warning JEEP XJ 1995 Service And Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 381 of 2158

The gauge needle moves as the movable permanent

magnet aligns itself to the changing magnetic fields

created around it by the electromagnets.

COOLANT TEMPERATURE GAUGE

The coolant temperature gauge gives an indication

of engine coolant temperature. The coolant tempera-

ture sending unit is a thermistor that changes elec-

trical resistance with changes in engine coolant

temperature. High sending unit resistance causes

low coolant temperature readings. Low resistance

causes high coolant temperature readings. Sending

unit resistance values are shown in a chart in Spec-

ifications.

FUEL GAUGE

The fuel gauge gives an indication of the level of

fuel in the fuel tank. The fuel gauge sending unit has

a float attached to a swing-arm in the fuel tank. The

float moves up or down within the fuel tank as fuel

level changes. As the float moves, an electrical con-

tact on the swing-arm wipes across a resistor coil,

which changes sending unit resistance. High sending

unit resistance causes high fuel level readings. Low

resistance causes low fuel level readings. Sending

unit resistance values are shown in a chart in Spec-

ifications.

OIL PRESSURE GAUGE

The oil pressure gauge gives an indication of en-

gine oil pressure. The combination oil pressure send-

ing unit contains a flexible diaphragm. The

diaphragm moves in response to changes in engine

oil pressure. As the diaphragm moves, sending unit

resistance increases or decreases. High resistance on

the gauge side of the sending unit causes high oil

pressure readings. Low resistance causes low oil

pressure readings. Sending unit resistance values are

shown in a chart in Specifications.

SPEEDOMETER/ODOMETER

The speedometer/odometer give an indication of ve-

hicle speed and travel distance. The speedometer re-

ceives a vehicle speed pulse signal from the Vehicle

Speed Sensor (VSS). An electronic integrated circuit

contained within the speedometer reads and analyzes

the pulse signal. It then adjusts the ground path re-

sistance of one electromagnet in the gauge to control

needle movement. It also sends signals to an electric

stepper motor to control movement of the odometer

number rolls. Frequency values for the pulse signal

are shown in a chart in Specifications.

The VSS is mounted to an adapter near the trans-

fer case output shaft. The sensor is driven through

the adapter by a speedometer pinion gear. The

adapter and pinion vary with transmission, axle ratio

and tire size. Refer to Group 21 - Transmission and

Transfer Case for more information.

TACHOMETER

The tachometer gives an indication of engine speed

in Revolutions-Per-Minute (RPM). With the engine

running, the tachometer receives an engine speed

pulse signal from the Powertrain Control Module

(PCM). An electronic integrated circuit contained

within the tachometer reads and analyzes the pulse

signal. It then adjusts the ground path resistance of

one electromagnet in the gauge to control needle

movement. Frequency values for the pulse signal are

shown in a chart in Specifications.

TRIP ODOMETER

The trip odometer is driven by the same electronic

integrated circuit as the speedometer/odometer. How-

ever, by depressing the trip odometer reset knob on

the face of the speedometer, the trip odometer can be

reset to zero. The trip odometer is serviced only as a

part of the speedometer/odometer gauge assembly.

VOLTMETER

The voltmeter is connected in parallel with the bat-

tery. With the ignition switch ON, the voltmeter in-

dicates battery or generator output voltage,

whichever is greater.

INDICATOR LAMPS

All indicator lamps, except the four-wheel drive in-

dicator, are located in the main cluster tell-tale area

above the steering column opening. Each of the

lamps is served by the main cluster printed circuit

and cluster connector. The four-wheel drive indicator

lamp is located in the gauge package cluster and is

served by the gauge package printed circuit and clus-

ter connector.

Up to eleven indicator lamps can be found in the

tell-tale area of the main cluster. These lamps are ar-

ranged in two rows, with six lamps in the upper row

and five lamps in the lower row.

ANTI-LOCK BRAKE SYSTEM LAMP

The Anti-Lock Brake System (ABS) lamp is

switched to ground by the ABS module. The module

lights the lamp when the ignition switch is turned to

the START position as a bulb test. The lamp will

stay on for 3 to 5 seconds after vehicle start-up to in-

dicate a system self-test is in process. If the lamp re-

mains on after start-up, or comes on and stays on

while driving, it may indicate that the ABS module

has detected a system malfunction or that the system

has become inoperative. Refer to Group 5 - Brakes

for more information.

BRAKE WARNING LAMP

The brake warning lamp warns the driver that the

parking brake is applied or that the pressures in the

two halves of the split brake hydraulic system are

unequal. With the ignition switch turned ON, battery

JINSTRUMENT PANEL AND GAUGESÐYJ 8E - 25

Page 382 of 2158

voltage is supplied to one side of the indicator bulb. A

ground path for the bulb is provided by 3 switches.

The bulb will light when:

²the brake warning switch is closed (indicating un-

equal brake system hydraulic pressures possibly due

to brake fluid leakage)

²the ignition switch is in the START position (bulb

test)

²the parking brake switch is closed (parking brake

is applied).

Refer to Group 5 - Brakes for more information.

FOUR-WHEEL DRIVE INDICATOR LAMP

This lamp lights when the transfer case is engaged

in the 4H or 4L position. Voltage is supplied to one

side of the indicator bulb. A switch on the front axle

disconnect housing is connected to the other side of

the indicator bulb. When the switch is closed, a path

to ground is provided and the indicator bulb lights.

HEADLAMP HIGH BEAM INDICATOR LAMP

The high beam indicator lamp is controlled by the

headlamp dimmer switch. One side of the indicator

bulb is grounded at all times. The other side of the

bulb receives battery feed through the contacts of the

dimmer switch when the turn signal switch lever is

actuated to turn the headlamp high beams on. Refer

to Group 8L - Lamps for more information.

MALFUNCTION INDICATOR LAMP

The CHECK ENGINE or Malfunction Indicator

Lamp (MIL) lights each time the ignition switch is

turned ON, and stays on for 3 seconds as a bulb test.

If the Powertrain Control Module (PCM) receives an

incorrect signal or no signal from certain fuel or

emission system related circuits or components, the

lamp is turned on. This will indicate that the PCM

has recorded a Diagnostic Trouble Code (DTC) in

electronic memory for a circuit or component mal-

function. Refer to Group 14 - Fuel System for more

information.

SEAT BELT REMINDER LAMP

The seat belt reminder lamp lights for 4 to 8 sec-

onds after the ignition switch is turned to the ON po-sition. A timer in the chime/buzzer module controls

ignition-switched battery feed to the lamp. Refer to

Group 8U - Chime/Buzzer Warning Systems for more

information.

TURN SIGNAL INDICATOR LAMPS

The left and right turn signal indicator lamps are

controlled by the turn signal and hazard warning

switches. One side of the bulb for each lamp is

grounded at all times. The other side of the bulb re-

ceives battery feed through the contacts of the turn

signal switch, when the turn signal lever or hazard

warning button are actuated. Refer to Group 8J -

Turn Signal and Hazard Warning Systems for more

information.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have

an optional upshift indicator lamp. Ground feed for

the lamp is switched by the Powertrain Control Mod-

ule (PCM). The lamp lights to indicate when the

driver should shift to the next highest gear for best

fuel economy. The PCM will turn the lamp off after 3

to 5 seconds if the upshift is not performed. The lamp

will remain off until the vehicle stops accelerating

and is brought back to the range of lamp operation,

or until the transmission is shifted into another gear.

