headlamp JEEP XJ 1995 Service And Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 484 of 2158

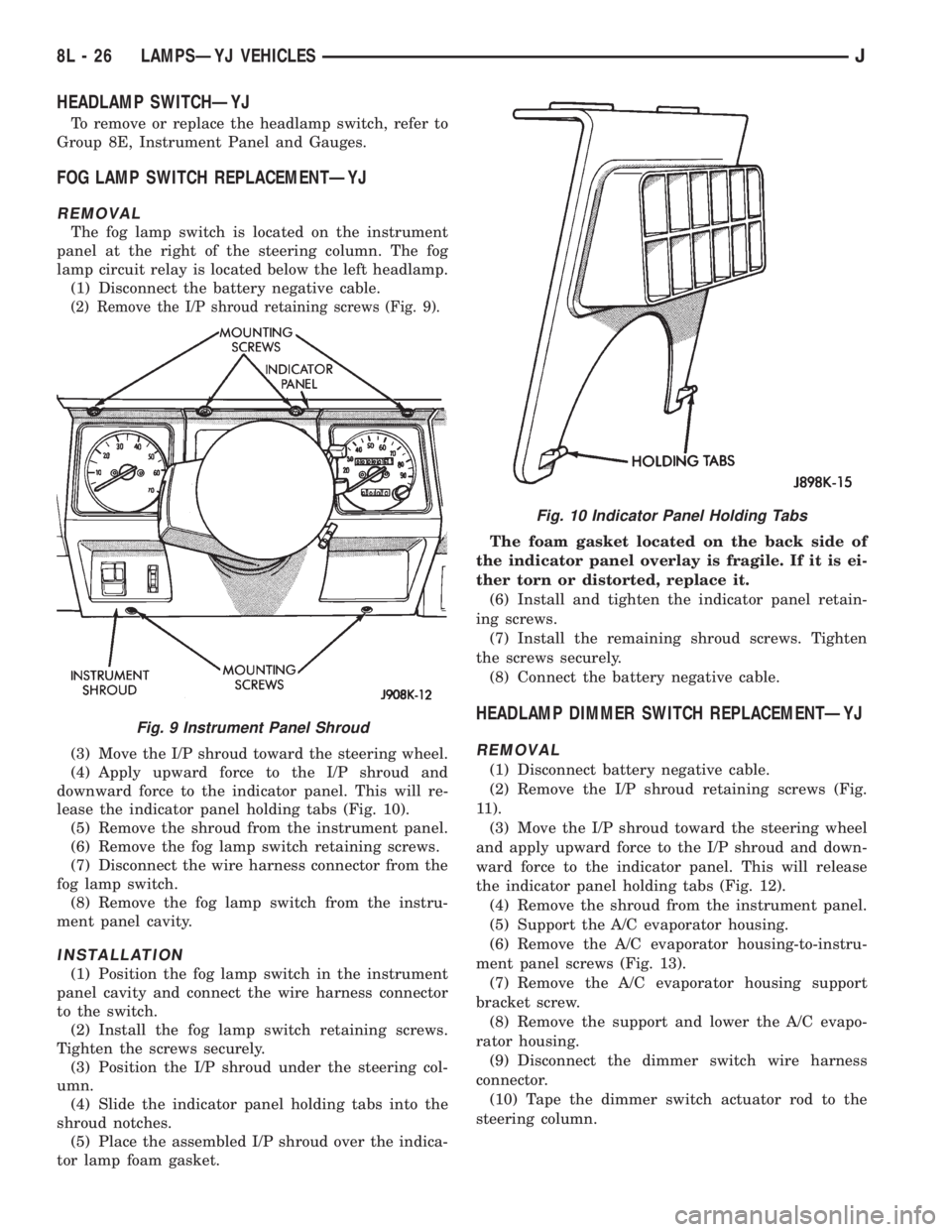

(3) Remove the bulb/element from the holder.

INSTALLATION

(1) Use a clean cloth to install a replacement bulb

holder.(2) Install the bulb holder in the lens/reflector.

(3) Position the stone shield and reflector on the

lamp housing. Install the screws that attach the

stone shield and the reflector to the lamp housing.

Tighten the screws securely.

