alarm KIA CARNIVAL 2007 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 1249 of 1575

18Burglar Alarm horn ON/OFFContiuously ON with 60

cycles per minute, Duty:50%

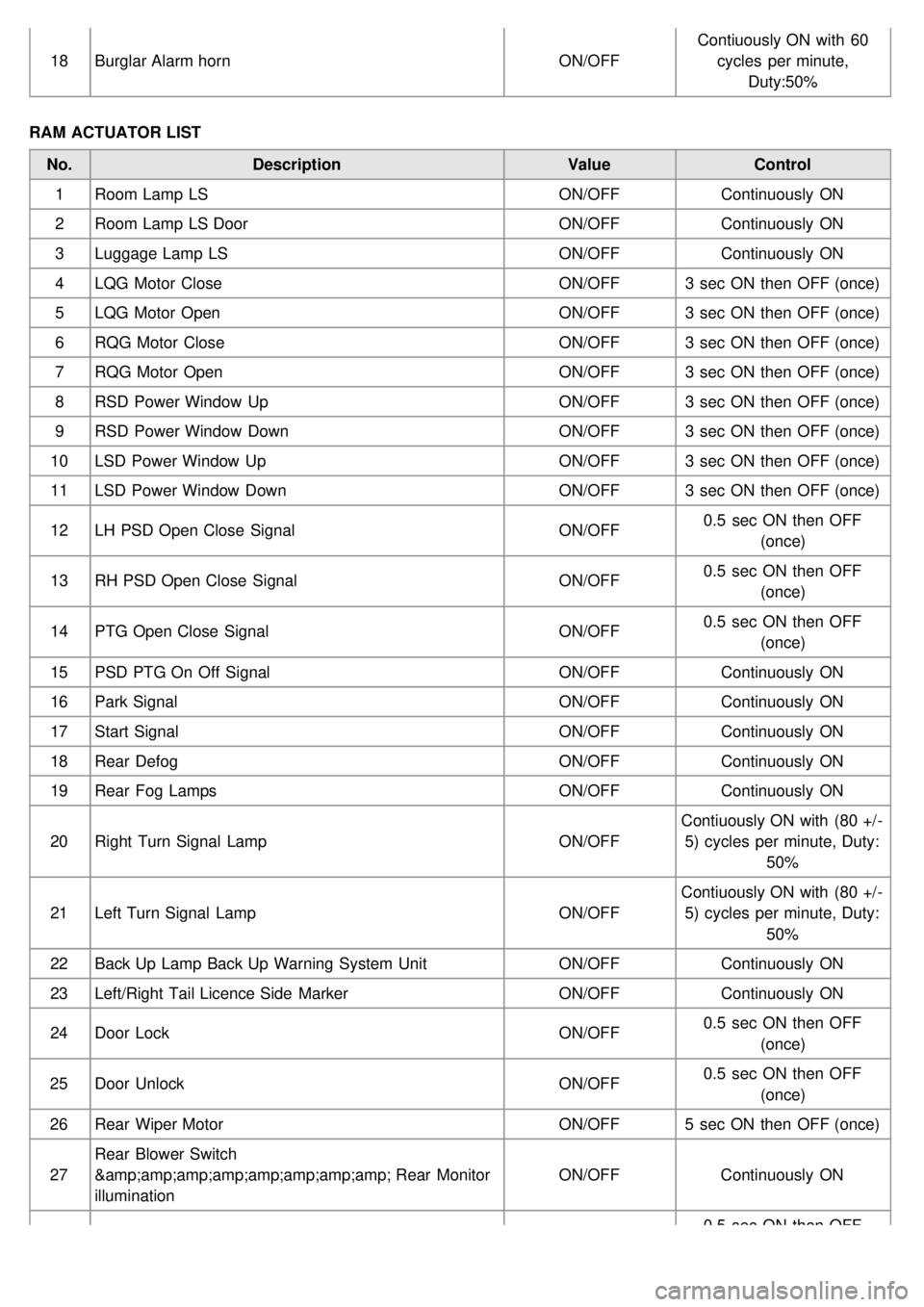

RAM ACTUATOR LIST No. Description ValueControl

1 Room Lamp LS ON/OFFContinuously ON

2 Room Lamp LS Door ON/OFFContinuously ON

3 Luggage Lamp LS ON/OFFContinuously ON

4 LQG Motor Close ON/OFF3 sec ON then OFF (once)

5 LQG Motor Open ON/OFF3 sec ON then OFF (once)

6 RQG Motor Close ON/OFF3 sec ON then OFF (once)

7 RQG Motor Open ON/OFF3 sec ON then OFF (once)

8 RSD Power Window Up ON/OFF3 sec ON then OFF (once)

9 RSD Power Window Down ON/OFF3 sec ON then OFF (once)

10 LSD Power Window Up ON/OFF3 sec ON then OFF (once)

11 LSD Power Window Down ON/OFF3 sec ON then OFF (once)

12 LH PSD Open Close Signal ON/OFF0.5 sec ON then OFF

(once)

13 RH PSD Open Close Signal ON/OFF0.5 sec ON then OFF

(once)

14 PTG Open Close Signal ON/OFF0.5 sec ON then OFF

(once)

15 PSD PTG On Off Signal ON/OFFContinuously ON

16 Park Signal ON/OFFContinuously ON

17 Start Signal ON/OFFContinuously ON

18 Rear Defog ON/OFFContinuously ON

19 Rear Fog Lamps ON/OFFContinuously ON

20 Right Turn Signal Lamp ON/OFFContiuously ON with (80 +/ -

5) cycles per minute, Duty: 50%

21 Left Turn Signal Lamp ON/OFFContiuously ON with (80 +/ -

5) cycles per minute, Duty: 50%

22 Back Up Lamp Back Up Warning System Unit ON/OFFContinuously ON

23 Left/Right Tail Licence Side Marker ON/OFFContinuously ON

24 Door Lock ON/OFF0.5 sec ON then OFF

(once)

25 Door Unlock ON/OFF0.5 sec ON then OFF

(once)

26 Rear Wiper Motor ON/OFF5 sec ON then OFF (once)

27 Rear Blower Switch

& Rear Monitor

illumination ON/OFF

Continuously ON

0.5 sec ON then OFF

Page 1262 of 1575

Error conditionBelow 6 pulses in 2 sec. Below 6 pulses in 1 sec.

Prerequisite FR/RR limit SW on Limit setting complete

a. Stop the related motor(seat / pedal) if an error is detected during playing or Easy access function operation.