The indicator lamp is normally on when the igni-

tion switch is turned ON and is turned off when the

engine is started. The lamp will be turned on during

vehicle operation according to engine speed and load.

CLUSTER ILLUMINATION LAMPS

All cluster illumination lamps receive battery feed

from the instrument lamps fuse in the fuseblock

module through the panel dimmer switch. When the

park or headlamps are on, the cluster illumination

lamps light. Illumination brightness can be adjusted

by rotating the panel dimmer thumb-wheel, which is

next to the headlamp switch.

8E - 26 INSTRUMENT PANEL AND GAUGESÐYJJ

Page 388 of 2158

INDICATOR LAMPS

If an individual indicator lamp is inoperative, see

the diagnostic procedure under the heading for that

lamp. If more than one indicator lamp or a combina-

tion of lamps and gauges in the main cluster or the

gauge package cluster is inoperative, see Gauges in

this section for diagnosis.

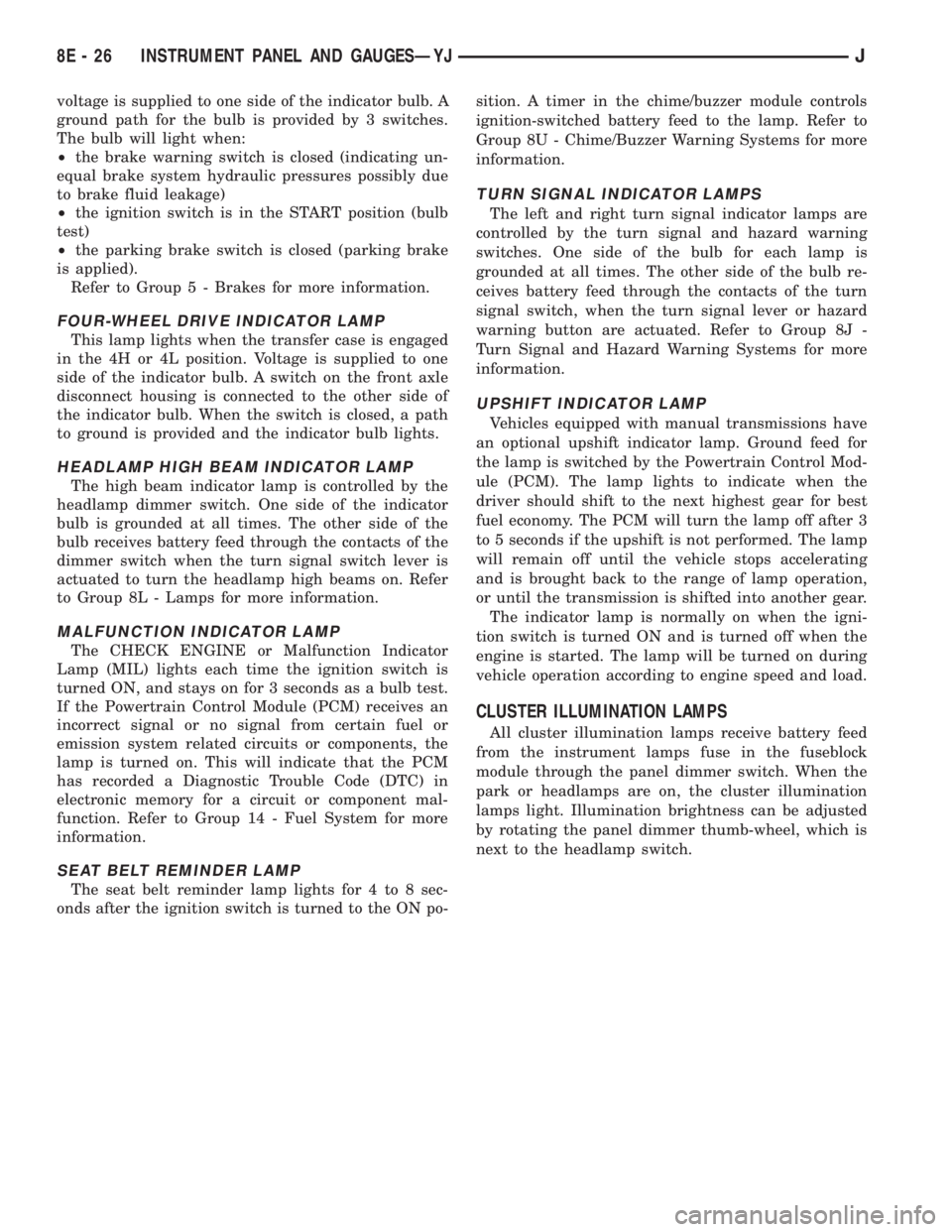

ANTI-LOCK BRAKE SYSTEM LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the ABS lamp stays on with the ig-

nition switch in the ON position, or comes on and

stays on while driving, refer to Group 5 - Brakes for

diagnosis. If no ABS problem is found, the following

procedure will help locate a short or open in the ABS

lamp circuit.

(1) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Disconnect ABS control module connector.

(2) Install a jumper wire between cavity 6 of clus-

ter connector and a good ground. Connect battery

negative cable. Turn ignition switch to ON. Lamp

should light. If OK, remove jumper wire and go to

next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable and unplug cluster connector. Check

for continuity between cavity 6 of cluster connector

and a good ground. There should be no continuity. If

OK, go to next step. If not OK, repair short circuit as

required.

(4) Check continuity between cavity 6 of cluster

connector and cavity 52 of ABS control module con-

nector (Fig. 6). There should be continuity. If OK, re-

fer to Group 5 - Brakes for diagnosis of ABS control

module. If not OK, repair open circuit as required.

BRAKE WARNING LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the brake warning lamp stays on

with the ignition switch in the ON position and the

parking brake released, refer to Group 5 - Brakes for

diagnosis. If no service brake or parking brake prob-

lem is found, the following procedure will help locate

a short circuit or faulty switch.

(1) Unplug parking brake switch connector. Turn

ignition switch to START position. Lamp should

light. Release ignition switch to ON position. Lamp

should go off. If OK, go to step 10. If not OK, go to

next step.

(2) Unplug brake warning switch connector. Install

a jumper wire between two cavities of connector.

Turn ignition switch to START. Lamp should light.

Remove jumper wire and lamp should go off. If OK,

replace brake warning switch. If not OK, remove

jumper wire and go to next step.

(3) Turn ignition switch to ON position. Install a

jumper wire between brake warning switch connectorcavity for circuit G9 and a good ground. Lamp should

light. If OK, go to step 5. If not OK, go to next step.

(4) Turn ignition switch to OFF. Remove jumper

wire and disconnect battery negative cable. Remove

left instrument cluster bezel and main cluster. Install

a jumper wire between cavity 1 of cluster connector

and a good ground. Connect battery negative cable

and turn ignition switch to ON. Lamp should light. If

OK, repair open in circuit to brake warning switch. If

not OK, replace bulb.

(5) Turn ignition switch to OFF and remove

jumper wire. Disconnect battery negative cable.

Check for continuity between brake warning switch

connector cavity for circuit G11 and a good ground

with ignition switch in START position. There should

be continuity. If not OK, go to next step.

(6) Turn ignition switch to OFF and remove

jumper wire. Unplug ignition switch connectors.