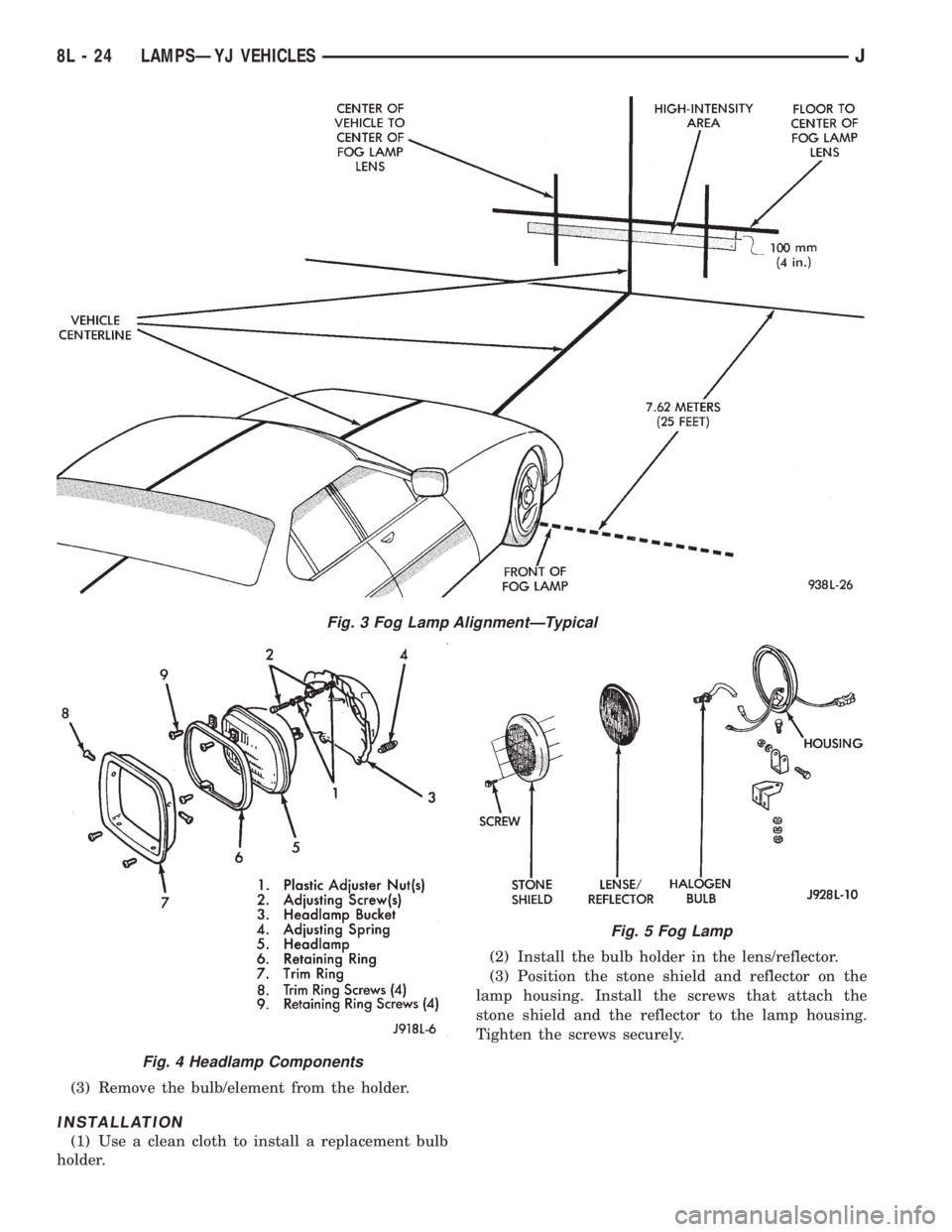

Fig. 3 Fog Lamp AlignmentÐTypical

Fig. 4 Headlamp Components

Fig. 5 Fog Lamp

8L - 24 LAMPSÐYJ VEHICLESJ

Page 486 of 2158

HEADLAMP SWITCHÐYJ

To remove or replace the headlamp switch, refer to

Group 8E, Instrument Panel and Gauges.

FOG LAMP SWITCH REPLACEMENTÐYJ

REMOVAL

The fog lamp switch is located on the instrument

panel at the right of the steering column. The fog

lamp circuit relay is located below the left headlamp.

(1) Disconnect the battery negative cable.

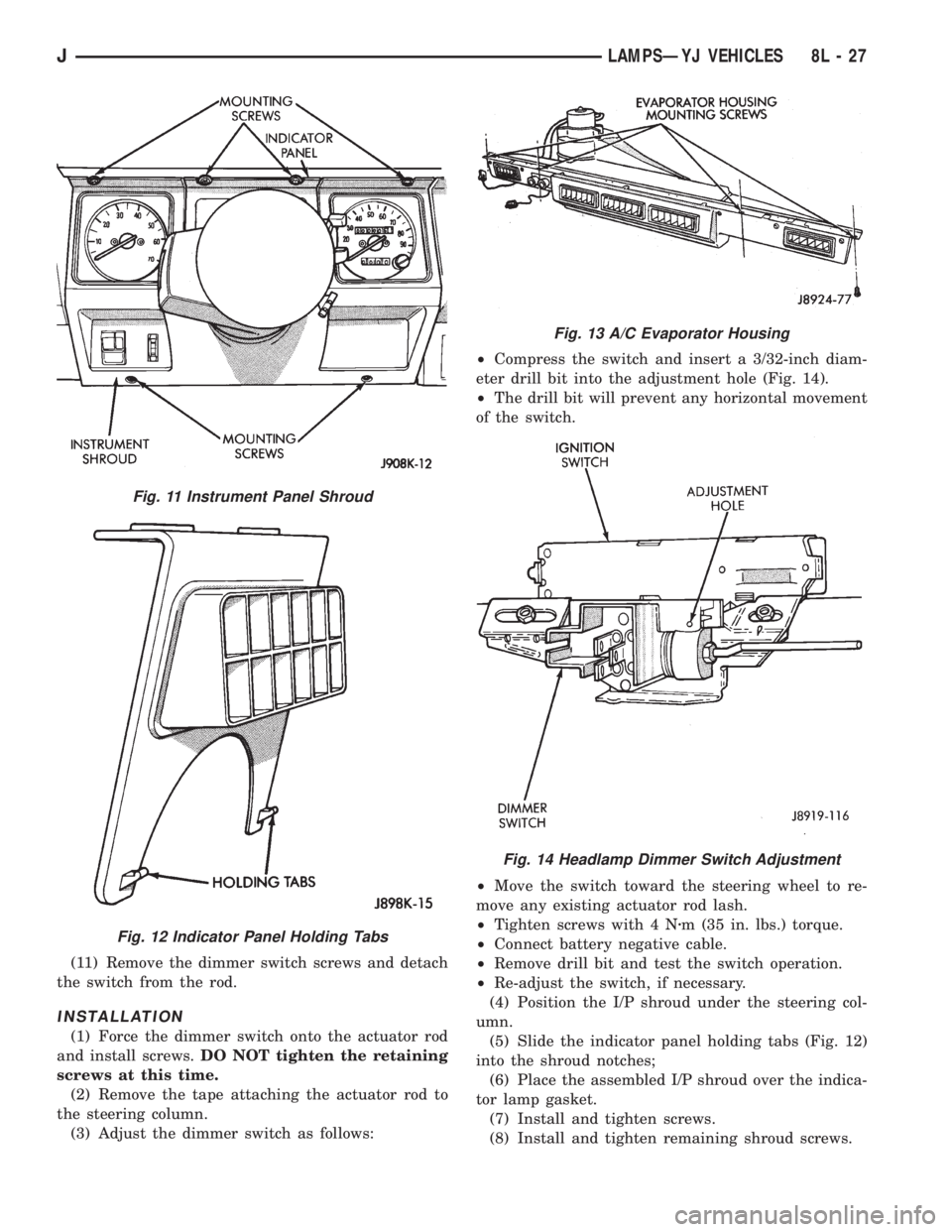

(2) Remove the I/P shroud retaining screws (Fig. 9).

(3) Move the I/P shroud toward the steering wheel.

(4) Apply upward force to the I/P shroud and

downward force to the indicator panel. This will re-

lease the indicator panel holding tabs (Fig. 10).

(5) Remove the shroud from the instrument panel.

(6) Remove the fog lamp switch retaining screws.

(7) Disconnect the wire harness connector from the

fog lamp switch.

(8) Remove the fog lamp switch from the instru-

ment panel cavity.

INSTALLATION

(1) Position the fog lamp switch in the instrument

panel cavity and connect the wire harness connector

to the switch.

(2) Install the fog lamp switch retaining screws.

Tighten the screws securely.

(3) Position the I/P shroud under the steering col-

umn.