b. Stop the corresponding motor if an error is detected during manual operation (excluding slide motor).

b. If seat sensor Vcc below 1V is detected by 1s

a. Stop all seat motors running if seat sensor Vcc error is detected during playing or Easy access function operation.

(no buzzer output)

c. Return if seat sensor Vcc is 4V or more.

DETECTING ERRORS FOR ADJUST PEDAL

1.If signal change is below 0.06V per sec though motor is running.

a. Stop the corresponding motor if error is detected during playing or Easy access function operation.

2. If adjust pedal sensor Vcc below 1V is detected by 1s

a. Stop pedal motor running if pedal sensor Vcc error is detected during playing or Easy access function operation.

(no buzzer output)

3. Return if adjust pedal sensor Vcc is 4V or more.

HANDLING ERRORS

1.If errors are discovered, regard them as harness disconnection or sensor failure, and conduct the following

measures.

a. Stop auto control (play or Easy access function operation) if it is under auto control and set off buzzer 10 times

(however, have motors other than the one with an error operate normally).

b. Set off alarm again in case of recurrence of error after restoration of a motor with an error.

c. Complete alarm 10 times though it comes back to normal during error alarm.

d. Stop alarm if receiving memory recall or play order, and set off buzzer in the corresponding function.

e. Manual operation control is allowed even for a motor with errors.

f. Set off buzzer if memory or play order is received even during error.

g. The timing to lift auto control suspension is when repair for the failing motor is completed, and the criteria for

the completion point are as follows:

a. Seat: if signal input is normal with over 6 pulses within a sec. from position sensor of a motor with an error

caused by manual switch.

b. Adjust pedal: if there is change in input of over 3 LSB within 1 sec. from sensor by manual switch.

