roof rack JEEP XJ 1995 Service And Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 322 of 2158

(4) With the degaussing tool still energized, slowly

back it away from the screw until the tool is at least

2 feet from the screw head, then unplug the tool.

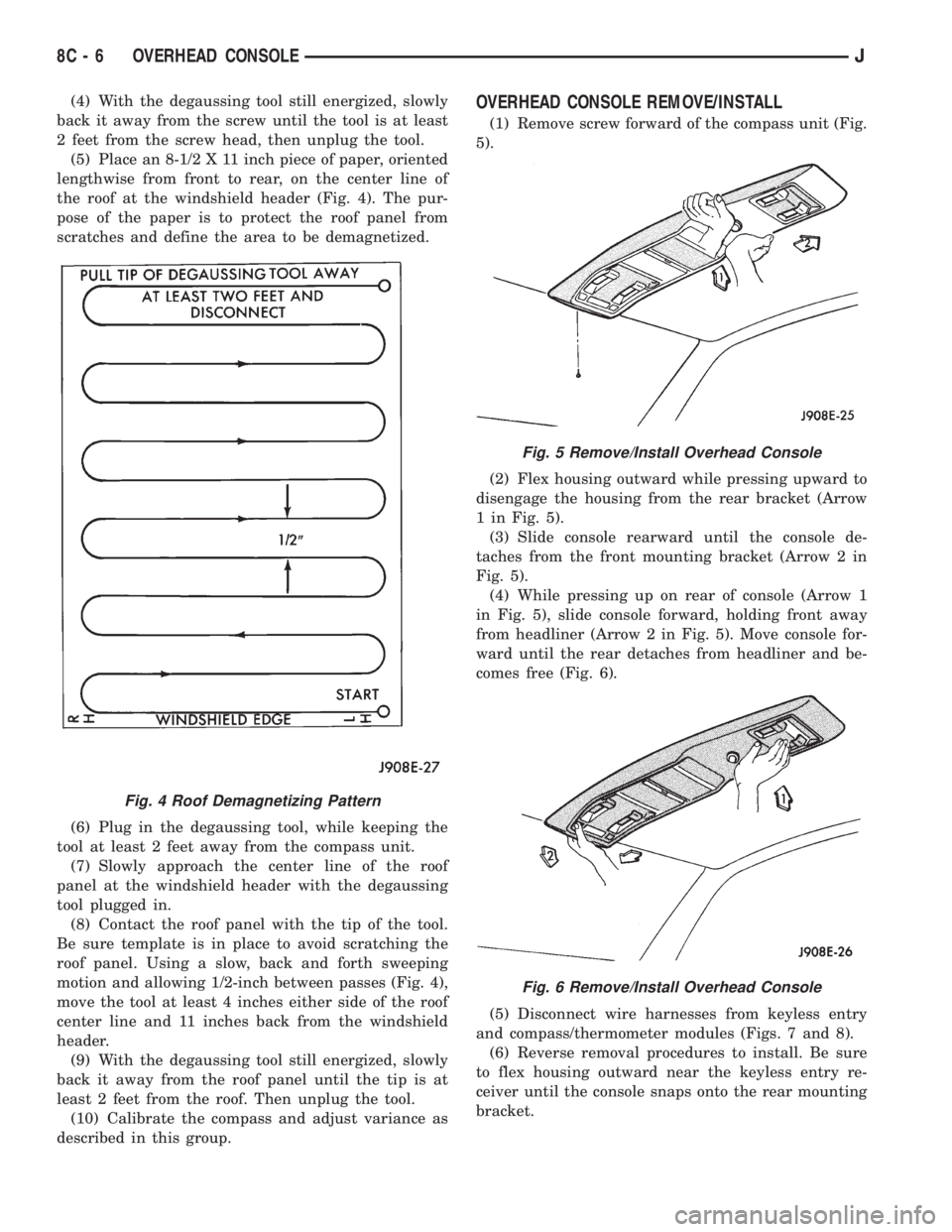

(5) Place an 8-1/2 X 11 inch piece of paper, oriented

lengthwise from front to rear, on the center line of

the roof at the windshield header (Fig. 4). The pur-

pose of the paper is to protect the roof panel from

scratches and define the area to be demagnetized.

(6) Plug in the degaussing tool, while keeping the

tool at least 2 feet away from the compass unit.

(7) Slowly approach the center line of the roof

panel at the windshield header with the degaussing

tool plugged in.

(8) Contact the roof panel with the tip of the tool.

Be sure template is in place to avoid scratching the

roof panel. Using a slow, back and forth sweeping

motion and allowing 1/2-inch between passes (Fig. 4),

move the tool at least 4 inches either side of the roof

center line and 11 inches back from the windshield

header.

(9) With the degaussing tool still energized, slowly

back it away from the roof panel until the tip is at

least 2 feet from the roof. Then unplug the tool.