(4) Slide the indicator panel holding tabs into the

shroud notches.

(5) Place the assembled I/P shroud over the indica-

tor lamp foam gasket.The foam gasket located on the back side of

the indicator panel overlay is fragile. If it is ei-

ther torn or distorted, replace it.

(6) Install and tighten the indicator panel retain-

ing screws.

(7) Install the remaining shroud screws. Tighten

the screws securely.

(8) Connect the battery negative cable.

HEADLAMP DIMMER SWITCH REPLACEMENTÐYJ

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove the I/P shroud retaining screws (Fig.

11).

(3) Move the I/P shroud toward the steering wheel

and apply upward force to the I/P shroud and down-

ward force to the indicator panel. This will release

the indicator panel holding tabs (Fig. 12).

(4) Remove the shroud from the instrument panel.

(5) Support the A/C evaporator housing.

(6) Remove the A/C evaporator housing-to-instru-

ment panel screws (Fig. 13).

(7) Remove the A/C evaporator housing support

bracket screw.

(8) Remove the support and lower the A/C evapo-

rator housing.

(9) Disconnect the dimmer switch wire harness

connector.

(10) Tape the dimmer switch actuator rod to the

steering column.

Fig. 9 Instrument Panel Shroud

Fig. 10 Indicator Panel Holding Tabs

8L - 26 LAMPSÐYJ VEHICLESJ

Page 487 of 2158

(11) Remove the dimmer switch screws and detach

the switch from the rod.

INSTALLATION

(1) Force the dimmer switch onto the actuator rod

and install screws.DO NOT tighten the retaining

screws at this time.

(2) Remove the tape attaching the actuator rod to

the steering column.

(3) Adjust the dimmer switch as follows:²Compress the switch and insert a 3/32-inch diam-

eter drill bit into the adjustment hole (Fig. 14).

²The drill bit will prevent any horizontal movement

of the switch.

²Move the switch toward the steering wheel to re-

move any existing actuator rod lash.

²Tighten screws with 4 Nzm (35 in. lbs.) torque.

²Connect battery negative cable.

²Remove drill bit and test the switch operation.

²Re-adjust the switch, if necessary.

(4) Position the I/P shroud under the steering col-

umn.

(5) Slide the indicator panel holding tabs (Fig. 12)

into the shroud notches;

(6) Place the assembled I/P shroud over the indica-

tor lamp gasket.

(7) Install and tighten screws.

(8) Install and tighten remaining shroud screws.

Fig. 11 Instrument Panel Shroud

Fig. 12 Indicator Panel Holding Tabs

Fig. 13 A/C Evaporator Housing

Fig. 14 Headlamp Dimmer Switch Adjustment

JLAMPSÐYJ VEHICLES 8L - 27

Page 490 of 2158

(3) Insert a replacement bulb in the lamp base

socket and rotate it clockwise.

(4) Connect the wire harness connector to the

lamp.

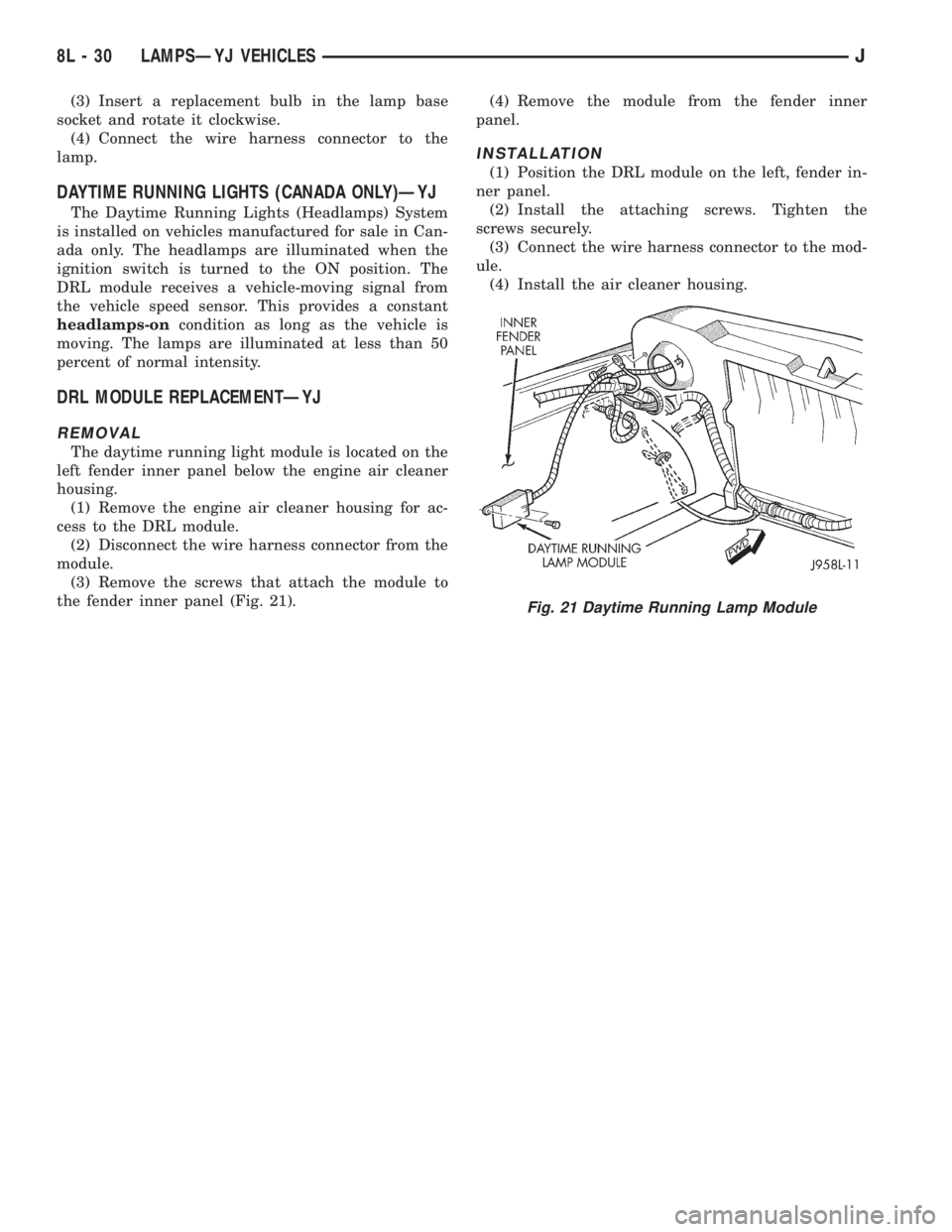

DAYTIME RUNNING LIGHTS (CANADA ONLY)ÐYJ

The Daytime Running Lights (Headlamps) System

is installed on vehicles manufactured for sale in Can-

ada only. The headlamps are illuminated when the

ignition switch is turned to the ON position. The

DRL module receives a vehicle-moving signal from

the vehicle speed sensor. This provides a constant

headlamps-oncondition as long as the vehicle is

moving. The lamps are illuminated at less than 50

percent of normal intensity.

