter (tell-tale) connector B and a good ground. Connect

battery negative cable and turn ignition switch to

ON. Lamp should light. If OK, remove jumper wire

and go to next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable and unplug cluster connector B. Check

for continuity between cavity 6 of cluster connector B

and a good ground. There should be no continuity. If

OK, go to next step. If not OK, repair short circuit as

required.(4) Check continuity between cavity 6 of cluster

connector B and cavity 52 of ABS control module con-

nector (Fig. 6). There should be continuity. If OK, re-

fer to Group 5 - Brakes for diagnosis of ABS control

module. If not OK, repair open circuit as required.

BRAKE WARNING LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the brake warning lamp stays on

with the ignition switch in the ON position and the

parking brake released, refer to Group 5 - Brakes for

diagnosis. If no service brake or parking brake prob-

lem is found, the following procedure will help locate

a short circuit or faulty switch.

(1) Unplug parking brake switch connector. Turn

ignition switch to START position. Lamp should

light. Release ignition switch to ON position. Lamp

should go OFF. If OK, go to step 10. If not OK, go to

next step.

(2) Unplug brake warning switch connector. Install

a jumper wire between two cavities of connector.

Turn ignition switch to START. Lamp should light.

Remove jumper wire and lamp should go off. If OK,

replace brake warning switch. If not OK, remove

jumper wire and go to next step.

(3) Turn ignition switch to ON position. Install a

jumper wire between cavity B (cavity A - RHD) of

brake warning switch connector and a good ground.

Lamp should light. If OK, go to step 5. If not OK, go

to next step.

(4) Turn ignition switch to OFF. Remove jumper

wire and disconnect battery negative cable. Remove

instrument cluster bezel and cluster assembly. Install

a jumper wire between cavity 8 (cavity 9 - RHD) of

cluster (tell-tale) connector B and a good ground.

Fig. 6 ABS Control Module Connector

8E - 12 INSTRUMENT PANEL AND GAUGESÐXJJ

Page 369 of 2158

Connect battery negative cable and turn ignition

switch to ON. Lamp should light. If OK, repair open

circuit to brake warning switch. If not OK, replace

bulb.

(5) Turn ignition switch to OFF and remove

jumper wire. Disconnect battery negative cable.

Check for continuity between cavity A (cavity B -

RHD) of brake warning switch connector and a good

ground with ignition switch in START position.

There should be continuity. If not OK, go to next

step.

(6) Turn ignition switch to OFF and remove

jumper wire. Disconnect battery negative cable. Un-

plug ignition switch connector. Check for continuity

between ignition switch connector cavity 3 and a

good ground. There should be no continuity. If OK, go

to next step. If not OK, repair short circuit between

ignition switch and brake warning switch connectors

as required.

(7) Check for continuity between ignition switch

connector cavity 3 and brake warning switch connec-

tor cavity A (cavity B - RHD). There should be conti-

nuity. If OK, go to next step. If not OK, repair open

circuit as required.

(8) Check for continuity between metal steering

column jacket and a good ground. There should be

continuity. If OK, go to next step. If not OK, refer to

Group 19 - Steering to check steering column ground

clip installation.

(9) Turn ignition switch to START position and

hold there. Check for continuity between terminal 3

of ignition switch and a good ground. There should

be continuity. If not OK, replace ignition switch.

(10) Unplug brake warning switch connector.

Check for continuity between parking brake switch

connector and a good ground. There should be no

continuity. If OK, go to next step. If not OK, repair

short circuit as required.

(11) Check for continuity between parking brake

switch connector and cavity B (cavity A - RHD) of

brake warning switch connector. There should be

continuity. If OK, replace parking brake switch. If

not OK, repair open circuit to brake warning switch

as required.

COOLANT TEMPERATURE WARNING LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the problem being diagnosed is re-

lated to lamp accuracy, be certain to confirm that

problem is with lamp and not with cooling system

performance. Actual engine coolant temperature

should be checked with a test gauge or thermometer

before proceeding with lamp diagnosis. Refer to

Group 7 - Cooling System for more information.