(10) Calibrate the compass and adjust variance as

described in this group.OVERHEAD CONSOLE REMOVE/INSTALL

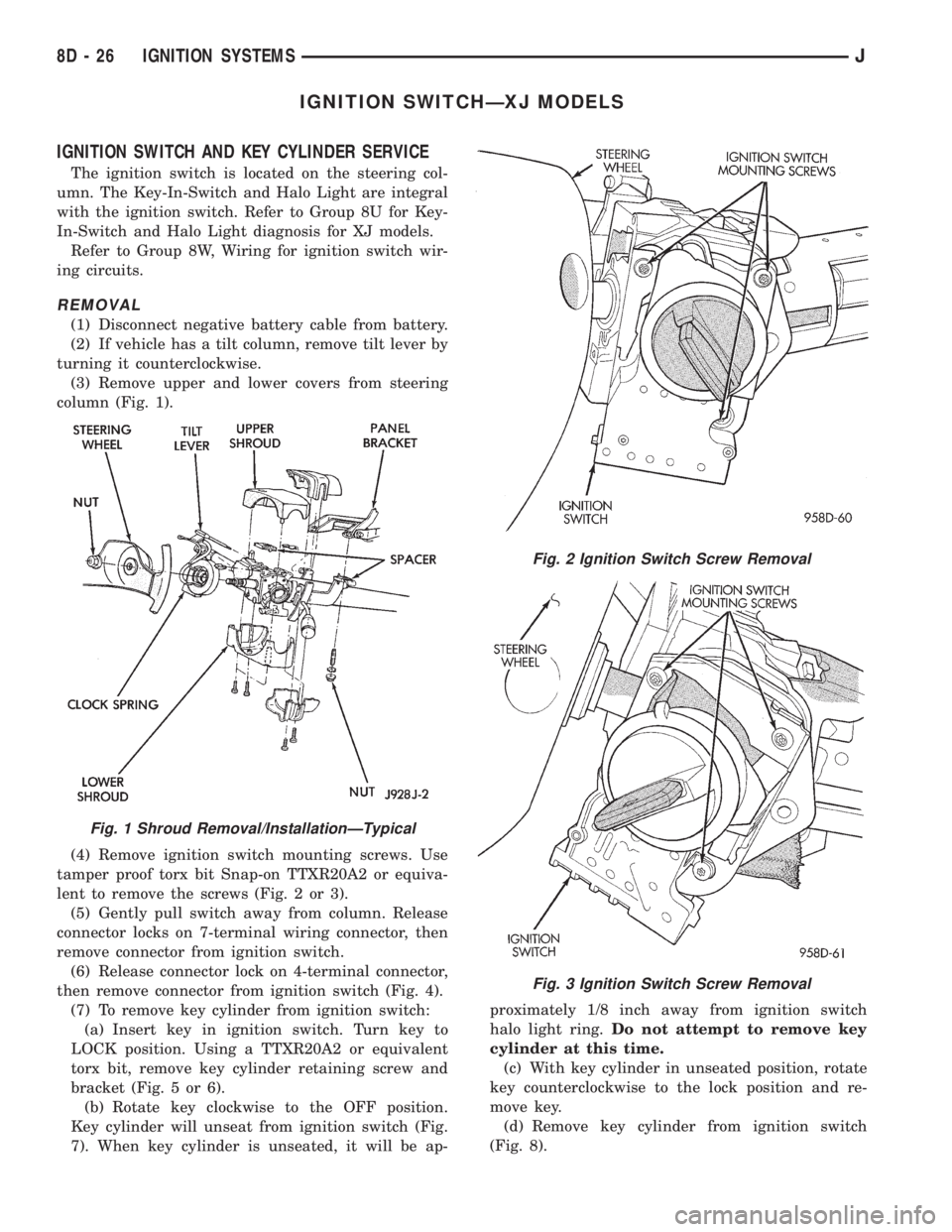

(1) Remove screw forward of the compass unit (Fig.

5).

(2) Flex housing outward while pressing upward to

disengage the housing from the rear bracket (Arrow

1 in Fig. 5).

(3) Slide console rearward until the console de-

taches from the front mounting bracket (Arrow 2 in

Fig. 5).

(4) While pressing up on rear of console (Arrow 1

in Fig. 5), slide console forward, holding front away

from headliner (Arrow 2 in Fig. 5). Move console for-

ward until the rear detaches from headliner and be-

comes free (Fig. 6).

(5) Disconnect wire harnesses from keyless entry

and compass/thermometer modules (Figs. 7 and 8).

(6) Reverse removal procedures to install. Be sure

to flex housing outward near the keyless entry re-

ceiver until the console snaps onto the rear mounting

bracket.

Fig. 4 Roof Demagnetizing Pattern

Fig. 5 Remove/Install Overhead Console

Fig. 6 Remove/Install Overhead Console

8C - 6 OVERHEAD CONSOLEJ

Page 350 of 2158

IGNITION SWITCHÐXJ MODELS

IGNITION SWITCH AND KEY CYLINDER SERVICE

The ignition switch is located on the steering col-

umn. The Key-In-Switch and Halo Light are integral

with the ignition switch. Refer to Group 8U for Key-

In-Switch and Halo Light diagnosis for XJ models.

Refer to Group 8W, Wiring for ignition switch wir-

ing circuits.

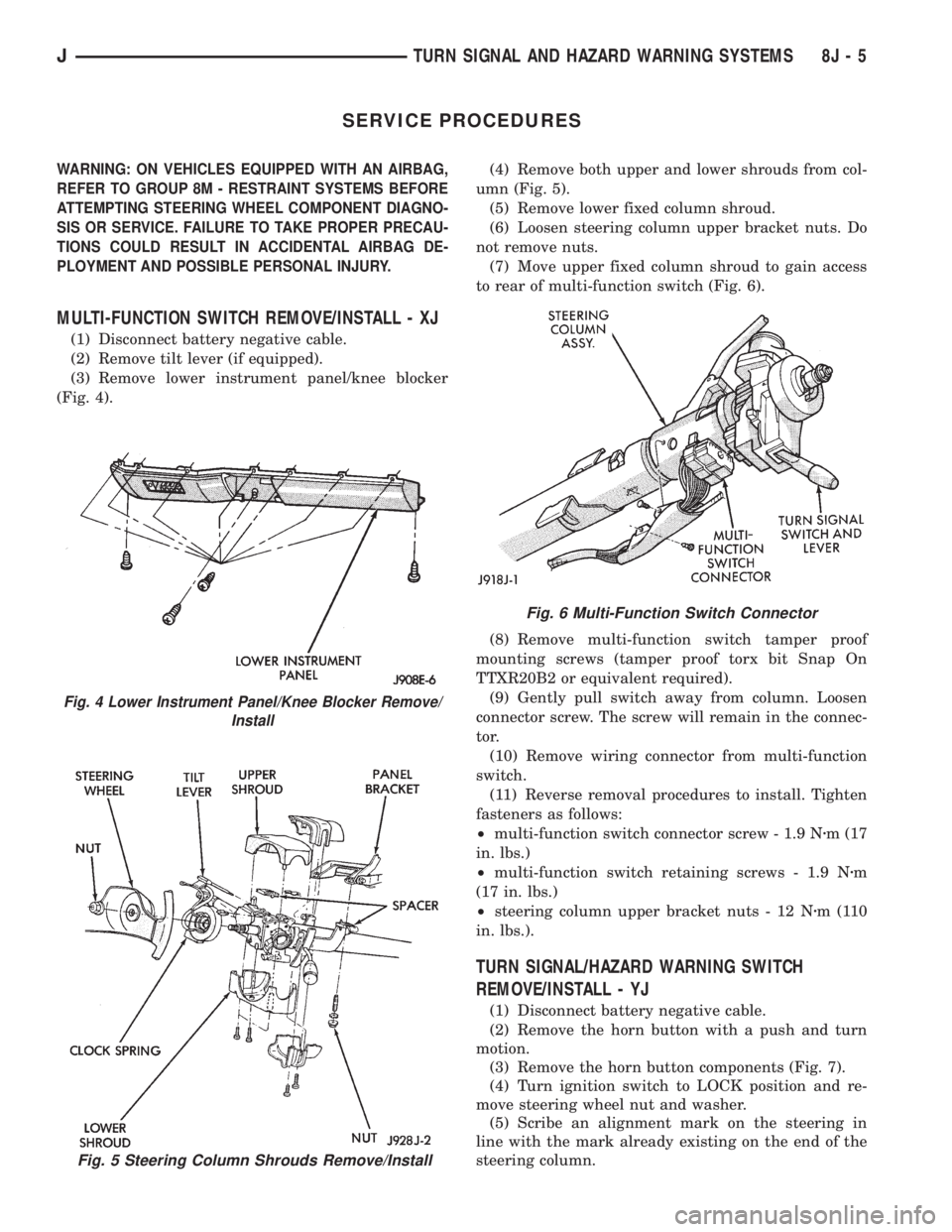

REMOVAL

(1) Disconnect negative battery cable from battery.