DRL MODULE REPLACEMENTÐYJ

REMOVAL

The daytime running light module is located on the

left fender inner panel below the engine air cleaner

housing.

(1) Remove the engine air cleaner housing for ac-

cess to the DRL module.

(2) Disconnect the wire harness connector from the

module.

(3) Remove the screws that attach the module to

the fender inner panel (Fig. 21).(4) Remove the module from the fender inner

panel.

INSTALLATION

(1) Position the DRL module on the left, fender in-

ner panel.

(2) Install the attaching screws. Tighten the

screws securely.

(3) Connect the wire harness connector to the mod-

ule.

(4) Install the air cleaner housing.

Fig. 21 Daytime Running Lamp Module

8L - 30 LAMPSÐYJ VEHICLESJ

Page 492 of 2158

BULB APPLICATIONÐYJ VEHICLES

GENERAL INFORMATION

The following Bulb Application Table lists the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the Bulb Applica-

tion Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

oily surfaces. Bulb life will be reduced.

EXTERIOR LAMPSÐYJ

Back-up .................................................................1156

Center High Mounted Stoplamp ..........................912

Fog ............................................................................H3

Front Side Marker .................................................194

Headlamp/Sealed Beam....................................H6054

Park/Turn Signal..................................................3157

Tail/Stop ................................................................1157

INTERIOR LAMPSÐYJ

Service procedures for most of the lamps in the in-

strument panel, Instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges.

Some components have lamps that can only be ser-

viced by an Authorized Service Center (ASC) after

the component is removed from the vehicle. Contact

local dealer for location of nearest ASC.Dome/Cargo .........................................................212-2

Glove Compartment ...............................................194

Under Hood ............................................................105

Underpanel Courtesy...............................................89

INDICATOR LAMPS

Service procedures for most of the lamps in the in-

strument panel, instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges.

A/C Control ...............................................................74

Anti-lock Brake ........................................................74

Ash Receiver .........................................................1891

Brake Warning .........................................................74

Cigar Lighter ............................................................53

Fasten Seat Belts ....................................................74

Four Wheel Drive ....................................................74

Generator ................................................................194

Hazard.......................................................................74

Heater Control .......................................................194

High Beam..............................................................194

Illumination ............................................................194

Low Coolant..............................................................74

Radio ......................................................................ASC

Rocker Switch...........................................................74

Seat Belt ...................................................................74

Shift ...........................................................................74

Turn Signal.............................................................194

8L - 32 LAMPSÐYJ VEHICLESJ

Page 531 of 2158

CHIME/BUZZER WARNING SYSTEMS

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 4

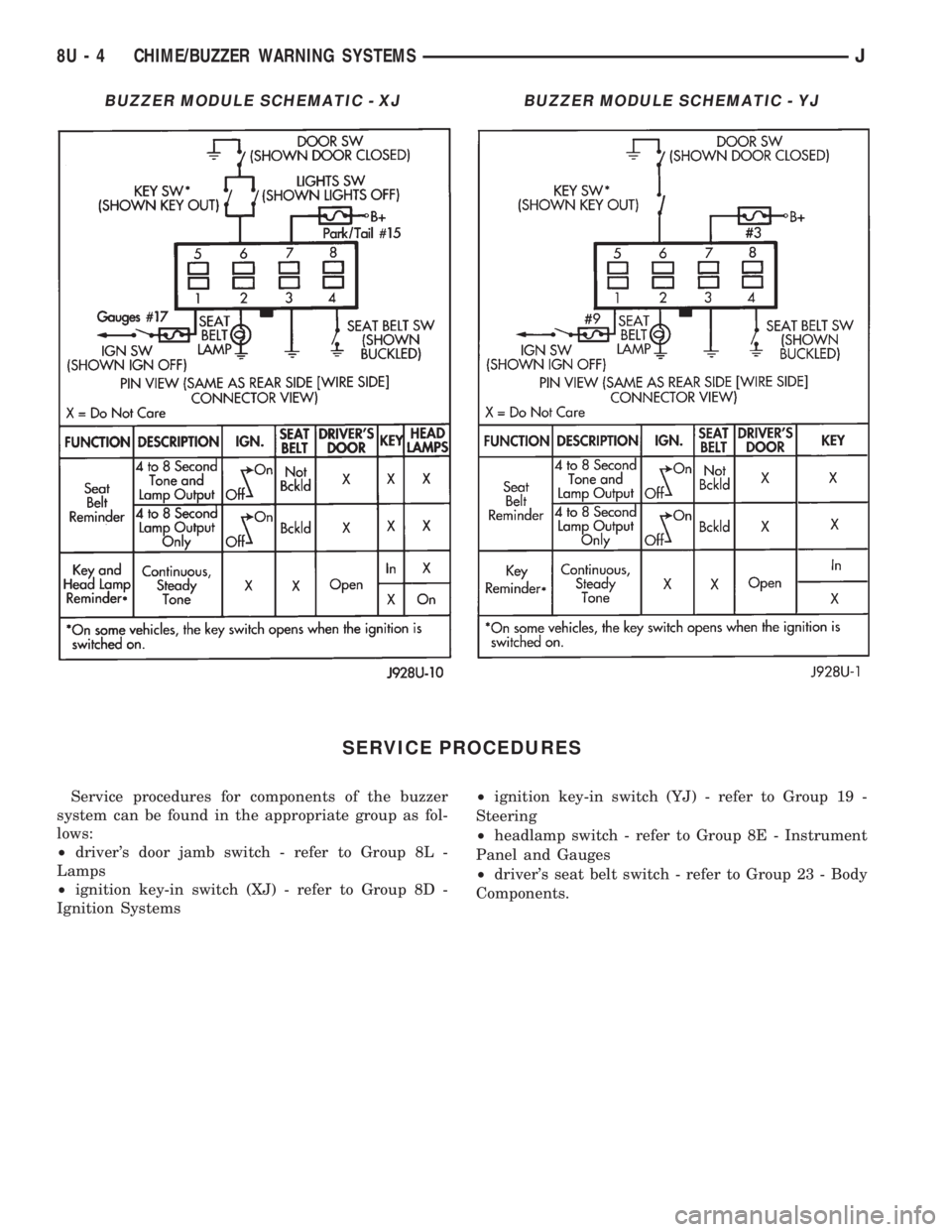

GENERAL INFORMATION

This group covers the buzzer warning system,

which is standard equipment on XJ (Cherokee)/YJ

(Wrangler) models. The system provides an audible

warning to the driver when it monitors the following

conditions:

²key is in ignition switch with the driver's door

open

²head or park lamps are on with driver's door open

(XJ only)

²driver's seat belt is not buckled with ignition

switch in ON position.