Check for continuity between ignition switch connec-

tor cavity for G11 circuit and a good ground. There

should be no continuity. If OK, go to next step. If not

OK, repair short circuit between ignition switch and

brake warning switch connectors as required.

(7) Check for continuity between ignition switch

connector cavity for G11 circuit and brake warning

switch connector cavity for G11 circuit. There should

be continuity. If OK, go to next step. If not OK, re-

pair open circuit as required.

(8) Check for continuity between metal steering

column jacket and a good ground. There should be

continuity. If OK, go to next step. If not OK, refer to

Group 19 - Steering to check steering column ground

clip installation.

Fig. 6 ABS Control Module Connector

8E - 32 INSTRUMENT PANEL AND GAUGESÐYJJ

Page 389 of 2158

(9) Turn ignition switch to START position and

hold there. Check for continuity between terminal for

circuit G11 of ignition switch and a good ground.

There should be continuity. If not OK, replace igni-

tion switch.

(10) Unplug brake warning switch connector.

Check for continuity between parking brake switch

connector and a good ground. There should be no

continuity. If OK, go to next step. If not OK, repair

short circuit as required.

(11) Check for continuity between parking brake

switch connector and brake warning switch connector

cavity for circuit G11. There should be continuity. If

OK, replace parking brake switch. If not OK, repair

open circuit to brake warning switch as required.

FOUR-WHEEL DRIVE INDICATOR LAMP

(1) Apply parking brake, start engine, vehicle in

4WD Lock or 4WD.

(2) Unplug switch and touch harness side of wire

to ground. Lamp should light. If OK, check switch

operation, replace if bad. If bulb is OK, repair open

to indicator.

HEADLAMP HIGH BEAM INDICATOR LAMP

(1) Check that headlamp high beams are func-

tional. If OK, go to next step. If not OK, refer to

Group 8L - Lamps for diagnosis of headlamp system.

(2) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Unplug cluster connector. Connect battery negative

cable. Turn headlamps on and select high beam.

Check for battery voltage at cavity 17 of cluster con-

nector. If OK, replace indicator bulb. If not OK, re-

pair circuit to headlamp dimmer switch as required.

MALFUNCTION INDICATOR LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the lamp comes on and stays on

with engine running, refer to Group 14 - Fuel System

for diagnosis. If no fuel or emission system problem

is found, the following procedure will help locate a

short or open in the lamp circuit.

(1) Disconnect battery negative cable. Unplug PCM

connector. Install a jumper wire from cavity 32 of

PCM connector (Fig. 5) to a good ground. Connect

battery negative cable. Turn ignition switch to ON.

Lamp should light. Remove jumper wire and lamp

should go OFF. If OK, refer to Powertrain Diagnostic

Procedures to check PCM. If not OK, go to next step.

(2) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove left instrument cluster bezel

and main cluster assembly. Install a jumper wire

from cavity 2 of cluster connector to a good ground.

Connect battery negative cable. Turn ignition switch

to ON. Lamp should light. If OK, go to next step. If

not OK, replace bulb.(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug cluster connector. Check for

continuity between cavity 2 of cluster connector and

a good ground. There should be no continuity. If OK,

go to next step. If not OK, repair short circuit to

PCM as required.

(4) Check continuity between cavity 2 of cluster

connector and cavity 32 of PCM connector. There

should be continuity. If not OK, repair open circuit to

PCM as required.

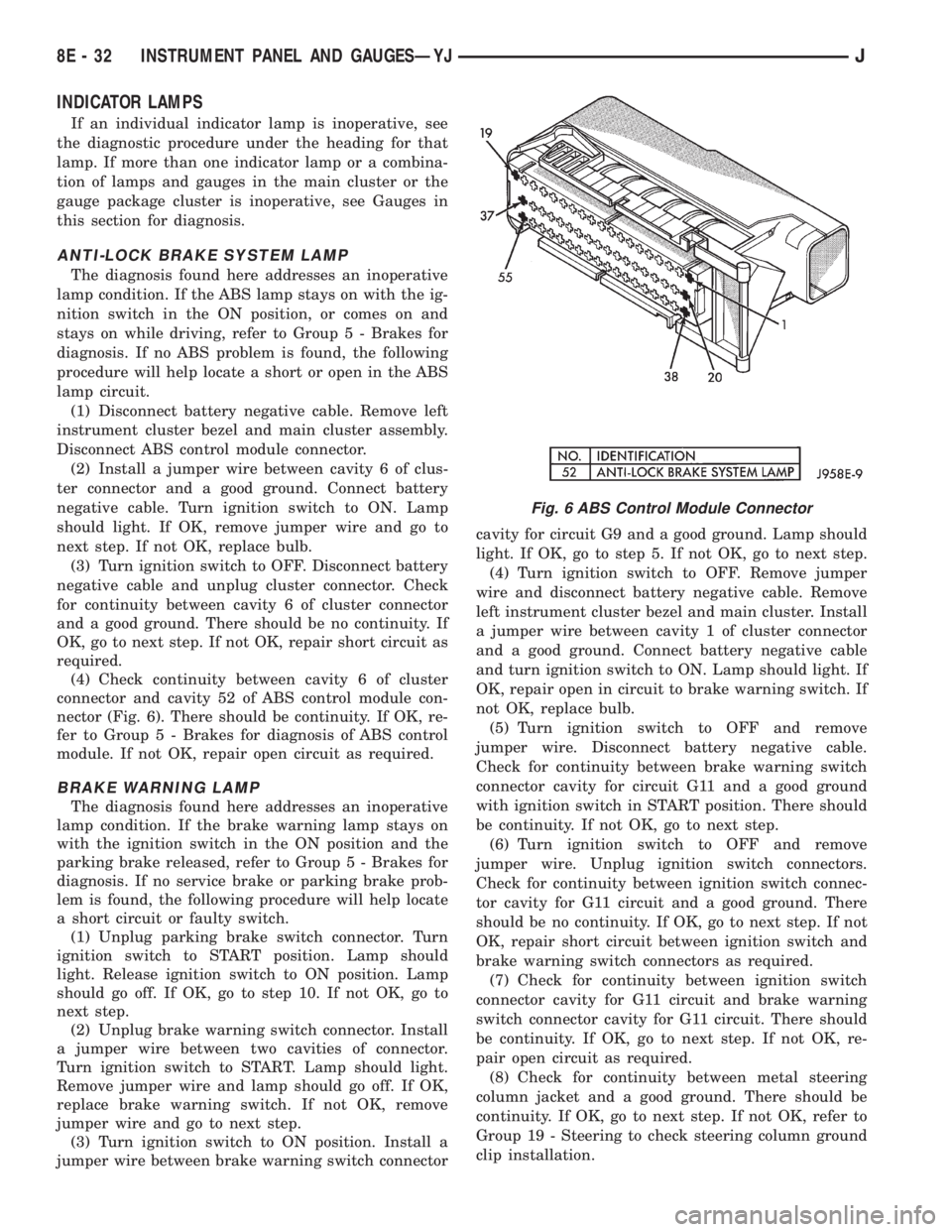

SEAT BELT REMINDER LAMP

(1) Refer to Group 8U - Chime/Buzzer Warning

Systems to check chime/buzzer module operation. If

OK, go to next step. If not OK, replace chime/buzzer

module.