(2) If vehicle has a tilt column, remove tilt lever by

turning it counterclockwise.

(3) Remove upper and lower covers from steering

column (Fig. 1).

(4) Remove ignition switch mounting screws. Use

tamper proof torx bit Snap-on TTXR20A2 or equiva-

lent to remove the screws (Fig. 2 or 3).

(5) Gently pull switch away from column. Release

connector locks on 7-terminal wiring connector, then

remove connector from ignition switch.

(6) Release connector lock on 4-terminal connector,

then remove connector from ignition switch (Fig. 4).

(7) To remove key cylinder from ignition switch:

(a) Insert key in ignition switch. Turn key to

LOCK position. Using a TTXR20A2 or equivalent

torx bit, remove key cylinder retaining screw and

bracket (Fig. 5 or 6).

(b) Rotate key clockwise to the OFF position.

Key cylinder will unseat from ignition switch (Fig.

7). When key cylinder is unseated, it will be ap-proximately 1/8 inch away from ignition switch

halo light ring.Do not attempt to remove key

cylinder at this time.

(c) With key cylinder in unseated position, rotate

key counterclockwise to the lock position and re-

move key.

(d) Remove key cylinder from ignition switch

(Fig. 8).

Fig. 1 Shroud Removal/InstallationÐTypical

Fig. 2 Ignition Switch Screw Removal

Fig. 3 Ignition Switch Screw Removal

8D - 26 IGNITION SYSTEMSJ

Page 431 of 2158

SERVICE PROCEDURES

WARNING: ON VEHICLES EQUIPPED WITH AN AIRBAG,

REFER TO GROUP 8M - RESTRAINT SYSTEMS BEFORE

ATTEMPTING STEERING WHEEL COMPONENT DIAGNO-

SIS OR SERVICE. FAILURE TO TAKE PROPER PRECAU-

TIONS COULD RESULT IN ACCIDENTAL AIRBAG DE-

PLOYMENT AND POSSIBLE PERSONAL INJURY.

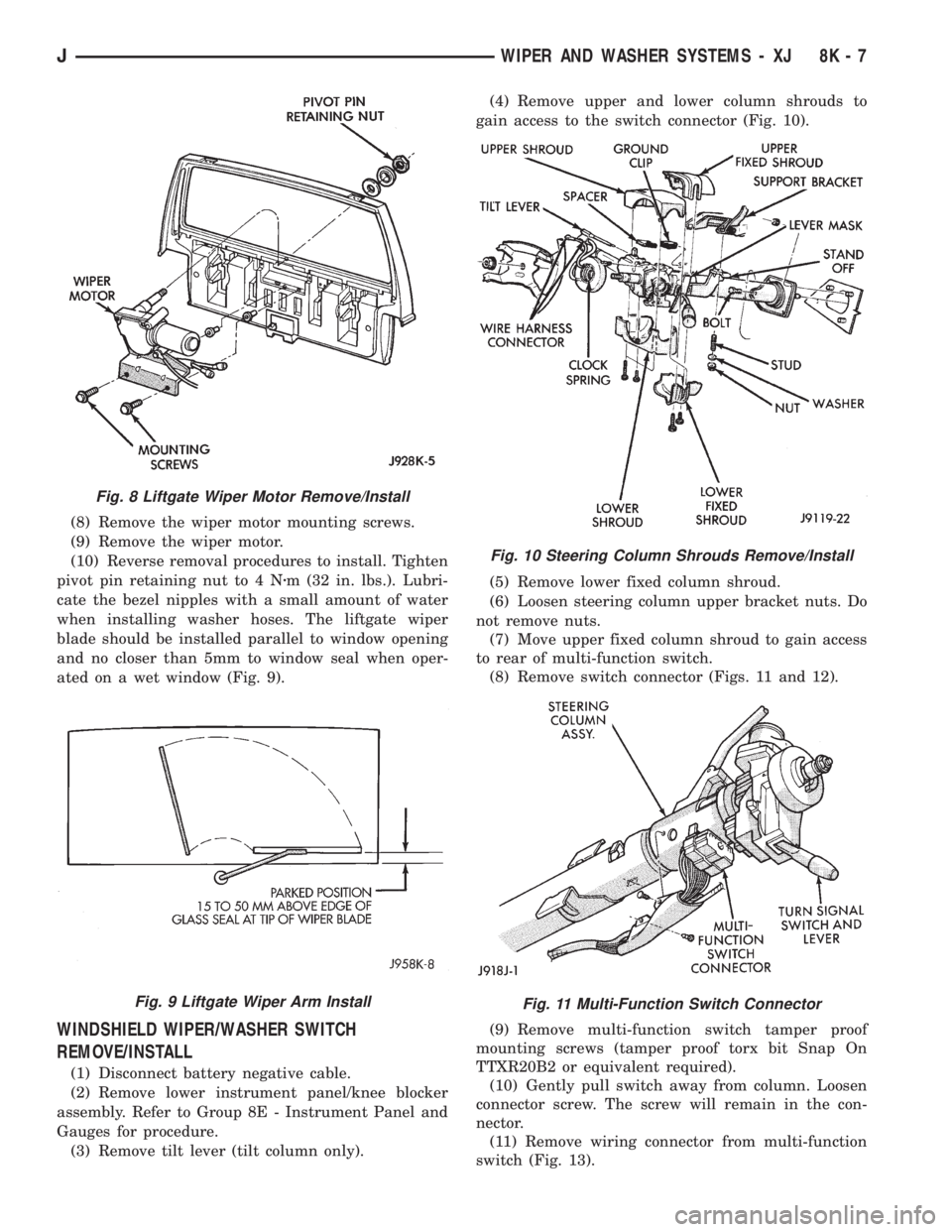

MULTI-FUNCTION SWITCH REMOVE/INSTALL - XJ

(1) Disconnect battery negative cable.

(2) Remove tilt lever (if equipped).

(3) Remove lower instrument panel/knee blocker

(Fig. 4).(4) Remove both upper and lower shrouds from col-

umn (Fig. 5).