(1) Turn ignition switch to START position. Lamp

should light. If OK, go to next step. If not OK, go to

step 3.(2) Turn ignition switch to ON. Disconnect coolant

temperature switch connector (Fig. 1). Jump switch

connector to ground. Lamp should light. If OK, re-

place switch. If not OK, go to next step.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug coolant temperature switch

connector. Remove instrument cluster bezel and clus-

ter assembly. Disconnect cluster connector A and

probe cavity A1. Check for continuity to a good

ground. There should be no continuity. If OK, go to

next step. If not OK, repair short circuit to coolant

temperature switch or ignition switch as required.

(4) Connect cluster connector A to cluster. Install a

jumper wire from cavity A1 of cluster connector A to

a good ground. Connect battery negative cable and

turn ignition switch to ON. Lamp should light. If OK,

repair open circuit to coolant temperature switch or

ignition switch as required. If not OK, replace bulb.

FOUR-WHEEL DRIVE INDICATOR LAMPS

(1) Apply parking brake, start engine, vehicle in

4WD Lock or 4WD.

(2) Unplug switch and touch harness side of wire

to ground. Lamp should light. If OK, check switch

operation, replace if bad. If bulb is OK, repair open

to indicator.

GENERATOR WARNING LAMP

(1) Disconnect battery negative cable and unplug

PCM connector. Install a jumper wire between cavity

36 of PCM connector (Fig. 5) and a good ground. Con-

nect battery negative cable and turn ignition switch

to ON. Lamp should light. Unplug jumper wire and

lamp should go off. If OK, refer to Powertrain Diag-

nostic Procedures to check PCM. If not OK, go to

next step.

(2) Turn ignition switch to OFF and disconnect

battery negative cable. Remove instrument cluster

bezel and cluster assembly. Install a jumper wire be-

tween cavity B8 of cluster connector A and a good

ground. Connect battery negative cable and turn ig-

nition switch to ON. Lamp should light. If OK, go to

next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF and disconnect

battery negative cable. Unplug cluster connector A.

Probe cavity B8 of cluster connector A and check for

continuity to a good ground. There should be no con-

tinuity. If OK, go to next step. If not OK, repair short

circuit as required.

(4) Check for continuity between cavity B8 of clus-

ter connector A and cavity 36 of PCM connector.

There should be continuity. If not OK, repair open

circuit as required.

HEADLAMP HIGH BEAM INDICATOR LAMP

(1) Check that headlamp high beams are func-

tional. If OK, go to next step. If not OK, refer to

Group 8L - Lamps for diagnosis of headlamp system.

JINSTRUMENT PANEL AND GAUGESÐXJ 8E - 13

Page 370 of 2158

(2) Disconnect battery negative cable. Remove in-

strument cluster bezel and cluster assembly. Unplug

cluster connector A. Connect battery negative cable.

Turn headlamps on and select high beam. Check for

battery voltage at cavity A4 of cluster connector A. If

OK, replace indicator bulb. If not OK, repair circuit

to headlamp dimmer (multi-function) switch as re-

quired.

LOW FUEL WARNING LAMP

(1) Check that fuel gauge is operating as designed.

See Fuel Gauge Calibration chart in Specifications. If

OK, go to next step. If not OK, see Fuel Gauge in

this section for diagnosis.

(2) With at least 10 gallons of fuel in fuel tank, un-

plug fuel tank sending unit connector. Turn ignition

switch to ON and wait 10 seconds. Lamp (LED)

should light. Reconnect fuel tank sending unit and

wait 20 seconds. Lamp (LED) should go off. If not

OK, replace low fuel warning lamp module.

LOW OIL PRESSURE WARNING LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the problem being diagnosed is re-

lated to lamp accuracy, be certain to confirm that

problem is with lamp and not with engine oiling sys-

tem. Actual engine oil pressure should be checked

with a test gauge before you proceed with lamp diag-

nosis. Refer to Group 9 - Engines for more informa-

tion.