(2) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Unplug cluster connector. Check for continuity be-

tween cavity 20 of cluster connector and a good

ground. There should be continuity. If OK, plug clus-

ter connector back into cluster and go to next step. If

not OK, repair open circuit to ground as required.

(3) Connect battery negative cable. Install a

jumper wire between a 12-volt battery feed and cav-

ity 16 of cluster connector. Lamp should light. If OK,

go to next step. If not OK, replace bulb.

(4) Disconnect battery negative cable. Unplug

chime/buzzer module from fuseblock module. Unplug

cluster connector. Check for continuity between cav-

ity 16 of cluster connector and a good ground. There

should be no continuity. If OK, go to next step. If not

OK, repair short circuit to chime/buzzer module as

required.

(5) Check continuity between cavity 16 of cluster

connector and cavity for terminal A3 of chime/buzzer

module (Fig. 7) in fuseblock module. There should be

continuity. If not OK, repair open circuit to chime/

buzzer module as required.

Fig. 7 Chime/Buzzer Module Receptacle

JINSTRUMENT PANEL AND GAUGESÐYJ 8E - 33

Page 390 of 2158

TURN SIGNAL INDICATOR LAMPS

(1) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Probe cavity 20 of cluster connector. Check for conti-

nuity to a good ground. There should be continuity. If

OK, go to next step. If not OK, repair open circuit to

ground.

(2) Connect battery negative cable. Install a

jumper wire from cavity 18 (left indicator) or cavity 7

(right indicator) of cluster connector to a 12-volt bat-

tery feed. Lamp should light. If OK, continue to next

step. If not OK, replace bulb.

(3) Disconnect battery negative cable. Check for

continuity between cavity 18 (left indicator) or cavity

7 (right indicator) of cluster connector and cavity H

(left front turn signal) or cavity J (right front turn

signal) of steering column wiring connector. There

should be continuity. If OK, refer to Group 8J - Turn

Signal and Hazard Warning Systems for further di-

agnosis. If not OK, repair open circuit as required.

UPSHIFT INDICATOR LAMP

(1) Disconnect battery negative cable. Unplug PCM

connector. Connect battery negative cable. Turn igni-

tion switch to ON. Install a jumper wire from cavity

54 of PCM connector (Fig. 5) to a good ground. Lamp

should light. Remove jumper from ground. Lamp

should go off. If OK, refer to Powertrain Diagnostic

Procedures manual to diagnose PCM. If not OK, turn

ignition switch to OFF and go to next step.

(2) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Install a jumper wire from cavity 5 of cluster connec-

tor to a good ground. Connect battery negative cable.

Turn ignition switch to ON. Lamp should light. If

OK, go to next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug cluster connector. Check for

continuity between cavity 5 of cluster connector and

a good ground. There should be no continuity. If OK,

go to next step. If not OK, repair short circuit as re-

quired.(4) Check for continuity between cavity 5 of cluster

connector and cavity 54 of PCM connector. There

should be continuity. If not OK, repair open circuit as

required.

CLUSTER ILLUMINATION LAMPS

(1) Check fuse 10 in fuseblock module. If OK, go to

next step. If not OK, replace fuse.

(2) Turn park lamps on at headlamp switch. Rotate

panel dimmer switch thumb-wheel to HI position,

just before interior lamps detent. Check for battery

voltage at fuse 10 in fuseblock module. Rotate panel

dimmer thumb-wheel towards LO position while ob-

serving test voltmeter. Reading should go from bat-

tery voltage to zero volts. If OK, go to next step. If

not OK, repair open circuit to headlamp switch or re-

fer to Group 8L - Lamps to diagnose headlamp

switch.

(3) Disconnect battery negative cable. Remove left

or center instrument cluster bezel and main or gauge

package cluster assembly. Unplug cluster connector.

Connect battery negative cable. Turn park lamps on

at headlamp switch. Rotate panel dimmer thumb-

wheel to HI position, just before interior lamps de-

tent. Check for battery voltage at cavity 21 of main

cluster connector, or cavity 7 of gauge package clus-

ter connector. If OK, go to next step. If not OK, re-

pair open circuit to fuse as required.

(4) Turn park lamps off. Disconnect battery nega-

tive cable. Remove fuse 10 from fuseblock module.

Probe cavity 21 of main cluster connector, or cavity 7

of gauge package cluster connector. Check for conti-

nuity to a good ground. There should be no continu-

ity. If OK, go to next step. If not OK, repair short

circuit as required.

(5) Probe cavity 20 of main cluster connector, or

cavities 1 and 13 of gauge package cluster connector.

Check for continuity to ground. There should be con-

tinuity. If not OK, repair open circuit as required.

8E - 34 INSTRUMENT PANEL AND GAUGESÐYJJ

Page 412 of 2158

DIAGNOSIS

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO GROUP 8M - RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POS-

SIBLE PERSONAL INJURY.

(1) Inspect fuses (F8 and F16 in PDC on YJ)(11 in

fuseblock module and F14 in PDC on XJ). Replace

fuses, as required.