(5) Remove lower fixed column shroud.

(6) Loosen steering column upper bracket nuts. Do

not remove nuts.

(7) Move upper fixed column shroud to gain access

to rear of multi-function switch (Fig. 6).

(8) Remove multi-function switch tamper proof

mounting screws (tamper proof torx bit Snap On

TTXR20B2 or equivalent required).

(9) Gently pull switch away from column. Loosen

connector screw. The screw will remain in the connec-

tor.

(10) Remove wiring connector from multi-function

switch.

(11) Reverse removal procedures to install. Tighten

fasteners as follows:

²multi-function switch connector screw - 1.9 Nzm (17

in. lbs.)

²multi-function switch retaining screws - 1.9 Nzm

(17 in. lbs.)

²steering column upper bracket nuts - 12 Nzm(110

in. lbs.).

TURN SIGNAL/HAZARD WARNING SWITCH

REMOVE/INSTALL - YJ

(1) Disconnect battery negative cable.

(2) Remove the horn button with a push and turn

motion.

(3) Remove the horn button components (Fig. 7).

(4) Turn ignition switch to LOCK position and re-

move steering wheel nut and washer.

(5) Scribe an alignment mark on the steering in

line with the mark already existing on the end of the

steering column.

Fig. 5 Steering Column Shrouds Remove/Install

Fig. 4 Lower Instrument Panel/Knee Blocker Remove/

Install

Fig. 6 Multi-Function Switch Connector

JTURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 5

Page 441 of 2158

(8) Remove the wiper motor mounting screws.

(9) Remove the wiper motor.

(10) Reverse removal procedures to install. Tighten

pivot pin retaining nut to 4 Nzm (32 in. lbs.). Lubri-

cate the bezel nipples with a small amount of water

when installing washer hoses. The liftgate wiper

blade should be installed parallel to window opening

and no closer than 5mm to window seal when oper-

ated on a wet window (Fig. 9).

WINDSHIELD WIPER/WASHER SWITCH

REMOVE/INSTALL

(1) Disconnect battery negative cable.

(2) Remove lower instrument panel/knee blocker

assembly. Refer to Group 8E - Instrument Panel and

Gauges for procedure.

(3) Remove tilt lever (tilt column only).(4) Remove upper and lower column shrouds to

gain access to the switch connector (Fig. 10).

(5) Remove lower fixed column shroud.

(6) Loosen steering column upper bracket nuts. Do

not remove nuts.

(7) Move upper fixed column shroud to gain access

to rear of multi-function switch.

(8) Remove switch connector (Figs. 11 and 12).

(9) Remove multi-function switch tamper proof

mounting screws (tamper proof torx bit Snap On

TTXR20B2 or equivalent required).

(10) Gently pull switch away from column. Loosen

connector screw. The screw will remain in the con-

nector.

(11) Remove wiring connector from multi-function

switch (Fig. 13).

Fig. 8 Liftgate Wiper Motor Remove/Install

Fig. 9 Liftgate Wiper Arm Install

Fig. 10 Steering Column Shrouds Remove/Install

Fig. 11 Multi-Function Switch Connector

JWIPER AND WASHER SYSTEMS - XJ 8K - 7

Page 471 of 2158

INSTALLATION

(1) Squeeze the tabs on the side of the fog lamp

switch and insert the switch in the instrument panel

cavity.

(2) Connect the wire harness connector to the

switch.

(3) Install the fog lamp switch cover.

(4) Position the bezel on the instrument panel and

install the attaching screws. Tighten the screws se-

curely.

MULTI-FUNCTION SWITCH SERVICE

PROCEDURESÐXJ

REMOVAL

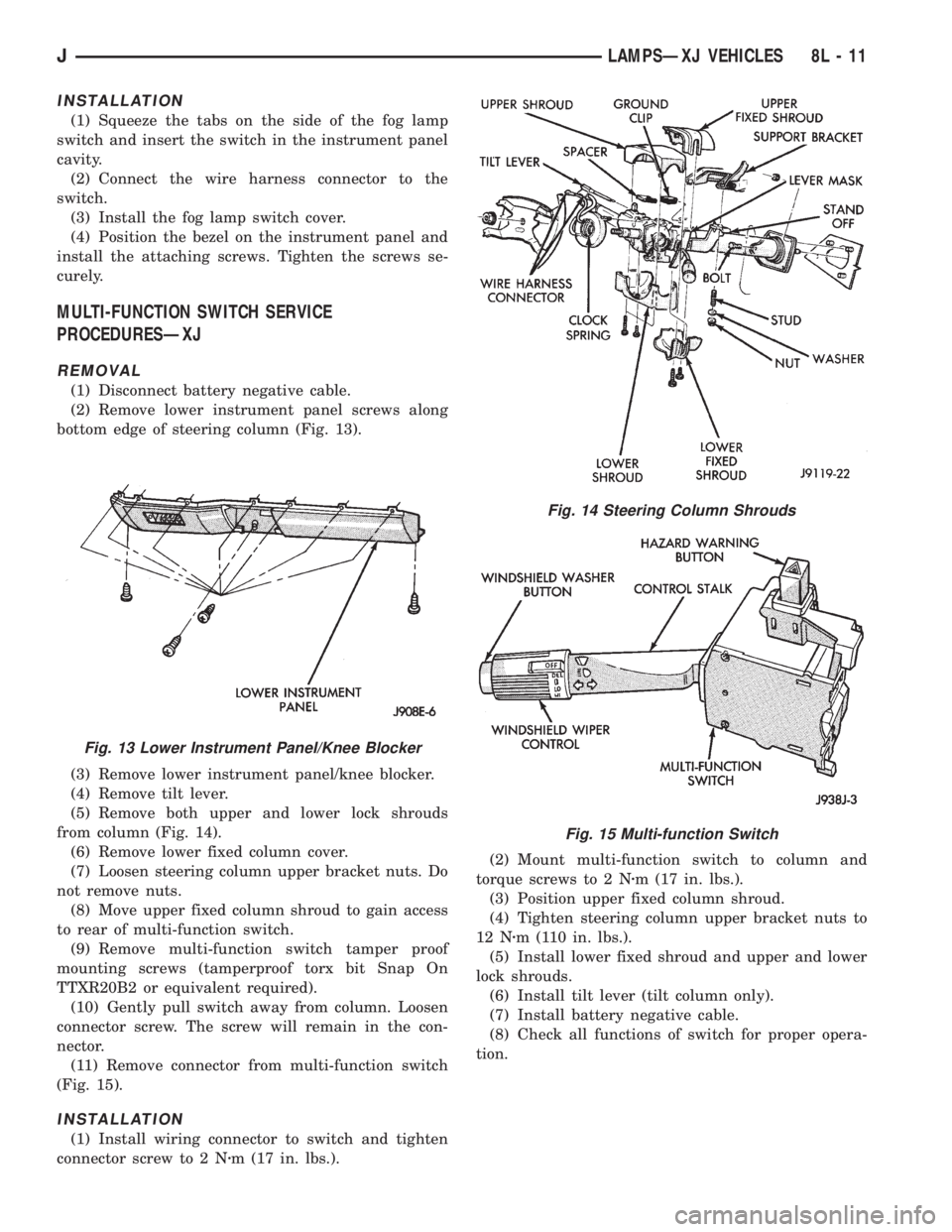

(1) Disconnect battery negative cable.