(1) Turn ignition switch to ON. Lamp should light.

Start engine. Lamp should go off. If not OK, turn en-

gine off and go to next step.

(2) Unplug connector at oil pressure switch (Fig.

3). The switch is located on right side of engine block.

On 2.5L engine, it is just forward of ignition distrib-

utor and just to the rear of generator mounting

bracket. On 4.0L engine, it is just to the rear of igni-

tion distributor and above oil filter adapter. Install a

jumper wire from connector to a good ground. Turn

ignition switch to ON. Lamp should light. Unplug

jumper wire. Lamp should go out. If OK, replace oil

pressure switch. If not OK, go to next step.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove instrument cluster bezel and

cluster assembly. Install a jumper wire from cavity

B7 (cavity B8 - RHD) of cluster connector A to a good

ground. Connect battery negative cable and turn ig-

nition switch to ON. Lamp should light. If OK, go to

next step. If not OK, replace lamp bulb.

(4) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug instrument cluster connector

A. Check continuity between cavity B7 (cavity B8 -

RHD) of cluster connector A and a good ground.

There should be no continuity. If OK, go to next step.

If not OK, repair short circuit as required.

(5) Check continuity between cavity B7 (cavity B8

- RHD) of cluster connector A and oil pressure switchconnector. There should be continuity. If not OK, re-

pair open circuit as required.

LOW WASHER FLUID WARNING LAMP

(1) Unplug washer fluid level switch connector.

Turn ignition switch to ON. Check for battery voltage

at connector cavity A. If OK, turn ignition switch to

OFF and go to next step. If not OK, repair open cir-

cuit to fuse F6 in PDC.

(2) Install a jumper wire from cavity A to cavity B

of washer fluid level switch connector. Turn ignition

switch to ON. Lamp should light. Unplug jumper and

lamp should go OFF. If OK, replace washer fluid

level switch. If not OK, go to next step.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove instrument cluster bezel and

cluster assembly. Unplug instrument cluster (tell-

tale) connector B. Check continuity between cavity 16

(cavity 1 - RHD) of cluster connector B and a good

ground. There should be continuity. If OK, plug clus-

ter connector B back into cluster and go to next step.

If not OK, repair open circuit to ground as required.

(4) Connect battery negative cable. Install a

jumper wire from a 12-volt battery feed to cavity 1

(cavity 16 - RHD) of cluster connector B. Lamp

should light. If OK, go to next step. If not OK, re-

place bulb.

(5) Disconnect battery negative cable. Unplug clus-

ter connector B. Check continuity between cavity 1

(cavity 16 - RHD) of cluster connector B and a good

ground. There should be no continuity. If OK, go to

next step. If not OK, repair short circuit to switch as

required.

(6) Check continuity between cavity 1 (cavity 16 -

RHD) of cluster connector B and cavity B of washer

fluid level switch connector. There should be continu-

ity. If not OK, repair open circuit to switch as re-

quired.

MALFUNCTION INDICATOR LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the lamp comes on and stays on

with engine running, refer to Group 14 - Fuel System

for diagnosis. If no fuel or emission system problem

is found, the following procedure will help locate a

short or open in the lamp circuit.

(1) Disconnect battery negative cable. Unplug PCM

connector. Install a jumper wire from cavity 32 of

PCM connector (Fig. 5) to a good ground. Connect

battery negative cable. Turn ignition switch to ON.

Lamp should light. Remove jumper wire and lamp

should go OFF. If OK, refer to Powertrain Diagnostic

Procedures to check PCM. If not OK, go to next step.

(2) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove instrument cluster bezel and

cluster assembly. Install a jumper wire from cavity 2

(cavity 15 - RHD) of cluster (tell-tale) connector B to

a good ground. Connect battery negative cable. Turn

8E - 14 INSTRUMENT PANEL AND GAUGESÐXJJ