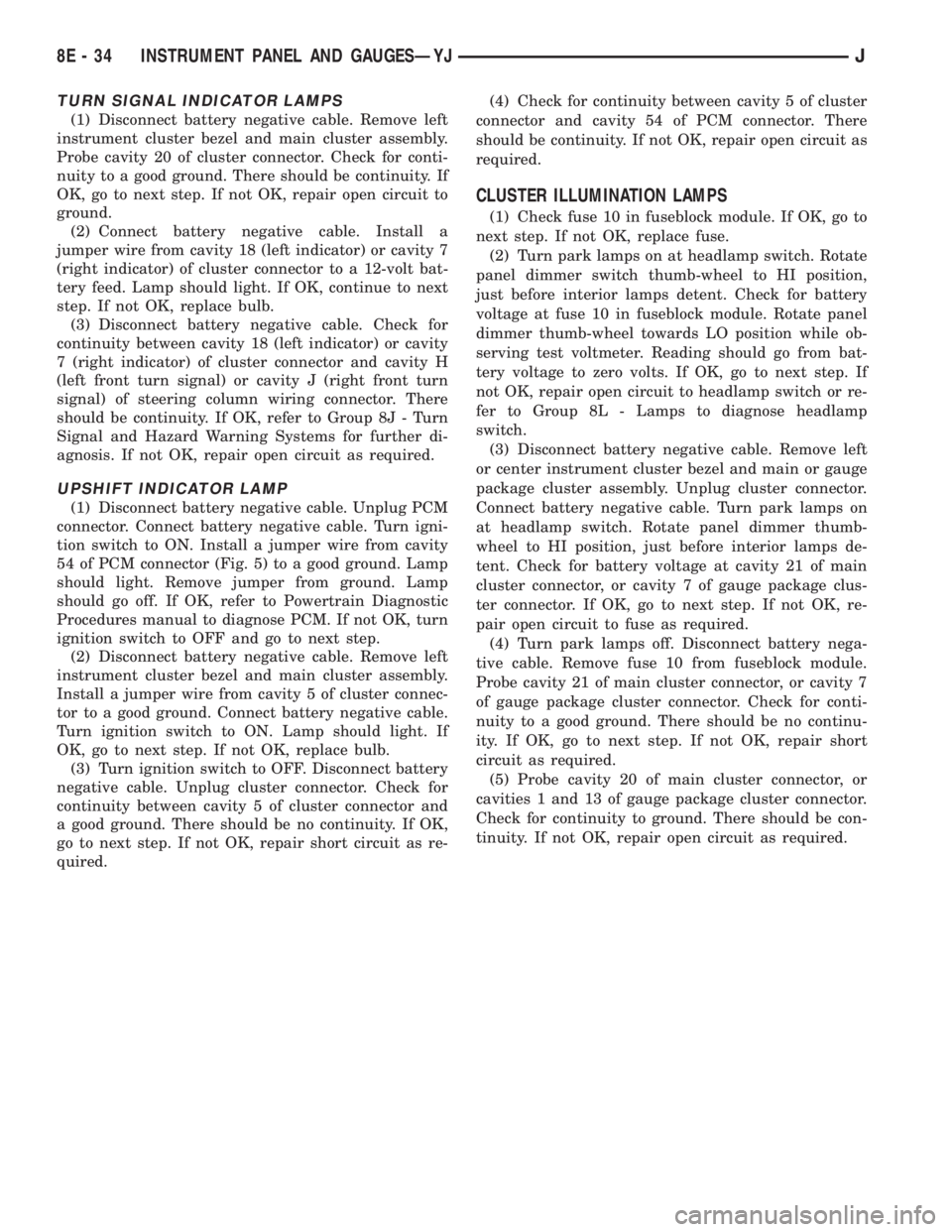

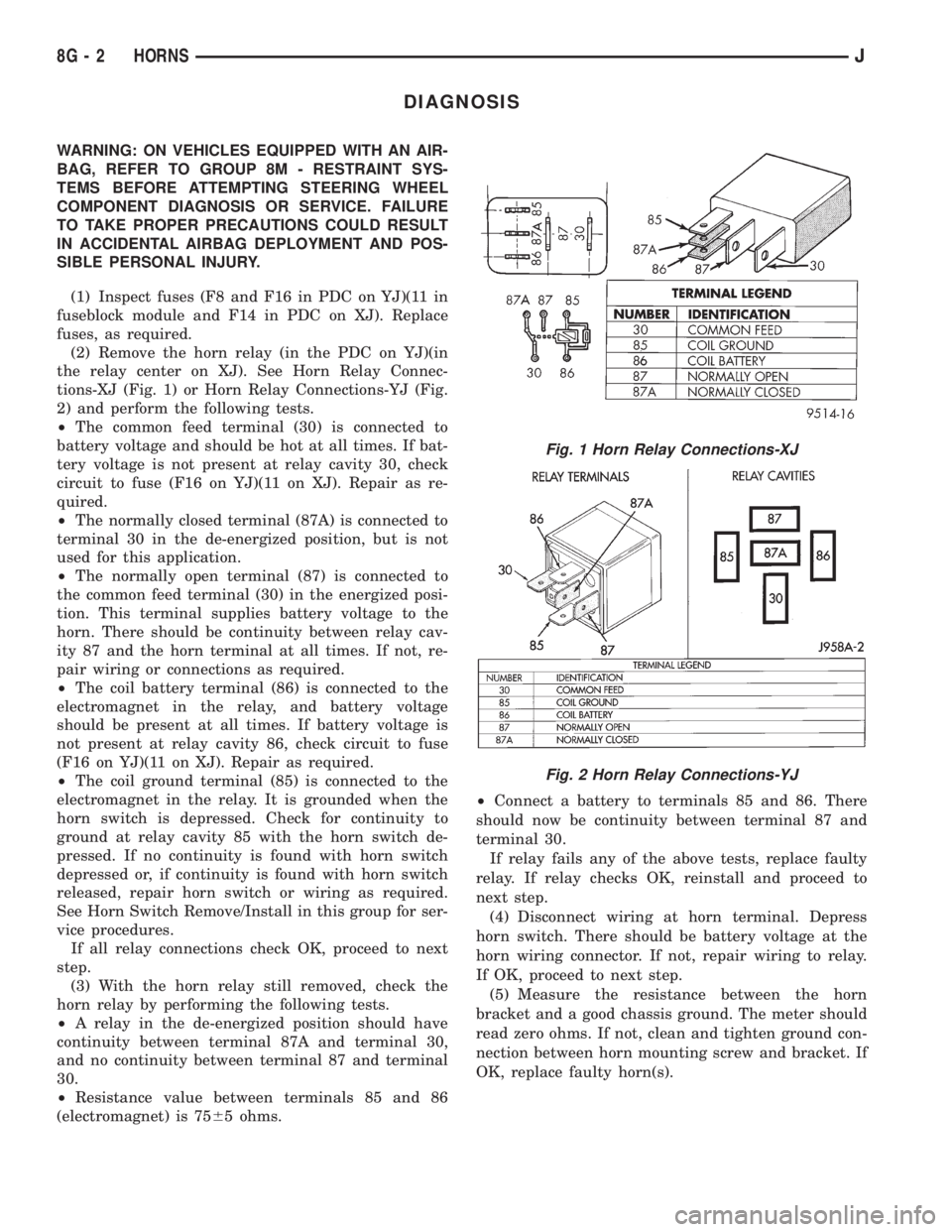

(2) Remove the horn relay (in the PDC on YJ)(in

the relay center on XJ). See Horn Relay Connec-

tions-XJ (Fig. 1) or Horn Relay Connections-YJ (Fig.

2) and perform the following tests.

²The common feed terminal (30) is connected to

battery voltage and should be hot at all times. If bat-

tery voltage is not present at relay cavity 30, check

circuit to fuse (F16 on YJ)(11 on XJ). Repair as re-

quired.

²The normally closed terminal (87A) is connected to

terminal 30 in the de-energized position, but is not

used for this application.

²The normally open terminal (87) is connected to

the common feed terminal (30) in the energized posi-

tion. This terminal supplies battery voltage to the

horn. There should be continuity between relay cav-

ity 87 and the horn terminal at all times. If not, re-

pair wiring or connections as required.

²The coil battery terminal (86) is connected to the

electromagnet in the relay, and battery voltage

should be present at all times. If battery voltage is

not present at relay cavity 86, check circuit to fuse

(F16 on YJ)(11 on XJ). Repair as required.

²The coil ground terminal (85) is connected to the

electromagnet in the relay. It is grounded when the

horn switch is depressed. Check for continuity to

ground at relay cavity 85 with the horn switch de-

pressed. If no continuity is found with horn switch

depressed or, if continuity is found with horn switch

released, repair horn switch or wiring as required.

See Horn Switch Remove/Install in this group for ser-

vice procedures.

If all relay connections check OK, proceed to next

step.

(3) With the horn relay still removed, check the

horn relay by performing the following tests.

²A relay in the de-energized position should have

continuity between terminal 87A and terminal 30,

and no continuity between terminal 87 and terminal

30.

²Resistance value between terminals 85 and 86

(electromagnet) is 7565 ohms.²Connect a battery to terminals 85 and 86. There

should now be continuity between terminal 87 and

terminal 30.

If relay fails any of the above tests, replace faulty

relay. If relay checks OK, reinstall and proceed to

next step.

(4) Disconnect wiring at horn terminal. Depress

horn switch. There should be battery voltage at the

horn wiring connector. If not, repair wiring to relay.

If OK, proceed to next step.

(5) Measure the resistance between the horn

bracket and a good chassis ground. The meter should

read zero ohms. If not, clean and tighten ground con-

nection between horn mounting screw and bracket. If

OK, replace faulty horn(s).