Following are general descriptions of the major

components in the buzzer warning system. Refer to

Group 8W - Wiring Diagrams for complete circuit de-

scriptions and diagrams.

BUZZER MODULE

The buzzer module is located in the fuseblock mod-

ule under the left end of the instrument panel. It re-

ceives battery voltage at all times from (fuse 15 - XJ,

fuse 3 - YJ) the fuseblock module. It also receives a

second battery feed (fuse 17 - XJ, fuse 9 - YJ) when

the ignition switch is in the ON or START position.

Other inputs to the module include the driver's door

jamb switch, the driver's seat belt switch, the ignition

key-in switch, and the headlamp switch (XJ only). The

only output of the module is a timed 4 to 8 second feed

to the seat belt reminder lamp in the message center of

the instrument cluster. The timer function begins after

the ignition switch is turned to the ON position.

The buzzer module can not be repaired. If faulty, it

must be replaced.

DRIVER'S DOOR JAMB SWITCH

The driver's door jamb switch is mounted to the

driver's door hinge pillar. The switch closes a path to

ground for the buzzer module through the key-in

switch or headlamp switch (XJ only) when the driv-

er's door is opened, and opens when the driver's door

is closed. This switch can not be repaired. If faulty, it

must be replaced.

IGNITION KEY-IN SWITCH

XJ MODELS

The key-in switch is integral to the ignition switch,

which is mounted on the right side of the steering col-

umn. It closes a path to ground for the buzzer module

when the ignition key is inserted in the ignition lock cyl-

inder and the driver's door jamb switch is closed (door

open). The switch opens when the key is removed from

the ignition lock cylinder. This switch can not be re-

paired. If faulty, the entire ignition switch must be re-

placed. Refer to Group 8D - Ignition Systems for service

procedures.

YJ MODELS

The key-in switch is mounted within the steering col-

umn in the lock cylinder housing. It closes a path to

ground for the buzzer module when the ignition key is

inserted in the ignition lock cylinder and the driver's

door jamb switch is closed (door open). The switch opens

when the key is removed from the ignition lock cylinder.

This switch is available for service replacement. Refer

to Group 19 - Steering for service procedures.

HEADLAMP SWITCH (XJ ONLY)

The headlamp switch is located in the instrument

panel. It closes a path to ground for the buzzer module

when the park or headlamps are on and the driver's

door jamb switch is closed (door open). The switch opens

the ground path when the park and headlamps are

turned off. The headlamp switch can not be repaired. If

faulty, it must be replaced. Refer to Group 8E - Instru-

ment Panel and Gauges for service procedures.

DRIVER'S SEAT BELT SWITCH

The driver's seat belt switch is integral to the driv-

er's seat belt buckle-half assembly. The switch is nor-

mally closed, providing a ground path to the buzzer

module. When the tip-half of the seat belt is inserted

into the seat belt buckle, the switch opens the buzzer

module ground path. The seat belt switch can not be

repaired. If faulty, the entire driver's seat belt buck-

le-half must be replaced. Refer to Group 23 - Body

Components for service procedures.