(2) Remove lower instrument panel screws along

bottom edge of steering column (Fig. 13).

(3) Remove lower instrument panel/knee blocker.

(4) Remove tilt lever.

(5) Remove both upper and lower lock shrouds

from column (Fig. 14).

(6) Remove lower fixed column cover.

(7) Loosen steering column upper bracket nuts. Do

not remove nuts.

(8) Move upper fixed column shroud to gain access

to rear of multi-function switch.

(9) Remove multi-function switch tamper proof

mounting screws (tamperproof torx bit Snap On

TTXR20B2 or equivalent required).

(10) Gently pull switch away from column. Loosen

connector screw. The screw will remain in the con-

nector.

(11) Remove connector from multi-function switch

(Fig. 15).

INSTALLATION

(1) Install wiring connector to switch and tighten

connector screw to 2 Nzm (17 in. lbs.).(2) Mount multi-function switch to column and

torque screws to 2 Nzm (17 in. lbs.).

(3) Position upper fixed column shroud.

(4) Tighten steering column upper bracket nuts to

12 Nzm (110 in. lbs.).

(5) Install lower fixed shroud and upper and lower

lock shrouds.

(6) Install tilt lever (tilt column only).

(7) Install battery negative cable.

(8) Check all functions of switch for proper opera-

tion.

Fig. 13 Lower Instrument Panel/Knee Blocker

Fig. 14 Steering Column Shrouds

Fig. 15 Multi-function Switch

JLAMPSÐXJ VEHICLES 8L - 11

Page 1946 of 2158

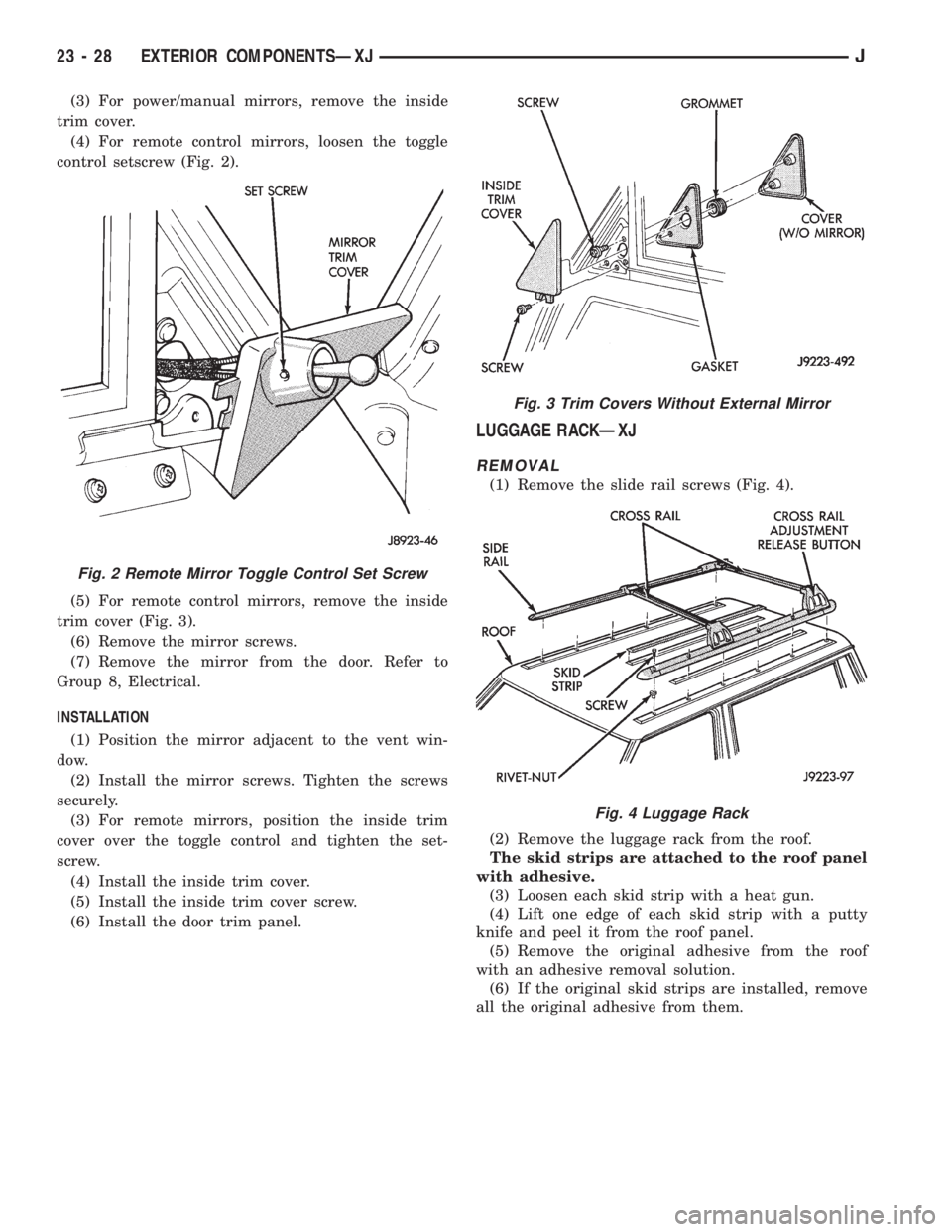

(3) For power/manual mirrors, remove the inside

trim cover.

(4) For remote control mirrors, loosen the toggle

control setscrew (Fig. 2).

(5) For remote control mirrors, remove the inside

trim cover (Fig. 3).

(6) Remove the mirror screws.

(7) Remove the mirror from the door. Refer to

Group 8, Electrical.

INSTALLATION

(1) Position the mirror adjacent to the vent win-

dow.

(2) Install the mirror screws. Tighten the screws

securely.

(3) For remote mirrors, position the inside trim

cover over the toggle control and tighten the set-

screw.

(4) Install the inside trim cover.

(5) Install the inside trim cover screw.