Page 1503 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

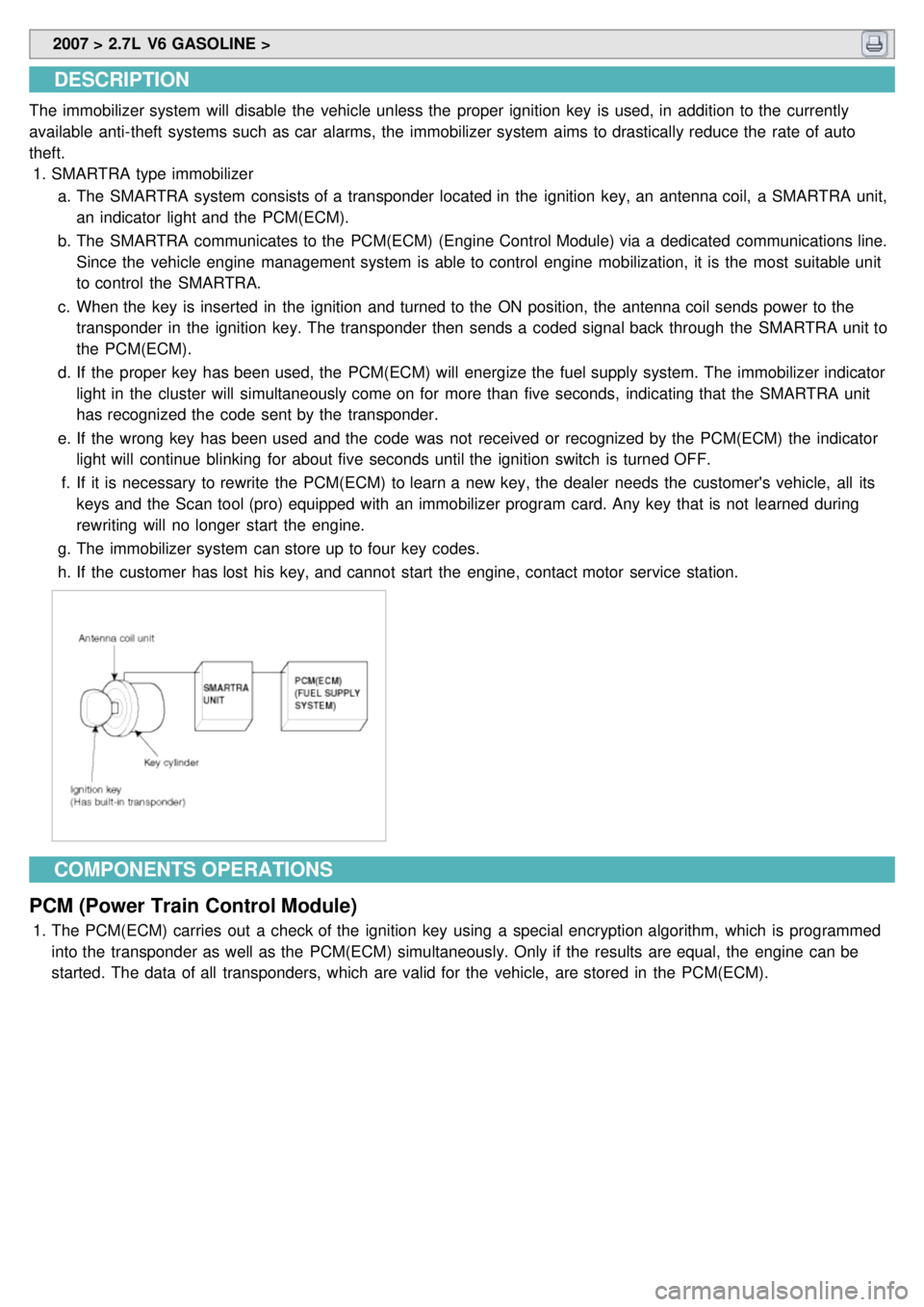

The immobilizer system will disable the vehicle unless the proper ignition key is used, in addition to the currently