Fig. 1 Horn Relay Connections-XJ

Fig. 2 Horn Relay Connections-YJ

8G - 2 HORNSJ

Page 413 of 2158

SERVICE PROCEDURES

HORN REMOVE/INSTALL

XJ

(1) Raise and support the vehicle.

(2) Remove the front underbody splash shield.

(3) Remove horn mounting bolt and horn (Fig. 3).

(4) Remove wire from horn.

(5) Reverse removal procedures to install.

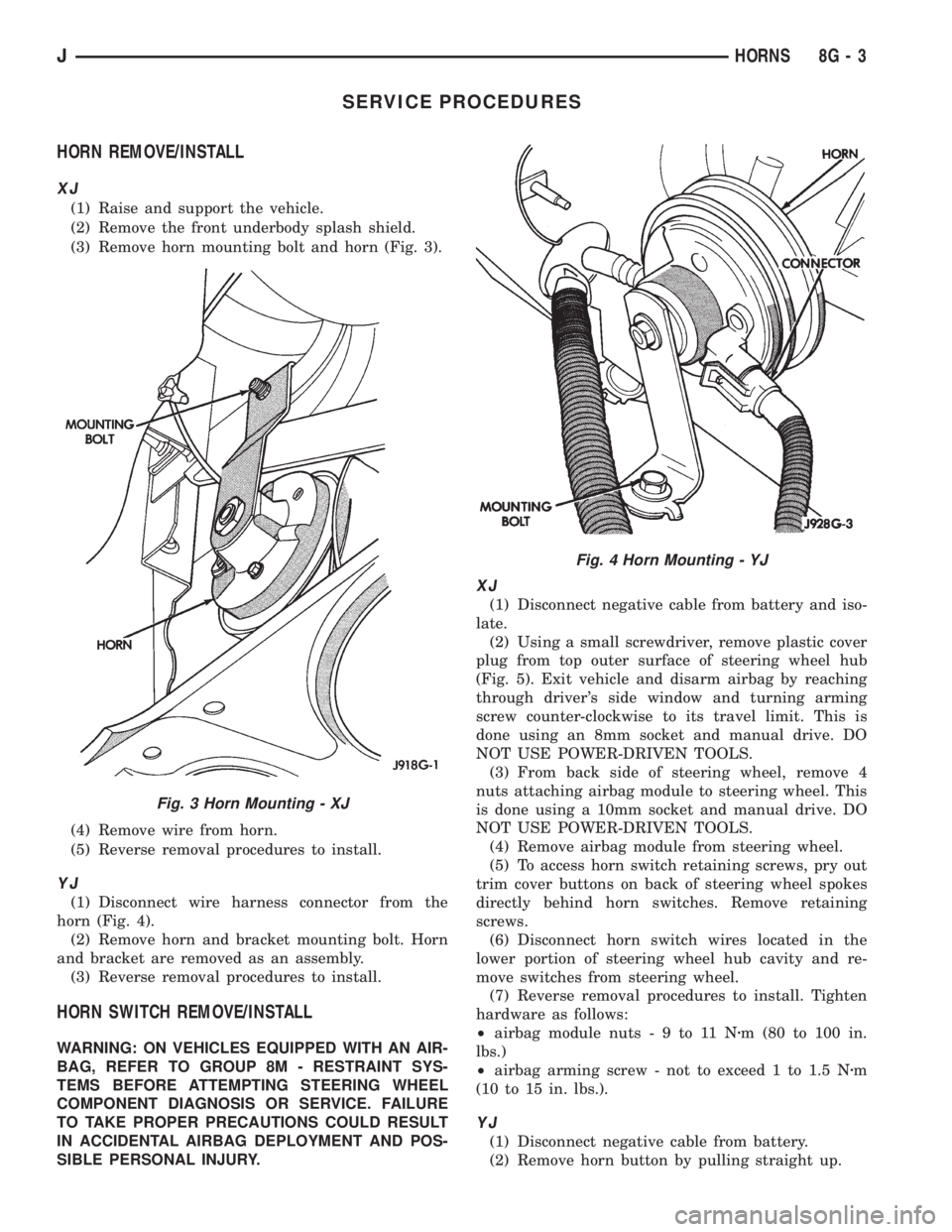

YJ

(1) Disconnect wire harness connector from the

horn (Fig. 4).

(2) Remove horn and bracket mounting bolt. Horn

and bracket are removed as an assembly.

(3) Reverse removal procedures to install.

HORN SWITCH REMOVE/INSTALL

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO GROUP 8M - RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POS-

SIBLE PERSONAL INJURY.

XJ

(1) Disconnect negative cable from battery and iso-

late.

(2) Using a small screwdriver, remove plastic cover

plug from top outer surface of steering wheel hub

(Fig. 5). Exit vehicle and disarm airbag by reaching

through driver's side window and turning arming

screw counter-clockwise to its travel limit. This is

done using an 8mm socket and manual drive. DO

NOT USE POWER-DRIVEN TOOLS.

(3) From back side of steering wheel, remove 4

nuts attaching airbag module to steering wheel. This

is done using a 10mm socket and manual drive. DO

NOT USE POWER-DRIVEN TOOLS.

(4) Remove airbag module from steering wheel.

(5) To access horn switch retaining screws, pry out

trim cover buttons on back of steering wheel spokes

directly behind horn switches. Remove retaining

screws.

(6) Disconnect horn switch wires located in the

lower portion of steering wheel hub cavity and re-

move switches from steering wheel.

(7) Reverse removal procedures to install. Tighten

hardware as follows:

²airbag module nuts-9to11Nzm (80 to 100 in.

lbs.)

²airbag arming screw - not to exceed 1 to 1.5 Nzm

(10 to 15 in. lbs.).

YJ

(1) Disconnect negative cable from battery.

(2) Remove horn button by pulling straight up.