(6) Install the door trim panel.

LUGGAGE RACKÐXJ

REMOVAL

(1) Remove the slide rail screws (Fig. 4).

(2) Remove the luggage rack from the roof.

The skid strips are attached to the roof panel

with adhesive.

(3) Loosen each skid strip with a heat gun.

(4) Lift one edge of each skid strip with a putty

knife and peel it from the roof panel.

(5) Remove the original adhesive from the roof

with an adhesive removal solution.

(6) If the original skid strips are installed, remove

all the original adhesive from them.

Fig. 2 Remote Mirror Toggle Control Set Screw

Fig. 3 Trim Covers Without External Mirror

Fig. 4 Luggage Rack

23 - 28 EXTERIOR COMPONENTSÐXJJ

Page 1947 of 2158

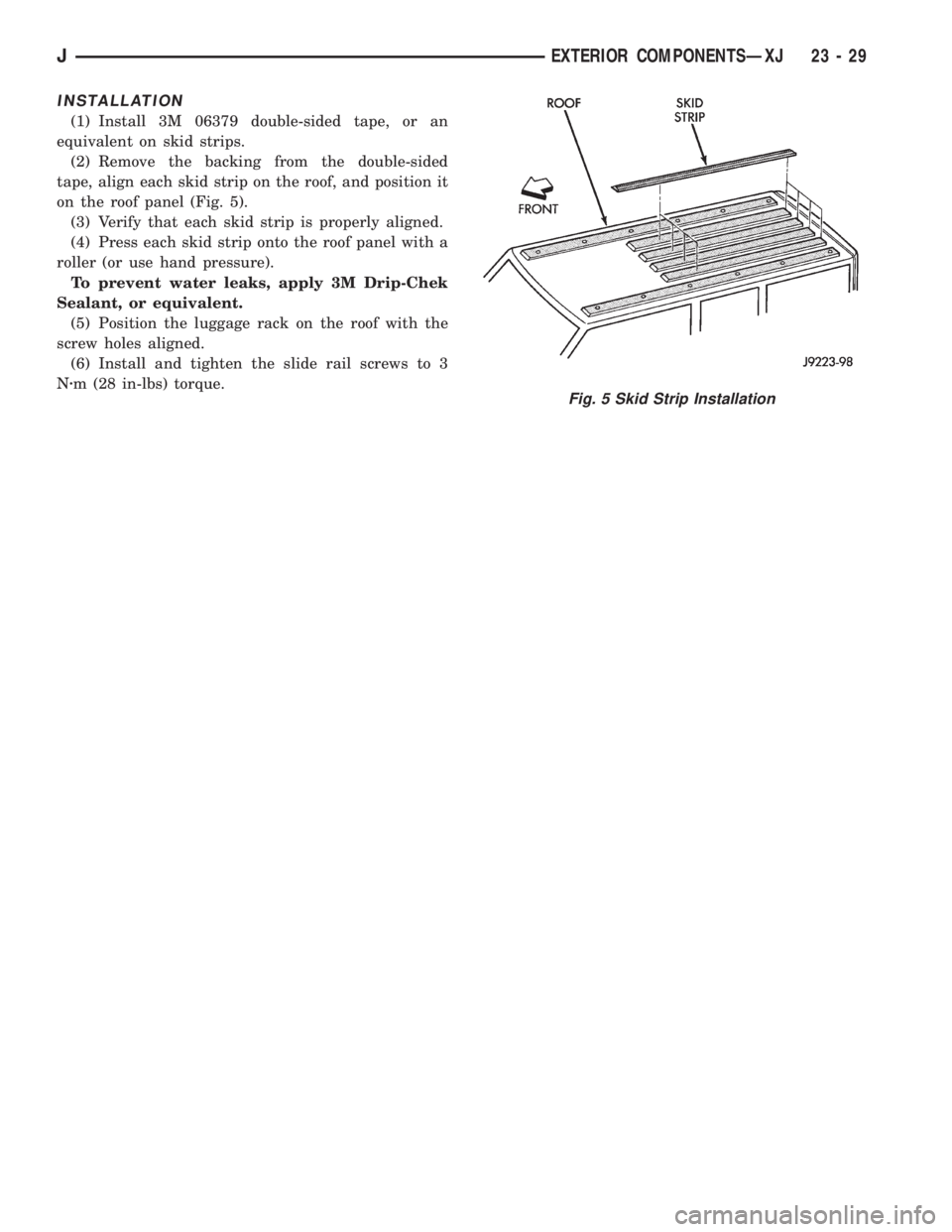

INSTALLATION

(1) Install 3M 06379 double-sided tape, or an

equivalent on skid strips.

(2) Remove the backing from the double-sided

tape, align each skid strip on the roof, and position it

on the roof panel (Fig. 5).

(3) Verify that each skid strip is properly aligned.

(4) Press each skid strip onto the roof panel with a

roller (or use hand pressure).

To prevent water leaks, apply 3M Drip-Chek

Sealant, or equivalent.

(5) Position the luggage rack on the roof with the

screw holes aligned.

(6) Install and tighten the slide rail screws to 3

Nzm (28 in-lbs) torque.

Fig. 5 Skid Strip Installation

JEXTERIOR COMPONENTSÐXJ 23 - 29

Page 1985 of 2158

INSTALLATION

(1) Apply adhesive to the act surface on the sup-

port bracket according as follows:

²crush the vial in the plastic housing of the accel-

erator to saturate the felt applicator.

²remove the paper sleeve.

²apply a generous amount of accelerator to the con-

tact surface on the mirror support bracket.

²do not touch the support bracket contact surface

after the accelerator has been applied.

²

allow the accelerator to dry for at least five minutes.

and

(2) Apply accelerator to the support bracket con-

tact surface on the windshield glass. Allow the accel-

erator to dry for one minute.

(3) Install the mirror bracket on the windshield

glass as follows:

²apply one drop of adhesive at the center of support

bracket contact surface on windshield glass.

²immediately apply an even coat of adhesive to the

contact surface on the support bracket.

²align the support bracket with the position refer-

ence lines on the windshield glass, then

²press and hold the support bracket in-place for at

least one minute.

Ensure that the mirror support bracket is

correctly aligned because the adhesive will

cure rapidly.

(4) Allow the adhesive to cure for 8-10 minutes,

then remove any residue adhesive with an alcohol-

dampened cloth.

(5) Allow the adhesive to cure for an additional

8-10 minutes before installing the mirror base on the

support bracket.

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR THE URE-

THANE ADHESIVE TO CURE. IF IT IS NOT CURED,

THE WINDSHIELD MAY NOT PERFORM PROPERLY

IN AN ACCIDENT.