JCHIME/BUZZER WARNING SYSTEMS 8U - 1

Page 532 of 2158

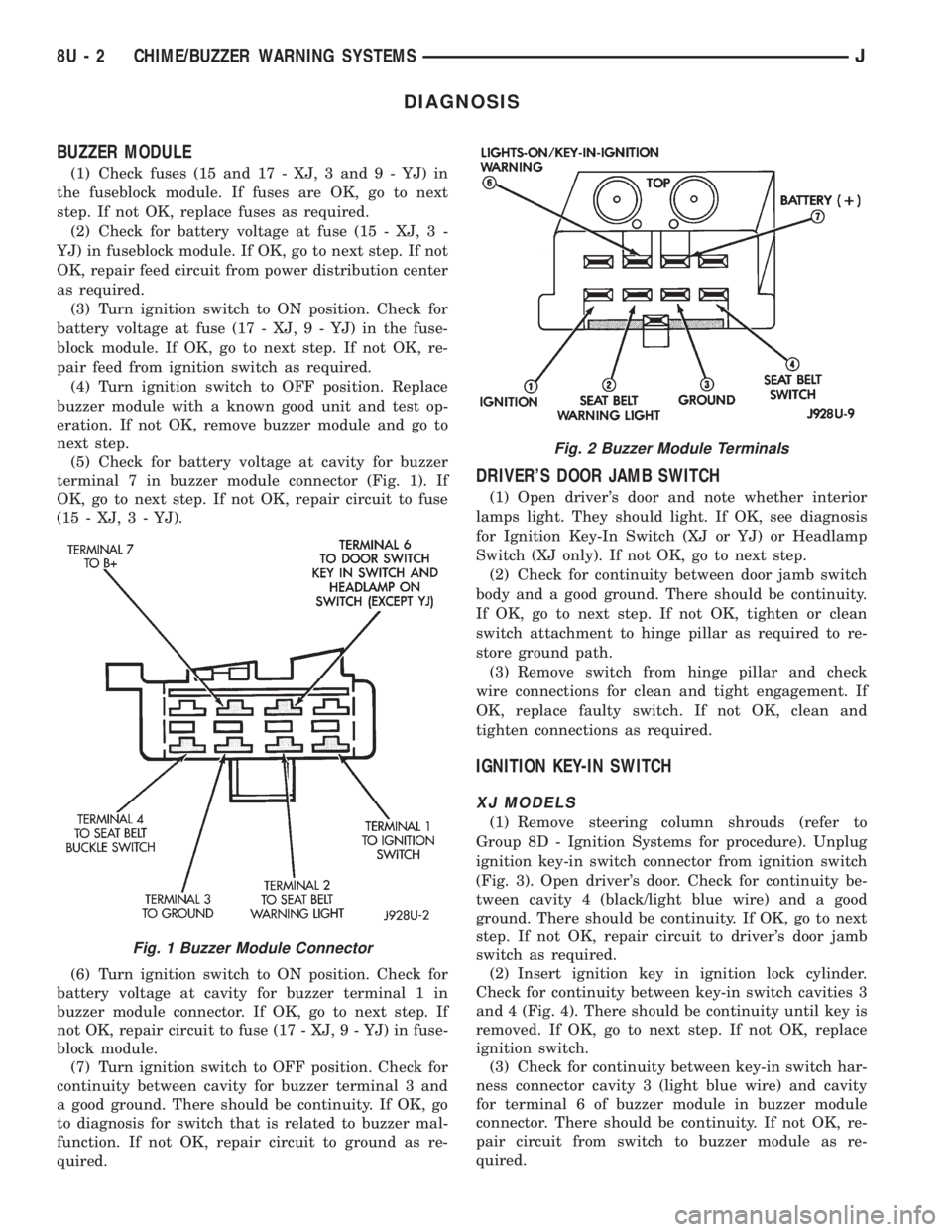

DIAGNOSIS

BUZZER MODULE

(1) Check fuses (15 and 17 - XJ, 3 and 9 - YJ) in

the fuseblock module. If fuses are OK, go to next

step. If not OK, replace fuses as required.

(2) Check for battery voltage at fuse (15 - XJ, 3 -

YJ) in fuseblock module. If OK, go to next step. If not

OK, repair feed circuit from power distribution center

as required.

(3) Turn ignition switch to ON position. Check for

battery voltage at fuse (17 - XJ, 9 - YJ) in the fuse-

block module. If OK, go to next step. If not OK, re-

pair feed from ignition switch as required.

(4) Turn ignition switch to OFF position. Replace

buzzer module with a known good unit and test op-

eration. If not OK, remove buzzer module and go to

next step.

(5) Check for battery voltage at cavity for buzzer

terminal 7 in buzzer module connector (Fig. 1). If

OK, go to next step. If not OK, repair circuit to fuse

(15 - XJ, 3 - YJ).

(6) Turn ignition switch to ON position. Check for

battery voltage at cavity for buzzer terminal 1 in

buzzer module connector. If OK, go to next step. If

not OK, repair circuit to fuse (17 - XJ, 9 - YJ) in fuse-

block module.

(7) Turn ignition switch to OFF position. Check for

continuity between cavity for buzzer terminal 3 and

a good ground. There should be continuity. If OK, go

to diagnosis for switch that is related to buzzer mal-

function. If not OK, repair circuit to ground as re-

quired.

DRIVER'S DOOR JAMB SWITCH

(1) Open driver's door and note whether interior

lamps light. They should light. If OK, see diagnosis

for Ignition Key-In Switch (XJ or YJ) or Headlamp

Switch (XJ only). If not OK, go to next step.

(2) Check for continuity between door jamb switch

body and a good ground. There should be continuity.

If OK, go to next step. If not OK, tighten or clean

switch attachment to hinge pillar as required to re-

store ground path.

(3) Remove switch from hinge pillar and check

wire connections for clean and tight engagement. If

OK, replace faulty switch. If not OK, clean and

tighten connections as required.