Fig. 3 Horn Mounting - XJ

Fig. 4 Horn Mounting - YJ

JHORNS 8G - 3

Page 418 of 2158

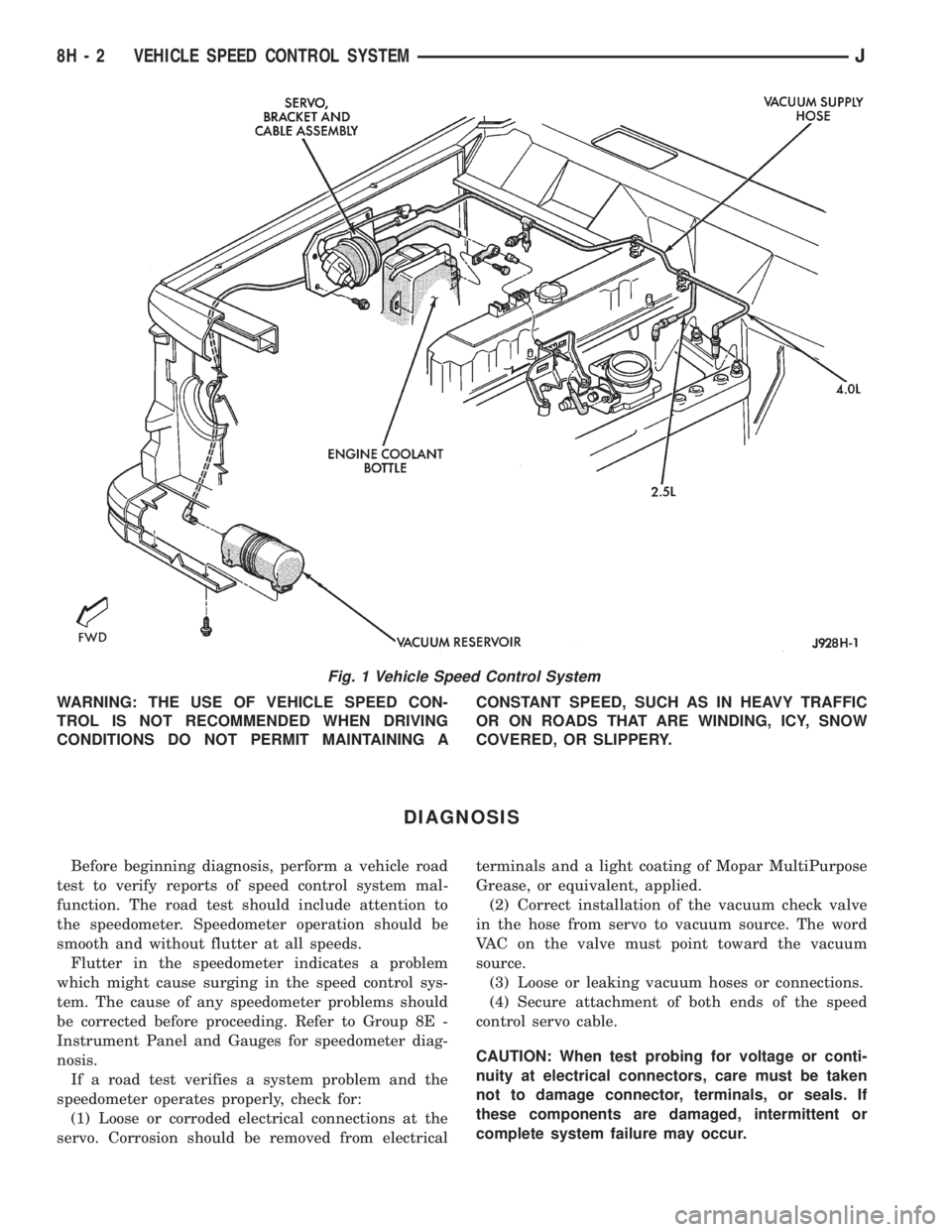

WARNING: THE USE OF VEHICLE SPEED CON-

TROL IS NOT RECOMMENDED WHEN DRIVING

CONDITIONS DO NOT PERMIT MAINTAINING ACONSTANT SPEED, SUCH AS IN HEAVY TRAFFIC

OR ON ROADS THAT ARE WINDING, ICY, SNOW

COVERED, OR SLIPPERY.

DIAGNOSIS

Before beginning diagnosis, perform a vehicle road

test to verify reports of speed control system mal-

function. The road test should include attention to

the speedometer. Speedometer operation should be

smooth and without flutter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Group 8E -

Instrument Panel and Gauges for speedometer diag-

nosis.

If a road test verifies a system problem and the

speedometer operates properly, check for:

(1) Loose or corroded electrical connections at the

servo. Corrosion should be removed from electricalterminals and a light coating of Mopar MultiPurpose

Grease, or equivalent, applied.

(2) Correct installation of the vacuum check valve

in the hose from servo to vacuum source. The word

VAC on the valve must point toward the vacuum

source.

(3) Loose or leaking vacuum hoses or connections.

(4) Secure attachment of both ends of the speed

control servo cable.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals, or seals. If

these components are damaged, intermittent or

complete system failure may occur.

Fig. 1 Vehicle Speed Control System

8H - 2 VEHICLE SPEED CONTROL SYSTEMJ

Page 422 of 2158

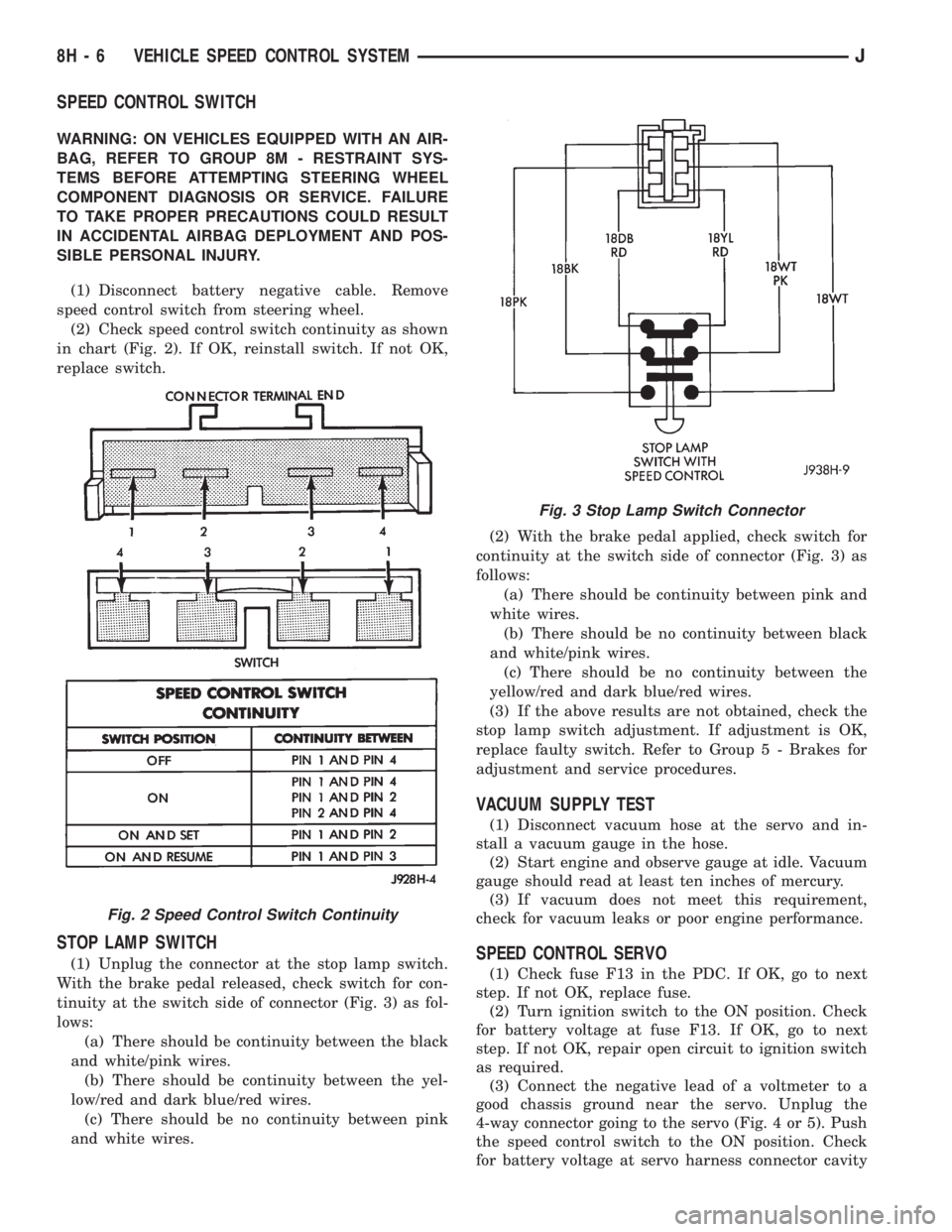

SPEED CONTROL SWITCH

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO GROUP 8M - RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POS-

SIBLE PERSONAL INJURY.