URETHANE ADHESIVES ARE APPLIED AS A SYS-

TEM. USE GLASS CLEANER, GLASS PREP SOL-

VENT, GLASS PRIMER, AND PINCHWELD (FENCE)

PRIMER PROVIDED BY THE ADHESIVE MANUFAC-

TURER. IF NOT, STRUCTURAL INTEGRITY COULD

BE COMPROMISED.

BE SURE TO REFER TO THE URETHANE MANU-

FACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE AF-

TER ITS EXPIRATION DATE.

VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY, USE THEM IN A WELL VENTI-

LATED AREA.

SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED, OR PERSONAL INJURY MAY

RESULT.

ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted or trimmed surfaces

from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

It is difficult to salvage a windshield during the re-

moval operation. The windshield is part of the struc-

tural support for the roof. The urethane bonding

used to secure the windshield to the fence is difficult

to cut or clean from any surface. If the moldings are

set in urethane, it would also be unlikely they could

be salvaged. Before removing the windshield, check

the availability of the windshield and moldings from

the parts supplier.

JSTATIONARY WINDOW GLASSÐXJ 23 - 671995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995

Page 2011 of 2158

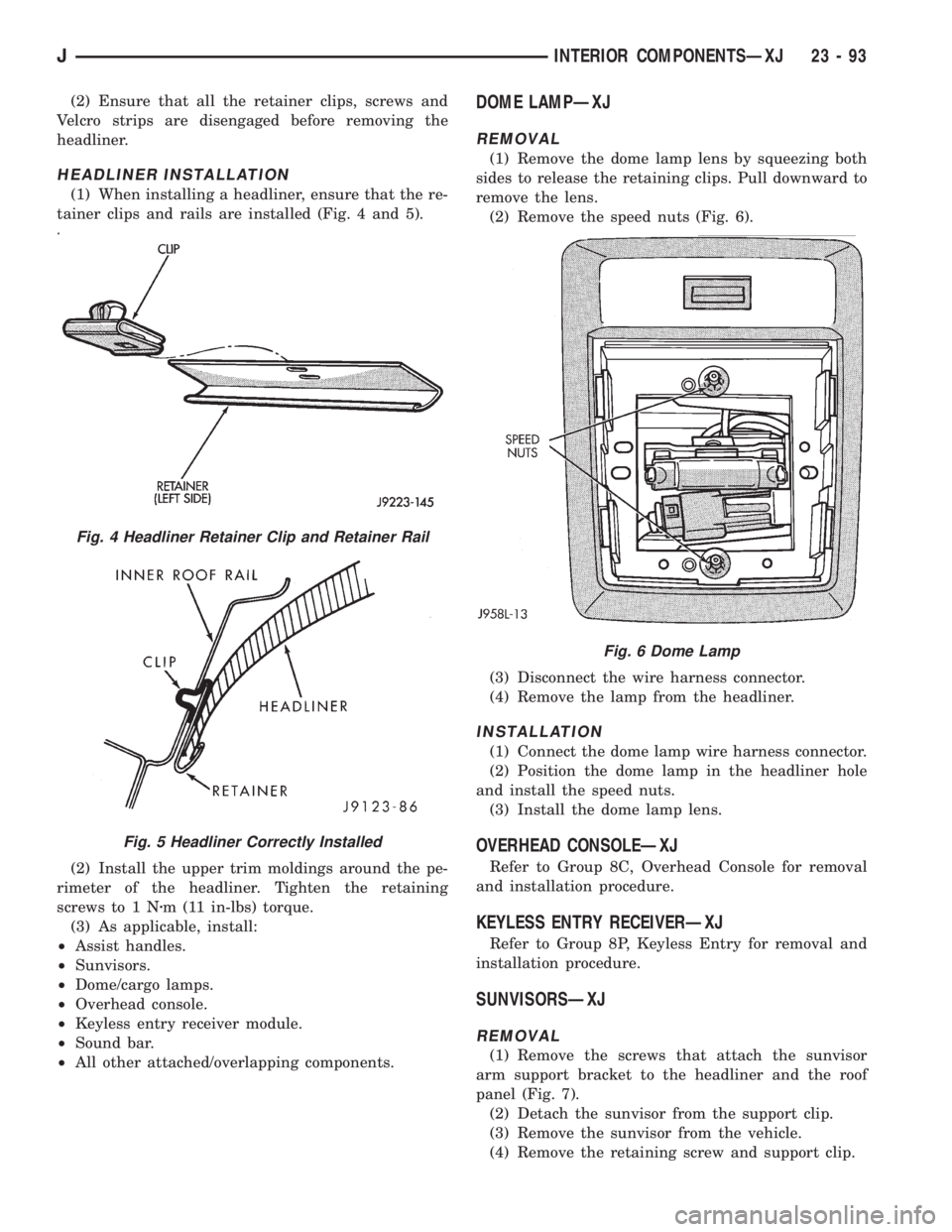

(2) Ensure that all the retainer clips, screws and

Velcro strips are disengaged before removing the

headliner.

HEADLINER INSTALLATION

(1) When installing a headliner, ensure that the re-

tainer clips and rails are installed (Fig. 4 and 5).

(2) Install the upper trim moldings around the pe-

rimeter of the headliner. Tighten the retaining

screws to 1 Nzm (11 in-lbs) torque.

(3) As applicable, install:

²Assist handles.

²Sunvisors.

²Dome/cargo lamps.

²Overhead console.

²Keyless entry receiver module.

²Sound bar.

²All other attached/overlapping components.

DOME LAMPÐXJ

REMOVAL

(1) Remove the dome lamp lens by squeezing both

sides to release the retaining clips. Pull downward to

remove the lens.

(2) Remove the speed nuts (Fig. 6).

(3) Disconnect the wire harness connector.

(4) Remove the lamp from the headliner.

INSTALLATION

(1) Connect the dome lamp wire harness connector.

(2) Position the dome lamp in the headliner hole

and install the speed nuts.

(3) Install the dome lamp lens.

OVERHEAD CONSOLEÐXJ

Refer to Group 8C, Overhead Console for removal

and installation procedure.

KEYLESS ENTRY RECEIVERÐXJ

Refer to Group 8P, Keyless Entry for removal and

installation procedure.

SUNVISORSÐXJ

REMOVAL

(1) Remove the screws that attach the sunvisor

arm support bracket to the headliner and the roof

panel (Fig. 7).

(2) Detach the sunvisor from the support clip.

(3) Remove the sunvisor from the vehicle.

(4) Remove the retaining screw and support clip.