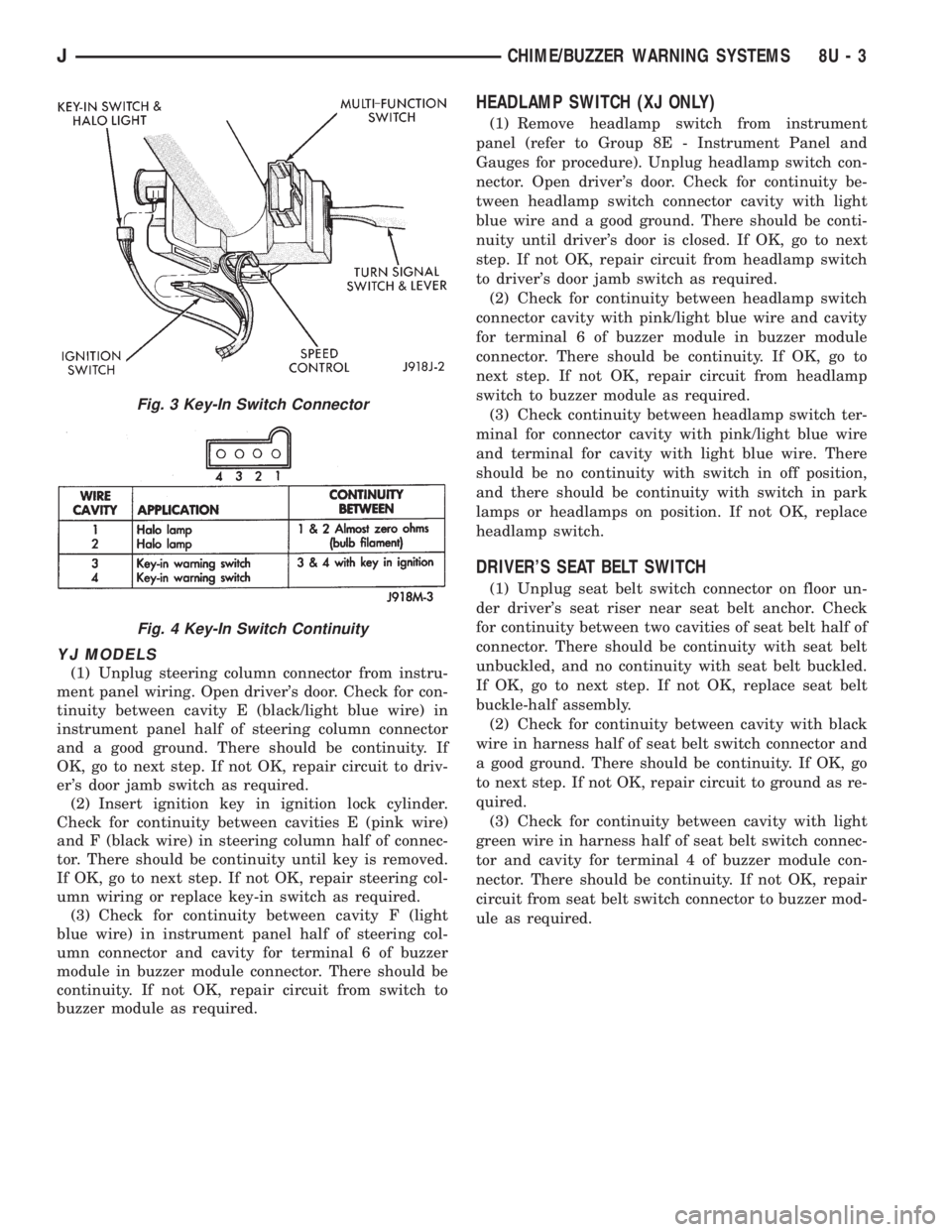

IGNITION KEY-IN SWITCH

XJ MODELS

(1) Remove steering column shrouds (refer to

Group 8D - Ignition Systems for procedure). Unplug

ignition key-in switch connector from ignition switch

(Fig. 3). Open driver's door. Check for continuity be-

tween cavity 4 (black/light blue wire) and a good

ground. There should be continuity. If OK, go to next

step. If not OK, repair circuit to driver's door jamb

switch as required.

(2) Insert ignition key in ignition lock cylinder.

Check for continuity between key-in switch cavities 3

and 4 (Fig. 4). There should be continuity until key is

removed. If OK, go to next step. If not OK, replace

ignition switch.

(3) Check for continuity between key-in switch har-

ness connector cavity 3 (light blue wire) and cavity

for terminal 6 of buzzer module in buzzer module

connector. There should be continuity. If not OK, re-

pair circuit from switch to buzzer module as re-

quired.

Fig. 1 Buzzer Module Connector

Fig. 2 Buzzer Module Terminals

8U - 2 CHIME/BUZZER WARNING SYSTEMSJ

Page 533 of 2158

YJ MODELS

(1) Unplug steering column connector from instru-

ment panel wiring. Open driver's door. Check for con-

tinuity between cavity E (black/light blue wire) in

instrument panel half of steering column connector

and a good ground. There should be continuity. If

OK, go to next step. If not OK, repair circuit to driv-

er's door jamb switch as required.

(2) Insert ignition key in ignition lock cylinder.

Check for continuity between cavities E (pink wire)

and F (black wire) in steering column half of connec-

tor. There should be continuity until key is removed.

If OK, go to next step. If not OK, repair steering col-

umn wiring or replace key-in switch as required.

(3) Check for continuity between cavity F (light

blue wire) in instrument panel half of steering col-

umn connector and cavity for terminal 6 of buzzer

module in buzzer module connector. There should be

continuity. If not OK, repair circuit from switch to

buzzer module as required.

HEADLAMP SWITCH (XJ ONLY)

(1) Remove headlamp switch from instrument

panel (refer to Group 8E - Instrument Panel and

Gauges for procedure). Unplug headlamp switch con-

nector. Open driver's door. Check for continuity be-

tween headlamp switch connector cavity with light

blue wire and a good ground. There should be conti-

nuity until driver's door is closed. If OK, go to next

step. If not OK, repair circuit from headlamp switch

to driver's door jamb switch as required.

(2) Check for continuity between headlamp switch

connector cavity with pink/light blue wire and cavity

for terminal 6 of buzzer module in buzzer module

connector. There should be continuity. If OK, go to

next step. If not OK, repair circuit from headlamp

switch to buzzer module as required.

(3) Check continuity between headlamp switch ter-

minal for connector cavity with pink/light blue wire

and terminal for cavity with light blue wire. There

should be no continuity with switch in off position,

and there should be continuity with switch in park

lamps or headlamps on position. If not OK, replace

headlamp switch.

DRIVER'S SEAT BELT SWITCH

(1) Unplug seat belt switch connector on floor un-

der driver's seat riser near seat belt anchor. Check

for continuity between two cavities of seat belt half of

connector. There should be continuity with seat belt

unbuckled, and no continuity with seat belt buckled.

If OK, go to next step. If not OK, replace seat belt

buckle-half assembly.

(2) Check for continuity between cavity with black

wire in harness half of seat belt switch connector and

a good ground. There should be continuity. If OK, go

to next step. If not OK, repair circuit to ground as re-

quired.

(3) Check for continuity between cavity with light

green wire in harness half of seat belt switch connec-

tor and cavity for terminal 4 of buzzer module con-

nector. There should be continuity. If not OK, repair

circuit from seat belt switch connector to buzzer mod-

ule as required.

Fig. 3 Key-In Switch Connector

Fig. 4 Key-In Switch Continuity

JCHIME/BUZZER WARNING SYSTEMS 8U - 3

Page 534 of 2158

SERVICE PROCEDURES

Service procedures for components of the buzzer

system can be found in the appropriate group as fol-

lows:

²driver's door jamb switch - refer to Group 8L -

Lamps

²ignition key-in switch (XJ) - refer to Group 8D -

Ignition Systems²ignition key-in switch (YJ) - refer to Group 19 -

Steering

²headlamp switch - refer to Group 8E - Instrument

Panel and Gauges

²driver's seat belt switch - refer to Group 23 - Body

Components.