(1) Disconnect battery negative cable. Remove

speed control switch from steering wheel.

(2) Check speed control switch continuity as shown

in chart (Fig. 2). If OK, reinstall switch. If not OK,

replace switch.

STOP LAMP SWITCH

(1) Unplug the connector at the stop lamp switch.

With the brake pedal released, check switch for con-

tinuity at the switch side of connector (Fig. 3) as fol-

lows:

(a) There should be continuity between the black

and white/pink wires.

(b) There should be continuity between the yel-

low/red and dark blue/red wires.

(c) There should be no continuity between pink

and white wires.(2) With the brake pedal applied, check switch for

continuity at the switch side of connector (Fig. 3) as

follows:

(a) There should be continuity between pink and

white wires.

(b) There should be no continuity between black

and white/pink wires.

(c) There should be no continuity between the

yellow/red and dark blue/red wires.

(3) If the above results are not obtained, check the

stop lamp switch adjustment. If adjustment is OK,

replace faulty switch. Refer to Group 5 - Brakes for

adjustment and service procedures.

VACUUM SUPPLY TEST

(1) Disconnect vacuum hose at the servo and in-

stall a vacuum gauge in the hose.

(2) Start engine and observe gauge at idle. Vacuum

gauge should read at least ten inches of mercury.

(3) If vacuum does not meet this requirement,

check for vacuum leaks or poor engine performance.

SPEED CONTROL SERVO

(1) Check fuse F13 in the PDC. If OK, go to next

step. If not OK, replace fuse.

(2) Turn ignition switch to the ON position. Check

for battery voltage at fuse F13. If OK, go to next

step. If not OK, repair open circuit to ignition switch

as required.

(3) Connect the negative lead of a voltmeter to a

good chassis ground near the servo. Unplug the

4-way connector going to the servo (Fig. 4 or 5). Push

the speed control switch to the ON position. Check

for battery voltage at servo harness connector cavity

Fig. 2 Speed Control Switch Continuity

Fig. 3 Stop Lamp Switch Connector

8H - 6 VEHICLE SPEED CONTROL SYSTEMJ

Page 425 of 2158

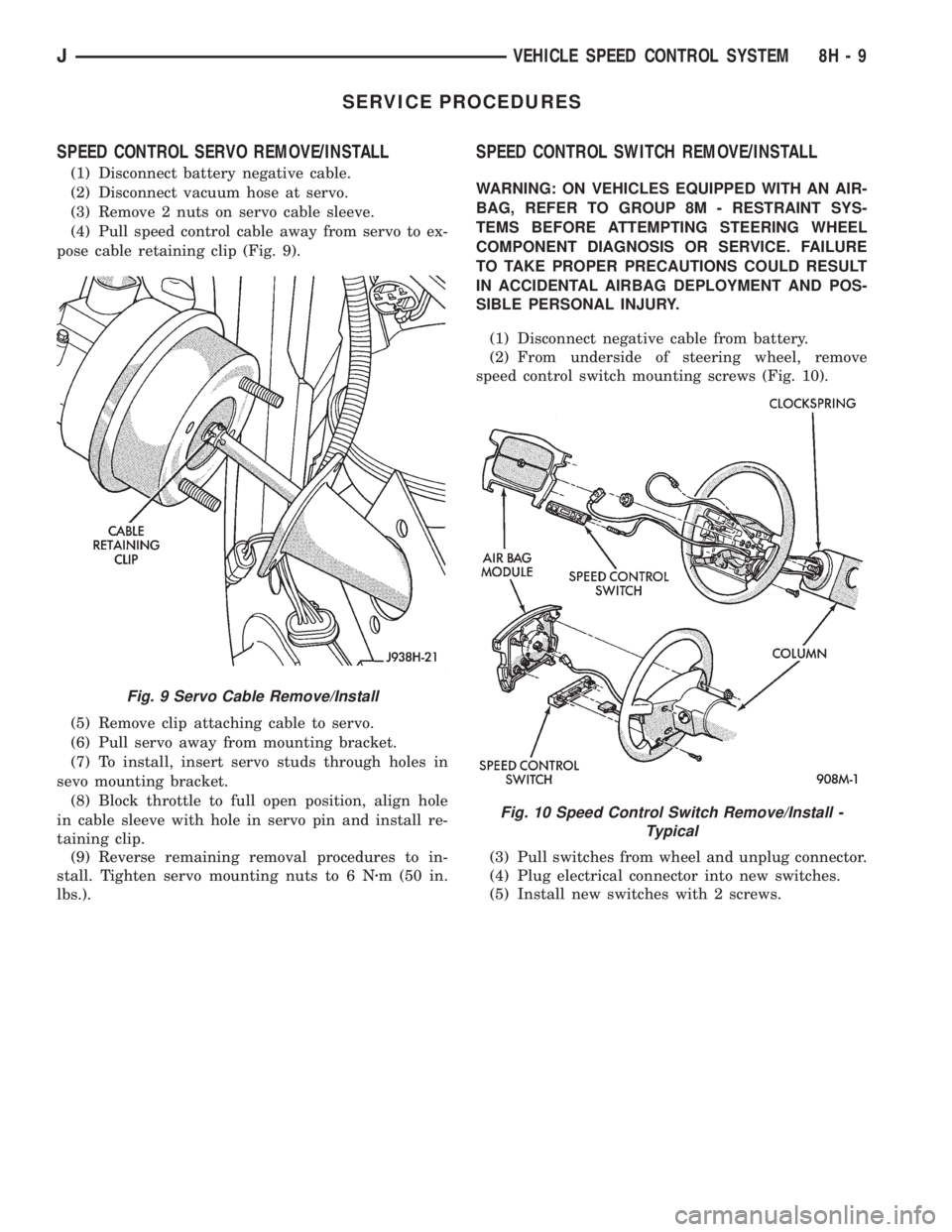

SERVICE PROCEDURES

SPEED CONTROL SERVO REMOVE/INSTALL

(1) Disconnect battery negative cable.

(2) Disconnect vacuum hose at servo.

(3) Remove 2 nuts on servo cable sleeve.

(4) Pull speed control cable away from servo to ex-

pose cable retaining clip (Fig. 9).

(5) Remove clip attaching cable to servo.

(6) Pull servo away from mounting bracket.

(7) To install, insert servo studs through holes in

sevo mounting bracket.

(8) Block throttle to full open position, align hole

in cable sleeve with hole in servo pin and install re-

taining clip.

(9) Reverse remaining removal procedures to in-

stall. Tighten servo mounting nuts to 6 Nzm (50 in.

lbs.).

SPEED CONTROL SWITCH REMOVE/INSTALL

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO GROUP 8M - RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POS-

SIBLE PERSONAL INJURY.

(1) Disconnect negative cable from battery.

(2) From underside of steering wheel, remove

speed control switch mounting screws (Fig. 10).

(3) Pull switches from wheel and unplug connector.

(4) Plug electrical connector into new switches.

(5) Install new switches with 2 screws.

Fig. 9 Servo Cable Remove/Install

Fig. 10 Speed Control Switch Remove/Install -

Typical

JVEHICLE SPEED CONTROL SYSTEM 8H - 9