available anti- theft systems such as car alarms, the immobilizer system aims to drastically reduce the rate of auto

theft.

1. SMARTRA type immobilizer

a. The SMARTRA system consists of a transponder located in the ignition key, an antenna coil, a SMARTRA unit,

an indicator light and the PCM(ECM).

b. The SMARTRA communicates to the PCM(ECM) (Engine Control Module) via a dedicated communications line.

Since the vehicle engine management system is able to control engine mobilization, it is the most suitable unit

to control the SMARTRA.

c. When the key is inserted in the ignition and turned to the ON position, the antenna coil sends power to the

transponder in the ignition key. The transponder then sends a coded signal back through the SMARTRA unit to

the PCM(ECM).

d. If the proper key has been used, the PCM(ECM) will energize the fuel supply system. The immobilizer indicator

light in the cluster will simultaneously come on for more than five seconds, indicating that the SMARTRA unit

has recognized the code sent by the transponder.

e. If the wrong key has been used and the code was not received or recognized by the PCM(ECM) the indicator

light will continue blinking for about five seconds until the ignition switch is turned OFF.

f. If it is necessary to rewrite the PCM(ECM) to learn a new key, the dealer needs the customer's vehicle, all its

keys and the Scan tool (pro) equipped with an immobilizer program card. Any key that is not learned during

rewriting will no longer start the engine.

g. The immobilizer system can store up to four key codes.

h. If the customer has lost his key, and cannot start the engine, contact motor service station.

COMPONENTS OPERATIONS

PCM (Power Train Control Module)

1. The PCM(ECM) carries out a check of the ignition key using a special encryption algorithm, which is programmed

into the transponder as well as the PCM(ECM) simultaneously. Only if the results are equal, the engine can be

started. The data of all transponders, which are valid for the vehicle, are stored in the PCM(ECM).

Page 1533 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

When reversing, the driver is not easy to find objects in the blind spots and to determine the distance from the object.

In order to provide the driver safety and convenience, back warning system will operate upon shifting to "R" Ultrasonic

sensor will emit ultrasonic wave rearward and detect the reflected wave. Control unit will calculate distance to the

object using the sensor signal input and output buzzer alarm in three steps (first, second and third alarm).

ALARM RANGE

Upon detecting an object at each range out of 3 ranges as stated below within the operation range, it will generate

alarm.

First alarm : Object comes near to the sensor located at the rear of vehicle, within 81- 120cm ± 15cm

Second alarm : Object comes near to the sensor located at the rear of vehicle, within 41- 80cm ± 10cm

Third alarm : Object comes near to the sensor located at the rear of vehicle, within 40cm ± 10cm

a.Time tolerance of the above waveform : Time ± 10%

b. At nearer distance than 40cm, detection may not occur.

c. Alarm will be generated with vehicle reversing speed 10km/h or less.

For moving target, maximum operation speed shall be target approach speed of 10km/h.

d. When the vehicle or the target is moving, sequential alarm generation or effective alarm may be failed.

e. False alarm, or failure of the alarm to trigger may occur in the following conditions.

a. Irregular road surface, gravel road, reversing toward grass.

b. Horn, motor cycle engine noise, large vehicle air brake, or other object generating ultrasonic wave is near.

c. When a wireless transmitter is used near to the sensor.

d. Dirt on the sensor.

e. Sequential alarm may not occur due to the reversing speed or the target shape.