BUZZER MODULE SCHEMATIC - XJBUZZER MODULE SCHEMATIC - YJ

8U - 4 CHIME/BUZZER WARNING SYSTEMSJ

Page 543 of 2158

WIRING DIAGRAMS

CONTENTS

page page

8W-01 GENERAL INFORMATIONÐWIRING

DIAGRAMS.................... 8W-01-1

8W-10 FUSE/FUSE BLOCK........... 8W-10-1

8W-11 POWER DISTRIBUTION........ 8W-11-1

8W-15 GROUND DISTRIBUTION....... 8W-15-1

8W-20 CHARGING SYSTEM.......... 8W-20-1

8W-21 STARTING SYSTEM........... 8W-21-1

8W-30 FUEL/IGNITION.............. 8W-30-1

8W-31 TRANSMISSION CONTROLS.... 8W-31-1

8W-32 ANTI-LOCK BRAKES.......... 8W-32-1

8W-33 VEHICLE SPEED CONTROL..... 8W-33-1

8W-40 INSTRUMENT CLUSTER....... 8W-40-1

8W-41 HORN/CIGAR LIGHTER......... 8W-41-1

8W-42 AIR CONDITIONING/HEATER.... 8W-42-1

8W-44 INTERIOR LIGHTING.......... 8W-44-1

8W-47 AUDIO SYSTEM.............. 8W-47-18W-48 HEATED REAR WINDOW....... 8W-48-1

8W-49 OVERHEAD CONSOLE......... 8W-49-1

8W-50 FRONT LIGHTING............. 8W-50-1

8W-51 REAR LIGHTING............. 8W-51-1

8W-52 TURN SIGNALS.............. 8W-52-1

8W-53 WIPERS..................... 8W-53-1

8W-54 TRAILER TOW................ 8W-54-1

8W-60 POWER WINDOWS.......... 8W-60-1

8W-61 POWER DOOR LOCKS......... 8W-61-1

8W-62 POWER MIRRORS............ 8W-62-1

8W-63 POWER SEAT................ 8W-63-1

8W-70 SPLICE INFORMATION........ 8W-70-1

8W-80 CONNECTOR PIN OUTS....... 8W-80-1

8W-90 CONNECTOR LOCATIONS...... 8W-90-1

8W-95 SPLICE LOCATIONS........... 8W-95-1

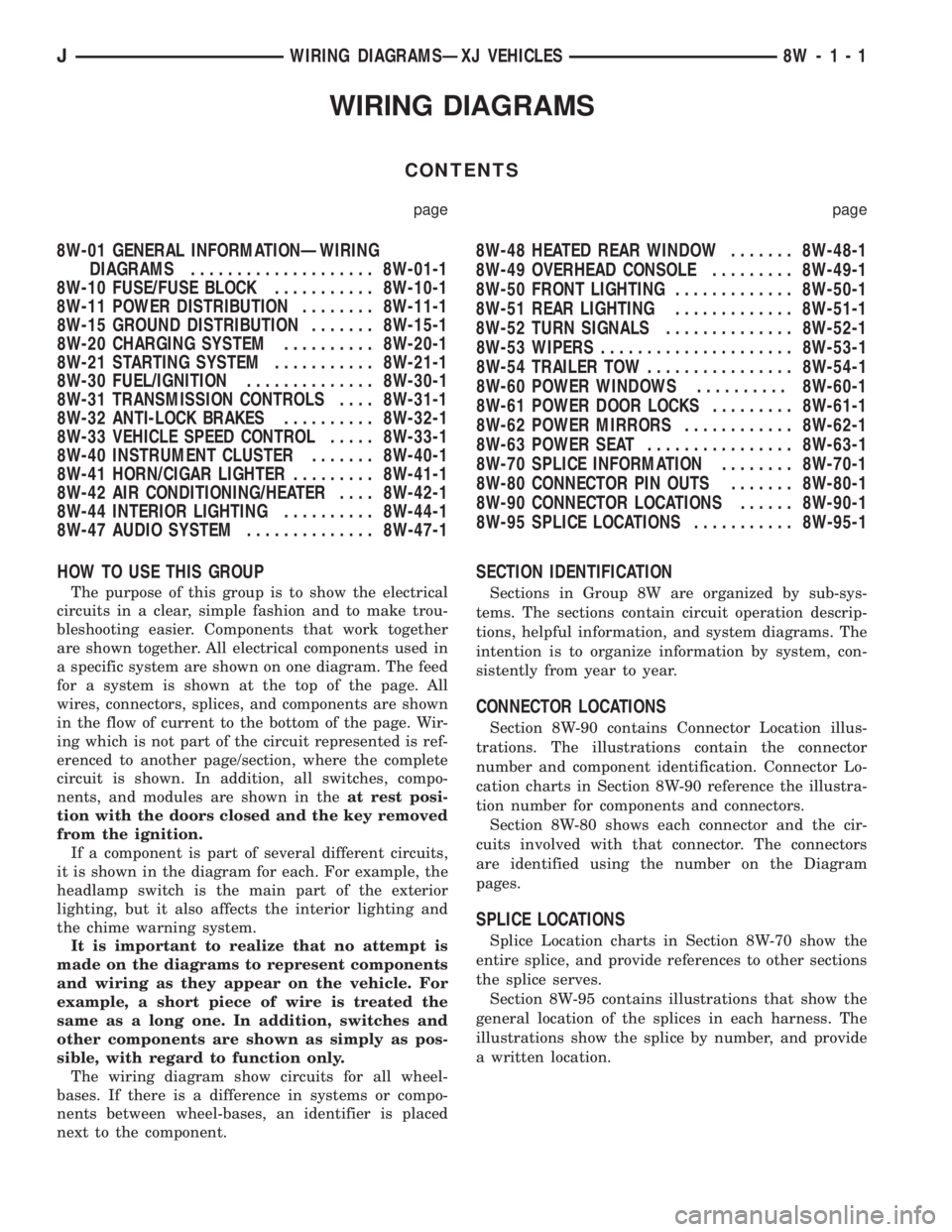

HOW TO USE THIS GROUP

The purpose of this group is to show the electrical

circuits in a clear, simple fashion and to make trou-

bleshooting easier. Components that work together

are shown together. All electrical components used in

a specific system are shown on one diagram. The feed

for a system is shown at the top of the page. All

wires, connectors, splices, and components are shown

in the flow of current to the bottom of the page. Wir-

ing which is not part of the circuit represented is ref-

erenced to another page/section, where the complete

circuit is shown. In addition, all switches, compo-

nents, and modules are shown in theat rest posi-

tion with the doors closed and the key removed

from the ignition.

If a component is part of several different circuits,

it is shown in the diagram for each. For example, the

headlamp switch is the main part of the exterior

lighting, but it also affects the interior lighting and

the chime warning system.

It is important to realize that no attempt is

made on the diagrams to represent components

and wiring as they appear on the vehicle. For

example, a short piece of wire is treated the

same as a long one. In addition, switches and

other components are shown as simply as pos-

sible, with regard to function only.

The wiring diagram show circuits for all wheel-

bases. If there is a difference in systems or compo-

nents between wheel-bases, an identifier is placed

next to the component.

SECTION IDENTIFICATION

Sections in Group 8W are organized by sub-sys-

tems. The sections contain circuit operation descrip-

tions, helpful information, and system diagrams. The

intention is to organize information by system, con-

sistently from year to year.

CONNECTOR LOCATIONS

Section 8W-90 contains Connector Location illus-

trations. The illustrations contain the connector

number and component identification. Connector Lo-

cation charts in Section 8W-90 reference the illustra-

tion number for components and connectors.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the number on the Diagram

pages.

SPLICE LOCATIONS

Splice Location charts in Section 8W-70 show the

entire splice, and provide references to other sections

the splice serves.

Section 8W-95 contains illustrations that show the

general location of the splices in each harness. The

illustrations show the splice by number, and provide

a written location.

JWIRING DIAGRAMSÐXJ VEHICLES 8W - 1 - 1