Fig. 4 Headliner Retainer Clip and Retainer Rail

Fig. 5 Headliner Correctly Installed

Fig. 6 Dome Lamp

JINTERIOR COMPONENTSÐXJ 23 - 93

Page 2012 of 2158

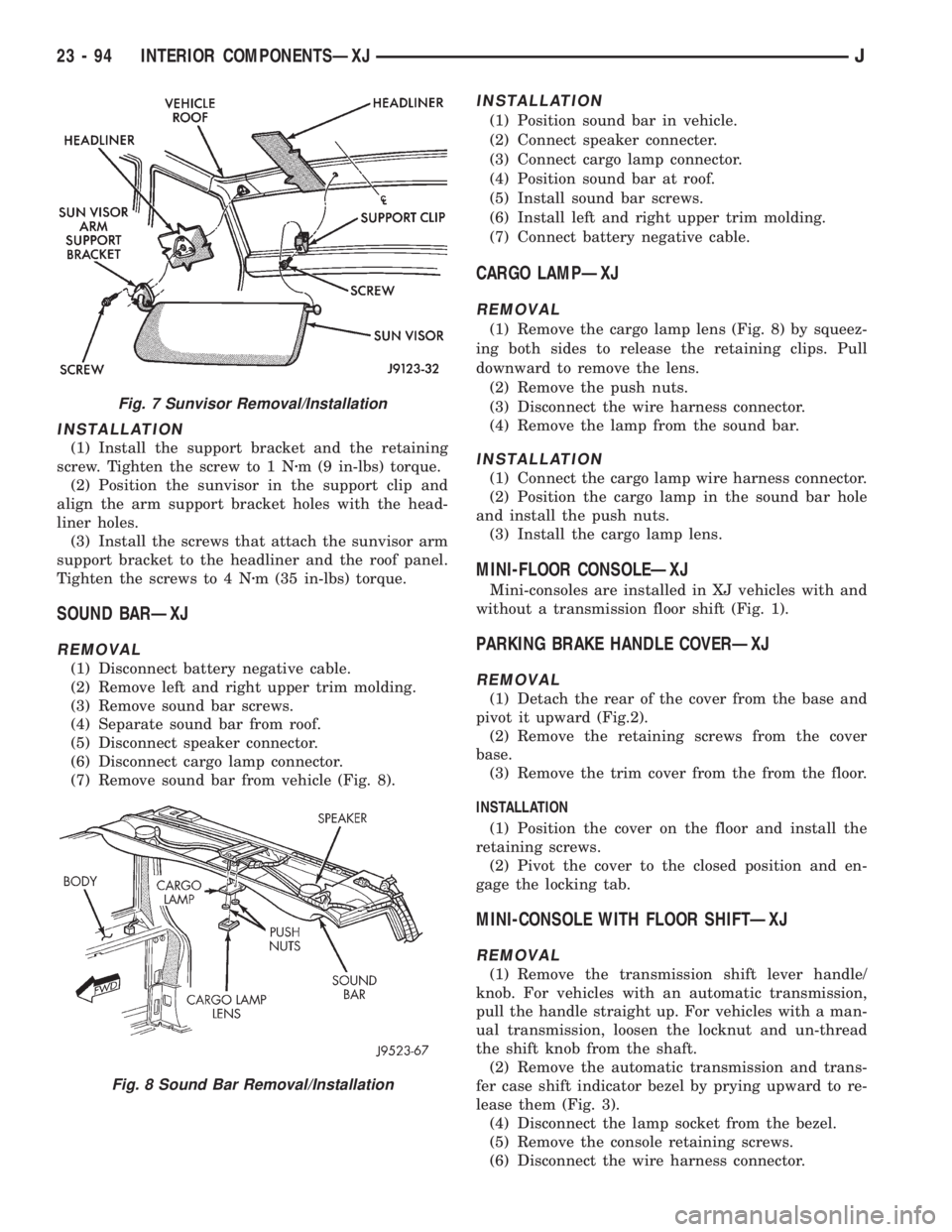

INSTALLATION

(1) Install the support bracket and the retaining

screw. Tighten the screw to 1 Nzm (9 in-lbs) torque.

(2) Position the sunvisor in the support clip and

align the arm support bracket holes with the head-

liner holes.

(3) Install the screws that attach the sunvisor arm

support bracket to the headliner and the roof panel.

Tighten the screws to 4 Nzm (35 in-lbs) torque.

SOUND BARÐXJ

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove left and right upper trim molding.

(3) Remove sound bar screws.

(4) Separate sound bar from roof.

(5) Disconnect speaker connector.

(6) Disconnect cargo lamp connector.

(7) Remove sound bar from vehicle (Fig. 8).

INSTALLATION

(1) Position sound bar in vehicle.

(2) Connect speaker connecter.

(3) Connect cargo lamp connector.

(4) Position sound bar at roof.

(5) Install sound bar screws.

(6) Install left and right upper trim molding.

(7) Connect battery negative cable.

CARGO LAMPÐXJ

REMOVAL

(1) Remove the cargo lamp lens (Fig. 8) by squeez-

ing both sides to release the retaining clips. Pull

downward to remove the lens.

(2) Remove the push nuts.

(3) Disconnect the wire harness connector.

(4) Remove the lamp from the sound bar.

INSTALLATION

(1) Connect the cargo lamp wire harness connector.

(2) Position the cargo lamp in the sound bar hole

and install the push nuts.

(3) Install the cargo lamp lens.

MINI-FLOOR CONSOLEÐXJ

Mini-consoles are installed in XJ vehicles with and

without a transmission floor shift (Fig. 1).

PARKING BRAKE HANDLE COVERÐXJ

REMOVAL

(1) Detach the rear of the cover from the base and

pivot it upward (Fig.2).

(2) Remove the retaining screws from the cover

base.

(3) Remove the trim cover from the from the floor.

INSTALLATION

(1) Position the cover on the floor and install the

retaining screws.

(2) Pivot the cover to the closed position and en-

gage the locking tab.

MINI-CONSOLE WITH FLOOR SHIFTÐXJ

REMOVAL

(1) Remove the transmission shift lever handle/

knob. For vehicles with an automatic transmission,

pull the handle straight up. For vehicles with a man-

ual transmission, loosen the locknut and un-thread

the shift knob from the shaft.

(2) Remove the automatic transmission and trans-

fer case shift indicator bezel by prying upward to re-

lease them (Fig. 3).

(4) Disconnect the lamp socket from the bezel.

(5) Remove the console retaining screws.

(6) Disconnect the wire harness connector.

Fig. 7 Sunvisor Removal/Installation

Fig. 8 Sound Bar Removal/Installation

23 - 94 INTERIOR COMPONENTSÐXJJ