Page 1535 of 1575

2007 > 2.7L V6 GASOLINE >

DIAGNOSIS

1.DIAGNOSIS

Turn the ignition switch ON, then shift the transaxle lever to 'R'. The Back Warning System is then checked.

If no trouble, it generates buzzer alarm sound for 0.3 seconds after 0.5 seconds from power approval. In case of

system failure, buzzer alarm is generated 3 times continuously with the interval of 0.3 seconds.

2.DIAGNOSIS MODE

Switch on diagnosis mode upon system failure.

In case of system failure, then it indicates the failed point as follows.

SENSOR CONNECTION CHECKING

Page 1537 of 1575

(2)Cotton, snow and other material absorbing ultrasonic wave

(for example, fire extinguisher device covered with snow)

4.Reversing toward the sloped walls.

5.Reversing toward the sloped terrain.

6.False alarm may operate in the following condition: irregular road surface, gravel road, sloped road and grass.

Upon alarm generation by grass the alarm may be generated by rock behind grass. Always visually check the area

behind the vehicle before backing up.

The sensors cannot discriminate between materials.

7. Sensors may not operate correctly in the below conditions.

Ensure sensors are clean from mud or dirt

(1) When spraying the bumper, the sensor opening is covered with something in order not to be contaminated. If

sensor opening is contaminated with mud, snow, or dirt, detection range will be reduced and alarm may not be

generated under the crash condition. Dirt accumulated on the sensor opening shall be removed with water.

Do not wipe or scrape sensor with a rod or a hard object.

(2) If the sensor is frozen, alarm may not operate until sensor thaws.

Page 1538 of 1575

(3)If a vehicle stays under extremely hot or cold environment, the detection range may be reduced. It will be

restored at the normal temperature.

(4) When heavy cargo is loaded in rear cargo area, it changes the vehicle balance, which reduces the detection

range.

(5) When other vehicle's horn, motor cycle engine noise, or other ultra - sonic wave sources are near.

(6) Under heavy rain.

(7) When reversing towards a vertical wall and the gap between the vehicle and the wall is 15cm. (Alarm may

sound despite the absence of a barrier)

(8) If radio antenna is installed at the rear.

(9) If the vehicle rear wiring is re- routed or electrical component is added at the rear part.

(10) Vehicle balance is changed due to the replacement of the rear spring.

(11) The unit will operate normally when the vehicle speed is 5km/h or less.

Above this speed, the unit may not operate normally

8. Check the rear bumper for installation condition and deformation. If installed improperly or the sensor orientation is

deviated, it may cause malfunction.

9. Be careful not to apply shock during sensor installation on the transmission or reception unit.

10. When adding electrical devices or modifying harness at the rear body of the vehicle, ensure not to change the

transmission and reception unit wiring.

Tagging the transmission side and reception side, it may cause malfunction.

11. High power radio transmitter (above 10W) may cause malfunction. Do not install it on the vehicle.

12. Be careful that excessive heat or sharp objects shall not touch ultrasonic sensor surface.

Do not cover the sensor opening or press the sensor.

Page 1541 of 1575

2007 > 2.7L V6 GASOLINE >

Operation principle

The sensor emits ultrasonic wave to the objects, and it measures the time until reflected wave returns, and calculates

the distance to the object.

Distance detection type

Direct detection type and indirect detection type are used together for improving effectiveness of the detection.

1. Direct detection type: One sensor transmits and receives signals to measure the distance.

2.Indirect detection type: One sensor transmits signals and the other sensor receives the signals to measure the

distance.

Measurement principle

Back warning system (BWS) is a complementary device for reversing. BWS detects objects behind vehicle and

provides the driver with buzzer alarm finding objects in a certain area, using ultrasonic wave propagation speed and

time.

The propagation speed formula of ultrasonic wave in air is following :

v=331.5 + 0.6t (m/s)

v=ultrasonic wave propagation speed

t=ambient temperature

The basic principle of distance measurement using ultrasonic wave is :

Sensor detection range